tires JAGUAR XFR 2010 1.G Owners Manual

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 2010, Model line: XFR, Model: JAGUAR XFR 2010 1.GPages: 3039, PDF Size: 58.49 MB

Page 1824 of 3039

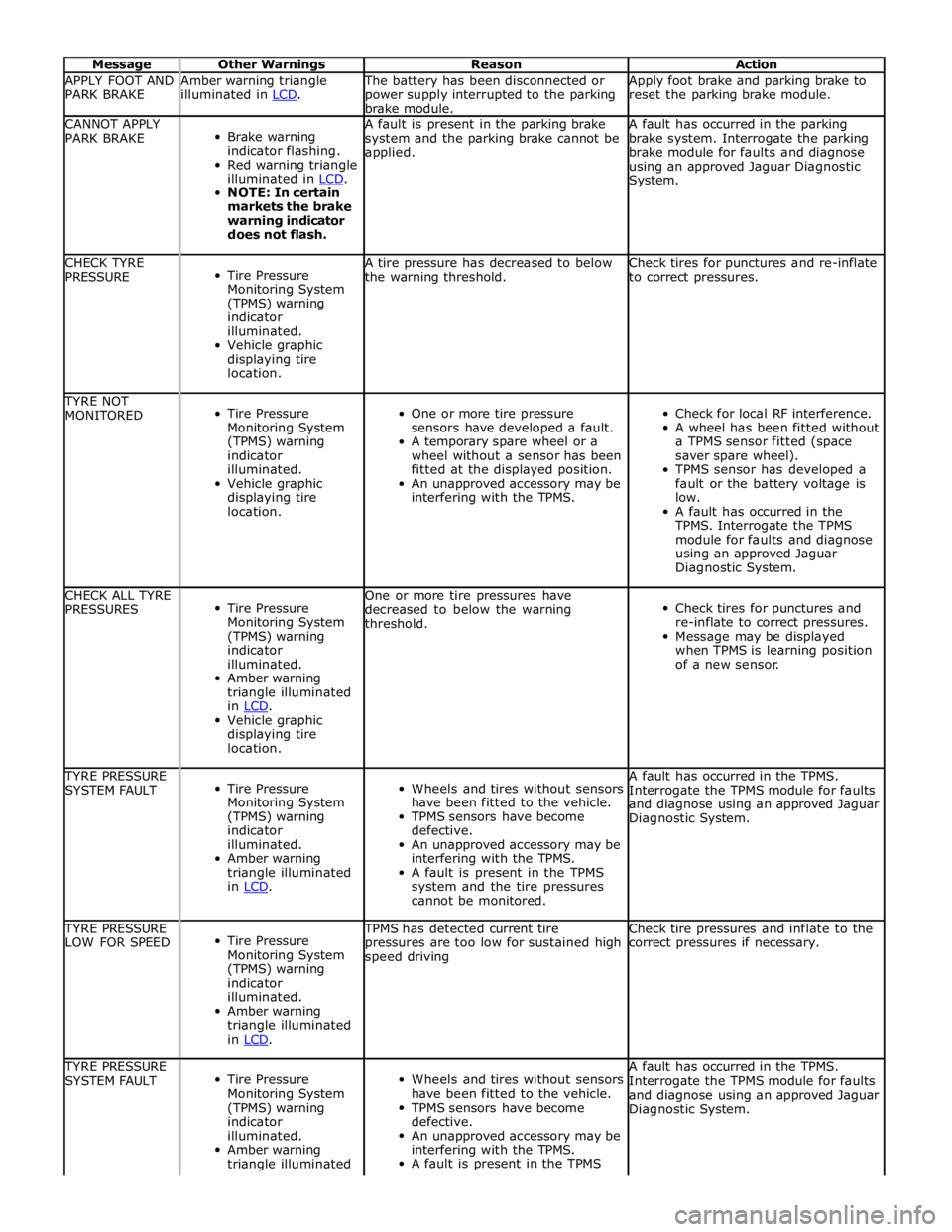

Message Other Warnings Reason Action APPLY FOOT AND

PARK BRAKE Amber warning triangle

illuminated in LCD. The battery has been disconnected or

power supply interrupted to the parking

brake module. Apply foot brake and parking brake to

reset the parking brake module. CANNOT APPLY

PARK BRAKE

Brake warning

indicator flashing.

