instrument cluster JAGUAR XFR 2010 1.G Manual PDF

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 2010, Model line: XFR, Model: JAGUAR XFR 2010 1.GPages: 3039, PDF Size: 58.49 MB

Page 1423 of 3039

The TCM can be reprogrammed using a Jaguar approved diagnostic system using a flash code. The TCM processor has a 440 kb internal flash memory. Of this capacity, approximately 370 kb are used by the basic transmission program. The remainder,

approximately 70 kb is used to store vehicle-specific application data.

Engine Stall

If the vehicle stalls it will coast down in gear, with the transmission providing drive to the engine. A restart can be attempted

at this point and the engine may start and the driver can continue.

If the coast down speed reduces such that the speed of the engine is less than 600 rev/min, the transmission will go to

neutral, D illumination will flash in the instrument cluster. The driver needs to select neutral or park and then press the brake

pedal to restart the engine.

If the start/stop button is pressed when driving, the message ENGINE STOP BUTTON PRESSED is displayed in the message

center but there will be no change to the ignition state. If the driver requires to switch off the engine, the start/stop button

must be pressed for a second time. The engine will be stopped and will be back driven by the transmission as the vehicle

coasts down. When the engine speed is less than 600 rev/min the transmission engages neutral (flashing D illumination in the

instrument cluster). When vehicle speed is less than 2 km/h (1.2 mph) Park is engaged. The JaguarDrive selector automatically

rotates back to its lowered P position and the vehicle ignition is switched off.

The park engagement is prevented in a stall case as the ignition power is on and D was the last selected gear. The park

engagement speed at ignition off is from the least value of the wheel speeds (CAN signal) and transmission output speed (internal signal).

TRANSMISSION Component Description

The transmission comprises the main casing which houses all of the transmission components. The main casing also

incorporates an integral bell housing.

A fluid pan is attached to the lower face of the main casing and is secured with bolts. The fluid pan is sealed to the main

casing with a gasket. Removal of the fluid pan allows access to the Mechatronic valve block. The fluid pan has a magnet

located around the drain plug which collects any metallic particles present in the transmission fluid.

A fluid filter is located inside the fluid pan. If the transmission fluid becomes contaminated or after any service work, the fluid

pan with integral filter must be replaced.

The integral bell housing provides protection for the torque converter assembly and also provides the attachment for the

gearbox to the engine cylinder block. The torque converter is a non-serviceable assembly which also contains the lock-up clutch

mechanism. The torque converter drives a crescent type pump via drive tangs. The fluid pump is located in the main casing,

behind the torque converter.

The main casing contains the following major components:

Input shaft

Output shaft

Mechatronic valve block which contains the solenoids, speed sensors and the TCM Three rotating multiplate drive clutches

Two fixed multiplate brake clutches

A single planetary gear train and a double planetary gear train.

