Fuel JAGUAR XFR 2010 1.G Workshop Manual

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 2010, Model line: XFR, Model: JAGUAR XFR 2010 1.GPages: 3039, PDF Size: 58.49 MB

Page 1565 of 3039

Published: 01-Aug-2012

Fuel System - General Information - Fuel System Pressure Release V8 5.0L

Petrol/V8 S/C 5.0L Petrol

General Procedures

Draining

1. Remove the fuel pump fuse.

2. Remove the fuel filler cap.

3. CAUTION: When depressurising the fuel system, make sure that

there is no throttle input. Failure to follow this instruction may cause

damage to the vehicle.

Start the engine and allow it to idle until the engine stalls.

4. Crank the engine for approximately five seconds to make sure that the

fuel rail pressure is released.

Filling

1. NOTE: Make sure all repairs have been carried out before

proceeding to the following steps.

Install the fuel pump fuse.

2. Install the fuel filler cap.

3. Read and clear stored DTC fault codes.

Page 1566 of 3039

Safety Precautions (100-00 General Information, Description and Operation).

All except vehicles with diesel engine

2. For additional information, refer to: Petrol and Petrol-Ethanol Fuel Systems Health and Safety Precautions (100-00 General Information, Description and Operation).

Vehicles with 3.0L or 4.2L engine

3. Release the pressure in the fuel system.

For additional information, refer to: Fuel System Pressure Release - V6 3.0L Petrol (310-00 Fuel System - General Information, General Procedures).

Vehicles with 5.0L engine

4. Release the pressure in the fuel system.

For additional information, refer to: Fuel System Pressure Release - V8 5.0L Petrol/V8 S/C 5.0L Petrol (310-00 Fuel System - General Information, General Procedures).

All vehicles

5. Remove the rear seat cushion.

For additional information, refer to: Rear Seat Cushion (501-10 Seating, Removal and Installation).

6. Detach and reposition the door opening weatherstrip. Fuel tank drain adaptor

310-154 Special Tool(s)

Page 1568 of 3039

11.

12. CAUTION: The correct measurement must be used to

remove the fuel tank drain port top. Failure to follow this

instruction may result in damage to the vehicle.

NOTE: Vehicles without Diesel engine shown, vehicles

with Diesel engine similar.

Using a suitable tool, remove the top of the fuel tank drain

port.

NOTES:

A fuel vacuum drain unit must be attached to the

special tool to achieve full fuel tank drain.

Vehicles without Diesel engine shown, vehicles with

Diesel engine similar.

Using the special tool, drain the right-hand side of the fuel

tank.

Page 1569 of 3039

13.

14. NOTE: Vehicles without Diesel engine shown, vehicles

with Diesel engine similar.

Remove the special tool.

CAUTION: Make sure the new fuel tank drain port

sealing cap is correctly installed. Failure to follow this

instruction may result in damage to the vehicle.

NOTE: Vehicles without Diesel engine shown, vehicles

with Diesel engine similar.

Install a new fuel tank drain port sealing cap.

Page 1570 of 3039

15.

16. CAUTION: The correct measurement must be used to

remove the fuel tank drain port top. Failure to follow this

instruction may result in damage to the vehicle.

NOTE: Vehicles without Diesel engine shown, vehicles

with Diesel engine similar.

Using a suitable tool, remove the top of the fuel tank drain

port.

NOTES:

A fuel vacuum drain unit must be attached to the

special tool to achieve full fuel tank drain.

Vehicles without Diesel engine shown, vehicles with

Diesel engine similar.

Using the special tool, drain the left-hand side of the fuel

tank.

Page 1571 of 3039

17.

18. NOTE: Vehicles without Diesel engine shown, vehicles

with Diesel engine similar.

Remove the special tool.

CAUTION: Make sure the new fuel tank drain port

sealing cap is correctly installed. Failure to follow this

instruction may result in damage to the vehicle.

NOTE: Vehicles without Diesel engine shown, vehicles

with Diesel engine similar.

Install a new fuel tank drain port sealing cap.

19.

Install the floor aperture cover.

Page 1573 of 3039

Fuel System - General Information - Spring Lock Couplings

General Procedures Published: 11-May-2011

Disconnect

1. WARNINGS:

Place the vehicle in a quarantined area and arrange "No

Smoking/Petrol Fumes" signs about the vehicle.

