diagram JAGUAR XFR 2010 1.G Workshop Manual

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 2010, Model line: XFR, Model: JAGUAR XFR 2010 1.GPages: 3039, PDF Size: 58.49 MB

Page 1803 of 3039

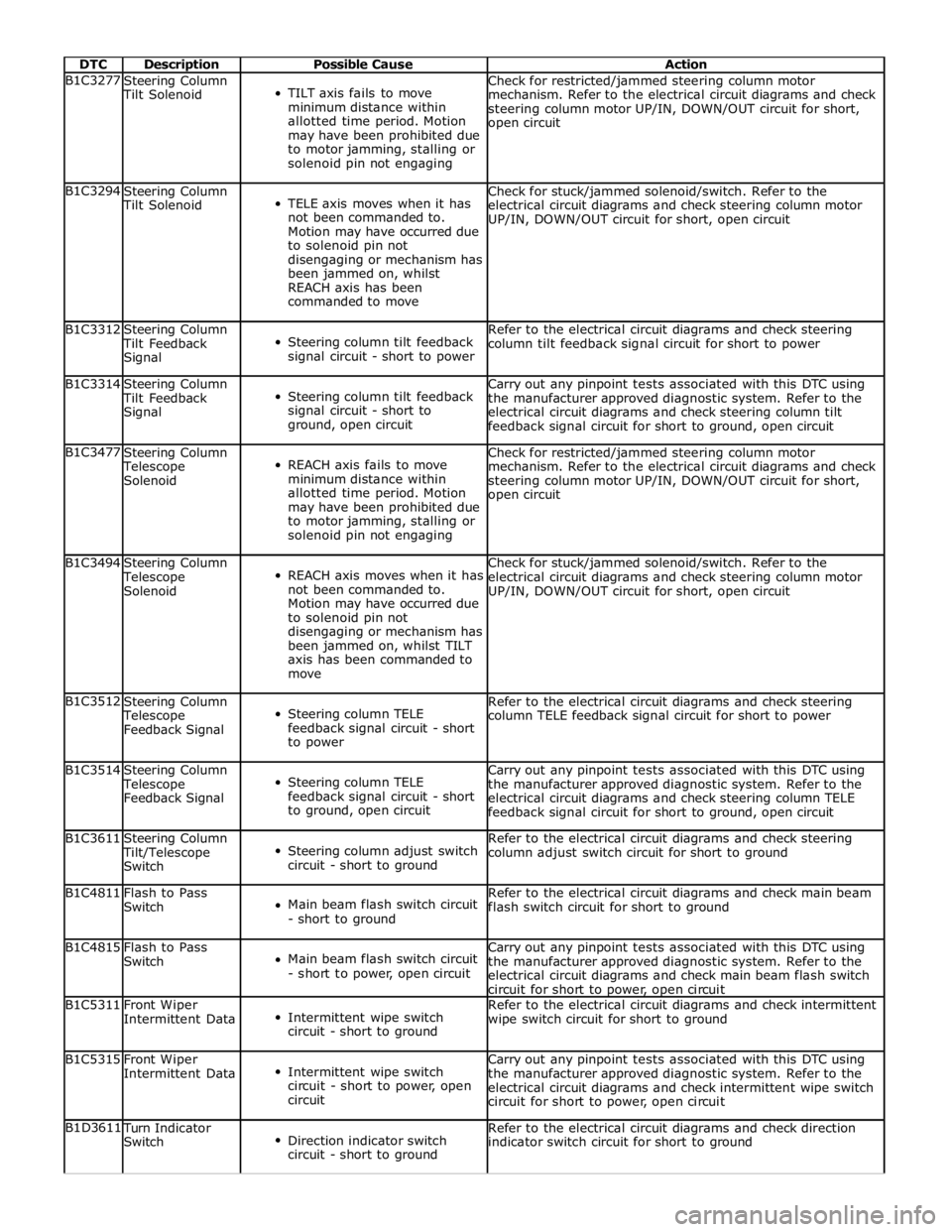

DTC Description Possible Cause Action B1C3277

Steering Column

Tilt Solenoid

TILT axis fails to move

minimum distance within

allotted time period. Motion

may have been prohibited due

to motor jamming, stalling or

solenoid pin not engaging Check for restricted/jammed steering column motor

mechanism. Refer to the electrical circuit diagrams and check

steering column motor UP/IN, DOWN/OUT circuit for short,

open circuit B1C3294

Steering Column

Tilt Solenoid

TELE axis moves when it has

not been commanded to.

