steering JAGUAR XFR 2010 1.G Workshop Manual

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 2010, Model line: XFR, Model: JAGUAR XFR 2010 1.GPages: 3039, PDF Size: 58.49 MB

Page 799 of 3039

8 Steering column LH (left-hand) multifunction switch 9 Steering column RH (right-hand) multifunction switch 10 Instrument cluster 11 Speed control switches 12 Audio/telephone switches 13 Clockspring 14 Information and entertainment module 15 Media Oriented System Transport (MOST) ring connection to other vehicle systems 16 Medium speed CAN (controller area network) bus to other vehicle systems

LEFT HAND MULTIFUNCTION SWITCH

Turn Signal Indicators System Operation

The instrument cluster outputs a reference voltage to the turn signal indicator switch. When the switch is in the central off

position, the voltage flows through 3 resistors which are connected in series and back to the instrument cluster which monitors

the signal and determines the turn signal indicators are off. This information is broadcast on the medium speed CAN bus to the CJB.

When the switch is operated in the LH turn signal indicator position, the reference voltage from the instrument cluster is routed via 1 of the resistors. The returned signal voltage is detected by the instrument cluster which outputs a message on

the medium speed CAN bus to the CJB. The CJB activates the applicable turn signal indicators until it receives an off message from the instrument cluster.

When the switch is operated in the RH turn signal indicator position, the reference voltage from the instrument cluster is routed via 2 of the resistors. The returned signal voltage is detected by the instrument cluster which outputs a message on

the medium speed CAN bus to the CJB. The CJB activates the applicable turn signal indicators until it receives an off message from the instrument cluster.

Lighting Control Switch

The instrument cluster outputs 2 reference voltages to the rotary lighting control switch; one feed being supplied to the light

selection function of the switch and the second feed being supplied to the autolamp exit delay function. The switch position is

determined by instrument cluster by the change in returned signal voltage which is routed through up to 4 resistors in series

depending on the selection made.

When the lighting control switch is in the off position, the reference voltage flows through 1 of the resistors. The returned

signal voltage is detected by the instrument cluster which outputs a message on the medium speed CAN bus to the CJB that no lighting selection is made. The reference voltage to the autolamp exit delay switch is routed through 4 resistors which is

detected by the instrument cluster which outputs a message on the medium speed CAN bus to the CJB that autolamp or exit delay has not been selected.

When the lighting control switch is in the sidelamp position, the reference voltage flows through 2 of the resistors. The

returned signal voltage is detected by the instrument cluster which outputs a message on the medium speed CAN bus to the CJB to activate the sidelamps. The reference voltage to the autolamp exit delay switch is routed through 4 resistors which is detected by the instrument cluster which outputs a message on the medium speed CAN bus to the CJB that autolamp or exit delay has not been selected.

When the lighting control switch is in the headlamp position, the reference voltage flows through 3 of the resistors. The

returned signal voltage is detected by the instrument cluster which outputs a message on the medium speed CAN bus to the CJB to activate the headlamps. The reference voltage to the autolamp exit delay switch is routed through 4 resistors which is detected by the instrument cluster which outputs a message on the medium speed CAN bus to the CJB that autolamp or exit delay has not been selected.

When the lighting control switch is in the autolamp position, the reference voltage flows through 4 of the resistors. The

returned signal voltage is detected by the instrument cluster which outputs a message on the medium speed CAN bus to the CJB to activate the autolamp function. The reference voltage to the autolamp exit delay switch is routed through 4 resistors which is detected by the instrument cluster which outputs a message on the medium speed CAN bus to the CJB that autolamp has been selected.

Autolamp Exit Delay

When the lighting control switch is in any of the autolamp exit delay position, the lighting control switch reference voltage

flows through 4 of the resistors. The returned signal voltage is detected by the instrument cluster which outputs a message on

the medium speed CAN bus to the CJB that autolamps has been selected.

Depending on the selected position, the reference voltage to the autolamp exit delay switch is routed through 3, 2 or 1

resistors which is detected by the instrument cluster. The cluster outputs a message on the medium speed CAN bus to the CJB that autolamp exit delay period has been selected at 30, 60 or 120 seconds respectively.

Trip Function Button

The instrument cluster outputs a reference voltage to the trip function button. When the function button is pressed a ground

Page 800 of 3039

path is completed and a signal voltage is returned to the instrument cluster via a resistor. The returned reference voltage is

detected by the instrument cluster and performs the requested trip function.

