diagram JAGUAR XFR 2010 1.G Workshop Manual

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 2010, Model line: XFR, Model: JAGUAR XFR 2010 1.GPages: 3039, PDF Size: 58.49 MB

Page 2067 of 3039

Published: 11-May-2011

Module Communications Network - Communications Network - Overview

Description and Operation

OVERVIEW

A number of different types of communication network are incorporated into the vehicle wiring harnesses for the transmission

of commands and information between control modules. The configuration installed on a particular vehicle depends on the

model and equipment level.

NOTE: The control diagrams shown later in this section are schematics reflecting communications networks fitted to LH

(left-hand) vehicles only. For detailed layouts of the various communications networks fitted to LHD (left-hand drive) and RHD

(right-hand drive) vehicles, refer to the Electrical Guide.

The communications networks available on the vehicle are shown in the table below.

Network Baud Rate LIN (local interconnect network) bus 9.6 kbits/s Medium speed CAN (controller area network) bus 125 kbits/s High speed CAN bus 500 kbits/s Media Orientated System Transport (MOST) ring 24 mbits/s

Page 2068 of 3039

Published: 11-May-2011

Module Communications Network - Communications Network - System

Operation and Component Description

Description and Operation

Control Diagram

NOTE:

CONTROL DIAGRAM - LIN BUS - SHEET 1 OF 2

Item Description O = LIN (local interconnect network) bus 1 CJB (central junction box) 2 Battery backed sounder 3 Intrusion detection module

Page 2070 of 3039

O = LIN bus 1 ATC (automatic temperature control) module 2 Stepper motor - Windshield defrost 3 Stepper motor - Face/feet distribution 4 Stepper motor - LH (left-hand) temperature blend 5 Stepper motor - RH (right-hand) temperature blend 6 Electric booster heater 7 Stepper motor - RH outer face level vent 8 Stepper motor - RH inner face level vent 9 Stepper motor - LH inner face level vent 10 Stepper motor - LH outer face level vent CONTROL DIAGRAM - LIN BUS - SHEET 2 OF 2

