ECU JAGUAR XFR 2010 1.G Workshop Manual

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 2010, Model line: XFR, Model: JAGUAR XFR 2010 1.GPages: 3039, PDF Size: 58.49 MB

Page 1871 of 3039

Published: 21-Dec-2012

Battery and Charging System - General Information - Quiescent Drain

Description and Operation

VEHICLE QUIESCENT CURRENT TESTING

On vehicles fitted with a Battery Monitoring System (BMS), the diagnostic routine for quiescent drain testing in the approved

Jaguar or Land Rover diagnostic system should be utilized.

If a customer complains of a vehicle battery that discharges continuously or when left for a prolonged period of time, it is

recommended that a quiescent drain test is performed as described below.

The battery drain should be measured using the approved Jaguar or Land Rover diagnostic system or a Digital Multi-Meter

(DVOM). A procedure for quiescent drain measurement using the diagnostic system is available in the Diagnosis and Testing

section of the Workshop Manual. The vehicle should be in the locked/armed state (for example vehicle alarm fully armed), all

doors, engine and luggage compartment lids are open and latched (so as to appear closed from an electrical point of view).

The test should take place after the vehicle has entered shutdown mode. The time taken for this to occur after the ignition is

switched off varies according to model (Refer to the Topix On line resource for details).

When the vehicle is armed, the effect of the security system Light Emitting Diode (LED) flashing is to cause a pulsation in the

measured current drain. In this case, either the average current should be taken (using a Digital Multi- Meter (DVOM) with an

averaging system) or the current reading taken, ignoring the brief high current peaks.

EQUIPMENT

Approved Jaguar or Land Rover diagnostic system with current probeOR Digital Multi-Meter (DVOM) with current probe.

METHOD OF MEASUREMENT

Using an Approved Jaguar or Land Rover Diagnostic System.

1. Switch off all electrical loads and ensure that the ignition is off

2. Connect the current probe to the approved Jaguar or Land Rover diagnostic system

3. Calibrate the probe

4. Install a clamp around the battery lead/junction box lead

5. Go to the Quiescent Current Testing section in this procedure

Using a digital multimeter

Do not use an in-line DVOM to measure the quiescent drain on vehicles fitted with an electronic throttle (for example XK 2006

onwards). The current exceeds the maximum amount the fuse in the DVOM is capable of handling.

1. Switch off all electrical loads and ensure that the ignition is off

2. Connect the current probe to the digital multmeter

3. Calibrate the probe

4. Install a clamp around the battery lead/junction box lead

5. Go to the Quiescent Current Testing section in this procedure

QUIESCENT CURRENT TESTING

1. Switch ignition to ‘on’ or select ignition mode in keyless vehicles and switch to ‘off’ (do not crank)

2. Remove key from ignition switch (if equipped)

3. Open and latch all doors, hood and luggage compartment lid

4. Lock the vehicle using the remote function on the remote handset. (Single lock only to avoid volumetric alarm arming)

5. Remove any other potential electrical drains such as accessories plugged into accessory sockets

6. Record the amperage readings after the shutdown period referenced in the Topix on line resource for details. Note all

cars from 10MY onwards and XK from 07MY and XF from 08MY should be less than 30mA after 30 minutes

7. Record the final reading on the battery report form

The preferred method of testing following an excessive current consumption figure is to use a current probe around individual

junction box leads to the various suspected circuits to identify a potential cause. This is in preference to the old method of

removing fuses for the following reasons:

The drain may be caused by a module remaining active and preventing the quiescent drain from reducing to normal

levels

The drain may be caused by a relay winding that is activated. Pulling the fuse can allow this to ‘reset’ and the drain will

be lost and go un-diagnosed

QUIESCENT DRAIN - TYPICAL VALUES

NOTE: The quiescent drain after the initial shutdown period should not exceed the value shown in the table.

Jaguar Quiescent Drain Values

MODEL SHUT DOWN PERIOD (minutes) TYPICAL VALUES BATTERY DRAIN (mA) XJS 3.2 60 <30 Sovereign 3.2 60 <37.3

Page 1878 of 3039

Battery, Mounting and Cables - Battery and Cables - Overview

Description and Operation

OVERVIEW

Single Battery Vehicles Published: 18-Jun-2014

Mounted on the battery negative terminal is a BMS (battery monitoring system) module. The BMS module is integral with the

battery negative cable and is controlled by the ECM (engine control module).

CAUTION: To avoid damaging the battery monitoring system module, always use a suitable body ground point rather than

the battery negative terminal when connecting a slave power supply to the vehicle.

If a new battery is fitted to the vehicle, the BMS module will require re-calibrating using the Jaguar approved diagnostic

system.

Fitted on the battery positive terminal is a transit relay. The transit relay must be removed from the vehicle during the

Pre-Delivery Inspection (PDI). For additional information, refer to the PDI Manual.

The vehicle battery provides power to the BJB (battery junction box). The BJB contains 3 megafuses, delivering power to the RJB (rear junction box), the CJB (central junction box) and the EJB (engine junction box). In addition to containing fuses and

relays, the RJB and RJB contain software to control a number of vehicle systems. These functions are covered in the appropriate sections of this manual.

Dual Battery System Vehicles - TD42.2L Engine Variants Only

Two batteries are fitted to accommodate the dual battery system used for the Stop/Start system.

A primary battery is located in the luggage compartment floor in a plastic molded tray and secured with a metal rod. The

secondary battery is located in the DBJB (dual battery junction box).

The primary battery is a 90Ahr, 850A CCA AGM Battery.

The secondary battery is a 14Ahr, 200A CCA Absorbed Glass Mat (AGM) Battery.

