tires JAGUAR XFR 2010 1.G Repair Manual

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 2010, Model line: XFR, Model: JAGUAR XFR 2010 1.GPages: 3039, PDF Size: 58.49 MB

Page 474 of 3039

Published: 11-May-2011

Wheels and Tires - Tire Pressure Monitoring System (TPMS) Module

Removal and Installation

Removal

NOTE: Removal steps in this procedure may contain installation details.

1. Switch the igntion off.

2. Remove the right-hand front seat.

Refer to: Front Seat (501-10 Seating, Removal and Installation).

3. Refer to: B-Pillar Lower Trim Panel (501-05 Interior Trim and Ornamentation, Removal and Installation).

4. Detach and reposition the floor covering.

5. www.JagDocs.com

Page 476 of 3039

Published: 11-May-2011

Wheels and Tires - Tire Pressure Monitoring System (TPMS) Receiver

Removal and Installation

Removal

NOTES:

Removal steps in this procedure may contain installation details.

The tire pressure monitoring system receiver is installed in the same location on both LHD and RHD vehicles.

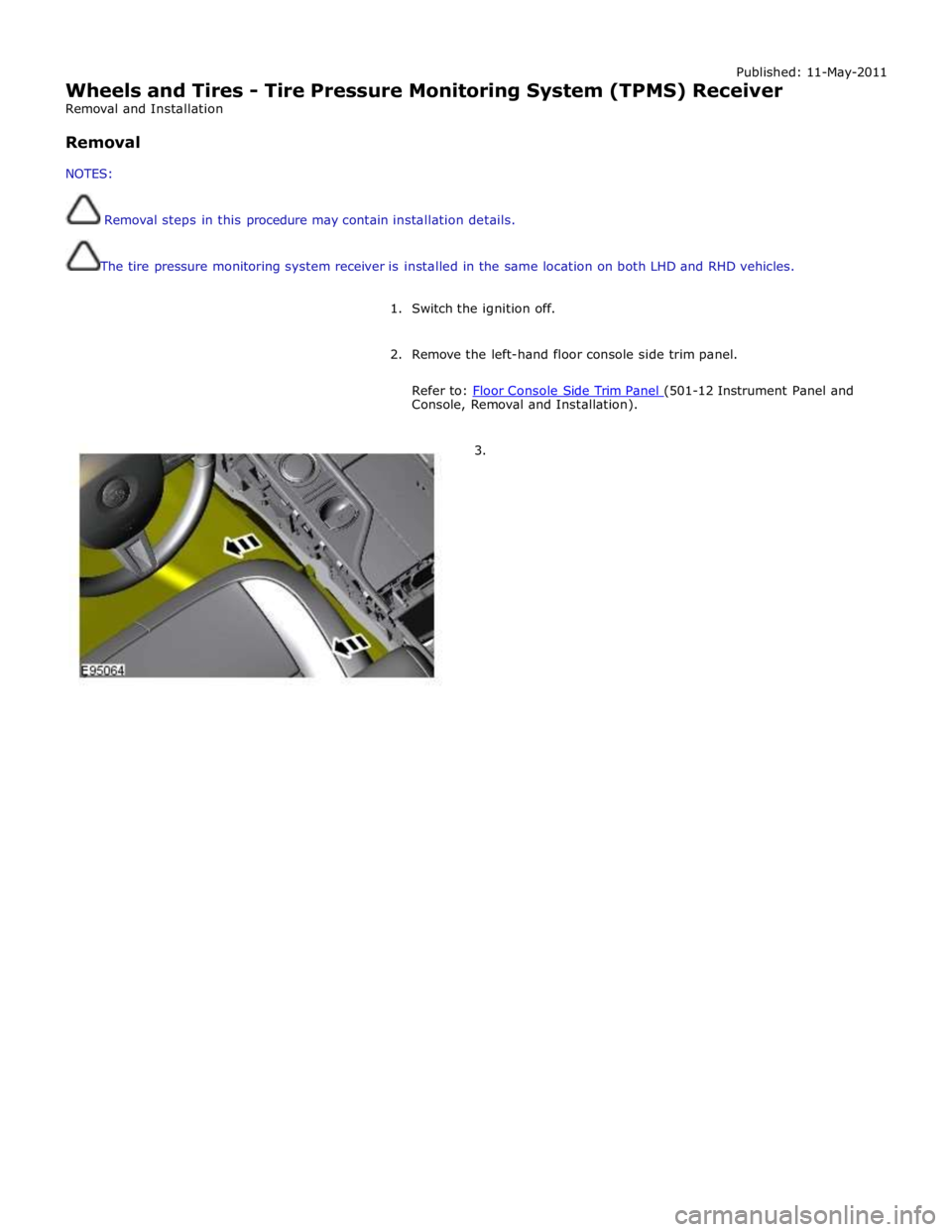

1. Switch the ignition off.

2. Remove the left-hand floor console side trim panel.

Refer to: Floor Console Side Trim Panel (501-12 Instrument Panel and Console, Removal and Installation).

3.

Page 478 of 3039

Wheels and Tires - Wheel and Tire

Removal and Installation

Removal

NOTE: Removal steps in this procedure may contain installation details. Published: 11-May-2011