www.JagDocs.com

Page 2072 of 3039

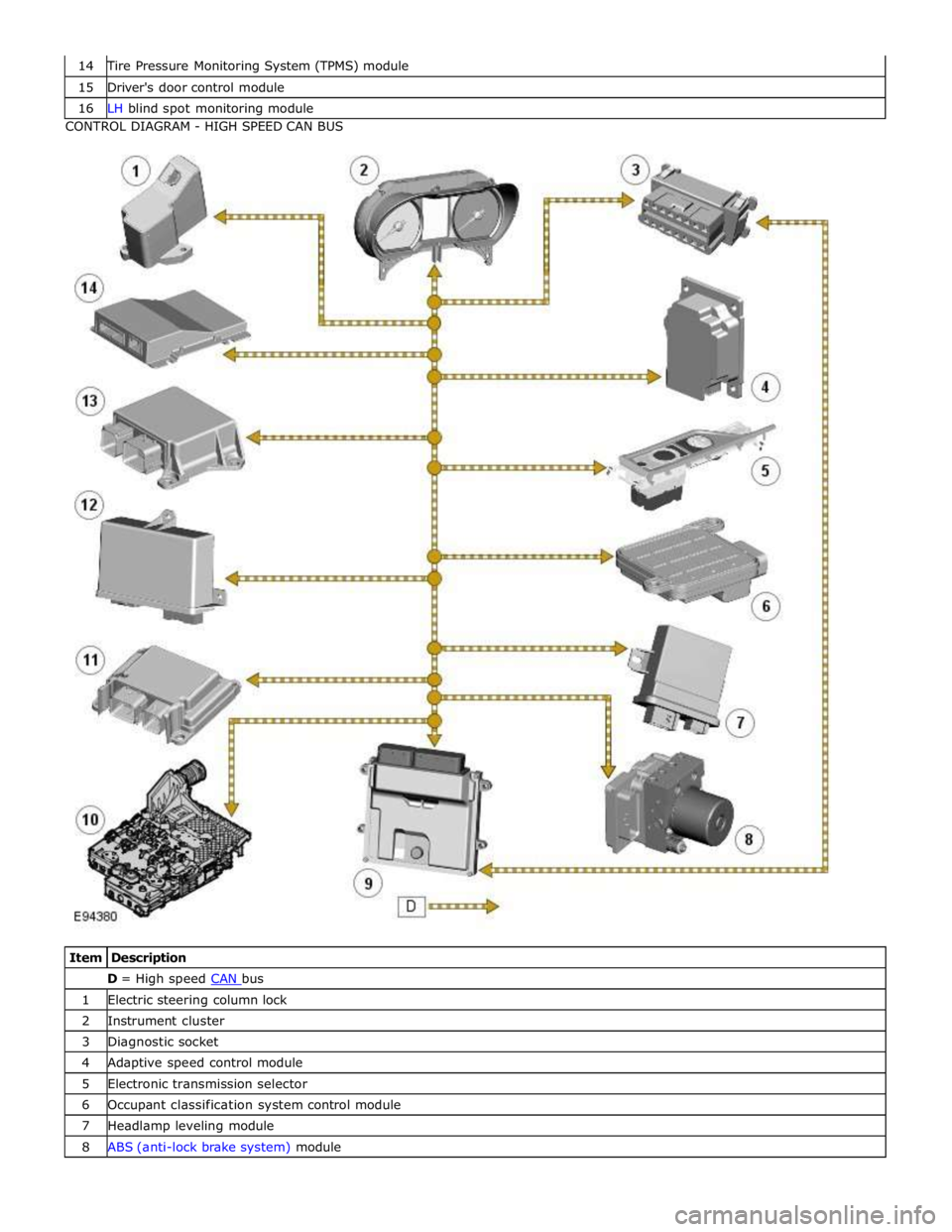

Tire Pressure Monitoring System (TPMS) module 15 Driver's door control module 16 LH blind spot monitoring module CONTROL DIAGRAM - HIGH SPEED CAN BUS

Item Description D = High speed CAN bus 1 Electric steering column lock 2 Instrument cluster 3 Diagnostic socket 4 Adaptive speed control module 5 Electronic transmission selector 6 Occupant classification system control module 7 Headlamp leveling module 8 ABS (anti-lock brake system) module

