seat adjustment JAGUAR XFR 2010 1.G User Guide

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 2010, Model line: XFR, Model: JAGUAR XFR 2010 1.GPages: 3039, PDF Size: 58.49 MB

Page 1784 of 3039

7 Instrument cluster 8 Steering column motor 9 High speed CAN bus connection to other vehicle systems 10 Engine oil pressure switch 11 Steering column adjustment switch 12 Brake fluid level switch 13 LH (left-hand) steering column multifunction switch 14 Start control module 15 Clockspring 16 RH (right-hand) steering column multifunction switch 17 Engine coolant level sensor 18 Auxiliary lighting switch

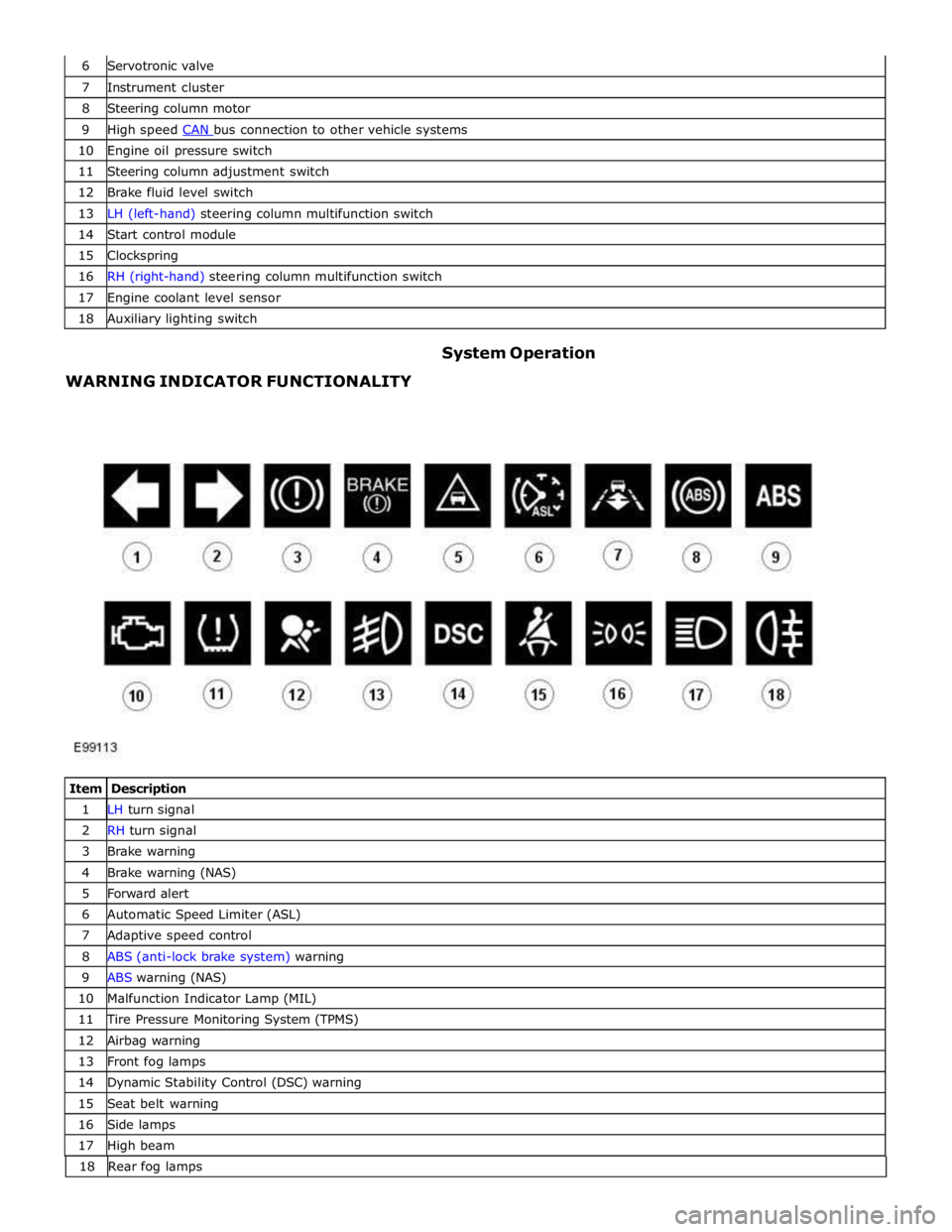

WARNING INDICATOR FUNCTIONALITY System Operation

Item Description 1 LH turn signal 2 RH turn signal 3 Brake warning 4 Brake warning (NAS) 5 Forward alert 6 Automatic Speed Limiter (ASL) 7 Adaptive speed control 8 ABS (anti-lock brake system) warning 9 ABS warning (NAS) 10 Malfunction Indicator Lamp (MIL) 11 Tire Pressure Monitoring System (TPMS) 12 Airbag warning 13 Front fog lamps 14 Dynamic Stability Control (DSC) warning 15 Seat belt warning 16 Side lamps 17 High beam 18 Rearfoglamps

Page 1827 of 3039

NO SPEECH

DETECTED None

Jaguar Voice system is expecting a voice

command . Repeat required voice command. STORING None

Jaguar Voice system is storing input telephone information. None COMMAND

CANCELLED None

Jaguar Voice button has been pressed

and held. Previous command cancelled. SEARCHING None

Jaguar Voice system is searching for requested information from phone book. None HOLD BUTTON TO CANCEL None

Jaguar Voice system has requested a

command to be cancelled. None FUEL LEVEL LOW

Amber warning triangle

illuminated LCD. Fuel level in fuel tank has fallen below

low fuel warning limit. Replenish fuel tank. FUEL PUMP

SYSTEM FAULT Amber warning triangle

illuminated LCD. Fuel pump or FPDM fault has occurred.