Motion may have occurred due

to solenoid pin not

disengaging or mechanism has

been jammed on, whilst

REACH axis has been

commanded to move Check for stuck/jammed solenoid/switch. Refer to the

electrical circuit diagrams and check steering column motor

UP/IN, DOWN/OUT circuit for short, open circuit B1C3312

Steering Column

Tilt Feedback

Signal

Steering column tilt feedback

signal circuit - short to power Refer to the electrical circuit diagrams and check steering

column tilt feedback signal circuit for short to power B1C3314

Steering Column

Tilt Feedback

Signal

Steering column tilt feedback

signal circuit - short to

ground, open circuit Carry out any pinpoint tests associated with this DTC using

the manufacturer approved diagnostic system. Refer to the

electrical circuit diagrams and check steering column tilt

feedback signal circuit for short to ground, open circuit B1C3477

Steering Column

Telescope

Solenoid

REACH axis fails to move

minimum distance within

allotted time period. Motion

may have been prohibited due

to motor jamming, stalling or

solenoid pin not engaging Check for restricted/jammed steering column motor

mechanism. Refer to the electrical circuit diagrams and check

steering column motor UP/IN, DOWN/OUT circuit for short,

open circuit B1C3494

Steering Column

Telescope

Solenoid

REACH axis moves when it has

not been commanded to.

Motion may have occurred due

to solenoid pin not

disengaging or mechanism has

been jammed on, whilst TILT

axis has been commanded to

move Check for stuck/jammed solenoid/switch. Refer to the

electrical circuit diagrams and check steering column motor

UP/IN, DOWN/OUT circuit for short, open circuit B1C3512

Steering Column

Telescope

Feedback Signal

Steering column TELE

feedback signal circuit - short

to power Refer to the electrical circuit diagrams and check steering

column TELE feedback signal circuit for short to power B1C3514

Steering Column

Telescope

Feedback Signal

Steering column TELE

feedback signal circuit - short

to ground, open circuit Carry out any pinpoint tests associated with this DTC using

the manufacturer approved diagnostic system. Refer to the

electrical circuit diagrams and check steering column TELE

feedback signal circuit for short to ground, open circuit B1C3611

Steering Column

Tilt/Telescope

Switch

Steering column adjust switch

circuit - short to ground Refer to the electrical circuit diagrams and check steering

column adjust switch circuit for short to ground B1C4811

Flash to Pass

Switch

Main beam flash switch circuit

- short to ground Refer to the electrical circuit diagrams and check main beam

flash switch circuit for short to ground B1C4815

Flash to Pass

Switch

Main beam flash switch circuit

- short to power, open circuit Carry out any pinpoint tests associated with this DTC using

the manufacturer approved diagnostic system. Refer to the

electrical circuit diagrams and check main beam flash switch

circuit for short to power, open circuit B1C5311

Front Wiper

Intermittent Data

Intermittent wipe switch

circuit - short to ground Refer to the electrical circuit diagrams and check intermittent

wipe switch circuit for short to ground B1C5315

Front Wiper

Intermittent Data

Intermittent wipe switch

circuit - short to power, open

circuit Carry out any pinpoint tests associated with this DTC using

the manufacturer approved diagnostic system. Refer to the

electrical circuit diagrams and check intermittent wipe switch

circuit for short to power, open circuit B1D3611

Turn Indicator

Switch

Direction indicator switch

circuit - short to ground Refer to the electrical circuit diagrams and check direction

