pinpoint JAGUAR XFR 2010 1.G Workshop Manual

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 2010, Model line: XFR, Model: JAGUAR XFR 2010 1.GPages: 3039, PDF Size: 58.49 MB

Page 2097 of 3039

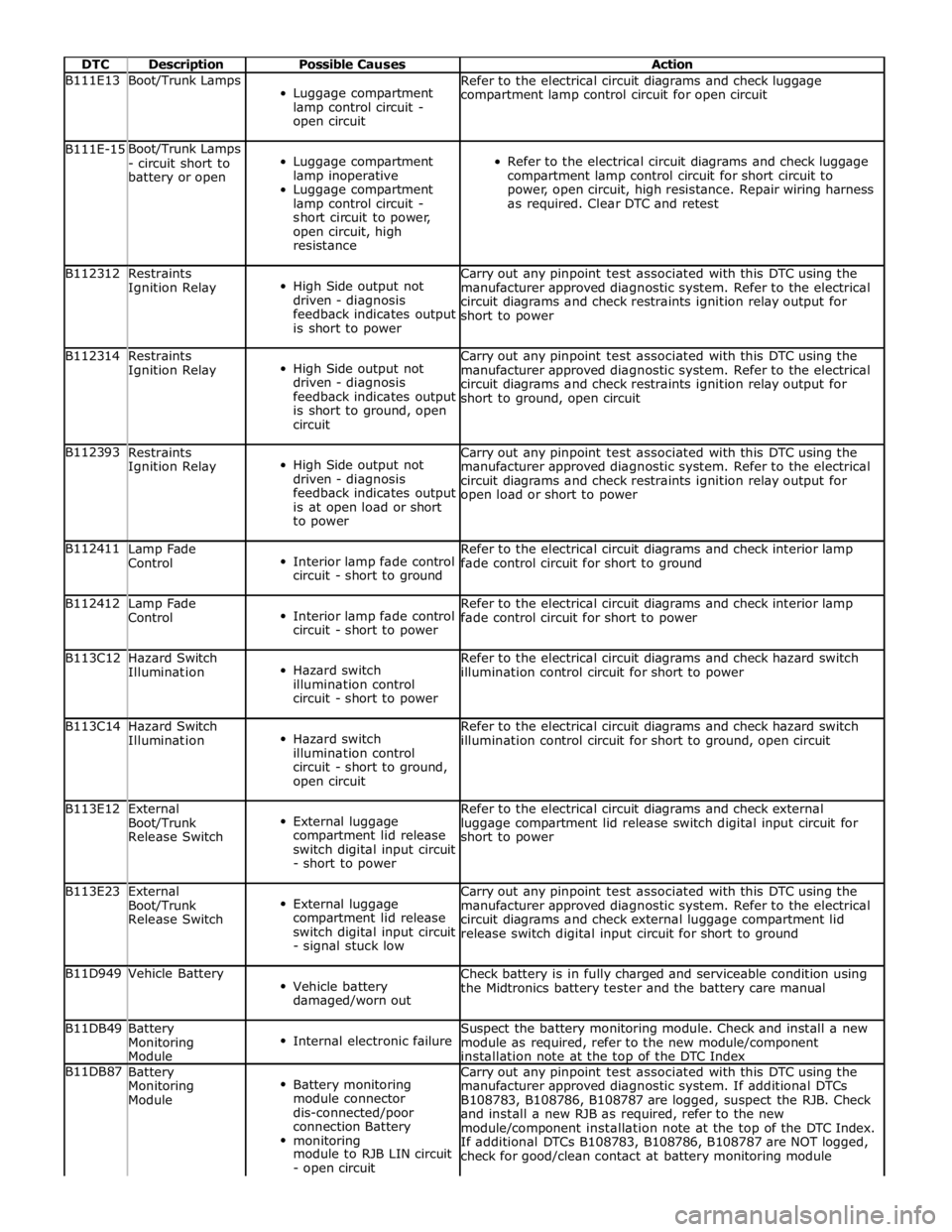

DTC Description Possible Causes Action B111E13 Boot/Trunk Lamps

Luggage compartment

lamp control circuit -

open circuit Refer to the electrical circuit diagrams and check luggage

compartment lamp control circuit for open circuit B111E-15 Boot/Trunk Lamps

- circuit short to

battery or open

Luggage compartment

lamp inoperative

Luggage compartment

lamp control circuit -

short circuit to power,

open circuit, high

resistance

Refer to the electrical circuit diagrams and check luggage

compartment lamp control circuit for short circuit to

power, open circuit, high resistance. Repair wiring harness

as required. Clear DTC and retest B112312

Restraints

Ignition Relay

High Side output not

driven - diagnosis

feedback indicates output

is short to power Carry out any pinpoint test associated with this DTC using the

manufacturer approved diagnostic system. Refer to the electrical

circuit diagrams and check restraints ignition relay output for

short to power B112314

Restraints

Ignition Relay

High Side output not

driven - diagnosis

feedback indicates output

is short to ground, open

circuit Carry out any pinpoint test associated with this DTC using the

manufacturer approved diagnostic system. Refer to the electrical

circuit diagrams and check restraints ignition relay output for

short to ground, open circuit B112393

Restraints

Ignition Relay

High Side output not

driven - diagnosis

feedback indicates output

is at open load or short

to power Carry out any pinpoint test associated with this DTC using the

manufacturer approved diagnostic system. Refer to the electrical

circuit diagrams and check restraints ignition relay output for

open load or short to power B112411

Lamp Fade

Control

Interior lamp fade control

circuit - short to ground Refer to the electrical circuit diagrams and check interior lamp

fade control circuit for short to ground B112412

Lamp Fade

Control

Interior lamp fade control

circuit - short to power Refer to the electrical circuit diagrams and check interior lamp

fade control circuit for short to power B113C12

Hazard Switch

Illumination

Hazard switch

illumination control

circuit - short to power Refer to the electrical circuit diagrams and check hazard switch

illumination control circuit for short to power B113C14

Hazard Switch

Illumination

Hazard switch

illumination control

circuit - short to ground,

open circuit Refer to the electrical circuit diagrams and check hazard switch

illumination control circuit for short to ground, open circuit B113E12

External

Boot/Trunk

Release Switch

External luggage

compartment lid release

switch digital input circuit

- short to power Refer to the electrical circuit diagrams and check external

luggage compartment lid release switch digital input circuit for

short to power B113E23

External

Boot/Trunk

Release Switch

External luggage

compartment lid release

switch digital input circuit

- signal stuck low Carry out any pinpoint test associated with this DTC using the

manufacturer approved diagnostic system. Refer to the electrical

circuit diagrams and check external luggage compartment lid

release switch digital input circuit for short to ground B11D949 Vehicle Battery

Vehicle battery

damaged/worn out Check battery is in fully charged and serviceable condition using

the Midtronics battery tester and the battery care manual B11DB49

Battery

Monitoring

Module

Internal electronic failure Suspect the battery monitoring module. Check and install a new

module as required, refer to the new module/component

installation note at the top of the DTC Index B11DB87

Battery

Monitoring

Module

Battery monitoring

module connector

dis-connected/poor

connection Battery

monitoring

module to RJB LIN circuit

- open circuit Carry out any pinpoint test associated with this DTC using the

manufacturer approved diagnostic system. If additional DTCs

B108783, B108786, B108787 are logged, suspect the RJB. Check

and install a new RJB as required, refer to the new

module/component installation note at the top of the DTC Index.

