Fuel JAGUAR XFR 2010 1.G Workshop Manual

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 2010, Model line: XFR, Model: JAGUAR XFR 2010 1.GPages: 3039, PDF Size: 58.49 MB

Page 2726 of 3039

metal surfaces are bolted together always interpose a suitable interface material such as weldable zinc rich primer, extruded

strip, or zinc tape.

Steam Cleaning

Due to the high pressure/temperature generated by steam cleaning equipment, there is a risk that certain adhesives and

corrosion prevention material may become softened or liquified.

Take care not to allow the steam jet to dwell on one area, and keep the nozzle at least 300mm from the panel surface.

CAUTION: Do not remove wax or lacquer from underbody areas during repairs.

Inspection During Maintenance Servicing

It is a requirement of the corrosion warranty that the vehicle is inspected for corrosion by a Jaguar Authorised Repairer during a

routine service, to ensure that the factory-applied protection remains effective.

Rectify any bodywork damage or evidence of corrosion found during inspection as soon as is practicable, both to minimise the

extent of the damage and to ensure the long term effectiveness of the factory-applied corrosion prevention treatment.

Underbody Protection Repairs

Whenever body repairs have been carried out, ensure that full sealing and corrosion protection treatments are reinstated. This

applies both to the damaged areas and also to areas where protection has been indirectly impaired, as a result either of

accident damage or repair operations.

Remove corrosion protection from the damaged areas before straightening or panel beating. This applies in particular to panels

coated with wax, PVC underbody sealer, sound deadening pads etc.

CAUTION: Do not use oxy-acetylene to remove corrosion prevention material. Large volumes of fumes and gases are

liberated by these materials when they burn.

The most common method of removal is by means of a hot air blower with an integral scraper. High temperatures can be

generated with this equipment which may cause fumes. Take care during its use.

Structural Adhesive

CAUTION: When separating a joint with metal to metal adhesive, it is important to avoid distortion. Heat gradually until

the bond weakens sufficiently to permit panel separation - do not apply excessive heat.

NOTE: When spot welding through metal to metal adhesive, take particular care to adjust the equipment setting to

ensure a suitable weld.

Metal to metal adhesive is applied to critical joint areas during factory assembly. The material used is a high temperature,

heat cured, nitrile phenolic which serves to bond two metal surfaces and also to seal the joint against ingress of dust,

moisture and fumes. This material is not suitable for service use and, during repair, should be substituted by an approved

structural adhesive. For panel specific information and to identify the areas of structural adhesive application in repair, refer to

the relevant sheet metal removal and installation procedure.

Expanding Foam Acoustic Seals

Expanding foam acoustic seals are used in various closed-sections of the body to improve vehicle refinement. The seals are

installed during the vehicle body manufacture and expand during the paint process up to ten times original size, thus locking

them into position. They are located such that they prevent noise accentuation along a section and reflect air borne noise

away from the cabin.

The seals have spilt functionality depending on location. The seals located at the base of the body pillars have a primary

function of preventing water ingress when wading. Their secondary function is to prevent noise and dust ingress.