Page 1441 of 3039

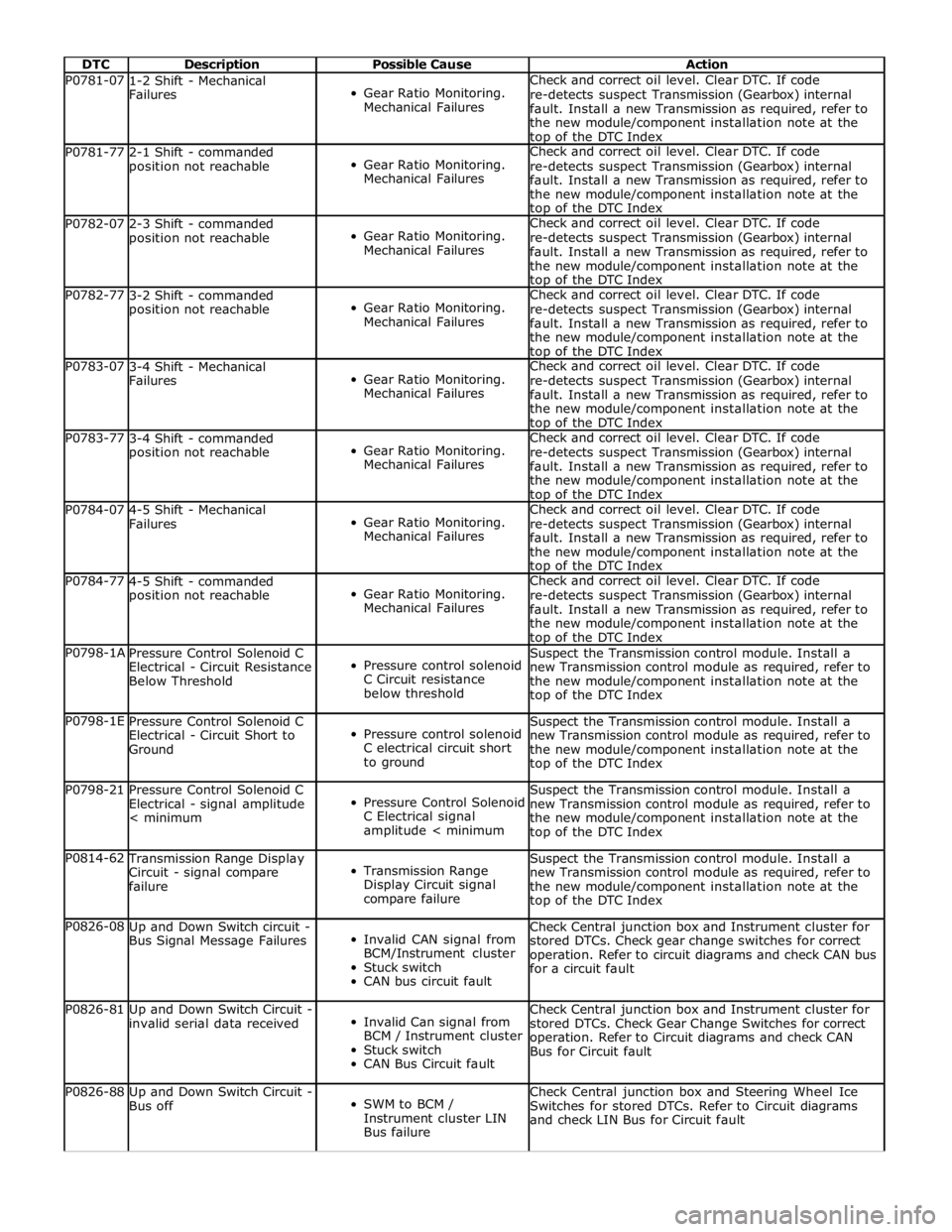

DTC Description Possible Cause Action P0781-07

1-2 Shift - Mechanical

Failures

Gear Ratio Monitoring.

Mechanical Failures Check and correct oil level. Clear DTC. If code

re-detects suspect Transmission (Gearbox) internal

fault. Install a new Transmission as required, refer to

the new module/component installation note at the top of the DTC Index P0781-77

2-1 Shift - commanded

position not reachable

Gear Ratio Monitoring.

Mechanical Failures Check and correct oil level. Clear DTC. If code

re-detects suspect Transmission (Gearbox) internal

fault. Install a new Transmission as required, refer to

the new module/component installation note at the top of the DTC Index P0782-07

2-3 Shift - commanded

position not reachable

Gear Ratio Monitoring.

Mechanical Failures Check and correct oil level. Clear DTC. If code

re-detects suspect Transmission (Gearbox) internal

fault. Install a new Transmission as required, refer to

the new module/component installation note at the top of the DTC Index P0782-77

3-2 Shift - commanded

position not reachable

Gear Ratio Monitoring.

Mechanical Failures Check and correct oil level. Clear DTC. If code

re-detects suspect Transmission (Gearbox) internal

fault. Install a new Transmission as required, refer to

the new module/component installation note at the top of the DTC Index P0783-07

3-4 Shift - Mechanical

Failures

Gear Ratio Monitoring.

Mechanical Failures Check and correct oil level. Clear DTC. If code

re-detects suspect Transmission (Gearbox) internal

fault. Install a new Transmission as required, refer to

the new module/component installation note at the top of the DTC Index P0783-77

3-4 Shift - commanded

position not reachable

Gear Ratio Monitoring.

Mechanical Failures Check and correct oil level. Clear DTC. If code

re-detects suspect Transmission (Gearbox) internal

fault. Install a new Transmission as required, refer to

the new module/component installation note at the top of the DTC Index P0784-07

4-5 Shift - Mechanical

Failures

Gear Ratio Monitoring.

Mechanical Failures Check and correct oil level. Clear DTC. If code

re-detects suspect Transmission (Gearbox) internal

fault. Install a new Transmission as required, refer to

the new module/component installation note at the top of the DTC Index P0784-77

4-5 Shift - commanded

position not reachable

Gear Ratio Monitoring.