Investigate cause of fault. Interrogate

ECM for faults and diagnose using an approved Jaguar Diagnostic System. WASHER FLUID

LOW Amber warning triangle

illuminated LCD. Fluid level has fallen below low level

switch in windshield washer reservoir. Replenish reservoir. DOOR OPEN

Red text is illuminated in

LCD and vehicle view Door is open or incorrectly closed. Close open door. showing open luggage

compartment lid is

displayed. BOOT OPEN

Red text is illuminated in

LCD and vehicle view Luggage compartment lid is open or incorrectly closed. Close open luggage compartment lid. showing open door location

is displayed. COLUMN ADJUST None

Manual column adjust has been selected

on steering column adjustment switch. None COLUMN ADJUST

AUTO None

Automatic column adjust has been

selected on steering column adjustment

switch. None MEMORY 1 / 2 / 3 / 4 SETTINGS

RECALLED None

Memory button has been pressed to

recall memory positions for seat, steering column and mirrors. None MEMORY 1 / 2 / 3 / 4 SETTINGS

SAVED None

Memory has been saved for one of the

memory button positions. None SEAT BELT

MINDER None

Engine has been started and driver

and/or front passenger seat belt has not

been fastened. Fasten seat belt(s). CHECK

PEDESTRIAN

SYSTEM Red warning triangle

illuminated in LCD. A fault has occurred with the pedestrian

protection system. Investigate cause of fault. Interrogate

pedestrian protection system control

module for faults and diagnose using

an approved Jaguar Diagnostic System. INERTIA SWITCH TRIPPED Amber warning triangle

illuminated LCD. Message appears when the crash status

signal from the RCM (restraints control

module) changes to crash detected or a

fault in the restraints system prevents

the message from being transmitted. RCM can be rest with an ignition on/off cycle. If fault has occurred, then

investigate cause of fault and

interrogate the RCM for faults and diagnose using an approved Jaguar

Diagnostic System. VALET MODE None

Confirmation that valet mode has been

entered. None VEHICLE ARMED None

Confirmation that alarm and

immobilization has been achieved. None SMART KEY NOT

FOUND PLEASE

INSERT IN SLOT Red warning triangle

illuminated in LCD. Smart key has not been detected by the

passive system inside the vehicle. Smart key not present in vehicle. May

be caused by a flat smart key battery.

Replace internal battery in smart key.

May also be due to a communications problem. CHECK SMART

KEY None The smart key detected is not the

correct smart key for the vehicle. Use the correct smart key coded to the

vehicle. REMOVE SMART

KEY None

Smart key is in the start control module

and has been recognized by the passive

start system. Remove smart key from the start

control module. SMART KEY

BATTERY LOW None

Battery voltage in smart key is

becoming low, resulting in a decrease in

effective range of the smart key

transmitter. Replace smart key internal battery. PRESS BRAKE

WHEN STARTING None The stop/start button has been pressed

without the brake pedal depressed. This

will turn on the ignition power mode 6. To start engine, press brake pedal,

then press stop/start button. GEARBOX NOT IN

PARK None The transmission is not in the 'park'

position. Engine starting will be prohibited until 'park' is selected. Put transmission in the park position. www.JagDocs.com

Page 1949 of 3039

systems.

A typical example of information transfer is vehicle speed information from the ABS (anti-lock brake system) module used to

control the automatic volume control function. The vehicle speed information from the ABS module is sent on the high speed

CAN network and collected by the instrument panel gateway. The signal is passed to the medium speed CAN network and onto the ICM gateway. The ICM calculates the volume adjustment required. The corrected audio volume level signal is sent on the

MOST network to the IAM or Power amplifier (dependant on vehicle equipment level) for output to the speaker system.

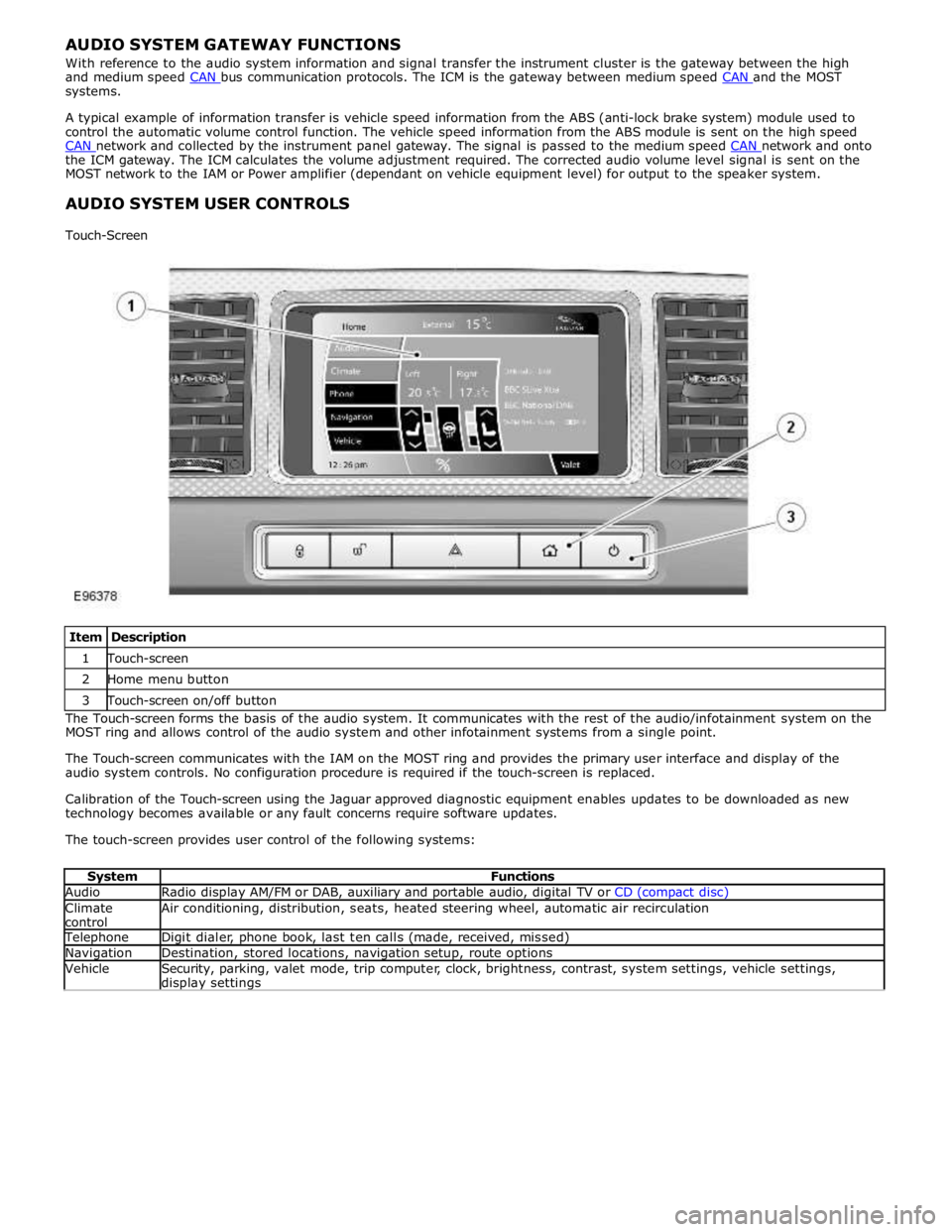

AUDIO SYSTEM USER CONTROLS

Touch-Screen

Item Description 1 Touch-screen 2 Home menu button 3 Touch-screen on/off button The Touch-screen forms the basis of the audio system. It communicates with the rest of the audio/infotainment system on the

MOST ring and allows control of the audio system and other infotainment systems from a single point.