If additional DTCs B108783, B108786, B108787 are NOT logged,

check for good/clean contact at battery monitoring module

Page 2099 of 3039

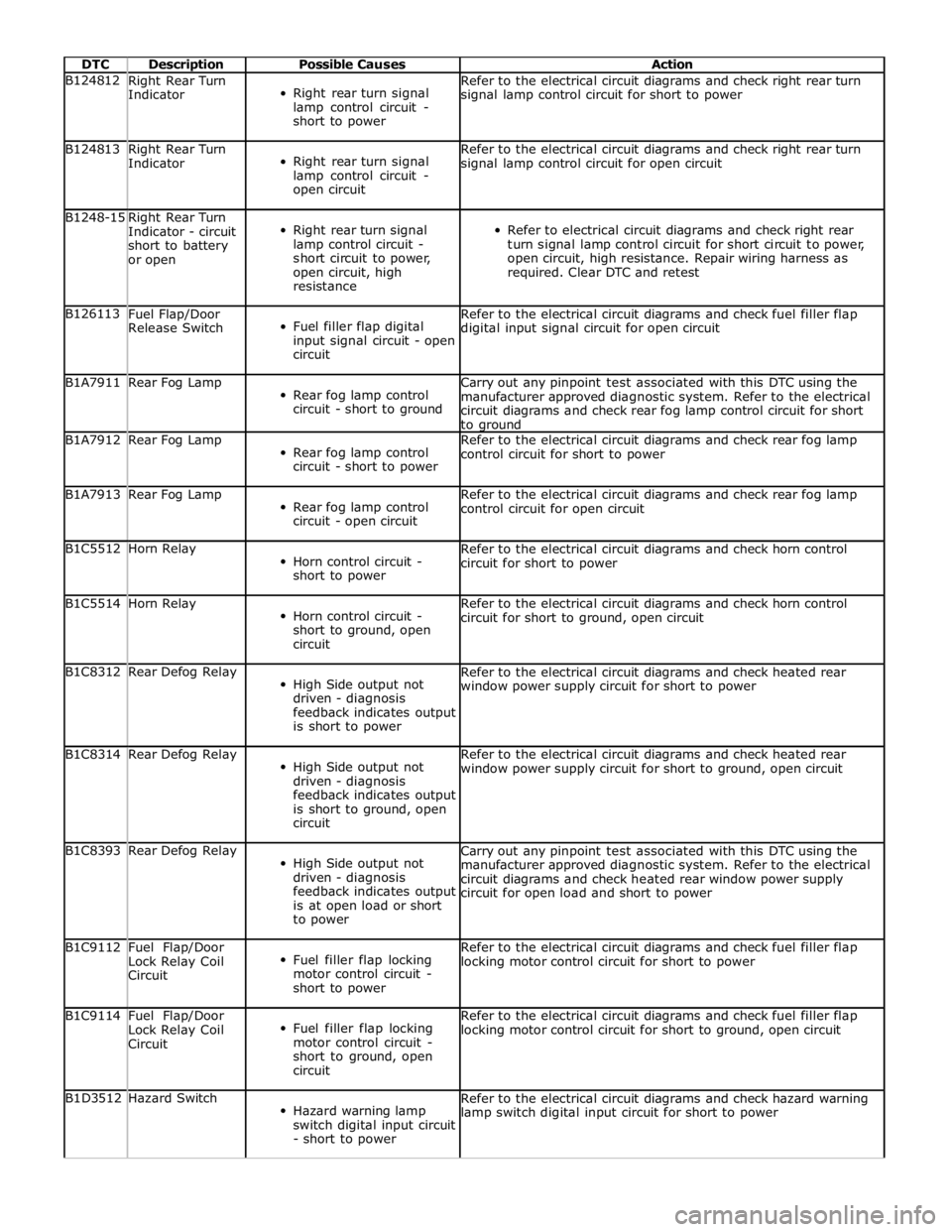

DTC Description Possible Causes Action B124812

Right Rear Turn

Indicator

Right rear turn signal

lamp control circuit -

short to power Refer to the electrical circuit diagrams and check right rear turn

signal lamp control circuit for short to power B124813

Right Rear Turn

Indicator

Right rear turn signal

lamp control circuit -

open circuit Refer to the electrical circuit diagrams and check right rear turn

signal lamp control circuit for open circuit B1248-15

Right Rear Turn

Indicator - circuit

short to battery

or open

Right rear turn signal

lamp control circuit -

short circuit to power,

open circuit, high

resistance

Refer to electrical circuit diagrams and check right rear

turn signal lamp control circuit for short circuit to power,

open circuit, high resistance. Repair wiring harness as

required. Clear DTC and retest B126113

Fuel Flap/Door

Release Switch

Fuel filler flap digital

input signal circuit - open

circuit Refer to the electrical circuit diagrams and check fuel filler flap

digital input signal circuit for open circuit B1A7911 Rear Fog Lamp

Rear fog lamp control

circuit - short to ground Carry out any pinpoint test associated with this DTC using the

manufacturer approved diagnostic system. Refer to the electrical

circuit diagrams and check rear fog lamp control circuit for short

to ground B1A7912 Rear Fog Lamp

Rear fog lamp control

circuit - short to power Refer to the electrical circuit diagrams and check rear fog lamp

control circuit for short to power B1A7913 Rear Fog Lamp

Rear fog lamp control

circuit - open circuit Refer to the electrical circuit diagrams and check rear fog lamp

control circuit for open circuit B1C5512 Horn Relay

Horn control circuit -

short to power Refer to the electrical circuit diagrams and check horn control

circuit for short to power B1C5514 Horn Relay

Horn control circuit -

short to ground, open

circuit Refer to the electrical circuit diagrams and check horn control

circuit for short to ground, open circuit B1C8312 Rear Defog Relay

High Side output not

driven - diagnosis

feedback indicates output

is short to power Refer to the electrical circuit diagrams and check heated rear

window power supply circuit for short to power B1C8314 Rear Defog Relay

High Side output not

driven - diagnosis

feedback indicates output

is short to ground, open

circuit Refer to the electrical circuit diagrams and check heated rear

window power supply circuit for short to ground, open circuit B1C8393 Rear Defog Relay

