temperature JAGUAR XFR 2010 1.G Workshop Manual

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 2010, Model line: XFR, Model: JAGUAR XFR 2010 1.GPages: 3039, PDF Size: 58.49 MB

Page 2171 of 3039

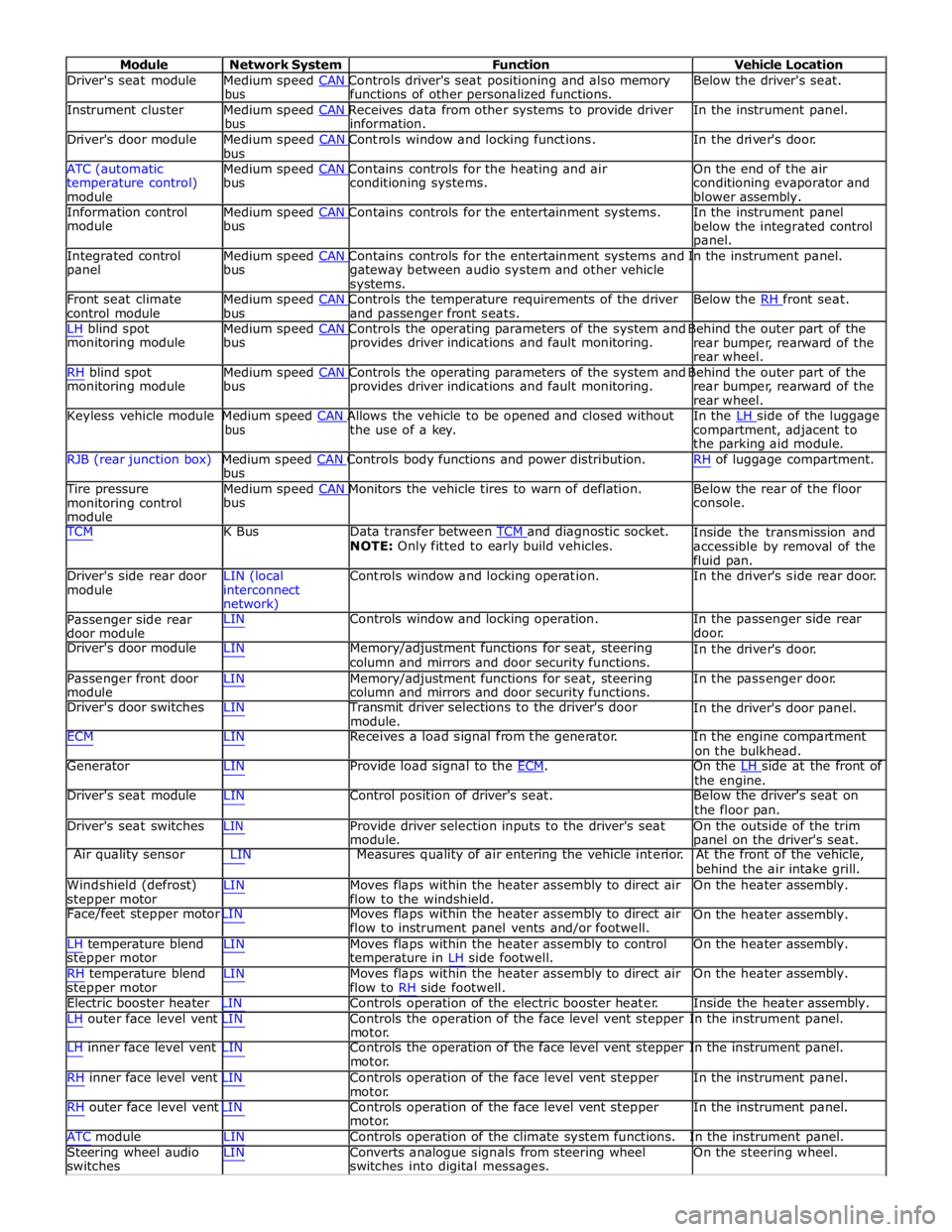

Module Network System Function Vehicle Location

Driver's seat module Medium speed CAN Controls driver's seat positioning and also memory Below the driver's seat. bus functions of other personalized functions.

Instrument cluster Medium speed CAN Receives data from other systems to provide driver In the instrument panel. bus information.

Driver's door module Medium speed CAN Controls window and locking functions. In the driver's door. bus

ATC (automatic Medium speed CAN Contains controls for the heating and air On the end of the air

temperature control)

module bus conditioning systems.

conditioning evaporator and

blower assembly.

Information control Medium speed CAN Contains controls for the entertainment systems. In the instrument panel module bus

below the integrated control

panel.

Integrated control Medium speed CAN Contains controls for the entertainment systems and In the instrument panel. panel bus

gateway between audio system and other vehicle

systems.

Front seat climate Medium speed CAN Controls the temperature requirements of the driver Below the RH front seat. control module bus and passenger front seats.

LH blind spot Medium speed CAN Controls the operating parameters of the system and Behind the outer part of the monitoring module bus provides driver indications and fault monitoring.

rear bumper, rearward of the

rear wheel.

RH blind spot Medium speed CAN Controls the operating parameters of the system and Behind the outer part of the monitoring module bus provides driver indications and fault monitoring.

rear bumper, rearward of the

rear wheel.

Keyless vehicle module Medium speed CAN Allows the vehicle to be opened and closed without In the LH side of the luggage bus the use of a key.

compartment, adjacent to

the parking aid module.

RJB (rear junction box) Medium speed CAN Controls body functions and power distribution. RH of luggage compartment. bus

Tire pressure Medium speed CAN Monitors the vehicle tires to warn of deflation. Below the rear of the floor monitoring control

module bus console.

TCM K Bus Data transfer between TCM and diagnostic socket. NOTE: Only fitted to early build vehicles. Inside the transmission and

accessible by removal of the

fluid pan.

Driver's side rear door

module LIN (local

interconnect

network) Controls window and locking operation. In the driver's side rear door.

Passenger side rear

door module LIN Controls window and locking operation. In the passenger side rear

door.

Driver's door module LIN Memory/adjustment functions for seat, steering

column and mirrors and door security functions. In the driver's door.

Passenger front door

module LIN Memory/adjustment functions for seat, steering

column and mirrors and door security functions. In the passenger door.

Driver's door switches LIN Transmit driver selections to the driver's door

module. In the driver's door panel.

ECM LIN Receives a load signal from the generator. In the engine compartment

on the bulkhead.

Generator LIN Provide load signal to the ECM. On the LH side at the front of the engine.

Driver's seat module LIN Control position of driver's seat. Below the driver's seat on

the floor pan.

Driver's seat switches LIN Provide driver selection inputs to the driver's seat

module. On the outside of the trim

panel on the driver's seat.