The Touch-screen communicates with the IAM on the MOST ring and provides the primary user interface and display of the

audio system controls. No configuration procedure is required if the touch-screen is replaced.

Calibration of the Touch-screen using the Jaguar approved diagnostic equipment enables updates to be downloaded as new

technology becomes available or any fault concerns require software updates.

The touch-screen provides user control of the following systems:

System Functions Audio Radio display AM/FM or DAB, auxiliary and portable audio, digital TV or CD (compact disc) Climate

control Air conditioning, distribution, seats, heated steering wheel, automatic air recirculation Telephone Digit dialer, phone book, last ten calls (made, received, missed) Navigation Destination, stored locations, navigation setup, route options Vehicle

Security, parking, valet mode, trip computer, clock, brightness, contrast, system settings, vehicle settings, display settings

Page 2170 of 3039

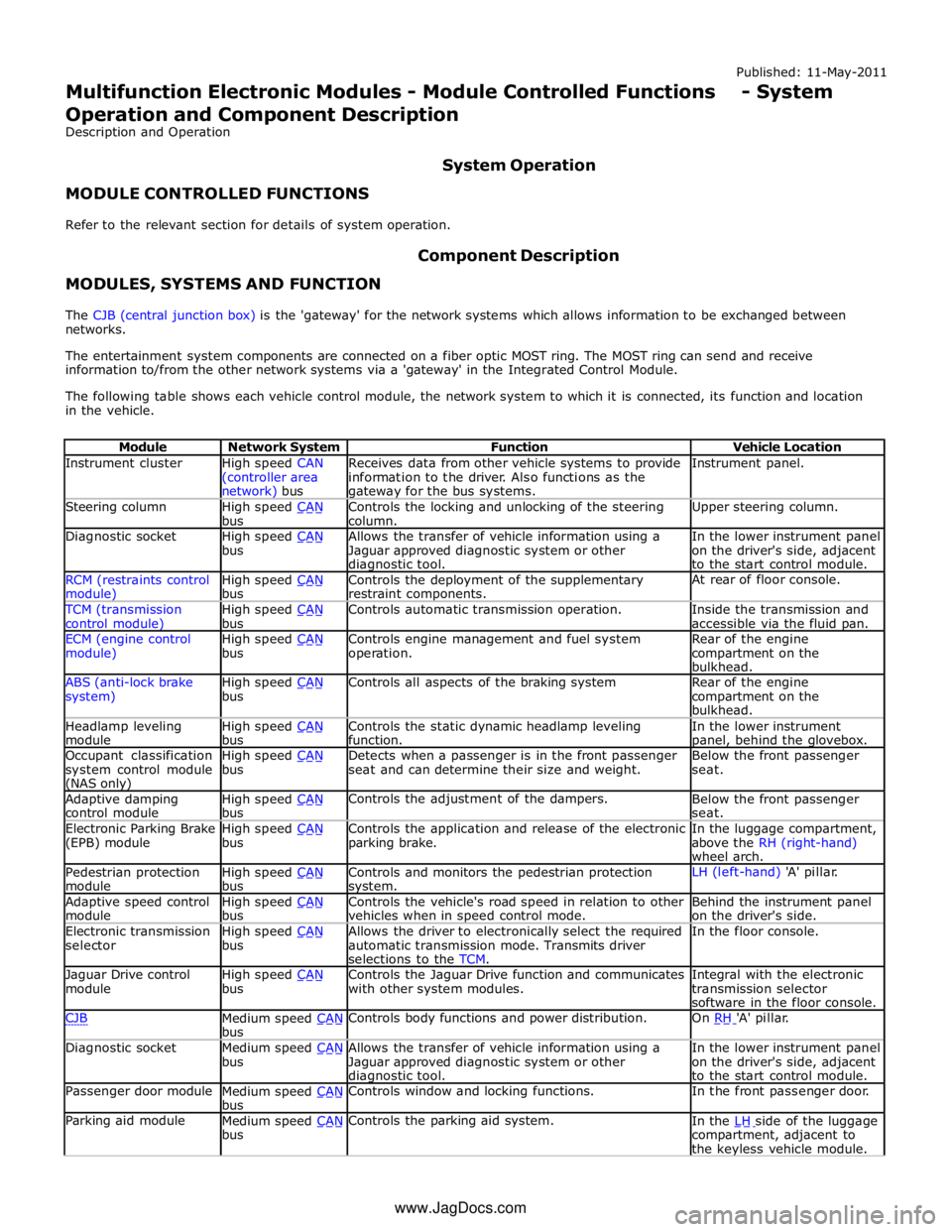

Instrument cluster

High speed CAN

(controller area network) bus Receives data from other vehicle systems to provide

information to the driver. Also functions as the gateway for the bus systems. Instrument panel. Steering column

High speed CAN bus Controls the locking and unlocking of the steering

column. Upper steering column. Diagnostic socket

High speed CAN bus Allows the transfer of vehicle information using a

Jaguar approved diagnostic system or other diagnostic tool. In the lower instrument panel

on the driver's side, adjacent

to the start control module. RCM (restraints control module) High speed CAN bus Controls the deployment of the supplementary

restraint components. At rear of floor console. TCM (transmission

control module) High speed CAN bus Controls automatic transmission operation.

Inside the transmission and

accessible via the fluid pan. ECM (engine control

module) High speed CAN bus Controls engine management and fuel system

operation. Rear of the engine

compartment on the

bulkhead. ABS (anti-lock brake

system) High speed CAN bus Controls all aspects of the braking system

Rear of the engine

compartment on the

bulkhead. Headlamp leveling

module High speed CAN bus Controls the static dynamic headlamp leveling

function. In the lower instrument panel, behind the glovebox. Occupant classification

system control module (NAS only) High speed CAN bus Detects when a passenger is in the front passenger

seat and can determine their size and weight. Below the front passenger

seat. Adaptive damping

control module High speed CAN bus Controls the adjustment of the dampers.