Before any work is carried out on the fuel system, ground the

vehicle to earth and maintain the ground connection until the work is

complete.

Do not smoke or carry lighted tobacco or open flame of any type

when working on or near any fuel related components. Highly flammable

vapors are always present and may ignite. Failure to follow these

instructions may result in personal injury.

The fuel system remains pressurized for a long time after the

ignition is switched off. The fuel pressure must be relieved before

attempting any repairs. Failure to follow these instructions may result in

personal injury.

After carrying out repairs, the fuel system must be checked visually

for leaks. Failure to follow these instructions may result in personal

injury.

This procedure involves fuel handling. Be prepared for fuel spillage

at all times and always observe fuel handling precautions. Failure to

follow these instructions may result in personal injury.

If taken internally do not induce vomiting, seek immediate medical

attention. Failure to follow these instructions may result in personal

injury.

If fuel contacts the eyes, flush the eyes with cold water or

eyewash solution and seek medical attention.

Wash hands thoroughly after handling, as prolonged contact may

cause irritation. Should irritation develop, seek medical attention.

Relieve the fuel system pressure. For additional information, refer to the

procedure in this section: Pressure Relief. Spring Lock Coupling Tool or Equivalent

310-D005 (23-040) Special Tool(s)

Page 1577 of 3039

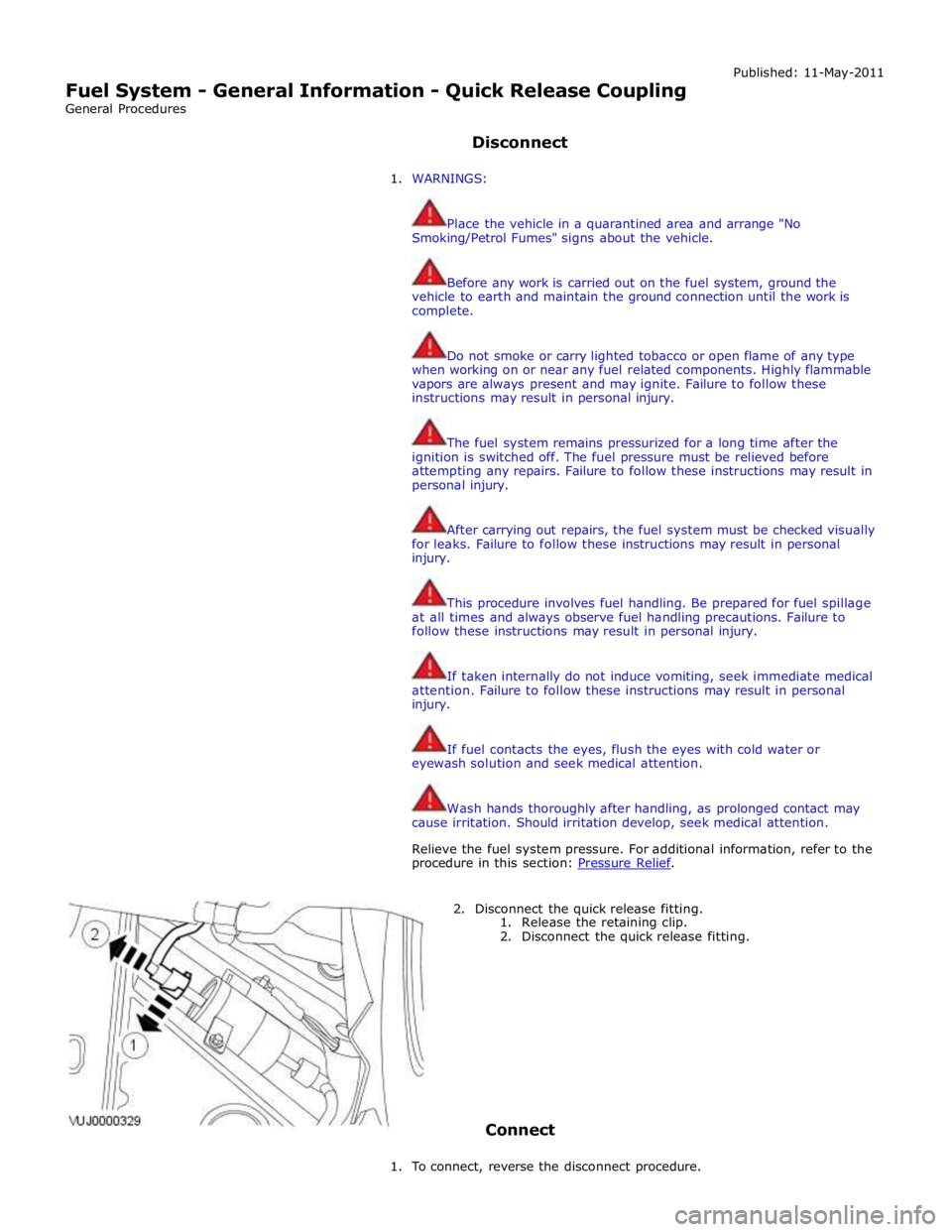

Fuel System - General Information - Quick Release Coupling

General Procedures

Disconnect Published: 11-May-2011

1. WARNINGS:

Place the vehicle in a quarantined area and arrange "No

Smoking/Petrol Fumes" signs about the vehicle.

Before any work is carried out on the fuel system, ground the

vehicle to earth and maintain the ground connection until the work is

complete.

Do not smoke or carry lighted tobacco or open flame of any type

when working on or near any fuel related components. Highly flammable

vapors are always present and may ignite. Failure to follow these

instructions may result in personal injury.

The fuel system remains pressurized for a long time after the

ignition is switched off. The fuel pressure must be relieved before

attempting any repairs. Failure to follow these instructions may result in

personal injury.

After carrying out repairs, the fuel system must be checked visually

for leaks. Failure to follow these instructions may result in personal

injury.

This procedure involves fuel handling. Be prepared for fuel spillage