Air quality sensor LIN Measures quality of air entering the vehicle interior. At the front of the vehicle,

behind the air intake grill.

Windshield (defrost)

stepper motor LIN Moves flaps within the heater assembly to direct air

flow to the windshield. On the heater assembly.

Face/feet stepper motor LIN Moves flaps within the heater assembly to direct air

flow to instrument panel vents and/or footwell. On the heater assembly.

LH temperature blend

stepper motor

RH temperature blend

stepper motor LIN Moves flaps within the heater assembly to control

temperature in LH side footwell.

LIN Moves flaps within the heater assembly to direct air

flow to RH side footwell. On the heater assembly.

On the heater assembly.

Electric booster heater LIN Controls operation of the electric booster heater. Inside the heater assembly.

LH outer face level vent LIN Controls the operation of the face level vent stepper In the instrument panel.

motor.

LH inner face level vent LIN Controls the operation of the face level vent stepper In the instrument panel.

motor.

RH inner face level vent LIN Controls operation of the face level vent stepper

motor.

RH outer face level vent LIN Controls operation of the face level vent stepper

motor. In the instrument panel.

In the instrument panel.

ATC module LIN Controls operation of the climate system functions. In the instrument panel.

Steering wheel audio

switches LIN Converts analogue signals from steering wheel

switches into digital messages. On the steering wheel.

Page 2292 of 3039

Rear View Mirrors - Rear View Mirrors - Overview

Description and Operation

Overview

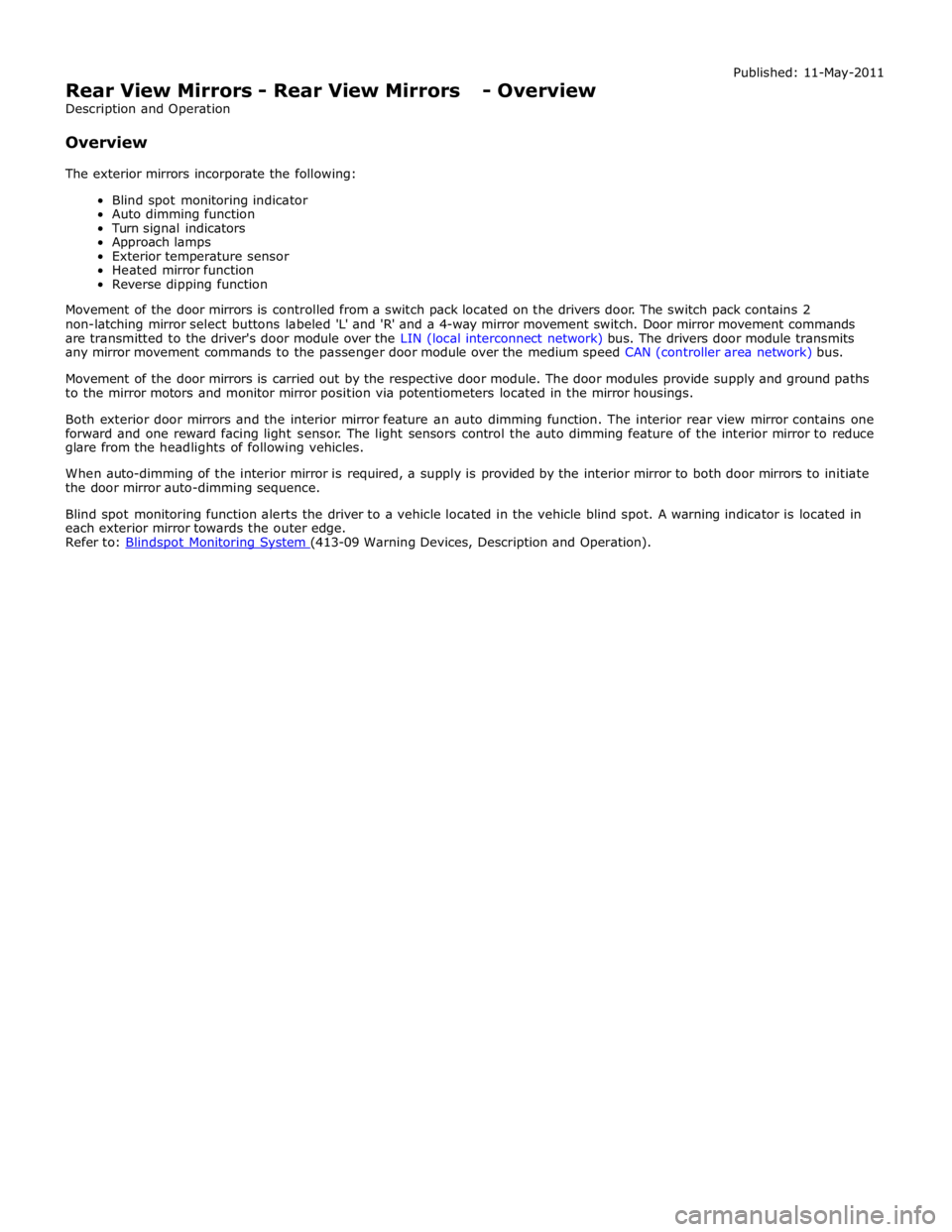

The exterior mirrors incorporate the following:

Blind spot monitoring indicator

Auto dimming function

Turn signal indicators

Approach lamps

Exterior temperature sensor

Heated mirror function

Reverse dipping function Published: 11-May-2011

Movement of the door mirrors is controlled from a switch pack located on the drivers door. The switch pack contains 2

non-latching mirror select buttons labeled 'L' and 'R' and a 4-way mirror movement switch. Door mirror movement commands

are transmitted to the driver's door module over the LIN (local interconnect network) bus. The drivers door module transmits

any mirror movement commands to the passenger door module over the medium speed CAN (controller area network) bus.

Movement of the door mirrors is carried out by the respective door module. The door modules provide supply and ground paths

to the mirror motors and monitor mirror position via potentiometers located in the mirror housings.

Both exterior door mirrors and the interior mirror feature an auto dimming function. The interior rear view mirror contains one

forward and one reward facing light sensor. The light sensors control the auto dimming feature of the interior mirror to reduce

glare from the headlights of following vehicles.

When auto-dimming of the interior mirror is required, a supply is provided by the interior mirror to both door mirrors to initiate

the door mirror auto-dimming sequence.

Blind spot monitoring function alerts the driver to a vehicle located in the vehicle blind spot. A warning indicator is located in

each exterior mirror towards the outer edge.

Refer to: Blindspot Monitoring System (413-09 Warning Devices, Description and Operation).