Red warning triangle

illuminated in LCD. NOTE: In certain

markets the brake

warning indicator

does not flash. A fault is present in the parking brake

system and the parking brake cannot be

applied. A fault has occurred in the parking

brake system. Interrogate the parking

brake module for faults and diagnose

using an approved Jaguar Diagnostic

System. CHECK TYRE

PRESSURE

Tire Pressure

Monitoring System

(TPMS) warning

indicator

illuminated.

Vehicle graphic

displaying tire

location. A tire pressure has decreased to below

the warning threshold. Check tires for punctures and re-inflate

to correct pressures. TYRE NOT

MONITORED

Tire Pressure

Monitoring System

(TPMS) warning

indicator

illuminated.

Vehicle graphic

displaying tire

location.

One or more tire pressure

sensors have developed a fault.

A temporary spare wheel or a

wheel without a sensor has been

fitted at the displayed position.

An unapproved accessory may be

interfering with the TPMS.

Check for local RF interference.

A wheel has been fitted without

a TPMS sensor fitted (space

saver spare wheel).

TPMS sensor has developed a

fault or the battery voltage is

low.

A fault has occurred in the

TPMS. Interrogate the TPMS

module for faults and diagnose

using an approved Jaguar

Diagnostic System. CHECK ALL TYRE

PRESSURES

Tire Pressure

Monitoring System

(TPMS) warning

indicator

illuminated.

Amber warning

triangle illuminated

in LCD. Vehicle graphic

displaying tire

location. One or more tire pressures have

decreased to below the warning

threshold.

Check tires for punctures and

re-inflate to correct pressures.

Message may be displayed

when TPMS is learning position

of a new sensor. TYRE PRESSURE

SYSTEM FAULT

Tire Pressure

Monitoring System

(TPMS) warning

indicator

illuminated.

Amber warning

triangle illuminated

in LCD.

Wheels and tires without sensors

have been fitted to the vehicle.

TPMS sensors have become

defective.

An unapproved accessory may be

interfering with the TPMS.

A fault is present in the TPMS

system and the tire pressures

cannot be monitored. A fault has occurred in the TPMS.

Interrogate the TPMS module for faults

and diagnose using an approved Jaguar

Diagnostic System. TYRE PRESSURE

LOW FOR SPEED

Tire Pressure

Monitoring System

(TPMS) warning

indicator

illuminated.

Amber warning

triangle illuminated

in LCD. TPMS has detected current tire

pressures are too low for sustained high

speed driving Check tire pressures and inflate to the

correct pressures if necessary. TYRE PRESSURE

SYSTEM FAULT

Tire Pressure

Monitoring System

(TPMS) warning

indicator

illuminated.

Amber warning

triangle illuminated

Wheels and tires without sensors

have been fitted to the vehicle.

TPMS sensors have become

defective.

An unapproved accessory may be

interfering with the TPMS.

A fault is present in the TPMS A fault has occurred in the TPMS.

Interrogate the TPMS module for faults

and diagnose using an approved Jaguar

Diagnostic System.