High Side output not

driven - diagnosis

feedback indicates output

is at open load or short

to power Carry out any pinpoint test associated with this DTC using the

manufacturer approved diagnostic system. Refer to the electrical

circuit diagrams and check heated rear window power supply

circuit for open load and short to power B1C9112

Fuel Flap/Door

Lock Relay Coil

Circuit

Fuel filler flap locking

motor control circuit -

short to power Refer to the electrical circuit diagrams and check fuel filler flap

locking motor control circuit for short to power B1C9114

Fuel Flap/Door

Lock Relay Coil

Circuit

Fuel filler flap locking

motor control circuit -

short to ground, open

circuit Refer to the electrical circuit diagrams and check fuel filler flap

locking motor control circuit for short to ground, open circuit B1D3512 Hazard Switch

Hazard warning lamp

switch digital input circuit

- short to power Refer to the electrical circuit diagrams and check hazard warning

lamp switch digital input circuit for short to power

Page 2100 of 3039

DTC Description Possible Causes Action B1D3523 Hazard Switch

Hazard warning lamp

switch digital input circuit

- signal stuck low Carry out any pinpoint test associated with this DTC using the

manufacturer approved diagnostic system. Refer to the electrical

circuit diagrams and check hazard warning lamp switch digital

input circuit for short to ground U001988

Low Speed CAN

Communication

Bus

Bus off Carry out any pinpoint test associated with this DTC using the

manufacturer approved diagnostic system U014000

Lost

Communication

With Body

Control Module

No sub type information Carry out any pinpoint test associated with this DTC using the

manufacturer approved diagnostic system U015500

Lost

Communication

With Instrument

Panel Cluster

(IPC) Control

Module

No sub type information Carry out any pinpoint test associated with this DTC using the

manufacturer approved diagnostic system U015900

Lost

Communication

With Parking

Assist Control

Module "A"

No sub type information Carry out any pinpoint test associated with this DTC using the

manufacturer approved diagnostic system U016400

Lost

Communication

With HVAC

Control Module

No sub type information Carry out any pinpoint test associated with this DTC using the

manufacturer approved diagnostic system U021400

Lost

Communication

With Remote

Function

Actuation

No sub type information Carry out any pinpoint test associated with this DTC using the

manufacturer approved diagnostic system U030046

Internal Control

Module Software

Incompatibility

Calibration/parameter

memory failure Suspect the RJB. Check and install a new RJB as required, refer

to the new module/component installation note at the top of the

DTC Index U100000

Solid State Driver

Protection Active

-Driver Disabled

No sub type information Carry out any pinpoint test associated with this DTC using the

manufacturer approved diagnostic system U1A1449

CAN Initialisation

Failure

Internal electronic failure Suspect the RJB. Check and install a new RJB as required, refer

to the new module/component installation note at the top of the

DTC Index U300049 Control Module

Internal electronic failure Suspect the RJB. Check and install a new RJB as required, refer

to the new module/component installation note at the top of the

DTC Index U300055 Control Module

Not configured Re-configure the RJB using the manufacturer approved diagnostic

system www.JagDocs.com

Page 2126 of 3039

Anti-Theft - Active - Anti-Theft - Active

Diagnosis and Testing

Principles of Operation Published: 26-Feb-2014

For a detailed description of the anti-theft - active system, refer to the relevant Description and Operation sections in the

workshop manual. REFER to: (419-01A Anti-Theft - Active)

Anti-Theft - Active (Description and Operation), Anti-Theft - Active (Description and Operation), Anti-Theft - Active (Description and Operation).

Inspection and Verification

CAUTION: Diagnosis by substitution from a donor vehicle is NOT acceptable. Substitution of control modules does not

guarantee confirmation of a fault, and may also cause additional faults in the vehicle being tested and/or the donor vehicle.

1. Verify the customer concern.

2. Visually inspect for obvious signs of damage and system integrity.

Visual Inspection

Mechanical Electrical

Door latch micro switches

Hood ajar switch

Passive anti-theft alarm horn (if installed)

Battery backed sounder (if installed) or battery backed sounder with tilt sensor (if

installed)

Vehicle horns

Fuse(s)

Electrical

connector(s)

Wiring Harness

3. If an obvious cause for an observed or reported concern is found, correct the cause (if possible) before proceeding to

the next step.

4. If the cause is not visually evident, check for Diagnostic Trouble Codes (DTCs) and refer to the relevant DTC Index. For

additional diagnosis and testing information, refer to the relevant Diagnosis and Testing section in the workshop

manual

REFER to: Remote Keyless Entry (RKE) Module (419-10 Multifunction Electronic Modules, Diagnosis and Testing).

DTC Index

CAUTION: Diagnosis by substitution from a donor vehicle is NOT acceptable. Substitution of control modules does not

guarantee confirmation of a fault, and may also cause additional faults in the vehicle being tested and/or the donor vehicle

NOTES:

If the control module or a component is suspect and the vehicle remains under manufacturer warranty, refer to the

Warranty Policy and Procedures manual (section B1.2), or determine if any prior approval programme is in operation, prior to

the installation of a new module/component.

Generic scan tools may not read the codes listed, or may read only five digit codes. Match the five digits from the scan

tool to the first five digits of the seven digit code listed to identify the fault (the last two digits give additional information

read by the manufacturer approved diagnostic system).

When performing electrical voltage or resistance tests, always use a digital multimeter (DMM) accurate to three decimal

places, and with an up-to-date calibration certificate. When testing resistance, always take the resistance of the DMM leads

into account.

Check and rectify basic faults before beginning diagnostic routines involving pinpoint tests.

Inspect connectors for signs of water ingress, and pins for damage and/or corrosion.

If DTCs are recorded and, after performing the pinpoint tests, a fault is not present, an intermittent concern may be the

cause. Always check for loose connections and corroded terminals.