RIGHT HAND MULTIFUNCTION SWITCH

The instrument cluster outputs 4 separate reference voltages to the following switch functions:

Wash/wipe switch

Intermittent wipe switch

Master wiper switch

Flick wipe switch.

Wash/Wipe Switch

The reference voltage is supplied to one of two resistors connected in parallel. When the switch is not being operated the

current flows through one resistor and the returned signal voltage is monitored by the instrument cluster. When the wash/wipe

switch is operated, a connection is made and the current flows through the second resistor. The change in signal voltage is

detected by the instrument cluster which outputs a message on the medium speed CAN bus to the CJB to activate the wash/wipe function.

Intermittent Delay/Auto Wipe Switch

The reference voltage is supplied to the switch and can pass through up to 7 resistors, connected in series, for intermittent

delay selections and the auto wipe function.

When the rotary switch is in the auto position the reference voltage flows through 1 resistor. The returned signal voltage is

detected by the instrument cluster which determines auto wipe is selected. The instrument cluster outputs a message on the

medium speed CAN bus to the CJB to activate the auto wipe function.

With the rotary switch in one of the intermittent positions, the reference voltage is routed through up to 7 of the resistors

depending on the delay period selected. The returned signal voltage is detected by the instrument cluster which determines

selected delay period. The instrument cluster outputs a message on the medium speed CAN bus to the CJB to activate the selected intermittent wipe function.

NOTE: The delay period for the intermittent selections can vary according to vehicle speed.

Master Wiper Switch

The reference voltage supplied from the instrument cluster to the master wiper switch. The voltage can pass through up to 4

resistors connected in series.

When the switch is in the off position, the reference voltage passes through 4 resistors and the returned voltage is monitored

by the instrument cluster. The instrument cluster outputs a message on the medium speed CAN bus to the CJB that no wiper selections have been requested.

With the switch in the intermittent, slow wipe or fast wipe position, the reference voltage passes through 3, 2 or 1 resistors

respectively. The returned signal voltage is detected by the instrument cluster which determines selected delay period. The

instrument cluster outputs a message on the medium speed CAN bus to the CJB to activate the selected wipe function. Flick Wipe Switch

The reference voltage is supplied to one of two resistors connected in parallel. When the switch is not being operated the

current flows through one resistor and the returned signal voltage is monitored by the instrument cluster. When the flick wipe

switch is operated, a connection is made and the current flows through the second resistor. The change in signal voltage is

detected by the instrument cluster which outputs a message on the medium speed CAN bus to the CJB to activate the flick wipe function.

STEERING COLUMN ADJUSTMENT SWITCH

The instrument cluster supplies 2 reference voltages to the column adjustment switch.

The first reference voltage is supplied to the joystick switch. When the switch is moved to one of its 4 positions, the switch

contact is completed and the reference voltage is passed through one of 4 different resistors with different values. The

returned signal voltage is measured by the instrument cluster which determines the selected column adjust request. The

instrument cluster outputs a supply to the steering column adjustment motor and energizes the applicable clutch solenoid to

move the column to the desired position.

The second reference voltage is supplied to the auto/manual selection of the switch. When the switch is in the auto position,

the reference voltage passes directly through the switch contacts and is measured by the instrument cluster. The instrument

cluster outputs a message on the medium speed CAN bus to the driver seat module which responds with the recorded memory position setting. The instrument cluster then activates the column adjustment motor and clutch solenoids to move the column

to the memorized position. When the switch is in the manual position the reference circuit is broken. The instrument cluster

detects the broken circuit and allows manual operation of the column adjustment switch to move the column.

HEATED STEERING WHEEL

The heated steering wheel receives a battery power supply via the CJB. The heated steering wheel is controlled by the driver using a selection on the TSD. When the driver selects the heated steering wheel to be active, the request is passed from the

TSD on the MOST ring to the information and entertainment module. The information and entertainment module converts the

Page 801 of 3039

battery power supply to be passed via the slip ring assembly in the steering wheel to the heated steering wheel control

module. The steering wheel module supplies power to the steering wheel heater element and also monitors the temperature

via a NTC (negative temperature coefficient) temperature sensor incorporated into the heater element. The control module

varies the power supply to the element to maintain the steering wheel rim at the optimum temperature.

Component Description STEERING COLUMN MULTIFUNCTION SWITCHES

The steering column multifunction switches are situated on the steering column and consists of the wiper switch, the turn

signal indicator/lighting switch and the trip computer switch.

The steering column adjustment switch is located in the steering column lower shroud on the LH side. The switch is a 4 position 'joystick' which controls reach and rake adjustment.