Page 2073 of 3039

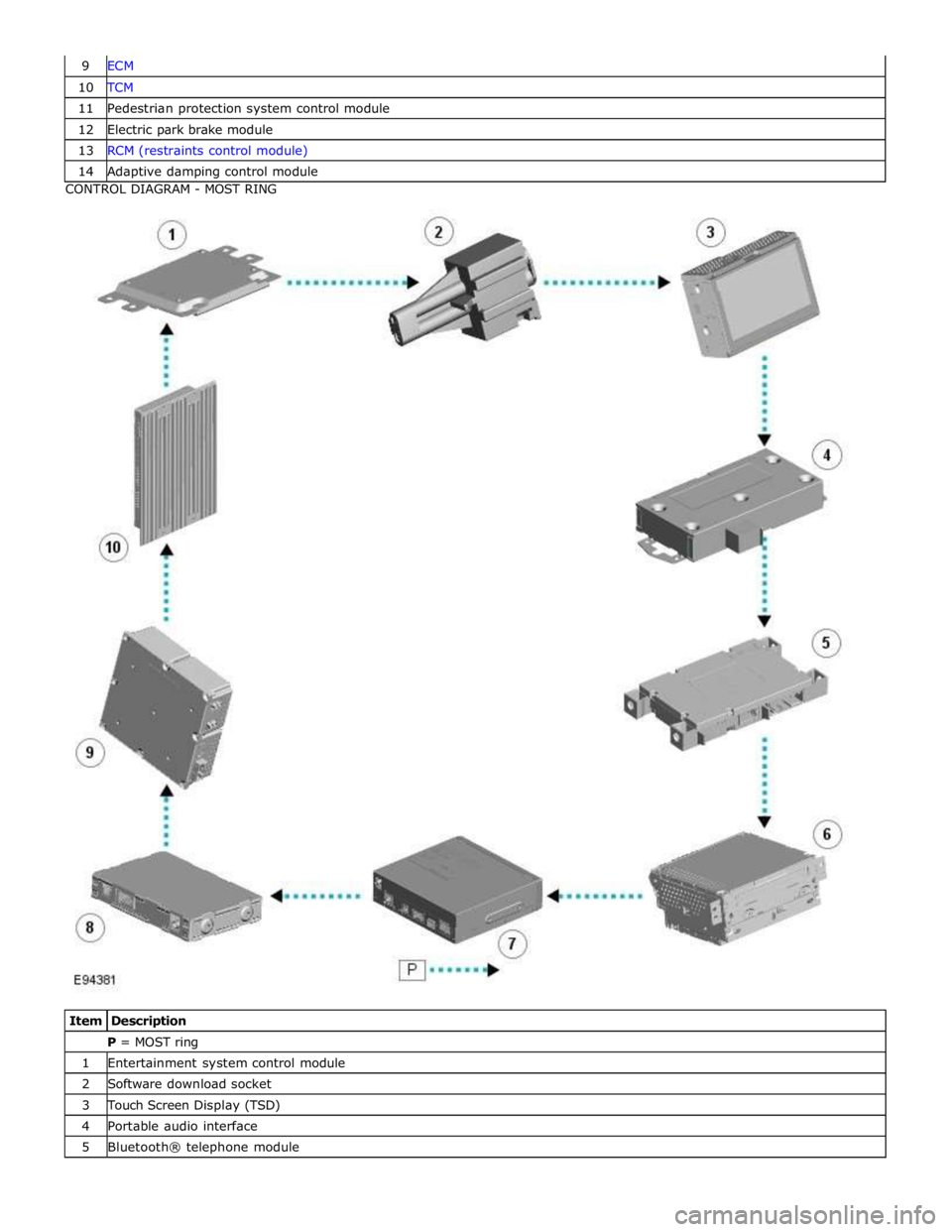

10 TCM 11 Pedestrian protection system control module 12 Electric park brake module 13 RCM (restraints control module) 14 Adaptive damping control module CONTROL DIAGRAM - MOST RING

Item Description P = MOST ring 1 Entertainment system control module 2 Software download socket 3 Touch Screen Display (TSD) 4 Portable audio interface 5 Bluetooth® telephone module

