Actuator JAGUAR XFR 2010 1.G User Guide

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 2010, Model line: XFR, Model: JAGUAR XFR 2010 1.GPages: 3039, PDF Size: 58.49 MB

Page 150 of 3039

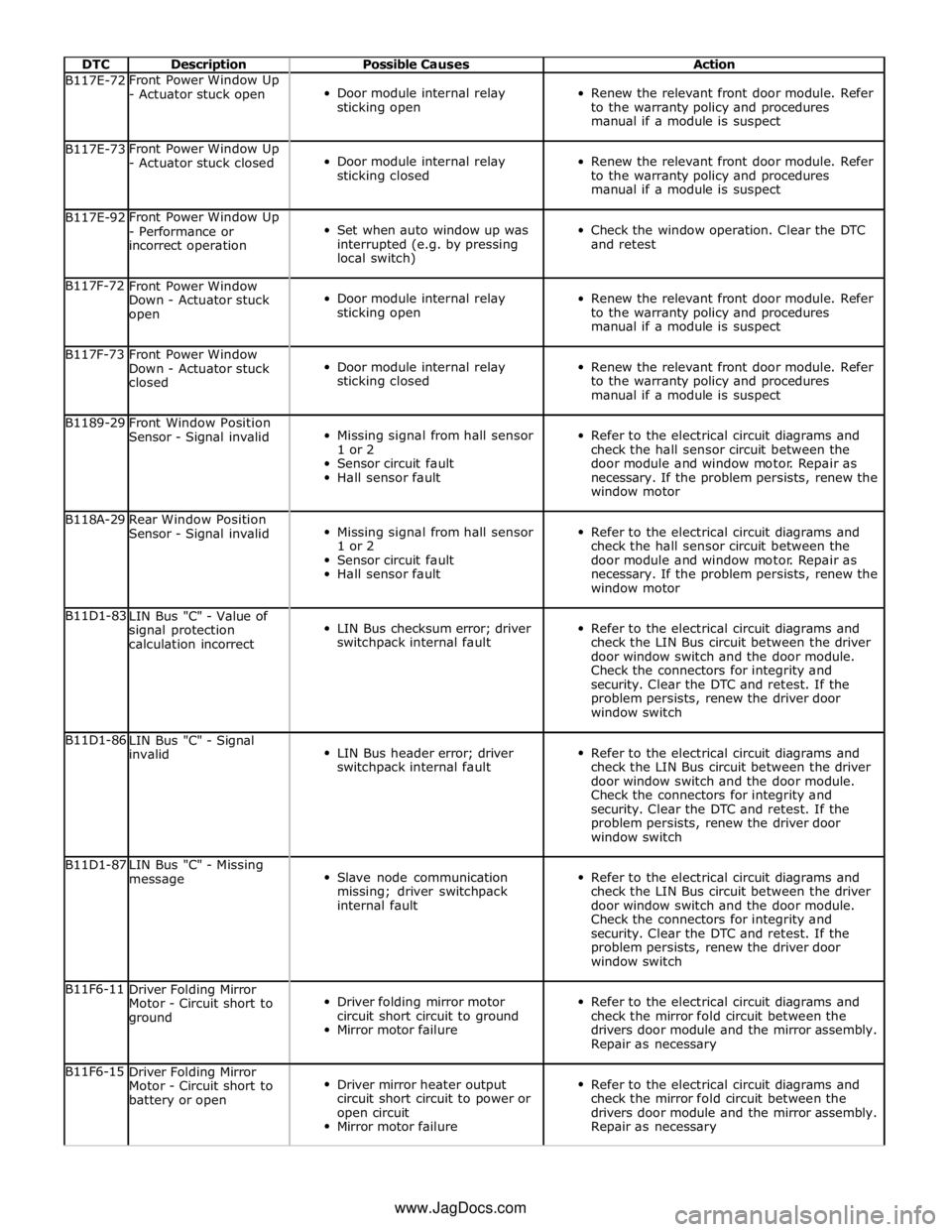

DTC Description Possible Causes Action B117E-72 Front Power Window Up

- Actuator stuck open

Door module internal relay

sticking open

Renew the relevant front door module. Refer

to the warranty policy and procedures

manual if a module is suspect B117E-73 Front Power Window Up

- Actuator stuck closed

Door module internal relay

sticking closed

Renew the relevant front door module. Refer

to the warranty policy and procedures

manual if a module is suspect B117E-92 Front Power Window Up

- Performance or

incorrect operation

Set when auto window up was

interrupted (e.g. by pressing

local switch)

Check the window operation. Clear the DTC

and retest B117F-72

Front Power Window

Down - Actuator stuck

open

Door module internal relay

sticking open

Renew the relevant front door module. Refer

to the warranty policy and procedures

manual if a module is suspect B117F-73

Front Power Window

Down - Actuator stuck

closed

Door module internal relay

sticking closed

Renew the relevant front door module. Refer

to the warranty policy and procedures

manual if a module is suspect B1189-29

Front Window Position

Sensor - Signal invalid

Missing signal from hall sensor

1 or 2

Sensor circuit fault

Hall sensor fault

Refer to the electrical circuit diagrams and

check the hall sensor circuit between the

door module and window motor. Repair as

necessary. If the problem persists, renew the

window motor B118A-29

Rear Window Position

Sensor - Signal invalid

Missing signal from hall sensor

1 or 2

Sensor circuit fault

Hall sensor fault

Refer to the electrical circuit diagrams and

check the hall sensor circuit between the

door module and window motor. Repair as

necessary. If the problem persists, renew the

window motor B11D1-83

LIN Bus "C" - Value of

signal protection

calculation incorrect

LIN Bus checksum error; driver

switchpack internal fault

Refer to the electrical circuit diagrams and

check the LIN Bus circuit between the driver

door window switch and the door module.

Check the connectors for integrity and

security. Clear the DTC and retest. If the

problem persists, renew the driver door

window switch B11D1-86

LIN Bus "C" - Signal

invalid

LIN Bus header error; driver

switchpack internal fault

Refer to the electrical circuit diagrams and

check the LIN Bus circuit between the driver

door window switch and the door module.

Check the connectors for integrity and

security. Clear the DTC and retest. If the

problem persists, renew the driver door

window switch B11D1-87

LIN Bus "C" - Missing

message

Slave node communication

missing; driver switchpack

internal fault

Refer to the electrical circuit diagrams and

check the LIN Bus circuit between the driver

door window switch and the door module.

Check the connectors for integrity and

security. Clear the DTC and retest. If the

problem persists, renew the driver door

window switch B11F6-11

Driver Folding Mirror

Motor - Circuit short to

ground

Driver folding mirror motor

circuit short circuit to ground

Mirror motor failure

Refer to the electrical circuit diagrams and

check the mirror fold circuit between the

drivers door module and the mirror assembly.

Repair as necessary B11F6-15

Driver Folding Mirror

Motor - Circuit short to

battery or open

Driver mirror heater output

circuit short circuit to power or

open circuit

Mirror motor failure

Refer to the electrical circuit diagrams and

check the mirror fold circuit between the

drivers door module and the mirror assembly.