Page 2294 of 3039

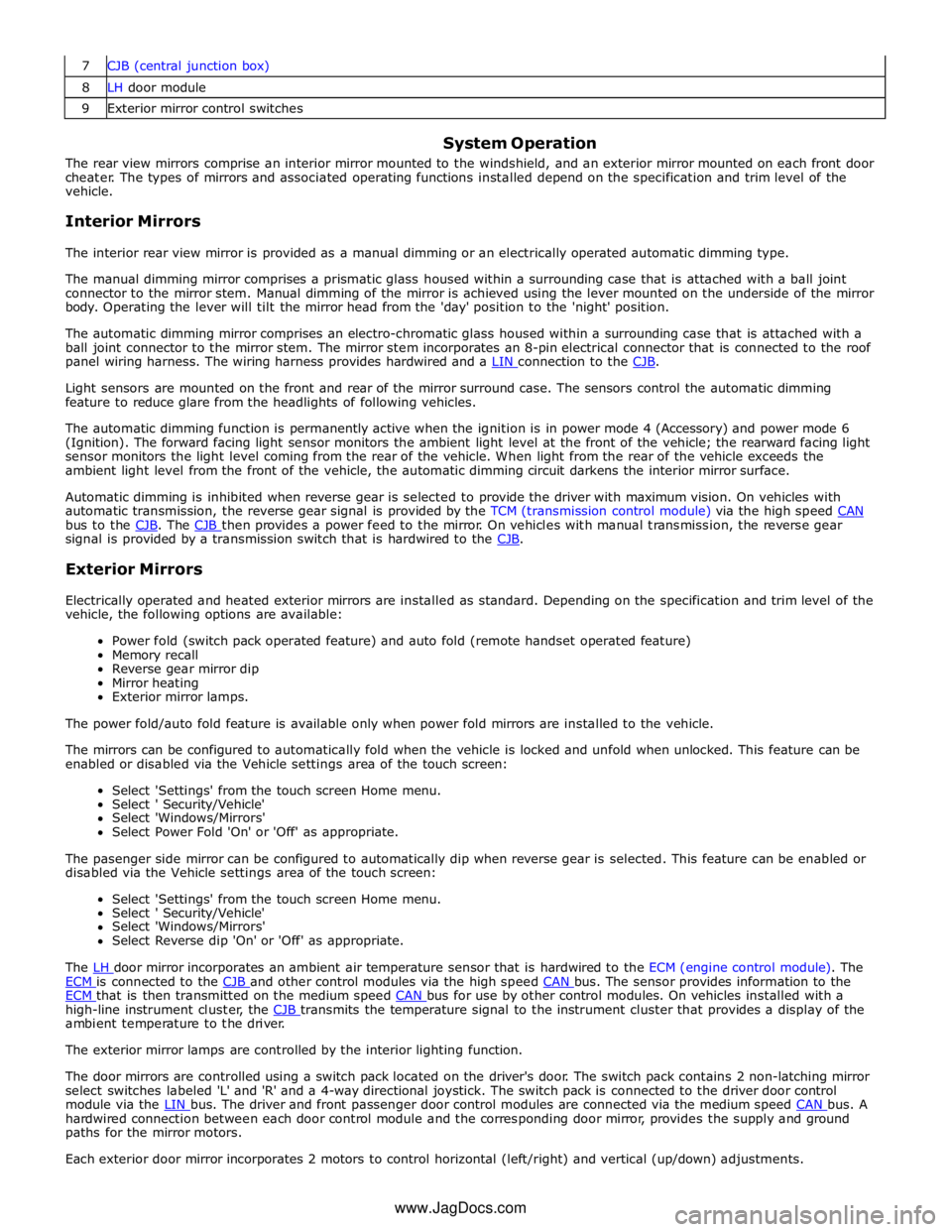

8 LH door module 9 Exterior mirror control switches

System Operation

The rear view mirrors comprise an interior mirror mounted to the windshield, and an exterior mirror mounted on each front door

cheater. The types of mirrors and associated operating functions installed depend on the specification and trim level of the

vehicle.

Interior Mirrors

The interior rear view mirror is provided as a manual dimming or an electrically operated automatic dimming type.

The manual dimming mirror comprises a prismatic glass housed within a surrounding case that is attached with a ball joint

connector to the mirror stem. Manual dimming of the mirror is achieved using the lever mounted on the underside of the mirror

body. Operating the lever will tilt the mirror head from the 'day' position to the 'night' position.

The automatic dimming mirror comprises an electro-chromatic glass housed within a surrounding case that is attached with a

ball joint connector to the mirror stem. The mirror stem incorporates an 8-pin electrical connector that is connected to the roof

panel wiring harness. The wiring harness provides hardwired and a LIN connection to the CJB.

Light sensors are mounted on the front and rear of the mirror surround case. The sensors control the automatic dimming

feature to reduce glare from the headlights of following vehicles.

The automatic dimming function is permanently active when the ignition is in power mode 4 (Accessory) and power mode 6

(Ignition). The forward facing light sensor monitors the ambient light level at the front of the vehicle; the rearward facing light

sensor monitors the light level coming from the rear of the vehicle. When light from the rear of the vehicle exceeds the

ambient light level from the front of the vehicle, the automatic dimming circuit darkens the interior mirror surface.

Automatic dimming is inhibited when reverse gear is selected to provide the driver with maximum vision. On vehicles with

automatic transmission, the reverse gear signal is provided by the TCM (transmission control module) via the high speed CAN bus to the CJB. The CJB then provides a power feed to the mirror. On vehicles with manual transmission, the reverse gear signal is provided by a transmission switch that is hardwired to the CJB.

Exterior Mirrors

Electrically operated and heated exterior mirrors are installed as standard. Depending on the specification and trim level of the

vehicle, the following options are available:

Power fold (switch pack operated feature) and auto fold (remote handset operated feature)

Memory recall

Reverse gear mirror dip

Mirror heating

Exterior mirror lamps.

The power fold/auto fold feature is available only when power fold mirrors are installed to the vehicle.

The mirrors can be configured to automatically fold when the vehicle is locked and unfold when unlocked. This feature can be

enabled or disabled via the Vehicle settings area of the touch screen:

Select 'Settings' from the touch screen Home menu.

Select ' Security/Vehicle'

Select 'Windows/Mirrors'

Select Power Fold 'On' or 'Off' as appropriate.

The pasenger side mirror can be configured to automatically dip when reverse gear is selected. This feature can be enabled or

disabled via the Vehicle settings area of the touch screen:

Select 'Settings' from the touch screen Home menu.

Select ' Security/Vehicle'

Select 'Windows/Mirrors'

Select Reverse dip 'On' or 'Off' as appropriate.

The LH door mirror incorporates an ambient air temperature sensor that is hardwired to the ECM (engine control module). The ECM is connected to the CJB and other control modules via the high speed CAN bus. The sensor provides information to the ECM that is then transmitted on the medium speed CAN bus for use by other control modules. On vehicles installed with a high-line instrument cluster, the CJB transmits the temperature signal to the instrument cluster that provides a display of the ambient temperature to the driver.