A BMS (battery monitoring system) control module is mounted on the primary battery negative terminal. The BMS control

module is integral with the battery negative cable and is controlled by the GWM (gateway module).

CAUTION: To avoid damaging the BMS control module, always use the ground (negative (-)) terminal stud point on the

right side top mount. Never connect directly to the primary battery negative terminal when connecting a slave power supply to

the vehicle, the BMS control module can be damaged.

If a new primary battery is fitted to the vehicle, the BMS control module will require re-calibrating using a Jaguar approved

diagnostic system.

When the vehicle leaves the factory, a transit relay is fitted to the battery positive terminal. The transit relay is connected to

the CJB which limits the electrical functions to essential items only, to reduce loads on the primary battery. The transit relay must be removed from the vehicle during the PDI (Pre-Delivery Inspection). For additional information, refer to the PDI.

The primary battery provides power to the BJB. The BJB contains three megafuses, delivering power to the RJB, the EJB and the starter motor and generator. In addition to containing fuses and relays, the RJB and CJB contain software to control a number of vehicle systems. These functions are covered in the appropriate sections of this manual.

A jump start terminal is located adjacent to the EJB. A cover protects the terminal when not in use. If jump starting is

required, the cover must be removed and the positive (+) jump lead attached securely. The negative (-) jump lead is attached

to a stud located on the right side top mount in the engine compartment. The cover must be fitted to the positive terminal

when not in use.

Dual Battery System

The dual battery system is used on vehicles with the stop/start system. The dual battery system prevents the vehicle

electrical systems being subjected to undesirably low voltages during repeated engine restarts. If the electrical systems are

subject to low voltages the customer may notice degraded performance of components and systems and incorrect fault DTC

(diagnostic trouble code)'s may be stored.

The dual battery system isolates all electrical components and systems sensitive to low supply voltage from the primary

battery while an engine start is in progress, and supplies them from the secondary battery. Without the dual battery system,

the electrical power required by the TSS (Tandem Solenoid Starter) motor to crank the engine for each start would cause a

voltage drop across the entire vehicle electrical network, and cause control modules to function incorrectly and in some cases

reset and/or record DTC's.

If the dual battery system is unable to prevent electrical supplies to the vehicle systems being subjected to low voltage levels

during engine stop/start operations, due to the condition of the primary and/or secondary batteries or a system fault, the

stop/start feature is disabled.

Page 1886 of 3039

the secondary battery (if fitted) and passes through a grommet in the floorpan.

On new vehicles the primary battery positive terminal is fitted with a transit relay. The transit relay must removed using the

correct process detailed in the Pre Delivery Inspection (PDI) manual.

The battery negative terminal is fitted with a BMS control module. The control module is integral with the battery negative

cable and communicates with the GWM via a LIN bus connection. The battery condition information is passed to the GWM

which controls the generator output accordingly.

CAUTION: To avoid damage to the BMS control module, always use the body ground point in the engine compartment and

not the battery negative terminal when connecting a slave power supply.

Failure to use the recommended ground point will lead to the setting of a DTC. Incorrect information of battery condition will

be retained by the BMS control module due to the unmonitored current flow into the battery. The system will however,

recognize and compensate for the change in battery status after a period of time.

If a new battery is fitted, the BMS control module will require re-calibration using a Jaguar approved diagnostic system.

Replacement of the BMS control module requires no action as the control module will re-calibrate automatically.

SECONDARY BATTERY - DUAL BATTERY VEHICLES ONLY

The secondary battery is located in a tray on the next of the primary battery and is secured to the DBJB with a bracket. The

battery negative (-) terminal is connected via a cable to the vehicle body. The positive (+) terminal is connected by a cable to

the DBJB. The battery is vented via a tube which is connected with a T piece to the vent from the primary battery and passes

through a grommet in the floorpan.

The state of charge of the secondary battery is monitored by the Gateway Module (GWM).

