Actuator JAGUAR XFR 2010 1.G Repair Manual

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 2010, Model line: XFR, Model: JAGUAR XFR 2010 1.GPages: 3039, PDF Size: 58.49 MB

Page 1438 of 3039

DTC Description Possible Cause Action P061B-02

Internal Control Module Torque Calculation

Performance - general signal

failure

Transmission control

module - positive torque

signal not valid Suspect the Transmission control module. Install a

new Transmission control module as required, refer to

the new module/component installation note at the

top of the DTC Index P061B-26

Internal Control Module Torque Calculation

Performance - signal rate of

change below threshold

Transmission control

module positive torque

signal not valid Suspect the Transmission control module. Install a

new Transmission control module as required, refer to

the new module/component installation note at the

top of the DTC Index P062F-04

Internal Control Module

EEPROM Error - System

Internal Failures

EEPROM communication

error Suspect the Transmission control module. Install a

new Transmission control module as required, refer to

the new module/component installation note at the top of the DTC Index P0642-21

Sensor Reference Voltage A

Circuit Low - signal

amplitude < minimum

Sensor supply voltage

fault low Suspect the Transmission control module. Install a

new Transmission control module as required, refer to

the new module/component installation note at the top of the DTC Index P0643-22

Sensor Reference Voltage A

Circuit High - signal

amplitude > maximum

Sensor supply voltage

fault high Suspect the Transmission control module. Install a

new Transmission control module as required, refer to

the new module/component installation note at the top of the DTC Index P0657-13

Actuator Supply Voltage A

Circuit / Open - Circuit Open

Actuator supply (pressure

control valves etc) Open

Circuit Suspect the Transmission control module. Install a

new Transmission control module as required, refer to

the new module/component installation note at the

top of the DTC Index P0657-1C

Actuator Supply Voltage A

Circuit / Open - Circuit

voltage out of range

Actuator supply (pressure

control valves etc)

voltage plausibility fault Refer to electrical Circuit diagrams and check

Transmission control module connector for signs of

water ingress or damage, check pin 7 for Short to

Power or Ground (should NOT be connected and

harness terminal should have a bung fitted). If no

fault identified, suspect the Transmission control

module. Check and install a new Transmission control

module as required, refer to the new

module/component installation note at the top of the

DTC Index P0658-11

Actuator Supply Voltage A

Circuit Low - Circuit Short to

Ground

Actuator supply (pressure

control valves etc)

voltage Short to Ground Suspect the Transmission control module. Install a

new Transmission control module as required, refer to

the new module/component installation note at the

top of the DTC Index P0659-12

Actuator Supply Voltage A

Circuit High - Circuit Short to

Battery

Actuator supply (pressure

control valves etc)

voltage Short to Power Suspect the Transmission control module. Install a

new Transmission control module as required, refer to

the new module/component installation note at the

top of the DTC Index P0667-01 PCM / Engine control module / Transmission control

module Internal Temperature

Sensor A Range/Performance

- General Electrical Failure

General electrical failure Suspect the Transmission control module. Install a

new Transmission control module as required, refer to

the new module/component installation note at the

top of the DTC Index P0667-04 PCM / Engine control module / Transmission control

module Internal Temperature

Sensor A Range/Performance

- System Internal Failures

Internal Electronic Failure Suspect the Transmission control module. Install a

new Transmission control module as required, refer to

the new module/component installation note at the

top of the DTC Index P0667-49 PCM / Engine control module / Transmission control

module Internal Temperature

Sensor A Range/Performance

- internal electronic failure

Internal electronic failure Suspect the Transmission control module. Install a

new Transmission control module as required, refer to

the new module/component installation note at the

top of the DTC Index P0700-02 Transmission Control System

(MIL Request) - General signal failure

General Signal failure Clear DTC, Road test and re-test, Read DTCs and

Investigate as required P0700-22 Transmission Control System

(MIL Request) - signal

amplitude > maximum

Double fault from

monitoring of internal

power supply and

pressure

regulator/solenoid

control software If any of the following DTCs are also present;