Mechanical Failures Check and correct oil level. Clear DTC. If code

re-detects suspect Transmission (Gearbox) internal

fault. Install a new Transmission as required, refer to

the new module/component installation note at the top of the DTC Index P0798-1A

Pressure Control Solenoid C

Electrical - Circuit Resistance

Below Threshold

Pressure control solenoid

C Circuit resistance

below threshold Suspect the Transmission control module. Install a

new Transmission control module as required, refer to

the new module/component installation note at the

top of the DTC Index P0798-1E

Pressure Control Solenoid C

Electrical - Circuit Short to

Ground

Pressure control solenoid

C electrical circuit short

to ground Suspect the Transmission control module. Install a

new Transmission control module as required, refer to

the new module/component installation note at the

top of the DTC Index P0798-21

Pressure Control Solenoid C

Electrical - signal amplitude

< minimum

Pressure Control Solenoid

C Electrical signal

amplitude < minimum Suspect the Transmission control module. Install a

new Transmission control module as required, refer to

the new module/component installation note at the

top of the DTC Index P0814-62 Transmission Range Display

Circuit - signal compare

failure

Transmission Range

Display Circuit signal

compare failure Suspect the Transmission control module. Install a

new Transmission control module as required, refer to

the new module/component installation note at the

top of the DTC Index P0826-08

Up and Down Switch circuit -

Bus Signal Message Failures

Invalid CAN signal from

BCM/Instrument cluster

Stuck switch

CAN bus circuit fault Check Central junction box and Instrument cluster for

stored DTCs. Check gear change switches for correct

operation. Refer to circuit diagrams and check CAN bus

for a circuit fault P0826-81

Up and Down Switch Circuit -

invalid serial data received

Invalid Can signal from

BCM / Instrument cluster

Stuck switch

CAN Bus Circuit fault Check Central junction box and Instrument cluster for

stored DTCs. Check Gear Change Switches for correct

operation. Refer to Circuit diagrams and check CAN

Bus for Circuit fault P0826-88

Up and Down Switch Circuit -

Bus off

SWM to BCM /

Instrument cluster LIN

Bus failure Check Central junction box and Steering Wheel Ice

Switches for stored DTCs. Refer to Circuit diagrams

and check LIN Bus for Circuit fault

Page 1447 of 3039

DTC Description Possible Cause Action U0103-82

Lost Communication With

Gear Shift Control Module

A-alive / sequence counter

incorrect / not updated

Alive counter fault Check Transmission shift module for stored DTCs.

Check CAN Bus Circuit for fault U0103-83

Lost Communication With

Gear Shift Control Module A

- value of signal protection

calculation incorrect

Checksum fault Check Transmission shift module for stored DTCs.

Check CAN Bus Circuit for fault U0103-87

Lost Communication With

Gear Shift Control Module A

- missing message

CAN Timeout Check Transmission shift module for stored DTCs.

Check CAN Bus Circuit for fault U0122-82

Lost Communication With

Vehicle Dynamics Control

Module - alive / sequence

counter incorrect / not updated

Alive counter fault Check Anti-lock braking system for stored DTCs. Check

CAN Bus Circuit for fault U0122-83

Lost Communication With

Vehicle Dynamics Control

Module - value of signal

protection calculation

incorrect

Checksum fault Check Anti-lock braking system for stored DTCs. Check

CAN Bus Circuit for fault U0122-87

Lost Communication With

Vehicle Dynamics Control

Module - missing message

CAN Timeout Check Anti-lock braking system for stored DTCs. Check

CAN Bus Circuit for fault U0126-00

Lost Communication With

Steering Angle Sensor

Module - no sub type

information

Lost Communication

With Steering Angle

Sensor Module Check Steering angle sensor for stored DTCs. Check

CAN Bus Circuit for fault U0128-87

Lost Communication With

Park Brake Control Module -

missing message

CAN timeout electronic

parking brake module Check Electronic Parking Brake Module for stored DTCs.

Check CAN Bus Circuit for fault U0140-82

Lost Communication With

Body Control Module - alive / sequence counter incorrect / not updated

Alive counter fault Check Central junction box for stored DTCs. Check CAN

Bus Circuit for fault U0140-83

Lost Communication With

Body Control Module - value

of signal protection

calculation incorrect

Checksum fault Check Central junction box for stored DTCs. Check CAN

Bus Circuit for fault U0140-87

Lost Communication With

Body Control Module - missing message

CAN Timeout Check Central junction box for stored DTCs. Check CAN

Bus Circuit for fault U0155-87

Lost Communication With

Instrument Panel Cluster

(Instrument cluster) Control

Module - missing message

CAN timeout instrument

cluster Check Instrument cluster for stored DTCs. Check CAN

Bus Circuit for fault U0300-68

Control Module - event

information

Transmission software

does not match vehicle

network Check Central junction box software level, Check

Transmission control module Software level, Update

software as required using the manufacturer approved

process U0401-08

Invalid Data Received From

Engine control module/PCM

A - Bus Signal Message

Failures

Inaccurate engine speed,

torque information Check Engine control module for stored DTCs, Check

CAN Bus circuit for faults U0401-68

Invalid Data Received from

Engine control module/PCM

A - event information

Inaccurate engine speed,

torque information Check Engine control module for stored DTCs. Check

CAN Bus Circuit for fault U0401-86

Invalid Data Received from

Engine control module/PCM

A - Signal Invalid

Inaccurate engine speed,

torque information Check Engine control module for stored DTCs. Check

CAN Bus Circuit for fault U0404-68

Invalid Data Received from

Gear Shift Control Module A

- event information

Incorrect CAN data

received from

Transmission shift

module Check Transmission Shift Module for stored DTCs.

Refer to Circuit diagrams and check CAN and LIN Bus

for Circuit fault U0404-81

Invalid Data Received from

Gear Shift Control Module A

- Invalid Serial Data

Received

Incorrect LIN data

received from

Transmission shift

module Check Transmission Shift Module for stored DTCs.

Refer to Circuit diagrams and check CAN and LIN Bus

for Circuit fault www.JagDocs.com

Page 1530 of 3039

6 Clockspring 7 Steering wheel audio switches 8 Upshift paddle switch 9 Downshift paddle switch 10 Instrument cluster 11 JaguarDrive selector

JAGUARDRIVE SELECTOR System Operation

Rotation of the JaguarDrive selector to any of the five positions is sensed by the TCM (transmission control module) via the

high speed CAN bus. A LIN bus connection is also provided, but is only used in the event of a CAN bus failure as a back-up. The TCM then reacts according to the selected position. The JaguarDrive selector is a magnetic system using Hall effect sensors to determine the position of the selector.

