Can bus JAGUAR XFR 2010 1.G Workshop Manual

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 2010, Model line: XFR, Model: JAGUAR XFR 2010 1.GPages: 3039, PDF Size: 58.49 MB

Page 2294 of 3039

8 LH door module 9 Exterior mirror control switches

System Operation

The rear view mirrors comprise an interior mirror mounted to the windshield, and an exterior mirror mounted on each front door

cheater. The types of mirrors and associated operating functions installed depend on the specification and trim level of the

vehicle.

Interior Mirrors

The interior rear view mirror is provided as a manual dimming or an electrically operated automatic dimming type.

The manual dimming mirror comprises a prismatic glass housed within a surrounding case that is attached with a ball joint

connector to the mirror stem. Manual dimming of the mirror is achieved using the lever mounted on the underside of the mirror

body. Operating the lever will tilt the mirror head from the 'day' position to the 'night' position.

The automatic dimming mirror comprises an electro-chromatic glass housed within a surrounding case that is attached with a

ball joint connector to the mirror stem. The mirror stem incorporates an 8-pin electrical connector that is connected to the roof

panel wiring harness. The wiring harness provides hardwired and a LIN connection to the CJB.

Light sensors are mounted on the front and rear of the mirror surround case. The sensors control the automatic dimming

feature to reduce glare from the headlights of following vehicles.

The automatic dimming function is permanently active when the ignition is in power mode 4 (Accessory) and power mode 6

(Ignition). The forward facing light sensor monitors the ambient light level at the front of the vehicle; the rearward facing light

sensor monitors the light level coming from the rear of the vehicle. When light from the rear of the vehicle exceeds the

ambient light level from the front of the vehicle, the automatic dimming circuit darkens the interior mirror surface.

Automatic dimming is inhibited when reverse gear is selected to provide the driver with maximum vision. On vehicles with

automatic transmission, the reverse gear signal is provided by the TCM (transmission control module) via the high speed CAN bus to the CJB. The CJB then provides a power feed to the mirror. On vehicles with manual transmission, the reverse gear signal is provided by a transmission switch that is hardwired to the CJB.

Exterior Mirrors

Electrically operated and heated exterior mirrors are installed as standard. Depending on the specification and trim level of the

vehicle, the following options are available:

Power fold (switch pack operated feature) and auto fold (remote handset operated feature)

Memory recall

Reverse gear mirror dip

Mirror heating

Exterior mirror lamps.

The power fold/auto fold feature is available only when power fold mirrors are installed to the vehicle.

The mirrors can be configured to automatically fold when the vehicle is locked and unfold when unlocked. This feature can be

enabled or disabled via the Vehicle settings area of the touch screen:

Select 'Settings' from the touch screen Home menu.

Select ' Security/Vehicle'

Select 'Windows/Mirrors'

Select Power Fold 'On' or 'Off' as appropriate.

The pasenger side mirror can be configured to automatically dip when reverse gear is selected. This feature can be enabled or

disabled via the Vehicle settings area of the touch screen:

Select 'Settings' from the touch screen Home menu.

Select ' Security/Vehicle'

Select 'Windows/Mirrors'

Select Reverse dip 'On' or 'Off' as appropriate.

The LH door mirror incorporates an ambient air temperature sensor that is hardwired to the ECM (engine control module). The ECM is connected to the CJB and other control modules via the high speed CAN bus. The sensor provides information to the ECM that is then transmitted on the medium speed CAN bus for use by other control modules. On vehicles installed with a high-line instrument cluster, the CJB transmits the temperature signal to the instrument cluster that provides a display of the ambient temperature to the driver.

The exterior mirror lamps are controlled by the interior lighting function.

The door mirrors are controlled using a switch pack located on the driver's door. The switch pack contains 2 non-latching mirror

select switches labeled 'L' and 'R' and a 4-way directional joystick. The switch pack is connected to the driver door control

module via the LIN bus. The driver and front passenger door control modules are connected via the medium speed CAN bus. A hardwired connection between each door control module and the corresponding door mirror, provides the supply and ground

paths for the mirror motors.

Each exterior door mirror incorporates 2 motors to control horizontal (left/right) and vertical (up/down) adjustments. www.JagDocs.com

Page 2295 of 3039

On vehicles installed with a driver's power operated memory seat and memory exterior mirrors, a potentiometer is incorporated

within each mirror motor and is used to provide information regarding the actual motor positions. The current position and

memory positions of each door mirror motor are maintained and stored within the corresponding door control module.

The memory exterior mirror positions are also monitored and stored within door control module memory when the reverse gear

mirror dip function is used.