P074013, P096712, P273912, P273012, P272112,

P096312, P276312, P097112, suspect the Transmission

control module, check and install a new Transmission

control module as required, refer to the new

module/component installation note at the top of the

DTC Index P0700-75 Transmission Control System

(MIL Request) - Emergency

Position Not Reachable

Emergency Position Not

Reachable Clear DTC, Road test and re-test, Read DTCs and

investigate as required

Page 1440 of 3039

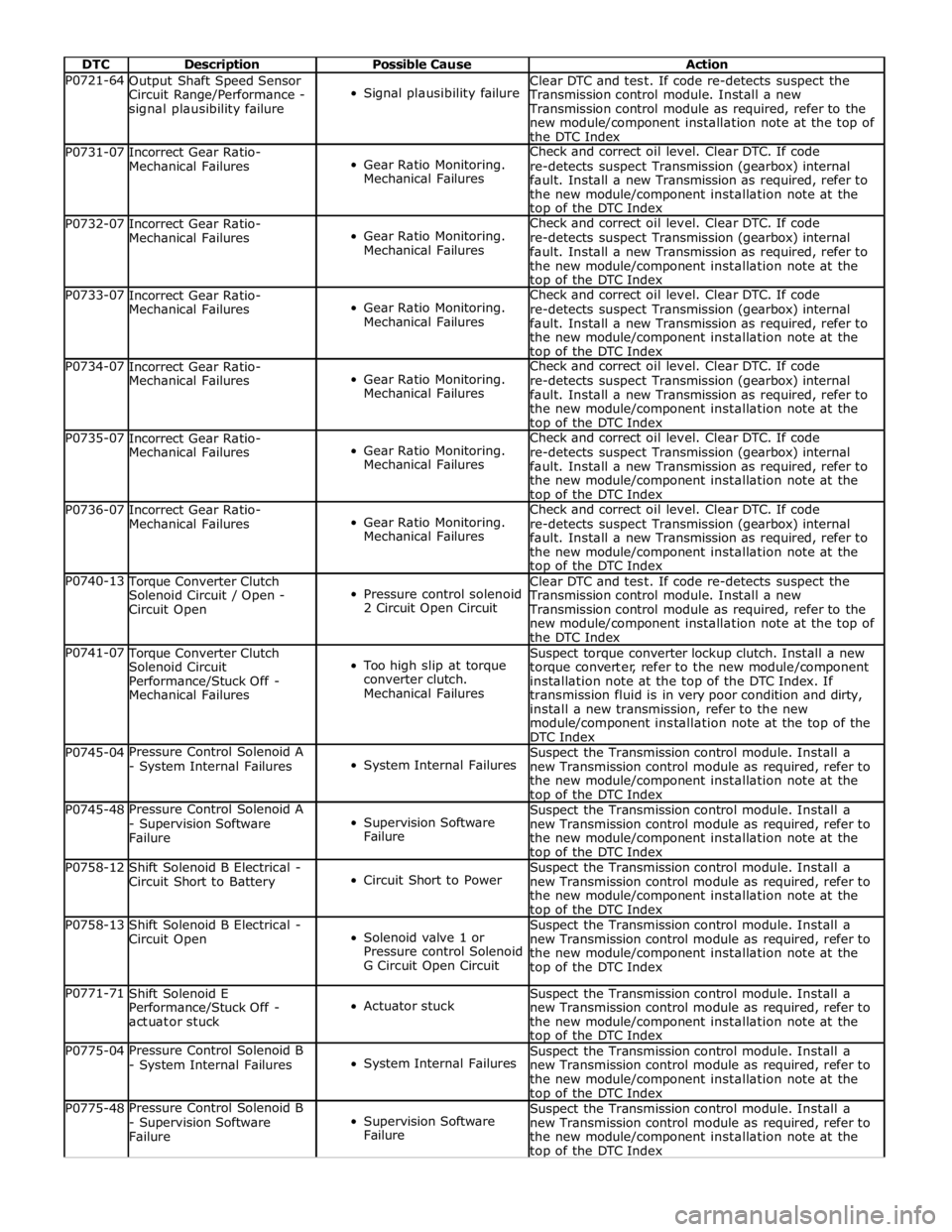

DTC Description Possible Cause Action P0721-64

Output Shaft Speed Sensor

Circuit Range/Performance -

signal plausibility failure

Signal plausibility failure Clear DTC and test. If code re-detects suspect the

Transmission control module. Install a new

Transmission control module as required, refer to the

new module/component installation note at the top of

the DTC Index P0731-07

Incorrect Gear Ratio-

Mechanical Failures

Gear Ratio Monitoring.

Mechanical Failures Check and correct oil level. Clear DTC. If code

re-detects suspect Transmission (gearbox) internal

fault. Install a new Transmission as required, refer to

the new module/component installation note at the top of the DTC Index P0732-07

Incorrect Gear Ratio-

Mechanical Failures

Gear Ratio Monitoring.

Mechanical Failures Check and correct oil level. Clear DTC. If code

re-detects suspect Transmission (gearbox) internal

fault. Install a new Transmission as required, refer to

the new module/component installation note at the top of the DTC Index P0733-07

Incorrect Gear Ratio-

Mechanical Failures

Gear Ratio Monitoring.

Mechanical Failures Check and correct oil level. Clear DTC. If code

re-detects suspect Transmission (gearbox) internal

fault. Install a new Transmission as required, refer to

the new module/component installation note at the top of the DTC Index P0734-07

Incorrect Gear Ratio-

Mechanical Failures

Gear Ratio Monitoring.

Mechanical Failures Check and correct oil level. Clear DTC. If code

re-detects suspect Transmission (gearbox) internal

fault. Install a new Transmission as required, refer to

the new module/component installation note at the top of the DTC Index P0735-07

Incorrect Gear Ratio-

Mechanical Failures

Gear Ratio Monitoring.

Mechanical Failures Check and correct oil level. Clear DTC. If code

re-detects suspect Transmission (gearbox) internal

fault. Install a new Transmission as required, refer to

the new module/component installation note at the top of the DTC Index P0736-07

Incorrect Gear Ratio-

Mechanical Failures

Gear Ratio Monitoring.

Mechanical Failures Check and correct oil level. Clear DTC. If code

re-detects suspect Transmission (gearbox) internal

fault. Install a new Transmission as required, refer to

the new module/component installation note at the top of the DTC Index P0740-13 Torque Converter Clutch

Solenoid Circuit / Open -

Circuit Open

Pressure control solenoid

2 Circuit Open Circuit Clear DTC and test. If code re-detects suspect the

Transmission control module. Install a new

Transmission control module as required, refer to the

new module/component installation note at the top of

the DTC Index P0741-07 Torque Converter Clutch

Solenoid Circuit

Performance/Stuck Off -

Mechanical Failures

Too high slip at torque

converter clutch.

