Rear Drive JAGUAR XFR 2010 1.G User Guide

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 2010, Model line: XFR, Model: JAGUAR XFR 2010 1.GPages: 3039, PDF Size: 58.49 MB

Page 148 of 3039

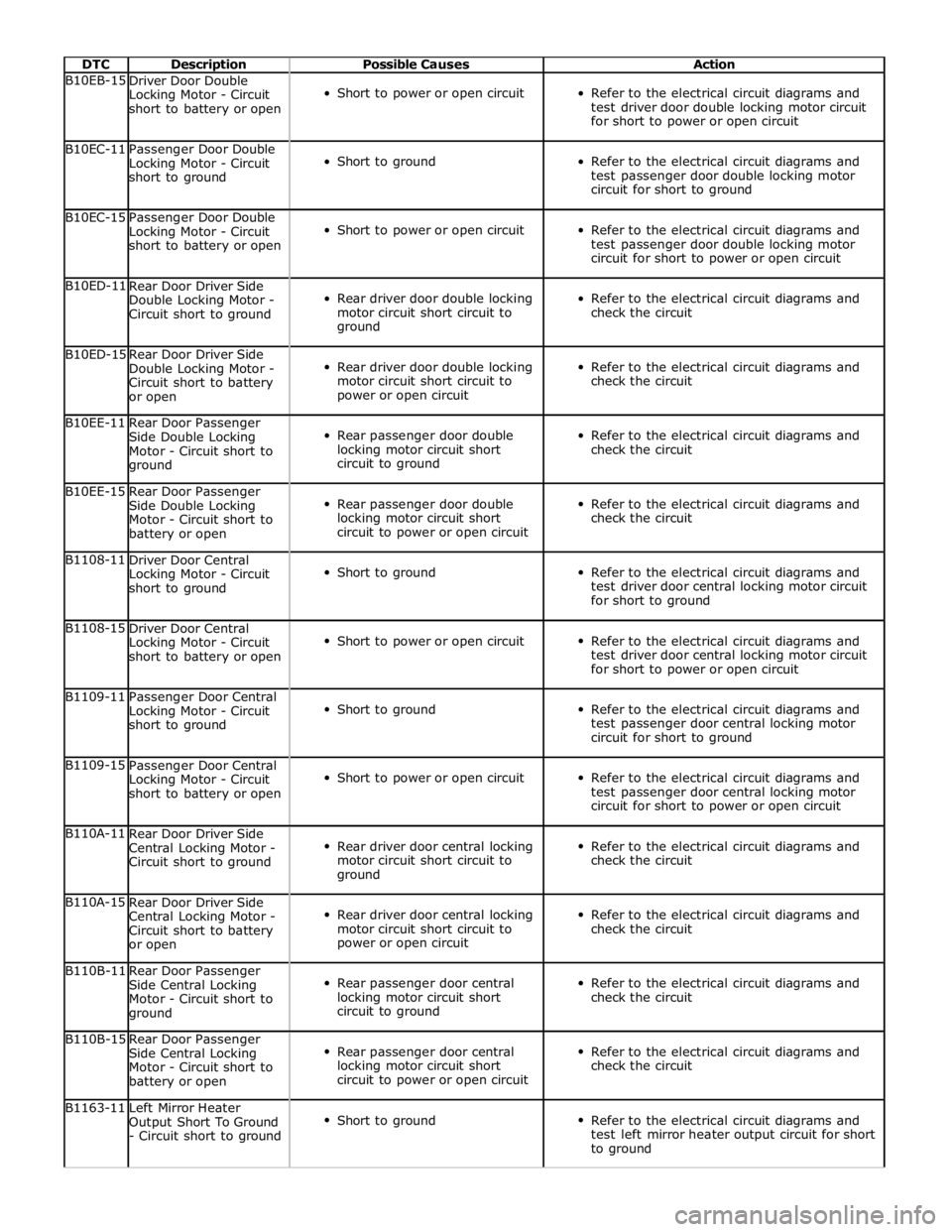

DTC Description Possible Causes Action B10EB-15

Driver Door Double

Locking Motor - Circuit

short to battery or open

Short to power or open circuit

Refer to the electrical circuit diagrams and

test driver door double locking motor circuit

for short to power or open circuit B10EC-11

Passenger Door Double

Locking Motor - Circuit

short to ground

Short to ground

Refer to the electrical circuit diagrams and

test passenger door double locking motor

circuit for short to ground B10EC-15

Passenger Door Double

Locking Motor - Circuit

short to battery or open

Short to power or open circuit

Refer to the electrical circuit diagrams and

test passenger door double locking motor

circuit for short to power or open circuit B10ED-11

Rear Door Driver Side

Double Locking Motor -

Circuit short to ground

Rear driver door double locking

motor circuit short circuit to

ground

Refer to the electrical circuit diagrams and

check the circuit B10ED-15

Rear Door Driver Side

Double Locking Motor -

Circuit short to battery

or open

Rear driver door double locking

motor circuit short circuit to

power or open circuit

Refer to the electrical circuit diagrams and

check the circuit B10EE-11

Rear Door Passenger

Side Double Locking

Motor - Circuit short to

ground

Rear passenger door double

locking motor circuit short

circuit to ground

Refer to the electrical circuit diagrams and

check the circuit B10EE-15

Rear Door Passenger

Side Double Locking

Motor - Circuit short to

battery or open

Rear passenger door double

locking motor circuit short

circuit to power or open circuit

Refer to the electrical circuit diagrams and

check the circuit B1108-11

Driver Door Central

Locking Motor - Circuit

short to ground

Short to ground

Refer to the electrical circuit diagrams and

test driver door central locking motor circuit

for short to ground B1108-15

Driver Door Central

Locking Motor - Circuit

short to battery or open

Short to power or open circuit

Refer to the electrical circuit diagrams and

test driver door central locking motor circuit

for short to power or open circuit B1109-11

Passenger Door Central

Locking Motor - Circuit

short to ground

Short to ground

Refer to the electrical circuit diagrams and

test passenger door central locking motor

circuit for short to ground B1109-15

Passenger Door Central

Locking Motor - Circuit

short to battery or open

Short to power or open circuit

Refer to the electrical circuit diagrams and

test passenger door central locking motor

circuit for short to power or open circuit B110A-11

Rear Door Driver Side

Central Locking Motor -

Circuit short to ground

Rear driver door central locking

motor circuit short circuit to

ground

Refer to the electrical circuit diagrams and

check the circuit B110A-15

Rear Door Driver Side

Central Locking Motor -

Circuit short to battery

or open

Rear driver door central locking

motor circuit short circuit to

power or open circuit

Refer to the electrical circuit diagrams and

check the circuit B110B-11

Rear Door Passenger

Side Central Locking

Motor - Circuit short to

ground

Rear passenger door central

locking motor circuit short

circuit to ground

Refer to the electrical circuit diagrams and

check the circuit B110B-15

Rear Door Passenger

Side Central Locking

Motor - Circuit short to

battery or open

Rear passenger door central

locking motor circuit short

circuit to power or open circuit

Refer to the electrical circuit diagrams and

check the circuit B1163-11