When reverse gear is selected, the door control module stores the current mirror positions and will then dip the passenger

mirror glass to a default dip position. While reverse gear is selected it is possible to store a preferred dipped mirror position by

adjusting the driver/passenger mirror glass to the desired position via the mirror switch pack. When the desired position is

achieved using the switch, the new dip positions will be automatically stored by the door control module when reverse gear is

de-selected. Therefore when reverse gear is re-selected, the dip position recalled by the door control module will be the new

reverse gear mirror dip stored position. When reverse gear is deselected the mirror glass will automatically move to the previous

stored position prior to reverse gear selection.

If the driver selects a memory recall function using the memory seat switch pack, the driver's memory seat and exterior

memory mirrors are moved to a stored memory position.

Exterior mirrors with the power fold/auto fold feature incorporate a motor located in the hinge of each exterior mirror arm.

Operation of the power fold feature is achieved using the exterior mirror switch pack. Operation of the auto fold feature is

achieved using the remote handset.

The power fold function is active when the ignition is in power mode 6 (Ignition).

Both exterior mirrors will power fold when the mirror switch pack 'L' and 'R' switches are pressed together. Pressing the

switches again will unfold the mirrors.

When the instrument cluster is configured for the auto fold feature, the mirrors will fold in when the remote handset lock

button is pressed. The mirrors will unfold when the vehicle is unlocked using the remote handset unlock button.

NOTE: If the mirrors are folded in using the mirror switch pack (power fold) and the vehicle is then locked, subsequent

unlocking of the vehicle will not unfold the mirrors.

When the remote handset unlock button is operated, the CJB recognizes the remote handset for that vehicle and acknowledges the request. The door control modules are connected directly to the AJB (auxiliary junction box) for power supply to the

exterior mirror folding motors.

When the vehicle is locked the door control modules reverse the polarity of the mirror fold motor, power and ground

connections to operate the mirrors in the opposite direction.

Exterior mirror heating is provided with heater elements bonded to the back of the mirror glass. Power supply for the mirror

heating elements is provided by the corresponding driver or passenger door control module via the RJB. The door control modules receive a power supply from the RJB, and are both connected on the medium speed CAN bus to the ATC (automatic temperature control) module. A ground terminal from each door control module completes the circuit. The ATC module automatically controls the mirror heating function whenever the ignition is in power mode 4 (Accessory) and power mode 6

(Ignition).

Operation of the exterior mirror heaters is fully automatic and not controllable by the driver. Exterior mirror heater operation is

determined by ambient air temperature and windshield wiper status. When ambient air temperature reaches a pre-determined

level, the ATC module broadcasts an exterior mirror heating request to the door modules over the medium speed CAN bus. On receipt of this message, the door modules provide feed and ground connections to both exterior mirror heater elements.

The mirror heating is controlled in two phases, the initial heating phase and a second PWM (pulse width modulation) controlled

phase. In the first phase the heater elements in the mirrors are permanently powered for a pre-determined length of time. This

length of time varies with the ambient temperature. During the second PWM phase, the heater elements are turned on and off every 30 seconds. The amount of time the exterior mirror heaters are operational increases if the windshield wipers are

switched on. This ensures the mirrors remain mist free in damp and wet conditions, where there is an increased risk of misting.

Page 2311 of 3039

Seating - Seats - Overview

Description and Operation

OVERVIEW

Leather Seat Covers Published: 20-Nov-2013

Leather is a natural product, therefore it bears natural characteristics, such as grain variations, growth & bush marks. These

non-weakening marks show the true nature of the hide and are the hallmarks of Leather. In order to maintain the beauty of the

vehicles natural Leather upholstery it requires regular cleaning, which if neglected, may cause deterioration. Where dust and

dirt are allowed to accumulate and become ingrained in the surface of the Leather, the upholstery may become permanently

damaged.

Light coloured upholstery can be particularly susceptible to soiling and staining and care should be taken to ensure that where

there is evidence of any soiling or staining on the upholstery then this should be cleaned immediately using the Jaguar/Land

Rover approved products, failure to do this could lead to the stain becoming permanent, this applies to all leather upholstery

and is not colour specific.

Leather trimmed seats will naturally exhibit areas of creasing and wrinkling over a period of time and is a normal characteristic

as the Leather ages.

Particular care should be taken where there is evidence of soiling or staining on the leather, this should be cleaned

immediately. Failure to do this could lead to the stain becoming permanent.

Particular care should be taken to prevent damage from studs, zips and buckles.

NOTES:

Please refer to Leather care label attached to seats for more information.

Creasing and wrinkling does not represent a manufacturing defect.

Damage from studs, zips and buckles do not represent manufacturing defects.

Use only Jaguar/Land Rover approved products in accordance with the instructions for use.

General

A number of front seating options are available. An 8-way electrically adjustable driver's seat is complemented by an 8-way

electrically adjustable passenger seat. A 10-way electrically adjustable driver's seat is complemented by an 10-way electrically

adjustable front passenger seat. A 16-way electrically adjustable driver's seat is complemented by a 12-way electrically

adjustable front passenger seat.