Mechanical Failures Suspect torque converter lockup clutch. Install a new

torque converter, refer to the new module/component

installation note at the top of the DTC Index. If

transmission fluid is in very poor condition and dirty,

install a new transmission, refer to the new

module/component installation note at the top of the

DTC Index P0745-04 Pressure Control Solenoid A

- System Internal Failures

System Internal Failures Suspect the Transmission control module. Install a

new Transmission control module as required, refer to

the new module/component installation note at the top of the DTC Index P0745-48 Pressure Control Solenoid A

- Supervision Software

Failure

Supervision Software

Failure Suspect the Transmission control module. Install a

new Transmission control module as required, refer to

the new module/component installation note at the top of the DTC Index P0758-12

Shift Solenoid B Electrical -

Circuit Short to Battery

Circuit Short to Power Suspect the Transmission control module. Install a

new Transmission control module as required, refer to

the new module/component installation note at the top of the DTC Index P0758-13

Shift Solenoid B Electrical -

Circuit Open

Solenoid valve 1 or

Pressure control Solenoid

G Circuit Open Circuit Suspect the Transmission control module. Install a

new Transmission control module as required, refer to

the new module/component installation note at the

top of the DTC Index P0771-71

Shift Solenoid E

Performance/Stuck Off -

actuator stuck

Actuator stuck Suspect the Transmission control module. Install a

new Transmission control module as required, refer to

the new module/component installation note at the top of the DTC Index P0775-04 Pressure Control Solenoid B

- System Internal Failures

System Internal Failures Suspect the Transmission control module. Install a

new Transmission control module as required, refer to

the new module/component installation note at the top of the DTC Index P0775-48 Pressure Control Solenoid B

- Supervision Software

Failure

Supervision Software

Failure Suspect the Transmission control module. Install a

new Transmission control module as required, refer to

the new module/component installation note at the top of the DTC Index

Page 1443 of 3039

DTC Description Possible Cause Action P0967-12

Pressure Control Solenoid B

Control Circuit High - Circuit

Short to Battery

Pressure control solenoid

2 Circuit Short to Power Suspect the Transmission control module. Install a

new Transmission control module as required, refer to

the new module/component installation note at the top of the DTC Index P0968-14

Pressure Control Solenoid C

Control Circuit / Open -

Circuit Short to Ground or

Open

Pressure control solenoid

3 Circuit Short to Ground

or Open Circuit Suspect the Transmission control module. Install a

new Transmission control module as required, refer to

the new module/component installation note at the

top of the DTC Index P0970-11

Pressure Control Solenoid C

Control Circuit Low - Circuit

Short to Ground

Pressure control solenoid

3 Circuit Short to Ground Suspect the Transmission control module. Install a

new Transmission control module as required, refer to

the new module/component installation note at the top of the DTC Index P0971-12

Pressure Control Solenoid C

Control Circuit High - Circuit

Short to Battery

Pressure control solenoid

3 Circuit Short to Power Suspect the Transmission control module. Install a

new Transmission control module as required, refer to

the new module/component installation note at the top of the DTC Index P0972-22

Shift Solenoid A Control

Circuit Range/Performance -

signal amplitude >

maximum

Pressure control solenoid

1 current too large Suspect the Transmission control module. Install a

new Transmission control module as required, refer to

the new module/component installation note at the top of the DTC Index P0973-11

Shift Solenoid A Control

Circuit Low - Circuit Short to

Ground

Shift solenoid A control

Circuit Short to Ground Suspect the Transmission control module. Install a

new Transmission control module as required, refer to

the new module/component installation note at the top of the DTC Index P0973-14

Shift Solenoid A Control

Circuit Low - Circuit Short to

Ground or Open

Pressure control solenoid

1 Circuit Short to Ground

or Open Circuit Suspect the Transmission control module. Install a

new Transmission control module as required, refer to

the new module/component installation note at the

top of the DTC Index P0973-1A

Shift Solenoid A Control

Circuit Low - Circuit

Resistance Below Threshold

Shift Solenoid A control

circuit resistance below

threshold Suspect the Transmission control module. Install a

new Transmission control module as required, refer to

the new module/component installation note at the

top of the DTC Index P0973-1E

Shift Solenoid A Control

Circuit Low - Circuit

Resistance Out Of Range

Shift Solenoid A control

circuit resistance out of

range Suspect the Transmission control module. Install a

new Transmission control module as required, refer to

the new module/component installation note at the

top of the DTC Index P0976-11

Shift Solenoid B Control

Circuit Low - Circuit Short to

Ground

Solenoid valve 2 Circuit

Short to Ground Suspect the Transmission control module. Install a

new Transmission control module as required, refer to

the new module/component installation note at the top of the DTC Index P0976-14

Shift Solenoid B Control

Circuit Low - Circuit Short to

Ground or Open

Solenoid valve 2 Circuit

Short to Ground or Open

Circuit Suspect the Transmission control module. Install a

new Transmission control module as required, refer to

the new module/component installation note at the

top of the DTC Index P1674-04

Control Module Software

Corrupted - System Internal

Failures

System internal failures Suspect the Transmission control module. Install a

new Transmission control module as required, refer to

the new module/component installation note at the top of the DTC Index P1674-48

Control Module Software

Corrupted - Supervision

Software Failure

Supervision software

failure Suspect the Transmission control module. Install a

new Transmission control module as required, refer to

the new module/component installation note at the top of the DTC Index P1707-07 Transfer Case Neutral or