Left Mirror Heater

Output Short To Ground

- Circuit short to ground

Short to ground

Refer to the electrical circuit diagrams and

test left mirror heater output circuit for short

to ground

Page 150 of 3039

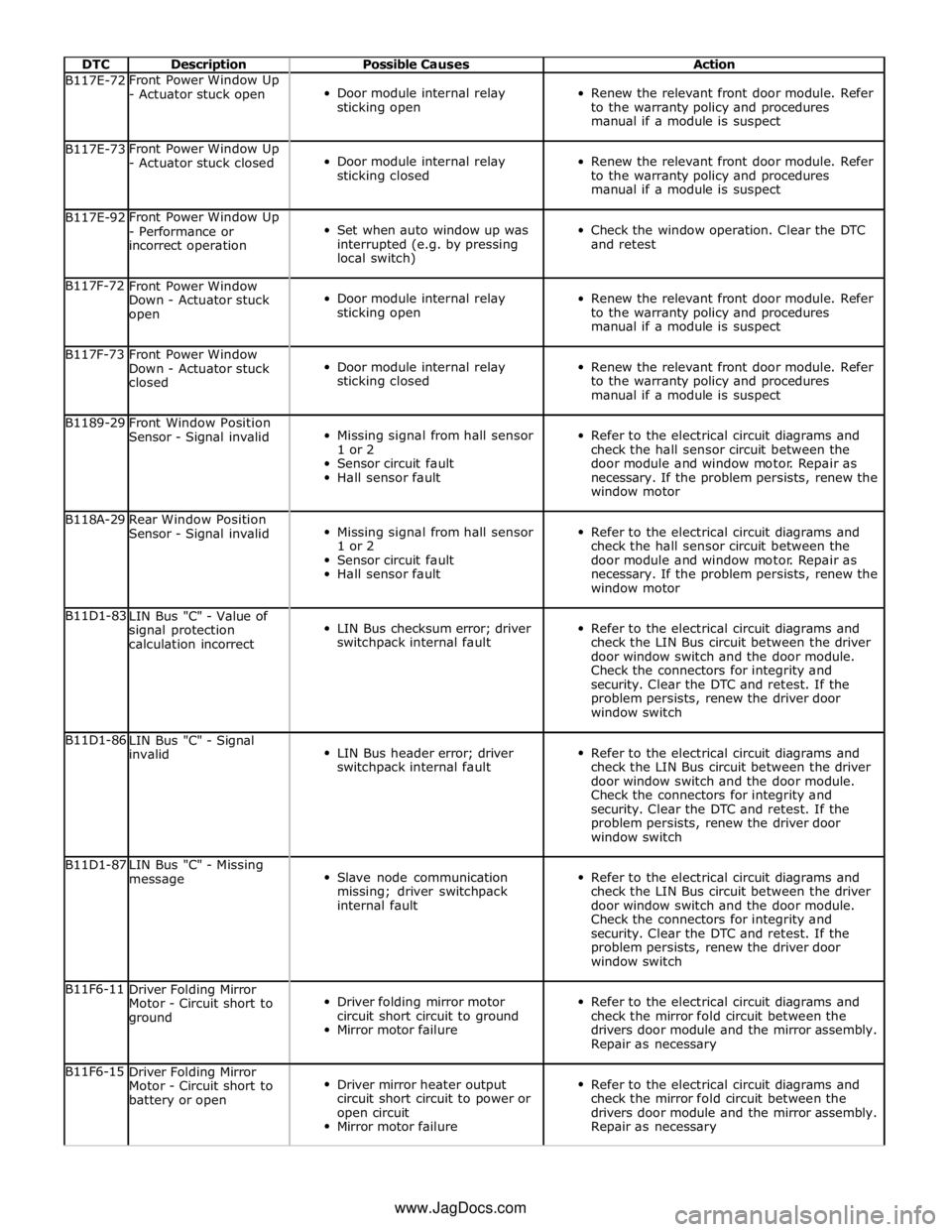

DTC Description Possible Causes Action B117E-72 Front Power Window Up

- Actuator stuck open

Door module internal relay

sticking open

Renew the relevant front door module. Refer

to the warranty policy and procedures

manual if a module is suspect B117E-73 Front Power Window Up

- Actuator stuck closed

Door module internal relay

sticking closed

Renew the relevant front door module. Refer

to the warranty policy and procedures

manual if a module is suspect B117E-92 Front Power Window Up

- Performance or

incorrect operation

Set when auto window up was

interrupted (e.g. by pressing

local switch)

Check the window operation. Clear the DTC

and retest B117F-72

Front Power Window

Down - Actuator stuck

open

Door module internal relay

sticking open

Renew the relevant front door module. Refer

to the warranty policy and procedures

manual if a module is suspect B117F-73

Front Power Window

Down - Actuator stuck

closed

Door module internal relay

sticking closed

Renew the relevant front door module. Refer

to the warranty policy and procedures

manual if a module is suspect B1189-29

Front Window Position

Sensor - Signal invalid

Missing signal from hall sensor

1 or 2

Sensor circuit fault

Hall sensor fault

Refer to the electrical circuit diagrams and

check the hall sensor circuit between the

door module and window motor. Repair as

necessary. If the problem persists, renew the

window motor B118A-29

Rear Window Position

Sensor - Signal invalid

Missing signal from hall sensor

1 or 2

Sensor circuit fault

Hall sensor fault

Refer to the electrical circuit diagrams and

check the hall sensor circuit between the

door module and window motor. Repair as

necessary. If the problem persists, renew the

window motor B11D1-83

LIN Bus "C" - Value of

signal protection

calculation incorrect

LIN Bus checksum error; driver

switchpack internal fault

Refer to the electrical circuit diagrams and

check the LIN Bus circuit between the driver

door window switch and the door module.

Check the connectors for integrity and

security. Clear the DTC and retest. If the

problem persists, renew the driver door

window switch B11D1-86

LIN Bus "C" - Signal

invalid

LIN Bus header error; driver

switchpack internal fault

Refer to the electrical circuit diagrams and

check the LIN Bus circuit between the driver

door window switch and the door module.

Check the connectors for integrity and

security. Clear the DTC and retest. If the

problem persists, renew the driver door

window switch B11D1-87

LIN Bus "C" - Missing

message

Slave node communication

missing; driver switchpack

internal fault

Refer to the electrical circuit diagrams and

check the LIN Bus circuit between the driver

door window switch and the door module.

Check the connectors for integrity and

security. Clear the DTC and retest. If the

problem persists, renew the driver door

window switch B11F6-11

Driver Folding Mirror

Motor - Circuit short to

ground

Driver folding mirror motor

circuit short circuit to ground

Mirror motor failure

Refer to the electrical circuit diagrams and

check the mirror fold circuit between the

drivers door module and the mirror assembly.

Repair as necessary B11F6-15

Driver Folding Mirror

Motor - Circuit short to

battery or open

Driver mirror heater output

circuit short circuit to power or

open circuit

Mirror motor failure

Refer to the electrical circuit diagrams and

check the mirror fold circuit between the

drivers door module and the mirror assembly.