at all times and always observe fuel handling precautions. Failure to

follow these instructions may result in personal injury.

If taken internally do not induce vomiting, seek immediate medical

attention. Failure to follow these instructions may result in personal

injury.

If fuel contacts the eyes, flush the eyes with cold water or

eyewash solution and seek medical attention.

Wash hands thoroughly after handling, as prolonged contact may

cause irritation. Should irritation develop, seek medical attention.

Relieve the fuel system pressure. For additional information, refer to the

procedure in this section: Pressure Relief.

2. Disconnect the quick release fitting.

1. Release the retaining clip.

2. Disconnect the quick release fitting.

Connect

1. To connect, reverse the disconnect procedure.

Page 1578 of 3039

Published: 11-May-2011

Fuel System - General Information - Quick Release Coupling - Push Connect

General Procedures

Disconnect

1. WARNINGS:

Place the vehicle in a quarantined area and arrange "No

Smoking/Petrol Fumes" signs about the vehicle.

Before any work is carried out on the fuel system, ground the

vehicle to earth and maintain the ground connection until the work is

complete.

Do not smoke or carry lighted tobacco or open flame of any type

when working on or near any fuel related components. Highly flammable

vapors are always present and may ignite. Failure to follow these

instructions may result in personal injury.

The fuel system remains pressurized for a long time after the

ignition is switched off. The fuel pressure must be relieved before

attempting any repairs. Failure to follow these instructions may result in

personal injury.

After carrying out repairs, the fuel system must be checked visually

for leaks. Failure to follow these instructions may result in personal

injury.

This procedure involves fuel handling. Be prepared for fuel spillage

at all times and always observe fuel handling precautions. Failure to

follow these instructions may result in personal injury.

If taken internally do not induce vomiting, seek immediate medical

attention. Failure to follow these instructions may result in personal

injury.

If fuel contacts the eyes, flush the eyes with cold water or

eyewash solution and seek medical attention.

Wash hands thoroughly after handling, as prolonged contact may

cause irritation. Should irritation develop, seek medical attention.

Relieve the fuel system pressure. For additional information, refer to the

procedure in this section:

For additional information, refer to: Fuel System Pressure Release

(310-00 Fuel System - General Information, General Procedures).