Page 2127 of 3039

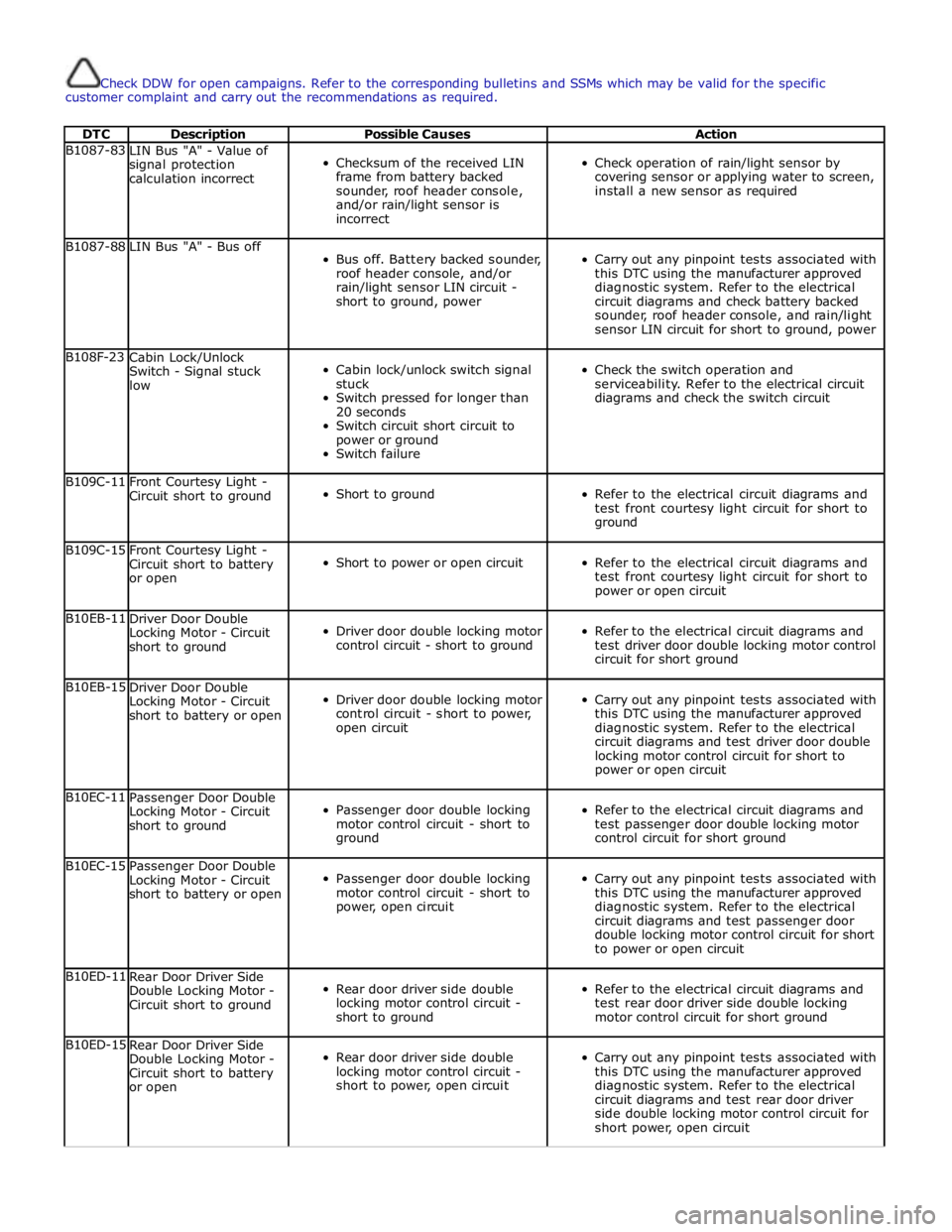

Check DDW for open campaigns. Refer to the corresponding bulletins and SSMs which may be valid for the specific

customer complaint and carry out the recommendations as required.