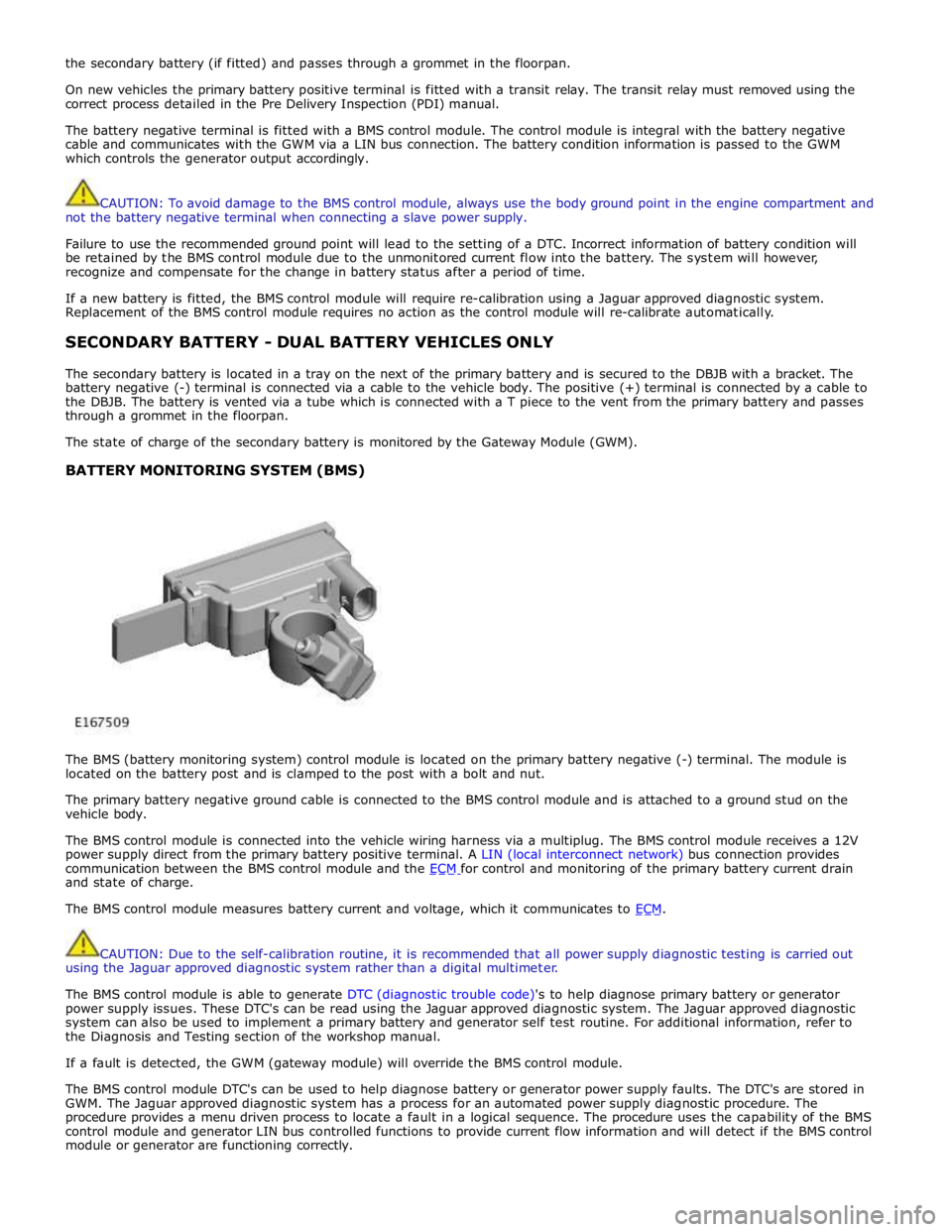

BATTERY MONITORING SYSTEM (BMS)

The BMS (battery monitoring system) control module is located on the primary battery negative (-) terminal. The module is

located on the battery post and is clamped to the post with a bolt and nut.

The primary battery negative ground cable is connected to the BMS control module and is attached to a ground stud on the

vehicle body.

The BMS control module is connected into the vehicle wiring harness via a multiplug. The BMS control module receives a 12V

power supply direct from the primary battery positive terminal. A LIN (local interconnect network) bus connection provides

communication between the BMS control module and the ECM for control and monitoring of the primary battery current drain and state of charge.

The BMS control module measures battery current and voltage, which it communicates to ECM.

CAUTION: Due to the self-calibration routine, it is recommended that all power supply diagnostic testing is carried out

using the Jaguar approved diagnostic system rather than a digital multimeter.

The BMS control module is able to generate DTC (diagnostic trouble code)'s to help diagnose primary battery or generator

power supply issues. These DTC's can be read using the Jaguar approved diagnostic system. The Jaguar approved diagnostic

system can also be used to implement a primary battery and generator self test routine. For additional information, refer to

the Diagnosis and Testing section of the workshop manual.

If a fault is detected, the GWM (gateway module) will override the BMS control module.

The BMS control module DTC's can be used to help diagnose battery or generator power supply faults. The DTC's are stored in

GWM. The Jaguar approved diagnostic system has a process for an automated power supply diagnostic procedure. The

procedure provides a menu driven process to locate a fault in a logical sequence. The procedure uses the capability of the BMS

control module and generator LIN bus controlled functions to provide current flow information and will detect if the BMS control

module or generator are functioning correctly.

Page 1887 of 3039

DUAL BATTERY MODULE (DBM)

The DBM (dual battery module) is located at the rear of the right wheel arch in the luggage compartment, adjacent to the

GWM (gateway module) and the RJB (rear junction box). The DBM is attached to a bracket, which is attached to a second

bracket secured to the vehicle body.

The DBM is connected by two hardwired connections to the DBJB (dual battery junction box). The DBM uses these two

connections to apply battery voltage to the contactor coils in the DBJB. A LIN bus connection from the GWM passes contactor operation signals to the DBM which operates the contactors as applicable.

The GWM will also instruct the DBM to apply charging to the secondary battery via a LIN bus message. The GWM instructs the

DBM of the charging current required for the secondary battery and the DBM applies the requested stabilized current to the

secondary battery via a dedicated connection direct to the secondary battery.

The DBM diagnoses the coils of the contactors and will report a fault via the LIN bus to the GWM.

The DBM receives a fused power supply from the RJB. www.JagDocs.com

Page 1889 of 3039

Battery, Mounting and Cables - Battery

Diagnosis and Testing

Principles of Operation Published: 10-Mar-2014

For a detailed description of the battery system and operation, refer to the relevant Description and Operation section of the

workshop manual. REFER to: Battery and Cables (414-01 Battery, Mounting and Cables, Description and Operation).

Inspection and Verification

CAUTION: Diagnosis by substitution from a donor vehicle is NOT acceptable. Substitution of control modules does not

guarantee confirmation of a fault and may also cause additional faults in the vehicle being checked and/or the donor vehicle.

NOTES:

Generic scan tools may not read the codes listed, or may read only five digit codes. Match the five digits from the scan

tool to the first five digits of the seven digit code listed to identify the fault (the last two digits give additional information

read by the manufacturer-approved diagnostic system).