The S (sport) position selection allows the TCM to operate the transmission using the semi-automatic Jaguar sequential shift. Gear selections are sensed by the TCM when the driver operates the steering wheel paddle switches. Once the JaguarDrive selector position is confirmed, the TCM outputs appropriate information on the high speed CAN bus which is received by the instrument cluster to display the gear selection information in the message center.

Refer to: Information and Message Center (413-08 Information and Message Center, Description and Operation).

The paddles can also be used on a temporary basis when the JaguarDrive selector is in the D (drive) position to override the

automatic gear selection if required.

PARK INTERLOCK AND NEUTRAL LOCK

Neutral lock is a requirement for the JaguarDrive selector. The selector is always locked at ignition on when the engine is not

running, except after an engine stall when the selector is not in P (park) or N (neutral).

If, when driving with the JaguarDrive selector in S, D or R (reverse) at a speed of more than 5 km/h (3 mph), the driver selects

P or N:

Without the brake pedal pressed, the JaguarDrive selector will be immediately locked once the vehicle speed falls to

below 5 km/h (3 mph).

With the brake pedal pressed, the JaguarDrive selector will remain locked for as long as the brake pedal remains

pressed, regardless of vehicle speed.

The transmission will only engage park once the vehicle speed is less than 2 km/h (1 mph).

If the driver selects N and releases the brake pedal with a vehicle speed of less than 5 km/h (3 mph), the JaguarDrive selector

will be locked 2 seconds after N is selected. The selector will remain locked until the driver presses the brake pedal again.

To ensure that a driver request to change from a non-driving range (N for example) to a driving range (D for example), the park

interlock and neutral lock features are used in conjunction with the intermediate position.

If the transmission receives a range change request without the brake pedal pressed, the TCM initiates a soft lock function. The transmission will remain in park or neutral, depending on the starting position.

If a transmission position letter is flashing in the message center and the vehicle has no drive, the driver must:

Press the brake pedal.

Reselect N or P on the JaguarDrive selector.

Select the required driving range, ensuring that the brake pedal is pressed.

Rocking Function

The rocking function compliments the neutral lock function. For all changes from a non-driving range to a driving range, it is

necessary to press the brake pedal (to release either the park interlock or neutral lock).

In situations where the driver will require to change the gear selection from R to D, or from D to R, without brake pedal input

(car park maneuvering, 3 point turns or 'rocking' the vehicle from a slippery surface for example), the rocking function gives a 2

second lock delay when N is selected on the JaguarDrive selector and the brake pedal is not pressed.

Intermediate Position

If the JaguarDrive selector is rotated slowly from P to S and back to position P with the brake pedal pressed, the R or D

position display letter in the message center will flash and the transmission will remain in park or neutral depending on the

previous starting position of the selector.

If the brake pedal is released when R or D is flashing in the message center and the JaguarDrive selector is rotated to the R or

D position, the required range will not be selected and the transmission will remain in park or neutral, depending on the

previous starting position. This feature is known as soft lock.

If the driving range letter in the message center is flashing and the vehicle has no drive, the driver should depress the brake

pedal to reselect N or P, and then select the required driving range while the brake pedal remains pressed.

Page 1532 of 3039

signal which is passed via the clockspring to the instrument cluster. The instrument cluster converts the signal into a high

speed CAN bus signal to the TCM.

Pulling the LH (left-hand) downshift - paddle provides down changes and pulling the RH (right-hand) upshift (+) paddle

provides up changes. The first operation of either paddle, after sport mode is selected, puts the transmission into permanent

manual Jaguar sequential shift mode. Rotation of the JaguarDrive selector back to the D position, returns the transmission to

conventional automatic operation.

Temporary operation of manual Jaguar sequential shift mode can also be operated with the JaguarDrive selector in the D

position. Operation of either the upshift or downshift paddles activates the manual mode operation. If the JaguarDrive selector

is in D, Jaguar sequential shift will cancel after a time period or can be cancelled by pressing and holding the + paddle for

approximately 2 seconds. PADDLE SWITCHES

Page 1591 of 3039

1 Magnetic foil 2 Spacer 3 Ceramic surface 4 Magnet 5 Resistance film The film resistors are arranged in a linear arc with resistance ranging from 51.2 to 992.11 Ohms. The electrical output signal is

proportional to the amount of fuel in the tank and the position of the float arm. The measured resistance is processed by the

instrument cluster to implement an anti-slosh function. This monitors the signal and updates the fuel gauge pointer position

at regular intervals, preventing constant pointer movement caused by fuel movement in the tank due to cornering or braking.

A warning lamp is incorporated in the instrument cluster and illuminates when the fuel level is low.

The fuel level sender signal is converted into a CAN message by the instrument cluster as a direct interpretation of the fuel tank contents in liters. The ECM uses the CAN message to store additional OBD (on-board diagnostic) 'P' Codes for misfire detection when the fuel level is below a predetermined capacity.