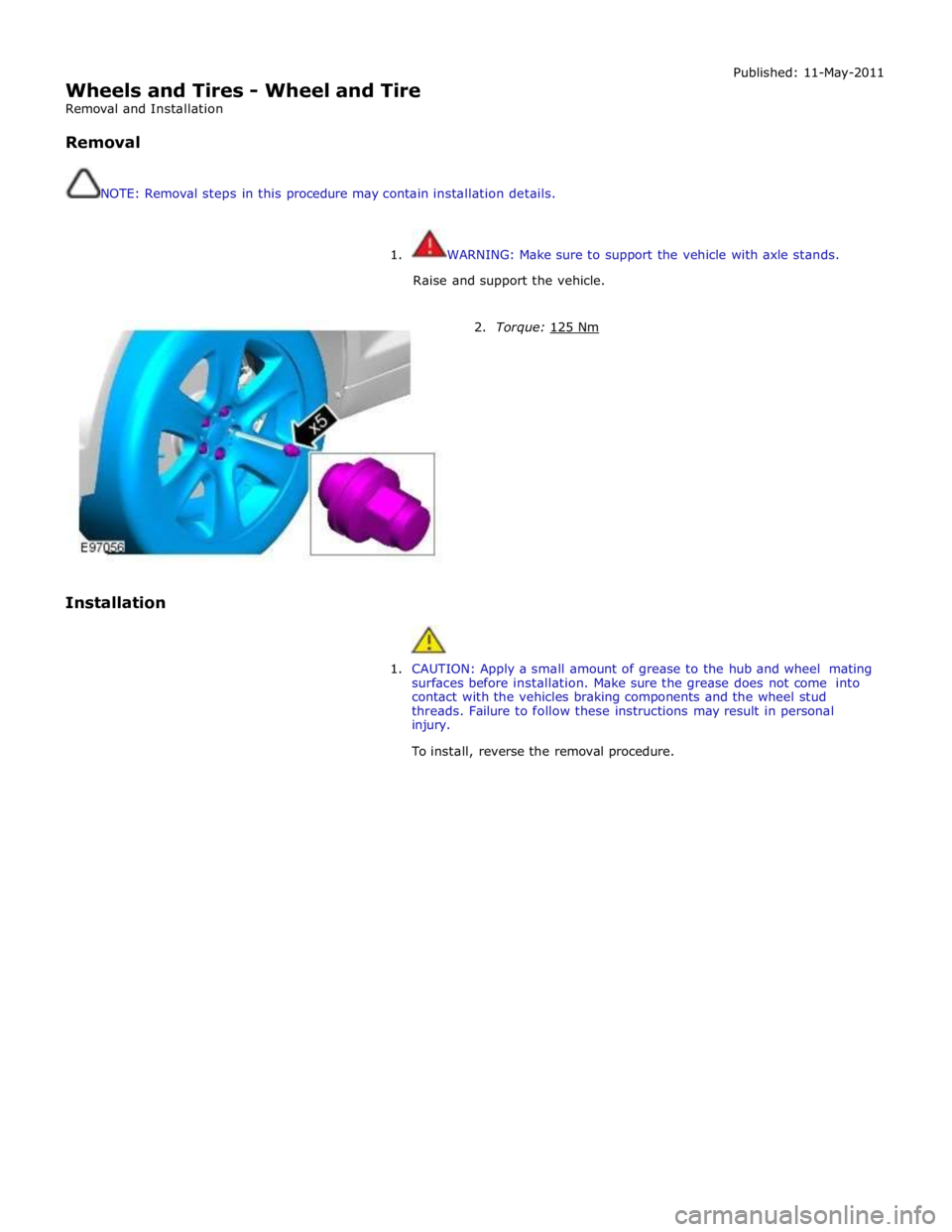

1. WARNING: Make sure to support the vehicle with axle stands.

Raise and support the vehicle.

Installation

2. Torque: 125 Nm

1. CAUTION: Apply a small amount of grease to the hub and wheel mating

surfaces before installation. Make sure the grease does not come into

contact with the vehicles braking components and the wheel stud

threads. Failure to follow these instructions may result in personal

injury.

To install, reverse the removal procedure.

Page 499 of 3039

Driveline System - General Information - Driveline System

Diagnosis and Testing

Principle of Operation Published: 11-May-2011

For a detailed description of driveline operation, refer to the relevant Description and Operation section in the workshop

manual. REFER to:

Driveshaft (205-01 Driveshaft, Description and Operation), Driveshaft (205-01 Driveshaft, Description and Operation), Driveshaft (205-01 Driveshaft, Description and Operation), Rear Drive Axle and Differential (205-02, Description and Operation),

Rear Drive Axle and Differential (205-02, Description and Operation),

Rear Drive Axle and Differential (205-02, Description and Operation),

Rear Drive Halfshafts (205-05 Rear Drive Halfshafts, Description and Operation), Rear Drive Halfshafts (205-05 Rear Drive Halfshafts, Description and Operation), Rear Drive Halfshafts (205-05 Rear Drive Halfshafts, Description and Operation).

Inspection and Verification

CAUTION: Only serviceable items can be renewed or adjusted. Failure to follow this instruction may result in the warranty

of the component being rejected.

Certain driveline trouble symptoms are also common to the engine, transmission, wheel bearings, tires, and other parts of the

vehicle. For this reason, make sure that the cause of the trouble is in the driveline before adjusting, repairing, or installing any

new components. For additional information, refer to Workshop Manual section 100-04 Noise, Vibration and Harshness.

1. Verify the customer concern by carrying out a road test of the vehicle.

2. Visually inspect for obvious signs of mechanical damage and system integrity.

3. If an obvious cause for an observed or reported concern is found, correct the cause (if possible) before proceeding to

the next step.

4. If the concern is not visually evident, verify the symptom and refer to the Symptom Chart.

Identify the Condition

Gear Howl and Whine

Howling or whining of the ring gear and pinion is due to an incorrect gear pattern, gear damage or incorrect bearing preload.