Page 2076 of 3039

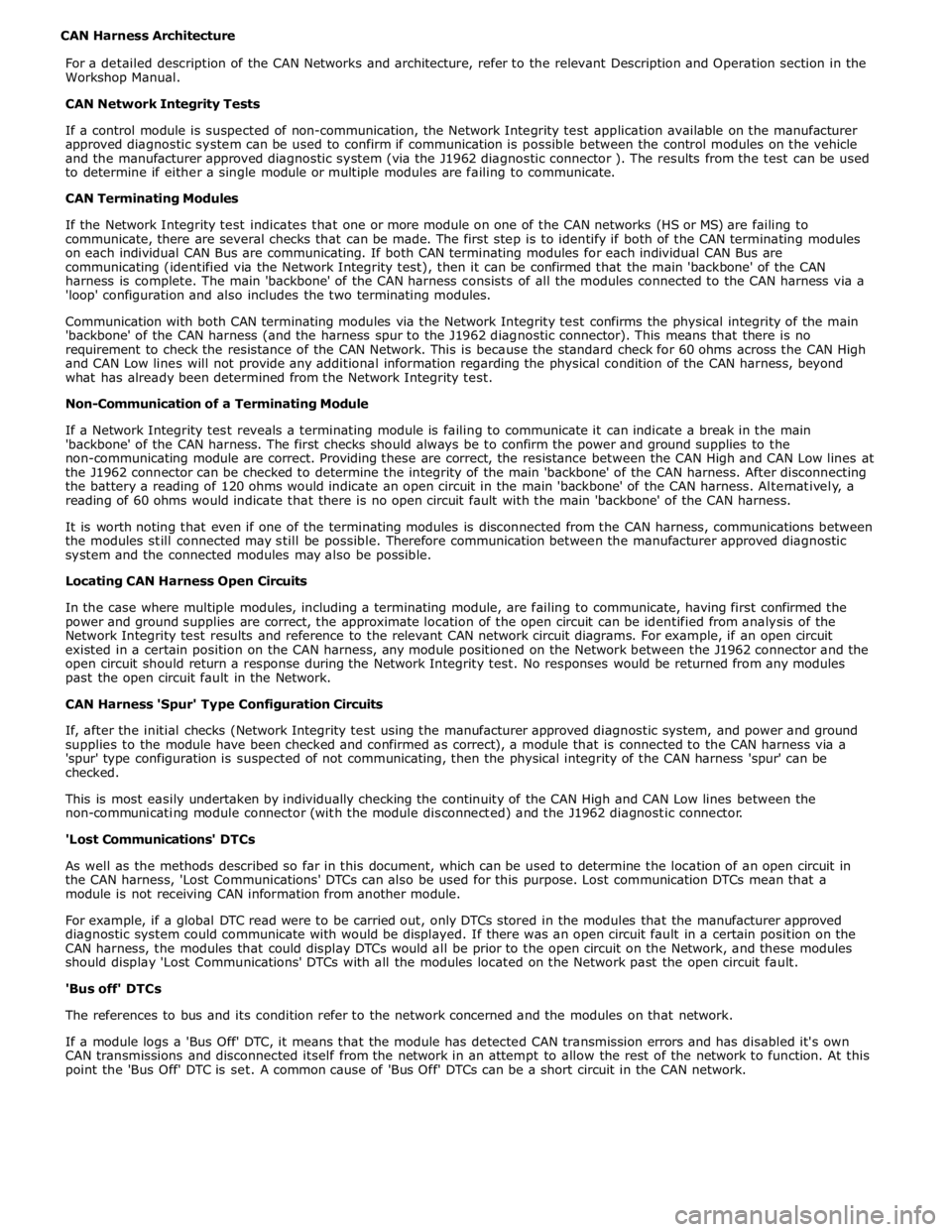

CAN Harness Architecture

For a detailed description of the CAN Networks and architecture, refer to the relevant Description and Operation section in the

Workshop Manual.

CAN Network Integrity Tests

If a control module is suspected of non-communication, the Network Integrity test application available on the manufacturer

approved diagnostic system can be used to confirm if communication is possible between the control modules on the vehicle

and the manufacturer approved diagnostic system (via the J1962 diagnostic connector ). The results from the test can be used

to determine if either a single module or multiple modules are failing to communicate.

CAN Terminating Modules

If the Network Integrity test indicates that one or more module on one of the CAN networks (HS or MS) are failing to

communicate, there are several checks that can be made. The first step is to identify if both of the CAN terminating modules

on each individual CAN Bus are communicating. If both CAN terminating modules for each individual CAN Bus are

communicating (identified via the Network Integrity test), then it can be confirmed that the main 'backbone' of the CAN

harness is complete. The main 'backbone' of the CAN harness consists of all the modules connected to the CAN harness via a

'loop' configuration and also includes the two terminating modules.

Communication with both CAN terminating modules via the Network Integrity test confirms the physical integrity of the main

'backbone' of the CAN harness (and the harness spur to the J1962 diagnostic connector). This means that there is no

requirement to check the resistance of the CAN Network. This is because the standard check for 60 ohms across the CAN High

and CAN Low lines will not provide any additional information regarding the physical condition of the CAN harness, beyond

what has already been determined from the Network Integrity test.

Non-Communication of a Terminating Module

If a Network Integrity test reveals a terminating module is failing to communicate it can indicate a break in the main

'backbone' of the CAN harness. The first checks should always be to confirm the power and ground supplies to the

non-communicating module are correct. Providing these are correct, the resistance between the CAN High and CAN Low lines at

the J1962 connector can be checked to determine the integrity of the main 'backbone' of the CAN harness. After disconnecting

the battery a reading of 120 ohms would indicate an open circuit in the main 'backbone' of the CAN harness. Alternatively, a

reading of 60 ohms would indicate that there is no open circuit fault with the main 'backbone' of the CAN harness.

It is worth noting that even if one of the terminating modules is disconnected from the CAN harness, communications between

the modules still connected may still be possible. Therefore communication between the manufacturer approved diagnostic

system and the connected modules may also be possible.