When performing electrical voltage or resistance tests, always use a digital multimeter (DMM) accurate to three decimal

places, and with an up-to-date calibration certificate. When testing resistance, always take the resistance of the DMM leads

into account.

Check and rectify basic faults before beginning diagnostic routines involving pinpoint tests.

If DTCs are recorded and, after performing the pinpoint tests, a fault is not present, an intermittent concern may be the

cause. Always check for loose connections and corroded terminals.

1. Verify the customer concern.

2. Visually inspect for obvious signs of mechanical or electrical damage.

Visual Inspection

Mechanical Electrical

Generator

Drive belt

Drive belt tensioner

Generator pulley

Check the security of the generator fixings

Generator

Battery

Battery connections

Starter motor

Harnesses and connectors

Fuses

Charge warning lamp function

Engine Control Module (ECM)

3. If an obvious cause for an observed or reported concern is found, correct the cause (if possible) before proceeding to

the next step.

4. If the cause is not visually evident check for Diagnostic Trouble Codes (DTCs) and refer to the DTC Index.

5. Check DDW for open campaigns. Refer to the corresponding bulletins and SSMs which may be valid for the specific

customer complaint and carry out the recommendations as required

Symptom Chart

Symptom Possible Causes Action

Battery power to vehicle

interrupted

High resistance between battery terminals and

clamps

GO to Pinpoint Test

A. Midtronics EXP-1080 User Guide

Carry out the following: -

Surface Voltage Removal Process

A vehicle which has had its battery charged or been driven in a 24 hour period before the test, must have its surface charge

removed

Page 1892 of 3039

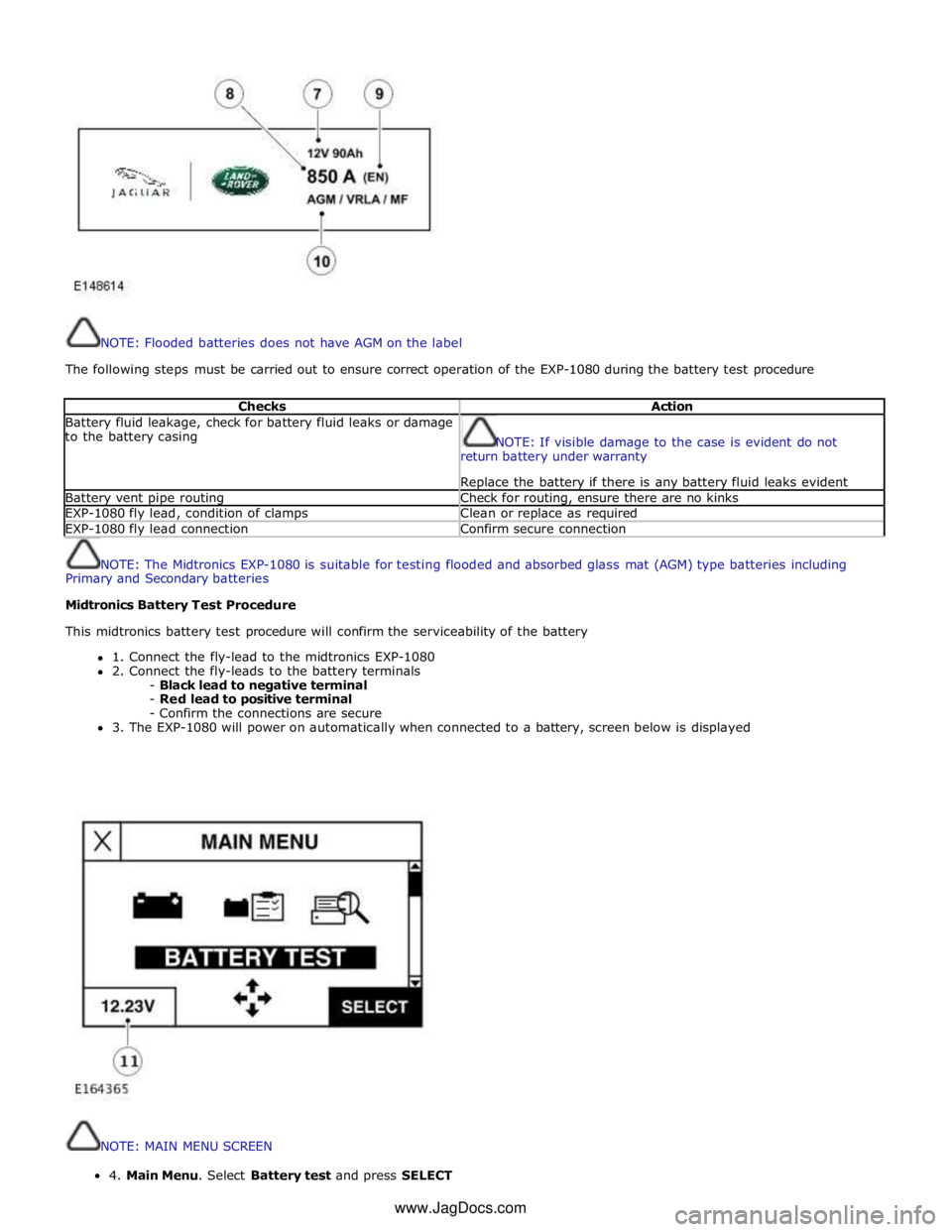

NOTE: Flooded batteries does not have AGM on the label

The following steps must be carried out to ensure correct operation of the EXP-1080 during the battery test procedure

Checks Action Battery fluid leakage, check for battery fluid leaks or damage

to the battery casing

NOTE: If visible damage to the case is evident do not

return battery under warranty

Replace the battery if there is any battery fluid leaks evident Battery vent pipe routing Check for routing, ensure there are no kinks EXP-1080 fly lead, condition of clamps Clean or replace as required EXP-1080 fly lead connection Confirm secure connection