Page 2171 of 3039

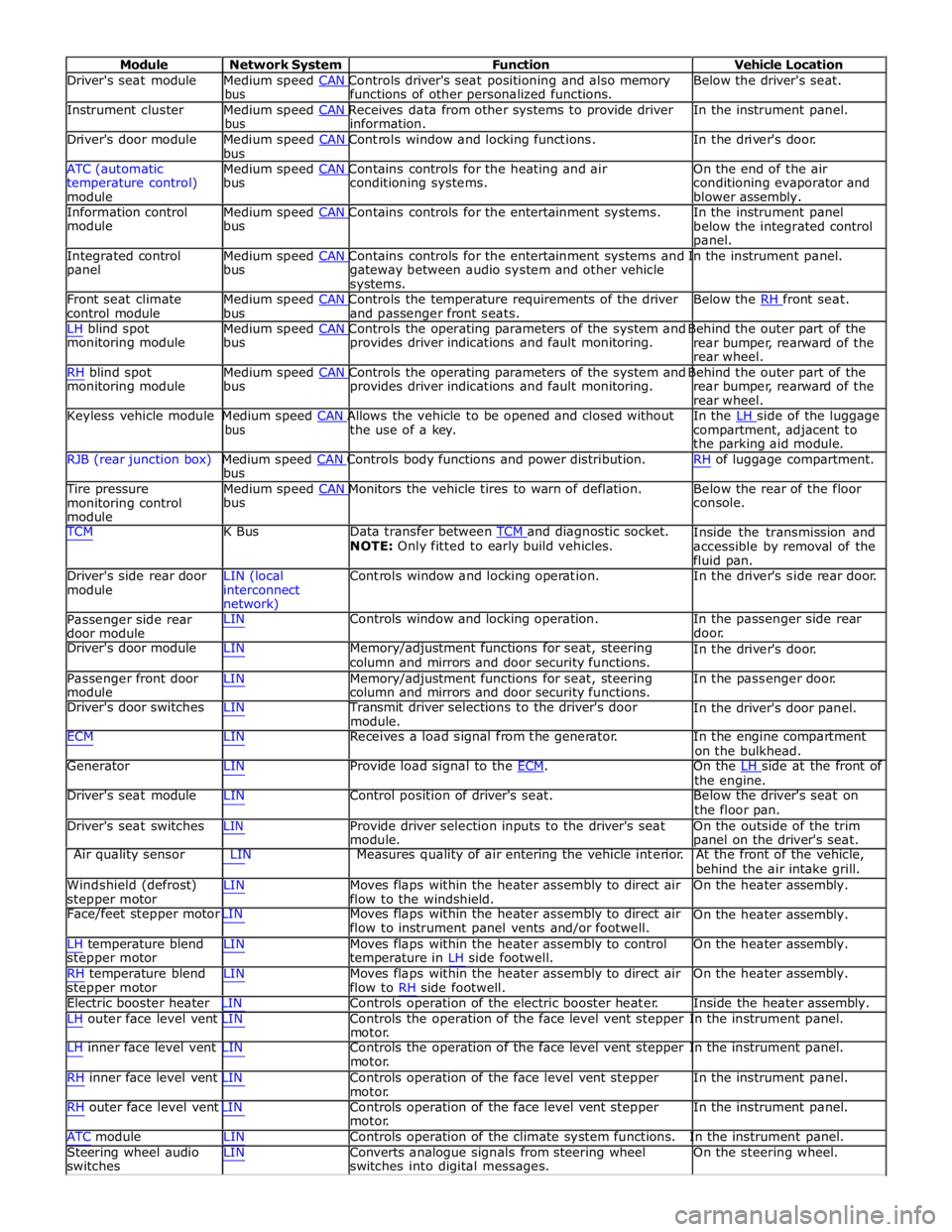

Module Network System Function Vehicle Location

Driver's seat module Medium speed CAN Controls driver's seat positioning and also memory Below the driver's seat. bus functions of other personalized functions.

Instrument cluster Medium speed CAN Receives data from other systems to provide driver In the instrument panel. bus information.

Driver's door module Medium speed CAN Controls window and locking functions. In the driver's door. bus

ATC (automatic Medium speed CAN Contains controls for the heating and air On the end of the air

temperature control)

module bus conditioning systems.

conditioning evaporator and

blower assembly.

Information control Medium speed CAN Contains controls for the entertainment systems. In the instrument panel module bus

below the integrated control

panel.

Integrated control Medium speed CAN Contains controls for the entertainment systems and In the instrument panel. panel bus

gateway between audio system and other vehicle

systems.

Front seat climate Medium speed CAN Controls the temperature requirements of the driver Below the RH front seat. control module bus and passenger front seats.

LH blind spot Medium speed CAN Controls the operating parameters of the system and Behind the outer part of the monitoring module bus provides driver indications and fault monitoring.

rear bumper, rearward of the

rear wheel.

RH blind spot Medium speed CAN Controls the operating parameters of the system and Behind the outer part of the monitoring module bus provides driver indications and fault monitoring.

rear bumper, rearward of the

rear wheel.

Keyless vehicle module Medium speed CAN Allows the vehicle to be opened and closed without In the LH side of the luggage bus the use of a key.

compartment, adjacent to

the parking aid module.

RJB (rear junction box) Medium speed CAN Controls body functions and power distribution. RH of luggage compartment. bus

Tire pressure Medium speed CAN Monitors the vehicle tires to warn of deflation. Below the rear of the floor monitoring control

module bus console.