The exterior mirror lamps are controlled by the interior lighting function.

The door mirrors are controlled using a switch pack located on the driver's door. The switch pack contains 2 non-latching mirror

select switches labeled 'L' and 'R' and a 4-way directional joystick. The switch pack is connected to the driver door control

module via the LIN bus. The driver and front passenger door control modules are connected via the medium speed CAN bus. A hardwired connection between each door control module and the corresponding door mirror, provides the supply and ground

paths for the mirror motors.

Each exterior door mirror incorporates 2 motors to control horizontal (left/right) and vertical (up/down) adjustments. www.JagDocs.com

Page 2295 of 3039

On vehicles installed with a driver's power operated memory seat and memory exterior mirrors, a potentiometer is incorporated

within each mirror motor and is used to provide information regarding the actual motor positions. The current position and

memory positions of each door mirror motor are maintained and stored within the corresponding door control module.

The memory exterior mirror positions are also monitored and stored within door control module memory when the reverse gear

mirror dip function is used.

When reverse gear is selected, the door control module stores the current mirror positions and will then dip the passenger

mirror glass to a default dip position. While reverse gear is selected it is possible to store a preferred dipped mirror position by

adjusting the driver/passenger mirror glass to the desired position via the mirror switch pack. When the desired position is

achieved using the switch, the new dip positions will be automatically stored by the door control module when reverse gear is

de-selected. Therefore when reverse gear is re-selected, the dip position recalled by the door control module will be the new

reverse gear mirror dip stored position. When reverse gear is deselected the mirror glass will automatically move to the previous

stored position prior to reverse gear selection.

If the driver selects a memory recall function using the memory seat switch pack, the driver's memory seat and exterior

memory mirrors are moved to a stored memory position.

Exterior mirrors with the power fold/auto fold feature incorporate a motor located in the hinge of each exterior mirror arm.

Operation of the power fold feature is achieved using the exterior mirror switch pack. Operation of the auto fold feature is

achieved using the remote handset.

The power fold function is active when the ignition is in power mode 6 (Ignition).

Both exterior mirrors will power fold when the mirror switch pack 'L' and 'R' switches are pressed together. Pressing the

switches again will unfold the mirrors.

When the instrument cluster is configured for the auto fold feature, the mirrors will fold in when the remote handset lock

button is pressed. The mirrors will unfold when the vehicle is unlocked using the remote handset unlock button.

NOTE: If the mirrors are folded in using the mirror switch pack (power fold) and the vehicle is then locked, subsequent

unlocking of the vehicle will not unfold the mirrors.

When the remote handset unlock button is operated, the CJB recognizes the remote handset for that vehicle and acknowledges the request. The door control modules are connected directly to the AJB (auxiliary junction box) for power supply to the

exterior mirror folding motors.

When the vehicle is locked the door control modules reverse the polarity of the mirror fold motor, power and ground

connections to operate the mirrors in the opposite direction.

Exterior mirror heating is provided with heater elements bonded to the back of the mirror glass. Power supply for the mirror

heating elements is provided by the corresponding driver or passenger door control module via the RJB. The door control modules receive a power supply from the RJB, and are both connected on the medium speed CAN bus to the ATC (automatic temperature control) module. A ground terminal from each door control module completes the circuit. The ATC module automatically controls the mirror heating function whenever the ignition is in power mode 4 (Accessory) and power mode 6

(Ignition).

Operation of the exterior mirror heaters is fully automatic and not controllable by the driver. Exterior mirror heater operation is

determined by ambient air temperature and windshield wiper status. When ambient air temperature reaches a pre-determined

level, the ATC module broadcasts an exterior mirror heating request to the door modules over the medium speed CAN bus. On receipt of this message, the door modules provide feed and ground connections to both exterior mirror heater elements.

The mirror heating is controlled in two phases, the initial heating phase and a second PWM (pulse width modulation) controlled

phase. In the first phase the heater elements in the mirrors are permanently powered for a pre-determined length of time. This

length of time varies with the ambient temperature. During the second PWM phase, the heater elements are turned on and off every 30 seconds. The amount of time the exterior mirror heaters are operational increases if the windshield wipers are

switched on. This ensures the mirrors remain mist free in damp and wet conditions, where there is an increased risk of misting.