Below the front passenger

seat. Electronic Parking Brake

(EPB) module High speed CAN bus Controls the application and release of the electronic

parking brake. In the luggage compartment,

above the RH (right-hand)

wheel arch. Pedestrian protection

module High speed CAN bus Controls and monitors the pedestrian protection system. LH (left-hand) 'A' pillar. Adaptive speed control

module High speed CAN bus Controls the vehicle's road speed in relation to other

vehicles when in speed control mode. Behind the instrument panel

on the driver's side. Electronic transmission

selector High speed CAN bus Allows the driver to electronically select the required

automatic transmission mode. Transmits driver

selections to the TCM. In the floor console. Jaguar Drive control

module High speed CAN bus Controls the Jaguar Drive function and communicates

with other system modules. Integral with the electronic

transmission selector

software in the floor console. CJB

Medium speed CAN bus Controls body functions and power distribution. On RH 'A' pillar. Diagnostic socket

Medium speed CAN bus Allows the transfer of vehicle information using a

Jaguar approved diagnostic system or other diagnostic tool. In the lower instrument panel

on the driver's side, adjacent

to the start control module. Passenger door module

Medium speed CAN bus Controls window and locking functions. In the front passenger door. Parking aid module

Medium speed CAN bus Controls the parking aid system.

In the LH side of the luggage compartment, adjacent to

the keyless vehicle module. www.JagDocs.com

Page 2171 of 3039

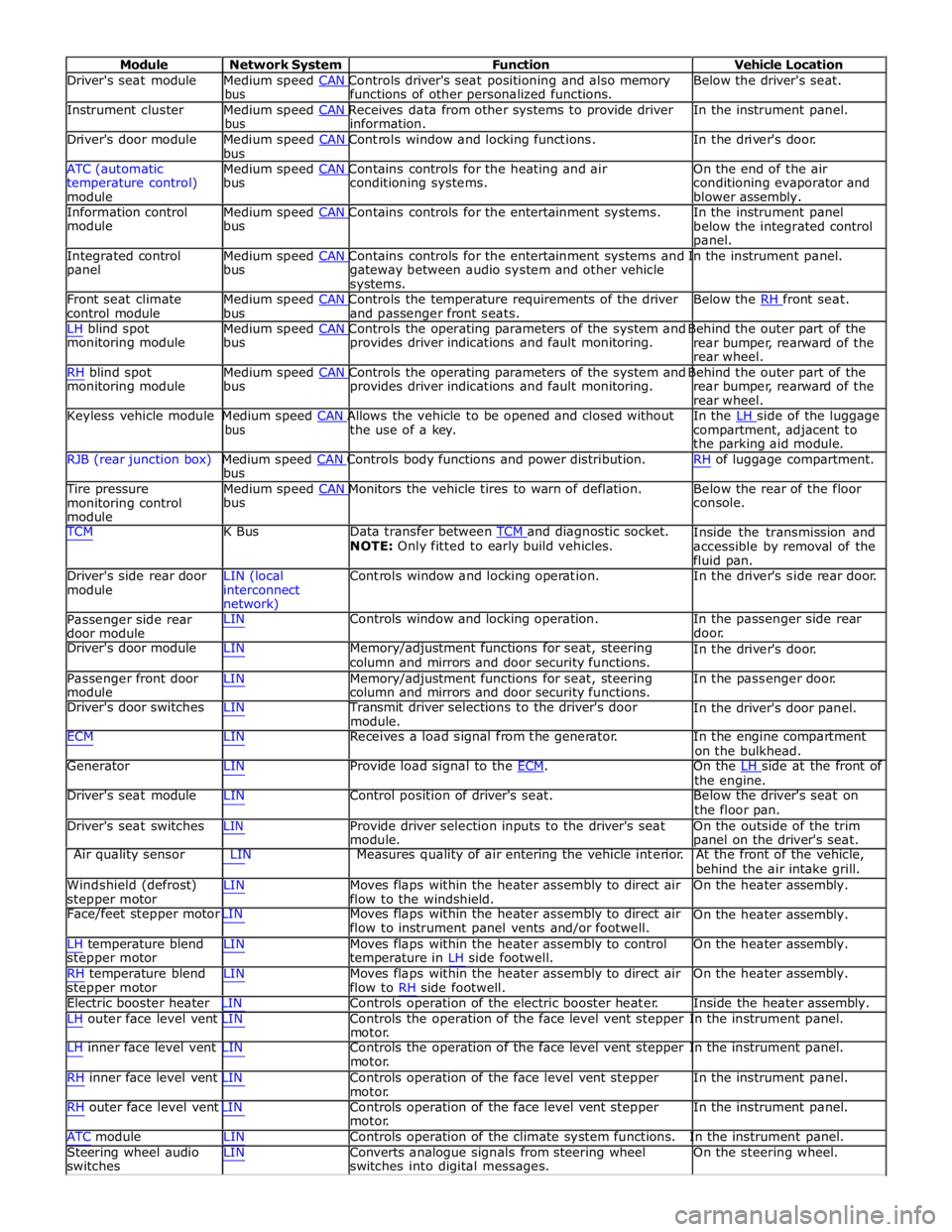

Module Network System Function Vehicle Location

Driver's seat module Medium speed CAN Controls driver's seat positioning and also memory Below the driver's seat. bus functions of other personalized functions.

Instrument cluster Medium speed CAN Receives data from other systems to provide driver In the instrument panel. bus information.

Driver's door module Medium speed CAN Controls window and locking functions. In the driver's door. bus

ATC (automatic Medium speed CAN Contains controls for the heating and air On the end of the air

temperature control)

module bus conditioning systems.

conditioning evaporator and

blower assembly.

Information control Medium speed CAN Contains controls for the entertainment systems. In the instrument panel module bus

below the integrated control

panel.

Integrated control Medium speed CAN Contains controls for the entertainment systems and In the instrument panel. panel bus

gateway between audio system and other vehicle

systems.

Front seat climate Medium speed CAN Controls the temperature requirements of the driver Below the RH front seat. control module bus and passenger front seats.

LH blind spot Medium speed CAN Controls the operating parameters of the system and Behind the outer part of the monitoring module bus provides driver indications and fault monitoring.

rear bumper, rearward of the

rear wheel.

RH blind spot Medium speed CAN Controls the operating parameters of the system and Behind the outer part of the monitoring module bus provides driver indications and fault monitoring.

rear bumper, rearward of the

rear wheel.

Keyless vehicle module Medium speed CAN Allows the vehicle to be opened and closed without In the LH side of the luggage bus the use of a key.

compartment, adjacent to

the parking aid module.

RJB (rear junction box) Medium speed CAN Controls body functions and power distribution. RH of luggage compartment. bus

Tire pressure Medium speed CAN Monitors the vehicle tires to warn of deflation. Below the rear of the floor monitoring control

module bus console.