NOTE: The Midtronics EXP-1080 is suitable for testing flooded and absorbed glass mat (AGM) type batteries including

Primary and Secondary batteries

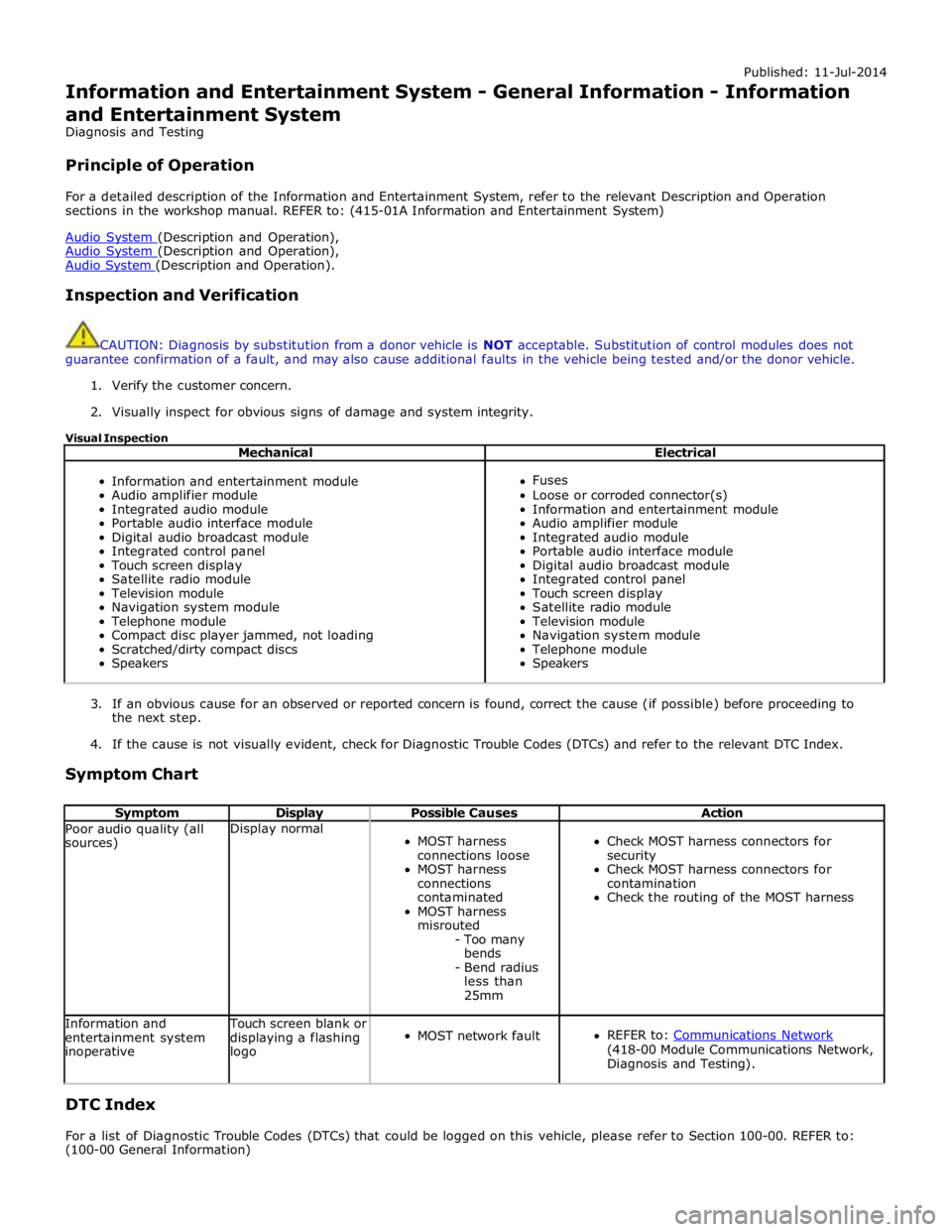

Midtronics Battery Test Procedure

This midtronics battery test procedure will confirm the serviceability of the battery

1. Connect the fly-lead to the midtronics EXP-1080

2. Connect the fly-leads to the battery terminals

- Black lead to negative terminal

- Red lead to positive terminal

- Confirm the connections are secure

3. The EXP-1080 will power on automatically when connected to a battery, screen below is displayed

NOTE: MAIN MENU SCREEN 4.MainMenu.SelectBatterytestandpressSELECT

www.JagDocs.com

Page 1932 of 3039

Published: 11-Jul-2014

Information and Entertainment System - General Information - Information

and Entertainment System

Diagnosis and Testing

Principle of Operation

For a detailed description of the Information and Entertainment System, refer to the relevant Description and Operation

sections in the workshop manual. REFER to: (415-01A Information and Entertainment System)

Audio System (Description and Operation), Audio System (Description and Operation), Audio System (Description and Operation).

Inspection and Verification

CAUTION: Diagnosis by substitution from a donor vehicle is NOT acceptable. Substitution of control modules does not

guarantee confirmation of a fault, and may also cause additional faults in the vehicle being tested and/or the donor vehicle.