Park/Neutral Indication

Circuit - commanded

position not reachable

Transfer case neutral or

park/neutral indication

circuit - mechanical

failures Clear the DTC. Test drive the Vehicle, engaging and

disengaging the parking lock several times. If the DTC

recurs, check parking lock components and replace as

required. If no faulty park lock component is found

Clear DTC and the DTC returns suspect the

Transmission control module. Install a new

Transmission control module as required, refer to the

new module/component installation note at the top of

the DTC Index P1707-72 Transfer Case Neutral or

Park/Neutral Indication

Circuit - Actuator Stuck Open

Transfer case neutral or

park/neutral indication

circuit - Actuator stuck

open Clear the DTC. Test drive the Vehicle, engaging and

disengaging the parking lock several times. If the DTC

recurs, check parking lock components and replace as

required. If no faulty park lock component is found

Clear DTC and the DTC returns suspect the

Transmission control module. Install a new

Transmission control module as required, refer to the

new module/component installation note at the top of

the DTC Index

Page 1632 of 3039

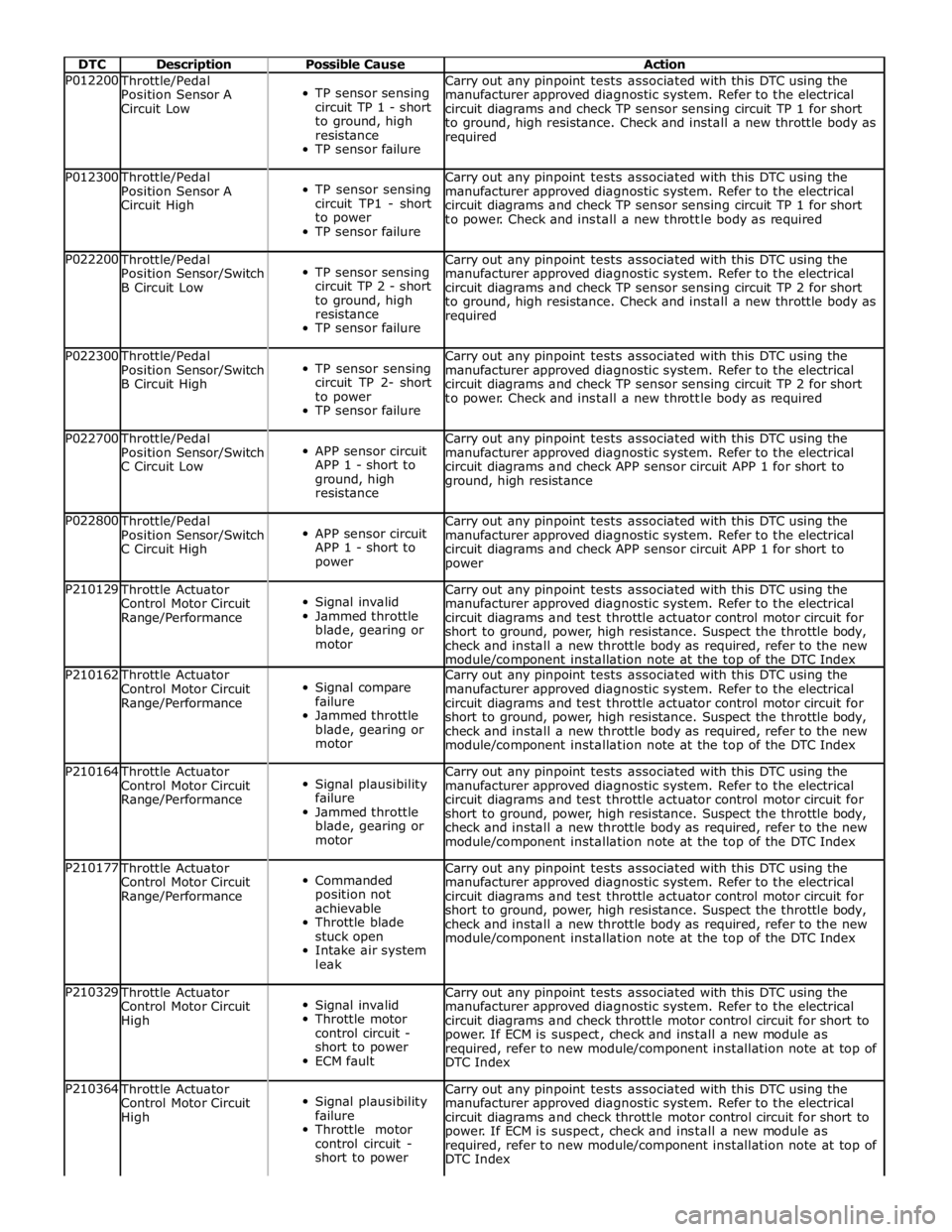

DTC Description Possible Cause Action P012200 Throttle/Pedal

Position Sensor A

Circuit Low

TP sensor sensing

circuit TP 1 - short

to ground, high

resistance

TP sensor failure Carry out any pinpoint tests associated with this DTC using the

manufacturer approved diagnostic system. Refer to the electrical

circuit diagrams and check TP sensor sensing circuit TP 1 for short

to ground, high resistance. Check and install a new throttle body as

required P012300 Throttle/Pedal

Position Sensor A

Circuit High

TP sensor sensing

circuit TP1 - short

to power

TP sensor failure Carry out any pinpoint tests associated with this DTC using the

manufacturer approved diagnostic system. Refer to the electrical

circuit diagrams and check TP sensor sensing circuit TP 1 for short

to power. Check and install a new throttle body as required P022200 Throttle/Pedal

Position Sensor/Switch

B Circuit Low

TP sensor sensing

circuit TP 2 - short

to ground, high

resistance

TP sensor failure Carry out any pinpoint tests associated with this DTC using the

manufacturer approved diagnostic system. Refer to the electrical

circuit diagrams and check TP sensor sensing circuit TP 2 for short

to ground, high resistance. Check and install a new throttle body as

required P022300 Throttle/Pedal

Position Sensor/Switch

B Circuit High

TP sensor sensing

circuit TP 2- short

to power

TP sensor failure Carry out any pinpoint tests associated with this DTC using the

manufacturer approved diagnostic system. Refer to the electrical

circuit diagrams and check TP sensor sensing circuit TP 2 for short

to power. Check and install a new throttle body as required P022700 Throttle/Pedal