Page 2310 of 3039

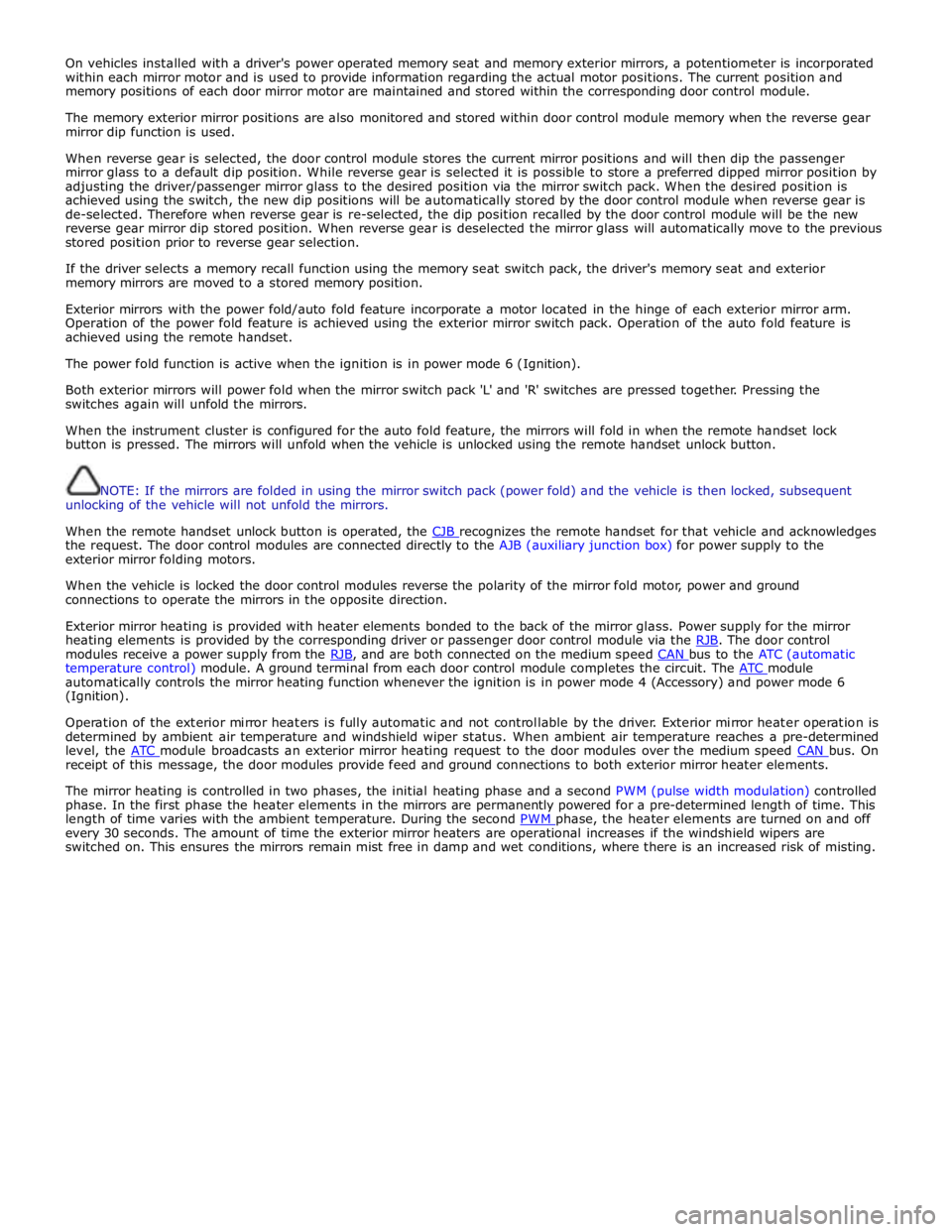

Note: Heated and cooled front seat shown 1 Squab liner 2 Squab climate module 3 Squab inlet duct 4 Squab blower 5 Cushion climate module 6 Cushion inlet duct 7 Cushion blower 8 Cushion liner 9 Front seat climate control module COMPONENT LOCATION - TEMPERATURE - CLIMATE SEATS - SHEET 2 OF 2

Page 2314 of 3039

Note:

A =

Hardwired;

N

=

Medium

speed

CAN

(controller

area

network) bus;

P

=

MOST

ring

1

Battery

2

BJB

3

ATC

(automatic

temperature

control) module

4

RJB

(rear

junction

box)

5

Touch Screen

Display

(TSD)

6

Information

and

Entertainment

module

www.JagDocs.com

Page 2315 of 3039

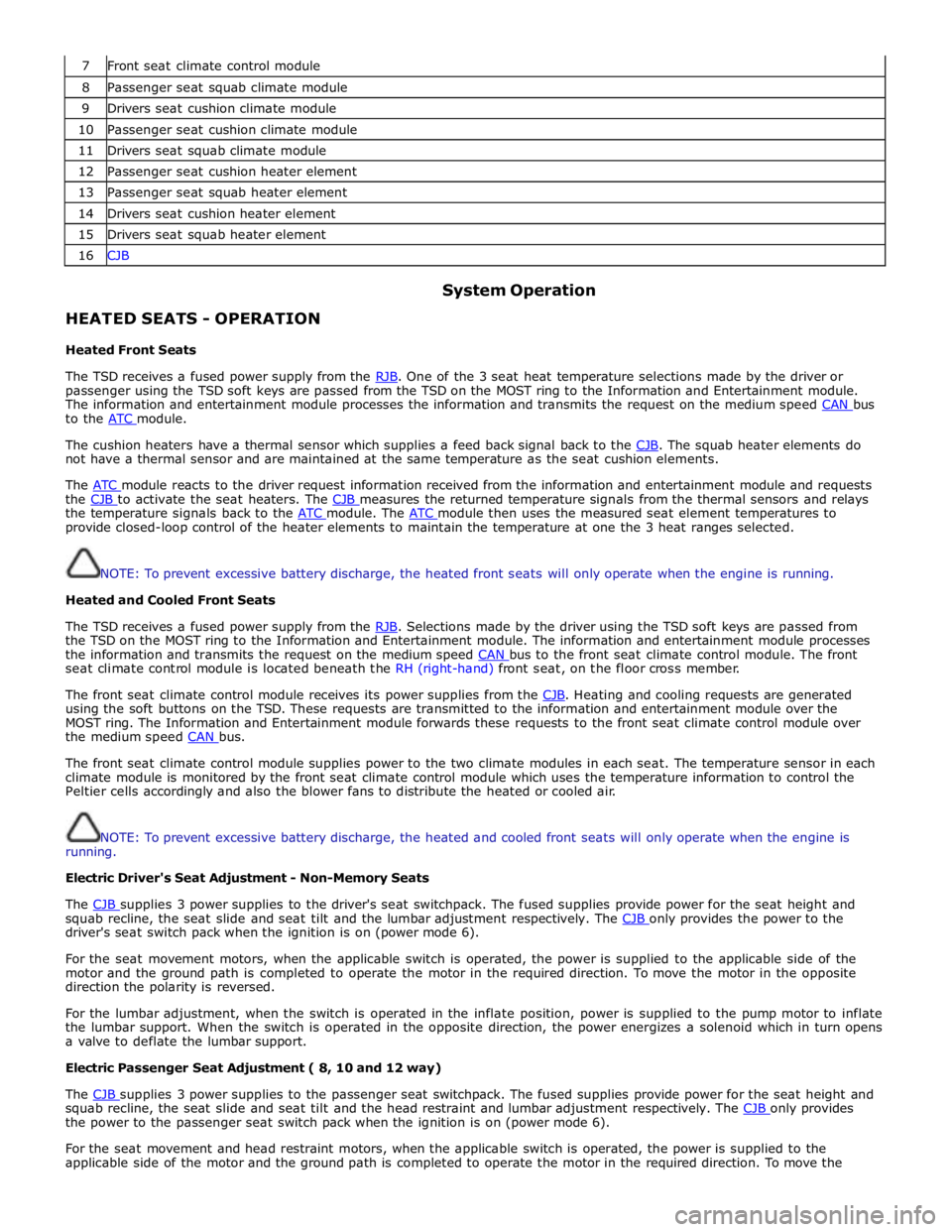

7 Front seat climate control module 8 Passenger seat squab climate module 9 Drivers seat cushion climate module 10 Passenger seat cushion climate module 11 Drivers seat squab climate module 12 Passenger seat cushion heater element 13 Passenger seat squab heater element 14 Drivers seat cushion heater element 15 Drivers seat squab heater element 16 CJB

HEATED SEATS - OPERATION

Heated Front Seats System Operation

The TSD receives a fused power supply from the RJB. One of the 3 seat heat temperature selections made by the driver or passenger using the TSD soft keys are passed from the TSD on the MOST ring to the Information and Entertainment module.

The information and entertainment module processes the information and transmits the request on the medium speed CAN bus to the ATC module.

The cushion heaters have a thermal sensor which supplies a feed back signal back to the CJB. The squab heater elements do not have a thermal sensor and are maintained at the same temperature as the seat cushion elements.