Steering wheel mounted switches on the LH side of the driver's airbag, control the audio and telephone functions. Switches on the RH side of the driver's airbag, control the speed control functions. For additional information, refer to:

Audio System (415-01A Information and Entertainment System, Description and Operation), Speed Control (310-03A, Description and Operation),

Speed Control (310-03B, Description and Operation),

Speed Control (310-03C, Description and Operation).

Two transmission paddle switches are located at the rear of the steering wheel.

Refer to: External Controls (307-05, Description and Operation).

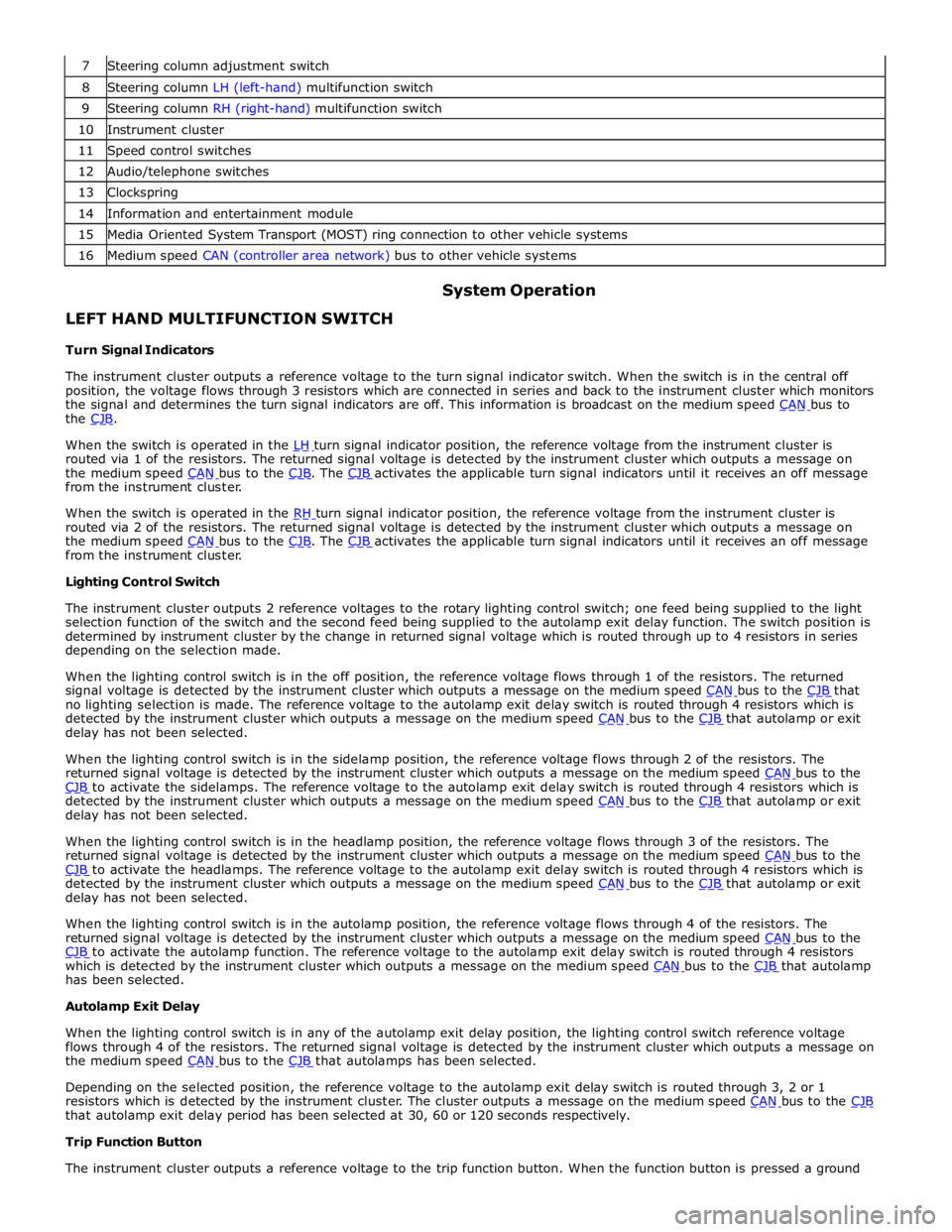

LH Multifunction Switch

Item Description 1 High beam 2 Lighting control rotary switch 3 RH turn signal indicator 4 Headlamp flash 5 LH turn signal indicator 6 Trip computer function button The LH multifunction switch controls the following windshield wiper functions:

Page 802 of 3039

Turn signal indicators

Side lamps

Headlamps

Auto lamps

High/low beam

Headlamp flash

Headlamp timer

Trip computer.