Position Sensor/Switch

C Circuit Low

APP sensor circuit

APP 1 - short to

ground, high

resistance Carry out any pinpoint tests associated with this DTC using the

manufacturer approved diagnostic system. Refer to the electrical

circuit diagrams and check APP sensor circuit APP 1 for short to

ground, high resistance P022800 Throttle/Pedal

Position Sensor/Switch

C Circuit High

APP sensor circuit

APP 1 - short to

power Carry out any pinpoint tests associated with this DTC using the

manufacturer approved diagnostic system. Refer to the electrical

circuit diagrams and check APP sensor circuit APP 1 for short to

power P210129 Throttle Actuator

Control Motor Circuit

Range/Performance

Signal invalid

Jammed throttle

blade, gearing or

motor Carry out any pinpoint tests associated with this DTC using the

manufacturer approved diagnostic system. Refer to the electrical

circuit diagrams and test throttle actuator control motor circuit for

short to ground, power, high resistance. Suspect the throttle body,

check and install a new throttle body as required, refer to the new module/component installation note at the top of the DTC Index P210162 Throttle Actuator

Control Motor Circuit

Range/Performance

Signal compare

failure

Jammed throttle

blade, gearing or

motor Carry out any pinpoint tests associated with this DTC using the

manufacturer approved diagnostic system. Refer to the electrical

circuit diagrams and test throttle actuator control motor circuit for

short to ground, power, high resistance. Suspect the throttle body,

check and install a new throttle body as required, refer to the new

module/component installation note at the top of the DTC Index P210164 Throttle Actuator

Control Motor Circuit

Range/Performance

Signal plausibility

failure

Jammed throttle

blade, gearing or

motor Carry out any pinpoint tests associated with this DTC using the

manufacturer approved diagnostic system. Refer to the electrical

circuit diagrams and test throttle actuator control motor circuit for

short to ground, power, high resistance. Suspect the throttle body,

check and install a new throttle body as required, refer to the new

module/component installation note at the top of the DTC Index P210177 Throttle Actuator

Control Motor Circuit

Range/Performance

Commanded

position not

achievable

Throttle blade

stuck open

Intake air system

leak Carry out any pinpoint tests associated with this DTC using the

manufacturer approved diagnostic system. Refer to the electrical

circuit diagrams and test throttle actuator control motor circuit for

short to ground, power, high resistance. Suspect the throttle body,

check and install a new throttle body as required, refer to the new

module/component installation note at the top of the DTC Index P210329 Throttle Actuator

