oil type JAGUAR XFR 2010 1.G User Guide

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 2010, Model line: XFR, Model: JAGUAR XFR 2010 1.GPages: 3039, PDF Size: 58.49 MB

Page 1270 of 3039

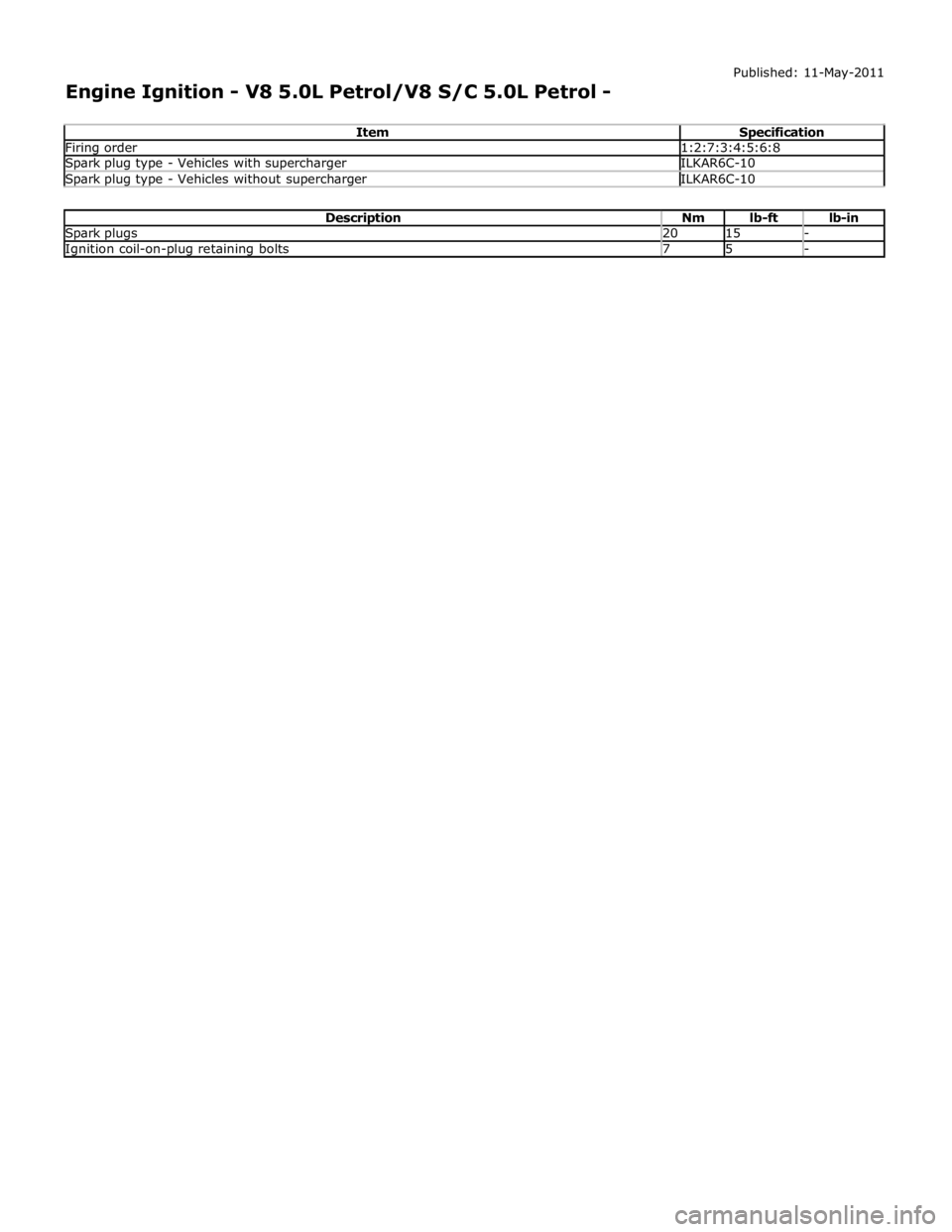

Firing order 1:2:7:3:4:5:6:8 Spark plug type - Vehicles with supercharger ILKAR6C-10 Spark plug type - Vehicles without supercharger ILKAR6C-10

Description Nm lb-ft lb-in Spark plugs 20 15 - Ignition coil-on-plug retaining bolts 7 5 -