TCM K Bus Data transfer between TCM and diagnostic socket. NOTE: Only fitted to early build vehicles. Inside the transmission and

accessible by removal of the

fluid pan.

Driver's side rear door

module LIN (local

interconnect

network) Controls window and locking operation. In the driver's side rear door.

Passenger side rear

door module LIN Controls window and locking operation. In the passenger side rear

door.

Driver's door module LIN Memory/adjustment functions for seat, steering

column and mirrors and door security functions. In the driver's door.

Passenger front door

module LIN Memory/adjustment functions for seat, steering

column and mirrors and door security functions. In the passenger door.

Driver's door switches LIN Transmit driver selections to the driver's door

module. In the driver's door panel.

ECM LIN Receives a load signal from the generator. In the engine compartment

on the bulkhead.

Generator LIN Provide load signal to the ECM. On the LH side at the front of the engine.

Driver's seat module LIN Control position of driver's seat. Below the driver's seat on

the floor pan.

Driver's seat switches LIN Provide driver selection inputs to the driver's seat

module. On the outside of the trim

panel on the driver's seat.

Air quality sensor LIN Measures quality of air entering the vehicle interior. At the front of the vehicle,

behind the air intake grill.

Windshield (defrost)

stepper motor LIN Moves flaps within the heater assembly to direct air

flow to the windshield. On the heater assembly.

Face/feet stepper motor LIN Moves flaps within the heater assembly to direct air

flow to instrument panel vents and/or footwell. On the heater assembly.

LH temperature blend

stepper motor

RH temperature blend

stepper motor LIN Moves flaps within the heater assembly to control

temperature in LH side footwell.

LIN Moves flaps within the heater assembly to direct air

flow to RH side footwell. On the heater assembly.

On the heater assembly.

Electric booster heater LIN Controls operation of the electric booster heater. Inside the heater assembly.

LH outer face level vent LIN Controls the operation of the face level vent stepper In the instrument panel.

motor.

LH inner face level vent LIN Controls the operation of the face level vent stepper In the instrument panel.

motor.

RH inner face level vent LIN Controls operation of the face level vent stepper

motor.

RH outer face level vent LIN Controls operation of the face level vent stepper

motor. In the instrument panel.

In the instrument panel.

ATC module LIN Controls operation of the climate system functions. In the instrument panel.

Steering wheel audio

switches LIN Converts analogue signals from steering wheel

switches into digital messages. On the steering wheel.

Page 2315 of 3039

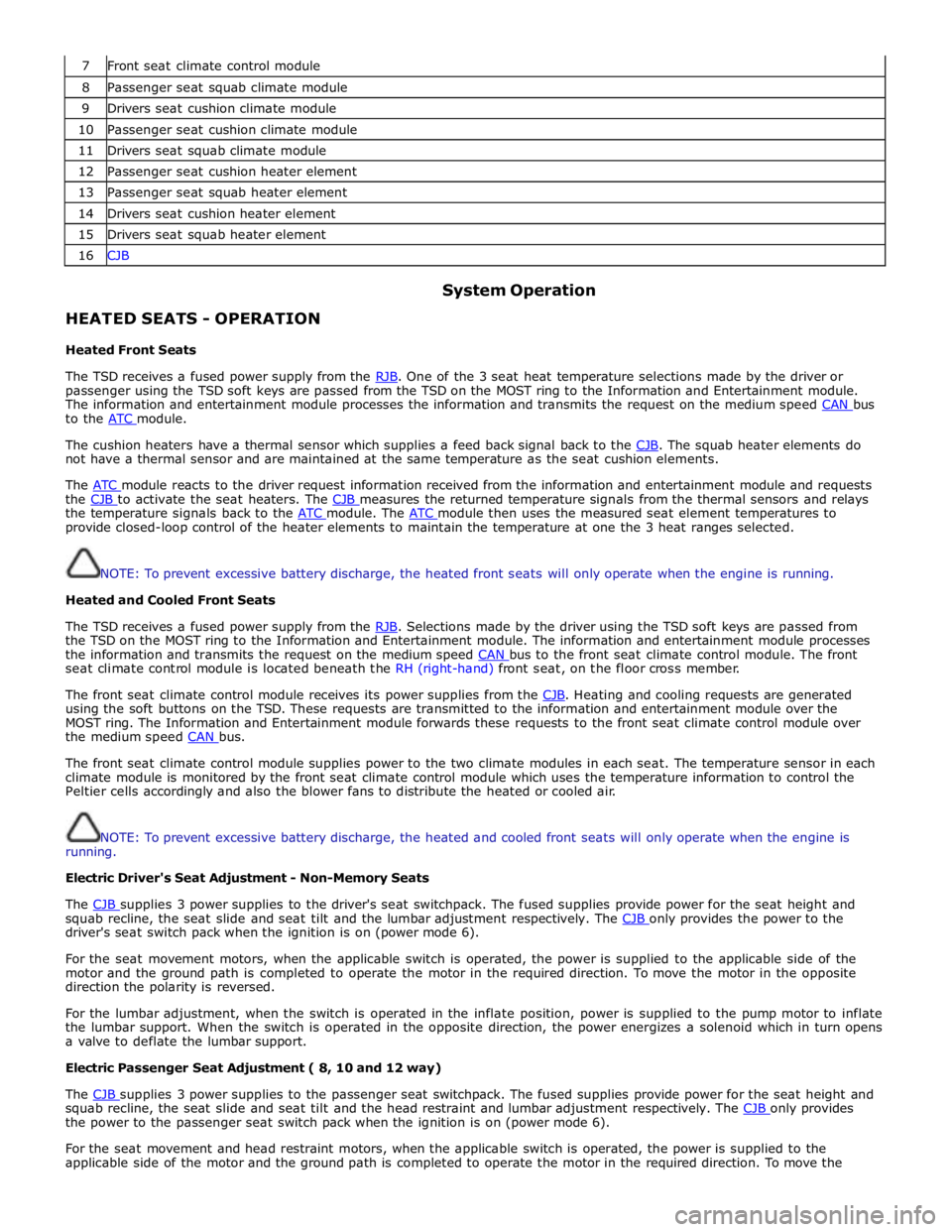

7 Front seat climate control module 8 Passenger seat squab climate module 9 Drivers seat cushion climate module 10 Passenger seat cushion climate module 11 Drivers seat squab climate module 12 Passenger seat cushion heater element 13 Passenger seat squab heater element 14 Drivers seat cushion heater element 15 Drivers seat squab heater element 16 CJB

HEATED SEATS - OPERATION

Heated Front Seats System Operation

The TSD receives a fused power supply from the RJB. One of the 3 seat heat temperature selections made by the driver or passenger using the TSD soft keys are passed from the TSD on the MOST ring to the Information and Entertainment module.