Control Motor Circuit

High

Signal invalid

Throttle motor

control circuit -

short to power

ECM fault Carry out any pinpoint tests associated with this DTC using the

manufacturer approved diagnostic system. Refer to the electrical

circuit diagrams and check throttle motor control circuit for short to

power. If ECM is suspect, check and install a new module as

required, refer to new module/component installation note at top of

DTC Index P210364 Throttle Actuator

Control Motor Circuit

High

Signal plausibility

failure

Throttle motor

control circuit -

short to power Carry out any pinpoint tests associated with this DTC using the

manufacturer approved diagnostic system. Refer to the electrical

circuit diagrams and check throttle motor control circuit for short to

power. If ECM is suspect, check and install a new module as

required, refer to new module/component installation note at top of

DTC Index

Page 1633 of 3039

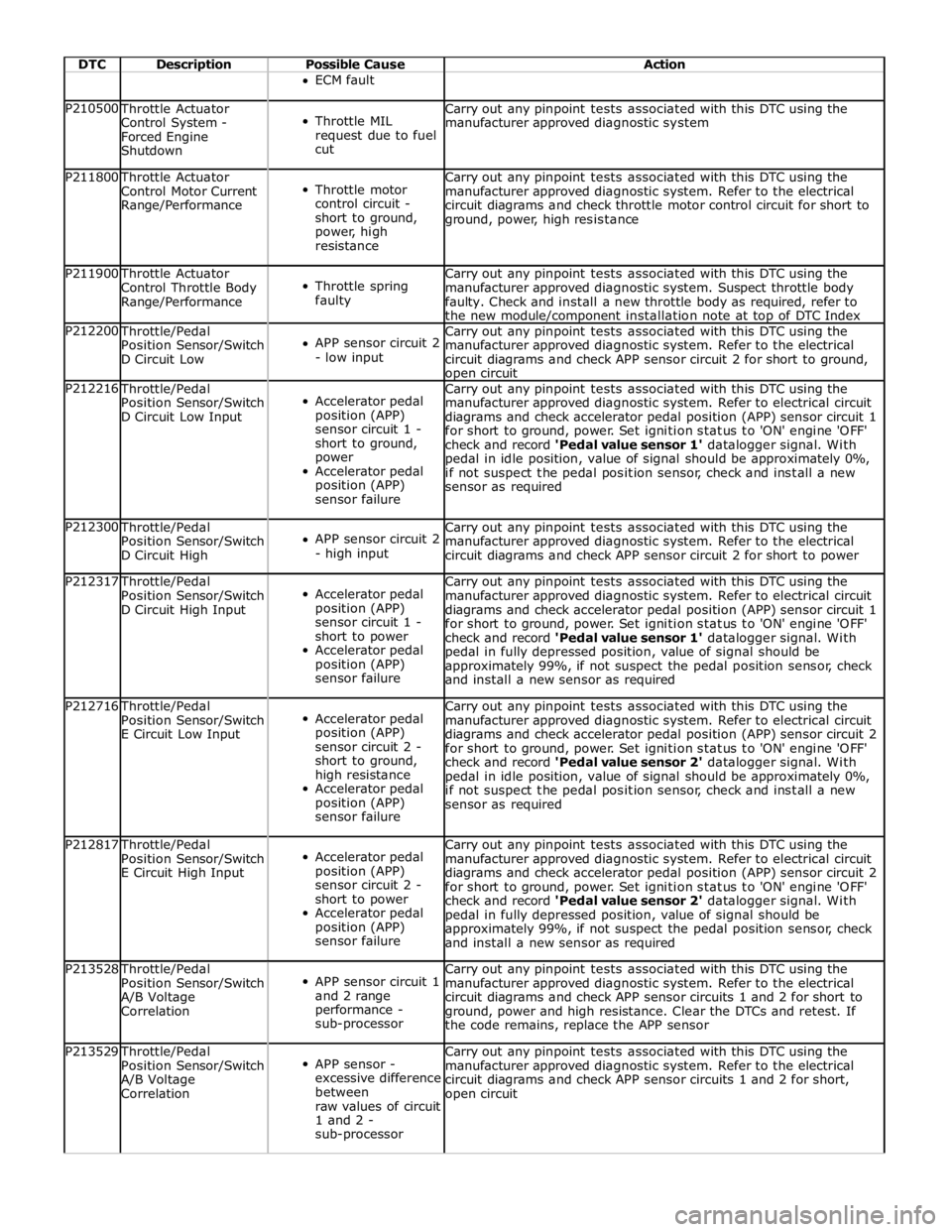

DTC Description Possible Cause Action ECM fault

P210500 Throttle Actuator

Control System -

Forced Engine

Shutdown

Throttle MIL

request due to fuel

cut Carry out any pinpoint tests associated with this DTC using the

manufacturer approved diagnostic system P211800 Throttle Actuator

Control Motor Current

Range/Performance

Throttle motor

control circuit -

short to ground,

power, high

resistance Carry out any pinpoint tests associated with this DTC using the

manufacturer approved diagnostic system. Refer to the electrical

circuit diagrams and check throttle motor control circuit for short to

ground, power, high resistance P211900 Throttle Actuator

Control Throttle Body

Range/Performance

Throttle spring

faulty Carry out any pinpoint tests associated with this DTC using the

manufacturer approved diagnostic system. Suspect throttle body

faulty. Check and install a new throttle body as required, refer to

the new module/component installation note at top of DTC Index P212200 Throttle/Pedal

Position Sensor/Switch

D Circuit Low

APP sensor circuit 2

- low input Carry out any pinpoint tests associated with this DTC using the

manufacturer approved diagnostic system. Refer to the electrical

circuit diagrams and check APP sensor circuit 2 for short to ground, open circuit P212216 Throttle/Pedal

Position Sensor/Switch

D Circuit Low Input

Accelerator pedal

position (APP)

sensor circuit 1 -

short to ground,

power

Accelerator pedal

position (APP)

sensor failure Carry out any pinpoint tests associated with this DTC using the

manufacturer approved diagnostic system. Refer to electrical circuit

diagrams and check accelerator pedal position (APP) sensor circuit 1

for short to ground, power. Set ignition status to 'ON' engine 'OFF'

check and record 'Pedal value sensor 1' datalogger signal. With

pedal in idle position, value of signal should be approximately 0%,

if not suspect the pedal position sensor, check and install a new

sensor as required P212300 Throttle/Pedal

Position Sensor/Switch

D Circuit High

APP sensor circuit 2

- high input Carry out any pinpoint tests associated with this DTC using the

manufacturer approved diagnostic system. Refer to the electrical

circuit diagrams and check APP sensor circuit 2 for short to power P212317 Throttle/Pedal

Position Sensor/Switch

D Circuit High Input

Accelerator pedal

position (APP)

sensor circuit 1 -

short to power

Accelerator pedal

position (APP)

sensor failure Carry out any pinpoint tests associated with this DTC using the

manufacturer approved diagnostic system. Refer to electrical circuit

diagrams and check accelerator pedal position (APP) sensor circuit 1

for short to ground, power. Set ignition status to 'ON' engine 'OFF'

check and record 'Pedal value sensor 1' datalogger signal. With

pedal in fully depressed position, value of signal should be

approximately 99%, if not suspect the pedal position sensor, check

and install a new sensor as required P212716 Throttle/Pedal

Position Sensor/Switch

E Circuit Low Input

Accelerator pedal

position (APP)

sensor circuit 2 -

short to ground,

high resistance

Accelerator pedal

position (APP)

sensor failure Carry out any pinpoint tests associated with this DTC using the

manufacturer approved diagnostic system. Refer to electrical circuit

diagrams and check accelerator pedal position (APP) sensor circuit 2

for short to ground, power. Set ignition status to 'ON' engine 'OFF'

check and record 'Pedal value sensor 2' datalogger signal. With

pedal in idle position, value of signal should be approximately 0%,

if not suspect the pedal position sensor, check and install a new

sensor as required P212817 Throttle/Pedal

Position Sensor/Switch

E Circuit High Input

Accelerator pedal

position (APP)

sensor circuit 2 -

short to power

Accelerator pedal

position (APP)

sensor failure Carry out any pinpoint tests associated with this DTC using the

manufacturer approved diagnostic system. Refer to electrical circuit

diagrams and check accelerator pedal position (APP) sensor circuit 2

for short to ground, power. Set ignition status to 'ON' engine 'OFF'