1. Verify the customer concern.

2. Visually inspect for obvious signs of damage and system integrity.

Visual Inspection

Mechanical Electrical

Information and entertainment module

Audio amplifier module

Integrated audio module

Portable audio interface module

Digital audio broadcast module

Integrated control panel

Touch screen display

Satellite radio module

Television module

Navigation system module

Telephone module

Compact disc player jammed, not loading

Scratched/dirty compact discs

Speakers

Fuses

Loose or corroded connector(s)

Information and entertainment module

Audio amplifier module

Integrated audio module

Portable audio interface module

Digital audio broadcast module

Integrated control panel

Touch screen display

Satellite radio module

Television module

Navigation system module

Telephone module

Speakers

3. If an obvious cause for an observed or reported concern is found, correct the cause (if possible) before proceeding to

the next step.

4. If the cause is not visually evident, check for Diagnostic Trouble Codes (DTCs) and refer to the relevant DTC Index.

Symptom Chart

Symptom Display Possible Causes Action Poor audio quality (all

sources) Display normal

MOST harness

connections loose

MOST harness

connections

contaminated

MOST harness

misrouted

- Too many

bends

- Bend radius

less than

25mm

Check MOST harness connectors for

security

Check MOST harness connectors for

contamination

Check the routing of the MOST harness Information and

entertainment system

inoperative Touch screen blank or

displaying a flashing

logo

MOST network fault

REFER to: Communications Network (418-00 Module Communications Network,

Diagnosis and Testing).

DTC Index

For a list of Diagnostic Trouble Codes (DTCs) that could be logged on this vehicle, please refer to Section 100-00. REFER to:

(100-00 General Information)

Page 1949 of 3039

systems.

A typical example of information transfer is vehicle speed information from the ABS (anti-lock brake system) module used to

control the automatic volume control function. The vehicle speed information from the ABS module is sent on the high speed

CAN network and collected by the instrument panel gateway. The signal is passed to the medium speed CAN network and onto the ICM gateway. The ICM calculates the volume adjustment required. The corrected audio volume level signal is sent on the

MOST network to the IAM or Power amplifier (dependant on vehicle equipment level) for output to the speaker system.

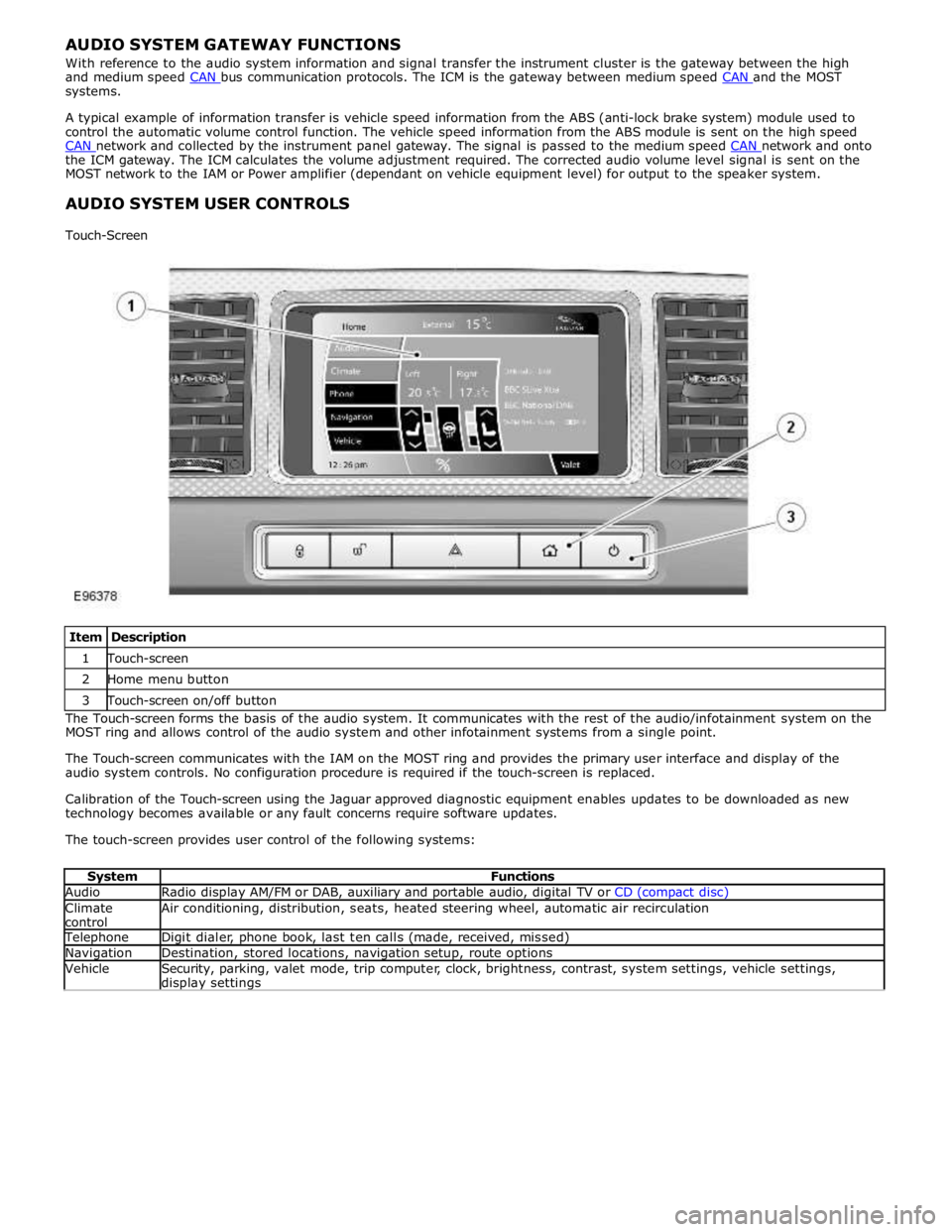

AUDIO SYSTEM USER CONTROLS

Touch-Screen

Item Description 1 Touch-screen 2 Home menu button 3 Touch-screen on/off button The Touch-screen forms the basis of the audio system. It communicates with the rest of the audio/infotainment system on the

MOST ring and allows control of the audio system and other infotainment systems from a single point.