The switch is located in a slot in the clockspring and secured with 2 plastic clips.

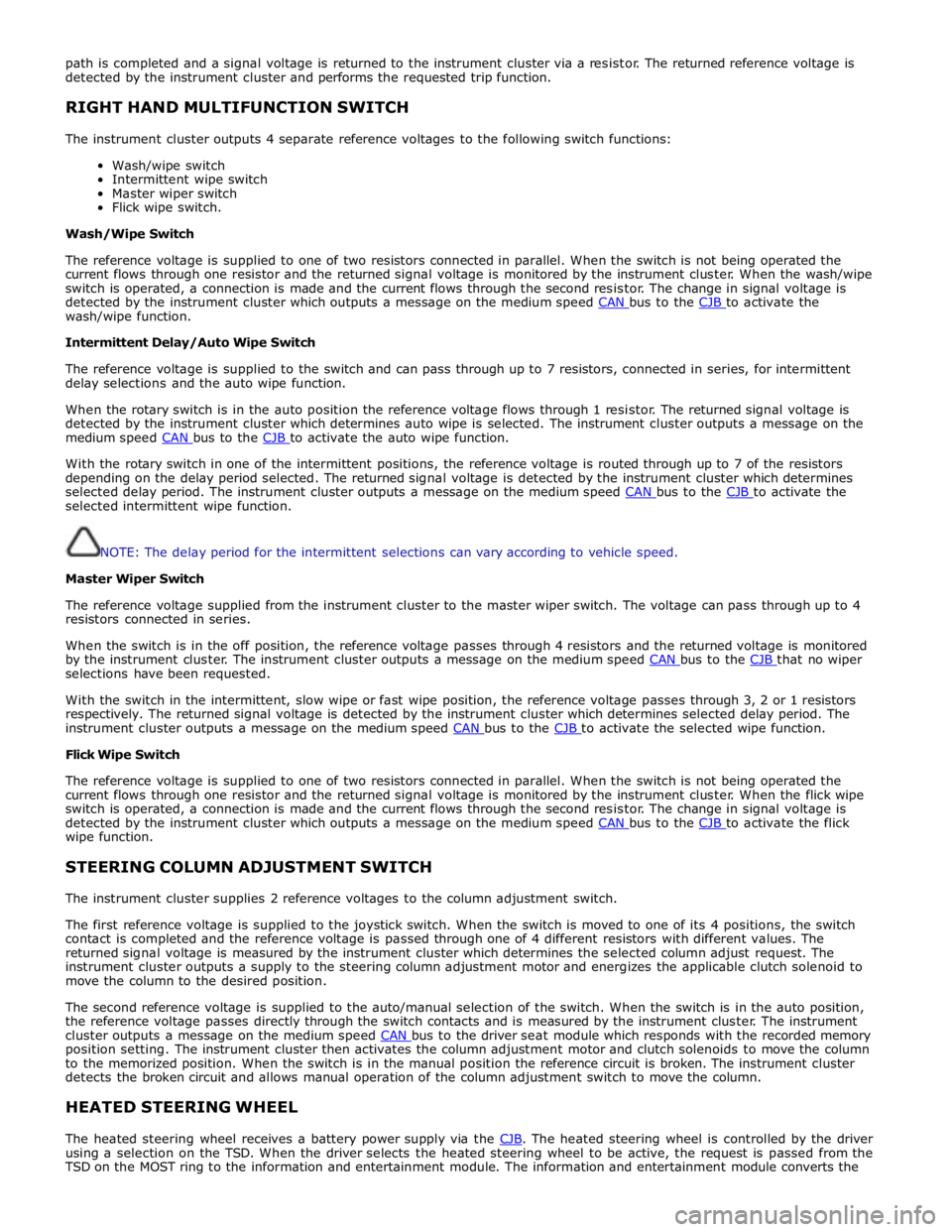

RH Multifunction Switch

The RH multifunction switch controls the following windshield wiper functions: Flick wipe

Intermittent wipe

Slow speed wipe

High speed wipe

Wash/Wipe

Headlamp powerwash

Rain sensing / variable wipe selection.

The switch is located in a slot in the clockspring and secured with 2 plastic clips.