check and record 'Pedal value sensor 2' datalogger signal. With

pedal in fully depressed position, value of signal should be

approximately 99%, if not suspect the pedal position sensor, check

and install a new sensor as required P213528 Throttle/Pedal

Position Sensor/Switch

A/B Voltage

Correlation

APP sensor circuit 1

and 2 range

performance -

sub-processor Carry out any pinpoint tests associated with this DTC using the

manufacturer approved diagnostic system. Refer to the electrical

circuit diagrams and check APP sensor circuits 1 and 2 for short to

ground, power and high resistance. Clear the DTCs and retest. If

the code remains, replace the APP sensor P213529 Throttle/Pedal

Position Sensor/Switch

A/B Voltage

Correlation

APP sensor -

excessive difference

between

raw values of circuit

1 and 2 -

sub-processor Carry out any pinpoint tests associated with this DTC using the

manufacturer approved diagnostic system. Refer to the electrical

circuit diagrams and check APP sensor circuits 1 and 2 for short,

open circuit

Page 1638 of 3039

10 Electric throttle actuator 11 ABS (anti-lock brake system) module www.JagDocs.com

Page 1639 of 3039

Published: 11-May-2011

Speed Control - V8 5.0L Petrol/V8 S/C 5.0L Petrol - Speed Control - Overview

Description and Operation

OVERVIEW

Speed Control

The speed control system is integrated with the engine management system and uses fueling intervention to automatically

maintain a set vehicle speed. Once engaged, the system can also be used to accelerate the vehicle without using the

accelerator pedal.

The speed control system comprises the following components:

On/Off/Suspend switch

'+' and '-' (set/accelerate and decelerate) steering wheel switches

Resume switch

Clock spring

Speed control warning indicator.

Adaptive Speed Control

The adaptive speed control system uses a forward looking radar sensor to scan the road ahead, looking for objects that are

moving at a different rate to itself. When a target is identified the adaptive speed control system will monitor the time gap

between it and the target vehicle. When that gap falls below a set driver selected level the adaptive speed control system will

intervene slowing the vehicle by backing off the throttle and/ or applying the brakes, until the correct gap is attained.

The adaptive speed control system comprises the following components:

Adaptive speed control sensor

Adaptive speed control module

Steering wheel control switches

ECM (engine control module)

Electric throttle actuator

ABS (anti-lock brake system) module and pump

Adaptive speed control warning indicator (in the instrument cluster).

Page 1641 of 3039

6 Clockspring 7 APP (accelerator pedal position) sensor 8 Electric throttle actuator 9 Brake lamp/brake test switch 10 Adaptive speed control radar sensor 11 Diagnostic socket 12 Instrument cluster 13 TCM (transmission control module) 14 Adaptive speed control module

SPEED CONTROL System Operation

The speed control system uses inputs from the brake lamp/brake test switch, the APP sensor, the ECM and the ABS module.

Speed control is operated by the driver using only the steering wheel switches. When speed control is active, the ECM regulates the PWM (pulse width modulation) signals to the fuel injectors to adjust the fuel supply as required to maintain the

set speed.

During speed control operation, the ECM controls vehicle speed by adjusting fuel injection duration and timing. When the accelerator pedal is pressed with speed control active, the ECM outputs a calculated throttle angle signal in place of the actual throttle angle signals produced by the APP sensor. The calculated throttle angle is derived from fuel demand.

The minimum set speed for speed control is 18 mph (30 (km/h). Speed control is automatically suspended if the following

conditions apply:

Vehicle speed falls below 18 mph (30 km/h)

The brake pedal is pressed

The cancel button is pressed

Neutral, park or reverse gear is selected

The difference between actual speed and the set speed is too great

If the engine speed becomes near to the red line (maximum engine speed)

If the accelerator pedal is used to accelerate beyond the set speed for too long.

ADAPTIVE SPEED CONTROL

The adaptive speed control system comprises the following components:

Adaptive speed control sensor

Adaptive speed control module

Steering wheel control switches

ECM

Electric throttle actuator

ABS module and pump Adaptive speed control warning indicator.

The adaptive speed control system uses a forward looking radar sensor to scan the road ahead, looking for objects that are

moving at a different rate to itself. When a target is identified the adaptive speed control system will monitor the time gap

between it and the target vehicle. When that gap falls below a set driver selected level the adaptive speed control system will

intervene slowing the vehicle by backing off the throttle and/ or applying the brakes, until the correct gap is attained. The

driver can chose between four gap settings, 1, 1.4, 1.8 and 2.2 seconds.

The system will detect but not react to the following:

Vehicles in the oncoming lane

Stationary vehicles

Pedestrians

Vehicles not in the same lane.

Adaptive speed control is active when the vehicle is moving. Adaptive Speed Control only functions when a set speed is

entered in normal speed control mode. The adaptive speed control system only intervenes with the set speed when it detects

a target vehicle, and then only if the minimum time gap is breached.

It is important to note that the system is intended for use in limited driving situations, does not remove control and

responsibility from the driver, and at all times can be quickly overridden. The adaptive speed control system is not a collision

warning system and will not react to stationary objects. The system does not operate below a minimum speed of

approximately 30 km/h (20 mph) since it is unsuitable for use in cities or congested traffic. The system is best suited to main

roads/ highways with gradual bends.

The ECM, throttle body and throttle control are unchanged from those used for non adaptive speed control variants.

The adaptive speed control system is based on the use of a front mounted radar sensor. The sensor transmits a 1.5° wide

beam forward of the vehicle and detects the returning signals reflected off other vehicles and objects ahead.