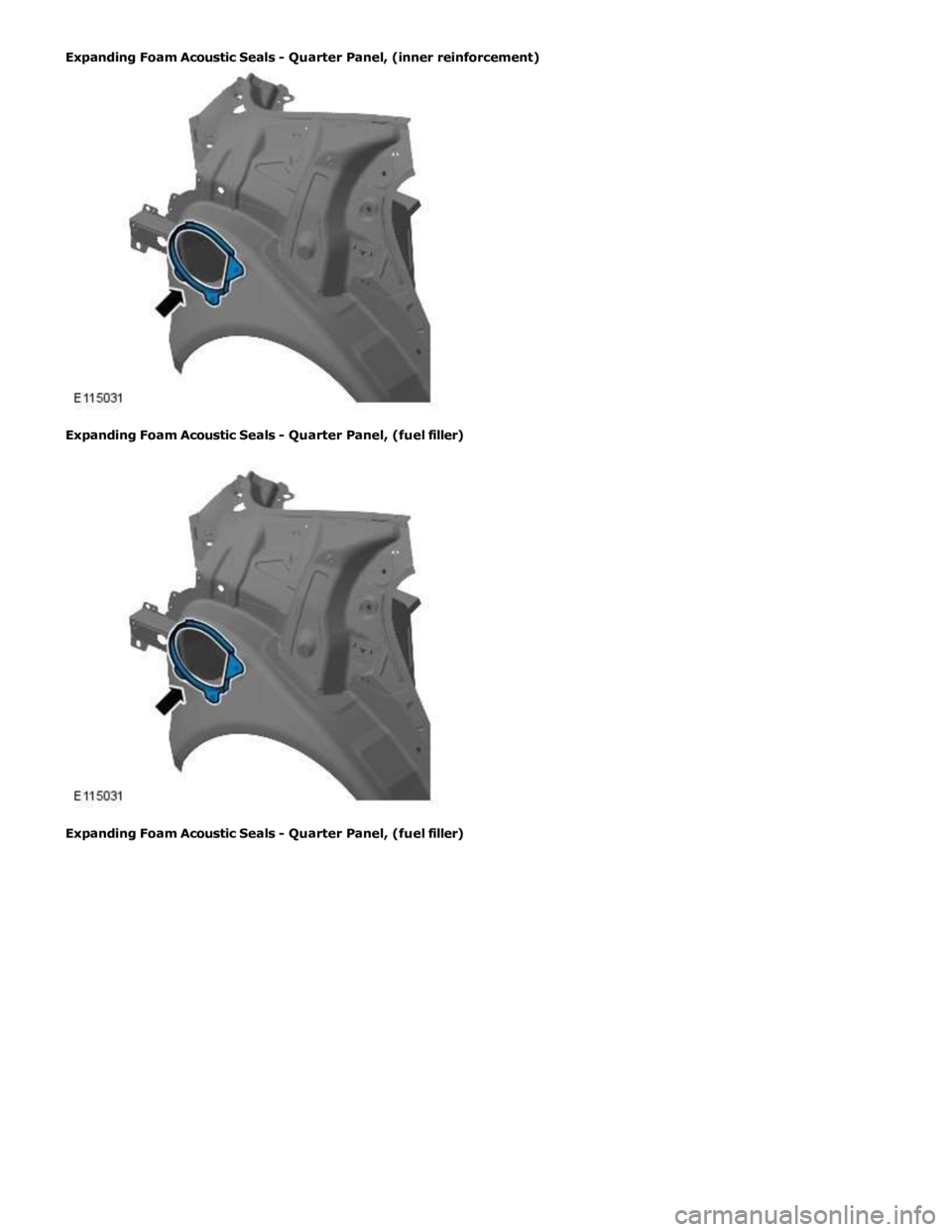

The seal around the fuel filler has a primary function of preventing both fuel and water ingress. With a secondary function of

preventing noise and dust ingress.

The remaining seals primary function is to prevent noise accentuation along a section and reflect air borne noise away from the

cabin.

Another advantage of the seals is that they marginally increase the overall stiffness of the body and its structural performance

in case of a crash.

The seals are manufactured from an expandible polymer.

Replacing Expanding Foam Acoustic Seals

As paint oven temperatures used in a repair workshop are significantly lower than those that are used during manufacture of

the vehicle, (the temperatures are not sufficient to expand the foam), a different process is required to replicate the foam in

repair.