DTC Description Possible Causes Action B1087-83

LIN Bus "A" - Value of

signal protection

calculation incorrect

Checksum of the received LIN

frame from battery backed

sounder, roof header console,

and/or rain/light sensor is

incorrect

Check operation of rain/light sensor by

covering sensor or applying water to screen,

install a new sensor as required B1087-88 LIN Bus "A" - Bus off

Bus off. Battery backed sounder,

roof header console, and/or

rain/light sensor LIN circuit -

short to ground, power

Carry out any pinpoint tests associated with

this DTC using the manufacturer approved

diagnostic system. Refer to the electrical

circuit diagrams and check battery backed

sounder, roof header console, and rain/light

sensor LIN circuit for short to ground, power B108F-23

Cabin Lock/Unlock

Switch - Signal stuck

low

Cabin lock/unlock switch signal

stuck

Switch pressed for longer than

20 seconds

Switch circuit short circuit to

power or ground

Switch failure

Check the switch operation and

serviceability. Refer to the electrical circuit

diagrams and check the switch circuit B109C-11

Front Courtesy Light -

Circuit short to ground

Short to ground

Refer to the electrical circuit diagrams and

test front courtesy light circuit for short to

ground B109C-15

Front Courtesy Light -

Circuit short to battery

or open

Short to power or open circuit

Refer to the electrical circuit diagrams and

test front courtesy light circuit for short to

power or open circuit B10EB-11

Driver Door Double

Locking Motor - Circuit

short to ground

Driver door double locking motor

control circuit - short to ground

Refer to the electrical circuit diagrams and

test driver door double locking motor control

circuit for short ground B10EB-15

Driver Door Double

Locking Motor - Circuit

short to battery or open

Driver door double locking motor

control circuit - short to power,

open circuit

Carry out any pinpoint tests associated with

this DTC using the manufacturer approved

diagnostic system. Refer to the electrical

circuit diagrams and test driver door double

locking motor control circuit for short to

power or open circuit B10EC-11

Passenger Door Double

Locking Motor - Circuit

short to ground

Passenger door double locking

motor control circuit - short to

ground

Refer to the electrical circuit diagrams and

test passenger door double locking motor

control circuit for short ground B10EC-15

Passenger Door Double

Locking Motor - Circuit

short to battery or open

Passenger door double locking

motor control circuit - short to

power, open circuit

Carry out any pinpoint tests associated with

this DTC using the manufacturer approved

diagnostic system. Refer to the electrical

circuit diagrams and test passenger door

double locking motor control circuit for short

to power or open circuit B10ED-11

Rear Door Driver Side

Double Locking Motor -

Circuit short to ground

Rear door driver side double

locking motor control circuit -

short to ground

Refer to the electrical circuit diagrams and

test rear door driver side double locking

motor control circuit for short ground B10ED-15

Rear Door Driver Side

Double Locking Motor -

Circuit short to battery

or open

Rear door driver side double

locking motor control circuit -

short to power, open circuit

Carry out any pinpoint tests associated with

this DTC using the manufacturer approved

diagnostic system. Refer to the electrical

circuit diagrams and test rear door driver

side double locking motor control circuit for

short power, open circuit

Page 2128 of 3039

DTC Description Possible Causes Action B10EE-11

Rear Door Passenger

Side Double Locking

Motor - Circuit short to

ground

Rear door passenger side double

locking motor control circuit -

short to ground

Refer to the electrical circuit diagrams and

test rear door passenger side double locking

motor control circuit for short ground B10EE-15

Rear Door Passenger

Side Double Locking

Motor - Circuit short to

battery or open

Rear door passenger side double

locking motor control circuit -

short to power, open circuit

Carry out any pinpoint tests associated with

this DTC using the manufacturer approved

diagnostic system. Refer to the electrical

circuit diagrams and test rear door

passenger side double locking motor control

circuit for short power, open circuit B10F1-11

Key In Switch - Circuit

short to ground

Keyless vehicle module, key IN

status circuit - short to ground

Carry out any pinpoint tests associated with

this DTC using the manufacturer approved

diagnostic system. Refer to the electrical

circuit diagrams and check keyless vehicle

module, key IN status circuit for short to

ground B10F1-12

Key In Switch - Circuit

short to battery

Keyless vehicle module, key IN

status circuit - short to power

Refer to the electrical circuit diagrams and

check keyless vehicle module, key IN status

circuit for short to power B10F1-13

Key In Switch - Circuit

open

Keyless vehicle module, key IN

status circuit - open circuit

Refer to the electrical circuit diagrams and

check keyless vehicle module, key IN status

circuit for open circuit B1108-11

Driver Door Central

Locking Motor - Circuit

short to ground

Driver door central locking motor

control circuit - short to ground

Refer to the electrical circuit diagrams and

test driver door central locking motor control

circuit for short ground B1108-15

Driver Door Central

Locking Motor - Circuit

short to battery or open

Driver door central locking motor

control circuit - short to power,

open circuit

Carry out any pinpoint tests associated with

this DTC using the manufacturer approved

diagnostic system. Refer to the electrical

circuit diagrams and test driver door central

locking motor control circuit for short to

power, open circuit B1109-11

Passenger Door Central

Locking Motor - Circuit

short to ground

Short to ground

Refer to the electrical circuit diagrams and

test passenger door central locking motor

circuit for short to ground B1109-15

Passenger Door Central

Locking Motor - Circuit

short to battery or open

Short to power or open circuit

Refer to the electrical circuit diagrams and

test passenger door central locking motor

circuit for short to power or open circuit B110A-11

Rear Door Driver Side

Central Locking Motor -

Circuit short to ground

Rear driver door central locking

motor control circuit - short to

ground

Refer to the electrical circuit diagrams and

test rear driver door central locking motor

control circuit for short ground B110A-15

Rear Door Driver Side

Central Locking Motor -

Circuit short to battery

or open

Rear driver door central locking

motor control circuit - short to

power, open circuit

Refer to the electrical circuit diagrams and

test rear driver door central locking motor

control circuit for short to power, open circuit B110B-11

Rear Door Passenger

Side Central Locking

Motor - Circuit short to

ground

Rear passenger door central

locking motor circuit short circuit

to ground

Refer to the electrical circuit diagrams and

check the circuit B110B-15

Rear Door Passenger

Side Central Locking

Motor - Circuit short to

battery or open

Rear passenger door central

locking motor circuit short circuit

to power or open circuit

Refer to the electrical circuit diagrams and

check the circuit B1163-11

Left Mirror Heater

Output Short To Ground

- Circuit short to ground

Short to ground

Refer to the electrical circuit diagrams and

test left mirror heater output circuit for short

to ground

Page 2133 of 3039

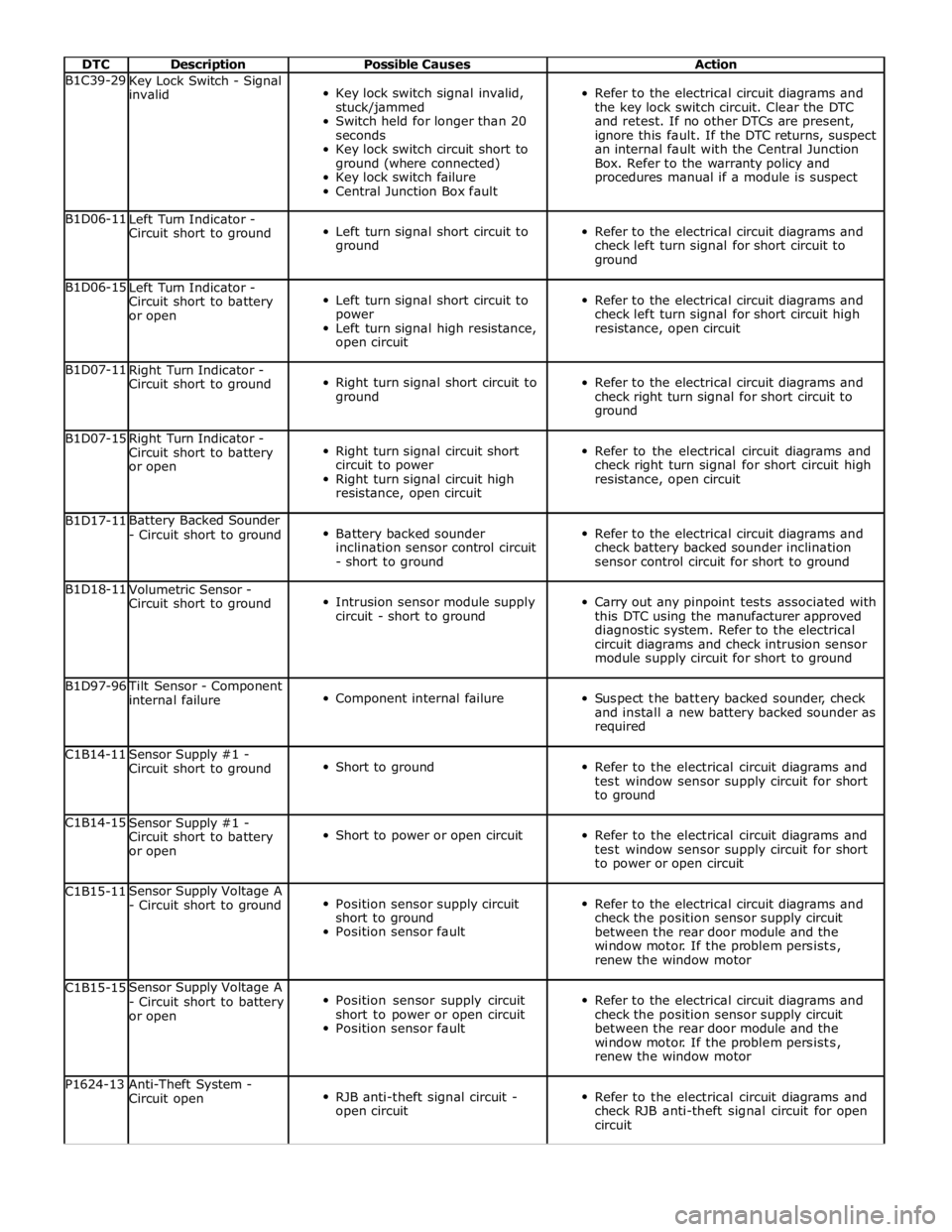

DTC Description Possible Causes Action B1C39-29

Key Lock Switch - Signal

invalid

Key lock switch signal invalid,

stuck/jammed

Switch held for longer than 20

seconds

Key lock switch circuit short to

ground (where connected)