The ATC module reacts to the driver request information received from the information and entertainment module and requests the CJB to activate the seat heaters. The CJB measures the returned temperature signals from the thermal sensors and relays the temperature signals back to the ATC module. The ATC module then uses the measured seat element temperatures to provide closed-loop control of the heater elements to maintain the temperature at one the 3 heat ranges selected.

NOTE: To prevent excessive battery discharge, the heated front seats will only operate when the engine is running.

Heated and Cooled Front Seats

The TSD receives a fused power supply from the RJB. Selections made by the driver using the TSD soft keys are passed from the TSD on the MOST ring to the Information and Entertainment module. The information and entertainment module processes

the information and transmits the request on the medium speed CAN bus to the front seat climate control module. The front seat climate control module is located beneath the RH (right-hand) front seat, on the floor cross member.

The front seat climate control module receives its power supplies from the CJB. Heating and cooling requests are generated using the soft buttons on the TSD. These requests are transmitted to the information and entertainment module over the

MOST ring. The Information and Entertainment module forwards these requests to the front seat climate control module over

the medium speed CAN bus.

The front seat climate control module supplies power to the two climate modules in each seat. The temperature sensor in each

climate module is monitored by the front seat climate control module which uses the temperature information to control the

Peltier cells accordingly and also the blower fans to distribute the heated or cooled air.

NOTE: To prevent excessive battery discharge, the heated and cooled front seats will only operate when the engine is

running.

Electric Driver's Seat Adjustment - Non-Memory Seats

The CJB supplies 3 power supplies to the driver's seat switchpack. The fused supplies provide power for the seat height and squab recline, the seat slide and seat tilt and the lumbar adjustment respectively. The CJB only provides the power to the driver's seat switch pack when the ignition is on (power mode 6).

For the seat movement motors, when the applicable switch is operated, the power is supplied to the applicable side of the

motor and the ground path is completed to operate the motor in the required direction. To move the motor in the opposite

direction the polarity is reversed.

For the lumbar adjustment, when the switch is operated in the inflate position, power is supplied to the pump motor to inflate

the lumbar support. When the switch is operated in the opposite direction, the power energizes a solenoid which in turn opens

a valve to deflate the lumbar support.

Electric Passenger Seat Adjustment ( 8, 10 and 12 way)

The CJB supplies 3 power supplies to the passenger seat switchpack. The fused supplies provide power for the seat height and squab recline, the seat slide and seat tilt and the head restraint and lumbar adjustment respectively. The CJB only provides the power to the passenger seat switch pack when the ignition is on (power mode 6).

For the seat movement and head restraint motors, when the applicable switch is operated, the power is supplied to the

applicable side of the motor and the ground path is completed to operate the motor in the required direction. To move the

Page 2337 of 3039

Seating - Heater Mats

Diagnosis and Testing

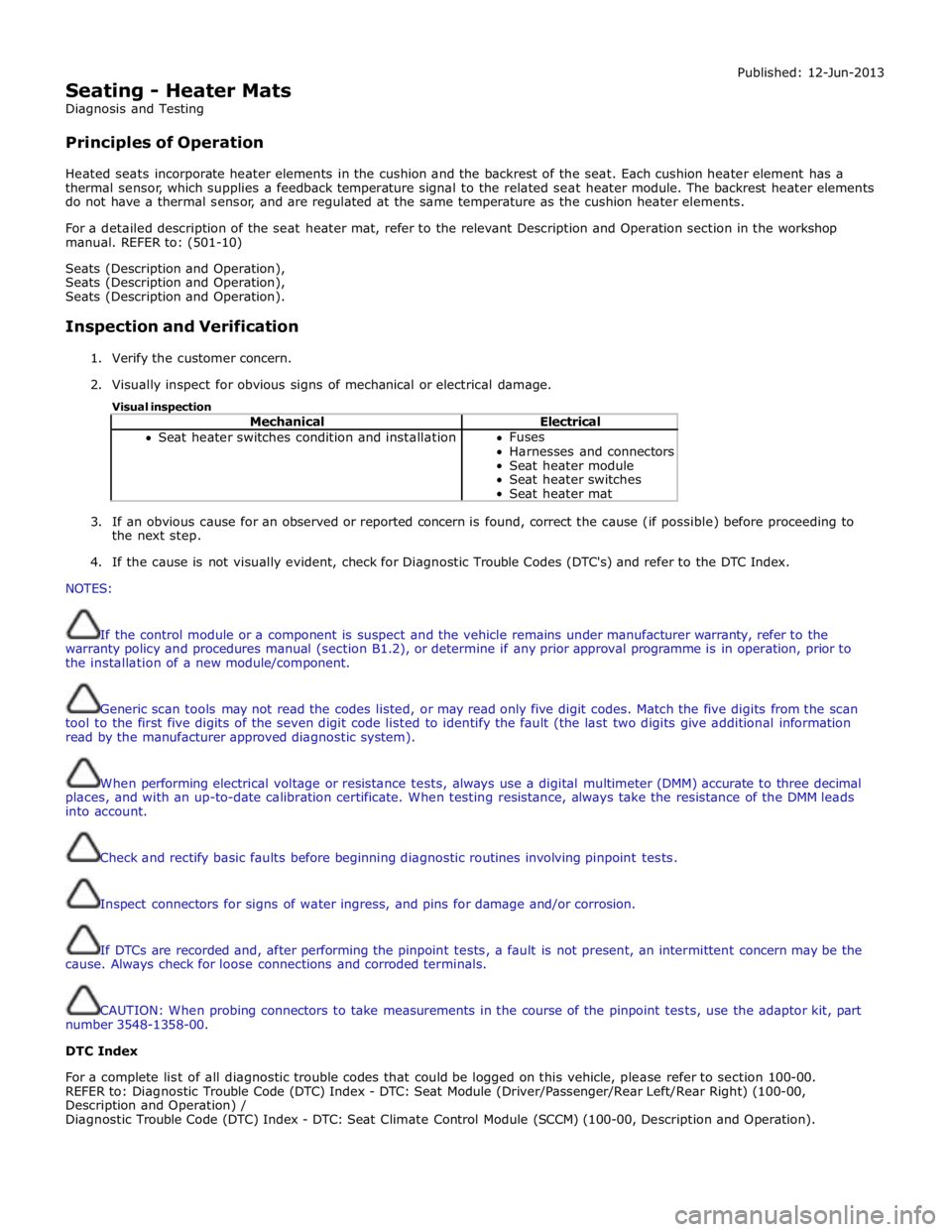

Principles of Operation Published: 12-Jun-2013

Heated seats incorporate heater elements in the cushion and the backrest of the seat. Each cushion heater element has a

thermal sensor, which supplies a feedback temperature signal to the related seat heater module. The backrest heater elements

do not have a thermal sensor, and are regulated at the same temperature as the cushion heater elements.