Page 2730 of 3039

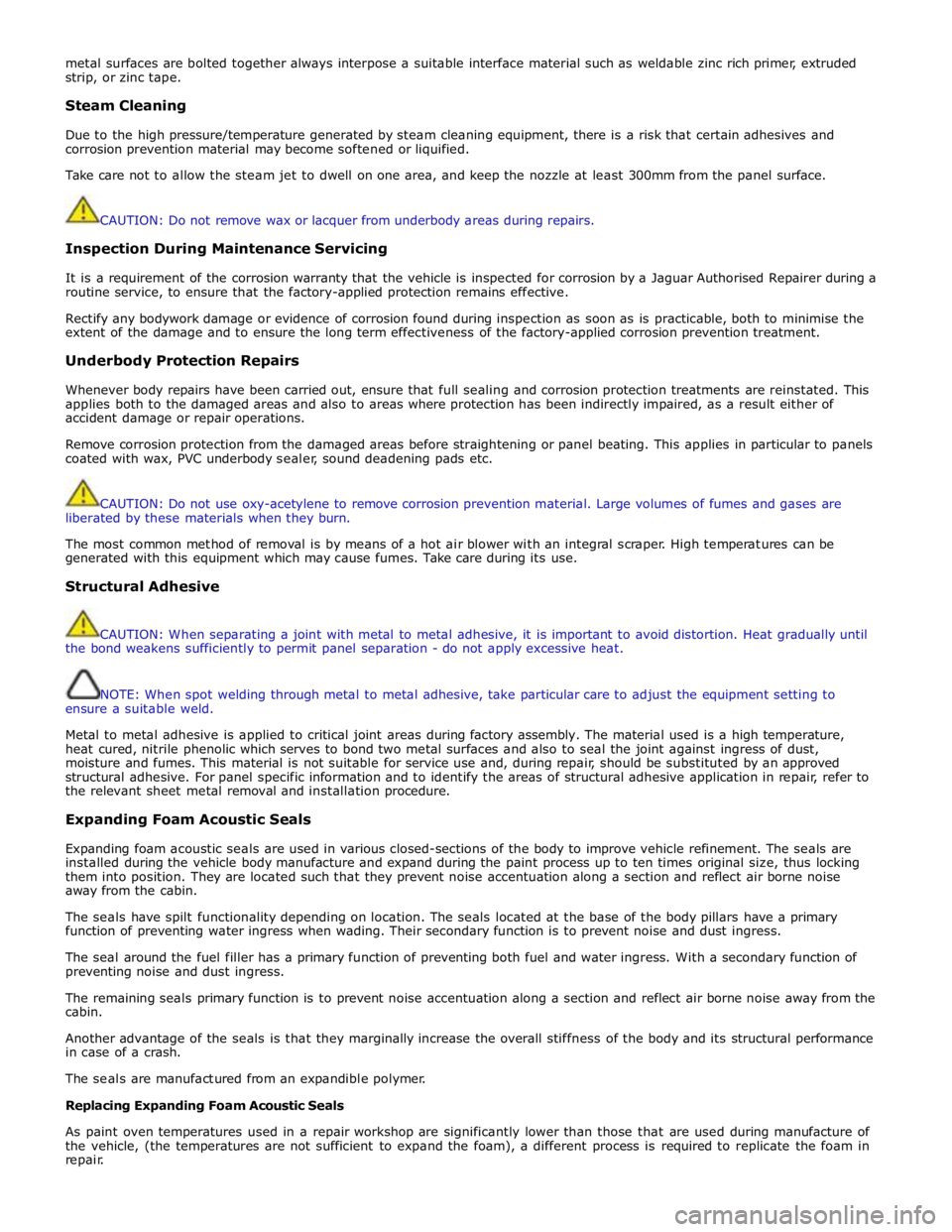

Expanding Foam Acoustic Seals - Quarter Panel, (inner reinforcement)

Expanding Foam Acoustic Seals - Quarter Panel, (fuel filler)

Expanding Foam Acoustic Seals - Quarter Panel, (fuel filler)

Page 2785 of 3039

Transmission (307-01A Automatic Transmission/Transaxle - V6 3.0L Petrol, Removal) /

Transmission - 4.2L (307-01, Removal) /

Transmission - V8 5.0L Petrol/V8 S/C 5.0L Petrol (307-01B Automatic Transmission/Transaxle - TDV6 3.0L Diesel /V8 5.0L Petrol/V8 S/C 5.0L

Petrol, Removal) /

Front Shock Absorber (204-01 Front Suspension, Removal and Installation) /

Front Subframe - 2.7L Diesel (502-00, Removal and Installation) /

Front Subframe - V6 3.0L Petrol (502-00 Uni-Body, Subframe and Mounting System, Removal and Installation) /

Front Subframe - 4.2L, Vehicles Without: Supercharger (502-00, Removal

and Installation) /

Front Subframe - 4.2L, Vehicles With: Supercharger (502-00, Removal

and Installation).

8. Remove the pedestrian protection hood actuator.

For additional information, refer to: Pedestrian Protection Hood Actuator LH (501-20C Pedestrian Protection System, Removal and Installation) / Pedestrian Protection Hood Actuator RH (501-20C Pedestrian Protection System, Removal and Installation).

9. If the drivers side front side member and suspension top mount is to be

repaired, remove the brake master cylinder and reservoir.

For additional information, refer to: Brake Master Cylinder (206-06 Hydraulic Brake Actuation, Removal and Installation) /

Brake Fluid Reservoir (206-06 Hydraulic Brake Actuation, Removal and Installation).

10. If the left-hand front side member and suspension top mount assembly

is to be repaired, remove the fuel supply and return lines.