TCM K Bus Data transfer between TCM and diagnostic socket. NOTE: Only fitted to early build vehicles. Inside the transmission and

accessible by removal of the

fluid pan.

Driver's side rear door

module LIN (local

interconnect

network) Controls window and locking operation. In the driver's side rear door.

Passenger side rear

door module LIN Controls window and locking operation. In the passenger side rear

door.

Driver's door module LIN Memory/adjustment functions for seat, steering

column and mirrors and door security functions. In the driver's door.

Passenger front door

module LIN Memory/adjustment functions for seat, steering

column and mirrors and door security functions. In the passenger door.

Driver's door switches LIN Transmit driver selections to the driver's door

module. In the driver's door panel.

ECM LIN Receives a load signal from the generator. In the engine compartment

on the bulkhead.

Generator LIN Provide load signal to the ECM. On the LH side at the front of the engine.

Driver's seat module LIN Control position of driver's seat. Below the driver's seat on

the floor pan.

Driver's seat switches LIN Provide driver selection inputs to the driver's seat

module. On the outside of the trim

panel on the driver's seat.

Air quality sensor LIN Measures quality of air entering the vehicle interior. At the front of the vehicle,

behind the air intake grill.

Windshield (defrost)

stepper motor LIN Moves flaps within the heater assembly to direct air

flow to the windshield. On the heater assembly.

Face/feet stepper motor LIN Moves flaps within the heater assembly to direct air

flow to instrument panel vents and/or footwell. On the heater assembly.

LH temperature blend

stepper motor

RH temperature blend

stepper motor LIN Moves flaps within the heater assembly to control

temperature in LH side footwell.

LIN Moves flaps within the heater assembly to direct air

flow to RH side footwell. On the heater assembly.

On the heater assembly.

Electric booster heater LIN Controls operation of the electric booster heater. Inside the heater assembly.

LH outer face level vent LIN Controls the operation of the face level vent stepper In the instrument panel.

motor.

LH inner face level vent LIN Controls the operation of the face level vent stepper In the instrument panel.

motor.

RH inner face level vent LIN Controls operation of the face level vent stepper

motor.

RH outer face level vent LIN Controls operation of the face level vent stepper

motor. In the instrument panel.

In the instrument panel.

ATC module LIN Controls operation of the climate system functions. In the instrument panel.

Steering wheel audio

switches LIN Converts analogue signals from steering wheel

switches into digital messages. On the steering wheel.

Page 2196 of 3039

Front End Body Panels - Fender Splash Shield

Removal and Installation

Removal

NOTE: Removal steps in this procedure may contain installation details. Published: 11-May-2011

1. WARNING: Make sure to support the vehicle with axle stands.

Raise and support the vehicle.

2. Refer to: Wheel and Tire (204-04 Wheels and Tires, Removal and Installation).

3.

Installation

1. To install, reverse the removal procedure.

Page 2724 of 3039

Cooper Pegler

Burgess Hill

Sussex

RH 15 9LA

Telephone (014446) 42526

Sika Ltd

Watchmead

Welwyn Garden City

Hertfordshire

AL7 1BQ

Telephone (01707) 394444

www.sika.co.uk

SATA Spray Equipment

Minden Industrial equipment

16 Greyfriars Road

Moreton Hall

Bury St Edmunds

Suffolk

IP32 7DX

Telephone (01284) 760791

www.sata.com

Henkel Loctite Adhesives Limited

Technologies House

Wood Lane End

Hemel Hempstead

Hertfordshire

HP2 4RQ

Telephone (01442) 278000

www.loctite.co.uk

Teroson

Henkel Ltd

Apollo Court

2 Bishops Square Business Park

Hatfield

Hertfordshire

AL10 9EY

Telephone (01707) 635000

www.henkel.co.uk

Underbody sealer

Under floor areas and the front part of the spare wheel well are treated with a plastisol PVC underbody sealer. This material is

not suitable for re-treatment. When repairing areas of underbody sealer, strip the factory-applied underbody sealer back to a

suitable break point. Ensure that a clean metal surface is exposed and that the edge of the existing adheres soundly to the

panel.