Page 1317 of 3039

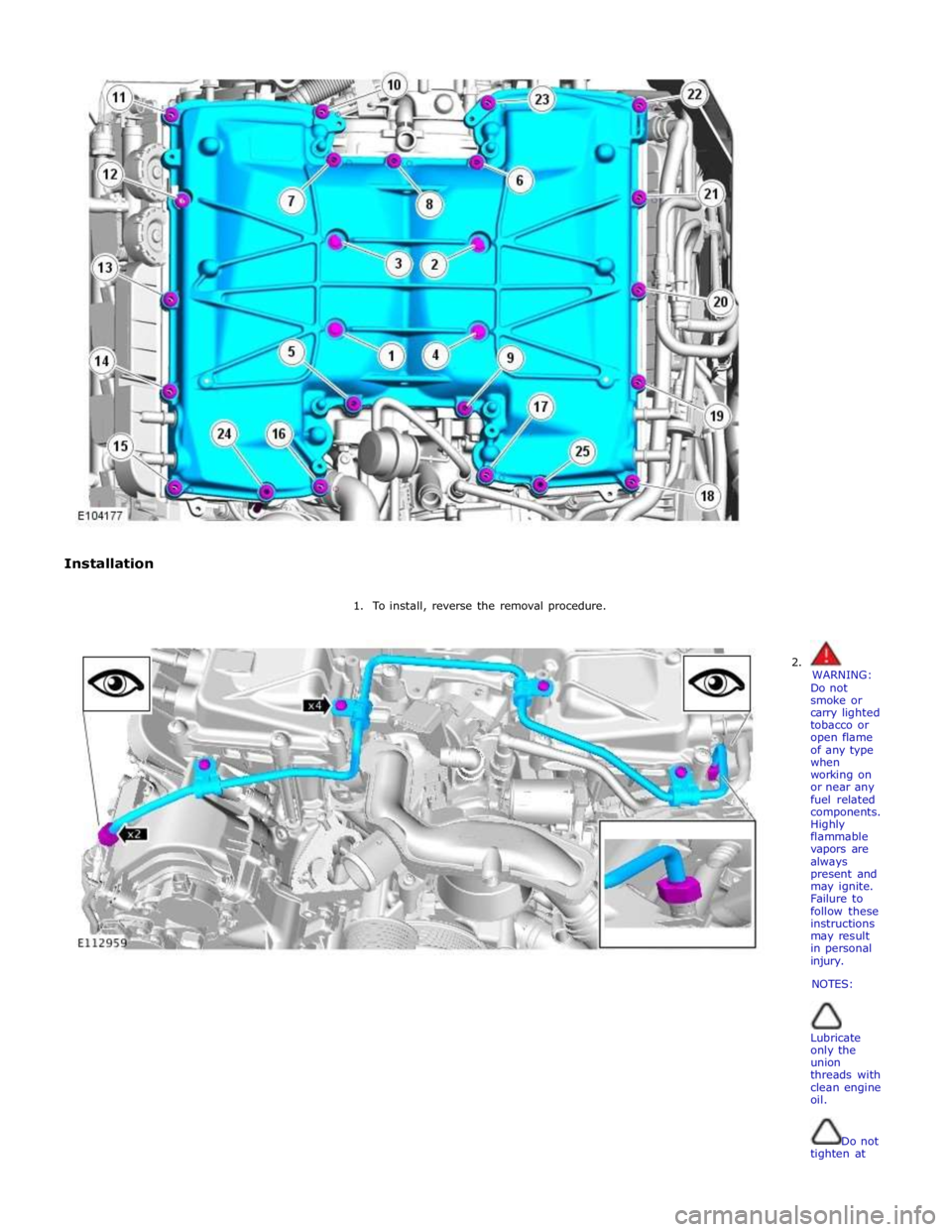

Installation

1. To install, reverse the removal procedure.

2.

WARNING:

Do not

smoke or

carry lighted

tobacco or

open flame

of any type

when

working on

or near any

fuel related

components.

Highly

flammable

vapors are

always

present and

may ignite.

Failure to

follow these

instructions

may result

in personal

injury.

NOTES:

Lubricate

only the

union

threads with

clean engine

oil.