On non-memory seats, the operation of the seats is controlled directly from the driver's seat switchpack. On memory seats,

the operation of the seat motors is controlled by a seat control module which is located on the underside of the driver's seat

frame.

The driver's seat is fitted with a seat position sensor which is located on the seat rail. The sensor is used by the RCM

(restraints control module) to determine the seat position and adjust the inflation time of the airbag deployment accordingly.

Refer to: Air Bag and Safety Belt Pretensioner Supplemental Restraint System (SRS) (501-20B Supplemental Restraint System, Description and Operation).

Page 2314 of 3039

Note:

A =

Hardwired;

N

=

Medium

speed

CAN

(controller

area

network) bus;

P

=

MOST

ring

1

Battery

2

BJB

3

ATC

(automatic

temperature

control) module

4

RJB

(rear

junction

box)

5

Touch Screen

Display

(TSD)

6

Information

and

Entertainment

module

www.JagDocs.com

Page 2315 of 3039

7 Front seat climate control module 8 Passenger seat squab climate module 9 Drivers seat cushion climate module 10 Passenger seat cushion climate module 11 Drivers seat squab climate module 12 Passenger seat cushion heater element 13 Passenger seat squab heater element 14 Drivers seat cushion heater element 15 Drivers seat squab heater element 16 CJB

HEATED SEATS - OPERATION

Heated Front Seats System Operation

The TSD receives a fused power supply from the RJB. One of the 3 seat heat temperature selections made by the driver or passenger using the TSD soft keys are passed from the TSD on the MOST ring to the Information and Entertainment module.

The information and entertainment module processes the information and transmits the request on the medium speed CAN bus to the ATC module.

The cushion heaters have a thermal sensor which supplies a feed back signal back to the CJB. The squab heater elements do not have a thermal sensor and are maintained at the same temperature as the seat cushion elements.

The ATC module reacts to the driver request information received from the information and entertainment module and requests the CJB to activate the seat heaters. The CJB measures the returned temperature signals from the thermal sensors and relays the temperature signals back to the ATC module. The ATC module then uses the measured seat element temperatures to provide closed-loop control of the heater elements to maintain the temperature at one the 3 heat ranges selected.

NOTE: To prevent excessive battery discharge, the heated front seats will only operate when the engine is running.

Heated and Cooled Front Seats

The TSD receives a fused power supply from the RJB. Selections made by the driver using the TSD soft keys are passed from the TSD on the MOST ring to the Information and Entertainment module. The information and entertainment module processes

the information and transmits the request on the medium speed CAN bus to the front seat climate control module. The front seat climate control module is located beneath the RH (right-hand) front seat, on the floor cross member.

The front seat climate control module receives its power supplies from the CJB. Heating and cooling requests are generated using the soft buttons on the TSD. These requests are transmitted to the information and entertainment module over the

MOST ring. The Information and Entertainment module forwards these requests to the front seat climate control module over

the medium speed CAN bus.

The front seat climate control module supplies power to the two climate modules in each seat. The temperature sensor in each

climate module is monitored by the front seat climate control module which uses the temperature information to control the

Peltier cells accordingly and also the blower fans to distribute the heated or cooled air.

NOTE: To prevent excessive battery discharge, the heated and cooled front seats will only operate when the engine is

running.

Electric Driver's Seat Adjustment - Non-Memory Seats

The CJB supplies 3 power supplies to the driver's seat switchpack. The fused supplies provide power for the seat height and squab recline, the seat slide and seat tilt and the lumbar adjustment respectively. The CJB only provides the power to the driver's seat switch pack when the ignition is on (power mode 6).

For the seat movement motors, when the applicable switch is operated, the power is supplied to the applicable side of the

motor and the ground path is completed to operate the motor in the required direction. To move the motor in the opposite

direction the polarity is reversed.

For the lumbar adjustment, when the switch is operated in the inflate position, power is supplied to the pump motor to inflate

the lumbar support. When the switch is operated in the opposite direction, the power energizes a solenoid which in turn opens

a valve to deflate the lumbar support.

Electric Passenger Seat Adjustment ( 8, 10 and 12 way)

The CJB supplies 3 power supplies to the passenger seat switchpack. The fused supplies provide power for the seat height and squab recline, the seat slide and seat tilt and the head restraint and lumbar adjustment respectively. The CJB only provides the power to the passenger seat switch pack when the ignition is on (power mode 6).

For the seat movement and head restraint motors, when the applicable switch is operated, the power is supplied to the

applicable side of the motor and the ground path is completed to operate the motor in the required direction. To move the

Page 2316 of 3039

supplies provide power for the movement motors in addition to the driver's seat switch pack. Power is only supplied to the

driver's seat module and the driver's seat switch pack when the ignition is on (power mode 6).