Repair as necessary www.JagDocs.com

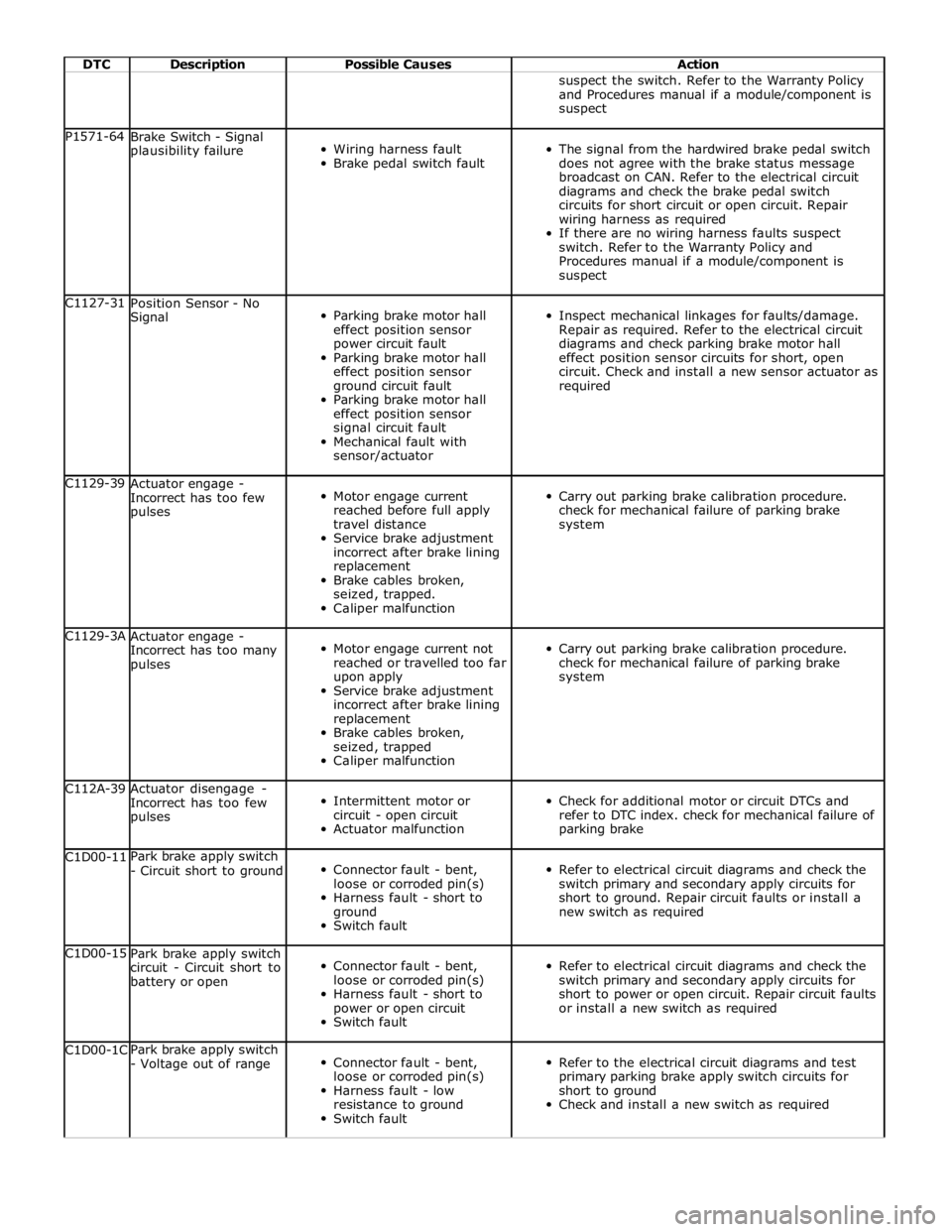

Page 159 of 3039

DTC Description Possible Causes Action suspect the switch. Refer to the Warranty Policy

and Procedures manual if a module/component is

suspect P1571-64

Brake Switch - Signal

plausibility failure

Wiring harness fault

Brake pedal switch fault

The signal from the hardwired brake pedal switch

does not agree with the brake status message

broadcast on CAN. Refer to the electrical circuit

diagrams and check the brake pedal switch

circuits for short circuit or open circuit. Repair

wiring harness as required

If there are no wiring harness faults suspect

switch. Refer to the Warranty Policy and

Procedures manual if a module/component is

suspect C1127-31

Position Sensor - No

Signal

Parking brake motor hall

effect position sensor

power circuit fault

Parking brake motor hall

effect position sensor

ground circuit fault

Parking brake motor hall

effect position sensor

signal circuit fault

Mechanical fault with

sensor/actuator

Inspect mechanical linkages for faults/damage.

Repair as required. Refer to the electrical circuit

diagrams and check parking brake motor hall

effect position sensor circuits for short, open

circuit. Check and install a new sensor actuator as

required C1129-39

Actuator engage -

Incorrect has too few

pulses

Motor engage current

reached before full apply

travel distance

Service brake adjustment

incorrect after brake lining

replacement

Brake cables broken,

seized, trapped.

Caliper malfunction

Carry out parking brake calibration procedure.

check for mechanical failure of parking brake

system C1129-3A

Actuator engage -

Incorrect has too many

pulses

Motor engage current not

reached or travelled too far

upon apply

Service brake adjustment

incorrect after brake lining

replacement

Brake cables broken,

seized, trapped

Caliper malfunction

Carry out parking brake calibration procedure.

check for mechanical failure of parking brake

system C112A-39

Actuator disengage -

Incorrect has too few

pulses

Intermittent motor or

circuit - open circuit

Actuator malfunction

Check for additional motor or circuit DTCs and

refer to DTC index. check for mechanical failure of

parking brake C1D00-11 Park brake apply switch

- Circuit short to ground

Connector fault - bent,

loose or corroded pin(s)

Harness fault - short to

ground

Switch fault

Refer to electrical circuit diagrams and check the

switch primary and secondary apply circuits for

short to ground. Repair circuit faults or install a

new switch as required C1D00-15

Park brake apply switch

circuit - Circuit short to

battery or open

Connector fault - bent,

loose or corroded pin(s)

Harness fault - short to

power or open circuit

Switch fault

Refer to electrical circuit diagrams and check the

switch primary and secondary apply circuits for

short to power or open circuit. Repair circuit faults

or install a new switch as required C1D00-1C Park brake apply switch

- Voltage out of range

Connector fault - bent,

loose or corroded pin(s)

Harness fault - low

resistance to ground

Switch fault

Refer to the electrical circuit diagrams and test

primary parking brake apply switch circuits for

short to ground

Check and install a new switch as required

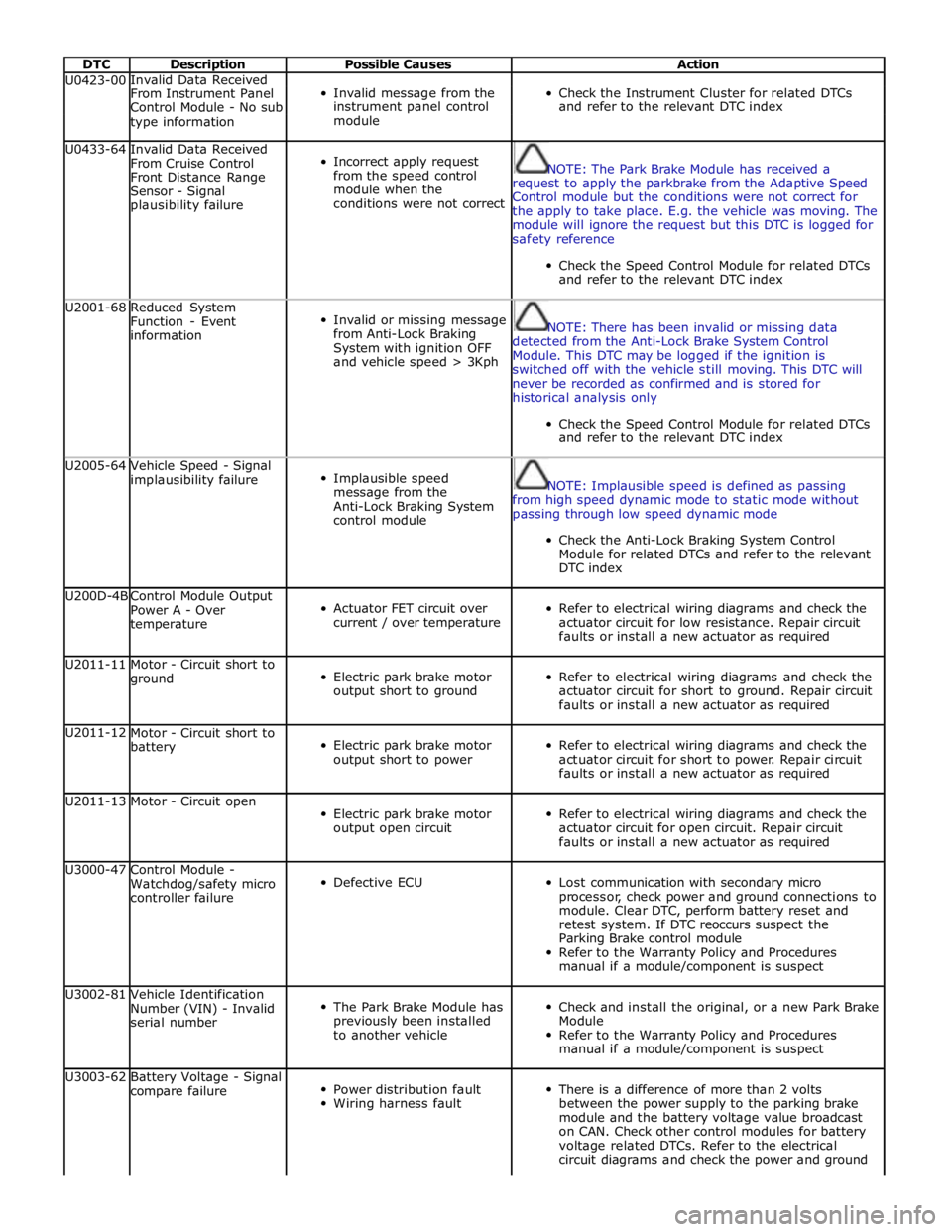

Page 162 of 3039

DTC Description Possible Causes Action U0423-00 Invalid Data Received

Invalid message from the

Check the Instrument Cluster for related DTCs From Instrument Panel Control Module - No sub instrument panel control and refer to the relevant DTC index type information module U0433-64