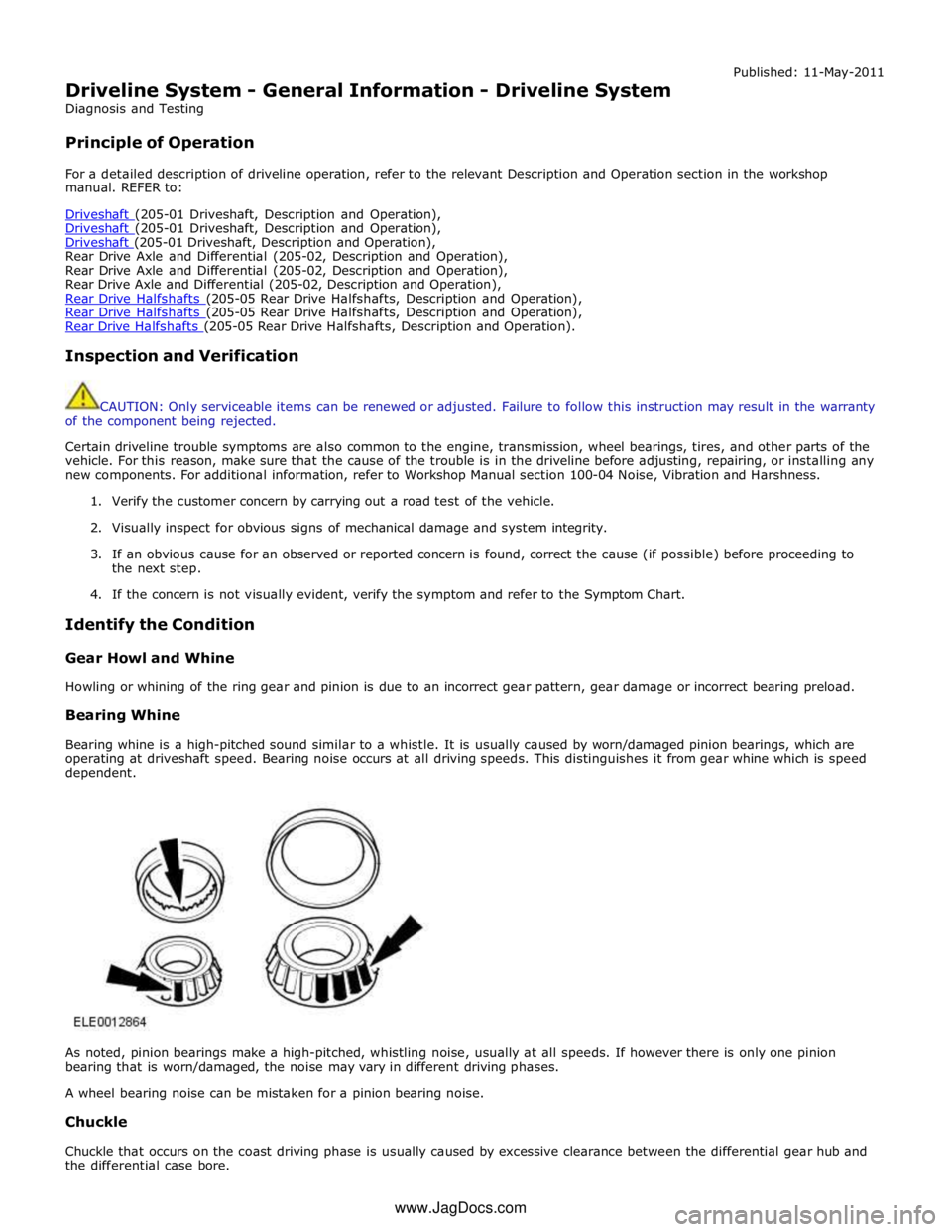

Bearing Whine

Bearing whine is a high-pitched sound similar to a whistle. It is usually caused by worn/damaged pinion bearings, which are

operating at driveshaft speed. Bearing noise occurs at all driving speeds. This distinguishes it from gear whine which is speed

dependent.

As noted, pinion bearings make a high-pitched, whistling noise, usually at all speeds. If however there is only one pinion

bearing that is worn/damaged, the noise may vary in different driving phases.

A wheel bearing noise can be mistaken for a pinion bearing noise.

Chuckle

Chuckle that occurs on the coast driving phase is usually caused by excessive clearance between the differential gear hub and