JET PUMP

The fuel system incorporates two jet pumps. One jet pump is integrated into the fuel pump and draws fuel from the RH side of the fuel tank. The other jet pump is located on the fuel delivery module on the RH side of the tank. There is a pipe that is located in the LH side of the tank that allows fuel to be drawn over from the LH side of the tank, delivering fuel into the swirl pot. The jet pumps operate on a venturi effect created by the fuel at pump output pressure passing through the jet pump. This

draws additional fuel from the LH side of the tank through ports in the jet pump body, delivering additional fuel to the swirl pot.

FUEL VENT VALVE

The fuel level vent valve is located in the upper half of the tank and is connected into a separator which is connected to the

Roll Over Valve (ROV) tank breather. The main purpose of the fuel level vent valve is to control the fill volume of the tank.

During filling, air trapped inside the tank and a small amount of vapor is passed via the fuel level vent valve to the tank

breather. The air and vapor mix then vents to atmosphere through the breather. During filling, when the tank reaches its full

level, the fuel level vent valve closes and prevents air/vapor passing through to the tank breather. The resulting back pressure

causes refueling to stop automatically.

The fuel level vent valve is always open when the fuel tank is below full, providing an unrestricted air/vapor outlet to the tank

breather.

www.JagDocs.com

Page 1597 of 3039

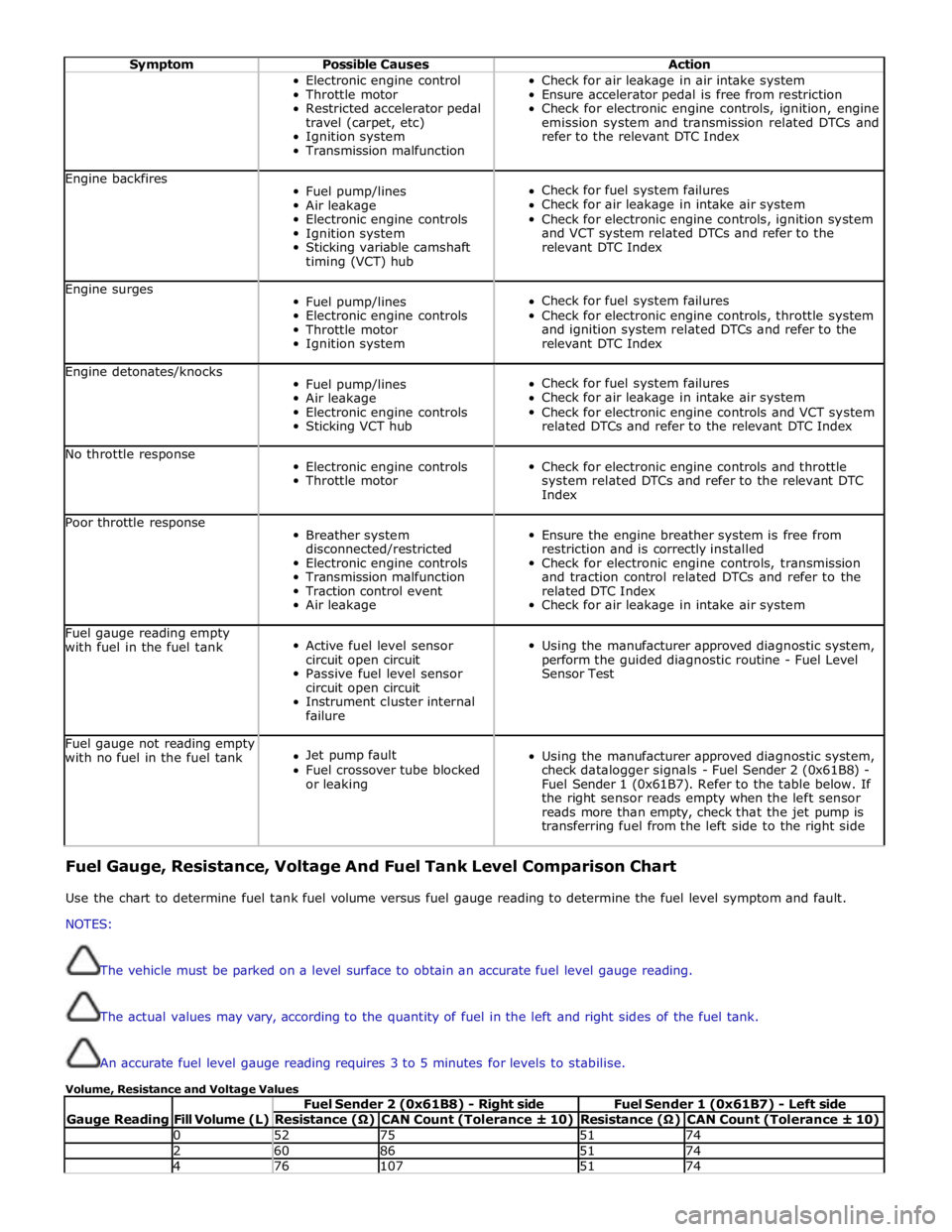

Symptom Possible Causes Action Electronic engine control

Throttle motor

Restricted accelerator pedal

travel (carpet, etc)