Invalid Data Received

From Cruise Control

Front Distance Range

Sensor - Signal

plausibility failure

Incorrect apply request

from the speed control

module when the

conditions were not correct

NOTE: The Park Brake Module has received a

request to apply the parkbrake from the Adaptive Speed

Control module but the conditions were not correct for

the apply to take place. E.g. the vehicle was moving. The

module will ignore the request but this DTC is logged for

safety reference

Check the Speed Control Module for related DTCs

and refer to the relevant DTC index U2001-68

Reduced System

Function - Event

information

Invalid or missing message

from Anti-Lock Braking

System with ignition OFF

and vehicle speed > 3Kph

NOTE: There has been invalid or missing data

detected from the Anti-Lock Brake System Control

Module. This DTC may be logged if the ignition is

switched off with the vehicle still moving. This DTC will

never be recorded as confirmed and is stored for

historical analysis only

Check the Speed Control Module for related DTCs

and refer to the relevant DTC index U2005-64

Vehicle Speed - Signal

implausibility failure

Implausible speed

message from the

Anti-Lock Braking System

control module

NOTE: Implausible speed is defined as passing

from high speed dynamic mode to static mode without

passing through low speed dynamic mode

Check the Anti-Lock Braking System Control

Module for related DTCs and refer to the relevant

DTC index U200D-4B

Control Module Output

Power A - Over

temperature

Actuator FET circuit over

current / over temperature

Refer to electrical wiring diagrams and check the

actuator circuit for low resistance. Repair circuit

faults or install a new actuator as required U2011-11

Motor - Circuit short to

ground

Electric park brake motor

output short to ground

Refer to electrical wiring diagrams and check the

actuator circuit for short to ground. Repair circuit

faults or install a new actuator as required U2011-12

Motor - Circuit short to

battery

Electric park brake motor

output short to power

Refer to electrical wiring diagrams and check the

actuator circuit for short to power. Repair circuit

faults or install a new actuator as required U2011-13 Motor - Circuit open

Electric park brake motor

output open circuit

Refer to electrical wiring diagrams and check the

actuator circuit for open circuit. Repair circuit

faults or install a new actuator as required U3000-47

Control Module -

Watchdog/safety micro

controller failure

Defective ECU

Lost communication with secondary micro

processor, check power and ground connections to

module. Clear DTC, perform battery reset and

retest system. If DTC reoccurs suspect the

Parking Brake control module

Refer to the Warranty Policy and Procedures

manual if a module/component is suspect U3002-81

Vehicle Identification

Number (VIN) - Invalid

serial number

The Park Brake Module has

previously been installed

to another vehicle

Check and install the original, or a new Park Brake

Module

Refer to the Warranty Policy and Procedures

manual if a module/component is suspect U3003-62

Battery Voltage - Signal

compare failure

Power distribution fault

Wiring harness fault

There is a difference of more than 2 volts

between the power supply to the parking brake

module and the battery voltage value broadcast

on CAN. Check other control modules for battery

voltage related DTCs. Refer to the electrical

circuit diagrams and check the power and ground

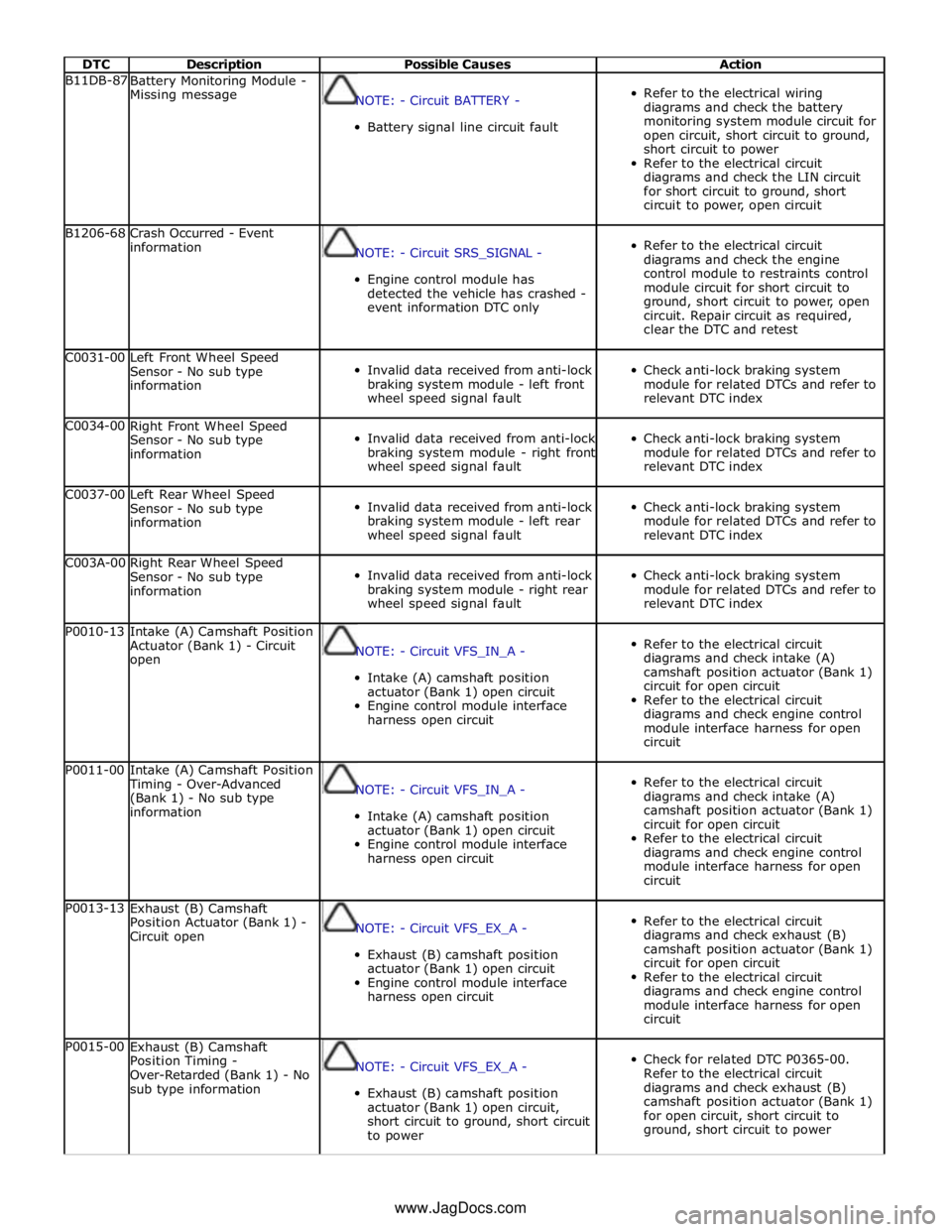

Page 166 of 3039

DTC Description Possible Causes Action B11DB-87

Battery Monitoring Module -

Missing message

NOTE: - Circuit BATTERY -

Battery signal line circuit fault

Refer to the electrical wiring

diagrams and check the battery

monitoring system module circuit for

open circuit, short circuit to ground,

short circuit to power

Refer to the electrical circuit

diagrams and check the LIN circuit

for short circuit to ground, short

circuit to power, open circuit B1206-68

Crash Occurred - Event

information

NOTE: - Circuit SRS_SIGNAL -

Engine control module has

detected the vehicle has crashed -

event information DTC only

Refer to the electrical circuit

diagrams and check the engine

control module to restraints control

module circuit for short circuit to

ground, short circuit to power, open

circuit. Repair circuit as required,

clear the DTC and retest C0031-00

Left Front Wheel Speed

Sensor - No sub type

information

Invalid data received from anti-lock

braking system module - left front

wheel speed signal fault

Check anti-lock braking system

module for related DTCs and refer to

relevant DTC index C0034-00

Right Front Wheel Speed

Sensor - No sub type

information

Invalid data received from anti-lock

braking system module - right front

wheel speed signal fault

Check anti-lock braking system

module for related DTCs and refer to

relevant DTC index C0037-00

Left Rear Wheel Speed

Sensor - No sub type

information

Invalid data received from anti-lock

braking system module - left rear

wheel speed signal fault

Check anti-lock braking system

module for related DTCs and refer to

relevant DTC index C003A-00

Right Rear Wheel Speed

Sensor - No sub type

information

Invalid data received from anti-lock

braking system module - right rear

wheel speed signal fault

Check anti-lock braking system

module for related DTCs and refer to

relevant DTC index P0010-13

Intake (A) Camshaft Position

Actuator (Bank 1) - Circuit

open

NOTE: - Circuit VFS_IN_A -

Intake (A) camshaft position

actuator (Bank 1) open circuit

Engine control module interface

harness open circuit

Refer to the electrical circuit

diagrams and check intake (A)

camshaft position actuator (Bank 1)

circuit for open circuit

Refer to the electrical circuit

diagrams and check engine control

module interface harness for open

circuit P0011-00

Intake (A) Camshaft Position

Timing - Over-Advanced

(Bank 1) - No sub type

information

NOTE: - Circuit VFS_IN_A -

Intake (A) camshaft position

actuator (Bank 1) open circuit

Engine control module interface

harness open circuit

Refer to the electrical circuit

diagrams and check intake (A)

camshaft position actuator (Bank 1)

circuit for open circuit

Refer to the electrical circuit

diagrams and check engine control

module interface harness for open

circuit P0013-13

Exhaust (B) Camshaft

Position Actuator (Bank 1) -

Circuit open

NOTE: - Circuit VFS_EX_A -

Exhaust (B) camshaft position

actuator (Bank 1) open circuit

Engine control module interface

harness open circuit

Refer to the electrical circuit

diagrams and check exhaust (B)

camshaft position actuator (Bank 1)

circuit for open circuit

Refer to the electrical circuit

diagrams and check engine control

module interface harness for open

circuit P0015-00

Exhaust (B) Camshaft

Position Timing -

Over-Retarded (Bank 1) - No

sub type information

NOTE: - Circuit VFS_EX_A -

Exhaust (B) camshaft position

actuator (Bank 1) open circuit,

short circuit to ground, short circuit

to power

Check for related DTC P0365-00.