the differential case bore. www.JagDocs.com

Page 502 of 3039

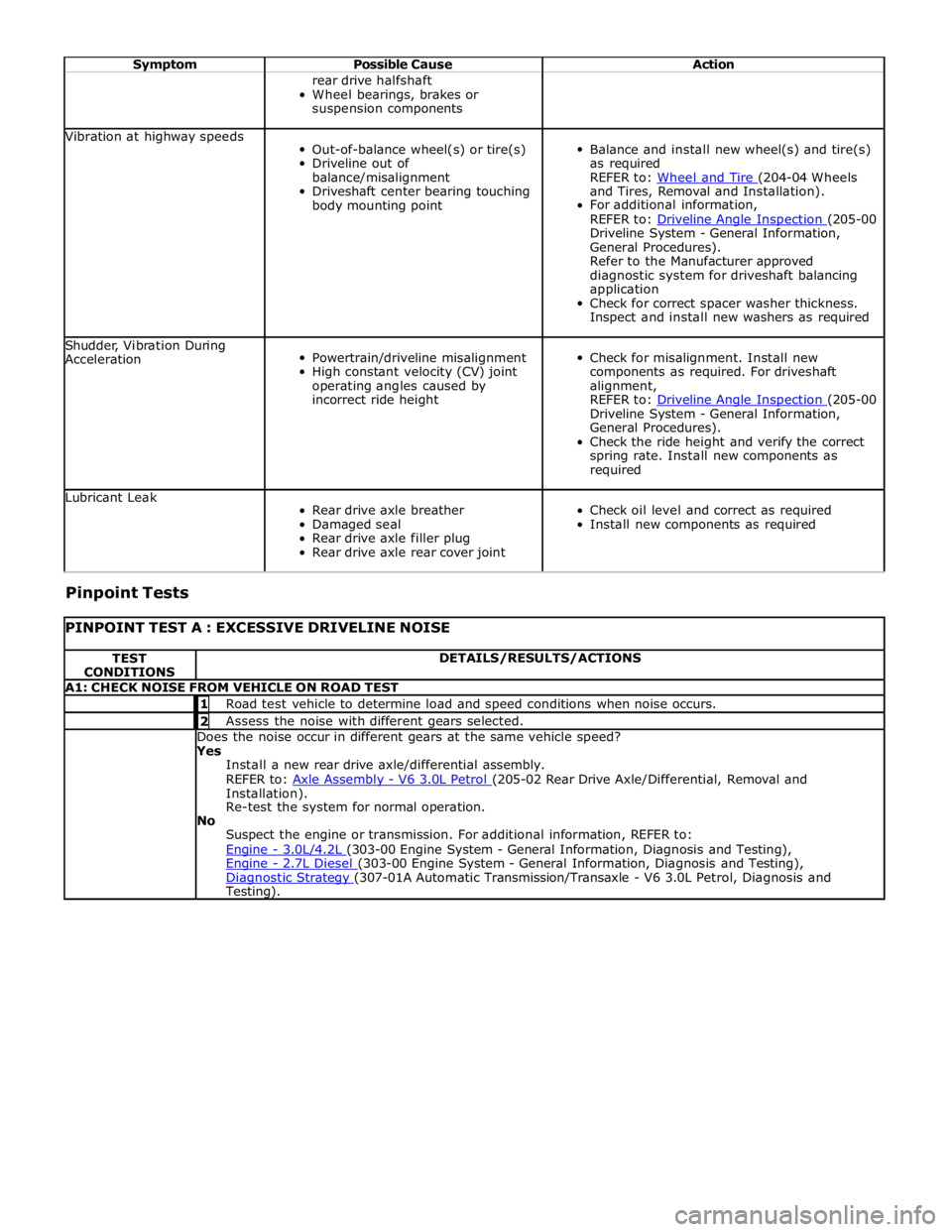

Symptom Possible Cause Action rear drive halfshaft

Wheel bearings, brakes or

suspension components Vibration at highway speeds

Out-of-balance wheel(s) or tire(s)

Driveline out of

balance/misalignment

Driveshaft center bearing touching

body mounting point

Balance and install new wheel(s) and tire(s)

as required

REFER to: Wheel and Tire (204-04 Wheels and Tires, Removal and Installation).

For additional information,

REFER to: Driveline Angle Inspection (205-00 Driveline System - General Information,

General Procedures).

Refer to the Manufacturer approved

diagnostic system for driveshaft balancing

application

Check for correct spacer washer thickness.

Inspect and install new washers as required Shudder, Vibration During

Acceleration

Powertrain/driveline misalignment

High constant velocity (CV) joint

operating angles caused by

incorrect ride height

Check for misalignment. Install new

components as required. For driveshaft

alignment,

REFER to: Driveline Angle Inspection (205-00 Driveline System - General Information,

General Procedures).

Check the ride height and verify the correct

spring rate. Install new components as

required Lubricant Leak

Rear drive axle breather

Damaged seal

Rear drive axle filler plug

Rear drive axle rear cover joint

Check oil level and correct as required

Install new components as required Pinpoint Tests

PINPOINT TEST A : EXCESSIVE DRIVELINE NOISE TEST

CONDITIONS DETAILS/RESULTS/ACTIONS A1: CHECK NOISE FROM VEHICLE ON ROAD TEST 1 Road test vehicle to determine load and speed conditions when noise occurs. 2 Assess the noise with different gears selected. Does the noise occur in different gears at the same vehicle speed? Yes

Install a new rear drive axle/differential assembly.

REFER to: Axle Assembly - V6 3.0L Petrol (205-02 Rear Drive Axle/Differential, Removal and Installation).

Re-test the system for normal operation.

No

Suspect the engine or transmission. For additional information, REFER to:

Engine - 3.0L/4.2L (303-00 Engine System - General Information, Diagnosis and Testing), Engine - 2.7L Diesel (303-00 Engine System - General Information, Diagnosis and Testing), Diagnostic Strategy (307-01A Automatic Transmission/Transaxle - V6 3.0L Petrol, Diagnosis and Testing).

Page 566 of 3039

Removal

1. WARNING: Do not work on or under a vehicle supported only by a jack.

Always support the vehicle on safety stands.

Raise and support the vehicle.

2. Remove the LH rear wheel and tire.

Refer to: Wheel and Tire (204-04 Wheels and Tires, Removal and Installation).