The driver's seat switch pack is connected to the driver's seat module by a LIN bus for the seat movement switches. Any selection for seat movement generates a message which is passed via the LIN to the driver's seat module. The seat module processes the request and operates the applicable seat function as required using the power supplies from the CJB.

Each seat motor contains a Hall position sensor. The sensor sends a feedback signal to the driver's seat module. The signal is

used for memory store and memory recall functions.

The lumbar adjustment switch on the driver's seat switch pack is wired direct to the lumbar pump and solenoids. The switch,

when moved to the inflate position for either the upper or lower inflatable cushion cell, provides a power supply to the lumbar

pump and simultaneously activates the applicable inflate solenoid valve. When the switch is released the pump stops and the

solenoid valve closes trapping the air in the inflatable cushion. When the switch is moved to the deflate position for either the

upper or lower inflatable cushion cell, power is supplied to the applicable deflate solenoid valve which opens to allow the air in

the cushion to escape. When the switch is released, the valve is closed and the remaining air in the cushion is retained.

FRONT SEATS - DESCRIPTION Component Description

The table below highlights the features available for each seating option.

Seat Type Non-Heated Heated Heated and Cooled Lumbar Support Memory 8-way Yes Optional No 2-way No 10-way Yes Optional Optional 2-way Optional (Driver's seat only) 12-way No No Yes 4-way No 16-way No No Yes 4-way Yes (Driver's seat only) Seat Heating

The 3-stage heated front seats feature 2 heater elements located in the seat cushion and a single heater element located in

the seat squab. Operation of the heated front seats is controlled by the ATC module via the TSD, information and entertainment control module and the CJB module on vehicles with heated seats. On vehicles with heated and cooled seats the operation is controlled by the TSD, information and entertainment control module and the front seat climate control

module.

The heated and cooled front seats each contain 2 climate modules; one in the cushion, one in the squab. The climate modules

contain 'Peltier' cells which are able to deliver heating and cooling based on a voltage provided by the front seat climate

control module. Each climate module also contains a fan, which blows air over the Peltier cells to distribute heated or cooled

air via liners in the seat cushion and squab. The fan is also controlled by the front seat climate control module. The TSD allows

the driver and passenger to select 3 ranges of heated or cooled ventilation; off, minimum and intermediate. Also, using the

selections on the TSD, the driver and passenger can select between full seat ventilation or squab backrest ventilation only.

Vehicles fitted with the 3-stage heated front seat option also feature a heated steering wheel.

Refer to: Steering Column Switches (211-05 Steering Column Switches, Description and Operation).

Electric Seat Adjustment

Lumbar Support

On 8, 10 and 12 way seats, a 2 way lumbar support is provided which allows the lumbar inflatable cushion to be inflated or

deflated as required. On 16 way seats, a 4 way lumbar support is fitted which comprises two separate cushion cells. The upper

and lower cells can be inflated or deflated individually allowing greater comfort adjustment for the driver and passenger.

The lumbar support comprises an inflatable cushion located in the seat squab, a pump and solenoids. The pump is activated

when the applicable seat switch is moved to the inflate position, inflating the cell(s) in the inflatable cushion. On 8 and 10

way seats, a single solenoid operated valve allows the inflatable cushion to be deflated. On 12 and 16 way seats, 4 solenoid

valves control the inflation and deflation of the upper and lower inflatable cushion cells, allowing each cell to be adjusted

individually.

Seat Motors

The head restraint motor is located in the upper section of each seat squab and is accessible by removal of the seat back. The

motor moves a cradle which is driven in a vertical motion by a rack and pinion arrangement. The cradle has the two head

restraint stems attached to it and therefore raises and lowers the head restraint as the motor moves the cradle. The motor

contains a Hall sensor which supplies positional information to the driver's seat module.

The seat slide motor is an integral component of the seat frame. The motor drives on a gear on a worm drive lead screw which

is integral with the floor rail. The lead screw has a stop at each end to limit the fore and aft seat movement.