Key lock switch failure

Central Junction Box fault

Refer to the electrical circuit diagrams and

the key lock switch circuit. Clear the DTC

and retest. If no other DTCs are present,

ignore this fault. If the DTC returns, suspect

an internal fault with the Central Junction

Box. Refer to the warranty policy and

procedures manual if a module is suspect B1D06-11

Left Turn Indicator -

Circuit short to ground

Left turn signal short circuit to

ground

Refer to the electrical circuit diagrams and

check left turn signal for short circuit to

ground B1D06-15

Left Turn Indicator -

Circuit short to battery

or open

Left turn signal short circuit to

power

Left turn signal high resistance,

open circuit

Refer to the electrical circuit diagrams and

check left turn signal for short circuit high

resistance, open circuit B1D07-11

Right Turn Indicator -

Circuit short to ground

Right turn signal short circuit to

ground

Refer to the electrical circuit diagrams and

check right turn signal for short circuit to

ground B1D07-15

Right Turn Indicator -

Circuit short to battery

or open

Right turn signal circuit short

circuit to power

Right turn signal circuit high

resistance, open circuit

Refer to the electrical circuit diagrams and

check right turn signal for short circuit high

resistance, open circuit B1D17-11 Battery Backed Sounder

- Circuit short to ground

Battery backed sounder

inclination sensor control circuit

- short to ground

Refer to the electrical circuit diagrams and

check battery backed sounder inclination

sensor control circuit for short to ground B1D18-11

Volumetric Sensor -

Circuit short to ground

Intrusion sensor module supply

circuit - short to ground

Carry out any pinpoint tests associated with

this DTC using the manufacturer approved

diagnostic system. Refer to the electrical

circuit diagrams and check intrusion sensor

module supply circuit for short to ground B1D97-96 Tilt Sensor - Component

internal failure

Component internal failure

Suspect the battery backed sounder, check

and install a new battery backed sounder as

required C1B14-11

Sensor Supply #1 -

Circuit short to ground

Short to ground

Refer to the electrical circuit diagrams and

test window sensor supply circuit for short

to ground C1B14-15

Sensor Supply #1 -

Circuit short to battery

or open

Short to power or open circuit

Refer to the electrical circuit diagrams and

test window sensor supply circuit for short

to power or open circuit C1B15-11 Sensor Supply Voltage A

- Circuit short to ground

Position sensor supply circuit

short to ground

Position sensor fault

Refer to the electrical circuit diagrams and

check the position sensor supply circuit

between the rear door module and the

window motor. If the problem persists,

renew the window motor C1B15-15 Sensor Supply Voltage A

- Circuit short to battery

or open

Position sensor supply circuit

short to power or open circuit

Position sensor fault

Refer to the electrical circuit diagrams and

check the position sensor supply circuit

between the rear door module and the

window motor. If the problem persists,

renew the window motor P1624-13

Anti-Theft System -

Circuit open

RJB anti-theft signal circuit -

open circuit

Refer to the electrical circuit diagrams and

check RJB anti-theft signal circuit for open

circuit

Page 2149 of 3039

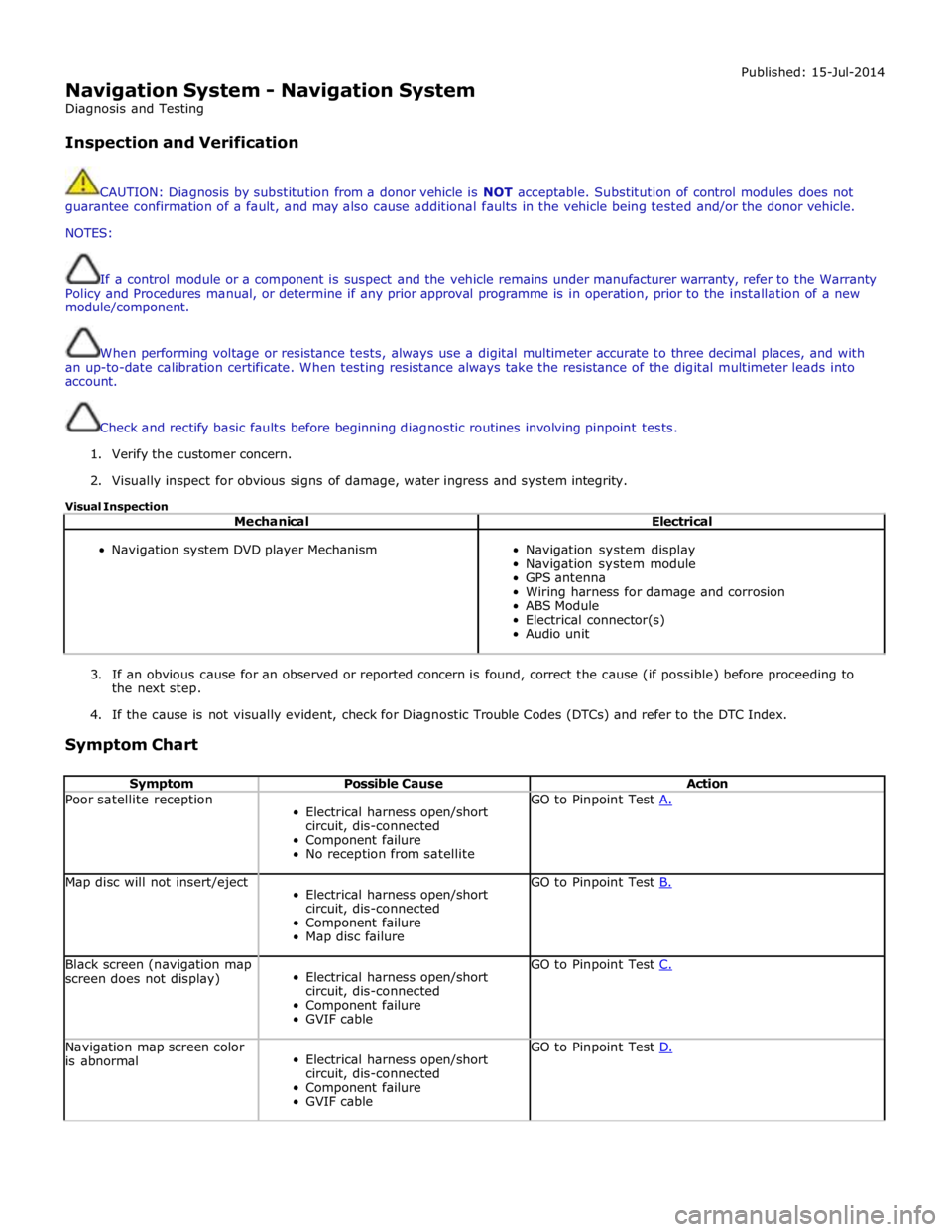

Navigation System - Navigation System

Diagnosis and Testing

Inspection and Verification Published: 15-Jul-2014

CAUTION: Diagnosis by substitution from a donor vehicle is NOT acceptable. Substitution of control modules does not

guarantee confirmation of a fault, and may also cause additional faults in the vehicle being tested and/or the donor vehicle.

NOTES:

If a control module or a component is suspect and the vehicle remains under manufacturer warranty, refer to the Warranty

Policy and Procedures manual, or determine if any prior approval programme is in operation, prior to the installation of a new

module/component.

When performing voltage or resistance tests, always use a digital multimeter accurate to three decimal places, and with

an up-to-date calibration certificate. When testing resistance always take the resistance of the digital multimeter leads into

account.

Check and rectify basic faults before beginning diagnostic routines involving pinpoint tests.

1. Verify the customer concern.

2. Visually inspect for obvious signs of damage, water ingress and system integrity.

Visual Inspection

Mechanical Electrical

Navigation system DVD player Mechanism

Navigation system display

Navigation system module

GPS antenna

Wiring harness for damage and corrosion

ABS Module

Electrical connector(s)

Audio unit

3. If an obvious cause for an observed or reported concern is found, correct the cause (if possible) before proceeding to

the next step.