Apply new underbody sealer between primer and surface paint operations. Apply seam sealer as necessary before application

of underbody sealer. Ensure that blanking plugs and grommets in the floor pan (except those used for wax injection) are fitted

before underbody sealer application. Refit any heat-fusible plugs which have been disturbed in repair with the aid of a hot air

blower, or replace with rubber grommets

CAUTION: Ensure that suspension units, wheels, tires, power unit, drive shafts, exhaust and brakes, (including all

mounting points), are shielded prior to application of fresh underbody sealer. www.JagDocs.com

Page 2846 of 3039

Ornamentation, Removal and Installation).

8. Remove the windshield glass.

For additional information, refer to: Windshield Glass (501-11 Glass, Frames and Mechanisms, Removal and Installation).

9. Remove the pedestrian protection hood actuator.

For additional information, refer to: Pedestrian Protection Hood Actuator LH (501-20C Pedestrian Protection System, Removal and Installation) / Pedestrian Protection Hood Actuator RH (501-20C Pedestrian Protection System, Removal and Installation).

10. Release and position the floor covering to one side.

11. Release and position the bulkhead insulating material to one side.

12. Release and position the inner rocker panel wiring harness to one side.

13. Remove the wheel and tire.

For additional information, refer to: Wheel and Tire (204-04 Wheels and Tires, Removal and Installation).

14. Remove the underfloor splash shield.

15. If the right-hand A-pillar outer panel is to be repaired, release and

position the underfloor wiring harness to one side.

16. Remove the front fender.

For additional information, refer to: Front Fender (501-27 Front End Sheet Metal Repairs, Removal and Installation).

17. Remove the front door.

For additional information, refer to: Front Door (501-03 Body Closures, Removal and Installation).

18. Remove the upper and lower front door hinges.

19. Remove the hood.

For additional information, refer to: Hood (501-02 Front End Body Panels, Removal and Installation).

20. Remove the hood hinge.

Page 2893 of 3039

Interior Trim and Ornamentation, Removal and Installation).

9. Remove the front safety belt retractor.

For additional information, refer to: Front Safety Belt Retractor (501-20A Safety Belt System, Removal and Installation).

10. Remove the B-pillar side impact sensor.

For additional information, refer to: B-Pillar Side Impact Sensor (501-20B Supplemental Restraint System, Removal and Installation).

11. Remove the C-pillar side impact sensor.

For additional information, refer to: C-Pillar Side Impact Sensor (501-20B Supplemental Restraint System, Removal and Installation).

12. Release and position the floor covering to one side.

13. Release and position the inner rocker panel wiring harness to one side.

14. Remove the rear wheel and tire.

For additional information, refer to: Wheel and Tire (204-04 Wheels and Tires, Removal and Installation).

15. Remove the rear fender splash shield.

16.

Remove the rocker panel outer moulding.

17. Remove the underfloor splash shield.

18. If the right-hand rocker panel is to be repaired, release and position the

underfloor wiring harness to one side.

19. Remove the front fender.

For additional information, refer to: Front Fender (501-27 Front End Sheet Metal Repairs, Removal and Installation).