Page 2329 of 3039

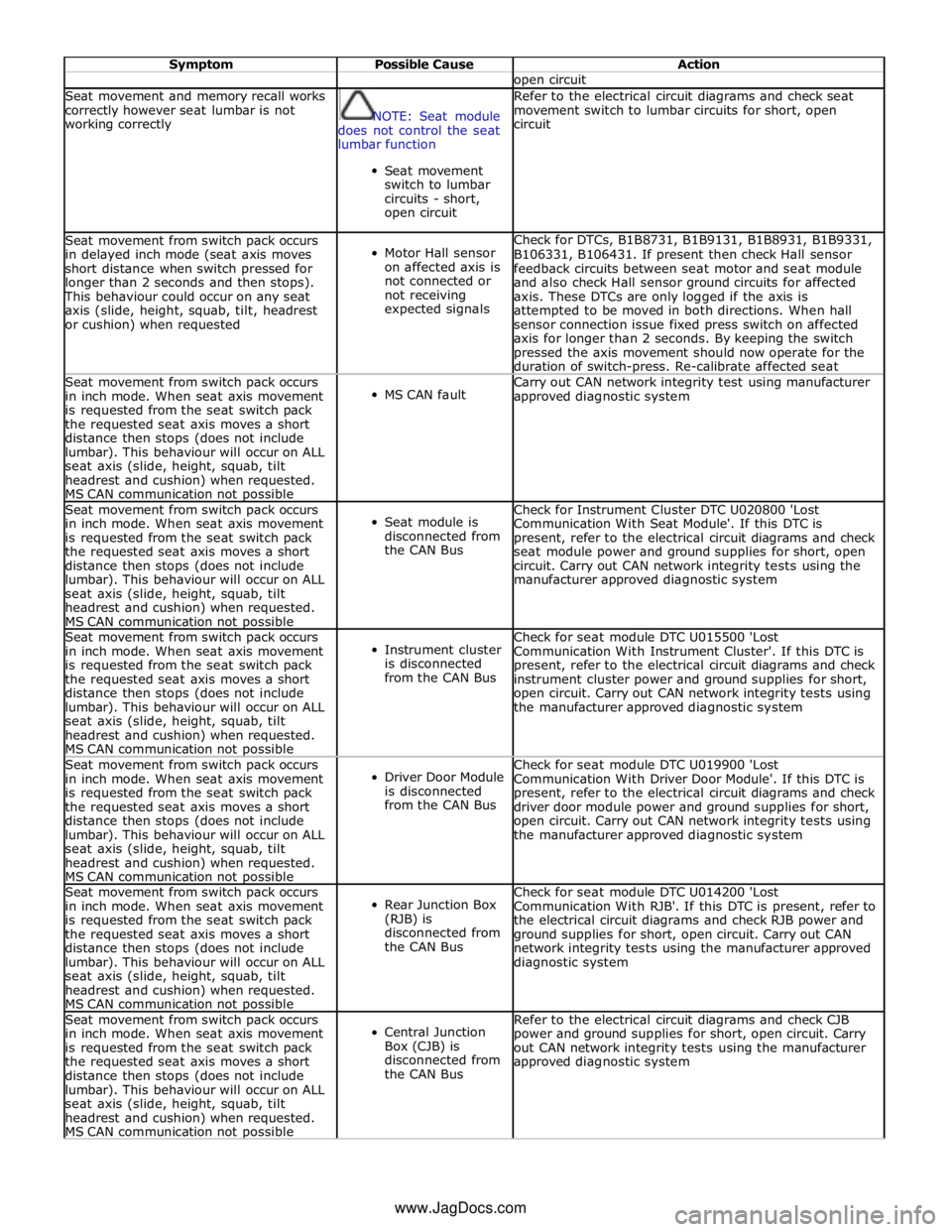

Symptom Possible Cause Action open circuit Seat movement and memory recall works

correctly however seat lumbar is not

working correctly

NOTE: Seat module

does not control the seat

lumbar function

Seat movement

switch to lumbar

circuits - short,

open circuit Refer to the electrical circuit diagrams and check seat

movement switch to lumbar circuits for short, open

circuit Seat movement from switch pack occurs

in delayed inch mode (seat axis moves

short distance when switch pressed for

longer than 2 seconds and then stops). This behaviour could occur on any seat

axis (slide, height, squab, tilt, headrest

or cushion) when requested

Motor Hall sensor

on affected axis is

not connected or

not receiving

expected signals Check for DTCs, B1B8731, B1B9131, B1B8931, B1B9331,

B106331, B106431. If present then check Hall sensor

feedback circuits between seat motor and seat module

and also check Hall sensor ground circuits for affected

axis. These DTCs are only logged if the axis is

attempted to be moved in both directions. When hall

sensor connection issue fixed press switch on affected

axis for longer than 2 seconds. By keeping the switch

pressed the axis movement should now operate for the

duration of switch-press. Re-calibrate affected seat Seat movement from switch pack occurs

in inch mode. When seat axis movement

is requested from the seat switch pack

the requested seat axis moves a short

distance then stops (does not include

lumbar). This behaviour will occur on ALL

seat axis (slide, height, squab, tilt

headrest and cushion) when requested.

MS CAN communication not possible

MS CAN fault Carry out CAN network integrity test using manufacturer

approved diagnostic system Seat movement from switch pack occurs

in inch mode. When seat axis movement

is requested from the seat switch pack

the requested seat axis moves a short

distance then stops (does not include

lumbar). This behaviour will occur on ALL

seat axis (slide, height, squab, tilt

headrest and cushion) when requested.