Repair as necessary www.JagDocs.com

Page 151 of 3039

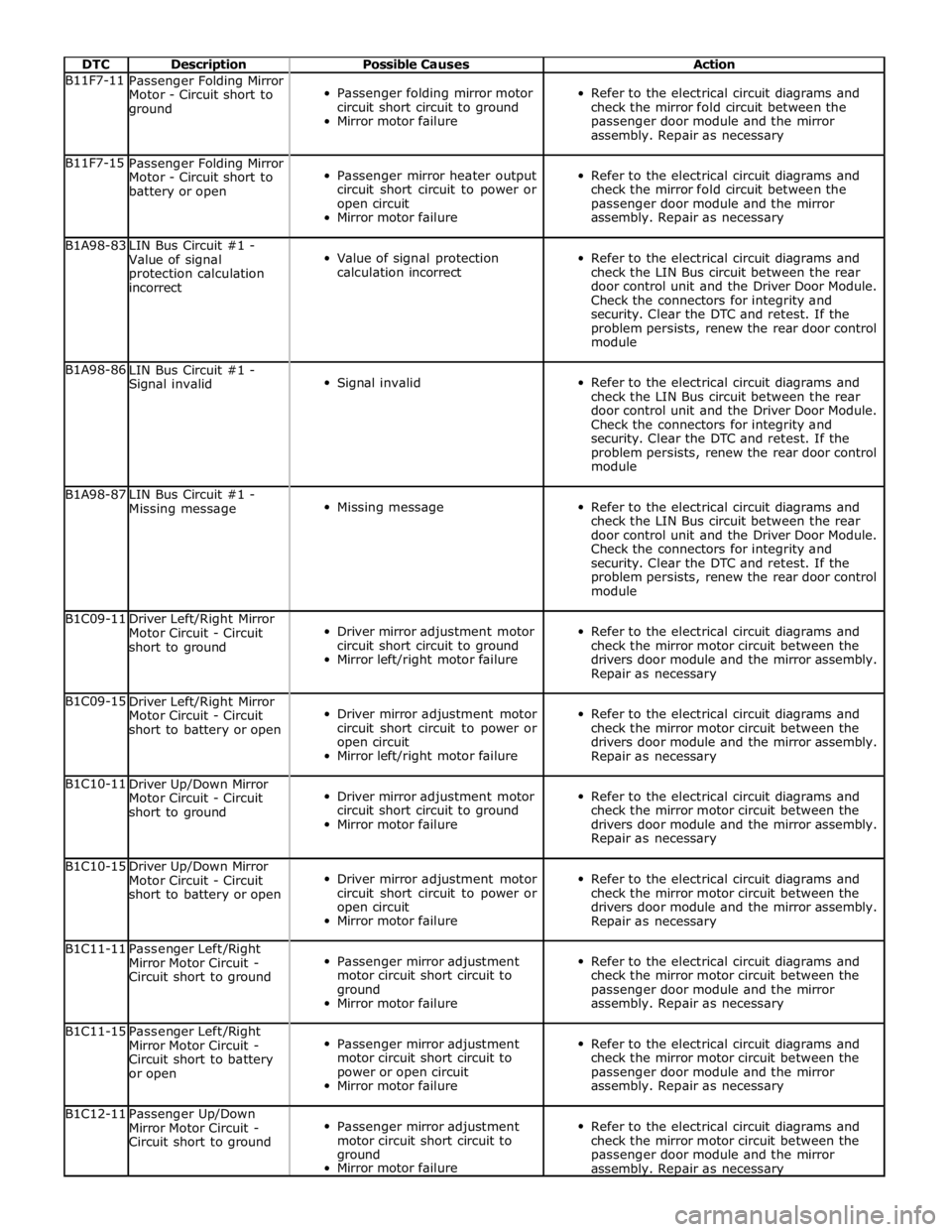

DTC Description Possible Causes Action B11F7-11

Passenger Folding Mirror

Motor - Circuit short to

ground

Passenger folding mirror motor

circuit short circuit to ground

Mirror motor failure

Refer to the electrical circuit diagrams and

check the mirror fold circuit between the

passenger door module and the mirror

assembly. Repair as necessary B11F7-15

Passenger Folding Mirror

Motor - Circuit short to

battery or open

Passenger mirror heater output

circuit short circuit to power or

open circuit

Mirror motor failure

Refer to the electrical circuit diagrams and

check the mirror fold circuit between the

passenger door module and the mirror

assembly. Repair as necessary B1A98-83

LIN Bus Circuit #1 -

Value of signal

protection calculation

incorrect

Value of signal protection

calculation incorrect

Refer to the electrical circuit diagrams and

check the LIN Bus circuit between the rear

door control unit and the Driver Door Module.

Check the connectors for integrity and

security. Clear the DTC and retest. If the

problem persists, renew the rear door control

module B1A98-86

LIN Bus Circuit #1 -

Signal invalid

Signal invalid

Refer to the electrical circuit diagrams and

check the LIN Bus circuit between the rear

door control unit and the Driver Door Module.

Check the connectors for integrity and

security. Clear the DTC and retest. If the

problem persists, renew the rear door control

module B1A98-87

LIN Bus Circuit #1 -

Missing message

Missing message

Refer to the electrical circuit diagrams and

check the LIN Bus circuit between the rear

door control unit and the Driver Door Module.

Check the connectors for integrity and

security. Clear the DTC and retest. If the

problem persists, renew the rear door control

module B1C09-11

Driver Left/Right Mirror

Motor Circuit - Circuit

short to ground

Driver mirror adjustment motor

circuit short circuit to ground

Mirror left/right motor failure

Refer to the electrical circuit diagrams and

check the mirror motor circuit between the

drivers door module and the mirror assembly.

Repair as necessary B1C09-15

Driver Left/Right Mirror

Motor Circuit - Circuit

short to battery or open

Driver mirror adjustment motor

circuit short circuit to power or

open circuit

Mirror left/right motor failure

Refer to the electrical circuit diagrams and

check the mirror motor circuit between the

drivers door module and the mirror assembly.

Repair as necessary B1C10-11

Driver Up/Down Mirror

Motor Circuit - Circuit

short to ground

Driver mirror adjustment motor

circuit short circuit to ground

Mirror motor failure

Refer to the electrical circuit diagrams and

check the mirror motor circuit between the

drivers door module and the mirror assembly.

Repair as necessary B1C10-15

Driver Up/Down Mirror

Motor Circuit - Circuit

short to battery or open

Driver mirror adjustment motor

circuit short circuit to power or

open circuit

Mirror motor failure

Refer to the electrical circuit diagrams and

check the mirror motor circuit between the

drivers door module and the mirror assembly.

