ABS JAGUAR XFR 2010 1.G Workshop Manual

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 2010, Model line: XFR, Model: JAGUAR XFR 2010 1.GPages: 3039, PDF Size: 58.49 MB

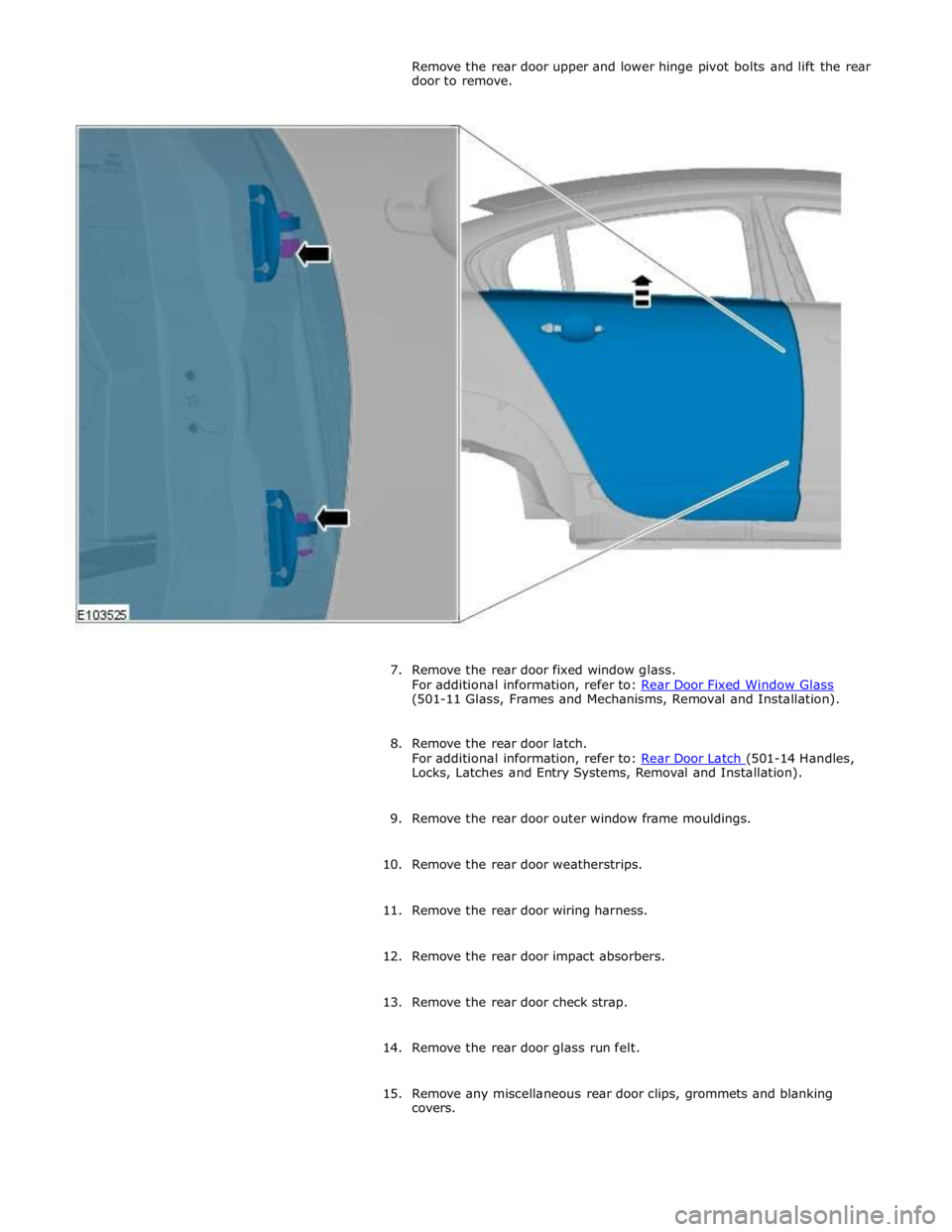

Page 2222 of 3039

(501-11 Glass, Frames and Mechanisms, Removal and Installation).