Do not

tighten at

Page 1373 of 3039

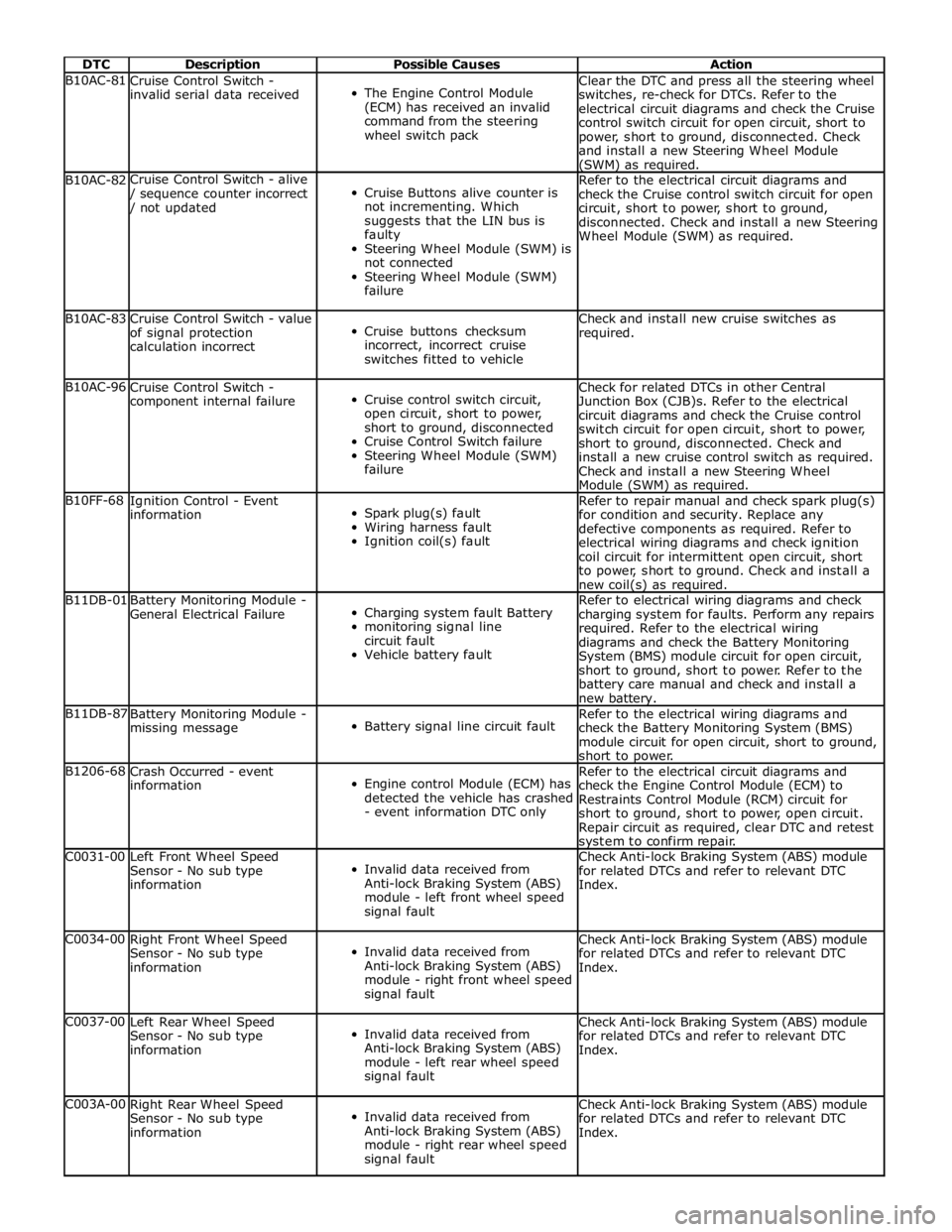

DTC Description Possible Causes Action B10AC-81

Cruise Control Switch -

invalid serial data received

The Engine Control Module

(ECM) has received an invalid

command from the steering

wheel switch pack Clear the DTC and press all the steering wheel

switches, re-check for DTCs. Refer to the

electrical circuit diagrams and check the Cruise

control switch circuit for open circuit, short to

power, short to ground, disconnected. Check

and install a new Steering Wheel Module (SWM) as required. B10AC-82 Cruise Control Switch - alive / sequence counter incorrect / not updated

Cruise Buttons alive counter is

not incrementing. Which

suggests that the LIN bus is

faulty

Steering Wheel Module (SWM) is

not connected

Steering Wheel Module (SWM)

failure Refer to the electrical circuit diagrams and

check the Cruise control switch circuit for open

circuit, short to power, short to ground,

disconnected. Check and install a new Steering

Wheel Module (SWM) as required. B10AC-83

Cruise Control Switch - value

of signal protection

calculation incorrect

Cruise buttons checksum

incorrect, incorrect cruise

switches fitted to vehicle Check and install new cruise switches as

required. B10AC-96

Cruise Control Switch -

component internal failure

Cruise control switch circuit,

open circuit, short to power,

short to ground, disconnected

Cruise Control Switch failure

Steering Wheel Module (SWM)

failure Check for related DTCs in other Central

Junction Box (CJB)s. Refer to the electrical

circuit diagrams and check the Cruise control

switch circuit for open circuit, short to power,

short to ground, disconnected. Check and

install a new cruise control switch as required.