The Touch-screen communicates with the IAM on the MOST ring and provides the primary user interface and display of the

audio system controls. No configuration procedure is required if the touch-screen is replaced.

Calibration of the Touch-screen using the Jaguar approved diagnostic equipment enables updates to be downloaded as new

technology becomes available or any fault concerns require software updates.

The touch-screen provides user control of the following systems:

System Functions Audio Radio display AM/FM or DAB, auxiliary and portable audio, digital TV or CD (compact disc) Climate

control Air conditioning, distribution, seats, heated steering wheel, automatic air recirculation Telephone Digit dialer, phone book, last ten calls (made, received, missed) Navigation Destination, stored locations, navigation setup, route options Vehicle

Security, parking, valet mode, trip computer, clock, brightness, contrast, system settings, vehicle settings, display settings

Page 1966 of 3039

Publi s hed: 11-May-2011

Information and Entertainment System - Cellular Phone - Overview

Des cript ion and Operat ion

Authori ng Templat e

OVERVIEW

The cel lul ar phone s yst em us es t he cus t omers own Bluetooth® capabl e hands et in conjuncti on wit h t he vehicle

informat ion and ent ertai nment sys tem. The t elephone cont rol module i s l ocated under t he left -hand front s eat, and has a

Bluet oot h® ant enna integrat ed i nt o t he unit . Tel ephone handset s mus t be paired wit h t he t el ephone control modul e,

requiring i nput of a PIN (pers onal i dent ificati on number) before t hey can be us ed wi th the vehicle sys tem. Once pai red, any

phone can be docked to the car wi thout re-ent eri ng a PIN (pers onal identi fi cat ion number). In addit ion t o t hi s , the l ast

connected device wi ll dock aut omati cal ly t he next ti me i t is pl aced i n t he vehi cl e a nd t he ignit ion i s i n power mode

(ignit ion on).

The s ys t em has t he abil it y to pai r and dock t elephone hands ets from t he tel ephones t hems elves . By s uppl yi ng a fixed PIN

(personal identi fi cat ion number), a us er wil l be abl e t o us e t hei r tel ephone or othe r t el ephone related Bluetooth® device

and pair wi th i t wit hout us i ng the touch s creen. This enables devices s uch as Blackberry's and ot her s ecure PDA's (pers onal

digit al ass i st ants ) t o pair and dock wit h t he vehi cl e s ys t em.

Up t o 5 telephone hands ets can be pai red wi th the vehicle, but only 1 tel ephone can be us ed at a t ime. The Touch-screen

dis plays phone functi onali ty, i ncl udi ng diali ng, and (if compati ble) t he hands et’s phone book. The Touch-s creen als o

dis plays t he phone's si gnal s trengt h and bat tery meter (if s upported by the phone). These functi ons al low the us er to vi ew

t he dis plays on t he Touch-s creen and not have to us e the handset .

• NOTE: There i s no physi cal connecti on (cradl e) bet ween t he phone hands et and the t elephone cont rol module.

Communicati ons bet ween t he 2 component s are purely Bl uet oot h®. This can l imi t t he avai lable funct ions dependant on

t he hands et used.

The s ys t em al lows t he dri ver t o make, receive and end phone cal ls us ing the Touch-s creen, s t eering wheel s wit ches and

voice recogni ti on s yst em (if fit t ed).

Phone di ali ng is achieved usi ng one of the foll owing met hods :

Dial ing a number us ing t he Touch-screen keypadSelecti ng a number from t he hands ets (aut omat icall y or manual ly downl oaded) phonebook on the Touch-s creenSelecti ng a number from t he hands ets (aut omat icall y or manual ly downl oaded) phonebook in t he i ns t rument clus ter

mes s age centerSelecti ng from t he hands et s (downloaded) cal l regis ter, typicall y the las t 10 cal ls made, received and mis s edThe t el ephone control modul e is connect ed t o t he informati on and entertainment s ys te m on the MOST (medi a oriented

s ys t ems t rans port) ring. This al lows audio and control si gnal s t o be rout ed t o and from t he t elephone control modul e.

Page 1968 of 3039

System Operation

PRINCIPLES OF OPERATION

Pri mary us er cont rol of t he phone s ys tem is vi a t he Touch-s creen and JaguarVoi ce cont rol s wit ch. Selecti on of

'phone/comms ' on the Touch-s creen home menu sends a control si gnal t o t he tel ephone cont rol unit on the MO ST (medi a

ori ent ated sys tems trans port ) ring, opening the phone s ubmenu opt ions .

W hen maki ng an outgoing phone call us ing t he JaguarVoice funct ion t he ICM (informat i on control modul e) proces s es the

anal ogue si gnal from the swi tch i nto a digit al s ignal . The digit al si gnal i s pass ed from the ICM (i nformat ion cont rol

module) onto the MO ST (medi a ori ent ated sys tems trans port ) s yst em t o t he JaguarVoi ce cont rol unit which i s int egral wit h

t he navi gat ion computer.

The navi gat ion comput er s ends an i ns t ructi on via MO ST (medi a ori ent ated sys tems trans port ) t o t he IAM (i ntegrat ed audi o

module) t o t urn on t he mi crophone faci li ty.

The voice command s ignals are rel ayed from t he IAM (i ntegrat ed audio module) vi a the MOST (medi a orientat ed s ys t ems

t ransport) ring t o t he navi gati on comput er for process ing.