8. Remove the rear door latch.

For additional information, refer to: Rear Door Latch (501-14 Handles, Locks, Latches and Entry Systems, Removal and Installation).

9. Remove the rear door outer window frame mouldings.

10. Remove the rear door weatherstrips.

11. Remove the rear door wiring harness.

12. Remove the rear door impact absorbers.

13. Remove the rear door check strap.

14. Remove the rear door glass run felt.

15. Remove any miscellaneous rear door clips, grommets and blanking

covers.

Page 2317 of 3039

memory positions to be stored and 'set' button with integral LED (light emitting diode). The seat, door mirror and steering

column motors have position sensors which provide feedback to driver's seat module.

Once the driver's seat, steering column and exterior mirrors have been adjusted, the vehicle is able to memorize these

settings for future use by using the following procedure:

Push the memory 'SET' button, the LED in the switch will illuminate Press the memory button 1 or 2 to memorize the current settings. The LED will extinguish, and a chime will sound to confirm that the settings have been memorized. If the ignition is on, power mode 6, the message center will display a

confirmation message.

The positions can be recalled by pressing the applicable button 1 or 2.

Stall Detection

Seat, steering column and mirror motors are deemed to have stalled if there is no change in the inputs that are received from

the corresponding feedback sensors for 200 ms (seat).

If a stall condition is detected then the drive to that motor is cancelled for the remainder of that memory operation (memory

recall) or until the switch is re-selected (manual movement).

If the motor movement has stopped due to loss of sensor feedback, either stall or sensor failure, then that motor may be

activated again, to move past the stall position, by re-selecting the appropriate switch and pressing for longer than 2 seconds.

This allows control of the motor to be maintained if sensor feedback is lost.

Upon re-selection of movement, if sensor pulses are detected then the motor will continue to be driven until the switch is

released or another stall condition is detected. If sensor feedback is not detected then the motor is only driven for 0.5 second

and then stops until the switch is released and then pressed again, when a further 0.5 second of activation is permitted, and

so on, this is known as inch mode.

For all seat motor manual movements, whenever a motor is driven and a stall occurs, the memory control module records the

position at which the stall occurred. If movement occurs beyond a stall position, then that position is erased from the control

modules memory. This will always allow movement past a previously recorded stall position once movement has been

registered beyond that position. This is the case for both manual and memory movement.

Initialization

When a replacement driver's seat module is fitted, it should be calibrated a Jaguar approved diagnostic system so that the

module can learn the seats absolute position.

Battery Monitor

If the battery voltage drops below 10.5 Volts, then the driver's seat module ignores all requests for a memory recall until the

battery voltage has reached 11.5 Volts. This will conserve as much power in the vehicle battery as possible to enable engine

cranking.

REAR SEATS - DESCRIPTION

The rear seat features a single piece cushion and a 60/40 split squab. Two latches are secured to the rear bulkhead by a pair

of M8 bolts to retain the seat squabs in the upright position. The latches can be released to fold down the individual cushions

by pulling a cable release located below the rear window parcel shelf in the luggage compartment.

ISOFIX fastening points are attached to the vehicle floor to provide secure fastening for compatible child seats.

A centrally mounted center arm rest can be folded down from the 60% squab. The arm rest contains two drinks holders.

Page 2354 of 3039

Seating - Seat Smoothing

General Procedures Published: 01-May-2014

WARNINGS: Check

Make sure that the steamer is in the OFF position before connecting or disconnecting from the electrical outlet.

Do not use another high wattage device on the same electrical circuit.

If the use of an extension cord is absolutely necessary, the cord must be rated at a minimum of 10 amps.

To avoid the risk of electrical shock, check the condition of the power cord and the steamer before use.

Make sure that the steamer is disconnected from the electrical outlet before filling or emptying the water reservoir.

The steamer must only be used and placed on its stand on a stable surface.