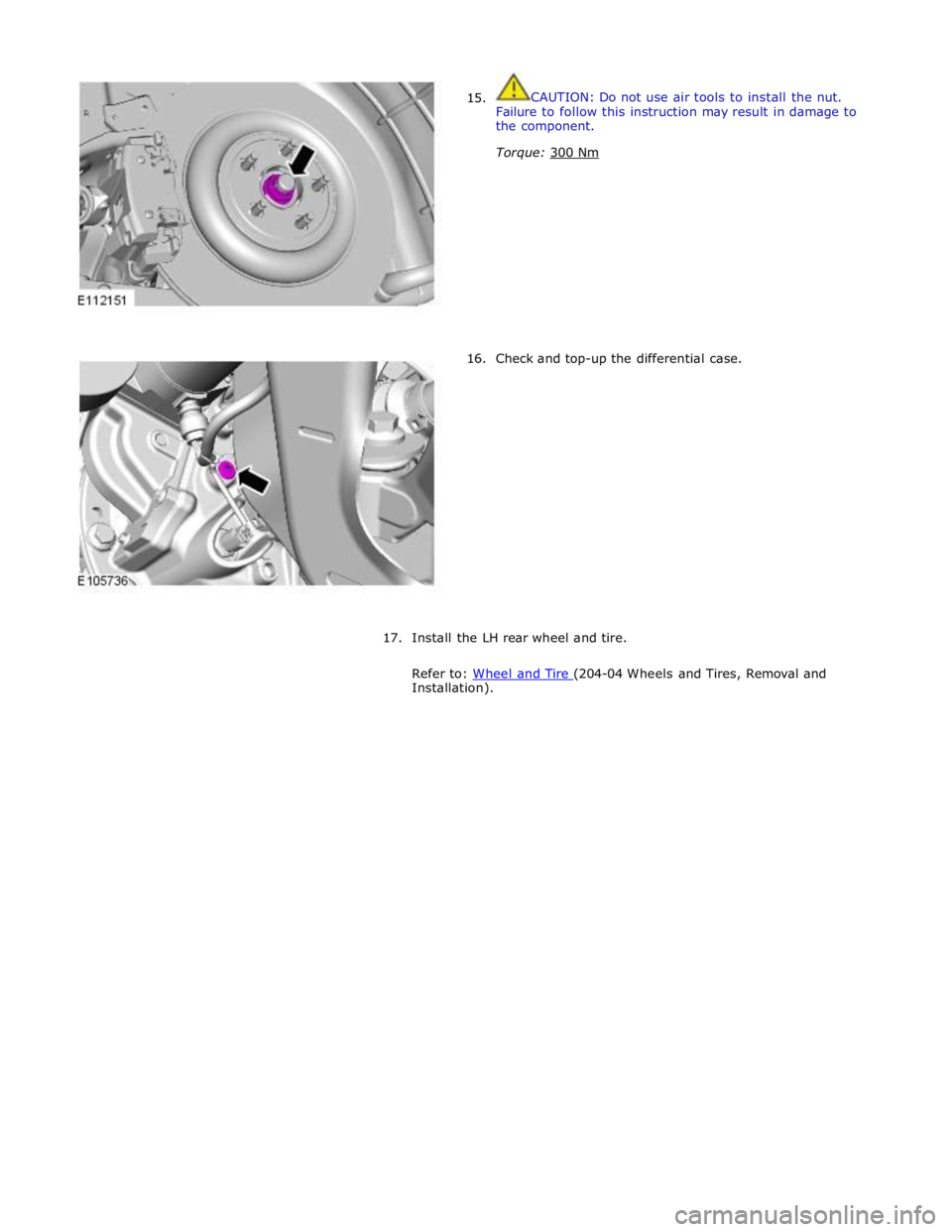

3. With assistance, remove the halfshaft retaining nut, and

retain it for the install procedure.

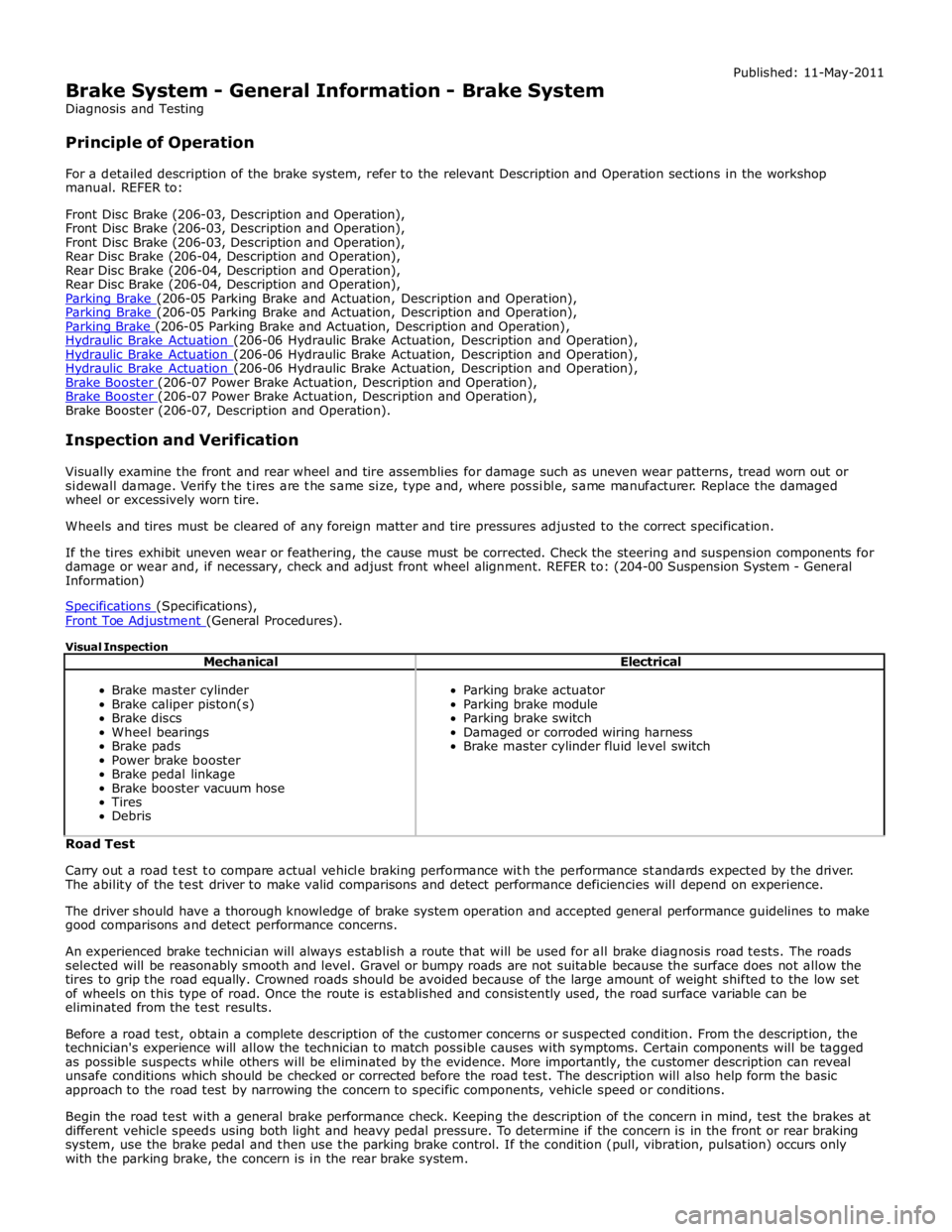

4. Release the brake caliper. 308-621-2

Installer/Guide, Halfshaft Oil Seal

Page 574 of 3039

15.