4. If the cause is not visually evident, check for Diagnostic Trouble Codes (DTCs) and refer to the DTC Index.

Symptom Chart

Symptom Possible Cause Action Poor satellite reception

Electrical harness open/short

circuit, dis-connected

Component failure

No reception from satellite GO to Pinpoint Test A. Map disc will not insert/eject

Electrical harness open/short

circuit, dis-connected

Component failure

Map disc failure GO to Pinpoint Test B. Black screen (navigation map

screen does not display)

Electrical harness open/short

circuit, dis-connected

Component failure

GVIF cable GO to Pinpoint Test C. Navigation map screen color

is abnormal

Electrical harness open/short

circuit, dis-connected

Component failure

GVIF cable GO to Pinpoint Test D.

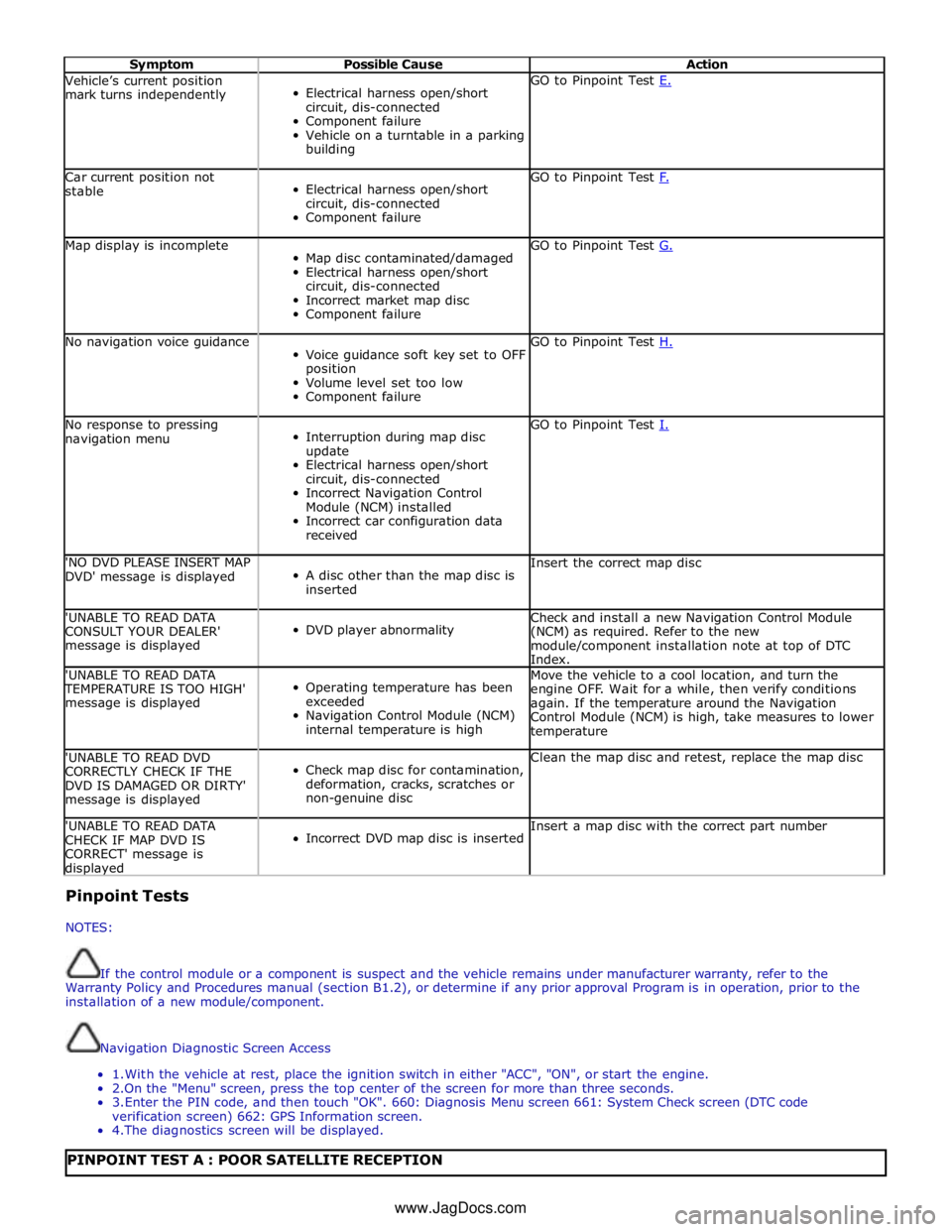

Page 2150 of 3039

Symptom Possible Cause Action Vehicle’s current position

mark turns independently

Electrical harness open/short

circuit, dis-connected

Component failure

Vehicle on a turntable in a parking

building GO to Pinpoint Test E. Car current position not

stable

Electrical harness open/short

circuit, dis-connected

Component failure GO to Pinpoint Test F. Map display is incomplete

Map disc contaminated/damaged

Electrical harness open/short

circuit, dis-connected

Incorrect market map disc

Component failure GO to Pinpoint Test G. No navigation voice guidance

Voice guidance soft key set to OFF

position

Volume level set too low

Component failure GO to Pinpoint Test H. No response to pressing

navigation menu

Interruption during map disc

update

Electrical harness open/short

circuit, dis-connected

Incorrect Navigation Control

Module (NCM) installed

Incorrect car configuration data

received GO to Pinpoint Test I. 'NO DVD PLEASE INSERT MAP

DVD' message is displayed

A disc other than the map disc is

inserted Insert the correct map disc 'UNABLE TO READ DATA

CONSULT YOUR DEALER'

message is displayed

DVD player abnormality Check and install a new Navigation Control Module

(NCM) as required. Refer to the new

module/component installation note at top of DTC

Index. 'UNABLE TO READ DATA TEMPERATURE IS TOO HIGH'

message is displayed

Operating temperature has been

exceeded

Navigation Control Module (NCM)

internal temperature is high Move the vehicle to a cool location, and turn the

engine OFF. Wait for a while, then verify conditions

again. If the temperature around the Navigation

Control Module (NCM) is high, take measures to lower

temperature 'UNABLE TO READ DVD

CORRECTLY CHECK IF THE

DVD IS DAMAGED OR DIRTY'

message is displayed

Check map disc for contamination,

deformation, cracks, scratches or

non-genuine disc Clean the map disc and retest, replace the map disc 'UNABLE TO READ DATA

CHECK IF MAP DVD IS

CORRECT' message is displayed

Incorrect DVD map disc is inserted Insert a map disc with the correct part number Pinpoint Tests

NOTES:

If the control module or a component is suspect and the vehicle remains under manufacturer warranty, refer to the

Warranty Policy and Procedures manual (section B1.2), or determine if any prior approval Program is in operation, prior to the

installation of a new module/component.

Navigation Diagnostic Screen Access

1. With the vehicle at rest, place the ignition switch in either "ACC", "ON", or start the engine.

2.On the "Menu" screen, press the top center of the screen for more than three seconds.

3. Enter the PIN code, and then touch "OK". 660: Diagnosis Menu screen 661: System Check screen (DTC code

verification screen) 662: GPS Information screen.