Locating CAN Harness Open Circuits

In the case where multiple modules, including a terminating module, are failing to communicate, having first confirmed the

power and ground supplies are correct, the approximate location of the open circuit can be identified from analysis of the

Network Integrity test results and reference to the relevant CAN network circuit diagrams. For example, if an open circuit

existed in a certain position on the CAN harness, any module positioned on the Network between the J1962 connector and the

open circuit should return a response during the Network Integrity test. No responses would be returned from any modules

past the open circuit fault in the Network.

CAN Harness 'Spur' Type Configuration Circuits

If, after the initial checks (Network Integrity test using the manufacturer approved diagnostic system, and power and ground

supplies to the module have been checked and confirmed as correct), a module that is connected to the CAN harness via a

'spur' type configuration is suspected of not communicating, then the physical integrity of the CAN harness 'spur' can be

checked.

This is most easily undertaken by individually checking the continuity of the CAN High and CAN Low lines between the

non-communicating module connector (with the module disconnected) and the J1962 diagnostic connector.

'Lost Communications' DTCs

As well as the methods described so far in this document, which can be used to determine the location of an open circuit in

the CAN harness, 'Lost Communications' DTCs can also be used for this purpose. Lost communication DTCs mean that a

module is not receiving CAN information from another module.

For example, if a global DTC read were to be carried out, only DTCs stored in the modules that the manufacturer approved

diagnostic system could communicate with would be displayed. If there was an open circuit fault in a certain position on the

CAN harness, the modules that could display DTCs would all be prior to the open circuit on the Network, and these modules

should display 'Lost Communications' DTCs with all the modules located on the Network past the open circuit fault.

'Bus off' DTCs

The references to bus and its condition refer to the network concerned and the modules on that network.

If a module logs a 'Bus Off' DTC, it means that the module has detected CAN transmission errors and has disabled it's own

CAN transmissions and disconnected itself from the network in an attempt to allow the rest of the network to function. At this

point the 'Bus Off' DTC is set. A common cause of 'Bus Off' DTCs can be a short circuit in the CAN network.