Repair as necessary B1C11-11

Passenger Left/Right

Mirror Motor Circuit -

Circuit short to ground

Passenger mirror adjustment

motor circuit short circuit to

ground

Mirror motor failure

Refer to the electrical circuit diagrams and

check the mirror motor circuit between the

passenger door module and the mirror

assembly. Repair as necessary B1C11-15

Passenger Left/Right

Mirror Motor Circuit -

Circuit short to battery

or open

Passenger mirror adjustment

motor circuit short circuit to

power or open circuit

Mirror motor failure

Refer to the electrical circuit diagrams and

check the mirror motor circuit between the

passenger door module and the mirror

assembly. Repair as necessary B1C12-11

Passenger Up/Down

Mirror Motor Circuit -

Circuit short to ground

Passenger mirror adjustment

motor circuit short circuit to

ground

Mirror motor failure

Refer to the electrical circuit diagrams and

check the mirror motor circuit between the

passenger door module and the mirror assembly. Repair as necessary

Page 197 of 3039

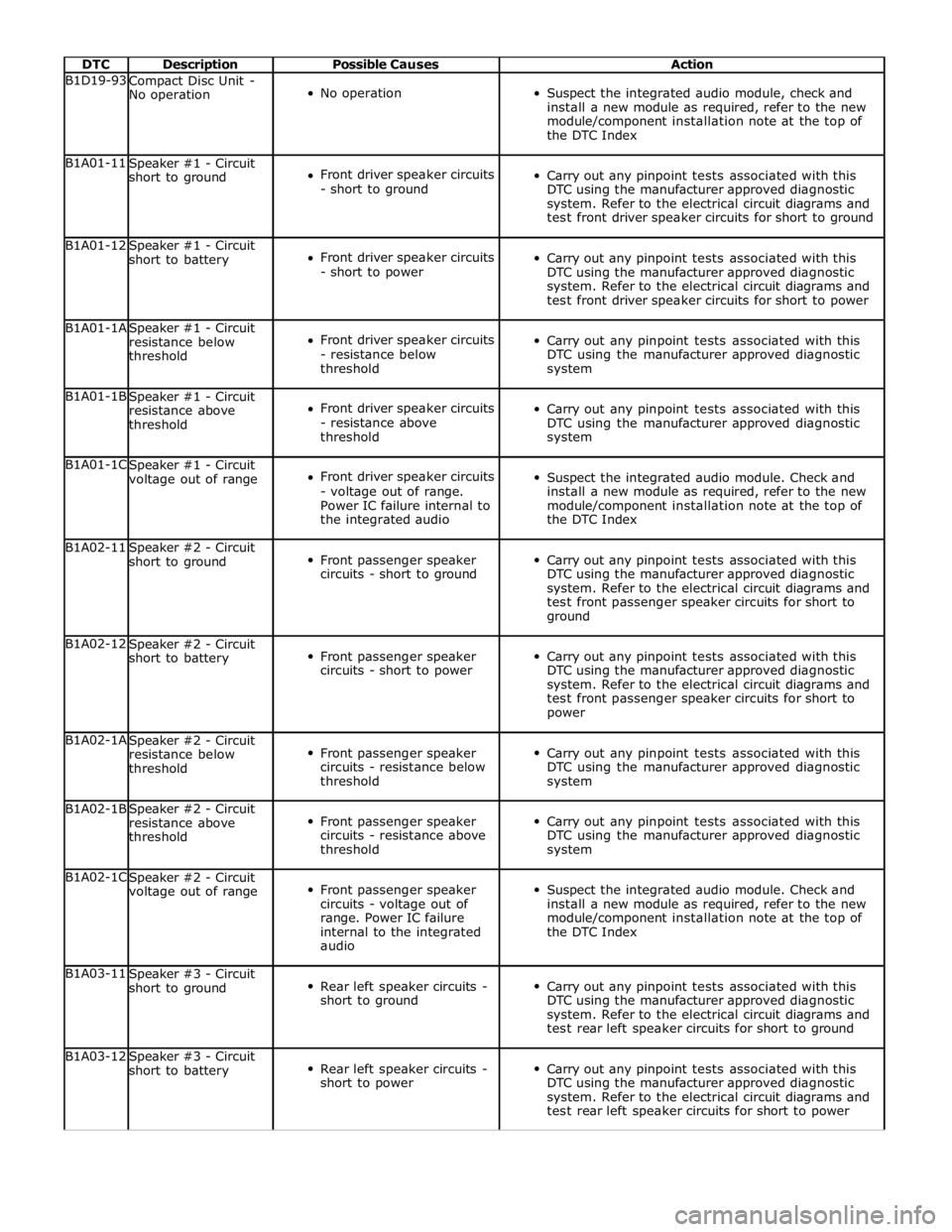

DTC Description Possible Causes Action B1D19-93

Compact Disc Unit -

No operation

No operation

Suspect the integrated audio module, check and

install a new module as required, refer to the new

module/component installation note at the top of

the DTC Index B1A01-11

Speaker #1 - Circuit

short to ground

Front driver speaker circuits

- short to ground

Carry out any pinpoint tests associated with this

DTC using the manufacturer approved diagnostic

system. Refer to the electrical circuit diagrams and

test front driver speaker circuits for short to ground B1A01-12

Speaker #1 - Circuit

short to battery

Front driver speaker circuits

- short to power

Carry out any pinpoint tests associated with this

DTC using the manufacturer approved diagnostic

system. Refer to the electrical circuit diagrams and

test front driver speaker circuits for short to power B1A01-1A

Speaker #1 - Circuit

resistance below

threshold

Front driver speaker circuits

- resistance below

threshold

Carry out any pinpoint tests associated with this

DTC using the manufacturer approved diagnostic

system B1A01-1B

Speaker #1 - Circuit

resistance above

threshold

Front driver speaker circuits

- resistance above

threshold

Carry out any pinpoint tests associated with this

DTC using the manufacturer approved diagnostic

system B1A01-1C

Speaker #1 - Circuit

voltage out of range

Front driver speaker circuits

- voltage out of range.

Power IC failure internal to

the integrated audio

Suspect the integrated audio module. Check and

install a new module as required, refer to the new

module/component installation note at the top of

the DTC Index B1A02-11

Speaker #2 - Circuit

short to ground

Front passenger speaker

circuits - short to ground

Carry out any pinpoint tests associated with this

DTC using the manufacturer approved diagnostic

system. Refer to the electrical circuit diagrams and

test front passenger speaker circuits for short to

ground B1A02-12

Speaker #2 - Circuit

short to battery

Front passenger speaker

circuits - short to power

Carry out any pinpoint tests associated with this

DTC using the manufacturer approved diagnostic

system. Refer to the electrical circuit diagrams and

test front passenger speaker circuits for short to

power B1A02-1A

Speaker #2 - Circuit

resistance below

threshold

Front passenger speaker

circuits - resistance below

threshold

Carry out any pinpoint tests associated with this

DTC using the manufacturer approved diagnostic

system B1A02-1B

Speaker #2 - Circuit

resistance above

threshold

Front passenger speaker

circuits - resistance above

threshold

Carry out any pinpoint tests associated with this

DTC using the manufacturer approved diagnostic

system B1A02-1C

Speaker #2 - Circuit

voltage out of range

Front passenger speaker

circuits - voltage out of

range. Power IC failure

internal to the integrated

audio

Suspect the integrated audio module. Check and

install a new module as required, refer to the new

module/component installation note at the top of

the DTC Index B1A03-11

Speaker #3 - Circuit

short to ground

Rear left speaker circuits -

short to ground

Carry out any pinpoint tests associated with this

DTC using the manufacturer approved diagnostic

system. Refer to the electrical circuit diagrams and

test rear left speaker circuits for short to ground B1A03-12

Speaker #3 - Circuit

short to battery

Rear left speaker circuits -

short to power

Carry out any pinpoint tests associated with this

DTC using the manufacturer approved diagnostic

system. Refer to the electrical circuit diagrams and

test rear left speaker circuits for short to power

Page 216 of 3039

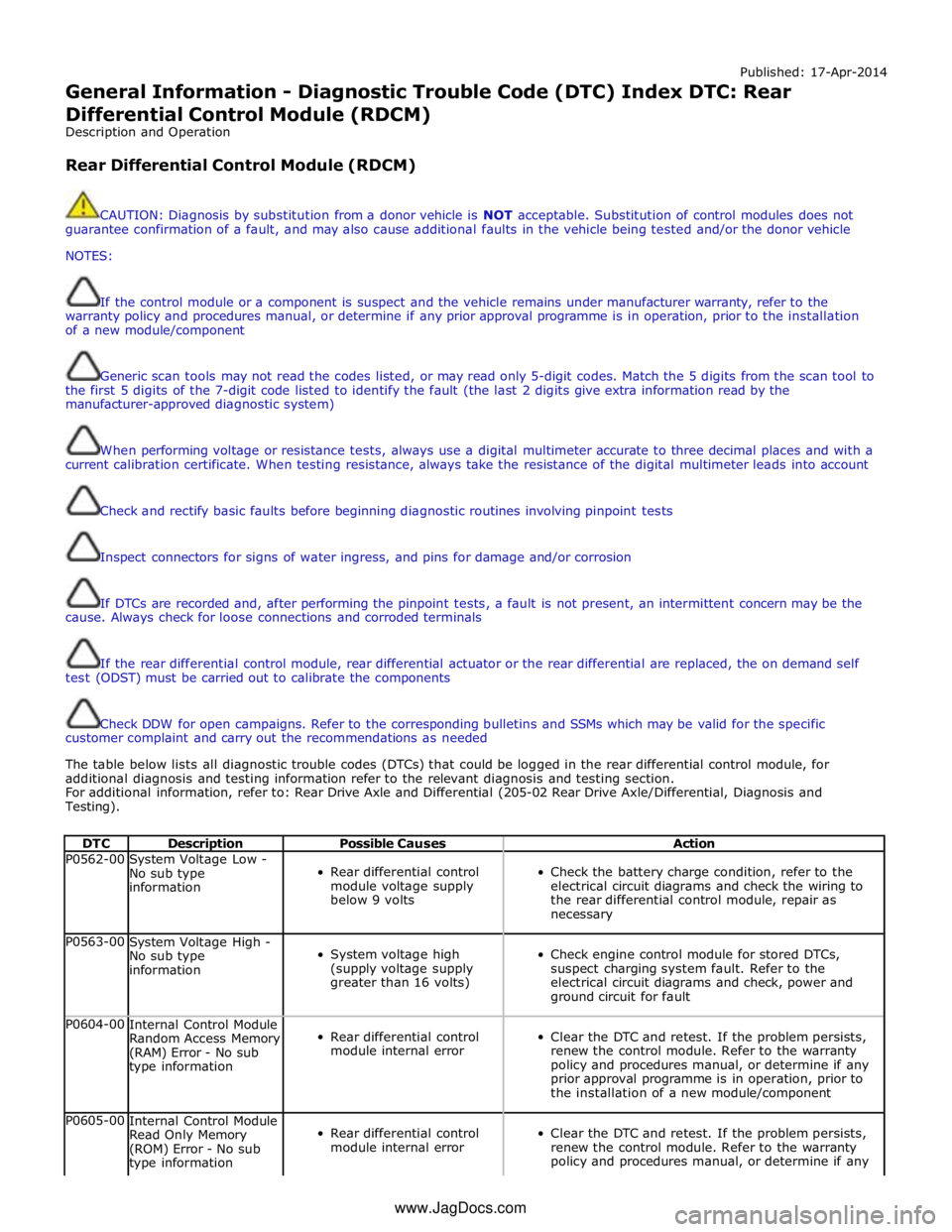

Published: 17-Apr-2014

General Information - Diagnostic Trouble Code (DTC) Index DTC: Rear

Differential Control Module (RDCM)