STEERING COLUMN ADJUSTMENT SWITCH

The column adjustment switch is located in the steering column lower shroud and held in place with a spring clip. The switch

allows the adjustment of the steering column for both reach and rake angle. The switch has an auto position which allows the

desired position of the column to be set by the driver using the driver's seat memory buttons. The column position is Item Description 1 Auto/intermittent rotary switch 2 Fast wipe 3 Slow wipe 4 Intermittent wipe 5 Off position 6 Wash/wipe 7 Flick wipe www.JagDocs.com

Page 803 of 3039

automatically reset once the applicable remote handset has been detected by the vehicle security systems.

STEERING WHEEL HEATER

On certain models the rim of the steering wheel contains a heater element. Operation of the heater is selected using the

Touch Screen Display (TSD).

The heater temperature is controlled by a heated steering wheel control module located within the steering wheel. Power for

the heater element is supplied to the steering wheel via 2 contacts on the clockspring and a slip ring mounted on the steering

wheel.

Page 804 of 3039

Steering Column Switches - Steering Column Switches

Diagnosis and Testing

Principle of Operation Published: 14-Jul-2014

For a detailed description of the steering column lock and switches, refer to the relevant Description and Operation section in

the workshop manual. REFER to: (211-05 Steering Column Switches)

Steering Column Switches (Description and Operation), Steering Column Switches (Description and Operation), Steering Column Switches (Description and Operation).

Inspection and Verification

CAUTION: Diagnosis by substitution from a donor vehicle is NOT acceptable. Substitution of control modules does not

guarantee confirmation of a fault, and may also cause additional faults in the vehicle being tested and/or the donor vehicle.

1. Verify the customer concern.

2. Visually inspect for obvious signs of damage and system integrity.

Visual Inspection

Mechanical Electrical

Switches

Steering column lock

Fuse(s)

Electrical connector(s)

Wiring Harness

3. If an obvious cause for an observed or reported concern is found, correct the cause (if possible) before proceeding to

the next step.

4. If the cause is not visually evident, check for DTCs and refer to the DTC Index.

DTC Index

For a list of Diagnostic Trouble Codes (DTCs) that could be logged on this vehicle, please refer to Section 100-00.

REFER to: Diagnostic Trouble Code (DTC) Index - DTC: Central Junction Box (CJB) (100-00 General Information, Description and Operation).