Check and install a new Steering Wheel

Module (SWM) as required. B10FF-68

Ignition Control - Event

information

Spark plug(s) fault

Wiring harness fault

Ignition coil(s) fault Refer to repair manual and check spark plug(s)

for condition and security. Replace any

defective components as required. Refer to

electrical wiring diagrams and check ignition

coil circuit for intermittent open circuit, short

to power, short to ground. Check and install a

new coil(s) as required. B11DB-01

Battery Monitoring Module -

General Electrical Failure

Charging system fault Battery

monitoring signal line

circuit fault

Vehicle battery fault Refer to electrical wiring diagrams and check

charging system for faults. Perform any repairs

required. Refer to the electrical wiring

diagrams and check the Battery Monitoring

System (BMS) module circuit for open circuit,

short to ground, short to power. Refer to the

battery care manual and check and install a

new battery. B11DB-87

Battery Monitoring Module -

missing message

Battery signal line circuit fault Refer to the electrical wiring diagrams and

check the Battery Monitoring System (BMS)

module circuit for open circuit, short to ground,

short to power. B1206-68

Crash Occurred - event

information

Engine control Module (ECM) has

detected the vehicle has crashed

- event information DTC only Refer to the electrical circuit diagrams and

check the Engine Control Module (ECM) to

Restraints Control Module (RCM) circuit for

short to ground, short to power, open circuit.

Repair circuit as required, clear DTC and retest

system to confirm repair. C0031-00

Left Front Wheel Speed

Sensor - No sub type

information

Invalid data received from

Anti-lock Braking System (ABS)

module - left front wheel speed

signal fault Check Anti-lock Braking System (ABS) module

for related DTCs and refer to relevant DTC

Index. C0034-00

Right Front Wheel Speed

Sensor - No sub type

information

Invalid data received from

Anti-lock Braking System (ABS)

module - right front wheel speed

signal fault Check Anti-lock Braking System (ABS) module

for related DTCs and refer to relevant DTC

Index. C0037-00

Left Rear Wheel Speed

Sensor - No sub type

information

Invalid data received from

Anti-lock Braking System (ABS)

module - left rear wheel speed

signal fault Check Anti-lock Braking System (ABS) module

for related DTCs and refer to relevant DTC

Index. C003A-00

Right Rear Wheel Speed

Sensor - No sub type

information

Invalid data received from

Anti-lock Braking System (ABS)

module - right rear wheel speed

signal fault Check Anti-lock Braking System (ABS) module

for related DTCs and refer to relevant DTC

Index.