Description and Operation

Rear Differential Control Module (RDCM)

CAUTION: Diagnosis by substitution from a donor vehicle is NOT acceptable. Substitution of control modules does not

guarantee confirmation of a fault, and may also cause additional faults in the vehicle being tested and/or the donor vehicle

NOTES:

If the control module or a component is suspect and the vehicle remains under manufacturer warranty, refer to the

warranty policy and procedures manual, or determine if any prior approval programme is in operation, prior to the installation

of a new module/component

Generic scan tools may not read the codes listed, or may read only 5-digit codes. Match the 5 digits from the scan tool to

the first 5 digits of the 7-digit code listed to identify the fault (the last 2 digits give extra information read by the

manufacturer-approved diagnostic system)

When performing voltage or resistance tests, always use a digital multimeter accurate to three decimal places and with a

current calibration certificate. When testing resistance, always take the resistance of the digital multimeter leads into account

Check and rectify basic faults before beginning diagnostic routines involving pinpoint tests

Inspect connectors for signs of water ingress, and pins for damage and/or corrosion

If DTCs are recorded and, after performing the pinpoint tests, a fault is not present, an intermittent concern may be the

cause. Always check for loose connections and corroded terminals

If the rear differential control module, rear differential actuator or the rear differential are replaced, the on demand self

test (ODST) must be carried out to calibrate the components

Check DDW for open campaigns. Refer to the corresponding bulletins and SSMs which may be valid for the specific

customer complaint and carry out the recommendations as needed

The table below lists all diagnostic trouble codes (DTCs) that could be logged in the rear differential control module, for

additional diagnosis and testing information refer to the relevant diagnosis and testing section.

For additional information, refer to: Rear Drive Axle and Differential (205-02 Rear Drive Axle/Differential, Diagnosis and

Testing).

DTC Description Possible Causes Action P0562-00

System Voltage Low -

No sub type

information

Rear differential control

module voltage supply

below 9 volts

Check the battery charge condition, refer to the

electrical circuit diagrams and check the wiring to

the rear differential control module, repair as

necessary P0563-00

System Voltage High -

No sub type

information

System voltage high

(supply voltage supply

greater than 16 volts)

Check engine control module for stored DTCs,

suspect charging system fault. Refer to the

electrical circuit diagrams and check, power and

ground circuit for fault P0604-00

Internal Control Module

Random Access Memory

(RAM) Error - No sub

type information

Rear differential control

module internal error

Clear the DTC and retest. If the problem persists,

renew the control module. Refer to the warranty

policy and procedures manual, or determine if any

prior approval programme is in operation, prior to

the installation of a new module/component P0605-00

Internal Control Module

Read Only Memory

(ROM) Error - No sub

type information

Rear differential control

module internal error

Clear the DTC and retest. If the problem persists,

renew the control module. Refer to the warranty

policy and procedures manual, or determine if any www.JagDocs.com

Page 218 of 3039

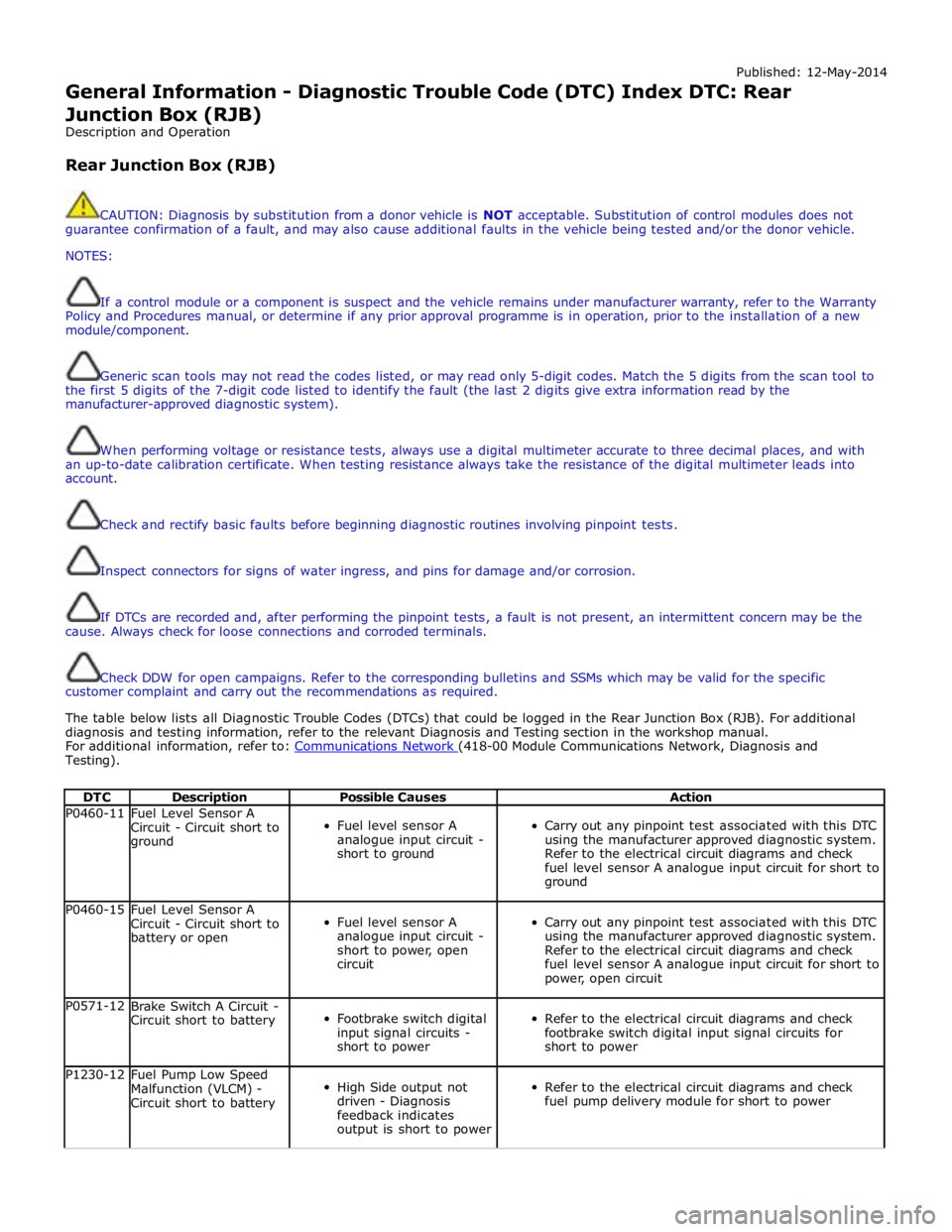

Published: 12-May-2014

General Information - Diagnostic Trouble Code (DTC) Index DTC: Rear

Junction Box (RJB)

Description and Operation

Rear Junction Box (RJB)

CAUTION: Diagnosis by substitution from a donor vehicle is NOT acceptable. Substitution of control modules does not

guarantee confirmation of a fault, and may also cause additional faults in the vehicle being tested and/or the donor vehicle.

NOTES:

If a control module or a component is suspect and the vehicle remains under manufacturer warranty, refer to the Warranty

Policy and Procedures manual, or determine if any prior approval programme is in operation, prior to the installation of a new

module/component.