Refer to the electrical circuit

diagrams and check exhaust (B)

camshaft position actuator (Bank 1)

for open circuit, short circuit to

ground, short circuit to power www.JagDocs.com

Page 167 of 3039

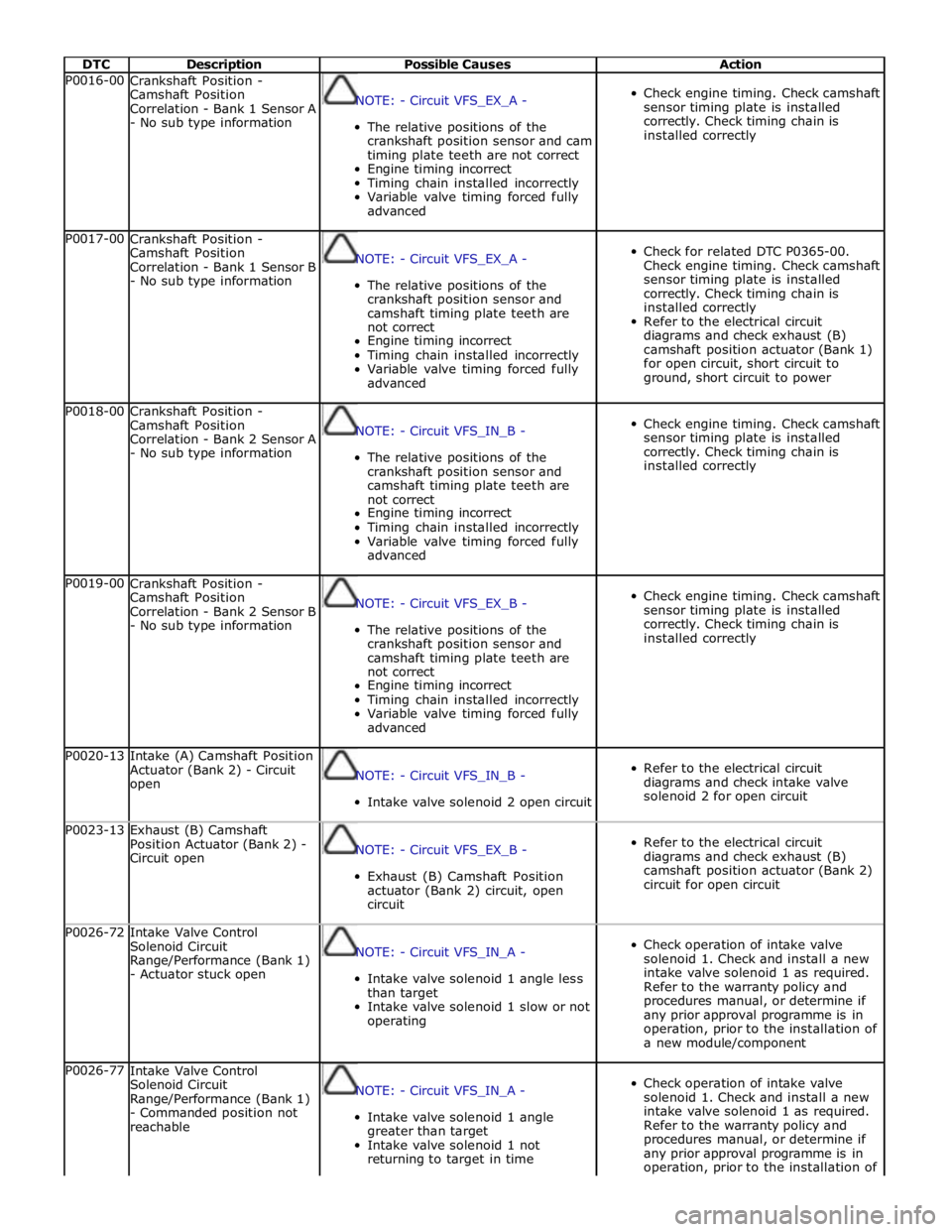

DTC Description Possible Causes Action P0016-00

Crankshaft Position -

Camshaft Position

Correlation - Bank 1 Sensor A

- No sub type information

NOTE: - Circuit VFS_EX_A -

The relative positions of the

crankshaft position sensor and cam

timing plate teeth are not correct

Engine timing incorrect

Timing chain installed incorrectly

Variable valve timing forced fully

advanced

Check engine timing. Check camshaft

sensor timing plate is installed

correctly. Check timing chain is

installed correctly P0017-00

Crankshaft Position -

Camshaft Position

Correlation - Bank 1 Sensor B

- No sub type information

NOTE: - Circuit VFS_EX_A -

The relative positions of the

crankshaft position sensor and

camshaft timing plate teeth are

not correct

Engine timing incorrect

Timing chain installed incorrectly

Variable valve timing forced fully

advanced

Check for related DTC P0365-00.

Check engine timing. Check camshaft

sensor timing plate is installed

correctly. Check timing chain is

installed correctly

Refer to the electrical circuit

diagrams and check exhaust (B)

camshaft position actuator (Bank 1)

for open circuit, short circuit to

ground, short circuit to power P0018-00

Crankshaft Position -

Camshaft Position

Correlation - Bank 2 Sensor A

- No sub type information

NOTE: - Circuit VFS_IN_B -

The relative positions of the

crankshaft position sensor and

camshaft timing plate teeth are

not correct

Engine timing incorrect

Timing chain installed incorrectly

Variable valve timing forced fully

advanced

Check engine timing. Check camshaft

sensor timing plate is installed

correctly. Check timing chain is

installed correctly P0019-00

Crankshaft Position -

Camshaft Position

Correlation - Bank 2 Sensor B

- No sub type information

NOTE: - Circuit VFS_EX_B -

The relative positions of the

crankshaft position sensor and

camshaft timing plate teeth are

not correct

Engine timing incorrect

Timing chain installed incorrectly

Variable valve timing forced fully

advanced

Check engine timing. Check camshaft

sensor timing plate is installed

correctly. Check timing chain is

installed correctly P0020-13

Intake (A) Camshaft Position

Actuator (Bank 2) - Circuit

open

NOTE: - Circuit VFS_IN_B -

Intake valve solenoid 2 open circuit

Refer to the electrical circuit

diagrams and check intake valve

solenoid 2 for open circuit P0023-13

Exhaust (B) Camshaft

Position Actuator (Bank 2) -

Circuit open

NOTE: - Circuit VFS_EX_B -

Exhaust (B) Camshaft Position

actuator (Bank 2) circuit, open

circuit

Refer to the electrical circuit

diagrams and check exhaust (B)

camshaft position actuator (Bank 2)

circuit for open circuit P0026-72

Intake Valve Control

Solenoid Circuit

Range/Performance (Bank 1)

- Actuator stuck open

NOTE: - Circuit VFS_IN_A -

Intake valve solenoid 1 angle less

than target

Intake valve solenoid 1 slow or not

operating

Check operation of intake valve

solenoid 1. Check and install a new

intake valve solenoid 1 as required.

Refer to the warranty policy and

procedures manual, or determine if

any prior approval programme is in

operation, prior to the installation of

a new module/component P0026-77

Intake Valve Control

Solenoid Circuit

Range/Performance (Bank 1)

- Commanded position not

reachable

NOTE: - Circuit VFS_IN_A -

Intake valve solenoid 1 angle

greater than target

Intake valve solenoid 1 not

returning to target in time

Check operation of intake valve

solenoid 1. Check and install a new

intake valve solenoid 1 as required.