MS CAN communication not possible

Seat module is

disconnected from

the CAN Bus Check for Instrument Cluster DTC U020800 'Lost

Communication With Seat Module'. If this DTC is

present, refer to the electrical circuit diagrams and check

seat module power and ground supplies for short, open

circuit. Carry out CAN network integrity tests using the

manufacturer approved diagnostic system Seat movement from switch pack occurs

in inch mode. When seat axis movement

is requested from the seat switch pack

the requested seat axis moves a short

distance then stops (does not include

lumbar). This behaviour will occur on ALL

seat axis (slide, height, squab, tilt

headrest and cushion) when requested.

MS CAN communication not possible

Instrument cluster

is disconnected

from the CAN Bus Check for seat module DTC U015500 'Lost

Communication With Instrument Cluster'. If this DTC is

present, refer to the electrical circuit diagrams and check

instrument cluster power and ground supplies for short,

open circuit. Carry out CAN network integrity tests using

the manufacturer approved diagnostic system Seat movement from switch pack occurs

in inch mode. When seat axis movement

is requested from the seat switch pack

the requested seat axis moves a short

distance then stops (does not include

lumbar). This behaviour will occur on ALL

seat axis (slide, height, squab, tilt

headrest and cushion) when requested.

MS CAN communication not possible

Driver Door Module

is disconnected

from the CAN Bus Check for seat module DTC U019900 'Lost

Communication With Driver Door Module'. If this DTC is

present, refer to the electrical circuit diagrams and check

driver door module power and ground supplies for short,

open circuit. Carry out CAN network integrity tests using

the manufacturer approved diagnostic system Seat movement from switch pack occurs

in inch mode. When seat axis movement

is requested from the seat switch pack

the requested seat axis moves a short

distance then stops (does not include

lumbar). This behaviour will occur on ALL

seat axis (slide, height, squab, tilt

headrest and cushion) when requested.

MS CAN communication not possible

Rear Junction Box

(RJB) is

disconnected from

the CAN Bus Check for seat module DTC U014200 'Lost

Communication With RJB'. If this DTC is present, refer to

the electrical circuit diagrams and check RJB power and

ground supplies for short, open circuit. Carry out CAN

network integrity tests using the manufacturer approved

diagnostic system Seat movement from switch pack occurs

in inch mode. When seat axis movement

is requested from the seat switch pack

the requested seat axis moves a short

distance then stops (does not include

lumbar). This behaviour will occur on ALL

seat axis (slide, height, squab, tilt

headrest and cushion) when requested.