The information and entertainment module processes the information and transmits the request on the medium speed CAN bus to the ATC module.

The cushion heaters have a thermal sensor which supplies a feed back signal back to the CJB. The squab heater elements do not have a thermal sensor and are maintained at the same temperature as the seat cushion elements.

The ATC module reacts to the driver request information received from the information and entertainment module and requests the CJB to activate the seat heaters. The CJB measures the returned temperature signals from the thermal sensors and relays the temperature signals back to the ATC module. The ATC module then uses the measured seat element temperatures to provide closed-loop control of the heater elements to maintain the temperature at one the 3 heat ranges selected.

NOTE: To prevent excessive battery discharge, the heated front seats will only operate when the engine is running.

Heated and Cooled Front Seats

The TSD receives a fused power supply from the RJB. Selections made by the driver using the TSD soft keys are passed from the TSD on the MOST ring to the Information and Entertainment module. The information and entertainment module processes

the information and transmits the request on the medium speed CAN bus to the front seat climate control module. The front seat climate control module is located beneath the RH (right-hand) front seat, on the floor cross member.

The front seat climate control module receives its power supplies from the CJB. Heating and cooling requests are generated using the soft buttons on the TSD. These requests are transmitted to the information and entertainment module over the

MOST ring. The Information and Entertainment module forwards these requests to the front seat climate control module over

the medium speed CAN bus.

The front seat climate control module supplies power to the two climate modules in each seat. The temperature sensor in each

climate module is monitored by the front seat climate control module which uses the temperature information to control the

Peltier cells accordingly and also the blower fans to distribute the heated or cooled air.

NOTE: To prevent excessive battery discharge, the heated and cooled front seats will only operate when the engine is

running.

Electric Driver's Seat Adjustment - Non-Memory Seats

The CJB supplies 3 power supplies to the driver's seat switchpack. The fused supplies provide power for the seat height and squab recline, the seat slide and seat tilt and the lumbar adjustment respectively. The CJB only provides the power to the driver's seat switch pack when the ignition is on (power mode 6).

For the seat movement motors, when the applicable switch is operated, the power is supplied to the applicable side of the

motor and the ground path is completed to operate the motor in the required direction. To move the motor in the opposite

direction the polarity is reversed.

For the lumbar adjustment, when the switch is operated in the inflate position, power is supplied to the pump motor to inflate

the lumbar support. When the switch is operated in the opposite direction, the power energizes a solenoid which in turn opens

a valve to deflate the lumbar support.

Electric Passenger Seat Adjustment ( 8, 10 and 12 way)

The CJB supplies 3 power supplies to the passenger seat switchpack. The fused supplies provide power for the seat height and squab recline, the seat slide and seat tilt and the head restraint and lumbar adjustment respectively. The CJB only provides the power to the passenger seat switch pack when the ignition is on (power mode 6).

For the seat movement and head restraint motors, when the applicable switch is operated, the power is supplied to the

applicable side of the motor and the ground path is completed to operate the motor in the required direction. To move the

Page 2316 of 3039

supplies provide power for the movement motors in addition to the driver's seat switch pack. Power is only supplied to the

driver's seat module and the driver's seat switch pack when the ignition is on (power mode 6).

The driver's seat switch pack is connected to the driver's seat module by a LIN bus for the seat movement switches. Any selection for seat movement generates a message which is passed via the LIN to the driver's seat module. The seat module processes the request and operates the applicable seat function as required using the power supplies from the CJB.

Each seat motor contains a Hall position sensor. The sensor sends a feedback signal to the driver's seat module. The signal is

used for memory store and memory recall functions.

The lumbar adjustment switch on the driver's seat switch pack is wired direct to the lumbar pump and solenoids. The switch,

when moved to the inflate position for either the upper or lower inflatable cushion cell, provides a power supply to the lumbar

pump and simultaneously activates the applicable inflate solenoid valve. When the switch is released the pump stops and the

solenoid valve closes trapping the air in the inflatable cushion. When the switch is moved to the deflate position for either the

upper or lower inflatable cushion cell, power is supplied to the applicable deflate solenoid valve which opens to allow the air in

the cushion to escape. When the switch is released, the valve is closed and the remaining air in the cushion is retained.

FRONT SEATS - DESCRIPTION Component Description

The table below highlights the features available for each seating option.

Seat Type Non-Heated Heated Heated and Cooled Lumbar Support Memory 8-way Yes Optional No 2-way No 10-way Yes Optional Optional 2-way Optional (Driver's seat only) 12-way No No Yes 4-way No 16-way No No Yes 4-way Yes (Driver's seat only) Seat Heating

The 3-stage heated front seats feature 2 heater elements located in the seat cushion and a single heater element located in

the seat squab. Operation of the heated front seats is controlled by the ATC module via the TSD, information and entertainment control module and the CJB module on vehicles with heated seats. On vehicles with heated and cooled seats the operation is controlled by the TSD, information and entertainment control module and the front seat climate control

module.

The heated and cooled front seats each contain 2 climate modules; one in the cushion, one in the squab. The climate modules

contain 'Peltier' cells which are able to deliver heating and cooling based on a voltage provided by the front seat climate

control module. Each climate module also contains a fan, which blows air over the Peltier cells to distribute heated or cooled

air via liners in the seat cushion and squab. The fan is also controlled by the front seat climate control module. The TSD allows

the driver and passenger to select 3 ranges of heated or cooled ventilation; off, minimum and intermediate. Also, using the

selections on the TSD, the driver and passenger can select between full seat ventilation or squab backrest ventilation only.

Vehicles fitted with the 3-stage heated front seat option also feature a heated steering wheel.

Refer to: Steering Column Switches (211-05 Steering Column Switches, Description and Operation).

Electric Seat Adjustment

Lumbar Support

On 8, 10 and 12 way seats, a 2 way lumbar support is provided which allows the lumbar inflatable cushion to be inflated or

deflated as required. On 16 way seats, a 4 way lumbar support is fitted which comprises two separate cushion cells. The upper

and lower cells can be inflated or deflated individually allowing greater comfort adjustment for the driver and passenger.