To prevent injury such as burns, take care whilst using the steamer. Avoid coming into contact with the hot surface of the

steamer and do not direct steam toward any persons.

The steamer must ALWAYS be switched off when not in use or left unattended.

Do not allow the power cord to come into contact with the hot surface of the steamer.

CAUTIONS:

Protect the surrounding paintwork to avoid damage.

Protect the paintwork during this operation.

Do not use any additives in the steamer. Damage to the steamer or the seat cover can result if used.

NOTE: Some variation in the illustrations may occur, but the essential information is always correct.

1. CAUTIONS:

Steam the leather cushions evenly and progressively. Do not use

excessive force.

Take care not to damage the leather whilst steaming into the

corners.

Do not hold the steamer in one place for longer than 10 seconds,

as this will burn the leather and damage the covers. www.JagDocs.com

Page 2449 of 3039

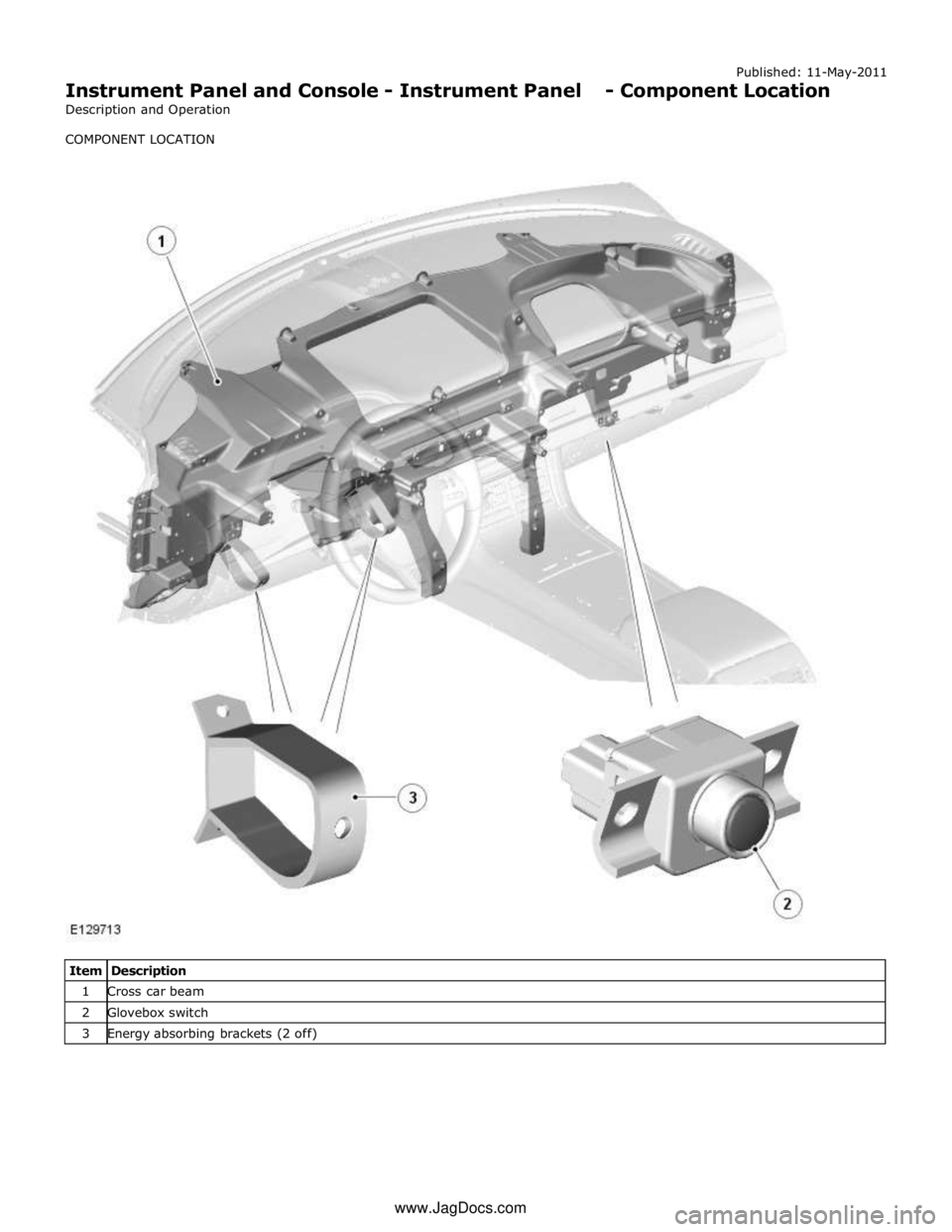

Published: 11-May-2011

Instrument Panel and Console - Instrument Panel - Component Location

Description and Operation

COMPONENT LOCATION

Item Description 1 Cross car beam 2 Glovebox switch 3 Energy absorbing brackets (2 off) www.JagDocs.com

Page 2559 of 3039

Published: 11-May-2011

Roof Opening Panel - Roof Opening Panel - Component Location

Description and Operation

Component Location

Item Description 1 CJB (central junction box) 2 Roof opening panel, rocker switch 3 Rear window sunblind, switch 4 Roof opening panel, motor 5 Roof opening panel, control module 6 Roof opening panel 7 Rear window sunblind 8 Rear window sunblind, motor assembly 9 Drain tubes (4 off) 10 ABS (anti-lock brake system) module www.JagDocs.com

Page 2561 of 3039

Published: 11-May-2011

Roof Opening Panel - Roof Opening Panel - System Operation and

Component Description

Description and Operation

Control Diagram

NOTE: A = Hardwired

Item Description 1 Battery 2 Megafuse (250 A) 3 Rear window sunblind, switch 4 Rear window sunblind, motor 5 ABS (anti-lock brake system) module 6 Roof opening panel, control module 7 Roof opening panel, rocker switch 8 CJB (central junction box)

Page 2562 of 3039

Roof opening panel System Operation

Operation of the roof opening panel is controlled by the roof opening panel control module, which is integral with the motor.