11. Release and position the front side member wiring harness to one side.

12. Remove any remaining miscellaneous components from the repair area.

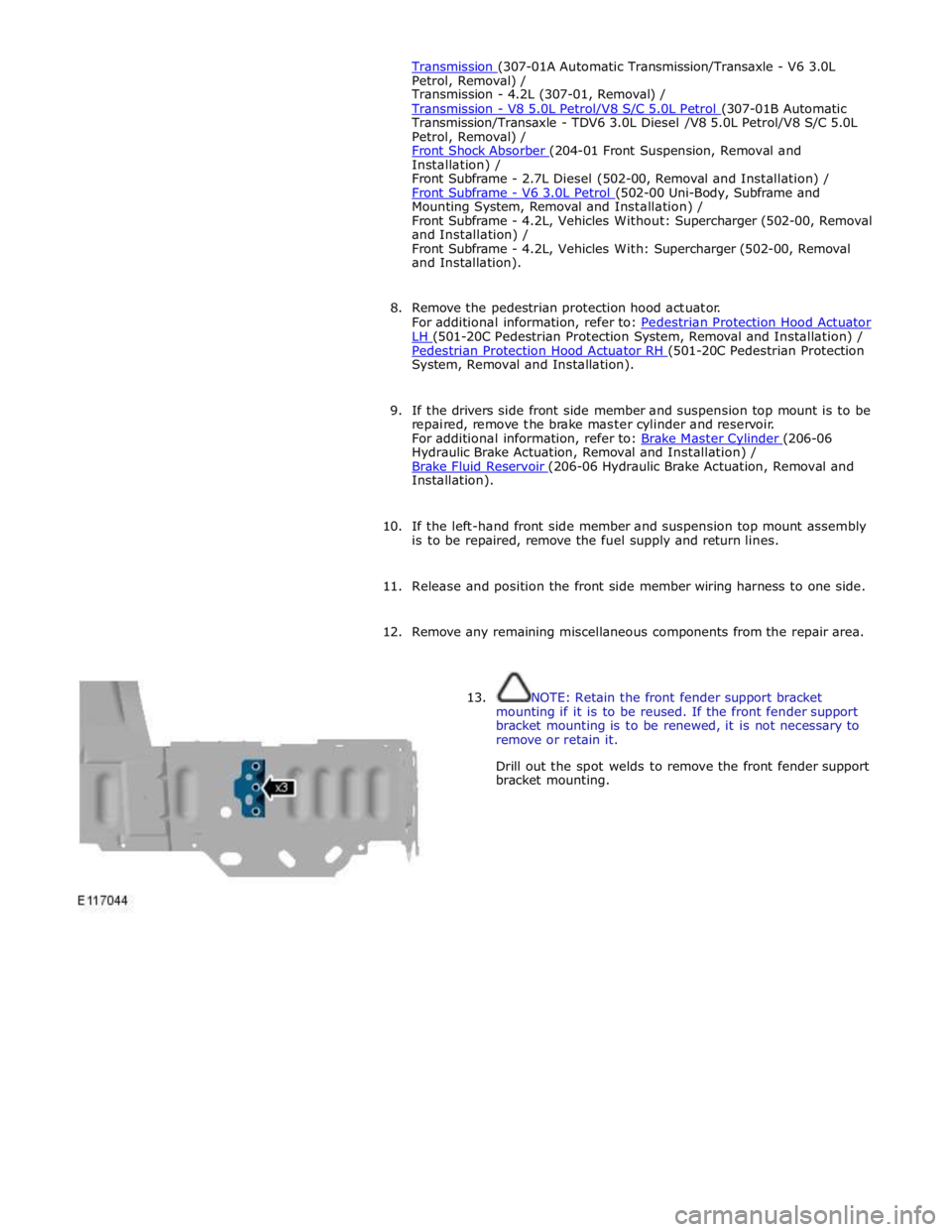

13. NOTE: Retain the front fender support bracket

mounting if it is to be reused. If the front fender support

bracket mounting is to be renewed, it is not necessary to

remove or retain it.

Drill out the spot welds to remove the front fender support

bracket mounting.

Page 2798 of 3039

Actuation, Removal and Installation).

12. Remove the left-hand and right-hand front seats.

For additional information, refer to: Front Seat (501-10 Seating, Removal and Installation).

13. Remove the heater core and evaporator core housing.

For additional information, refer to: Heater Core and Evaporator Core Housing (412-01 Climate Control, Removal and Installation).

14. Remove the front safety belt retractor.

For additional information, refer to: Front Safety Belt Retractor (501-20A Safety Belt System, Removal and Installation).

15. Remove the B-pillar side impact sensor.

For additional information, refer to: B-Pillar Side Impact Sensor (501-20B Supplemental Restraint System, Removal and Installation).

16. Remove the left-hand and right-hand front floor covering.

17. Remove the rear floor covering.

18. If the left-hand front side member and suspension top mount assembly

is to be repaired, remove the left-hand rear foot well duct.

19. If the right-hand front side member and suspension top mount assembly

is to be repaired, remove the right-hand rear foot well duct.

20. If the drivers side front side member and suspension top mount is being

repaired, remove the pedal box.

21. Release and position the insulating material at the inner bulkhead to

one side.

22. Release and position the inner bulkhead and floor panel wiring harness

to one side.

23. Drain the fuel tank.

For additional information, refer to: Fuel Tank Draining (310-00 Fuel System - General Information, General Procedures).

24. If the left-hand front side member and suspension top mount assembly

is to be repaired, remove the left-hand under shield.

25. If the right-hand front side member and suspension top mount assembly

is to be repaired, remove the right-hand under shield.

26. If the left-hand front side member and suspension top mount assembly

is to be repaired, remove the fuel supply and return pipes.

27. For diesel engine vehicles only, if the left-hand front side member and

suspension top mount assembly is to be repaired, remove the fuel

cooler.

28. If the right-hand front side member and suspension top mount assembly

is to be repaired, release and position the underfloor wiring harness to

Page 2950 of 3039

Supplemental Restraint System, Removal and Installation).

23. Remove the rear window glass.

24. Remove the audio unit antenna amplifier.

For additional information, refer to: Audio Unit Antenna Amplifier (415-01A Information and Entertainment System, Removal and

Installation).

25. If the left-hand rear quarter panel is to be repaired, remove the diversity

antenna module.

26. Remove the C-Pillar side impact sensor.

For additional information, refer to: C-Pillar Side Impact Sensor (501-20B Supplemental Restraint System, Removal and Installation).