Refer to the warranty policy and

procedures manual, or determine if

any prior approval programme is in

operation, prior to the installation of

Page 168 of 3039

DTC Description Possible Causes Action Intake valve solenoid 1 stuck

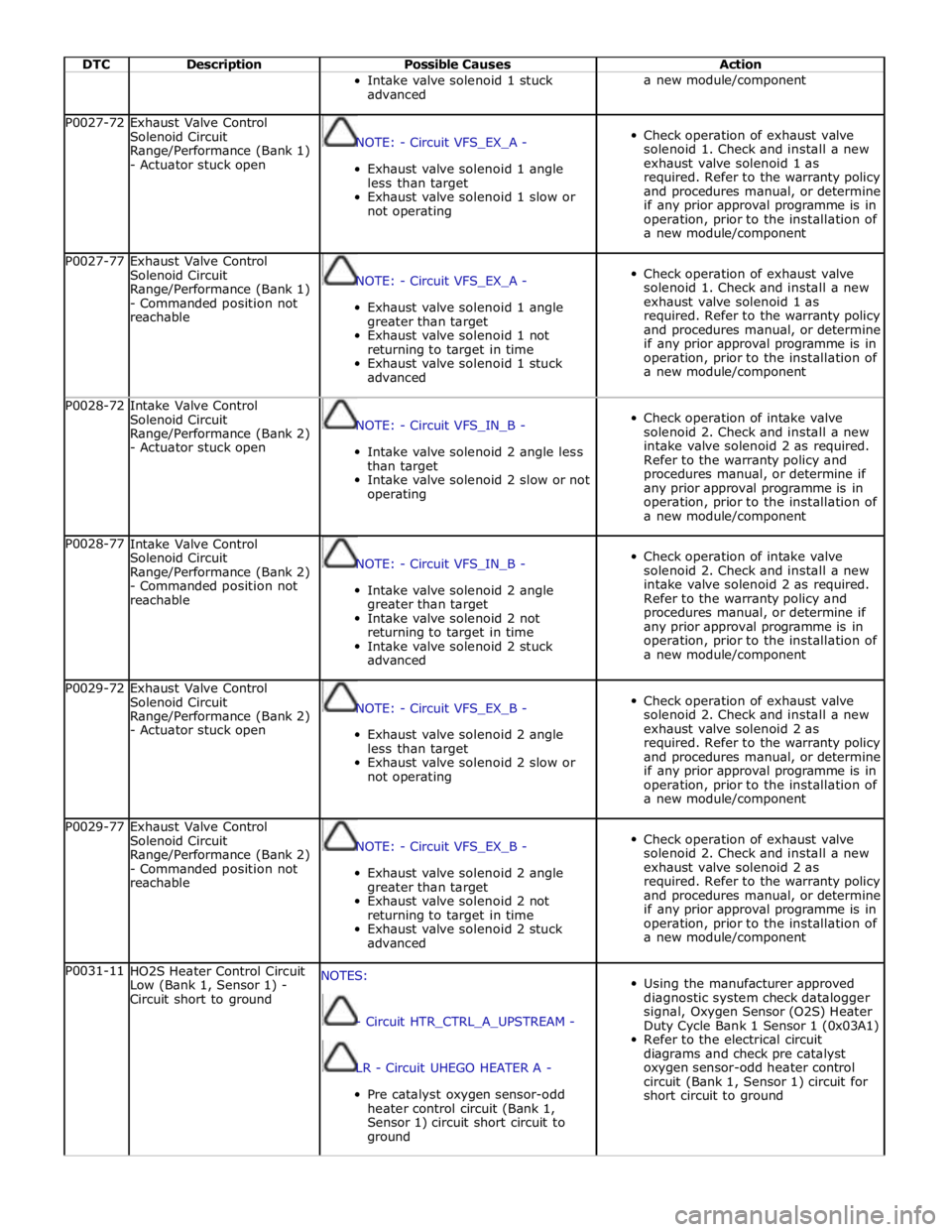

advanced a new module/component P0027-72

Exhaust Valve Control

Solenoid Circuit

Range/Performance (Bank 1)

- Actuator stuck open

NOTE: - Circuit VFS_EX_A -

Exhaust valve solenoid 1 angle

less than target

Exhaust valve solenoid 1 slow or

not operating

Check operation of exhaust valve

solenoid 1. Check and install a new

exhaust valve solenoid 1 as

required. Refer to the warranty policy

and procedures manual, or determine

if any prior approval programme is in

operation, prior to the installation of

a new module/component P0027-77

Exhaust Valve Control

Solenoid Circuit

Range/Performance (Bank 1)

- Commanded position not

reachable

NOTE: - Circuit VFS_EX_A -

Exhaust valve solenoid 1 angle

greater than target

Exhaust valve solenoid 1 not

returning to target in time

Exhaust valve solenoid 1 stuck

advanced

Check operation of exhaust valve

solenoid 1. Check and install a new

exhaust valve solenoid 1 as

required. Refer to the warranty policy

and procedures manual, or determine

if any prior approval programme is in

operation, prior to the installation of

a new module/component P0028-72

Intake Valve Control

Solenoid Circuit

Range/Performance (Bank 2)

- Actuator stuck open

NOTE: - Circuit VFS_IN_B -

Intake valve solenoid 2 angle less

than target

Intake valve solenoid 2 slow or not

operating

Check operation of intake valve

solenoid 2. Check and install a new

intake valve solenoid 2 as required.

Refer to the warranty policy and

procedures manual, or determine if

any prior approval programme is in

operation, prior to the installation of

a new module/component P0028-77

Intake Valve Control

Solenoid Circuit

Range/Performance (Bank 2)

- Commanded position not

reachable

NOTE: - Circuit VFS_IN_B -

Intake valve solenoid 2 angle

greater than target

Intake valve solenoid 2 not

returning to target in time

Intake valve solenoid 2 stuck

advanced

Check operation of intake valve

solenoid 2. Check and install a new

intake valve solenoid 2 as required.

Refer to the warranty policy and

procedures manual, or determine if

any prior approval programme is in

operation, prior to the installation of

a new module/component P0029-72

Exhaust Valve Control

Solenoid Circuit

Range/Performance (Bank 2)

- Actuator stuck open

NOTE: - Circuit VFS_EX_B -

Exhaust valve solenoid 2 angle

less than target

Exhaust valve solenoid 2 slow or

not operating

Check operation of exhaust valve

solenoid 2. Check and install a new

exhaust valve solenoid 2 as

required. Refer to the warranty policy

and procedures manual, or determine

if any prior approval programme is in

operation, prior to the installation of

a new module/component P0029-77

Exhaust Valve Control

Solenoid Circuit

Range/Performance (Bank 2)

- Commanded position not

reachable

NOTE: - Circuit VFS_EX_B -

Exhaust valve solenoid 2 angle

greater than target

Exhaust valve solenoid 2 not

returning to target in time

Exhaust valve solenoid 2 stuck

advanced

Check operation of exhaust valve

solenoid 2. Check and install a new

exhaust valve solenoid 2 as

required. Refer to the warranty policy

and procedures manual, or determine

if any prior approval programme is in

operation, prior to the installation of

a new module/component P0031-11

HO2S Heater Control Circuit

Low (Bank 1, Sensor 1) -

Circuit short to ground NOTES:

- Circuit HTR_CTRL_A_UPSTREAM -

LR - Circuit UHEGO HEATER A -

Pre catalyst oxygen sensor-odd

heater control circuit (Bank 1,

Sensor 1) circuit short circuit to

ground

Using the manufacturer approved

diagnostic system check datalogger

signal, Oxygen Sensor (O2S) Heater

Duty Cycle Bank 1 Sensor 1 (0x03A1)