The control module receives inputs from the CJB, which provides an 'open' or 'close' signal for remote handset operation, and

an 'enable' signal when the vehicle enters power mode 6.

The control module also receives a vehicle speed signal from the ABS module. The vehicle speed signal is used by the control

module to calibrate the anti-trap feature.

If the battery is disconnected, or the power supply is interrupted while the roof opening panel is in a partially open position,

the motor and control module will need to be calibrated to restore full functionality. To recalibrate:

1. Switch ignition on.

2. Press the front of the switch, so the roof opening panel is the tilt position, and then release the switch.

3. Press the front of the switch and hold for thirty seconds.

4. After thirty seconds the roof opening panel will begin to move. Keep the front of the switch pressed until the roof

opening panel has fully opened and then closed.

5. Once the open/close cycle has completed and the roof opening panel has stopped moving, release the switch.

6. The roof opening panel can now be operated as normal.

Drain hoses are connected to the front and rear corners of the roof opening panel frame. The drain hoses are located inside of

the cabin on the 'A' and 'D' post pillars to allow water, which has collected in the frame, to escape. One-way valves fitted to

the end of each drain hose, prevent the ingress of dirt and moisture.

Rear window sunblind

The powered rear window sunblind is operated through a switch in the roof console. Power to the sunblind motor is provided by

a pair of relays located in the CJB when the vehicle enters power mode 4. The sunblind motor is located beneath the rear parcel

shelf and is supplied as a sealed unit with the sunblind mechanism.

If the battery is disconnected or a replacement sunblind is fitted, the motor will require re-calibrating. To re-calibrate the

motor the sunblind should be powered through two-full cycles of movement.

Roof opening panel, motor Component Description

The roof opening panel motor has a worm drive which drives a gear in the cast housing attached to the end of the motor. The

gear has a small pinion gear attached to the outer part of its spindle. The pinion engages with two cables to form a rack and

pinion drive. Rotation of the motor turns the pinion which in turn drives the cables in the required direction.