Page 1429 of 3039

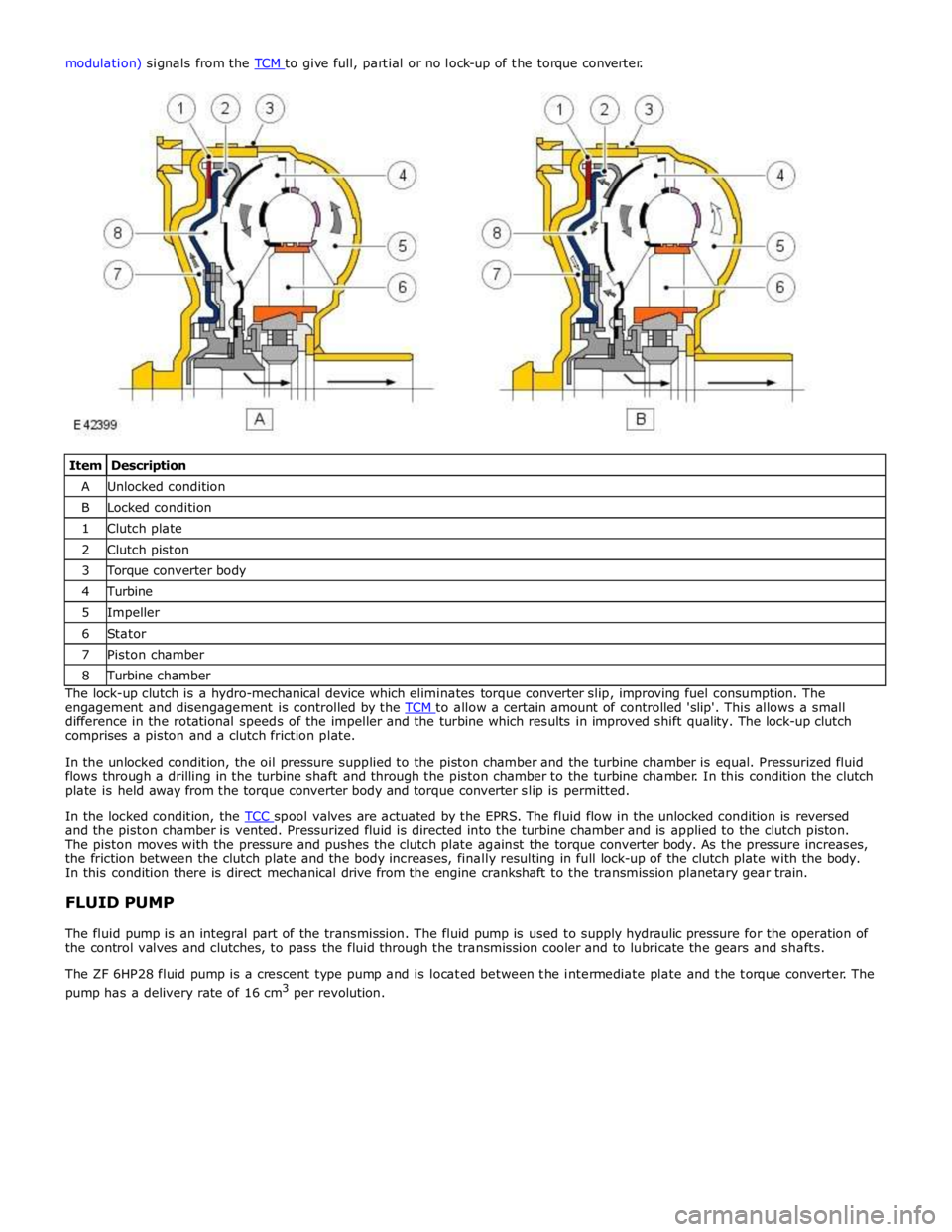

Item Description A Unlocked condition B Locked condition 1 Clutch plate 2 Clutch piston 3 Torque converter body 4 Turbine 5 Impeller 6 Stator 7 Piston chamber 8 Turbine chamber The lock-up clutch is a hydro-mechanical device which eliminates torque converter slip, improving fuel consumption. The

engagement and disengagement is controlled by the TCM to allow a certain amount of controlled 'slip'. This allows a small difference in the rotational speeds of the impeller and the turbine which results in improved shift quality. The lock-up clutch

comprises a piston and a clutch friction plate.

In the unlocked condition, the oil pressure supplied to the piston chamber and the turbine chamber is equal. Pressurized fluid

flows through a drilling in the turbine shaft and through the piston chamber to the turbine chamber. In this condition the clutch

plate is held away from the torque converter body and torque converter slip is permitted.

In the locked condition, the TCC spool valves are actuated by the EPRS. The fluid flow in the unlocked condition is reversed and the piston chamber is vented. Pressurized fluid is directed into the turbine chamber and is applied to the clutch piston.

The piston moves with the pressure and pushes the clutch plate against the torque converter body. As the pressure increases,

the friction between the clutch plate and the body increases, finally resulting in full lock-up of the clutch plate with the body.

In this condition there is direct mechanical drive from the engine crankshaft to the transmission planetary gear train.

FLUID PUMP

The fluid pump is an integral part of the transmission. The fluid pump is used to supply hydraulic pressure for the operation of

the control valves and clutches, to pass the fluid through the transmission cooler and to lubricate the gears and shafts.

The ZF 6HP28 fluid pump is a crescent type pump and is located between the intermediate plate and the torque converter. The

pump has a delivery rate of 16 cm3

per revolution.

Page 1435 of 3039

Published: 25-Aug-2011

Automatic Transmission/Transaxle - TDV6 3.0L Diesel /V8 5.0L Petrol/V8 S/C 5.0L Petrol - Diagnostics

Diagnosis and Testing

Principle of Operation

For a detailed description of the automatic transmission/transaxle, refer to the relevant Description and Operation section n

the workshop manual. REFER to: (307-01B Automatic Transmission/Transaxle - TDV6 3.0L Diesel /V8 5.0L Petrol/V8 S/C 5.0L

Petrol)

Transmission Description (Description and Operation), Transmission Description (Description and Operation), Transmission Description (Description and Operation).

Fluid Level and Condition Check

CAUTION: The vehicle should not be driven if the fluid level is low as internal failure can result.

NOTE: The transmission fluid temperature must not be allowed to exceed 50°C (122°F) whilst checking level. Should the

temperature rise above this figure, abort the check and allow the transmission fluid to cool to below 30°C (86°F).

This vehicle is not equipped with a fluid level indicator. An incorrect level may affect the transmission operation and could

result in transmission damage. To correctly check and add fluid to the transmission.

REFER to: Transmission Fluid Level Check (307-01B Automatic Transmission/Transaxle - TDV6 3.0L Diesel /V8 5.0L Petrol/V8 S/C 5.0L Petrol, General Procedures).

High Fluid Level

A fluid level that is too high may cause the fluid to become aerated due to the churning action of the rotating internal parts.