Refer to the electrical circuit

diagrams and check pre catalyst

oxygen sensor-odd heater control

circuit (Bank 1, Sensor 1) circuit for

short circuit to ground

Page 212 of 3039

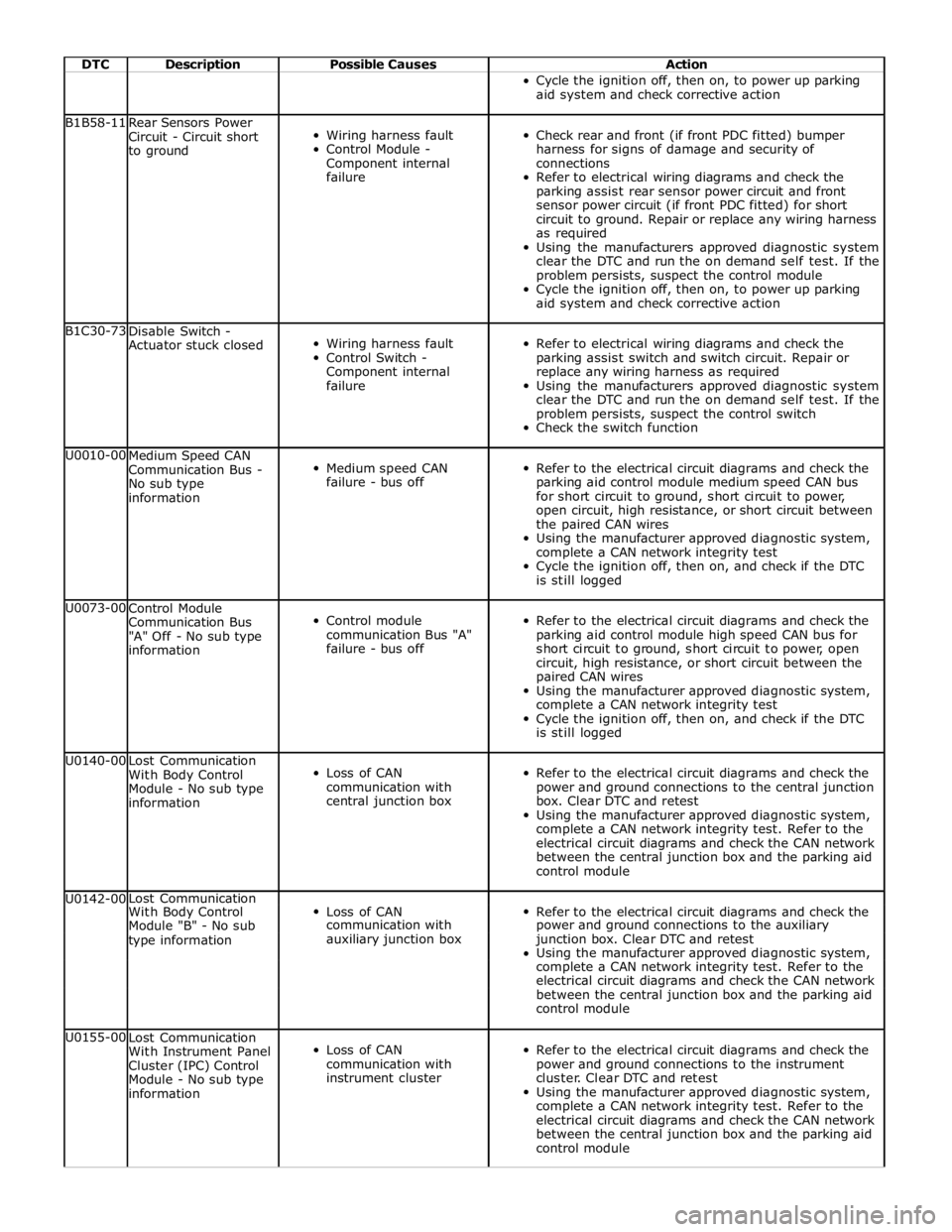

DTC Description Possible Causes Action Cycle the ignition off, then on, to power up parking

aid system and check corrective action B1B58-11

Rear Sensors Power

Circuit - Circuit short

to ground

Wiring harness fault

Control Module -

Component internal

failure

Check rear and front (if front PDC fitted) bumper

harness for signs of damage and security of

connections

Refer to electrical wiring diagrams and check the

parking assist rear sensor power circuit and front

sensor power circuit (if front PDC fitted) for short

circuit to ground. Repair or replace any wiring harness

as required

Using the manufacturers approved diagnostic system

clear the DTC and run the on demand self test. If the

problem persists, suspect the control module

Cycle the ignition off, then on, to power up parking

aid system and check corrective action B1C30-73

Disable Switch -

Actuator stuck closed

Wiring harness fault

Control Switch -

Component internal

failure

Refer to electrical wiring diagrams and check the

parking assist switch and switch circuit. Repair or

replace any wiring harness as required

Using the manufacturers approved diagnostic system

clear the DTC and run the on demand self test. If the

problem persists, suspect the control switch

Check the switch function U0010-00

Medium Speed CAN

Communication Bus -

No sub type

information

Medium speed CAN

failure - bus off

Refer to the electrical circuit diagrams and check the

parking aid control module medium speed CAN bus

for short circuit to ground, short circuit to power,

open circuit, high resistance, or short circuit between

the paired CAN wires

Using the manufacturer approved diagnostic system,

complete a CAN network integrity test

Cycle the ignition off, then on, and check if the DTC

is still logged U0073-00

Control Module

Communication Bus

"A" Off - No sub type

information

Control module

communication Bus "A"

failure - bus off

Refer to the electrical circuit diagrams and check the

parking aid control module high speed CAN bus for

short circuit to ground, short circuit to power, open

circuit, high resistance, or short circuit between the

paired CAN wires

Using the manufacturer approved diagnostic system,

complete a CAN network integrity test

Cycle the ignition off, then on, and check if the DTC

is still logged U0140-00

Lost Communication

With Body Control

Module - No sub type

information

Loss of CAN

communication with

central junction box

Refer to the electrical circuit diagrams and check the

power and ground connections to the central junction

box. Clear DTC and retest

Using the manufacturer approved diagnostic system,

complete a CAN network integrity test. Refer to the

electrical circuit diagrams and check the CAN network

between the central junction box and the parking aid

control module U0142-00 Lost Communication

Loss of CAN

Refer to the electrical circuit diagrams and check the With Body Control Module "B" - No sub communication with power and ground connections to the auxiliary type information auxiliary junction box junction box. Clear DTC and retest Using the manufacturer approved diagnostic system, complete a CAN network integrity test. Refer to the electrical circuit diagrams and check the CAN network between the central junction box and the parking aid control module U0155-00

Lost Communication

With Instrument Panel

Cluster (IPC) Control

Module - No sub type

information

Loss of CAN

communication with

instrument cluster

Refer to the electrical circuit diagrams and check the

power and ground connections to the instrument

cluster. Clear DTC and retest

Using the manufacturer approved diagnostic system,

complete a CAN network integrity test. Refer to the

electrical circuit diagrams and check the CAN network

between the central junction box and the parking aid

control module

Page 216 of 3039

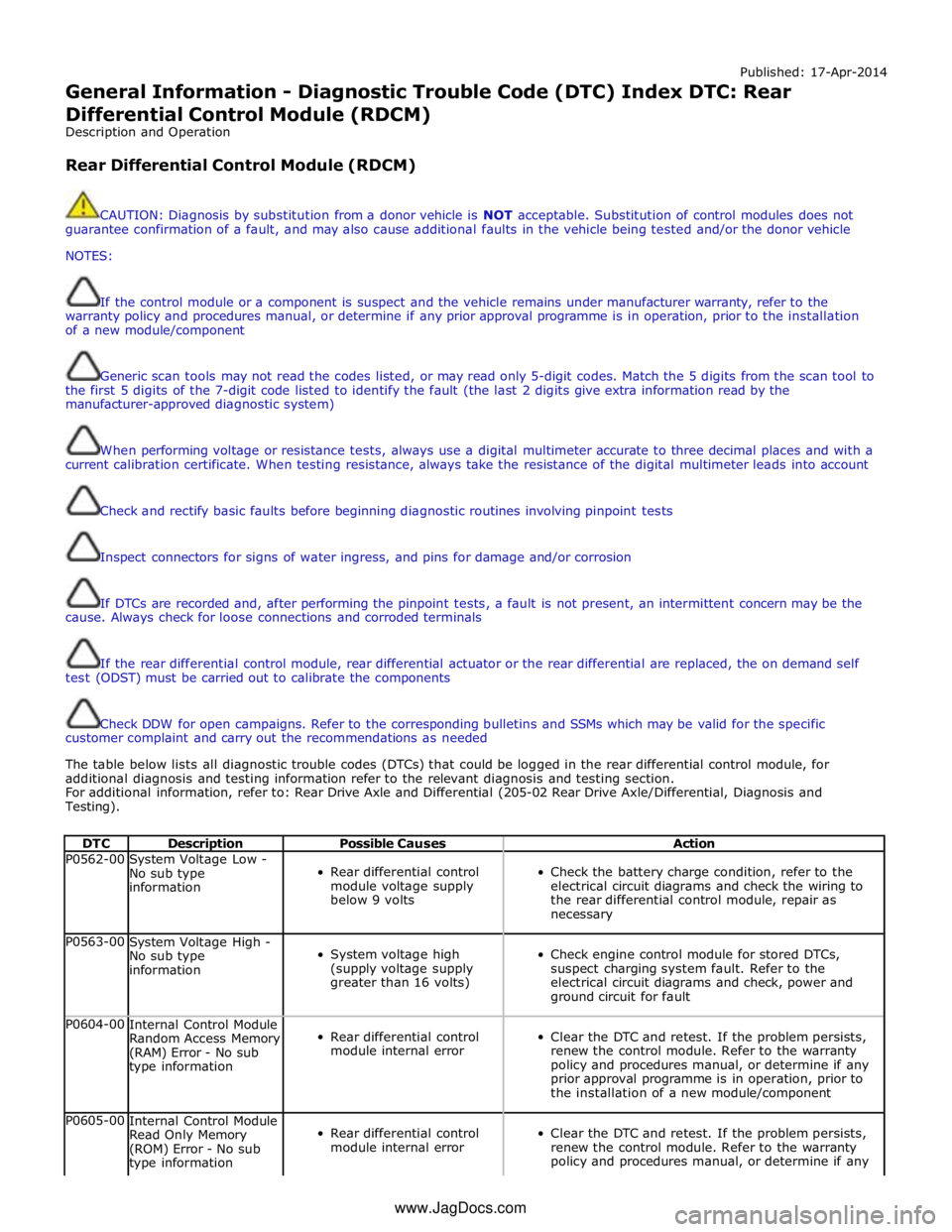

Published: 17-Apr-2014

General Information - Diagnostic Trouble Code (DTC) Index DTC: Rear

Differential Control Module (RDCM)