27. Remove the rear door striker.

28. Remove the luggage compartment lid.

29. If the right-hand rear quarter panel is to be repaired, drain the fuel tank.

For additional information, refer to: Fuel Tank Draining (310-00 Fuel System - General Information, General Procedures).

30. If the right-hand rear quarter panel is to be repaired, remove the fuel

filler door.

31. If the right-hand rear quarter panel is to be repaired, remove the fuel

tank filler pipe.

For additional information, refer to: Fuel Tank Filler Pipe (310-01 Fuel

Tank and Lines - 3.0L, Removal and Installation) /

Fuel Tank Filler Pipe (310-01 Fuel Tank and Lines - 4.2L, Removal and

Installation).

32. Remove the luggage compartment lid hinge.

Page 2980 of 3039

Rear End Sheet Metal Repairs - Rear Wheelhouse Outer

Removal and Installation

Removal Published: 11-May-2011

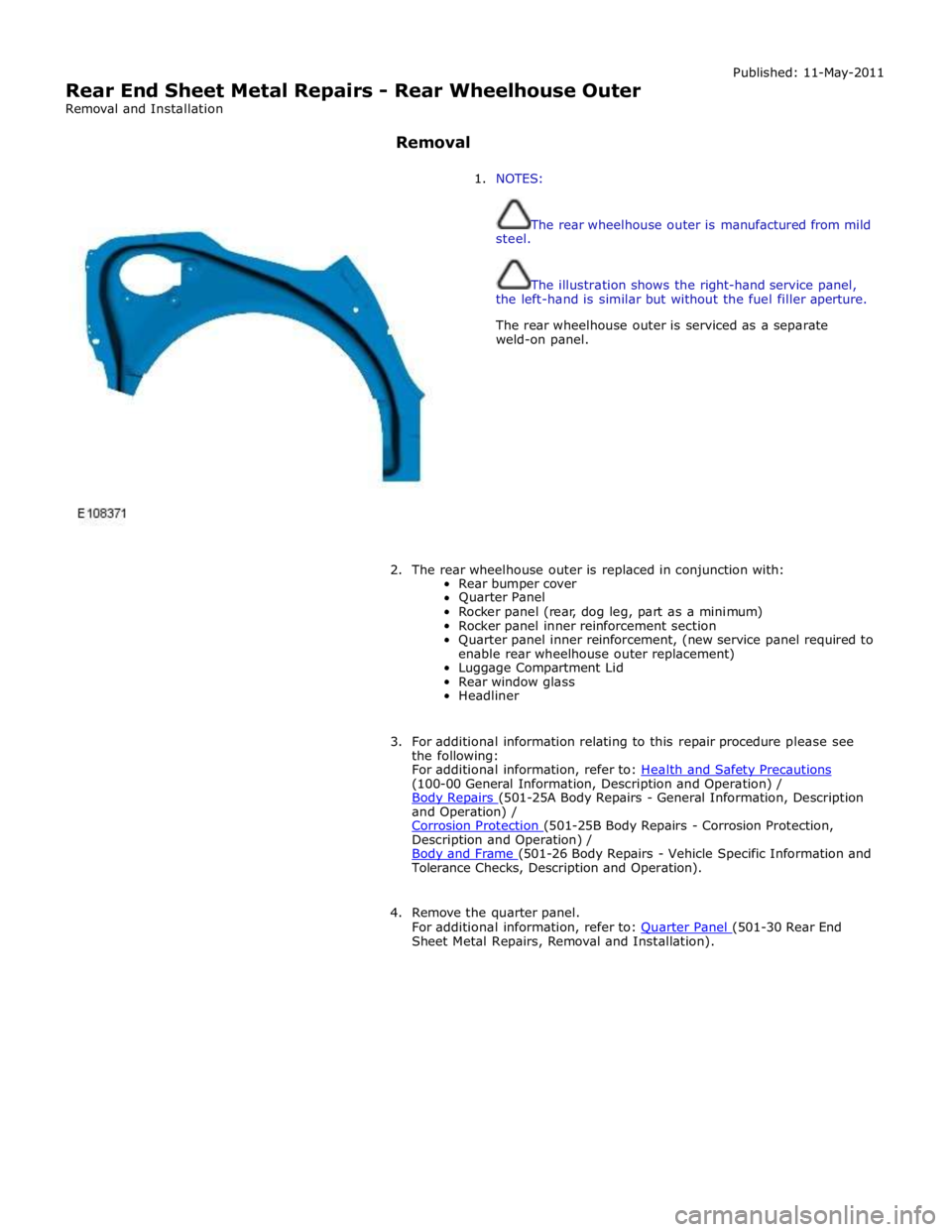

1. NOTES:

The rear wheelhouse outer is manufactured from mild

steel.

The illustration shows the right-hand service panel,

the left-hand is similar but without the fuel filler aperture.

The rear wheelhouse outer is serviced as a separate

weld-on panel.