Generic scan tools may not read the codes listed, or may read only 5-digit codes. Match the 5 digits from the scan tool to

the first 5 digits of the 7-digit code listed to identify the fault (the last 2 digits give extra information read by the

manufacturer-approved diagnostic system).

When performing voltage or resistance tests, always use a digital multimeter accurate to three decimal places, and with

an up-to-date calibration certificate. When testing resistance always take the resistance of the digital multimeter leads into

account.

Check and rectify basic faults before beginning diagnostic routines involving pinpoint tests.

Inspect connectors for signs of water ingress, and pins for damage and/or corrosion.

If DTCs are recorded and, after performing the pinpoint tests, a fault is not present, an intermittent concern may be the

cause. Always check for loose connections and corroded terminals.

Check DDW for open campaigns. Refer to the corresponding bulletins and SSMs which may be valid for the specific

customer complaint and carry out the recommendations as required.

The table below lists all Diagnostic Trouble Codes (DTCs) that could be logged in the Rear Junction Box (RJB). For additional

diagnosis and testing information, refer to the relevant Diagnosis and Testing section in the workshop manual.

For additional information, refer to: Communications Network (418-00 Module Communications Network, Diagnosis and Testing).

DTC Description Possible Causes Action P0460-11

Fuel Level Sensor A

Circuit - Circuit short to

ground

Fuel level sensor A

analogue input circuit -

short to ground

Carry out any pinpoint test associated with this DTC

using the manufacturer approved diagnostic system.

Refer to the electrical circuit diagrams and check

fuel level sensor A analogue input circuit for short to

ground P0460-15

Fuel Level Sensor A

Circuit - Circuit short to

battery or open

Fuel level sensor A

analogue input circuit -

short to power, open

circuit

Carry out any pinpoint test associated with this DTC

using the manufacturer approved diagnostic system.

Refer to the electrical circuit diagrams and check

fuel level sensor A analogue input circuit for short to

power, open circuit P0571-12

Brake Switch A Circuit -

Circuit short to battery

Footbrake switch digital

input signal circuits -

short to power

Refer to the electrical circuit diagrams and check

footbrake switch digital input signal circuits for

short to power P1230-12

Fuel Pump Low Speed

Malfunction (VLCM) -

Circuit short to battery

High Side output not

driven - Diagnosis

feedback indicates

output is short to power

Refer to the electrical circuit diagrams and check

fuel pump delivery module for short to power

Page 220 of 3039

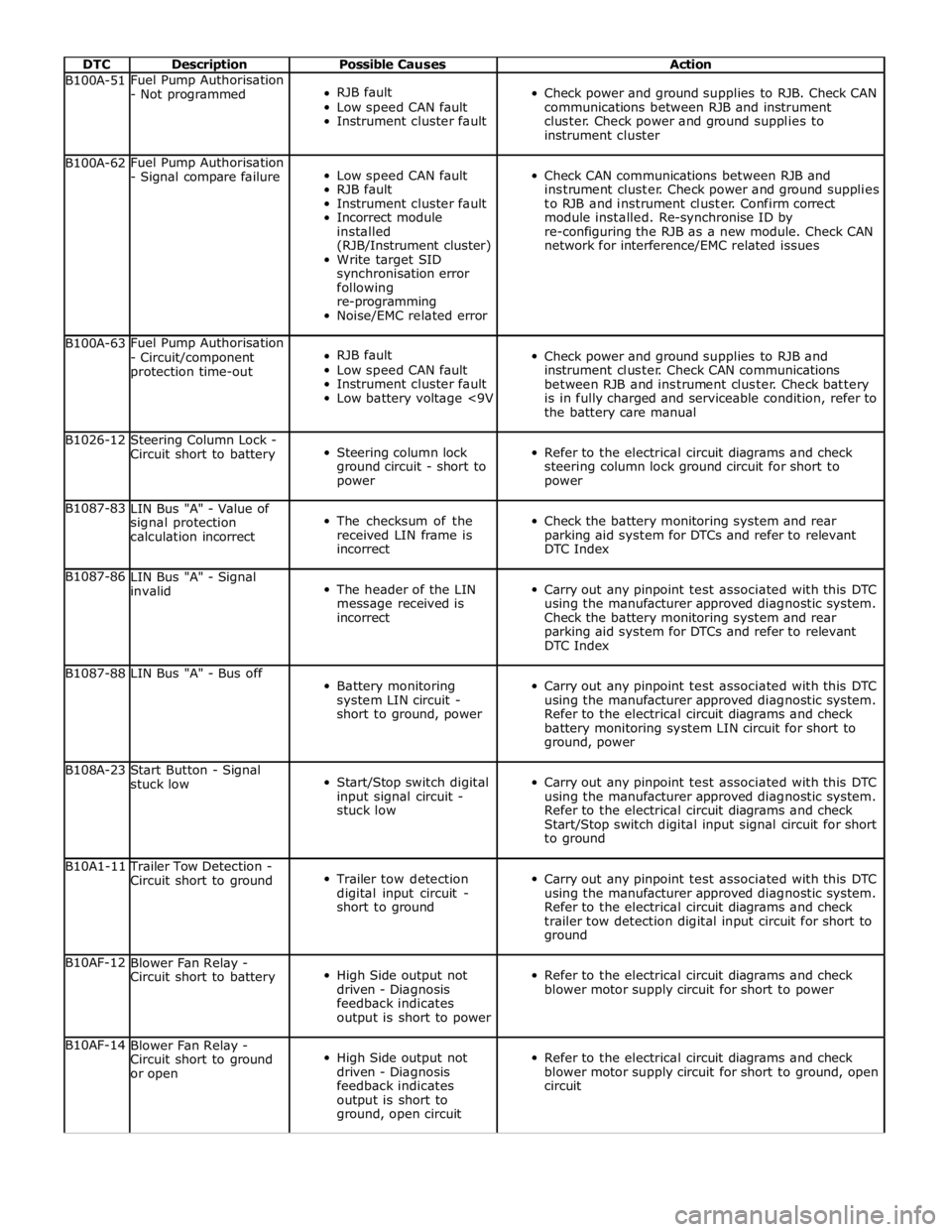

DTC Description Possible Causes Action B100A-51 Fuel Pump Authorisation

- Not programmed

RJB fault

Low speed CAN fault

Instrument cluster fault

Check power and ground supplies to RJB. Check CAN

communications between RJB and instrument

cluster. Check power and ground supplies to

instrument cluster B100A-62 Fuel Pump Authorisation

- Signal compare failure

Low speed CAN fault

RJB fault

Instrument cluster fault

Incorrect module

installed

(RJB/Instrument cluster)

Write target SID

synchronisation error

following

re-programming

Noise/EMC related error

Check CAN communications between RJB and

instrument cluster. Check power and ground supplies

to RJB and instrument cluster. Confirm correct

module installed. Re-synchronise ID by

re-configuring the RJB as a new module. Check CAN

network for interference/EMC related issues B100A-63 Fuel Pump Authorisation

- Circuit/component

protection time-out

RJB fault

Low speed CAN fault

Instrument cluster fault

Low battery voltage <9V

Check power and ground supplies to RJB and

instrument cluster. Check CAN communications

between RJB and instrument cluster. Check battery

is in fully charged and serviceable condition, refer to

the battery care manual B1026-12

Steering Column Lock -

Circuit short to battery

Steering column lock

ground circuit - short to

power

Refer to the electrical circuit diagrams and check

steering column lock ground circuit for short to

power B1087-83

LIN Bus "A" - Value of

signal protection

calculation incorrect

The checksum of the

received LIN frame is

incorrect

Check the battery monitoring system and rear

parking aid system for DTCs and refer to relevant

DTC Index B1087-86

LIN Bus "A" - Signal

invalid

The header of the LIN

message received is

incorrect

Carry out any pinpoint test associated with this DTC

using the manufacturer approved diagnostic system.