indicator switch circuit for short to ground

Page 1804 of 3039

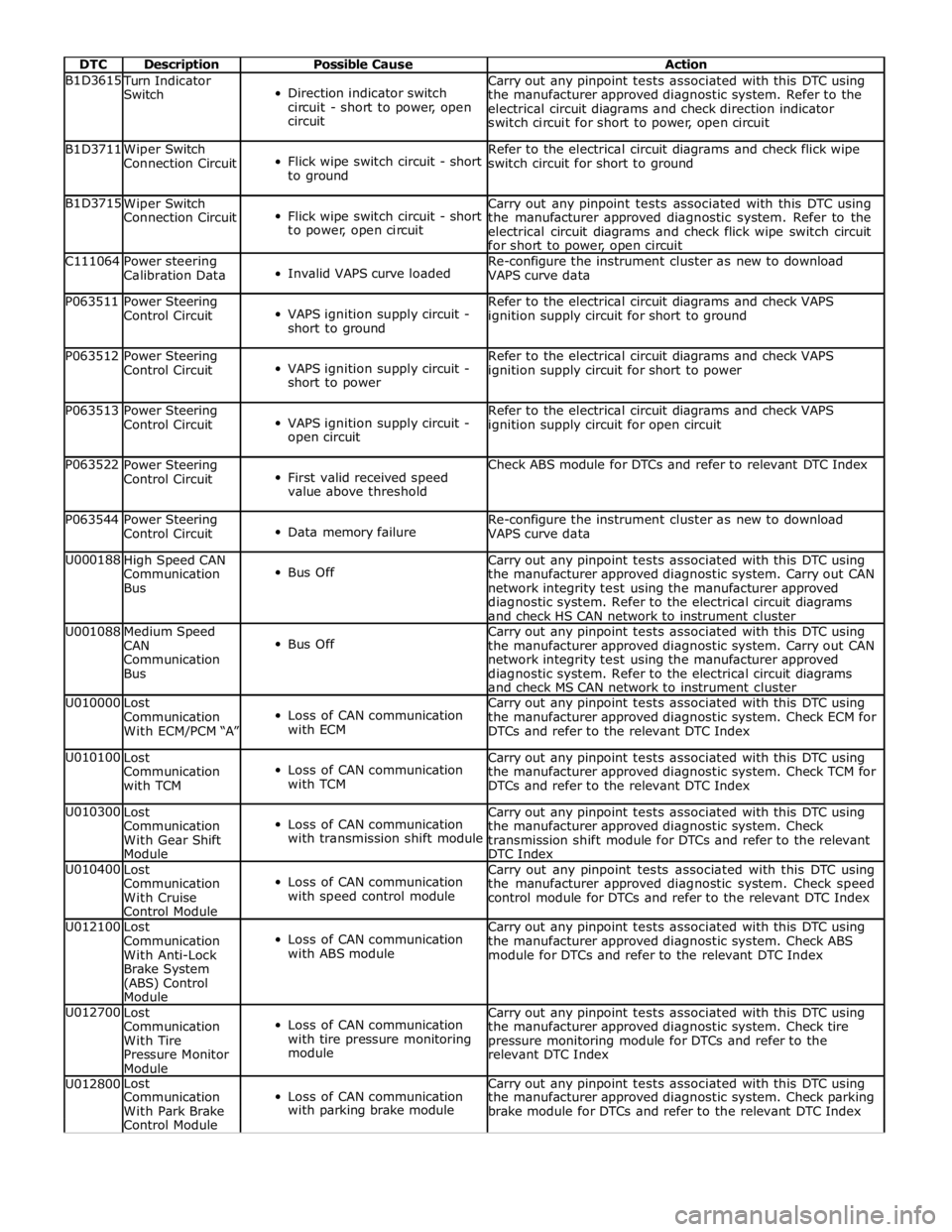

DTC Description Possible Cause Action B1D3615

Turn Indicator

Switch

Direction indicator switch

circuit - short to power, open

circuit Carry out any pinpoint tests associated with this DTC using

the manufacturer approved diagnostic system. Refer to the

electrical circuit diagrams and check direction indicator

switch circuit for short to power, open circuit B1D3711

Wiper Switch

Connection Circuit

Flick wipe switch circuit - short

to ground Refer to the electrical circuit diagrams and check flick wipe

switch circuit for short to ground B1D3715

Wiper Switch

Connection Circuit

Flick wipe switch circuit - short

to power, open circuit Carry out any pinpoint tests associated with this DTC using

the manufacturer approved diagnostic system. Refer to the

electrical circuit diagrams and check flick wipe switch circuit

for short to power, open circuit C111064

Power steering

Calibration Data

Invalid VAPS curve loaded Re-configure the instrument cluster as new to download

VAPS curve data P063511

Power Steering

Control Circuit

VAPS ignition supply circuit -

short to ground Refer to the electrical circuit diagrams and check VAPS

ignition supply circuit for short to ground P063512

Power Steering

Control Circuit

VAPS ignition supply circuit -

short to power Refer to the electrical circuit diagrams and check VAPS

ignition supply circuit for short to power P063513

Power Steering

Control Circuit

VAPS ignition supply circuit -

open circuit Refer to the electrical circuit diagrams and check VAPS

ignition supply circuit for open circuit P063522

Power Steering

Control Circuit

First valid received speed

value above threshold Check ABS module for DTCs and refer to relevant DTC Index P063544