16. CAUTION: Do not use air tools to install the nut.

Failure to follow this instruction may result in damage to

the component.

Torque: 300 Nm

Check and top-up the differential case.

17.

Install the LH rear wheel and tire.

Refer to: Wheel and Tire (204-04 Wheels and Tires, Removal and Installation).

Page 582 of 3039

Brake System - General Information - Brake System

Diagnosis and Testing

Principle of Operation Published: 11-May-2011

For a detailed description of the brake system, refer to the relevant Description and Operation sections in the workshop

manual. REFER to:

Front Disc Brake (206-03, Description and Operation),

Front Disc Brake (206-03, Description and Operation),

Front Disc Brake (206-03, Description and Operation),

Rear Disc Brake (206-04, Description and Operation),

Rear Disc Brake (206-04, Description and Operation),

Rear Disc Brake (206-04, Description and Operation),

Parking Brake (206-05 Parking Brake and Actuation, Description and Operation), Parking Brake (206-05 Parking Brake and Actuation, Description and Operation), Parking Brake (206-05 Parking Brake and Actuation, Description and Operation), Hydraulic Brake Actuation (206-06 Hydraulic Brake Actuation, Description and Operation), Hydraulic Brake Actuation (206-06 Hydraulic Brake Actuation, Description and Operation), Hydraulic Brake Actuation (206-06 Hydraulic Brake Actuation, Description and Operation), Brake Booster (206-07 Power Brake Actuation, Description and Operation), Brake Booster (206-07 Power Brake Actuation, Description and Operation), Brake Booster (206-07, Description and Operation).

Inspection and Verification

Visually examine the front and rear wheel and tire assemblies for damage such as uneven wear patterns, tread worn out or

sidewall damage. Verify the tires are the same size, type and, where possible, same manufacturer. Replace the damaged

wheel or excessively worn tire.

Wheels and tires must be cleared of any foreign matter and tire pressures adjusted to the correct specification.

If the tires exhibit uneven wear or feathering, the cause must be corrected. Check the steering and suspension components for

damage or wear and, if necessary, check and adjust front wheel alignment. REFER to: (204-00 Suspension System - General

Information)

Specifications (Specifications), Front Toe Adjustment (General Procedures).

Visual Inspection

Mechanical Electrical

Brake master cylinder

Brake caliper piston(s)

Brake discs

Wheel bearings

Brake pads

Power brake booster

Brake pedal linkage

Brake booster vacuum hose

Tires

Debris

Parking brake actuator

Parking brake module

Parking brake switch

Damaged or corroded wiring harness

Brake master cylinder fluid level switch Road Test

Carry out a road test to compare actual vehicle braking performance with the performance standards expected by the driver.

The ability of the test driver to make valid comparisons and detect performance deficiencies will depend on experience.

The driver should have a thorough knowledge of brake system operation and accepted general performance guidelines to make

good comparisons and detect performance concerns.

An experienced brake technician will always establish a route that will be used for all brake diagnosis road tests. The roads

selected will be reasonably smooth and level. Gravel or bumpy roads are not suitable because the surface does not allow the

tires to grip the road equally. Crowned roads should be avoided because of the large amount of weight shifted to the low set

of wheels on this type of road. Once the route is established and consistently used, the road surface variable can be

eliminated from the test results.

Before a road test, obtain a complete description of the customer concerns or suspected condition. From the description, the

technician's experience will allow the technician to match possible causes with symptoms. Certain components will be tagged

as possible suspects while others will be eliminated by the evidence. More importantly, the customer description can reveal

unsafe conditions which should be checked or corrected before the road test. The description will also help form the basic

approach to the road test by narrowing the concern to specific components, vehicle speed or conditions.

Begin the road test with a general brake performance check. Keeping the description of the concern in mind, test the brakes at

different vehicle speeds using both light and heavy pedal pressure. To determine if the concern is in the front or rear braking

system, use the brake pedal and then use the parking brake control. If the condition (pull, vibration, pulsation) occurs only

with the parking brake, the concern is in the rear brake system.

Page 583 of 3039

If the concern becomes evident during this check, verify it fits the description given before the road test. If the concern is not

evident, attempt to duplicate the condition using the information from the description.

If a concern exists, use the Symptom Chart in order to isolate it to a specific sub-system and condition description. From this

description, a list of possible sources can be used to further narrow the cause to a specific component or condition.