The lumbar support comprises an inflatable cushion located in the seat squab, a pump and solenoids. The pump is activated

when the applicable seat switch is moved to the inflate position, inflating the cell(s) in the inflatable cushion. On 8 and 10

way seats, a single solenoid operated valve allows the inflatable cushion to be deflated. On 12 and 16 way seats, 4 solenoid

valves control the inflation and deflation of the upper and lower inflatable cushion cells, allowing each cell to be adjusted

individually.

Seat Motors

The head restraint motor is located in the upper section of each seat squab and is accessible by removal of the seat back. The

motor moves a cradle which is driven in a vertical motion by a rack and pinion arrangement. The cradle has the two head

restraint stems attached to it and therefore raises and lowers the head restraint as the motor moves the cradle. The motor

contains a Hall sensor which supplies positional information to the driver's seat module.

The seat slide motor is an integral component of the seat frame. The motor drives on a gear on a worm drive lead screw which

is integral with the floor rail. The lead screw has a stop at each end to limit the fore and aft seat movement.

Page 2376 of 3039

Seating - Seat Base

Removal and Installation

Removal

WARNINGS: Published: 11-May-2011

To avoid accidental deployment, the restraints control module backup power supply must be depleted. Wait at least one

minute after disconnecting the battery ground cable(s) before commencing any repair or adjustment to the supplemental

restraint system (SRS), or any component(s) adjacent to the SRS sensors. Failure to follow these instructions may result in

personal injury.

Always wear safety glasses when working on an air bag equipped vehicle and when handling an air bag module. Failure to

follow this instruction may result in personal injury.

To minimize the possibility of premature deployment, do not use radio key code savers when working on the

supplemental restraint system. Failure to follow this instruction may result in personal injury.

To minimize the possibility of injury in the event of premature deployment, always carry a live air bag module with the

bag and trim cover pointed away from the body. Failure to follow this instruction may result in personal injury.

To minimize the possibility of premature deployment, live air bag modules must only be placed on work benches which

have been ground bonded and with the trim cover facing up. Failure to follow these instructions may result in personal injury.

Never probe the electrical connectors of air bag modules or any other supplemental restraint system component. Failure

to follow this instruction may result in personal injury.

Painting over the driver air bag module trim cover or instrument panel could lead to deterioration of the trim cover and air

bags. Do not for any reason attempt to paint discolored or damaged air bag module trim covers or instrument panel. Install a

new component. Failure to follow this instruction may result in personal injury.

NOTES:

Some variation in the illustrations may occur, but the essential information is always correct.

Removal steps in this procedure may contain installation details.

1. Make the air bag supplemental restraint system (SRS) safe.

Refer to: Standard Workshop Practices (100-00 General Information, Description and Operation).