2. The rear wheelhouse outer is replaced in conjunction with:

Rear bumper cover

Quarter Panel

Rocker panel (rear, dog leg, part as a minimum)

Rocker panel inner reinforcement section

Quarter panel inner reinforcement, (new service panel required to

enable rear wheelhouse outer replacement)

Luggage Compartment Lid

Rear window glass

Headliner

3. For additional information relating to this repair procedure please see

the following:

For additional information, refer to: Health and Safety Precautions (100-00 General Information, Description and Operation) /

Body Repairs (501-25A Body Repairs - General Information, Description and Operation) /

Corrosion Protection (501-25B Body Repairs - Corrosion Protection, Description and Operation) /

Body and Frame (501-26 Body Repairs - Vehicle Specific Information and Tolerance Checks, Description and Operation).

4. Remove the quarter panel.

For additional information, refer to: Quarter Panel (501-30 Rear End Sheet Metal Repairs, Removal and Installation).

Page 2990 of 3039

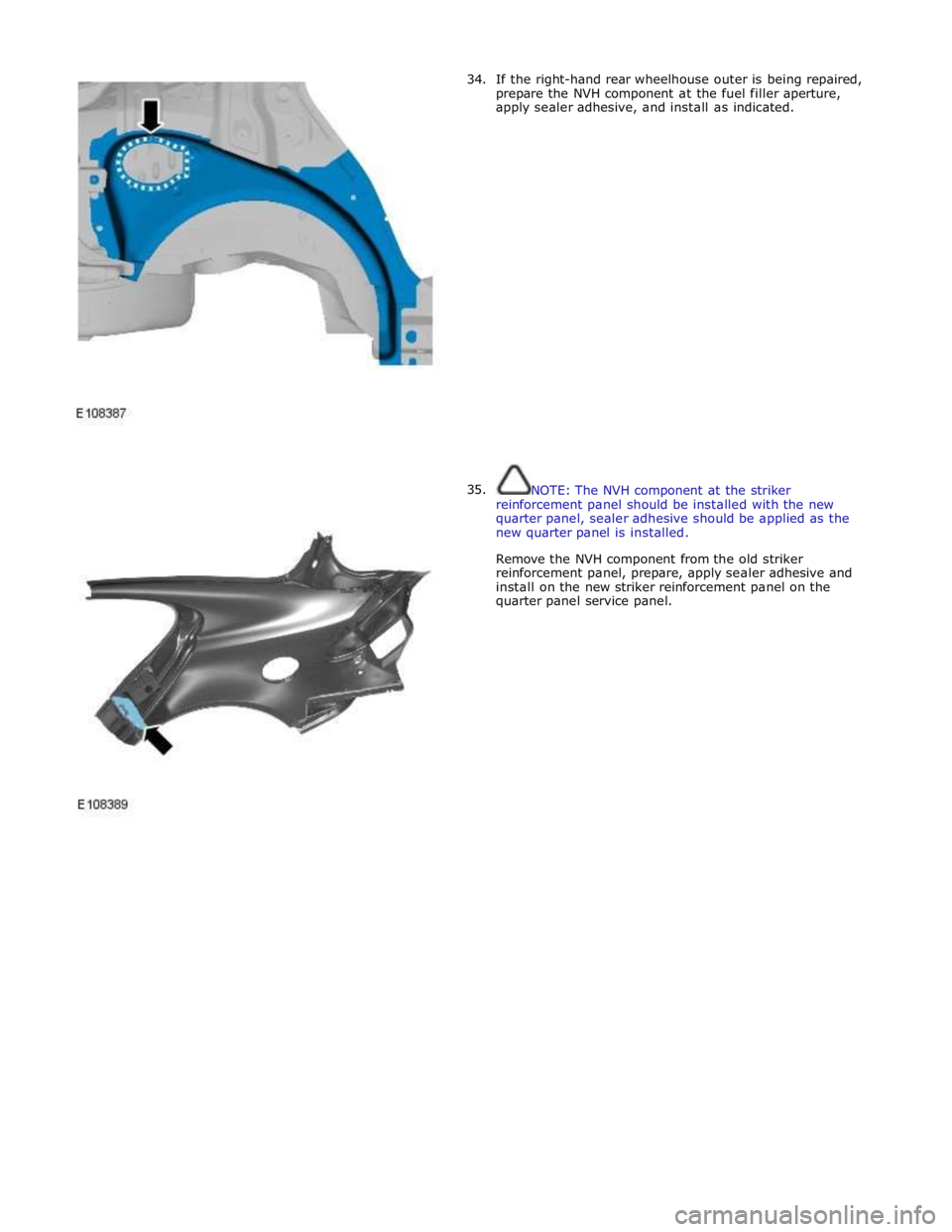

34.

35. If the right-hand rear wheelhouse outer is being repaired,

prepare the NVH component at the fuel filler aperture,

apply sealer adhesive, and install as indicated.