Page 805 of 3039

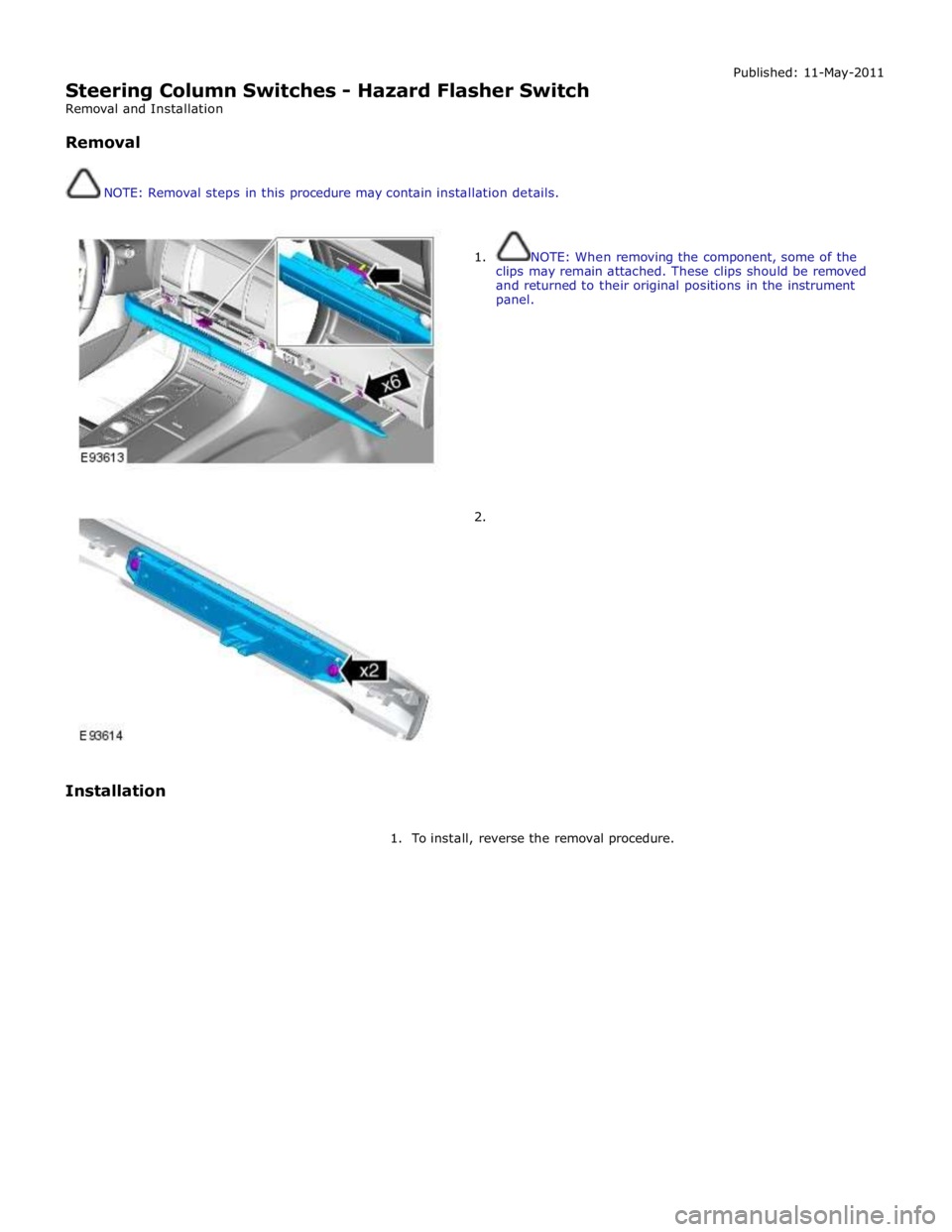

Steering Column Switches - Hazard Flasher Switch

Removal and Installation

Removal

NOTE: Removal steps in this procedure may contain installation details. Published: 11-May-2011

Installation

1. NOTE: When removing the component, some of the

clips may remain attached. These clips should be removed

and returned to their original positions in the instrument

panel.

2.