This will cause erratic control pressure, foaming, loss of fluid from the vent tube and possible transmission damage. If an

overfill condition is identified, with the engine at idle ensure the fluid temperature is within the specified range and allow the

excess fluid to drain until a small thread of fluid runs from the filler/level plug hole.

Low Fluid Level

A low fluid level could result in poor transmission engagement, slipping, or damage. This could also indicate a leak in one of

the transmission seals or gaskets.

REFER to: Transmission Fluid Level Check (307-01B Automatic Transmission/Transaxle - TDV6 3.0L Diesel /V8 5.0L Petrol/V8 S/C 5.0L Petrol, General Procedures).

Adding Fluid

CAUTION: The use of any other type of transmission fluid other than that specified can result in transmission damage.

If fluid needs to be added, add fluid in 0.50 liter increments through the fill hole Opening. Do not overfill the fluid. For fluid

type, refer to the General Specification chart in this section.

REFER to: Specifications (307-01B Automatic Transmission/Transaxle - TDV6 3.0L Diesel /V8 5.0L Petrol/V8 S/C 5.0L Petrol, Specifications).

Fluid Condition Check

1. Check the fluid level.

REFER to: Transmission Fluid Level Check (307-01B Automatic Transmission/Transaxle - TDV6 3.0L Diesel /V8 5.0L Petrol/V8 S/C 5.0L Petrol, General Procedures).

2. Observe the color and the odor of the fluid. The color under normal circumstances should be Honey.

3. Allow the fluid to drip onto a facial tissue and examine the stain.

4. If evidence of solid material is found, the transmission fluid pan should be removed for further inspection.

NOTE: In the event of a transmission unit replacement for internal failure, the oil cooler and pipes must also be replaced.

Inspection and Verification

1. Verify the customer concern.

2. Visually inspect for obvious signs of damage and system integrity.

Page 1448 of 3039

DTC Description Possible Cause Action U0416-68

Invalid Data Received From

Vehicle Dynamics Control

Module - event information

Event information brake

information Check Engine control module for stored DTCs. Check

CAN Bus Circuit for fault U0422-68

Invalid Data Received From

Body Control Module - event

information

Event information invalid

Power mode information Check Central junction box for stored DTCs. Check CAN

Bus Circuit for fault U101B-87

Lost Communication With

GSM - Multiple Bus-missing

message

Missing message lost

communication with

Transmission Shift

Module (multiple Bus) Check Transmission Shift Module for stored DTCs.

Refer to Circuit diagrams and check CAN and LIN Bus

for Circuit fault U3000-49

Control Module - internal

electronic failure

Internal electronic failure Suspect the Transmission control module. Install a

new Transmission control module as required, refer to

the new module/component installation note at the top of the DTC Index U3000-4B

Control Module - Circuit

resistance above threshold

Internal electronic failure Check and correct oil level. Check hydraulic flow

through oil cooler and pipe circuit for restriction or

blockage. If no restrictions found, suspect the

Transmission control module. Install a new

Transmission control module as required, refer to the

new module/component installation note at the top of

the DTC Index U3000-81

Control Module - invalid

serial data received

Vehicle or Engine type

signal incorrect from BCM

or incorrect Transmission

control module software

installed Reflash the Transmission control module using the

manufacturer approved process U3001-94

Control Module Improper

Shutdown - unexpected

operation

Control Module Improper

Shutdown (voltage

related) Check Engine control module For Power (generator)

faults. Check Power and Ground Circuit and Battery for

fault. Clear DTCs. Road Test. If DTC reoccurs suspect

the Transmission control module. Install a new

Transmission control module as required, refer to the

new module/component installation note at the top of

the DTC Index

Page 1669 of 3039

8. WARNING: Refrigerant must always be recycled before re-use to ensure

that the purity of the refrigerantis high enough for safe use in the air

conditioning system. Recycling should always be carried out with

equipment which is design certified by Underwriter Laboratory Inc. for

compliance with SEA J1991. Other equipment may not recycle refrigerant

to the required level of purity. R143a Refrigerant Recover Recycling

Recharging station must not be used with any other type of

refrigerant.Refrigerant R134a from domestic and comercial sources must

not be used in motor vehicles air conditioning systems.

Allow the system to recover the refrigerant from the system.

9. Close the valves on the refrigerant station.

10. Turn the main switch 'OFF'.

11. Close the valves on the connections.

12. Disconnect the high and low pressure connections.

13. Install the dust covers to the connectors.

14. Open the tap at the rear of the station to drain the refrigerant oil.

15. Measure and record the quantity of refrigerant oil recovered from the

system.