The two cables are attached either side of the pinion. One end of each cable is attached to the guide; the opposite end of

each cable is held in position on the pinion by a metal insert in the frame. The cables run in channels, in the panel frame to

the guides. As the panel is closed the cables are pushed through channels in the front of the frame. The displaced cable is

guided into a further two channels in the frame, which protect the cable and prevent it from snagging. The cables

manufactured from rigid spring steel can pull as well as push the panel along the guides.

The motor contains a micro-switch and Hall effect sensor. Signals received from these components enable the control module

to calculate the exact position of the roof opening panel. The Hall effect sensor is also responsible for the operation of the

anti-trap function.

If the anti-trap feature is activated while the roof opening panel is closing, the panel is reversed for 200mm or as far as

possible. The Hall effect sensor, located in the motor, monitors the speed of the motor and if the speed decreases below a set

threshold, indicating an obstruction, the power feed to the motor is reversed so the panel goes back. In an emergency the

anti-trap function can be overridden by holding the switch in the closed position.

Roof opening panel, control module

The roof opening panel control module is integrated within the motor. The control module receives inputs from the CJB, which

provides an 'open' or 'close' signal for remote handset operation, and an 'enable' signal when the vehicle enters power mode 6.

The control module also contains the algorithm for the anti-trap system and receives a vehicle speed signal from the ABS

module. The vehicle speed signal is used by the control module to calibrate the anti-trap feature.

Page 2694 of 3039

Part N-umber

Body Repairs - General Information - Body Repairs

Description and Operation

General Information

Introduction Published: 11-May-2011

The body plays a significant role in the increasing trend of ever more rapidly changing model variants. The different customer

groups are strongly influenced by the design and shape of the body. At the same time the stability of the body plays the most

important part in ensuring passenger and driver safety. Lightweight construction, alternative materials, composite materials,

plastics and appropriate joining processes are all design features that characterise modern Jaguar vehicle bodies.

In terms of manufacturing technology, modern safety cell bodies can be produced almost without any problems. Jaguar

guarantee high quality standards by ensuring that mechanical strength properties are tried and tested in numerous computer

simulations, crash tests, by testing materials and by employing sophisticated manufacturing technologies. In the event of

repairs it is vital that the production quality standards are upheld. This requires a well-equipped workshop, and places

particular emphasis on the qualifications of the workshop technicians. Up-to-date knowledge of current manufacturing

technologies and continuous training on new repair methods and techniques are vital for high-quality body repairs. The model-

specific repair manuals and the general repair techniques provide valuable support when undertaking body repairs.

Always follow the repair instructions published in this manual. Failure to observe this instruction can result in serious

impairment of vehicle safety. All specified safety requirements must be met after the work has been carried out.

Vehicle design

The body

The XF adopts the latest generation steels, especially in the upper body – including high carbon steels, dual-phase,

hot-formed boron steels, and bake-hardened steels to form a vertical safety ‘ring’ around the occupant cell. As well as

combining strength with lightness, these steels improve corrosion resistance, by making best use of zinc and improving e-coat

paint flow – and new thinking means that in spite of their strength, the XF’s A and B-pillars are impressively slim, to the

benefit of both visibility and accessibility. Similarly, the lower sills are the first component on any Jaguar to use incredibly

strong, dual-phase DP600 steel.

The safety of the driver and the passengers is paramount for every body design. There are two key safety aspects in the body:

Safety passenger cell

Crumple zones

Safety passenger cell

Stable pillars, rocker panel and door profiles.

Side impact protection in the doors.

Doors are designed to open even in the event of extreme deformation.

Crumple zone

Dynamic absorption of deforming forces.

Protection of the passenger cell. www.JagDocs.com

Page 2707 of 3039

For instance, the crumple zones absorb the bulk of the impact energy. If any unprofessional repair techniques or

methods are used in these areas then this can pose a fundamental threat to vehicle safety.