Description and Operation

Rear Differential Control Module (RDCM)

CAUTION: Diagnosis by substitution from a donor vehicle is NOT acceptable. Substitution of control modules does not

guarantee confirmation of a fault, and may also cause additional faults in the vehicle being tested and/or the donor vehicle

NOTES:

If the control module or a component is suspect and the vehicle remains under manufacturer warranty, refer to the

warranty policy and procedures manual, or determine if any prior approval programme is in operation, prior to the installation

of a new module/component

Generic scan tools may not read the codes listed, or may read only 5-digit codes. Match the 5 digits from the scan tool to

the first 5 digits of the 7-digit code listed to identify the fault (the last 2 digits give extra information read by the

manufacturer-approved diagnostic system)

When performing voltage or resistance tests, always use a digital multimeter accurate to three decimal places and with a

current calibration certificate. When testing resistance, always take the resistance of the digital multimeter leads into account

Check and rectify basic faults before beginning diagnostic routines involving pinpoint tests

Inspect connectors for signs of water ingress, and pins for damage and/or corrosion

If DTCs are recorded and, after performing the pinpoint tests, a fault is not present, an intermittent concern may be the

cause. Always check for loose connections and corroded terminals

If the rear differential control module, rear differential actuator or the rear differential are replaced, the on demand self

test (ODST) must be carried out to calibrate the components

Check DDW for open campaigns. Refer to the corresponding bulletins and SSMs which may be valid for the specific

customer complaint and carry out the recommendations as needed

The table below lists all diagnostic trouble codes (DTCs) that could be logged in the rear differential control module, for

additional diagnosis and testing information refer to the relevant diagnosis and testing section.

For additional information, refer to: Rear Drive Axle and Differential (205-02 Rear Drive Axle/Differential, Diagnosis and

Testing).

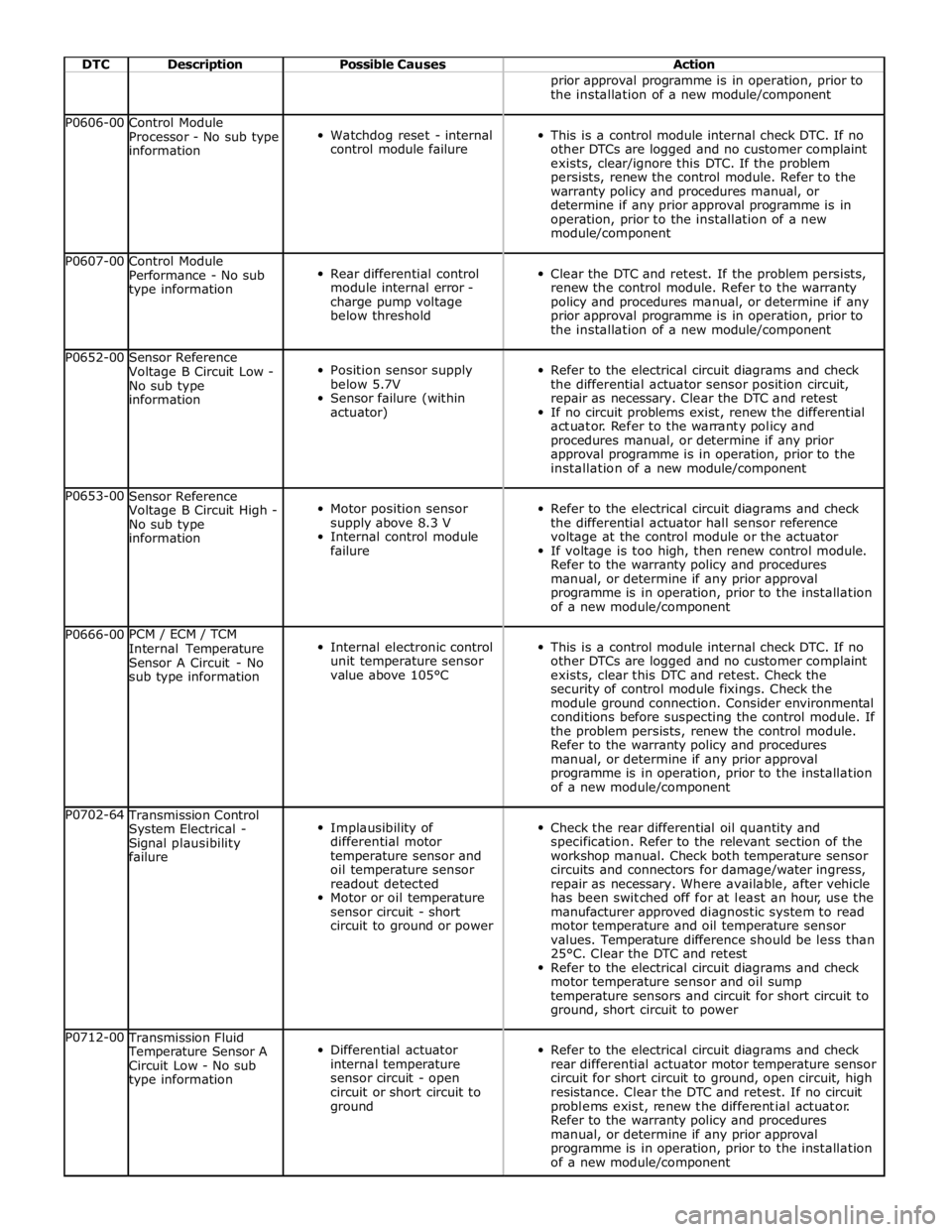

DTC Description Possible Causes Action P0562-00

System Voltage Low -

No sub type

information

Rear differential control

module voltage supply

below 9 volts

Check the battery charge condition, refer to the

electrical circuit diagrams and check the wiring to

the rear differential control module, repair as

necessary P0563-00

System Voltage High -

No sub type

information

System voltage high

(supply voltage supply

greater than 16 volts)

Check engine control module for stored DTCs,

suspect charging system fault. Refer to the

electrical circuit diagrams and check, power and

ground circuit for fault P0604-00

Internal Control Module

Random Access Memory

(RAM) Error - No sub

type information

Rear differential control

module internal error

Clear the DTC and retest. If the problem persists,

renew the control module. Refer to the warranty

policy and procedures manual, or determine if any

prior approval programme is in operation, prior to

the installation of a new module/component P0605-00

Internal Control Module

Read Only Memory

(ROM) Error - No sub

type information

Rear differential control

module internal error

Clear the DTC and retest. If the problem persists,

renew the control module. Refer to the warranty

policy and procedures manual, or determine if any www.JagDocs.com

Page 217 of 3039

DTC Description Possible Causes Action prior approval programme is in operation, prior to

the installation of a new module/component P0606-00

Control Module

Processor - No sub type

information

Watchdog reset - internal

control module failure

This is a control module internal check DTC. If no

other DTCs are logged and no customer complaint

exists, clear/ignore this DTC. If the problem

persists, renew the control module. Refer to the

warranty policy and procedures manual, or

determine if any prior approval programme is in

operation, prior to the installation of a new

module/component P0607-00

Control Module

Performance - No sub

type information

Rear differential control

module internal error -

charge pump voltage

below threshold

Clear the DTC and retest. If the problem persists,

renew the control module. Refer to the warranty

policy and procedures manual, or determine if any

prior approval programme is in operation, prior to

the installation of a new module/component P0652-00

Sensor Reference

Voltage B Circuit Low -

No sub type

information

Position sensor supply

below 5.7V

Sensor failure (within

actuator)

Refer to the electrical circuit diagrams and check

the differential actuator sensor position circuit,

repair as necessary. Clear the DTC and retest

If no circuit problems exist, renew the differential

actuator. Refer to the warranty policy and

procedures manual, or determine if any prior

approval programme is in operation, prior to the

installation of a new module/component P0653-00

Sensor Reference

Voltage B Circuit High -

No sub type

information

Motor position sensor

supply above 8.3 V

Internal control module

failure

Refer to the electrical circuit diagrams and check

the differential actuator hall sensor reference

voltage at the control module or the actuator

If voltage is too high, then renew control module.

Refer to the warranty policy and procedures

manual, or determine if any prior approval

programme is in operation, prior to the installation

of a new module/component P0666-00 PCM / ECM / TCM

Internal Temperature

Sensor A Circuit - No

sub type information

Internal electronic control

unit temperature sensor

value above 105°C

This is a control module internal check DTC. If no

other DTCs are logged and no customer complaint

exists, clear this DTC and retest. Check the

security of control module fixings. Check the

module ground connection. Consider environmental

conditions before suspecting the control module. If

the problem persists, renew the control module.