The process ed voice command i s rel ayed on the MO ST (medi a ori ent ated sys tems trans port ) ring from the navigat ion

comput er to the phone cont rol module.

Speech out put i nformat ion is t rans ferred from the phone control modul e via t he Bl uet oot h® connect ion to t he cell phone.

Incomi ng cal ls are received from the Bl uet ooth® phone by the phone cont rol module. The i nformat ion is proces sed by the

phone cont rol module and t rans ferred on t he MOST (media ori ent ated s ys tems trans port ) ri ng t o the power ampl ifi er or IAM

(integrat ed audio modul e) for audi o output t hrough the vehicle’s audi o s peaker s ys t e m.

A number of res pons es by t he t el ephone and voice s ys tems are reinforced by mess ages appearing i n the ins trument cl us t er

mes s age center di spl ay. Informat ion is relayed to the mess age cent er from t he phone cont rol module and navigat ion

comput er on t he MOST (media orientat ed s ys t ems t rans port) ring t o t he ICM (informat ion cont rol module).

The ICM (informati on cont rol module) i s the gat eway from t he MOST (media ori ent ated s ys tems trans port ) ri ng t o the

medium s peed CAN. The ICM (informat ion control modul e) trans fers t he mes sage center i nformat ion ont o t he medium

s peed CAN which i s received and process ed for dis play on t he ins t rument clus ter mes s age cente r.

Us ers can pair & dock t heir hands et us ing t hei r phone or t he t ouch s creen. If t here i s no phone already docked wit h t he

s ys t em, a us er can us e t heir phone to search for Bluetoot h Devices. If the vehicl es Bluetooth s ys t em has been s uccess fully

dis covered, t he phone wil l di spl ay "Jaguar" as a device t o pair & connect t o. Us ing t his met hod requires the us er t o enter

t he Jaguar PIN of 1313. Alt ernati vel y, after acces s ing t he phone menu from t he Touch-s creen home menu, sel ect ing

‘Search New’ s earches for the Bluetooth® enabl ed hands et s wit hin range, di spl ays t he ir ident it ies on s creen, and al lows

t he user t o pair and dock the phone ready for use, us ing a random four-di git s ecurit y code di s pl ayed on screen. The s yst em

wil l normall y t ry t o dock (aut omati cal ly) to the las t phone docked, but if a di ffere nt Bluetoot h® enabled phone enters the

car i t wil l become avail abl e on t he s creen’s l is t of hands ets once t he s earch has be en complet ed.

Once a phone is pai red and docked a digit di al s creen i s dis played, incl uding phonebook opti ons . W it h a Bl uet oot h®

compat ibl e hands et and s oft ware vers i on there is the opt ion, through t he s ett ings me nu, t o automat ically downl oad the

cont ents of t he hands et’s phonebook t o the vehicl e s ys t em. Becaus e t here is no indus try s tandard for arranging the

phonebook, t he downloaded li st s from individual hands ets may vary.

Cell phone hands et manufact urers cont inuall y updat e hardware and s oft ware t o s t andard specificati ons laid down by the

Bluet oot h® Special Int eres t Group (SIG), which defi ned how Bluet oot h® woul d work in an aut omoti ve envi ronment.

However, becaus e different makes and models may use different s oft ware, not all hands ets are full y compat ible wit h

Jaguar, but t hrough tes t ing i ndi vi dual handset models Jaguar has produced a lis t of compat ibl e hands et s and the

appropri at e s oft ware vers ion for Jaguar Bl uet ooth® connecti vi ty. Referral to the lis t als o des cri bes how to check the

s oft ware vers i on of each i ndi vidual cell phone manufacturer. This l is t mus t be cons ult ed by us ers , s al es & s ervi ce teams t o

confirm whet her cus tomer's handset s are compat ible or not .

Jaguar is conti nual ly vali dati ng compat ible hands et and software combinati ons . The mos t up-t o-dat e compat ibi lit y l is t wil l

always be avail abl e on-l ine from Jaguar.

• NOTE: To achieve ful l Bl uetooth® hands et functi onal it y it is crucial t hat t he phone s oftware l evel mat ches t he vers ion

detail ed in the lis t of compat ibl e hands et s.

The upgraded hands free profi le of t his s ys tem allows the di spl ay of t he network s ignal st rengt h, net work operat or and

phone bat tery level indicati on on t he vehi cl e dis play. Als o, if appli cable, t he phone hands et wil l s how a "car" or "heads et"

s ymbol t o i ndi cat e i t is i n hands free profil e.

BLUETOOTH®

Bluet oot h® i s a s hort -range RF (radio frequency) t echnology t hat operat es at 2.4 GHz and is capabl e of t rans mit ti ng voice

and data wirel ess l y. The effecti ve range of Bluetoot h® devices is 32 feet (10 meters ) wit h a dat a t ransfer rat e of 1 Mbps .

Bluet oot h® i s es sent iall y a wi rel es s connect ion whi ch operat es wi th the us er's own mobil e hands et , does not have to be

fi xed int o t he car and i s desi gned to funct ion wit hout an external aerial. The hands et can be l ocat ed anywhere wit hin t he

cabi n, even i n a bag, or jacket pocket . It could work from the luggage compart ment , al though t he s ignal could be

compromi sed. The hands et can be charged from t he 12 volt power s ocket or USB (if s upported) whil e in use.

Component Description

Touch-Screen

The Touch-screen communi cat es wit h t he tel ephone control modul e on t he MOST (media orientat ed s ys t ems t rans port) ring

and provides t he pri mary us er int erface and di spl ay of the phone s yst em.