16. Close the tap at the rear of the station.

17. Evacuation.

18. Remove the dust covers from the high and low pressure connections.

19. Connect the high and low pressure lines to the appropriate connections.

20. Open the valves on the connections.

21. Turn the valves on the station to the correct positions.

22. Turn the process switch to the correct position.

23. Turn the main switch to 'ON'.

24. Allow the station to evacuate the A/C system.

25. CAUTION: The system must be evacuated immediatley before

recharging commences. Delay between evacuation and recharging is not

permitted

Recharging

26. Close the valves on the refrigerant station.

Page 2032 of 3039

15 Xenon igniter unit and bulb 16 Xenon igniter electrical connector 17 Cornering/static bending lamp bulb (if fitted) 18 Side lamp bulb 19 High beam headlamp bulb 20 Cover - Side lamp, cornering/static bending lamp (if fitted) and high beam headlamp bulbs 21 Electrical connector Bi-Xenon Headlamp

The bi-xenon headlamp uses a projector lens, similar to the halogen headlamp. The projector module comprises an ellipsoidal

lens and a reflector. The projector reflector collects the light produced by the halogen bulb and projects the light into a focal

plane containing a shield. The contour of the shield is projected onto the road by the lens. A complex surface reflector is used

for the halogen fill in high beam lamp. This type of reflector is divided into separate parabolic segments, with each segment

having a different focal length. The low and high beam bulbs are quartz halogen H7, with a rating of 55W. The bulbs are

retained in the headlamp unit with conventional wire retaining clips.

A tourist lever mechanism is located on the right hand side of the projector module. This mechanism moves a flap to blank off

a portion of the beam spread to enable the vehicle to be driven in opposite drive hand markets without applying blanking

decals to the headlamp lens. The beam is changed by removing the access cover at the rear of the lamp assembly and moving

a small lever located near the bulb holder, at the side of the projector.

NOTE: The tourist lever is not fitted to NAS vehicles.

WARNING: The Xenon system generates up to 30000 volts and contact with this voltage could lead to fatality. Make sure

that the headlamps are switched off before working on the system.

The following safety precautions must be adhered to when working on the xenon low beam headlamp system:

DO NOT attempt any procedures on the xenon headlamps when the lights are switched on.

Handling of the D1S xenon bulb must be performed using suitable protective equipment; for example gloves and

goggles. The glass part of the bulb must not be touched.

Xenon bulbs must be disposed of as hazardous waste.

Only operate the bulb in a mounted condition in the projector module installed in the headlamp.

The xenon headlamp is known as 'bi-xenon' because it operates as both a low and high beam headlamp unit. The xenon lamp,

or High Intensity Discharge (HID) lamp as they are sometimes referred to, comprises an ellipsoidal lens with a solenoid

controlled shutter to change the beam output from low to high beam.

NOTE: If the lighting control switch is in the 'off' position, both the xenon lamp and the halogen high beam lamp will

operate when the high beam 'flash' function is operated.

The xenon headlamp system is controlled by the CJB using a control module for each headlamp and an igniter. The control modules and the igniters provide the regulated power supply required to illuminate the bulbs through their start-up phases of

operation.

The xenon headlamp is a self contained unit located within the headlamp assembly. The unit comprises a reflector, an adaptor

ring, the lens, a shutter controller and the xenon bulb, which together forms an assembly known as the projector module. The

reflector is curved and provides the mounting point for the xenon bulb. The bulb locates in a keyway to ensure the correct

alignment in the reflector and is secured by a plastic mounting ring. The bulb is an integral component of the igniter and is

electrically connected by a connector located in the igniter unit.

The shutter controller is a solenoid which operates the shutter mechanism via a lever. The shutter is used to change the beam

projection from low beam to high beam and vice versa.

The xenon bulbs illuminate when an arc of electrical current is established between 2 electrodes within the bulb. The xenon

gas sealed in the bulb reacts to the electrical excitation and the heat generated by the current flow to produce the

characteristic blue/white light.

To operate at full efficiency, the xenon bulb goes through 3 full stages of operation before full output for continuous operation

is achieved. The 3 phases are; start-up phase, warm-up phase and continuous phase.

In the start-up phase, the bulb requires an initial high voltage starting pulse of up to 30000 volts to establish the arc. This is

produced by the igniter. The warm-up phase begins once the arc is established. The xenon control module regulates the supply

to the bulb to 2.6A which gives a lamp output of 75W. During this phase, the xenon gas begins to illuminate brightly and the

environment within the bulb stabilizes, ensuring a continual current flow between the electrodes. When the warm-up phase is

complete, the xenon control module changes to continuous phase. The supply voltage to the bulb is reduced and the operating

power required for continual operation is reduced to 35W. The process from start-up to continuous phase is completed in a very

short time.