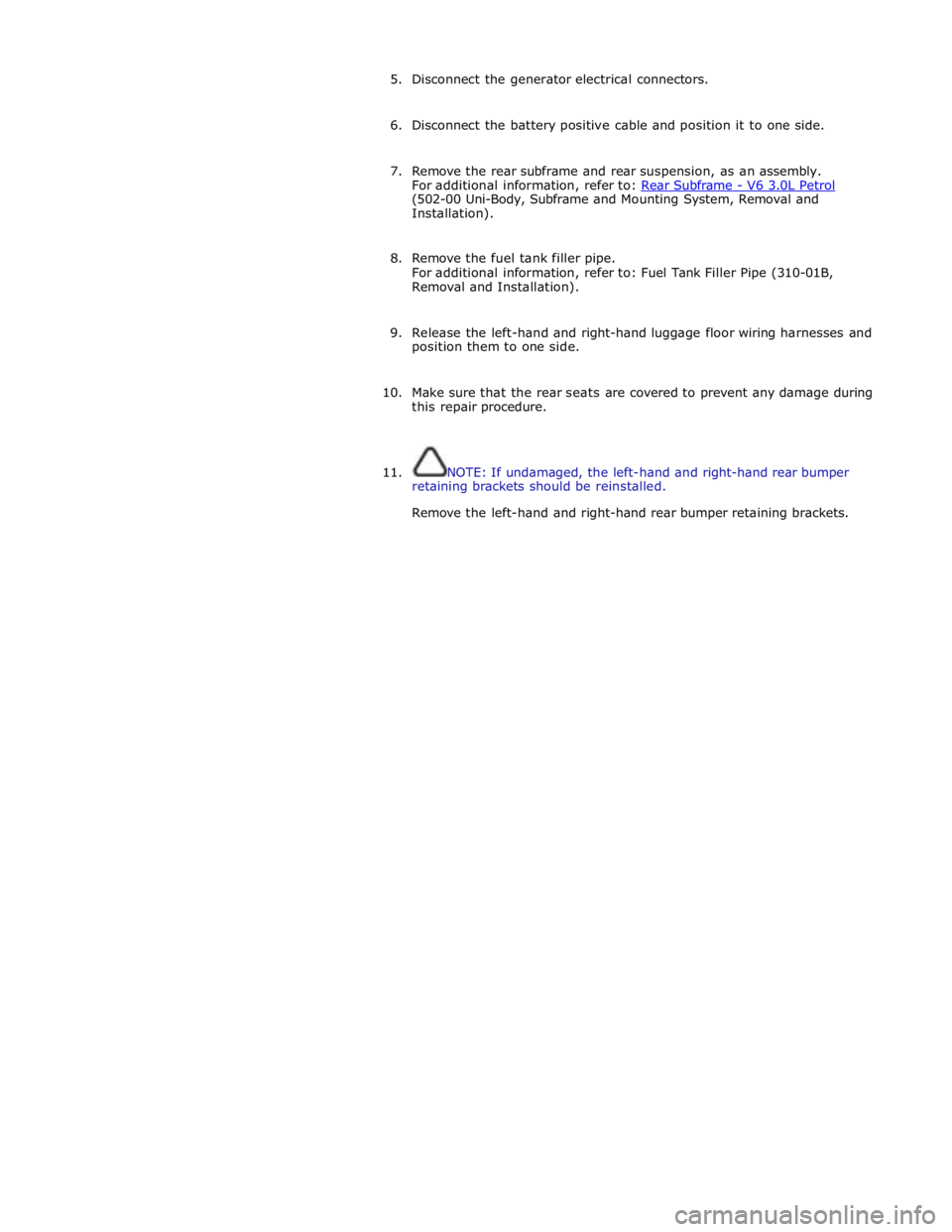

NOTE: The NVH component at the striker

reinforcement panel should be installed with the new

quarter panel, sealer adhesive should be applied as the

new quarter panel is installed.

Remove the NVH component from the old striker

reinforcement panel, prepare, apply sealer adhesive and

install on the new striker reinforcement panel on the

quarter panel service panel.

Page 2993 of 3039

5. Disconnect the generator electrical connectors.

6. Disconnect the battery positive cable and position it to one side.

7. Remove the rear subframe and rear suspension, as an assembly.

For additional information, refer to: Rear Subframe - V6 3.0L Petrol (502-00 Uni-Body, Subframe and Mounting System, Removal and

Installation).

8. Remove the fuel tank filler pipe.

For additional information, refer to: Fuel Tank Filler Pipe (310-01B,

Removal and Installation).

9. Release the left-hand and right-hand luggage floor wiring harnesses and

position them to one side.

10. Make sure that the rear seats are covered to prevent any damage during

this repair procedure.

11. NOTE: If undamaged, the left-hand and right-hand rear bumper

retaining brackets should be reinstalled.

Remove the left-hand and right-hand rear bumper retaining brackets.