MS CAN communication not possible

Central Junction

Box (CJB) is

disconnected from

the CAN Bus Refer to the electrical circuit diagrams and check CJB

power and ground supplies for short, open circuit. Carry

out CAN network integrity tests using the manufacturer

approved diagnostic system www.JagDocs.com

Page 2333 of 3039

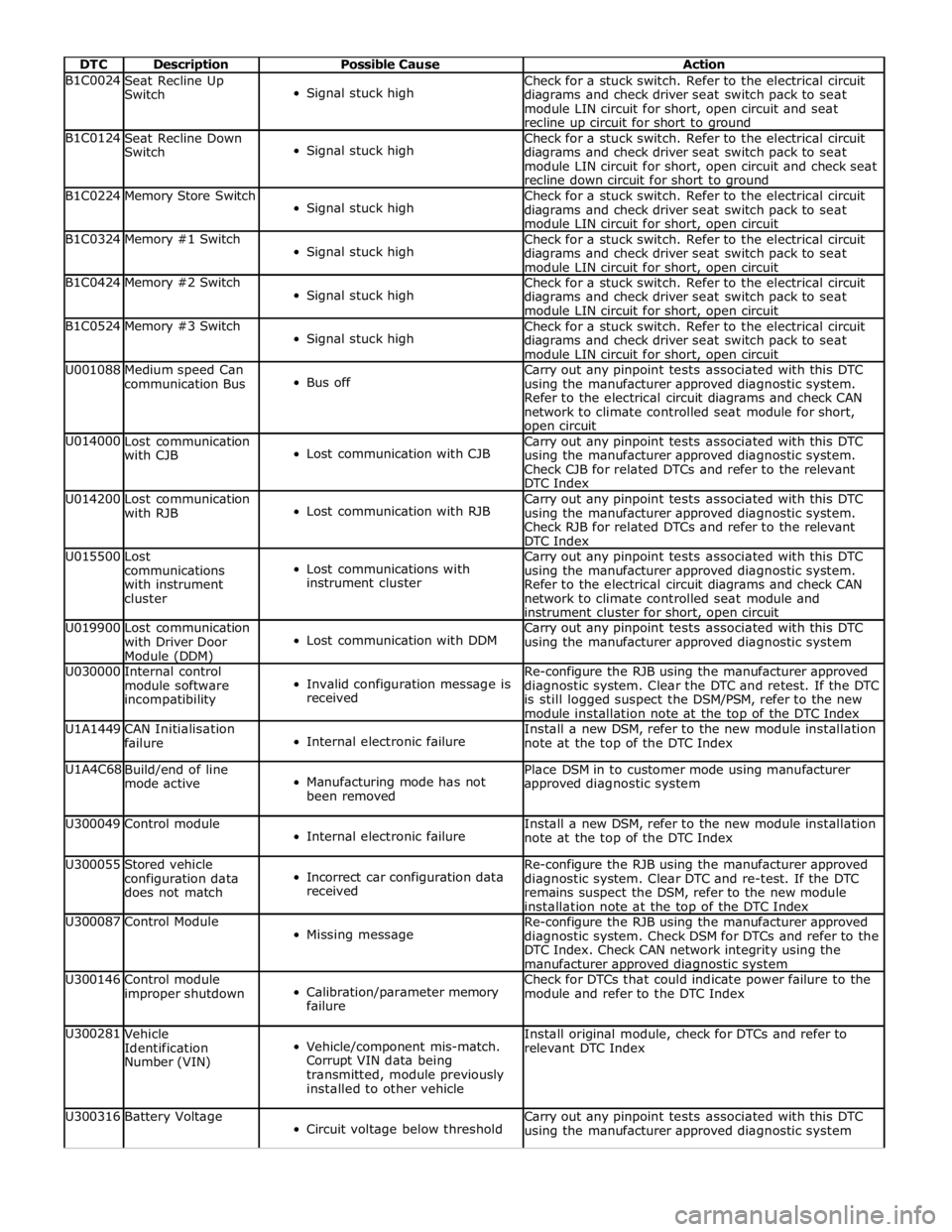

DTC Description Possible Cause Action B1C0024

Seat Recline Up

Switch

Signal stuck high Check for a stuck switch. Refer to the electrical circuit

diagrams and check driver seat switch pack to seat

module LIN circuit for short, open circuit and seat

recline up circuit for short to ground B1C0124

Seat Recline Down

Switch

Signal stuck high Check for a stuck switch. Refer to the electrical circuit

diagrams and check driver seat switch pack to seat

module LIN circuit for short, open circuit and check seat

recline down circuit for short to ground B1C0224 Memory Store Switch

Signal stuck high Check for a stuck switch. Refer to the electrical circuit

diagrams and check driver seat switch pack to seat

module LIN circuit for short, open circuit B1C0324 Memory #1 Switch

Signal stuck high Check for a stuck switch. Refer to the electrical circuit

diagrams and check driver seat switch pack to seat

module LIN circuit for short, open circuit B1C0424 Memory #2 Switch

Signal stuck high Check for a stuck switch. Refer to the electrical circuit

diagrams and check driver seat switch pack to seat

module LIN circuit for short, open circuit B1C0524 Memory #3 Switch

Signal stuck high Check for a stuck switch. Refer to the electrical circuit

diagrams and check driver seat switch pack to seat

module LIN circuit for short, open circuit U001088

Medium speed Can

communication Bus

Bus off Carry out any pinpoint tests associated with this DTC

using the manufacturer approved diagnostic system.

Refer to the electrical circuit diagrams and check CAN

network to climate controlled seat module for short, open circuit U014000

Lost communication

with CJB

Lost communication with CJB Carry out any pinpoint tests associated with this DTC

using the manufacturer approved diagnostic system.

Check CJB for related DTCs and refer to the relevant

DTC Index U014200

Lost communication

with RJB

Lost communication with RJB Carry out any pinpoint tests associated with this DTC

using the manufacturer approved diagnostic system.

Check RJB for related DTCs and refer to the relevant

DTC Index U015500

Lost

communications

with instrument

cluster

Lost communications with

instrument cluster Carry out any pinpoint tests associated with this DTC

using the manufacturer approved diagnostic system.

Refer to the electrical circuit diagrams and check CAN

network to climate controlled seat module and

instrument cluster for short, open circuit U019900

Lost communication

with Driver Door

Module (DDM)