The xenon control modules (one per headlamp) receive an operating voltage from the CJB when the headlamps are switched on. The modules regulate the power supply required through the phases of start-up.

The igniters (one per headlamp) generate the initial high voltage required to establish the arc. The igniters have integral coils

which generate high voltage pulses required for start-up. Once the xenon bulbs are operating, the igniters provide a closed

circuit for the regulated power supply from the control modules.

Page 2325 of 3039

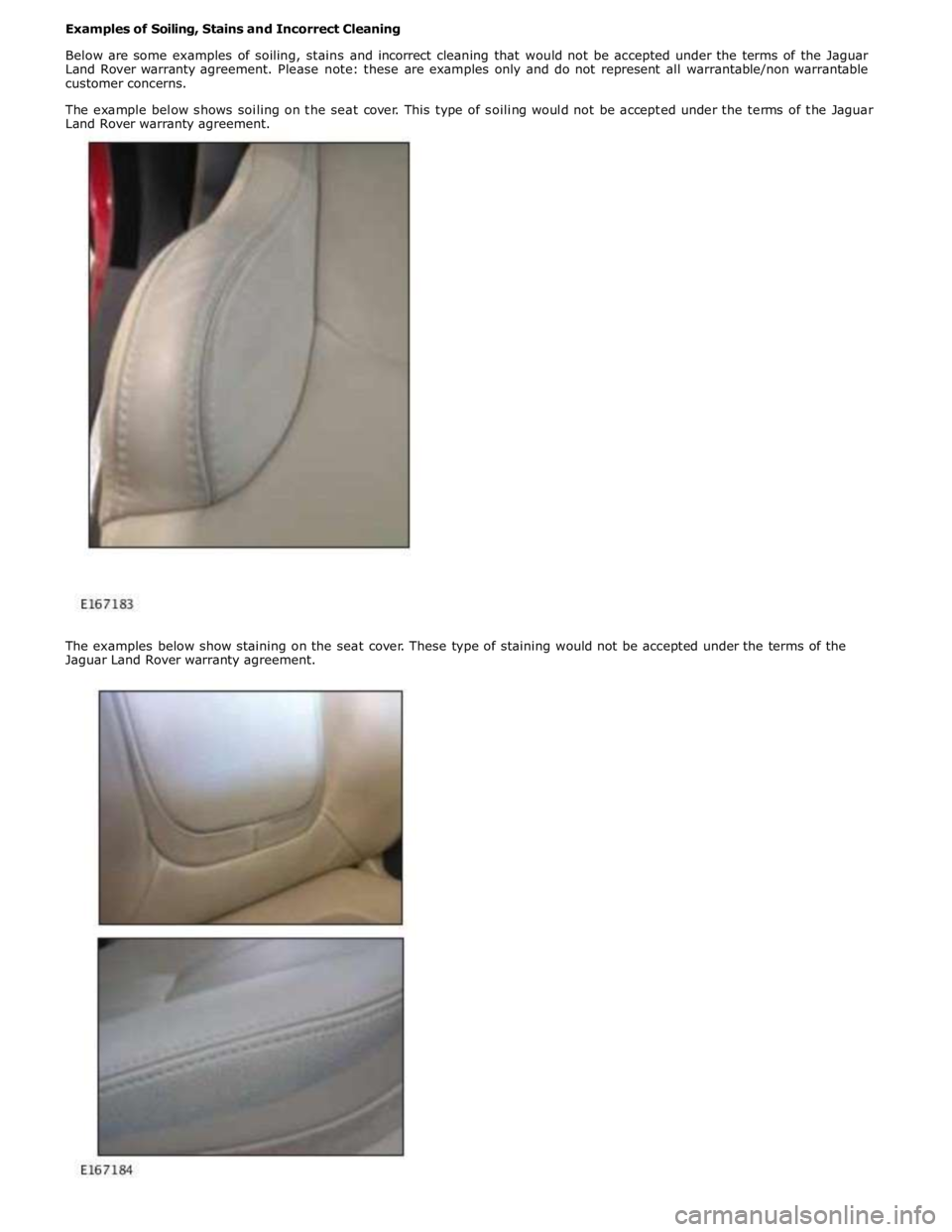

Examples of Soiling, Stains and Incorrect Cleaning

Below are some examples of soiling, stains and incorrect cleaning that would not be accepted under the terms of the Jaguar

Land Rover warranty agreement. Please note: these are examples only and do not represent all warrantable/non warrantable

customer concerns.

The example below shows soiling on the seat cover. This type of soiling would not be accepted under the terms of the Jaguar

Land Rover warranty agreement.

The examples below show staining on the seat cover. These type of staining would not be accepted under the terms of the

Jaguar Land Rover warranty agreement.