Ignition system

Transmission malfunction Check for air leakage in air intake system

Ensure accelerator pedal is free from restriction

Check for electronic engine controls, ignition, engine

emission system and transmission related DTCs and

refer to the relevant DTC Index Engine backfires

Fuel pump/lines

Air leakage

Electronic engine controls

Ignition system

Sticking variable camshaft

timing (VCT) hub

Check for fuel system failures

Check for air leakage in intake air system

Check for electronic engine controls, ignition system

and VCT system related DTCs and refer to the

relevant DTC Index Engine surges

Fuel pump/lines

Electronic engine controls

Throttle motor

Ignition system

Check for fuel system failures

Check for electronic engine controls, throttle system

and ignition system related DTCs and refer to the

relevant DTC Index Engine detonates/knocks

Fuel pump/lines

Air leakage

Electronic engine controls

Sticking VCT hub

Check for fuel system failures

Check for air leakage in intake air system

Check for electronic engine controls and VCT system

related DTCs and refer to the relevant DTC Index No throttle response

Electronic engine controls

Throttle motor

Check for electronic engine controls and throttle

system related DTCs and refer to the relevant DTC

Index Poor throttle response

Breather system

disconnected/restricted

Electronic engine controls

Transmission malfunction

Traction control event

Air leakage

Ensure the engine breather system is free from

restriction and is correctly installed

Check for electronic engine controls, transmission

and traction control related DTCs and refer to the

related DTC Index

Check for air leakage in intake air system Fuel gauge reading empty

with fuel in the fuel tank

Active fuel level sensor

circuit open circuit

Passive fuel level sensor

circuit open circuit

Instrument cluster internal

failure

Using the manufacturer approved diagnostic system,

perform the guided diagnostic routine - Fuel Level

Sensor Test Fuel gauge not reading empty

with no fuel in the fuel tank

Jet pump fault

Fuel crossover tube blocked

or leaking

Using the manufacturer approved diagnostic system,

check datalogger signals - Fuel Sender 2 (0x61B8) -

Fuel Sender 1 (0x61B7). Refer to the table below. If

the right sensor reads empty when the left sensor

reads more than empty, check that the jet pump is

transferring fuel from the left side to the right side Fuel Gauge, Resistance, Voltage And Fuel Tank Level Comparison Chart

Use the chart to determine fuel tank fuel volume versus fuel gauge reading to determine the fuel level symptom and fault.

NOTES:

The vehicle must be parked on a level surface to obtain an accurate fuel level gauge reading.

The actual values may vary, according to the quantity of fuel in the left and right sides of the fuel tank.

An accurate fuel level gauge reading requires 3 to 5 minutes for levels to stabilise.

Volume, Resistance and Voltage Values

Gauge Reading

Fill Volume (L) Fuel Sender 2 (0x61B8) - Right side Fuel Sender 1 (0x61B7) - Left side Resistance (Ω) CAN Count (Tolerance ± 10) Resistance (Ω) CAN Count (Tolerance ± 10) 0 52 75 51 74 2 60 86 51 74 4 76 107 51 74