20. Remove the front door.

Page 2904 of 3039

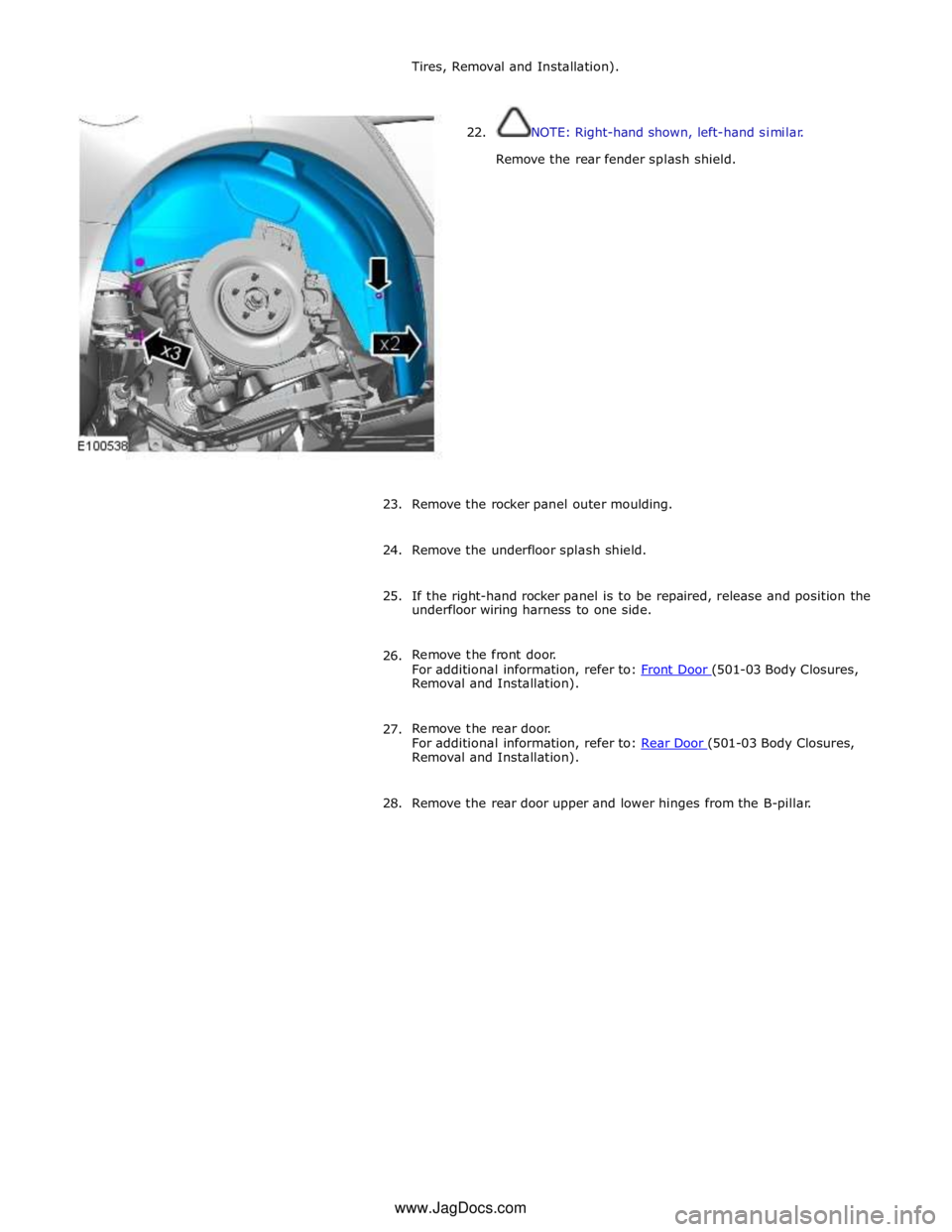

Tires, Removal and Installation).

22. NOTE: Right-hand shown, left-hand similar.

Remove the rear fender splash shield.

23. Remove the rocker panel outer moulding.

24. Remove the underfloor splash shield.

25. If the right-hand rocker panel is to be repaired, release and position the

underfloor wiring harness to one side.

26. Remove the front door.

For additional information, refer to: Front Door (501-03 Body Closures, Removal and Installation).

27. Remove the rear door.

For additional information, refer to: Rear Door (501-03 Body Closures, Removal and Installation).

28. Remove the rear door upper and lower hinges from the B-pillar. www.JagDocs.com

Page 2932 of 3039

Interior Trim and Ornamentation, Removal and Installation).

9. Remove the front safety belt retractor.

For additional information, refer to: Front Safety Belt Retractor (501-20A Safety Belt System, Removal and Installation).

10. Remove the B-pillar side impact sensor.

For additional information, refer to: B-Pillar Side Impact Sensor (501-20B Supplemental Restraint System, Removal and Installation).

11. Remove the C-pillar side impact sensor.

For additional information, refer to: C-Pillar Side Impact Sensor (501-20B Supplemental Restraint System, Removal and Installation).

12. Release and position the floor covering to one side.

13. Release and position the inner rocker panel wiring harness to one side.

14. Remove the rear wheel and tire.

For additional information, refer to: Wheel and Tire (204-04 Wheels and Tires, Removal and Installation).

15. Remove the rear fender splash shield.

16.

Remove the rocker panel outer moulding.

17. Remove the underfloor splash shield.

18. If the right-hand rocker panel rear section is to be repaired, release and

position the underfloor wiring harness to one side.

19. Remove the front door.

For additional information, refer to: Front Door (501-03 Body Closures, Removal and Installation).