Page 2080 of 3039

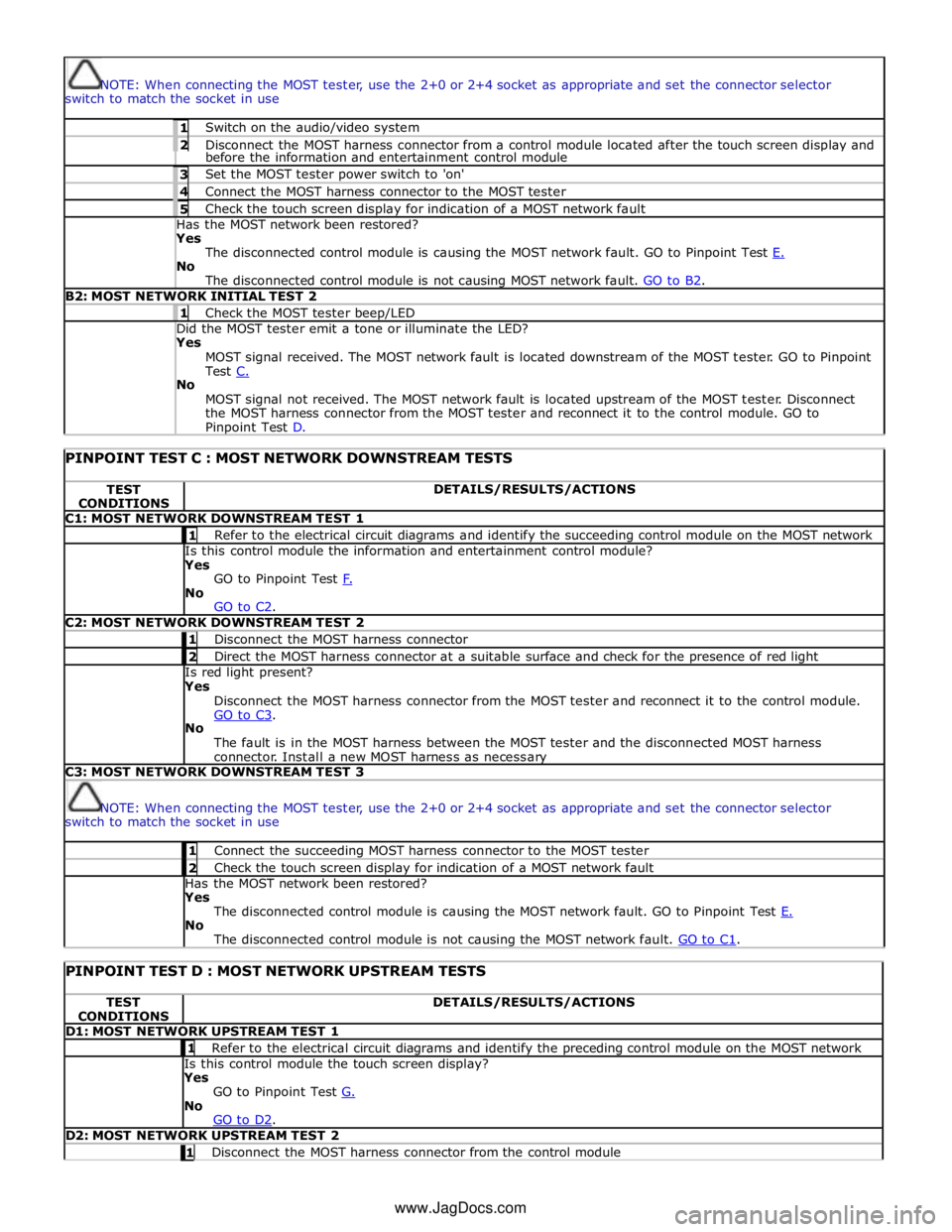

NOTE: When connecting the MOST tester, use the 2+0 or 2+4 socket as appropriate and set the connector selector

switch to match the socket in use 1 Switch on the audio/video system 2 Disconnect the MOST harness connector from a control module located after the touch screen display and before the information and entertainment control module 3 Set the MOST tester power switch to 'on' 4 Connect the MOST harness connector to the MOST tester 5 Check the touch screen display for indication of a MOST network fault Has the MOST network been restored? Yes

The disconnected control module is causing the MOST network fault. GO to Pinpoint Test E. No

The disconnected control module is not causing MOST network fault. GO to B2. B2: MOST NETWORK INITIAL TEST 2 1 Check the MOST tester beep/LED Did the MOST tester emit a tone or illuminate the LED? Yes

MOST signal received. The MOST network fault is located downstream of the MOST tester. GO to Pinpoint

Test C. No

MOST signal not received. The MOST network fault is located upstream of the MOST tester. Disconnect

the MOST harness connector from the MOST tester and reconnect it to the control module. GO to Pinpoint Test D.

PINPOINT TEST C : MOST NETWORK DOWNSTREAM TESTS TEST

CONDITIONS DETAILS/RESULTS/ACTIONS C1: MOST NETWORK DOWNSTREAM TEST 1 1 Refer to the electrical circuit diagrams and identify the succeeding control module on the MOST network Is this control module the information and entertainment control module?

Yes

GO to Pinpoint Test F. No

GO to C2. C2: MOST NETWORK DOWNSTREAM TEST 2 1 Disconnect the MOST harness connector 2 Direct the MOST harness connector at a suitable surface and check for the presence of red light Is red light present?

Yes

Disconnect the MOST harness connector from the MOST tester and reconnect it to the control module.

GO to C3. No

The fault is in the MOST harness between the MOST tester and the disconnected MOST harness

connector. Install a new MOST harness as necessary C3: MOST NETWORK DOWNSTREAM TEST 3

NOTE: When connecting the MOST tester, use the 2+0 or 2+4 socket as appropriate and set the connector selector

switch to match the socket in use 1 Connect the succeeding MOST harness connector to the MOST tester 2 Check the touch screen display for indication of a MOST network fault Has the MOST network been restored?

Yes

The disconnected control module is causing the MOST network fault. GO to Pinpoint Test E. No

The disconnected control module is not causing the MOST network fault. GO to C1.

PINPOINT TEST D : MOST NETWORK UPSTREAM TESTS TEST

CONDITIONS DETAILS/RESULTS/ACTIONS D1: MOST NETWORK UPSTREAM TEST 1 1 Refer to the electrical circuit diagrams and identify the preceding control module on the MOST network Is this control module the touch screen display?