Page 1637 of 3039

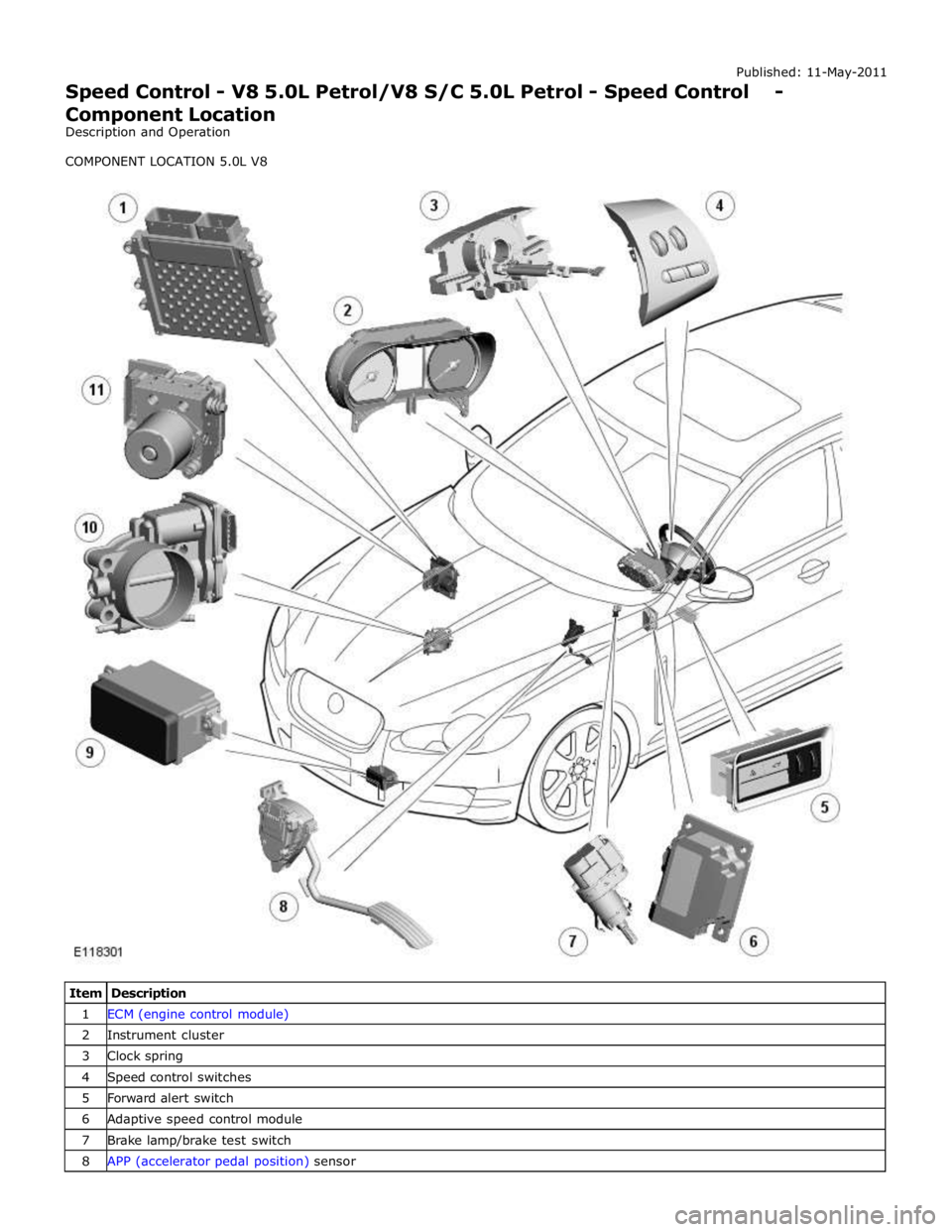

1 ECM (engine control module) 2 Instrument cluster 3 Clock spring 4 Speed control switches 5 Forward alert switch 6 Adaptive speed control module 7 Brake lamp/brake test switch 8 APP (accelerator pedal position) sensor

Page 1639 of 3039

Published: 11-May-2011

Speed Control - V8 5.0L Petrol/V8 S/C 5.0L Petrol - Speed Control - Overview

Description and Operation

OVERVIEW

Speed Control

The speed control system is integrated with the engine management system and uses fueling intervention to automatically

maintain a set vehicle speed. Once engaged, the system can also be used to accelerate the vehicle without using the

accelerator pedal.

The speed control system comprises the following components:

On/Off/Suspend switch

'+' and '-' (set/accelerate and decelerate) steering wheel switches

Resume switch

Clock spring

Speed control warning indicator.

Adaptive Speed Control

The adaptive speed control system uses a forward looking radar sensor to scan the road ahead, looking for objects that are

moving at a different rate to itself. When a target is identified the adaptive speed control system will monitor the time gap

between it and the target vehicle. When that gap falls below a set driver selected level the adaptive speed control system will

intervene slowing the vehicle by backing off the throttle and/ or applying the brakes, until the correct gap is attained.

The adaptive speed control system comprises the following components:

Adaptive speed control sensor

Adaptive speed control module

Steering wheel control switches

ECM (engine control module)

Electric throttle actuator

ABS (anti-lock brake system) module and pump

Adaptive speed control warning indicator (in the instrument cluster).