20. Remove the rear door.

Page 2948 of 3039

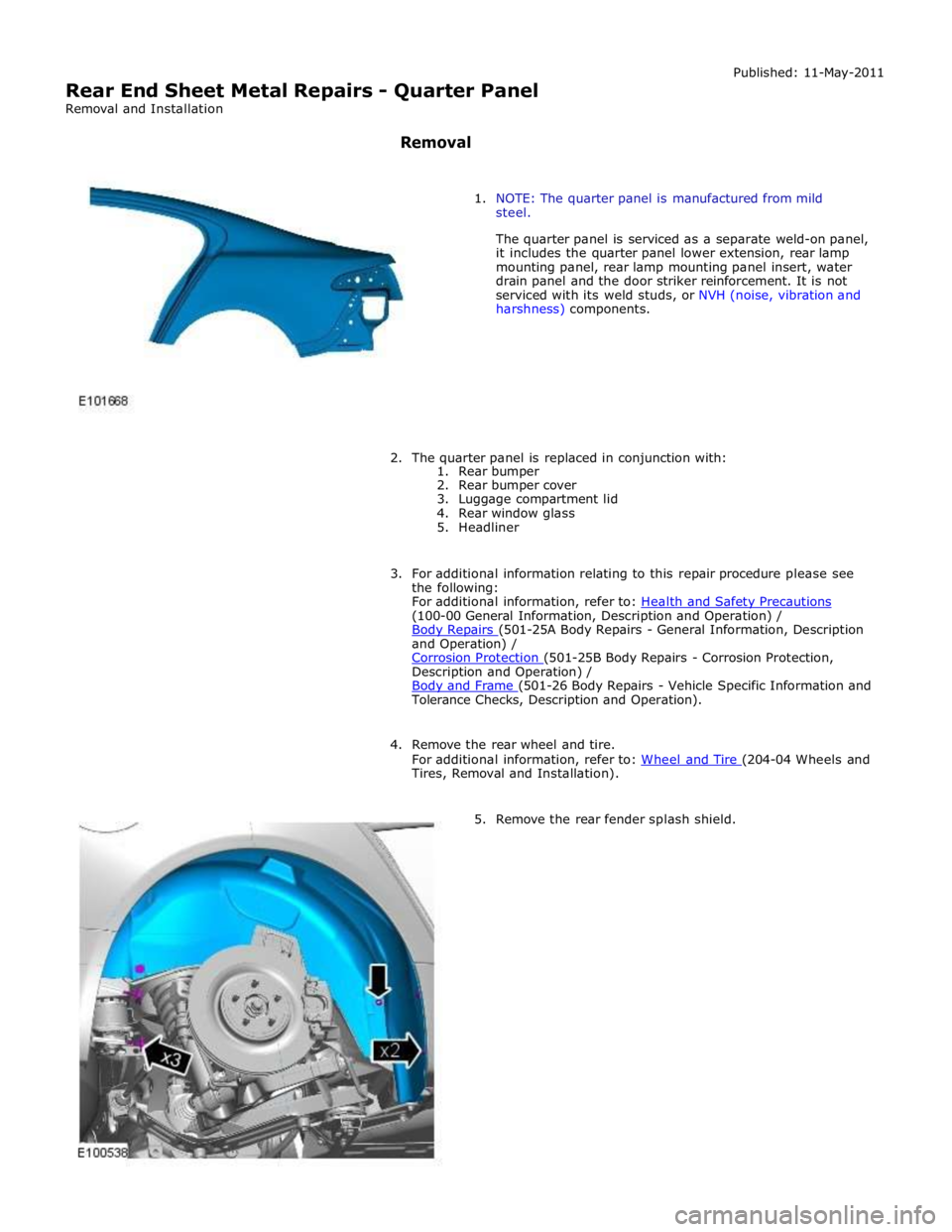

(100-00 General Information, Description and Operation) /

Body Repairs (501-25A Body Repairs - General Information, Description and Operation) /

Corrosion Protection (501-25B Body Repairs - Corrosion Protection, Description and Operation) /

Body and Frame (501-26 Body Repairs - Vehicle Specific Information and Tolerance Checks, Description and Operation).

4. Remove the rear wheel and tire.

For additional information, refer to: Wheel and Tire (204-04 Wheels and Tires, Removal and Installation).