Yes

GO to Pinpoint Test G. No

GO to D2. D2: MOST NETWORK UPSTREAM TEST 2 1 Disconnect the MOST harness connector from the control module www.JagDocs.com

Page 2081 of 3039

2 Direct the MOST harness connector at a suitable surface and check for the presence of red light Is red light present?

Yes

The MOST network fault is in the control module or the MOST harness to the succeeding control

module. GO to D3. No

The MOST network fault is located upstream of the disconnected control module. Reconnect the MOST

harness connector to the control module. GO to D1. D3: MOST NETWORK UPSTREAM TEST 3

NOTE: When connecting the MOST tester, use the 2+0 or 2+4 socket as appropriate and set the connector selector

switch to match the socket in use 1 Connect the MOST harness connector to the MOST tester 2 Check the touch screen display for indication of a MOST network fault Has the MOST network been restored?

Yes

The disconnected control module is causing the MOST network fault. GO to Pinpoint Test E. No

The fault is in the MOST harness between the MOST tester and the succeeding control module. Install a

new MOST harness as necessary

PINPOINT TEST E : CONTROL MODULE TESTS TEST

CONDITIONS DETAILS/RESULTS/ACTIONS E1: CONTROL MODULE TEST 1 NOTES:

When connecting the MOST tester, use the 2+0 or 2+4 socket as appropriate and set the connector selector switch to

match the socket in use

The MOST tester may continue to emit a tone or illuminate the LED after the test switch is released. This does not

indicate a fault. 1 Connect the MOST tester to the relevant control module using the adapter harness 2 Operate the test switch and check the MOST tester beep/LED Did the MOST tester emit a tone or illuminate the LED? Yes

MOST signal received. Tests inconclusive. Reconnect the MOST harness connector to the control module

and confirm that the MOST network fault is still present. Repeat the tests from the beginning. GO to

Pinpoint Test B. No

GO to E2. E2: CONTROL MODULE TEST 2 1 Refer to the electrical circuit diagrams and test the relevant control module power and ground circuits for open circuit, high resistance Are the power and ground circuits within specification? Yes

GO to E3. No

Repair the power and/or ground circuit E3: CONTROL MODULE TEST 3 1 Reconnect the MOST harness to the control module 2 Check the touch screen display for indication of a MOST network fault Has the MOST network been restored? Yes

Tests inconclusive. Repeat the tests from the beginning. GO to Pinpoint Test B. No

Install a new control module

PINPOINT TEST F : MOST NETWORK FINAL DOWNSTREAM TEST TEST

CONDITIONS DETAILS/RESULTS/ACTIONS F1: MOST NETWORK FINAL DOWNSTREAM TEST 1 NOTES:

When connecting the MOST tester, use the 2+0 or 2+4 socket as appropriate and set the connector selector switch to

match the socket in use

Page 2083 of 3039

1 Disconnect the MOST tester 2 Install the cover to the MOST diagnostic connector Has the MOST network been restored? Yes

No further action required

No

Install a new MOST diagnostic connector cover H3: BLANK SCREEN TEST 3 1 Check the MOST tester beep/LED Did the MOST tester emit a tone or illuminate the LED? Yes

MOST signal received. The MOST network fault is located downstream of the MOST tester. GO to H4. No

MOST signal not received. The MOST network fault is located upstream of the MOST tester. Disconnect

the MOST tester from the MOST diagnostic connector and install the cover. GO to H5. H4: BLANK SCREEN TEST 4 1 Disconnect the MOST harness connector from the touch screen display 2 Direct the MOST harness connector at a suitable surface and check for the presence of red light Is red light present? Yes

GO to Pinpoint Test J. No

The fault is in the MOST harness between the MOST diagnostic connector and the touch screen display.

Install a new MOST harness as necessary H5: BLANK SCREEN TEST 5 1 Disconnect the MOST harness connector from the information and entertainment control module 2 Direct the information and entertainment control module at a suitable surface and check for the presence of red light Is red light present? Yes

Install a new MOST harness between the information and entertainment control module and the MOST

diagnostic connector

No

GO to Pinpoint Test I.