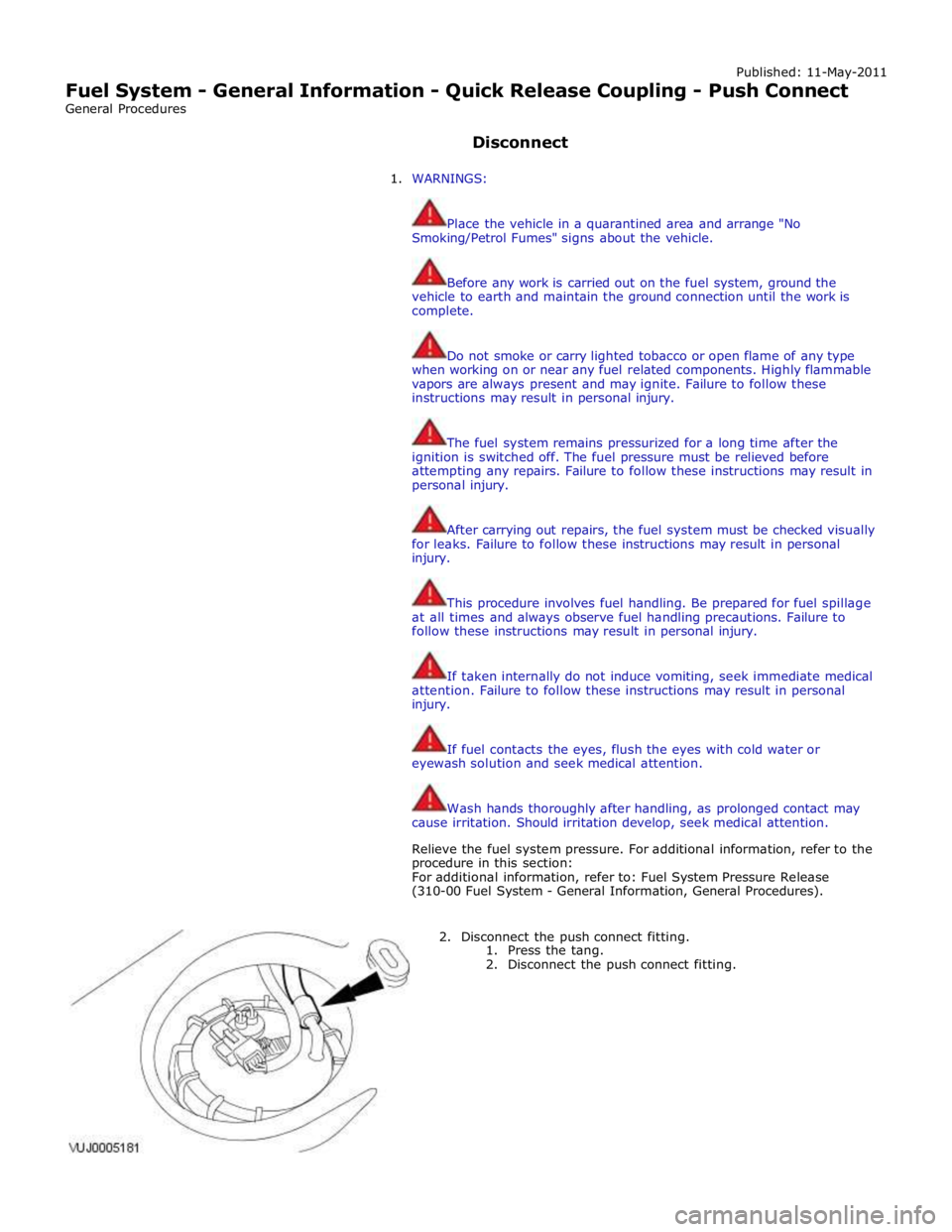

2. Disconnect the push connect fitting.

1. Press the tang.

2. Disconnect the push connect fitting.

Page 1580 of 3039

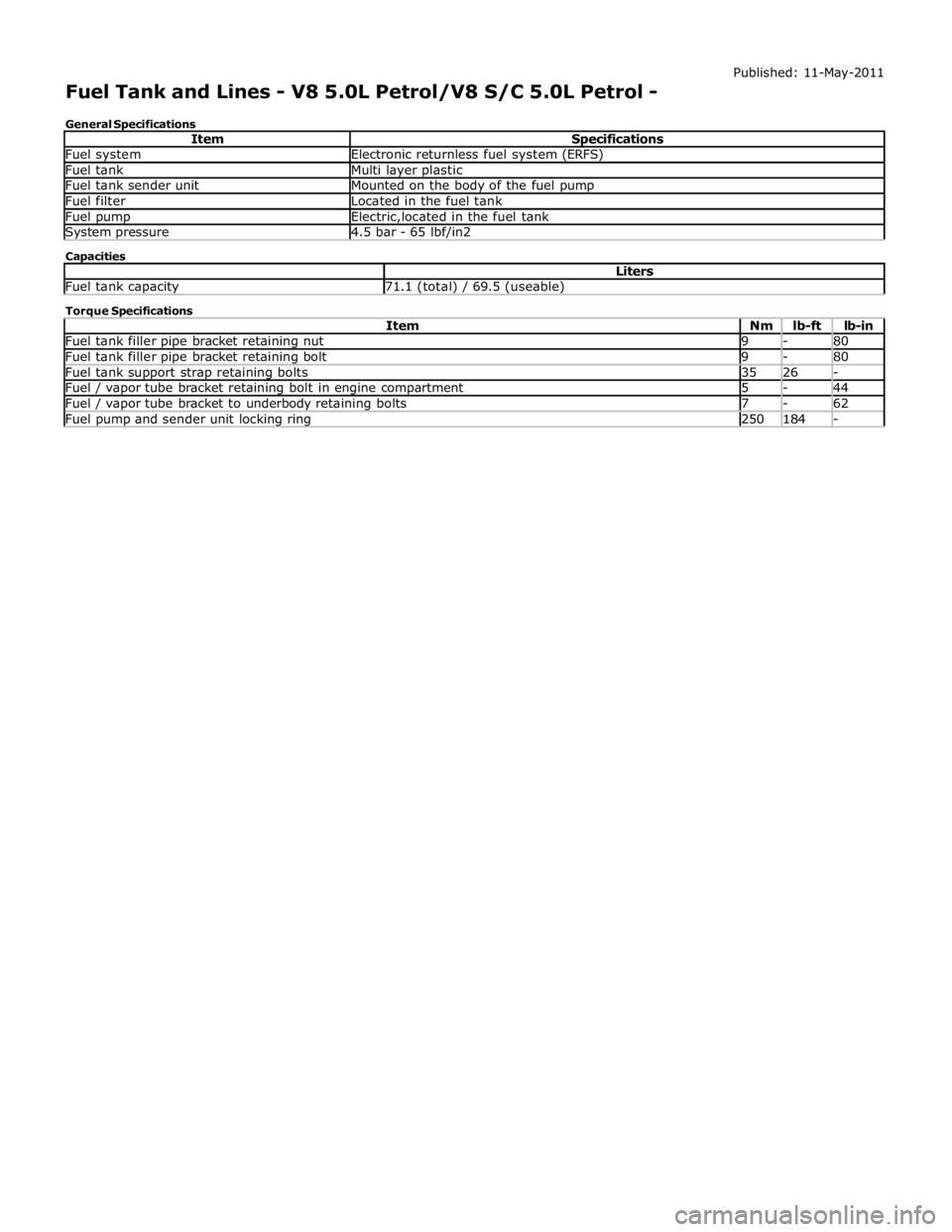

Fuel system Electronic returnless fuel system (ERFS) Fuel tank Multi layer plastic Fuel tank sender unit Mounted on the body of the fuel pump Fuel filter Located in the fuel tank Fuel pump Electric,located in the fuel tank System pressure 4.5 bar - 65 lbf/in2 Capacities Liters Fuel tank capacity 71.1 (total) / 69.5 (useable) Torque Specifications

Item Nm lb-ft lb-in Fuel tank filler pipe bracket retaining nut 9 - 80 Fuel tank filler pipe bracket retaining bolt 9 - 80 Fuel tank support strap retaining bolts 35 26 - Fuel / vapor tube bracket retaining bolt in engine compartment 5 - 44 Fuel / vapor tube bracket to underbody retaining bolts 7 - 62 Fuel pump and sender unit locking ring 250 184 -