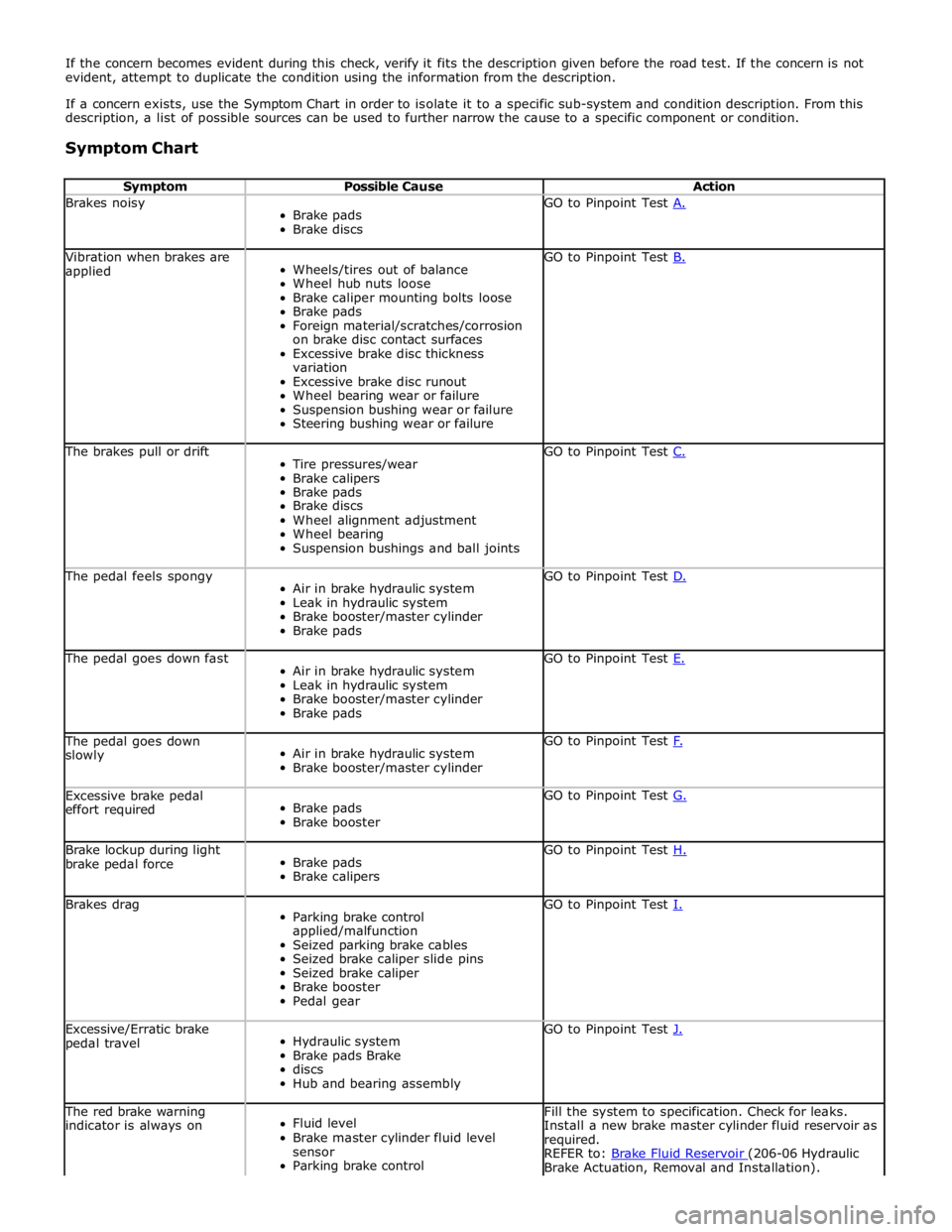

Symptom Chart

Symptom Possible Cause Action Brakes noisy

Brake pads

Brake discs GO to Pinpoint Test A. Vibration when brakes are

applied

Wheels/tires out of balance

Wheel hub nuts loose

Brake caliper mounting bolts loose

Brake pads

Foreign material/scratches/corrosion

on brake disc contact surfaces

Excessive brake disc thickness

variation

Excessive brake disc runout

Wheel bearing wear or failure

Suspension bushing wear or failure

Steering bushing wear or failure GO to Pinpoint Test B. The brakes pull or drift

Tire pressures/wear

Brake calipers

Brake pads

Brake discs

Wheel alignment adjustment

Wheel bearing

Suspension bushings and ball joints GO to Pinpoint Test C. The pedal feels spongy

Air in brake hydraulic system

Leak in hydraulic system

Brake booster/master cylinder

Brake pads GO to Pinpoint Test D. The pedal goes down fast

Air in brake hydraulic system

Leak in hydraulic system

Brake booster/master cylinder

Brake pads GO to Pinpoint Test E. The pedal goes down

slowly

Air in brake hydraulic system

Brake booster/master cylinder GO to Pinpoint Test F. Excessive brake pedal

effort required

Brake pads

Brake booster GO to Pinpoint Test G. Brake lockup during light

brake pedal force

Brake pads

Brake calipers GO to Pinpoint Test H. Brakes drag

Parking brake control

applied/malfunction

Seized parking brake cables

Seized brake caliper slide pins

Seized brake caliper

Brake booster

Pedal gear GO to Pinpoint Test I. Excessive/Erratic brake

pedal travel

Hydraulic system

Brake pads Brake

discs

Hub and bearing assembly GO to Pinpoint Test J. The red brake warning

indicator is always on

Fluid level

Brake master cylinder fluid level

sensor

Parking brake control Fill the system to specification. Check for leaks.

Install a new brake master cylinder fluid reservoir as

required.

REFER to: Brake Fluid Reservoir (206-06 Hydraulic Brake Actuation, Removal and Installation).

Page 584 of 3039

Symptom Possible Cause Action Electrical circuit

For parking brake control and circuit tests.

REFER to: Parking Brake (206-05, Diagnosis and Testing). Slow or incomplete brake