1. To install, reverse the removal procedure.

Page 810 of 3039

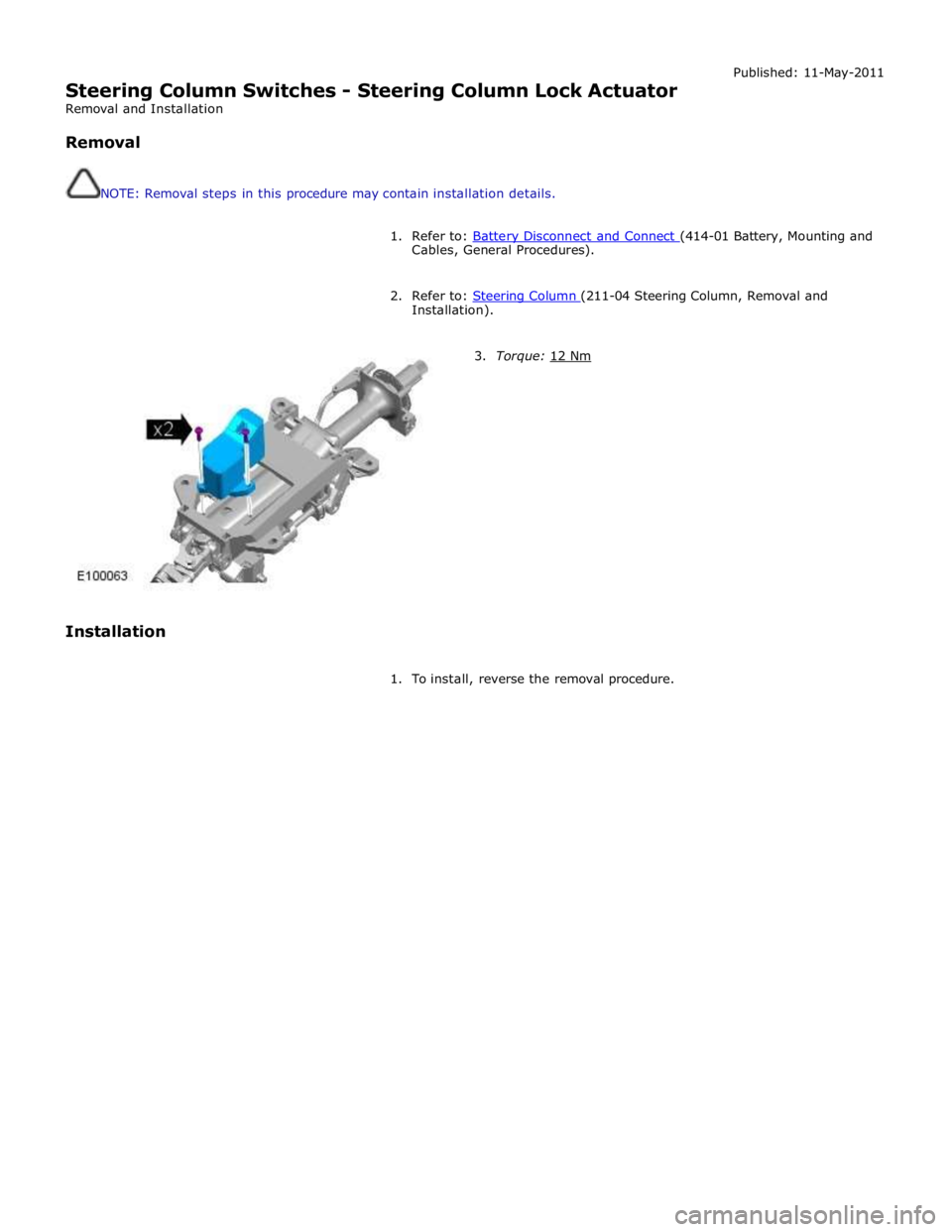

Steering Column Switches - Steering Column Lock Actuator

Removal and Installation

Removal

NOTE: Removal steps in this procedure may contain installation details. Published: 11-May-2011