For a detailed description of the seat heater mat, refer to the relevant Description and Operation section in the workshop

manual. REFER to: (501-10)

Seats (Description and Operation),

Seats (Description and Operation),

Seats (Description and Operation).

Inspection and Verification

1. Verify the customer concern.

2. Visually inspect for obvious signs of mechanical or electrical damage.

Visual inspection

Mechanical Electrical Seat heater switches condition and installation Fuses

Harnesses and connectors

Seat heater module

Seat heater switches

Seat heater mat

3. If an obvious cause for an observed or reported concern is found, correct the cause (if possible) before proceeding to

the next step.

4. If the cause is not visually evident, check for Diagnostic Trouble Codes (DTC's) and refer to the DTC Index.

NOTES:

If the control module or a component is suspect and the vehicle remains under manufacturer warranty, refer to the

warranty policy and procedures manual (section B1.2), or determine if any prior approval programme is in operation, prior to

the installation of a new module/component.

Generic scan tools may not read the codes listed, or may read only five digit codes. Match the five digits from the scan

tool to the first five digits of the seven digit code listed to identify the fault (the last two digits give additional information

read by the manufacturer approved diagnostic system).

When performing electrical voltage or resistance tests, always use a digital multimeter (DMM) accurate to three decimal

places, and with an up-to-date calibration certificate. When testing resistance, always take the resistance of the DMM leads

into account.

Check and rectify basic faults before beginning diagnostic routines involving pinpoint tests.

Inspect connectors for signs of water ingress, and pins for damage and/or corrosion.

If DTCs are recorded and, after performing the pinpoint tests, a fault is not present, an intermittent concern may be the

cause. Always check for loose connections and corroded terminals.

CAUTION: When probing connectors to take measurements in the course of the pinpoint tests, use the adaptor kit, part

number 3548-1358-00.

DTC Index

For a complete list of all diagnostic trouble codes that could be logged on this vehicle, please refer to section 100-00.

REFER to: Diagnostic Trouble Code (DTC) Index - DTC: Seat Module (Driver/Passenger/Rear Left/Rear Right) (100-00,

Description and Operation) /

Diagnostic Trouble Code (DTC) Index - DTC: Seat Climate Control Module (SCCM) (100-00, Description and Operation).

Page 2338 of 3039

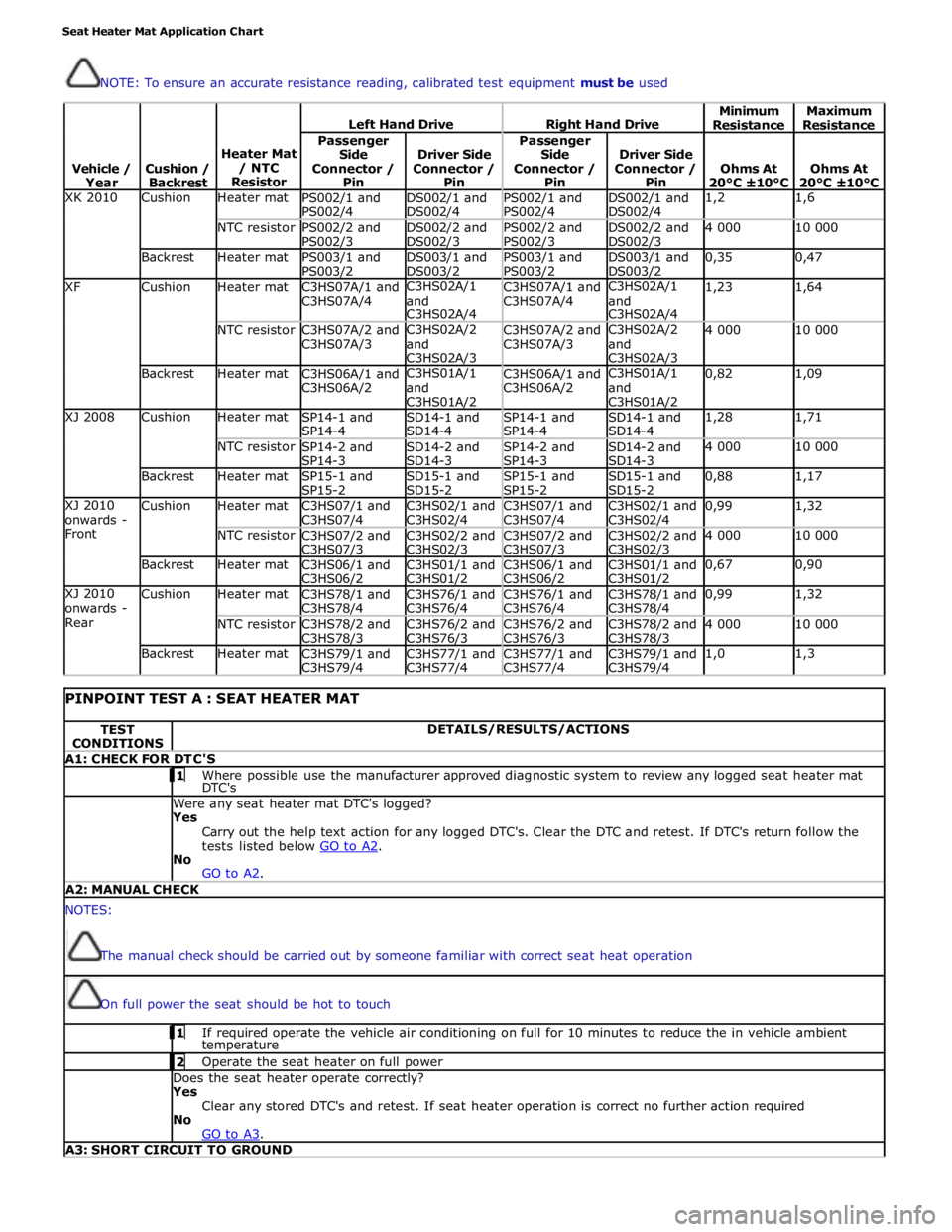

Seat Heater Mat Application Chart

NOTE: To ensure an accurate resistance reading, calibrated test equipment must be used