Page 3032 of 3039

Published: 11-May-2011

Uni-Body, Subframe and Mounting System - Rear Subframe V8 5.0L Petrol/V8 S/C 5.0L Petrol

Removal and Installation

General Equipment

Removal

NOTE: Removal steps in this procedure may contain installation details.

1. Refer to: Petrol and Petrol-Ethanol Fuel Systems Health and Safety Precautions (100-00 General Information, Description and Operation).

2. WARNING: Do not work on or under a vehicle supported only by a jack.

Always support the vehicle on safety stands.

Raise and support the vehicle.

3. Refer to: Fuel Tank Draining (310-00 Fuel System - General Information, General Procedures).

4. Refer to: Wheel and Tire (204-04 Wheels and Tires, Removal and Installation).

5. Refer to: Driveshaft - V8 5.0L Petrol/V8 S/C 5.0L Petrol (205-01 Driveshaft, Removal and Installation).

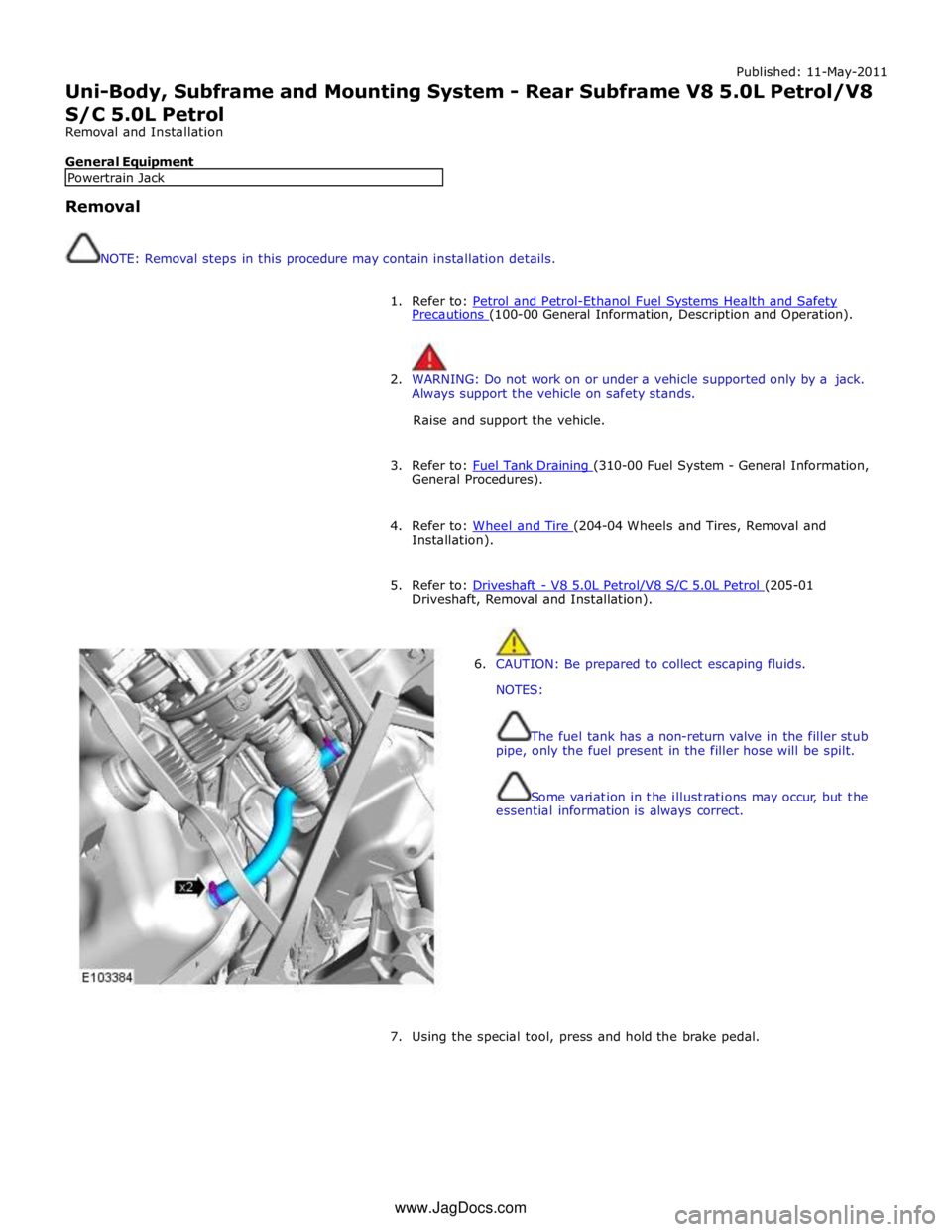

6. CAUTION: Be prepared to collect escaping fluids.

NOTES:

The fuel tank has a non-return valve in the filler stub

pipe, only the fuel present in the filler hose will be spilt.

Some variation in the illustrations may occur, but the

essential information is always correct.

7. Using the special tool, press and hold the brake pedal. Powertrain Jack www.JagDocs.com