Refer to the warranty policy and procedures

manual, or determine if any prior approval

programme is in operation, prior to the installation

of a new module/component P0702-64 Transmission Control

System Electrical -

Signal plausibility

failure

Implausibility of

differential motor

temperature sensor and

oil temperature sensor

readout detected

Motor or oil temperature

sensor circuit - short

circuit to ground or power

Check the rear differential oil quantity and

specification. Refer to the relevant section of the

workshop manual. Check both temperature sensor

circuits and connectors for damage/water ingress,

repair as necessary. Where available, after vehicle

has been switched off for at least an hour, use the

manufacturer approved diagnostic system to read

motor temperature and oil temperature sensor

values. Temperature difference should be less than

25°C. Clear the DTC and retest

Refer to the electrical circuit diagrams and check

motor temperature sensor and oil sump

temperature sensors and circuit for short circuit to

ground, short circuit to power P0712-00 Transmission Fluid Temperature Sensor A

Circuit Low - No sub

type information

Differential actuator

internal temperature

sensor circuit - open

circuit or short circuit to

ground

Refer to the electrical circuit diagrams and check

rear differential actuator motor temperature sensor

circuit for short circuit to ground, open circuit, high

resistance. Clear the DTC and retest. If no circuit

problems exist, renew the differential actuator.

Refer to the warranty policy and procedures

manual, or determine if any prior approval

programme is in operation, prior to the installation

of a new module/component

Page 222 of 3039

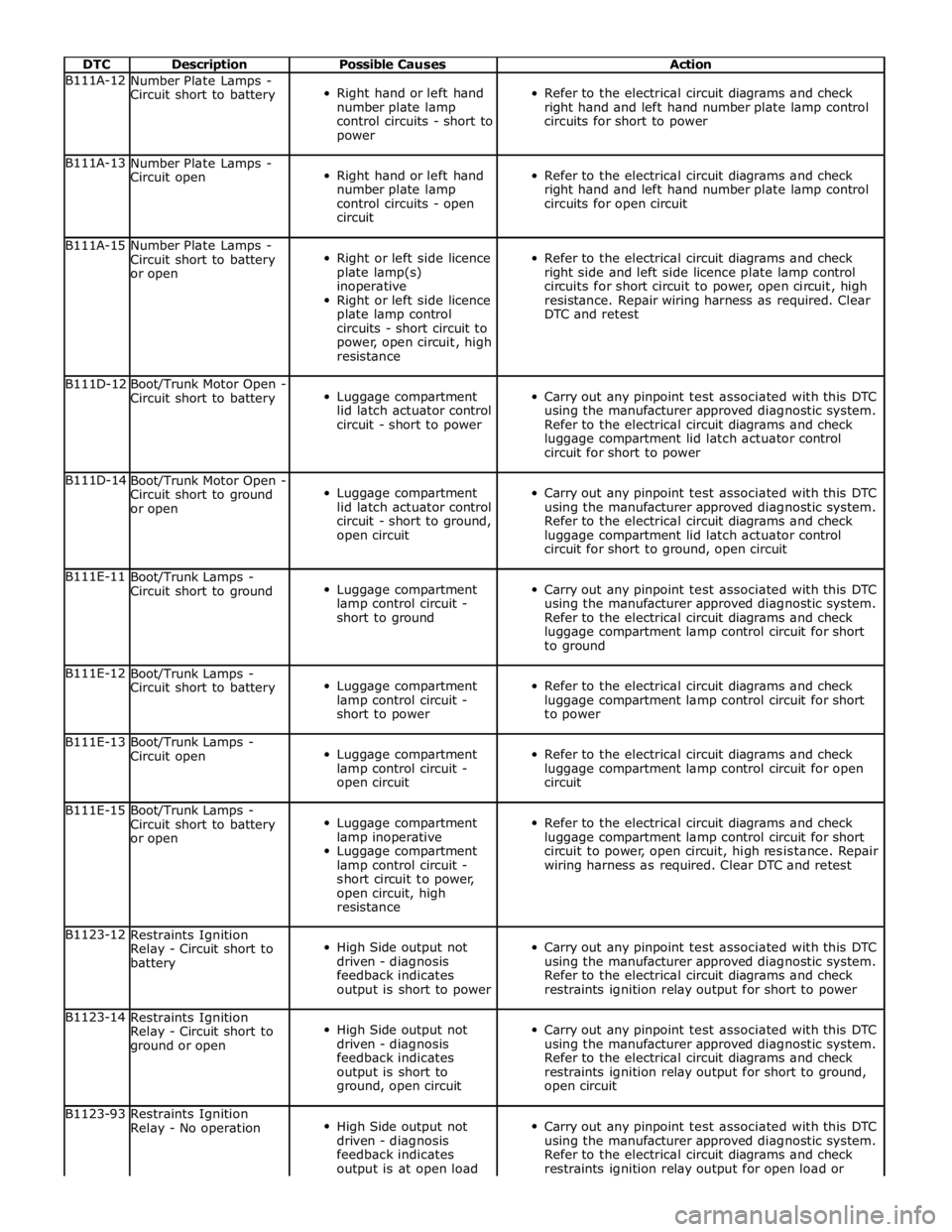

DTC Description Possible Causes Action B111A-12

Number Plate Lamps -

Circuit short to battery

Right hand or left hand

number plate lamp

control circuits - short to

power

Refer to the electrical circuit diagrams and check

right hand and left hand number plate lamp control

circuits for short to power B111A-13

Number Plate Lamps -

Circuit open

Right hand or left hand

number plate lamp

control circuits - open

circuit

Refer to the electrical circuit diagrams and check

right hand and left hand number plate lamp control

circuits for open circuit B111A-15

Number Plate Lamps -

Circuit short to battery

or open

Right or left side licence

plate lamp(s)

inoperative

Right or left side licence

plate lamp control

circuits - short circuit to

power, open circuit, high

resistance

Refer to the electrical circuit diagrams and check

right side and left side licence plate lamp control

circuits for short circuit to power, open circuit, high

resistance. Repair wiring harness as required. Clear

DTC and retest B111D-12

Boot/Trunk Motor Open -

Circuit short to battery

Luggage compartment

lid latch actuator control

circuit - short to power

Carry out any pinpoint test associated with this DTC

using the manufacturer approved diagnostic system.

Refer to the electrical circuit diagrams and check

luggage compartment lid latch actuator control

circuit for short to power B111D-14

Boot/Trunk Motor Open -

Circuit short to ground

or open

Luggage compartment

lid latch actuator control

circuit - short to ground,

open circuit

Carry out any pinpoint test associated with this DTC

using the manufacturer approved diagnostic system.

Refer to the electrical circuit diagrams and check

luggage compartment lid latch actuator control

circuit for short to ground, open circuit B111E-11

Boot/Trunk Lamps -

Circuit short to ground

Luggage compartment

lamp control circuit -

short to ground

Carry out any pinpoint test associated with this DTC

using the manufacturer approved diagnostic system.

Refer to the electrical circuit diagrams and check

luggage compartment lamp control circuit for short

to ground B111E-12

Boot/Trunk Lamps -

Circuit short to battery

Luggage compartment

lamp control circuit -

short to power

Refer to the electrical circuit diagrams and check

luggage compartment lamp control circuit for short

to power B111E-13

Boot/Trunk Lamps -

Circuit open

Luggage compartment

lamp control circuit -

open circuit

Refer to the electrical circuit diagrams and check

luggage compartment lamp control circuit for open

circuit B111E-15

Boot/Trunk Lamps -

Circuit short to battery

or open

Luggage compartment

lamp inoperative

Luggage compartment

lamp control circuit -

short circuit to power,

open circuit, high

resistance

Refer to the electrical circuit diagrams and check

luggage compartment lamp control circuit for short

circuit to power, open circuit, high resistance. Repair

wiring harness as required. Clear DTC and retest B1123-12

Restraints Ignition

Relay - Circuit short to

battery

High Side output not

driven - diagnosis

feedback indicates

output is short to power

Carry out any pinpoint test associated with this DTC

using the manufacturer approved diagnostic system.

Refer to the electrical circuit diagrams and check

restraints ignition relay output for short to power B1123-14

Restraints Ignition

Relay - Circuit short to

ground or open

High Side output not

driven - diagnosis

feedback indicates

output is short to

ground, open circuit

Carry out any pinpoint test associated with this DTC

using the manufacturer approved diagnostic system.

Refer to the electrical circuit diagrams and check

restraints ignition relay output for short to ground,

open circuit B1123-93

Restraints Ignition

Relay - No operation

High Side output not

driven - diagnosis

feedback indicates

output is at open load

Carry out any pinpoint test associated with this DTC

using the manufacturer approved diagnostic system.

Refer to the electrical circuit diagrams and check

restraints ignition relay output for open load or