Vehicle /

Year

Cushion /

Backrest

Heater Mat

/ NTC

Resistor

Left Hand Drive

Right Hand Drive Minimum

Resistance Maximum

Resistance Passenger

Side

Connector /

Pin

Driver Side

Connector /

Pin Passenger

Side

Connector /

Pin

Driver Side

Connector /

Pin

Ohms At

20°C ±10°C

Ohms At

20°C ±10°C XK 2010 Cushion Heater mat

PS002/1 and

PS002/4 DS002/1 and

DS002/4 PS002/1 and

PS002/4 DS002/1 and

DS002/4 1,2 1,6 NTC resistor

PS002/2 and

PS002/3 DS002/2 and

DS002/3 PS002/2 and

PS002/3 DS002/2 and

DS002/3 4 000 10 000 Backrest Heater mat

PS003/1 and

PS003/2 DS003/1 and

DS003/2 PS003/1 and

PS003/2 DS003/1 and

DS003/2 0,35 0,47 XF Cushion Heater mat

C3HS07A/1 and

C3HS07A/4 C3HS02A/1

and

C3HS02A/4 C3HS07A/1 and

C3HS07A/4 C3HS02A/1

and

C3HS02A/4 1,23 1,64 NTC resistor

C3HS07A/2 and

C3HS07A/3 C3HS02A/2

and

C3HS02A/3 C3HS07A/2 and

C3HS07A/3 C3HS02A/2

and

C3HS02A/3 4 000 10 000 Backrest Heater mat

C3HS06A/1 and

C3HS06A/2 C3HS01A/1

and

C3HS01A/2 C3HS06A/1 and

C3HS06A/2 C3HS01A/1

and

C3HS01A/2 0,82 1,09 XJ 2008 Cushion Heater mat

SP14-1 and

SP14-4 SD14-1 and

SD14-4 SP14-1 and

SP14-4 SD14-1 and

SD14-4 1,28 1,71 NTC resistor

SP14-2 and

SP14-3 SD14-2 and

SD14-3 SP14-2 and

SP14-3 SD14-2 and

SD14-3 4 000 10 000 Backrest Heater mat

SP15-1 and

SP15-2 SD15-1 and

SD15-2 SP15-1 and

SP15-2 SD15-1 and

SD15-2 0,88 1,17 XJ 2010

onwards -

Front Cushion Heater mat

C3HS07/1 and

C3HS07/4 C3HS02/1 and

C3HS02/4 C3HS07/1 and

C3HS07/4 C3HS02/1 and

C3HS02/4 0,99 1,32 NTC resistor

C3HS07/2 and

C3HS07/3 C3HS02/2 and

C3HS02/3 C3HS07/2 and

C3HS07/3 C3HS02/2 and

C3HS02/3 4 000 10 000 Backrest Heater mat

C3HS06/1 and

C3HS06/2 C3HS01/1 and

C3HS01/2 C3HS06/1 and

C3HS06/2 C3HS01/1 and

C3HS01/2 0,67 0,90 XJ 2010

onwards -

Rear Cushion Heater mat

C3HS78/1 and

C3HS78/4 C3HS76/1 and

C3HS76/4 C3HS76/1 and

C3HS76/4 C3HS78/1 and

C3HS78/4 0,99 1,32 NTC resistor

C3HS78/2 and

C3HS78/3 C3HS76/2 and

C3HS76/3 C3HS76/2 and

C3HS76/3 C3HS78/2 and

C3HS78/3 4 000 10 000 Backrest Heater mat

C3HS79/1 and

C3HS79/4 C3HS77/1 and

C3HS77/4 C3HS77/1 and

C3HS77/4 C3HS79/1 and

C3HS79/4 1,0 1,3

PINPOINT TEST A : SEAT HEATER MAT TEST

CONDITIONS DETAILS/RESULTS/ACTIONS A1: CHECK FOR DTC'S 1 Where possible use the manufacturer approved diagnostic system to review any logged seat heater mat DTC's Were any seat heater mat DTC's logged?

Yes

Carry out the help text action for any logged DTC's. Clear the DTC and retest. If DTC's return follow the

tests listed below GO to A2. No

GO to A2. A2: MANUAL CHECK NOTES:

The manual check should be carried out by someone familiar with correct seat heat operation

On full power the seat should be hot to touch 1 If required operate the vehicle air conditioning on full for 10 minutes to reduce the in vehicle ambient temperature 2 Operate the seat heater on full power Does the seat heater operate correctly?

Yes

Clear any stored DTC's and retest. If seat heater operation is correct no further action required

No

GO to A3. A3: SHORT CIRCUIT TO GROUND

Page 2339 of 3039

1 Refer to the electrical circuit diagrams and the seat heater mat application chart (see above) to identify the connector 2 Disconnect the connector 3 Refer to the electrical circuit diagrams and check the seat heater mat heater circuit and the NTC resistor circuit for short circuit to ground Are either of the circuits short circuit to ground?

Yes

Repair the circuit or replace the seat heater mat as required. Refer to the warranty policy and procedures

manual, or determine if any prior approval programme is in operation, prior to the installation of a new

module/component. Clear any stored DTC's and retest

No

GO to A4. A4: CIRCUIT CONTINUITY TEST 1 Refer to the electrical circuit diagrams and check the seat heater mat ( heater circuit ) for circuit continuity Does the seat heater mat heater circuit pass the continuity test?

Yes

GO to A5. No

Repair the circuit or replace the seat heater mat as required. Refer to the warranty policy and procedures

manual, or determine if any prior approval programme is in operation, prior to the installation of a new module/component. Clear any stored DTC's and retest A5: POWER CONSUMPTION

NOTE: The seat heater power supply cycles on and off dependant on the seat and cabin temperature and may only

switch on for 5 seconds in 30 seconds 1 Reconnect the connector 2 Operate the vehicle air conditioning on full for 10 minutes to reduce the in vehicle ambient temperature 3 Refer to the electrical circuit diagrams and check the seat heater mat ( heater circuit ) using a current clamp 4 Operate the seat heater on full power 5 Use the chart above to calculate typical value (V/R=I) (Volts divided by Resistance equals Current in Amps) 6 Examples (12 volts / 0.5 ohms =24 amps) (12 volts / 1 ohms = 12 amps) (12 volts / 2 ohms = 6 amps) Does the seat heater mat consume the correct level of current?

Yes

Clear any stored DTC's and retest. If operation correct, no further action required

No

GO to A6. A6: RESISTANCE CHECK NOTES:

Ensure the multimeter used is calibrated and a resistance reading of 0 ohms is shown when the test leads are connected

together, alternately subtract any resistance shown from the result

The seat heater mat circuits should be checked at the seat heater module connector

Refer to the electrical circuit diagrams and to confirm the total resistance of the circuit the cushion and backrest are

connected in series 1 Refer to the electrical circuit diagrams and the seat heater mat application chart (see above) to identify the terminals 2 Disconnect the connector 3 Using a multimeter, carry out a resistance check of the seat heater mat heater circuit and the NTC resistor circuit. Record the results 4 Compare the results to the chart (see above) Are the results within specification at the given ambient temperature? (tolerance +/- 0.5 Ohms)

Yes

Reconnect the connector. Clear any stored DTC's and retest. If customer concern or DTC's return refer to

electrical circuit diagrams and investigate the power and ground supply circuits

No

Replace the seat heater mat as required. Refer to the warranty policy and procedures manual, or

determine if any prior approval programme is in operation, prior to the installation of a new module/component. Clear any stored DTC's and retest www.JagDocs.com