Lost communication with DDM Carry out any pinpoint tests associated with this DTC

using the manufacturer approved diagnostic system U030000

Internal control

module software

incompatibility

Invalid configuration message is

received Re-configure the RJB using the manufacturer approved

diagnostic system. Clear the DTC and retest. If the DTC

is still logged suspect the DSM/PSM, refer to the new

module installation note at the top of the DTC Index U1A1449

CAN Initialisation

failure

Internal electronic failure Install a new DSM, refer to the new module installation

note at the top of the DTC Index U1A4C68

Build/end of line

mode active

Manufacturing mode has not

been removed Place DSM in to customer mode using manufacturer

approved diagnostic system U300049 Control module

Internal electronic failure Install a new DSM, refer to the new module installation

note at the top of the DTC Index U300055

Stored vehicle

configuration data

does not match

Incorrect car configuration data

received Re-configure the RJB using the manufacturer approved

diagnostic system. Clear DTC and re-test. If the DTC

remains suspect the DSM, refer to the new module

installation note at the top of the DTC Index U300087 Control Module

Missing message Re-configure the RJB using the manufacturer approved

diagnostic system. Check DSM for DTCs and refer to the

DTC Index. Check CAN network integrity using the

manufacturer approved diagnostic system U300146

Control module

improper shutdown

Calibration/parameter memory

failure Check for DTCs that could indicate power failure to the

module and refer to the DTC Index U300281

Vehicle

Identification

Number (VIN)

Vehicle/component mis-match.

Corrupt VIN data being

transmitted, module previously

installed to other vehicle Install original module, check for DTCs and refer to

relevant DTC Index U300316 Battery Voltage

Circuit voltage below threshold Carry out any pinpoint tests associated with this DTC

using the manufacturer approved diagnostic system

Page 2352 of 3039

DTC Description Possible Causes Action U0010-88

Medium Speed CAN

Communication Bus -

Bus off

Medium speed CAN

communication - Bus off

Refer to the electrical circuit diagrams and check

the power and ground connections to the module

Using the manufacturer approved diagnostic

system, complete a CAN network integrity test

Carry out on demand self test using manufacturer

approved diagnostic system to confirm rectification U0140-00

Lost Communication

With Body Control

Module - No sub type

information

Lost communication with

central junction box

NOTE: This DTC may be stored even though no fault

condition is present and should be ignored unless the

customer has reported a climate seat concern. Clear the

DTC and retest. Verify the customer concern prior to

diagnosis

Refer to the electrical circuit diagrams and check

the power and ground connections to the module

Using the manufacturer approved diagnostic

system, complete a CAN network integrity test

Refer to the electrical circuit diagrams and check

the CAN network between the front seat climate

control module and central junction box

Carry out on demand self test using manufacturer

approved diagnostic system to confirm rectification U0142-00 Lost Communication

Lost communication with

Refer to the electrical circuit diagrams and check With Body Control Module "B" - No sub rear junction box the power and ground connections to the module type information Using the manufacturer approved diagnostic system, complete a CAN network integrity test Refer to the electrical circuit diagrams and check the CAN network between the front seat climate control module and rear junction box Carry out on demand self test using manufacturer approved diagnostic system to confirm rectification U0155-00

Lost Communication

With Instrument Panel

Cluster (IPC) Control

Module - No sub type

information

Lost communication with

instrument cluster

Refer to the electrical circuit diagrams and check

the power and ground connections to the module

Using the manufacturer approved diagnostic

system, complete a CAN network integrity test

Refer to the electrical circuit diagrams and check

the CAN network between the front seat climate

control module and instrument cluster

Carry out on demand self test using manufacturer

approved diagnostic system to confirm rectification U0156-00 Lost Communication

Lost communication with

Refer to the electrical circuit diagrams and check With Information Center "A" - No sub rear seat entertainment the power and ground connections to the module type information control module Using the manufacturer approved diagnostic system, complete a CAN network integrity test Refer to the electrical circuit diagrams and check the CAN network between the front seat climate control module and rear seat entertainment control module Carry out on demand self test using manufacturer approved diagnostic system to confirm rectification U0300-00

Internal Control Module

Software

Incompatibility - No

sub type information

Software stored in front

seat climate control

module is not compatible

with master configuration

Check the front seat climate control module is

configured correctly

Reconfigure the front seat climate control module

using the manufacturer approved diagnostic

system. Clear the DTC and retest the system

Carry out on demand self test using manufacturer

approved diagnostic system to confirm rectification U0401-00

Invalid Data Received

From ECM/PCM - No

sub type information

The engine control module

has transmitted engine

speed quality factor CAN

signal at a specific value

for a greater than expected

time period

Check the engine control module for related DTCs

and refer to the relevant DTC index

On software levels previous to 8X23-14B663-AE

clear the DTC and take no further action if the

system is operating correctly

Page 2414 of 3039

Published: 24-Jan-2013

Glass, Frames and Mechanisms - Glass, Frames and Mechanisms - System

Operation and Component Description

Description and Operation

Control Diagram

NOTE: A = Hardwired; N = Medium speed CAN; O = LIN bus

Item Description 1 Battery 2 Megafuse (250 amp) 3 CJB (central junction box) 4 RJB (rear junction box) 5 Window control switches - driver's door 6 Door module – driver's door www.JagDocs.com