Power Steering

Control Circuit

Data memory failure Re-configure the instrument cluster as new to download

VAPS curve data U000188

High Speed CAN

Communication

Bus

Bus Off Carry out any pinpoint tests associated with this DTC using

the manufacturer approved diagnostic system. Carry out CAN

network integrity test using the manufacturer approved

diagnostic system. Refer to the electrical circuit diagrams

and check HS CAN network to instrument cluster U001088

Medium Speed

CAN

Communication

Bus

Bus Off Carry out any pinpoint tests associated with this DTC using

the manufacturer approved diagnostic system. Carry out CAN

network integrity test using the manufacturer approved

diagnostic system. Refer to the electrical circuit diagrams

and check MS CAN network to instrument cluster U010000

Lost

Communication

With ECM/PCM “A”

Loss of CAN communication

with ECM Carry out any pinpoint tests associated with this DTC using

the manufacturer approved diagnostic system. Check ECM for

DTCs and refer to the relevant DTC Index U010100

Lost

Communication

with TCM

Loss of CAN communication

with TCM Carry out any pinpoint tests associated with this DTC using

the manufacturer approved diagnostic system. Check TCM for

DTCs and refer to the relevant DTC Index U010300

Lost

Communication

With Gear Shift

Module

Loss of CAN communication

with transmission shift module Carry out any pinpoint tests associated with this DTC using

the manufacturer approved diagnostic system. Check

transmission shift module for DTCs and refer to the relevant

DTC Index U010400

Lost

Communication

With Cruise

Control Module

Loss of CAN communication

with speed control module Carry out any pinpoint tests associated with this DTC using

the manufacturer approved diagnostic system. Check speed

control module for DTCs and refer to the relevant DTC Index U012100

Lost

Communication

With Anti-Lock

Brake System

(ABS) Control

Module

Loss of CAN communication

with ABS module Carry out any pinpoint tests associated with this DTC using

the manufacturer approved diagnostic system. Check ABS

module for DTCs and refer to the relevant DTC Index U012700

Lost

Communication

With Tire

Pressure Monitor

Module

Loss of CAN communication

with tire pressure monitoring

module Carry out any pinpoint tests associated with this DTC using

the manufacturer approved diagnostic system. Check tire

pressure monitoring module for DTCs and refer to the

relevant DTC Index U012800 Lost

Loss of CAN communication Carry out any pinpoint tests associated with this DTC using Communication the manufacturer approved diagnostic system. Check parking With Park Brake with parking brake module