pedal return

Brake pedal binding

Brake booster/master cylinder GO to Pinpoint Test K. Pinpoint Tests

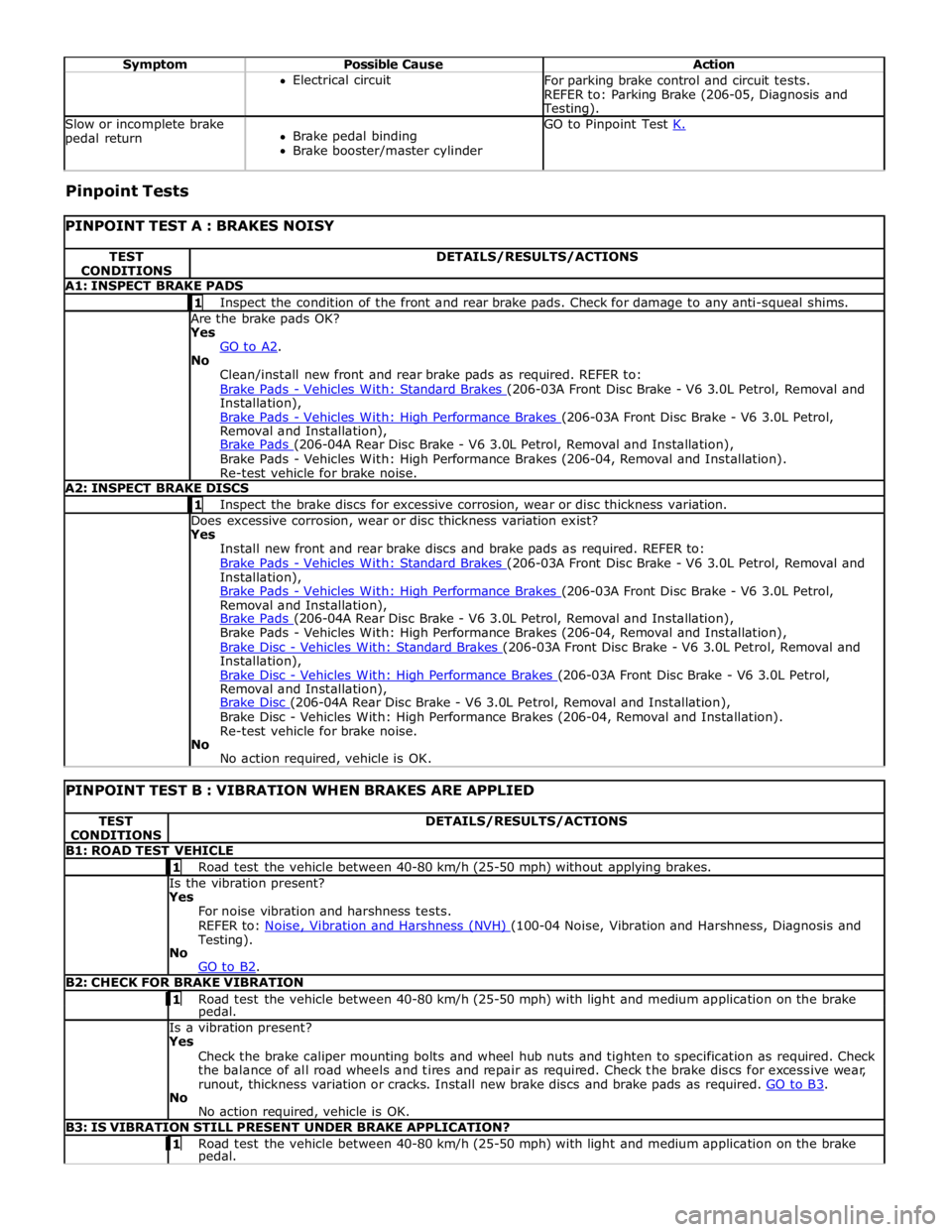

PINPOINT TEST A : BRAKES NOISY TEST

CONDITIONS DETAILS/RESULTS/ACTIONS A1: INSPECT BRAKE PADS 1 Inspect the condition of the front and rear brake pads. Check for damage to any anti-squeal shims. Are the brake pads OK? Yes

GO to A2. No

Clean/install new front and rear brake pads as required. REFER to:

Brake Pads - Vehicles With: Standard Brakes (206-03A Front Disc Brake - V6 3.0L Petrol, Removal and Installation),

Brake Pads - Vehicles With: High Performance Brakes (206-03A Front Disc Brake - V6 3.0L Petrol, Removal and Installation),

Brake Pads (206-04A Rear Disc Brake - V6 3.0L Petrol, Removal and Installation), Brake Pads - Vehicles With: High Performance Brakes (206-04, Removal and Installation).

Re-test vehicle for brake noise. A2: INSPECT BRAKE DISCS 1 Inspect the brake discs for excessive corrosion, wear or disc thickness variation. Does excessive corrosion, wear or disc thickness variation exist? Yes

Install new front and rear brake discs and brake pads as required. REFER to:

Brake Pads - Vehicles With: Standard Brakes (206-03A Front Disc Brake - V6 3.0L Petrol, Removal and Installation),

Brake Pads - Vehicles With: High Performance Brakes (206-03A Front Disc Brake - V6 3.0L Petrol, Removal and Installation),

Brake Pads (206-04A Rear Disc Brake - V6 3.0L Petrol, Removal and Installation), Brake Pads - Vehicles With: High Performance Brakes (206-04, Removal and Installation),

Brake Disc - Vehicles With: Standard Brakes (206-03A Front Disc Brake - V6 3.0L Petrol, Removal and Installation),

Brake Disc - Vehicles With: High Performance Brakes (206-03A Front Disc Brake - V6 3.0L Petrol, Removal and Installation),

Brake Disc (206-04A Rear Disc Brake - V6 3.0L Petrol, Removal and Installation), Brake Disc - Vehicles With: High Performance Brakes (206-04, Removal and Installation).

Re-test vehicle for brake noise.

No

No action required, vehicle is OK.

PINPOINT TEST B : VIBRATION WHEN BRAKES ARE APPLIED TEST

CONDITIONS DETAILS/RESULTS/ACTIONS B1: ROAD TEST VEHICLE 1 Road test the vehicle between 40-80 km/h (25-50 mph) without applying brakes. Is the vibration present?

Yes

For noise vibration and harshness tests.

REFER to: Noise, Vibration and Harshness (NVH) (100-04 Noise, Vibration and Harshness, Diagnosis and Testing).

No

GO to B2. B2: CHECK FOR BRAKE VIBRATION 1 Road test the vehicle between 40-80 km/h (25-50 mph) with light and medium application on the brake pedal. Is a vibration present?

Yes

Check the brake caliper mounting bolts and wheel hub nuts and tighten to specification as required. Check

the balance of all road wheels and tires and repair as required. Check the brake discs for excessive wear,

runout, thickness variation or cracks. Install new brake discs and brake pads as required. GO to B3. No

No action required, vehicle is OK. B3: IS VIBRATION STILL PRESENT UNDER BRAKE APPLICATION? 1 Road test the vehicle between 40-80 km/h (25-50 mph) with light and medium application on the brake pedal.