2. Refer to: Front Seat (501-10 Seating, Removal and Installation).

3. Refer to: Front Safety Belt Buckle (501-20A Safety Belt System, Removal and Installation).

4. Refer to: Front Seat Cushion Cover (501-10 Seating, Removal and Installation).

Page 2385 of 3039

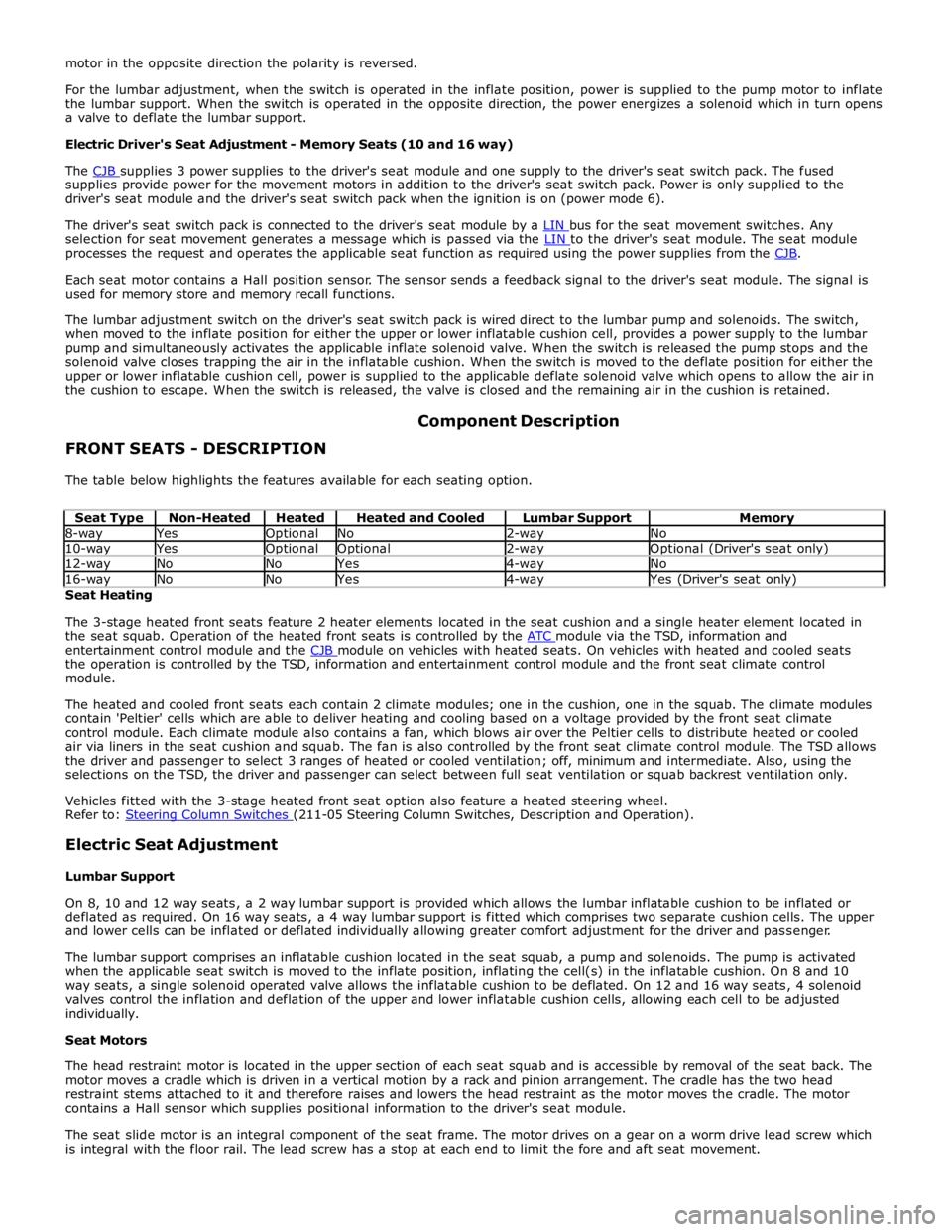

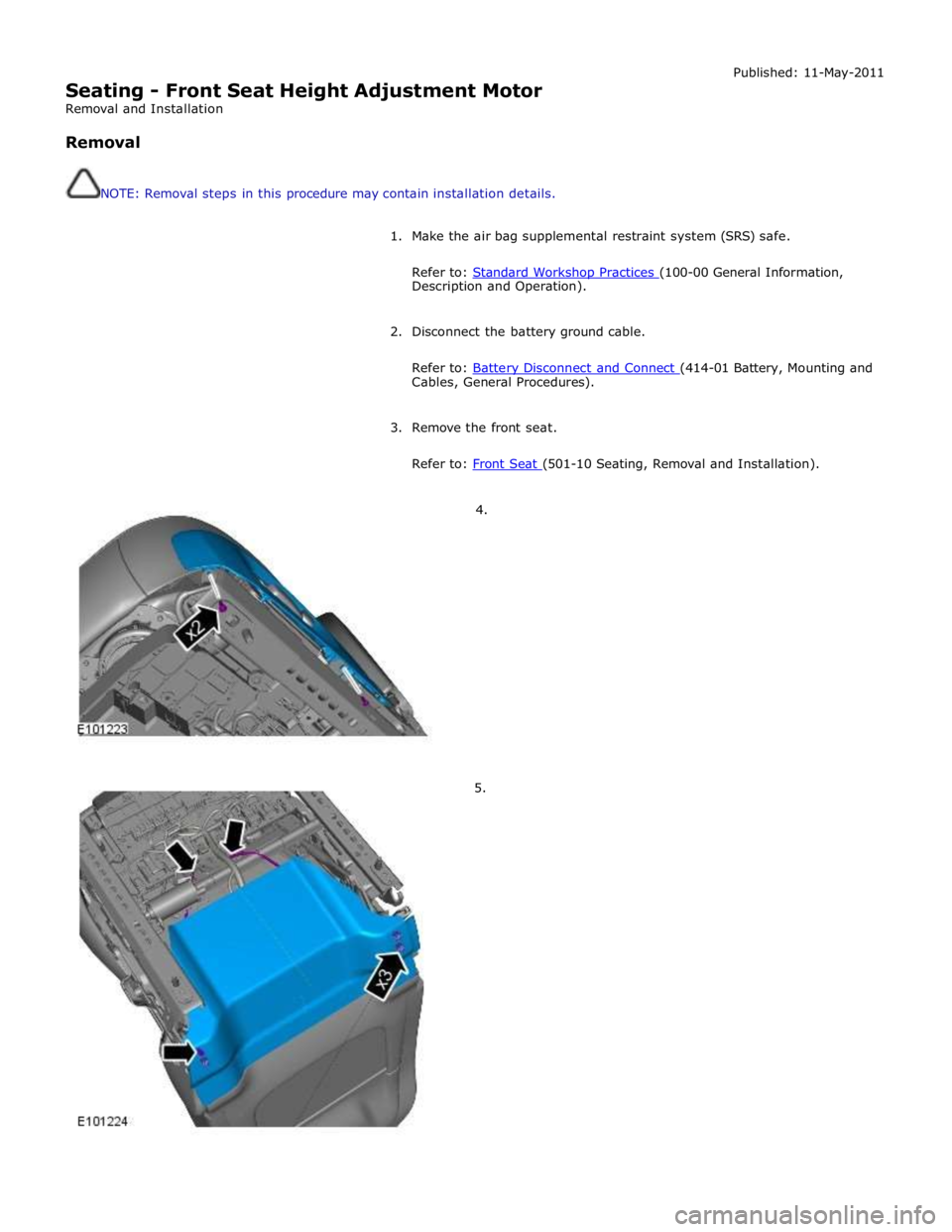

Seating - Front Seat Height Adjustment Motor

Removal and Installation

Removal

NOTE: Removal steps in this procedure may contain installation details. Published: 11-May-2011

1. Make the air bag supplemental restraint system (SRS) safe.

Refer to: Standard Workshop Practices (100-00 General Information, Description and Operation).

2. Disconnect the battery ground cable.

Refer to: Battery Disconnect and Connect (414-01 Battery, Mounting and Cables, General Procedures).

3. Remove the front seat.

Refer to: Front Seat (501-10 Seating, Removal and Installation).

4.

5.

Page 2638 of 3039

Published: 11-May-2011

Supplemental Restraint System - Occupant Classification Sensor

Removal and Installation

Removal

WARNINGS:

To avoid accidental deployment, the restraints control module backup power supply must be depleted. Wait at least one

minute after disconnecting the battery ground cable(s) before commencing any repair or adjustment to the supplemental

restraint system (SRS), or any component(s) adjacent to the SRS sensors. Failure to follow these instructions may result in

personal injury.

Always wear safety glasses when working on an air bag equipped vehicle and when handling an air bag module. Failure to

follow this instruction may result in personal injury.

To minimize the possibility of premature deployment, do not use radio key code savers when working on the

supplemental restraint system. Failure to follow this instruction may result in personal injury.

To minimize the possibility of injury in the event of premature deployment, always carry a live air bag module with the

bag and trim cover pointed away from the body. Failure to follow this instruction may result in personal injury.

To minimize the possibility of premature deployment, live air bag modules must only be placed on work benches which

have been ground bonded and with the trim cover facing up. Failure to follow these instructions may result in personal injury.

Never probe the electrical connectors of air bag modules or any other supplemental restraint system component. Failure

to follow this instruction may result in personal injury.

Painting over the driver air bag module trim cover or instrument panel could lead to deterioration of the trim cover and air

bags. Do not for any reason attempt to paint discoloured or damaged air bag module trim covers or instrument panel. Install a

new component. Failure to follow this instruction may result in personal injury.

CAUTIONS:

The front passenger seat occupant classification sensor is available only as a service kit. No attempt should be made to

replace individual components. Failure to follow this instruction may result in personal injury.

Check for correct operation of the front seat after completion of the procedure to make sure that the wiring harness has

not become trapped or stretched.

NOTES:

Note the routing of the seat harness.

Some variation in the illustrations may occur, but the essential information is always correct.

1. Make the air bag supplemental restraint system (SRS) safe.

Refer to: Standard Workshop Practices (100-00 General Information, Description and Operation).

2. Refer to: Battery Disconnect and Connect (414-01 Battery, Mounting and Cables, General Procedures).

3. Refer to: Front Seat Backrest Cover (501-10 Seating, Removal and Installation).