Check the battery monitoring system and rear

parking aid system for DTCs and refer to relevant

DTC Index B1087-88 LIN Bus "A" - Bus off

Battery monitoring

system LIN circuit -

short to ground, power

Carry out any pinpoint test associated with this DTC

using the manufacturer approved diagnostic system.

Refer to the electrical circuit diagrams and check

battery monitoring system LIN circuit for short to

ground, power B108A-23

Start Button - Signal

stuck low

Start/Stop switch digital

input signal circuit -

stuck low

Carry out any pinpoint test associated with this DTC

using the manufacturer approved diagnostic system.

Refer to the electrical circuit diagrams and check

Start/Stop switch digital input signal circuit for short

to ground B10A1-11 Trailer Tow Detection -

Circuit short to ground

Trailer tow detection

digital input circuit -

short to ground

Carry out any pinpoint test associated with this DTC

using the manufacturer approved diagnostic system.

Refer to the electrical circuit diagrams and check

trailer tow detection digital input circuit for short to

ground B10AF-12

Blower Fan Relay -

Circuit short to battery

High Side output not

driven - Diagnosis

feedback indicates

output is short to power

Refer to the electrical circuit diagrams and check

blower motor supply circuit for short to power B10AF-14

Blower Fan Relay -

Circuit short to ground

or open

High Side output not

driven - Diagnosis

feedback indicates

output is short to

ground, open circuit

Refer to the electrical circuit diagrams and check

blower motor supply circuit for short to ground, open

circuit

Page 225 of 3039

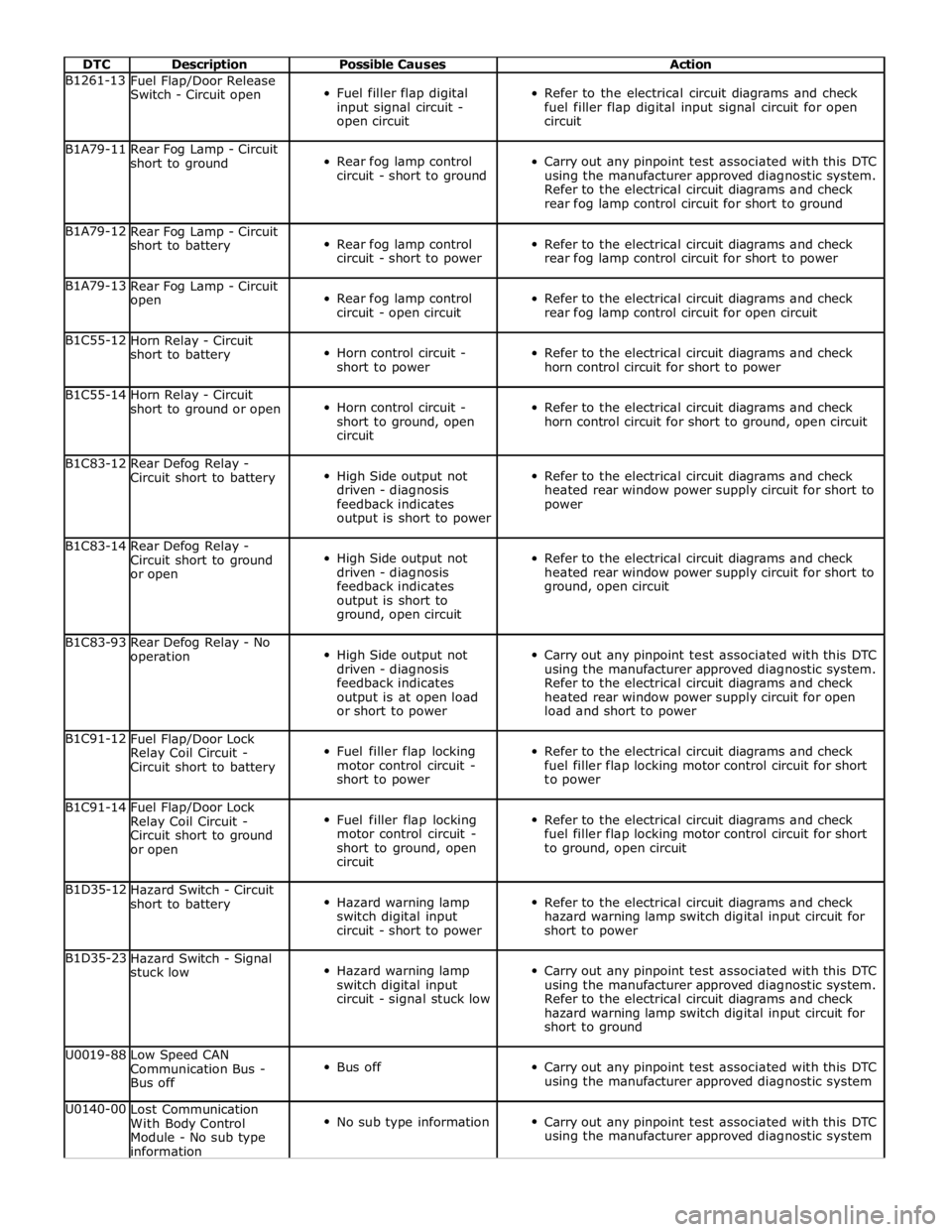

DTC Description Possible Causes Action B1261-13

Fuel Flap/Door Release

Switch - Circuit open

Fuel filler flap digital

input signal circuit -

open circuit

Refer to the electrical circuit diagrams and check

fuel filler flap digital input signal circuit for open

circuit B1A79-11

Rear Fog Lamp - Circuit

short to ground

Rear fog lamp control

circuit - short to ground

Carry out any pinpoint test associated with this DTC

using the manufacturer approved diagnostic system.

Refer to the electrical circuit diagrams and check

rear fog lamp control circuit for short to ground B1A79-12

Rear Fog Lamp - Circuit

short to battery

Rear fog lamp control

circuit - short to power

Refer to the electrical circuit diagrams and check

rear fog lamp control circuit for short to power B1A79-13

Rear Fog Lamp - Circuit

open

Rear fog lamp control

circuit - open circuit

Refer to the electrical circuit diagrams and check

rear fog lamp control circuit for open circuit B1C55-12

Horn Relay - Circuit

short to battery

Horn control circuit -

short to power

Refer to the electrical circuit diagrams and check

horn control circuit for short to power B1C55-14

Horn Relay - Circuit

short to ground or open

Horn control circuit -

short to ground, open

circuit

Refer to the electrical circuit diagrams and check

horn control circuit for short to ground, open circuit B1C83-12

Rear Defog Relay -

Circuit short to battery

High Side output not

driven - diagnosis

feedback indicates

output is short to power

Refer to the electrical circuit diagrams and check

heated rear window power supply circuit for short to

power B1C83-14

Rear Defog Relay -

Circuit short to ground

or open

High Side output not

driven - diagnosis

feedback indicates

output is short to

ground, open circuit

Refer to the electrical circuit diagrams and check

heated rear window power supply circuit for short to

ground, open circuit B1C83-93

Rear Defog Relay - No

operation

High Side output not

driven - diagnosis

feedback indicates

output is at open load

or short to power

Carry out any pinpoint test associated with this DTC

using the manufacturer approved diagnostic system.

Refer to the electrical circuit diagrams and check

heated rear window power supply circuit for open

load and short to power B1C91-12

Fuel Flap/Door Lock

Relay Coil Circuit -

Circuit short to battery

Fuel filler flap locking

motor control circuit -

short to power

Refer to the electrical circuit diagrams and check

fuel filler flap locking motor control circuit for short

to power B1C91-14

Fuel Flap/Door Lock

Relay Coil Circuit -

Circuit short to ground

or open

Fuel filler flap locking

motor control circuit -

short to ground, open

circuit

Refer to the electrical circuit diagrams and check

fuel filler flap locking motor control circuit for short

to ground, open circuit B1D35-12

Hazard Switch - Circuit

short to battery

Hazard warning lamp

switch digital input

circuit - short to power

Refer to the electrical circuit diagrams and check

hazard warning lamp switch digital input circuit for

short to power B1D35-23

Hazard Switch - Signal

stuck low

Hazard warning lamp

switch digital input

circuit - signal stuck low

Carry out any pinpoint test associated with this DTC

using the manufacturer approved diagnostic system.