Hidden damage

As well as looking at external indicators like flaked off paint, it is vital to check for hidden body damage or deformation

that is not visible from the outside. Large attached parts like bumpers and inner fenders often need to be removed to

allow accurate assessment of damage to underlying body parts.

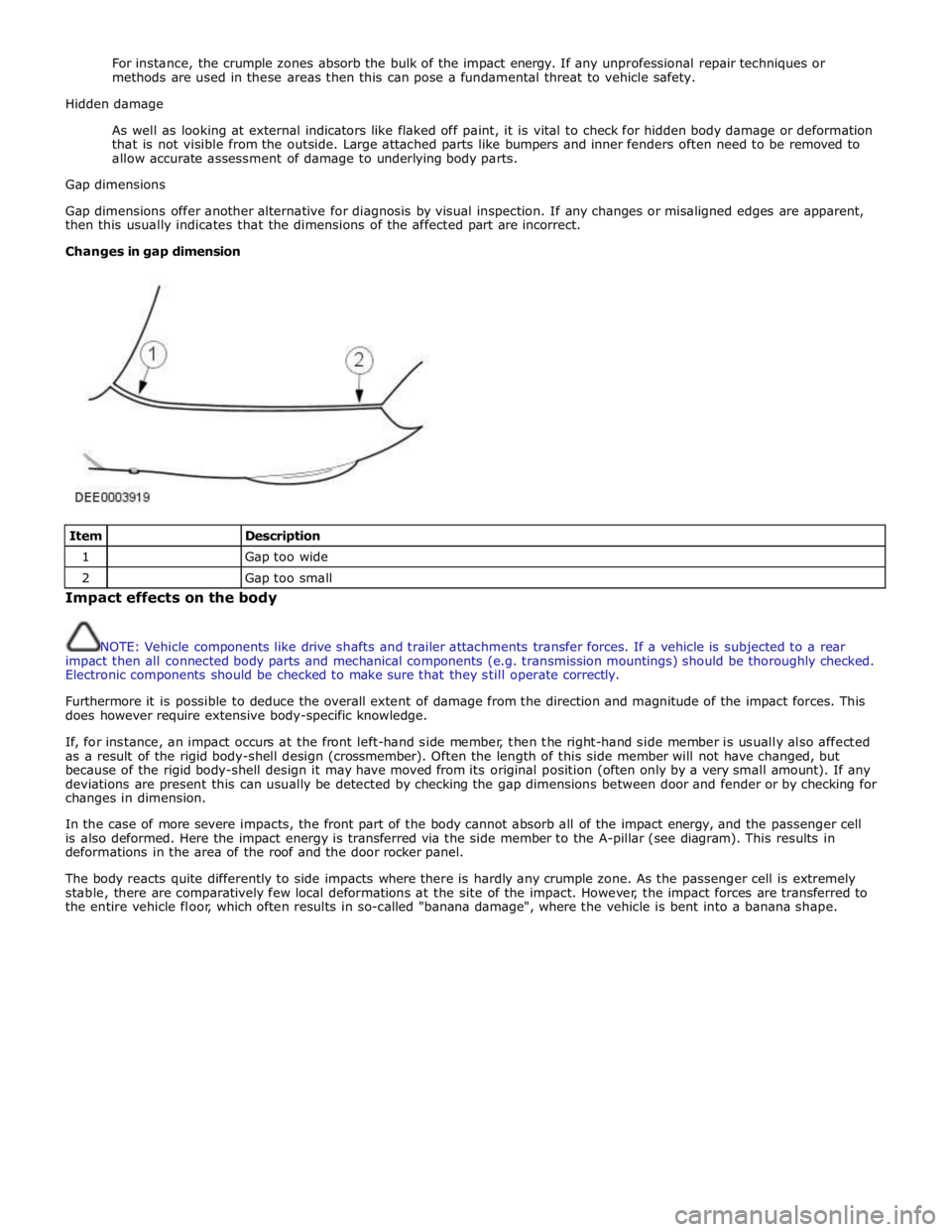

Gap dimensions

Gap dimensions offer another alternative for diagnosis by visual inspection. If any changes or misaligned edges are apparent,

then this usually indicates that the dimensions of the affected part are incorrect.