1. Refer to: Battery Disconnect and Connect (414-01 Battery, Mounting and Cables, General Procedures).

2. Refer to: Steering Column (211-04 Steering Column, Removal and Installation).

Installation

3. Torque: 12 Nm

1. To install, reverse the removal procedure.

Page 845 of 3039

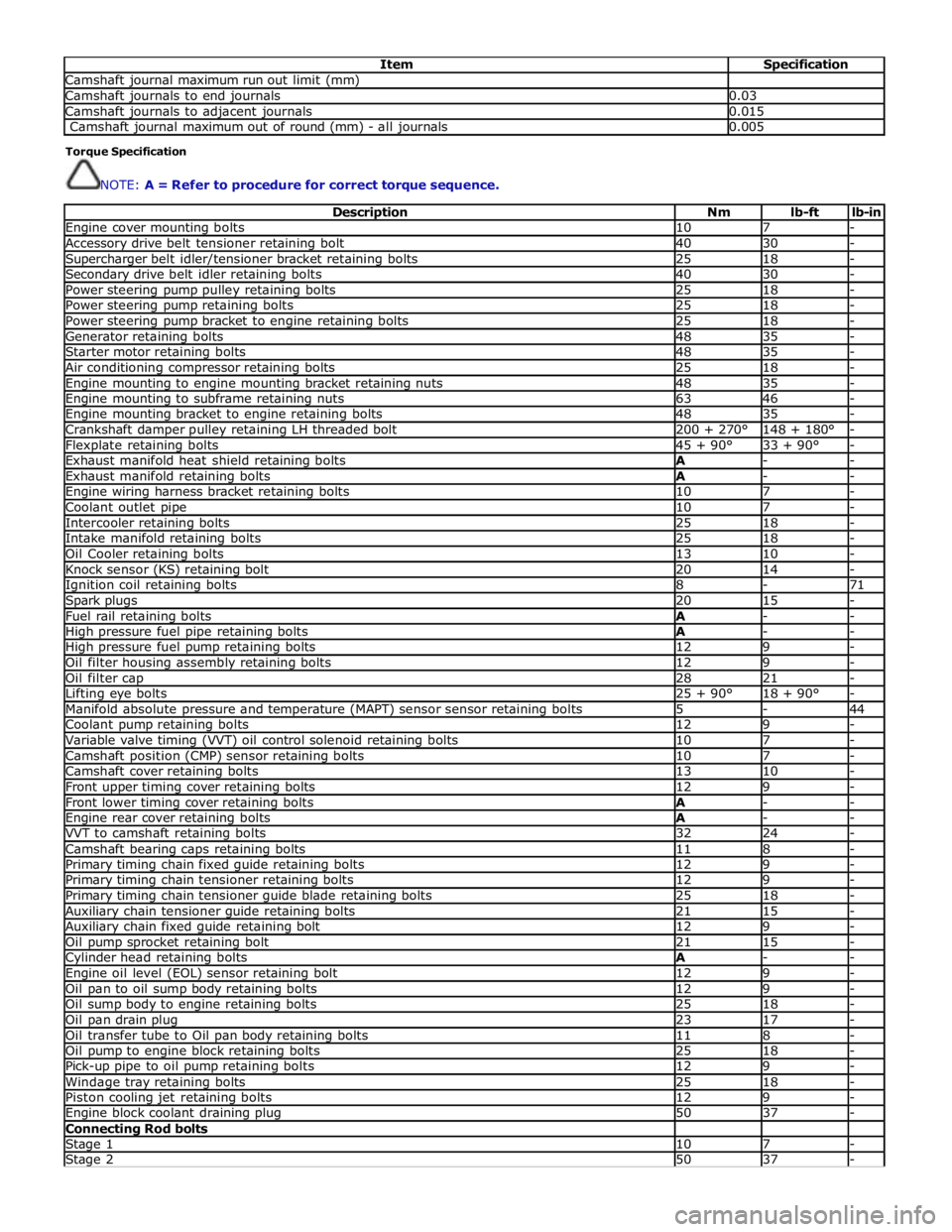

Item Specification Camshaft journal maximum run out limit (mm) Camshaft journals to end journals 0.03 Camshaft journals to adjacent journals 0.015 Camshaft journal maximum out of round (mm) - all journals 0.005 Torque Specification

NOTE: A = Refer to procedure for correct torque sequence.

Description Nm lb-ft lb-in Engine cover mounting bolts 10 7 - Accessory drive belt tensioner retaining bolt 40 30 - Supercharger belt idler/tensioner bracket retaining bolts 25 18 - Secondary drive belt idler retaining bolts 40 30 - Power steering pump pulley retaining bolts 25 18 - Power steering pump retaining bolts 25 18 - Power steering pump bracket to engine retaining bolts 25 18 - Generator retaining bolts 48 35 - Starter motor retaining bolts 48 35 - Air conditioning compressor retaining bolts 25 18 - Engine mounting to engine mounting bracket retaining nuts 48 35 - Engine mounting to subframe retaining nuts 63 46 - Engine mounting bracket to engine retaining bolts 48 35 - Crankshaft damper pulley retaining LH threaded bolt 200 + 270° 148 + 180° - Flexplate retaining bolts 45 + 90° 33 + 90° - Exhaust manifold heat shield retaining bolts A - - Exhaust manifold retaining bolts A - - Engine wiring harness bracket retaining bolts 10 7 - Coolant outlet pipe 10 7 - Intercooler retaining bolts 25 18 - Intake manifold retaining bolts 25 18 - Oil Cooler retaining bolts 13 10 - Knock sensor (KS) retaining bolt 20 14 - Ignition coil retaining bolts 8 - 71 Spark plugs 20 15 - Fuel rail retaining bolts A - - High pressure fuel pipe retaining bolts A - - High pressure fuel pump retaining bolts 12 9 - Oil filter housing assembly retaining bolts 12 9 - Oil filter cap 28 21 - Lifting eye bolts 25 + 90° 18 + 90° - Manifold absolute pressure and temperature (MAPT) sensor sensor retaining bolts 5 - 44 Coolant pump retaining bolts 12 9 - Variable valve timing (VVT) oil control solenoid retaining bolts 10 7 - Camshaft position (CMP) sensor retaining bolts 10 7 - Camshaft cover retaining bolts 13 10 - Front upper timing cover retaining bolts 12 9 - Front lower timing cover retaining bolts A - - Engine rear cover retaining bolts A - - VVT to camshaft retaining bolts 32 24 - Camshaft bearing caps retaining bolts 11 8 - Primary timing chain fixed guide retaining bolts 12 9 - Primary timing chain tensioner retaining bolts 12 9 - Primary timing chain tensioner guide blade retaining bolts 25 18 - Auxiliary chain tensioner guide retaining bolts 21 15 - Auxiliary chain fixed guide retaining bolt 12 9 - Oil pump sprocket retaining bolt 21 15 - Cylinder head retaining bolts A - - Engine oil level (EOL) sensor retaining bolt 12 9 - Oil pan to oil sump body retaining bolts 12 9 - Oil sump body to engine retaining bolts 25 18 - Oil pan drain plug 23 17 - Oil transfer tube to Oil pan body retaining bolts 11 8 - Oil pump to engine block retaining bolts 25 18 - Pick-up pipe to oil pump retaining bolts 12 9 - Windage tray retaining bolts 25 18 - Piston cooling jet retaining bolts 12 9 - Engine block coolant draining plug 50 37 - Connecting Rod bolts Stage 1 10 7 - Stage 2 50 37 -

Page 964 of 3039

Support and release the power steering rack.

Torque: 63 Nm Remove and discard the nut.

Torque: 48 Nm Raise the engine.