PINPOINT TEST I : INFORMATION AND ENTERTAINMENT CONTROL MODULE TESTS TEST

CONDITIONS DETAILS/RESULTS/ACTIONS I1: INFORMATION AND ENTERTAINMENT CONTROL MODULE TEST 1 1 Using the manufacturer approved diagnostic system, check the information and entertainment control module for related DTCs Is communication possible between the manufacturer approved diagnostic system and the information and

entertainment control module? Yes

Refer to the relevant DTC index

No

GO to I2. I2: INFORMATION AND ENTERTAINMENT CONTROL MODULE TEST 2 1 Refer to the electrical circuit diagrams and test the information and entertainment control module power and ground circuits for open circuit, high resistance Are the power and ground circuits within specification? Yes

GO to I3. No

Repair the power and/or ground circuit I3: INFORMATION AND ENTERTAINMENT CONTROL MODULE TEST 3 1 Using the manufacturer approved diagnostic system, perform a CAN network integrity test. Refer to the electrical circuit diagrams and test the medium speed CAN bus circuit for short circuit to ground, short

circuit to power, open circuit, high resistance Is the medium speed CAN bus within specification? Yes

Install a new information and entertainment control module

No

Repair the medium speed CAN bus circuit

PINPOINT TEST J : TOUCH SCREEN DISPLAY TESTS TEST

CONDITIONS DETAILS/RESULTS/ACTIONS J1: TOUCH SCREEN DISPLAY TEST 1 1 Refer to the electrical circuit diagrams and test the touch screen display power and ground circuits for open circuit, high resistance

Page 2084 of 3039

Are the power and ground circuits within specification?

Yes

GO to J2. No

Repair the power and/or ground circuit J2: TOUCH SCREEN DISPLAY TEST 2 1 Reconnect the MOST harness to the touch screen display 2 Check the touch screen display for indication of a MOST network fault Has the MOST network been restored?

Yes

Tests inconclusive. Repeat the tests from beginning. GO to Pinpoint Test B. No

Install a new touch screen display DTC Index

Central Junction Box (CJB)

CAUTIONS:

Diagnosis by substitution from a donor vehicle is NOT acceptable. Substitution of control modules does not guarantee

confirmation of a fault, and may also cause additional faults in the vehicle being tested and/or the donor vehicle

When probing connectors to take measurements in the course of the pinpoint tests, use the adaptor kit, part number

3548-1358-00

NOTES:

If the control module or a component is suspect and the vehicle remains under manufacturer warranty, refer to the

warranty policy and procedures manual (section B1.2), or determine if any prior approval programme is in operation, prior to

the installation of a new module/component

Generic scan tools may not read the codes listed, or may read only 5-digit codes. Match the 5 digits from the scan tool to

the first 5 digits of the 7-digit code listed to identify the fault (the last 2 digits give extra information read by the

manufacturer-approved diagnostic system)

When performing voltage or resistance tests, always use a digital multimeter accurate to three decimal places and with a

current calibration certificate. When testing resistance, always take the resistance of the digital multimeter leads into account

Check and rectify basic faults before beginning diagnostic routines involving pinpoint tests

Inspect connectors for signs of water ingress, and pins for damage and/or corrosion

If diagnostic trouble codes are recorded and, after performing the pinpoint tests, a fault is not present, an intermittent

concern may be the cause. Always check for loose connections and corroded terminals

Where an 'on demand self-test' is referred to, this can be accessed via the 'diagnostic trouble code monitor' tab on the

manufacturers approved diagnostic system

Check DDW for open campaigns. Refer to the corresponding bulletins and SSMs which may be valid for the specific

customer complaint and carry out the recommendations as required

DTC Description Possible Cause Action B00D511

Restraint System

Passenger Disable

Indicator

PAD lamp supply circuit - short

to ground Refer to the electrical circuit diagrams and check PAD

lamp supply circuit for short to ground B00D512

Restraint System

Passenger Disable

Indicator

PAD lamp supply circuit - short

to power Refer to the electrical circuit diagrams and check PAD

lamp supply circuit for short to power B00D513

Restraint System

Passenger Disable

Indicator

PAD lamp supply circuit - open

circuit Refer to the electrical circuit diagrams and check PAD

lamp supply circuit for open circuit