The 1.5° wide radar beam is mechanically scanned at a rate of 10 sweeps/second across a total arc of 15° centered on the

Page 1682 of 3039

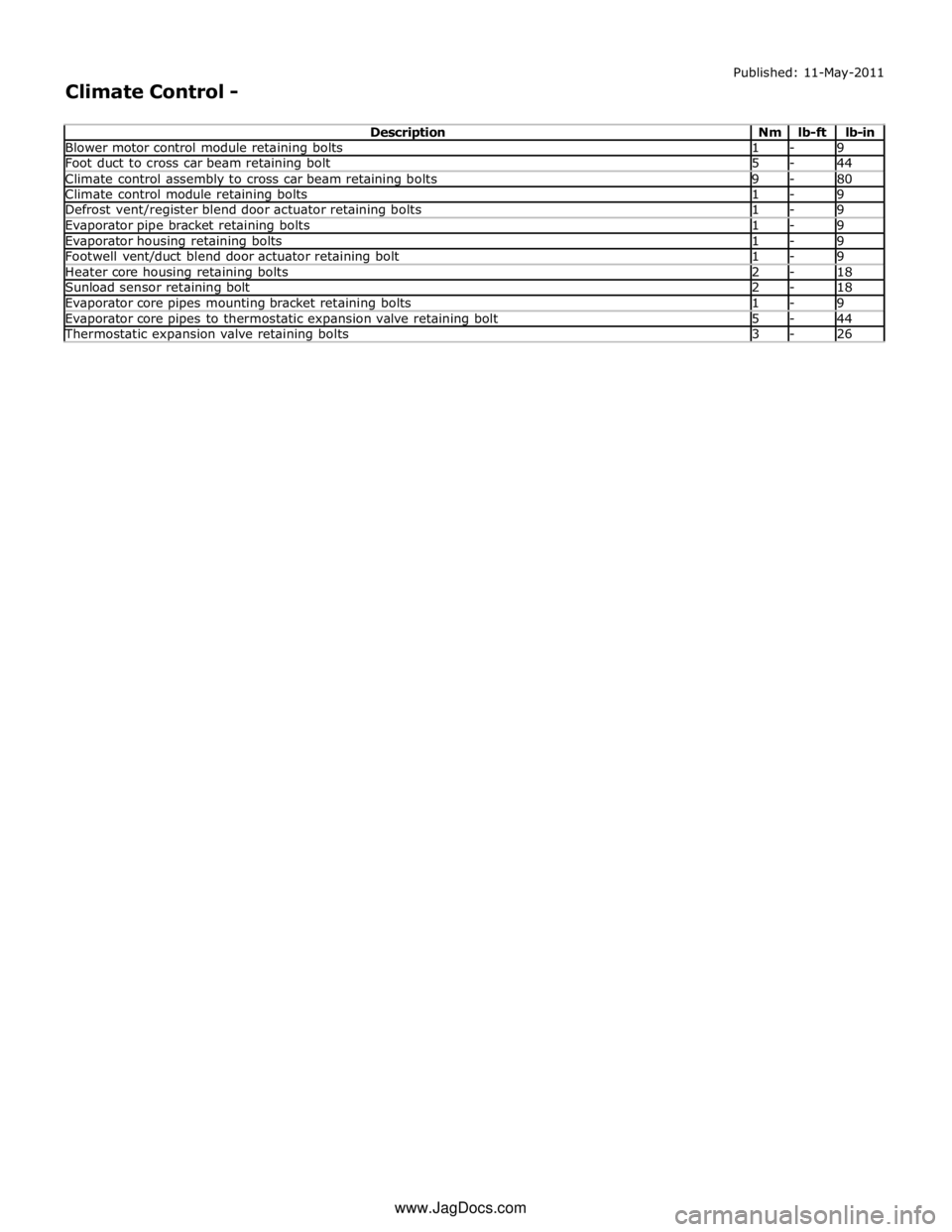

Blower motor control module retaining bolts 1 - 9 Foot duct to cross car beam retaining bolt 5 - 44 Climate control assembly to cross car beam retaining bolts 9 - 80 Climate control module retaining bolts 1 - 9 Defrost vent/register blend door actuator retaining bolts 1 - 9 Evaporator pipe bracket retaining bolts 1 - 9 Evaporator housing retaining bolts 1 - 9 Footwell vent/duct blend door actuator retaining bolt 1 - 9 Heater core housing retaining bolts 2 - 18 Sunload sensor retaining bolt 2 - 18 Evaporator core pipes mounting bracket retaining bolts 1 - 9 Evaporator core pipes to thermostatic expansion valve retaining bolt 5 - 44 Thermostatic expansion valve retaining bolts 3 - 26 www.JagDocs.com

Page 1715 of 3039

1 LH door mirror 2 Ambient air temperature sensor The ambient air temperature sensor is a NTC thermistor that provides the ATC module with an input of external air temperature. The sensor is hard wired to the ECM and its signal is transmitted to the instrument cluster on the high speed CAN bus. The instrument cluster acts as a gateway and transmits the ambient air temperature signal to the ATC module on the medium speed CAN bus. The sensor is installed in the LH door mirror, and is accessed by removing the mirror glass, cap and actuator.

Sunload Sensor

The sunload sensor consists of two photoelectric cells that provide the ATC module with inputs of light intensity; one as sensed coming from the left of the vehicle and one as sensed coming from the right. The inputs are a measure of the solar

heating effect on vehicle occupants, and are used by the ATC module to adjust blower speed, temperature and distribution to improve comfort.

The sensor is installed in the speaker grill on the upper surface of the instrument panel. Power for the sensor is provided by a

5 V feed from the instrument cluster.

The sensor also contains the active anti-theft alarm indicator.

Refer to: Anti-Theft - Active (419-01 Anti-Theft - Active, Description and Operation). Ambient Air Temperature Sensor