Changes in gap dimension

Item

Description 1

Gap too wide 2

Gap too small Impact effects on the body

NOTE: Vehicle components like drive shafts and trailer attachments transfer forces. If a vehicle is subjected to a rear

impact then all connected body parts and mechanical components (e.g. transmission mountings) should be thoroughly checked.

Electronic components should be checked to make sure that they still operate correctly.

Furthermore it is possible to deduce the overall extent of damage from the direction and magnitude of the impact forces. This

does however require extensive body-specific knowledge.

If, for instance, an impact occurs at the front left-hand side member, then the right-hand side member is usually also affected

as a result of the rigid body-shell design (crossmember). Often the length of this side member will not have changed, but

because of the rigid body-shell design it may have moved from its original position (often only by a very small amount). If any

deviations are present this can usually be detected by checking the gap dimensions between door and fender or by checking for

changes in dimension.

In the case of more severe impacts, the front part of the body cannot absorb all of the impact energy, and the passenger cell

is also deformed. Here the impact energy is transferred via the side member to the A-pillar (see diagram). This results in

deformations in the area of the roof and the door rocker panel.

The body reacts quite differently to side impacts where there is hardly any crumple zone. As the passenger cell is extremely

stable, there are comparatively few local deformations at the site of the impact. However, the impact forces are transferred to

the entire vehicle floor, which often results in so-called "banana damage", where the vehicle is bent into a banana shape.

Page 2732 of 3039

Part N-umber

Body Repairs - Water Leaks - Water Leaks

Description and Operation

General Published: 11-May-2011

If water leaks occur after bodywork repairs, the cause can be established using the checks described below. A

systematic and logical procedure is required to locate water leaks. Before beginning extensive checks, a thorough visual

inspection must be carried out.

Visual Inspection

- The following characteristics may indicate existing leaks:

- Check the clearance and accurate fit of ancillary components such as the hood, tailgate, liftgate, doors, and so

on.

- Check for correct fit and possible damage to sealing elements such as blanking plugs, rubber door seals, and so

on.

- Check water drain holes for unhindered flow.

Various tests can be used to provide further information on possible leaks:

- Water test

- Washer test

- Road test

- Chalk (powder) test

Practical execution of tests and checks

Water test

NOTE: Never aim a jet of water directly at a rubber seal.

Carry out the water test with a second person present (in the passenger compartment).

Use variable washer nozzles (concentrated water jet to fine spray mist).

Start in the lower section and spray the whole area, working upwards in stages.

Washer test

Further tests can be carried out in the washer system.

Some leaks originate here, or only occur here.

The relevant passenger compartment should be checked using a torch during the wash procedure.

Road test

If no leaks are located during the tests above, road tests should be carried out on wet roads.

Road tests under various conditions:

- At various speeds.

- On various road surfaces (asphalt to cobbles).

- With loaded or unloaded vehicle.

- Driving through puddles (splash water).

Chalk test (powder test)

In this test, the clamping load and the bearing surface of the seal are checked.

Performing the test:

- Dust the door seal with powder or coat with chalk.

- Coat the bearing surface of the seal with a thin film of Vaseline.

- Slowly close the door and open it again.

- Check the width and continuity of the imprint on the door seal.

Other test equipment

Other equipment such as stethoscopes, UV lamps, special mirrors or ultrasound measuring instruments can be used to

locate leaks.

Rectifying the leak using recommended tools, auxiliary equipment and materials

Tools and auxiliary equipment:

- Dry, absorbent cloths

- Variable washer nozzle

- Torch, fluorescent tube

- Mirror

- Compressed air

- Seal lip installer

- Wet/dry vacuum cleaner

- Sealing compound compressor

- Remover for interior trim

- Cutter blade or pocket knife

- Wedge (wood or plastic)

- Hot air blower

- Special mirror for concealed leaks