Page 1641 of 3039

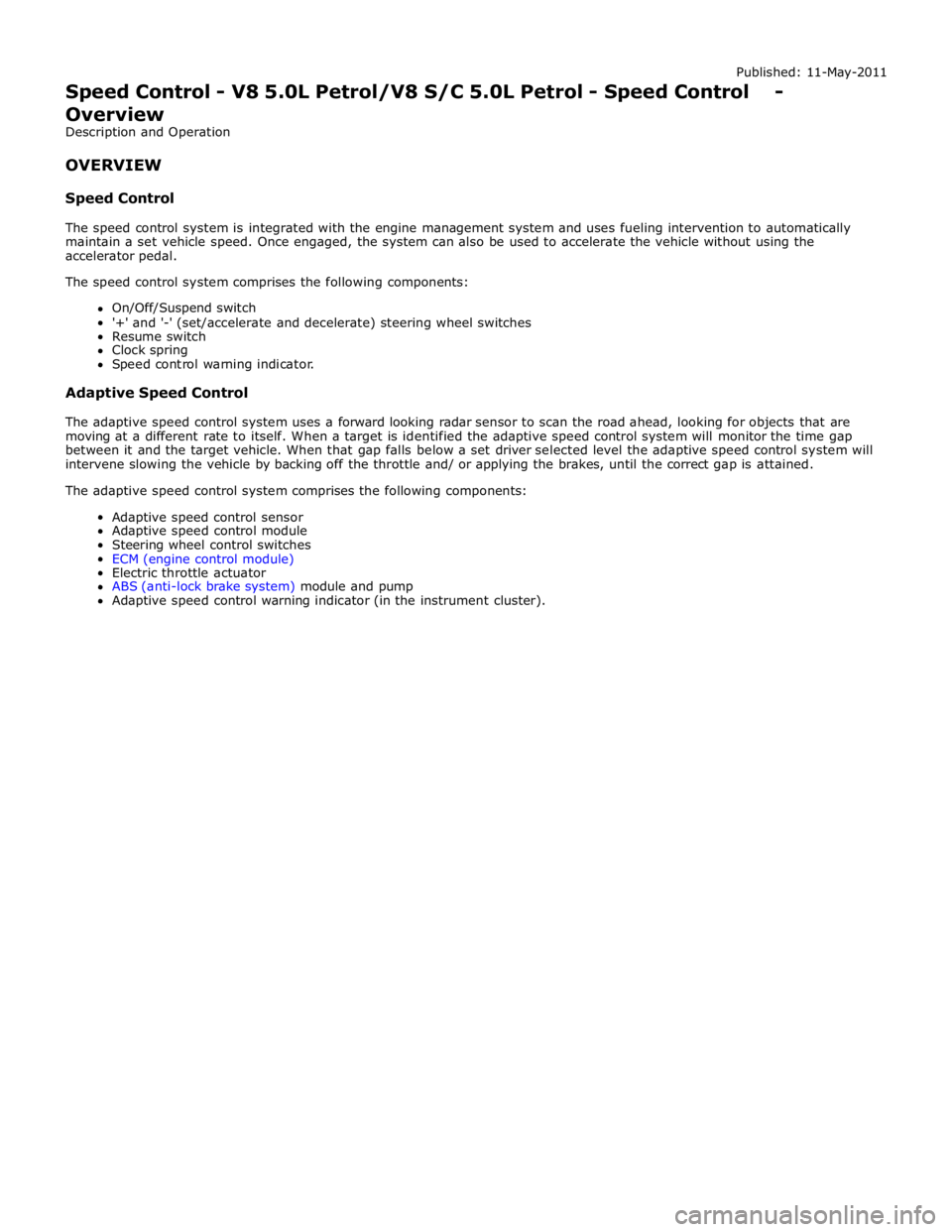

6 Clockspring 7 APP (accelerator pedal position) sensor 8 Electric throttle actuator 9 Brake lamp/brake test switch 10 Adaptive speed control radar sensor 11 Diagnostic socket 12 Instrument cluster 13 TCM (transmission control module) 14 Adaptive speed control module

SPEED CONTROL System Operation

The speed control system uses inputs from the brake lamp/brake test switch, the APP sensor, the ECM and the ABS module.

Speed control is operated by the driver using only the steering wheel switches. When speed control is active, the ECM regulates the PWM (pulse width modulation) signals to the fuel injectors to adjust the fuel supply as required to maintain the

set speed.

During speed control operation, the ECM controls vehicle speed by adjusting fuel injection duration and timing. When the accelerator pedal is pressed with speed control active, the ECM outputs a calculated throttle angle signal in place of the actual throttle angle signals produced by the APP sensor. The calculated throttle angle is derived from fuel demand.

The minimum set speed for speed control is 18 mph (30 (km/h). Speed control is automatically suspended if the following

conditions apply:

Vehicle speed falls below 18 mph (30 km/h)

The brake pedal is pressed

The cancel button is pressed

Neutral, park or reverse gear is selected

The difference between actual speed and the set speed is too great

If the engine speed becomes near to the red line (maximum engine speed)

If the accelerator pedal is used to accelerate beyond the set speed for too long.

ADAPTIVE SPEED CONTROL

The adaptive speed control system comprises the following components:

Adaptive speed control sensor

Adaptive speed control module

Steering wheel control switches

ECM

Electric throttle actuator

ABS module and pump Adaptive speed control warning indicator.

The adaptive speed control system uses a forward looking radar sensor to scan the road ahead, looking for objects that are

moving at a different rate to itself. When a target is identified the adaptive speed control system will monitor the time gap

between it and the target vehicle. When that gap falls below a set driver selected level the adaptive speed control system will

intervene slowing the vehicle by backing off the throttle and/ or applying the brakes, until the correct gap is attained. The

driver can chose between four gap settings, 1, 1.4, 1.8 and 2.2 seconds.

The system will detect but not react to the following:

Vehicles in the oncoming lane

Stationary vehicles

Pedestrians

Vehicles not in the same lane.

Adaptive speed control is active when the vehicle is moving. Adaptive Speed Control only functions when a set speed is

entered in normal speed control mode. The adaptive speed control system only intervenes with the set speed when it detects

a target vehicle, and then only if the minimum time gap is breached.

It is important to note that the system is intended for use in limited driving situations, does not remove control and

responsibility from the driver, and at all times can be quickly overridden. The adaptive speed control system is not a collision

warning system and will not react to stationary objects. The system does not operate below a minimum speed of

approximately 30 km/h (20 mph) since it is unsuitable for use in cities or congested traffic. The system is best suited to main

roads/ highways with gradual bends.

The ECM, throttle body and throttle control are unchanged from those used for non adaptive speed control variants.

The adaptive speed control system is based on the use of a front mounted radar sensor. The sensor transmits a 1.5° wide

beam forward of the vehicle and detects the returning signals reflected off other vehicles and objects ahead.

The 1.5° wide radar beam is mechanically scanned at a rate of 10 sweeps/second across a total arc of 15° centered on the