Refer to the electrical circuit diagrams and check

hazard warning lamp switch digital input circuit for

short to ground U0019-88

Low Speed CAN

Communication Bus -

Bus off

Bus off

Carry out any pinpoint test associated with this DTC

using the manufacturer approved diagnostic system U0140-00

Lost Communication

With Body Control

Module - No sub type

information

No sub type information

Carry out any pinpoint test associated with this DTC

using the manufacturer approved diagnostic system

Page 300 of 3039

Noise Conditions

Gear noise is typically a howling or whining due to gear damage or incorrect bearing preload. It can occur at various

speeds and driving conditions, or it can be continuous

Chuckle is a particular rattling noise that sounds like a stick against the spokes of a spinning bicycle wheel. It occurs

while decelerating from approximately 64 km/h (40 miles/h) and can usually be heard all the way to a stop. The

frequency varies with vehicle speed

Knock is very similar to chuckle, though it may be louder and occurs on acceleration or deceleration. The tear down will

disclose what has to be corrected

Check and rule out tires, exhaust and trim items before disassembling the transmission to diagnose and correct gear noise.

The noises described under Road Test usually have specific causes that can be diagnosed by observation as the unit is

disassembled. The initial clues are the type of noise heard on the road test and the driving conditions.

Vibration Conditions

wear. NOTE: New Constant Velocity (CV) joints should not be installed unless disassembly and inspection revealed unusual

Clicking, popping or grinding noises may be caused by the following:

Cut or damaged CV joint boots resulting in inadequate or contaminated lubricant in the outboard or inboard CV joint

bearing housings

Loose CV joint boot clamps

Another component contacting the rear drive half shaft

Worn, damaged or incorrectly installed wheel bearing, suspension or brake component

Vibration at highway speeds may be caused by the following:

Out-of-balance front or rear wheels

Out-of-round tires

Driveline imbalance

Driveline run-out (alignment)

NOTE: Rear drive half shafts are not balanced and are not likely to contribute to rotational vibration disturbance.

Shudder or vibration during acceleration (including from rest) may be caused by the following:

Driveline alignment

Excessively worn or damaged outboard or inboard CV joint bearing housing

Excessively high CV joint operating angles caused by incorrect ride height. Check ride height, verify correct spring rate

and check items under Inoperative Conditions

Excessively worn driveshaft components

Leakage Conditions

1. Inspect the CV joint boots for evidence of cracks, tears or splits.

2. Inspect the underbody for any indication of grease splatter in the vicinity of the rear drive half shaft, outboard and

inboard CV joint boot locations, which is an indication of CV joint boot or CV joint boot clamp damage.

3. Inspect the inboard CV joint bearing housing seal for leakage.

Inoperative Conditions

If a CV joint or rear drive half shaft pull-out occurs, check the following:

suspension components for correct location, damage or wear

bushings for wear

subframe for damage

bent or worn components

- Stabilizer bar link

- Left-hand rear suspension lower arm and bushing

- Right-hand rear suspension lower arm and bushing

- Rear wheel hub and rear drive half shaft

Road Test

A gear-driven unit will produce a certain amount of noise. Some noise is acceptable and may be audible at certain speeds or

under various driving conditions as on a newly paved blacktop road. The slight noise is in no way detrimental and must be

considered normal.

The road test and customer interview (if available) provide information needed to identify the condition and give direction to

the correct starting point for diagnosis.

1. Make notes throughout the diagnosis routine. Make sure to write down even the smallest piece of information, because

Page 301 of 3039

it may turn out to be the most important.

2. Do not touch anything until a road test and a thorough visual inspection of the vehicle have been carried out. Leave the

tire pressures and vehicle load just where they were when the condition was first observed. Adjusting tire pressures,

vehicle load or making other adjustments may reduce the conditions intensity to a point where it cannot be identified

clearly. It may also inject something new into the system, preventing correct diagnosis.

3. Make a visual inspection as part of the preliminary diagnosis routine, writing down anything that does not look right.

Note tire pressures, but do not adjust them yet. Note leaking fluids, loose nuts and bolts, or bright spots where

components may be rubbing against each other. Check the luggage compartment for unusual loads.

4. Road test the vehicle and define the condition by reproducing it several times during the road test.

5. Carry out the Road Test Quick Checks as soon as the condition is reproduced. This will identify the correct diagnostic

procedure. Carry out the Road Test Quick Checks more than once to verify they are providing a valid result. Remember,

the Road Test Quick Checks may not tell where the concern is, but they will tell where it is not.

Road Test Quick Checks

1. 24-80 km/h (15-50 miles/h): With light acceleration, a moaning noise is heard and possibly a vibration is felt in the

front floor pan. It is usually worse at a particular engine speed and at a particular throttle setting during acceleration at

that speed. It may also produce a moaning sound, depending on what component is causing it. Refer to Tip-In Moan in

the Symptom Chart.

2. Acceleration/deceleration: With slow acceleration and deceleration, a shake is sometimes noticed in the steering

wheel/column, seats, front floor pan, front door trim panel or front end sheet metal. It is a low frequency vibration

(around 9-15 cycles per second). It may or may not be increased by applying brakes lightly. Refer to Idle Boom/Shake

/Vibration in the Symptom Chart.

3. High speed: A vibration is felt in the front floor pan or seats with no visible shake, but with an accompanying sound or

rumble, buzz, hum, drone or booming noise. Coast with the clutch pedal depressed or shift control selector lever in

neutral and engine idling. If vibration is still evident, it may be related to wheels, tires, front brake discs, wheel hubs

or front wheel bearings. Refer to High Speed Shake in the Symptom Chart.

4. Engine rpm sensitive: A vibration is felt whenever the engine reaches a particular rpm. It will disappear in neutral

coasts. The vibration can be duplicated by operating the engine at the problem rpm while the vehicle is stationary. It

can be caused by any component, from the accessory drive belt to the torque converter which turns at engine speed

when the vehicle is stopped. Refer to High Speed Shake in the Symptom Chart.

5. Noise/vibration while turning: Clicking, popping, or grinding noises may be due to a worn, damaged, or incorrectly

installed front wheel bearing, rear drive half shaft or CV joint.

6. Noise/vibration that is road speed relative: This noise/vibration can be diagnosed independent of engine speed or gear

selected (engine speed varies but torque and road speed remain constant). The cause may be a rear drive

axle/differential whine.

Road Conditions

An experienced technician will always establish a route that will be used for all NVH diagnosis road tests. The road selected

should be reasonably smooth, level and free of undulations (unless a particular condition needs to be identified). A smooth

asphalt road that allows driving over a range of speeds is best. Gravel or bumpy roads are unsuitable because of the additional

road noise produced. Once the route is established and consistently used, the road noise variable is eliminated from the test

results.

NOTE: Some concerns may be apparent only on smooth asphalt roads.

If a customer complains of a noise or vibration on a particular road and only on a particular road, the source of the concern

may be the road surface. If possible, try to test the vehicle on the same type of road.

Vehicle Preparation

Carry out a thorough visual inspection of the vehicle before carrying out the road test. Note anything which is unusual. Do not

repair or adjust any condition until the road test is carried out, unless the vehicle is inoperative or the condition could pose a

hazard to the technician.

After verifying the condition has been corrected, make sure all components removed have been installed.

Lift Test

After a road test, it is sometimes useful to do a similar test on a lift.

When carrying out the high-speed shake diagnosis or engine accessory vibration diagnosis on a lift, observe the following

precautions:

WARNING: If only one drive wheel is allowed to rotate, speed must be limited to 55 km/h (35 miles/h) indicated on the

speedometer since actual wheel speed will be twice that indicated on the speedometer. Speed exceeding 55 km/h (35 miles/h)

or allowing the drive wheel to hang unsupported could result in tire disintegration, differential failure, constant velocity joint