5. Remove the rear fender splash shield.

Page 2961 of 3039

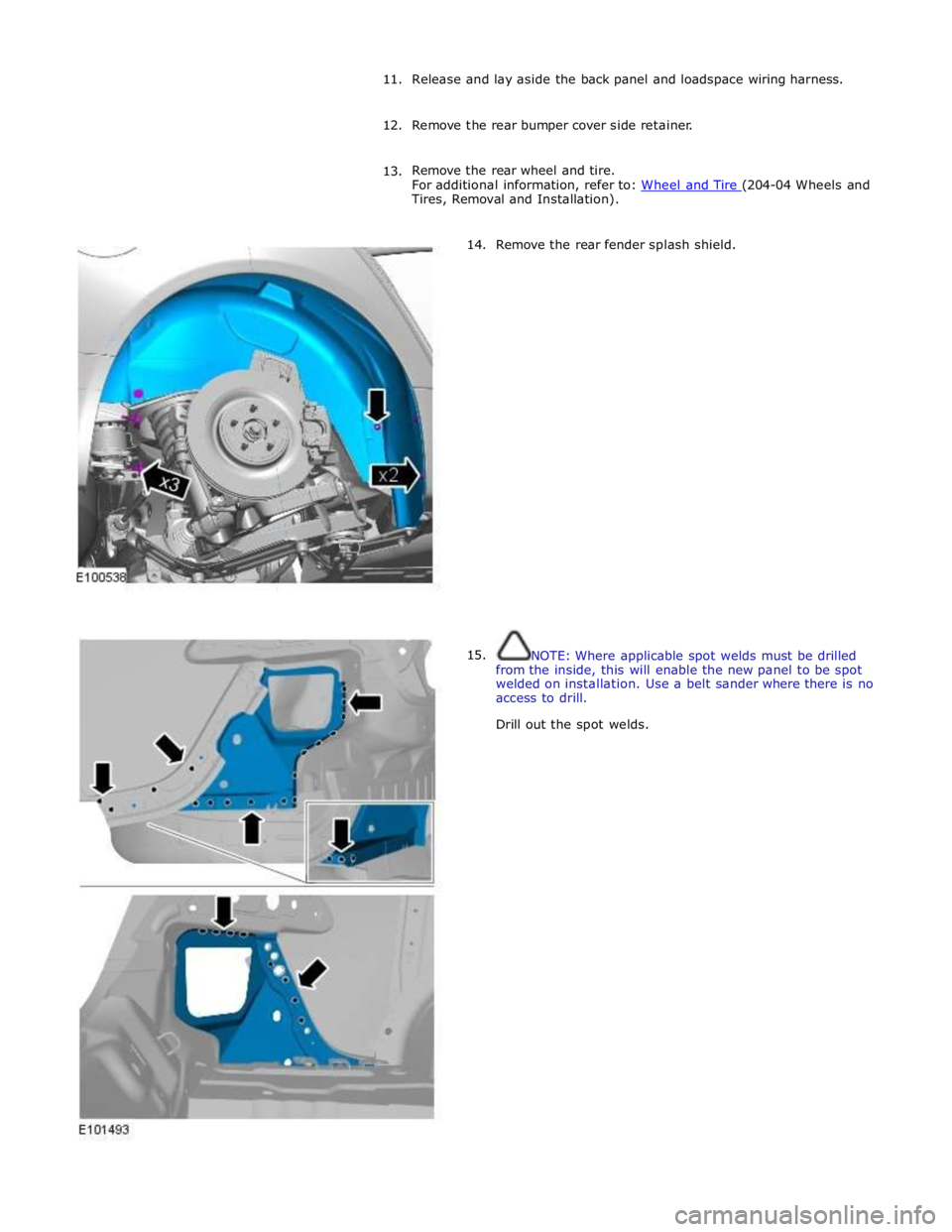

11. Release and lay aside the back panel and loadspace wiring harness.

12. Remove the rear bumper cover side retainer.

13. Remove the rear wheel and tire.

For additional information, refer to: Wheel and Tire (204-04 Wheels and Tires, Removal and Installation).

14.

15. Remove the rear fender splash shield.

NOTE: Where applicable spot welds must be drilled

from the inside, this will enable the new panel to be spot

welded on installation. Use a belt sander where there is no

access to drill.

Drill out the spot welds.