4. The diagnostics screen will be displayed.

PINPOINT TEST A : POOR SATELLITE RECEPTION www.JagDocs.com

Page 2151 of 3039

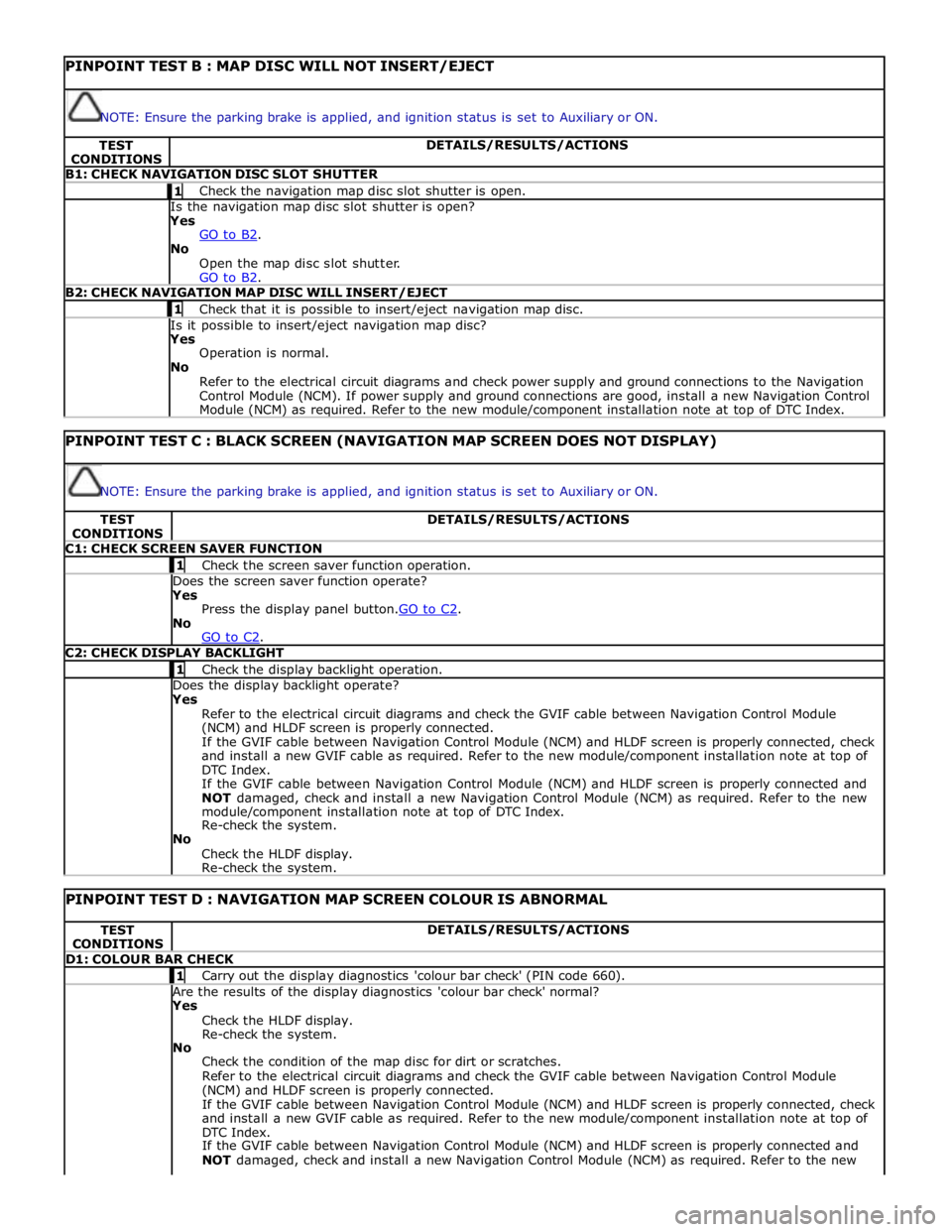

PINPOINT TEST B : MAP DISC WILL NOT INSERT/EJECT

NOTE: Ensure the parking brake is applied, and ignition status is set to Auxiliary or ON. TEST

CONDITIONS DETAILS/RESULTS/ACTIONS B1: CHECK NAVIGATION DISC SLOT SHUTTER 1 Check the navigation map disc slot shutter is open. Is the navigation map disc slot shutter is open? Yes

GO to B2. No

Open the map disc slot shutter.

GO to B2. B2: CHECK NAVIGATION MAP DISC WILL INSERT/EJECT 1 Check that it is possible to insert/eject navigation map disc. Is it possible to insert/eject navigation map disc? Yes

Operation is normal.

No

Refer to the electrical circuit diagrams and check power supply and ground connections to the Navigation

Control Module (NCM). If power supply and ground connections are good, install a new Navigation Control

Module (NCM) as required. Refer to the new module/component installation note at top of DTC Index.

PINPOINT TEST C : BLACK SCREEN (NAVIGATION MAP SCREEN DOES NOT DISPLAY)

NOTE: Ensure the parking brake is applied, and ignition status is set to Auxiliary or ON. TEST

CONDITIONS DETAILS/RESULTS/ACTIONS C1: CHECK SCREEN SAVER FUNCTION 1 Check the screen saver function operation. Does the screen saver function operate? Yes

Press the display panel button.GO to C2. No

GO to C2. C2: CHECK DISPLAY BACKLIGHT 1 Check the display backlight operation. Does the display backlight operate? Yes

Refer to the electrical circuit diagrams and check the GVIF cable between Navigation Control Module

(NCM) and HLDF screen is properly connected.

If the GVIF cable between Navigation Control Module (NCM) and HLDF screen is properly connected, check

and install a new GVIF cable as required. Refer to the new module/component installation note at top of

DTC Index.

If the GVIF cable between Navigation Control Module (NCM) and HLDF screen is properly connected and

NOT damaged, check and install a new Navigation Control Module (NCM) as required. Refer to the new

module/component installation note at top of DTC Index.

Re-check the system.

No

Check the HLDF display.

Re-check the system.

PINPOINT TEST D : NAVIGATION MAP SCREEN COLOUR IS ABNORMAL TEST

CONDITIONS DETAILS/RESULTS/ACTIONS D1: COLOUR BAR CHECK 1 Carry out the display diagnostics 'colour bar check' (PIN code 660). Are the results of the display diagnostics 'colour bar check' normal? Yes

Check the HLDF display.

Re-check the system.

No

Check the condition of the map disc for dirt or scratches.

Refer to the electrical circuit diagrams and check the GVIF cable between Navigation Control Module

(NCM) and HLDF screen is properly connected.

If the GVIF cable between Navigation Control Module (NCM) and HLDF screen is properly connected, check

and install a new GVIF cable as required. Refer to the new module/component installation note at top of

DTC Index.

If the GVIF cable between Navigation Control Module (NCM) and HLDF screen is properly connected and

NOT damaged, check and install a new Navigation Control Module (NCM) as required. Refer to the new