brake module for DTCs and refer to the relevant DTC Index Control Module

Page 1805 of 3039

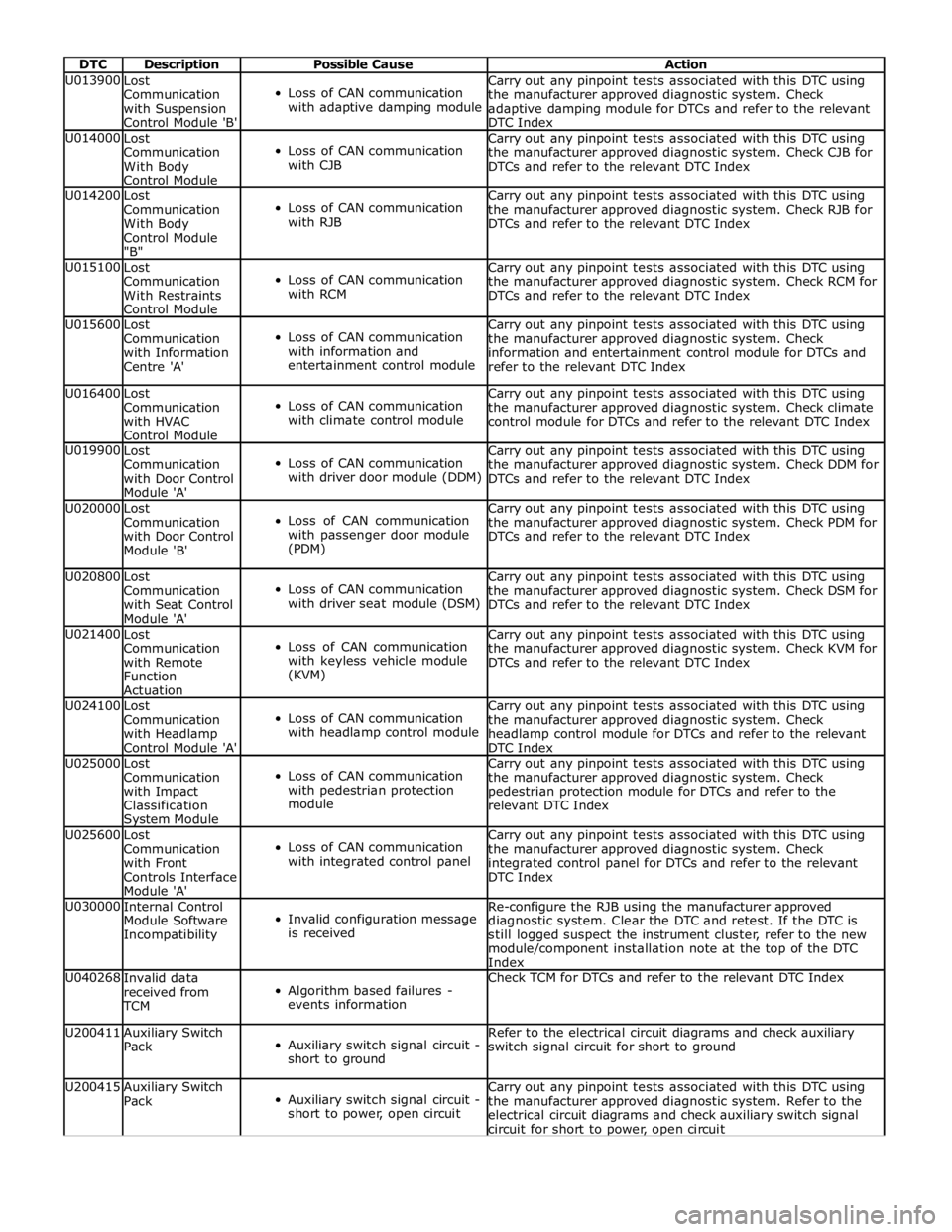

DTC Description Possible Cause Action U013900

Lost

Communication

with Suspension

Control Module 'B'

Loss of CAN communication

with adaptive damping module Carry out any pinpoint tests associated with this DTC using

the manufacturer approved diagnostic system. Check

adaptive damping module for DTCs and refer to the relevant

DTC Index U014000

Lost

Communication

With Body

Control Module

Loss of CAN communication

with CJB Carry out any pinpoint tests associated with this DTC using

the manufacturer approved diagnostic system. Check CJB for

DTCs and refer to the relevant DTC Index U014200

Lost

Communication

With Body

Control Module

"B"

Loss of CAN communication

with RJB Carry out any pinpoint tests associated with this DTC using

the manufacturer approved diagnostic system. Check RJB for

DTCs and refer to the relevant DTC Index U015100

Lost

Communication

With Restraints

Control Module

Loss of CAN communication

with RCM Carry out any pinpoint tests associated with this DTC using

the manufacturer approved diagnostic system. Check RCM for

DTCs and refer to the relevant DTC Index U015600

Lost

Communication

with Information

Centre 'A'

Loss of CAN communication

with information and

entertainment control module Carry out any pinpoint tests associated with this DTC using

the manufacturer approved diagnostic system. Check

information and entertainment control module for DTCs and

refer to the relevant DTC Index U016400

Lost

Communication

with HVAC

Control Module

Loss of CAN communication

with climate control module Carry out any pinpoint tests associated with this DTC using

the manufacturer approved diagnostic system. Check climate

control module for DTCs and refer to the relevant DTC Index U019900

Lost

Communication

with Door Control

Module 'A'

Loss of CAN communication

with driver door module (DDM) Carry out any pinpoint tests associated with this DTC using

the manufacturer approved diagnostic system. Check DDM for

DTCs and refer to the relevant DTC Index U020000

Lost

Communication

with Door Control

Module 'B'

Loss of CAN communication

with passenger door module

(PDM) Carry out any pinpoint tests associated with this DTC using

the manufacturer approved diagnostic system. Check PDM for

DTCs and refer to the relevant DTC Index U020800

Lost

Communication

with Seat Control

Module 'A'

Loss of CAN communication

with driver seat module (DSM) Carry out any pinpoint tests associated with this DTC using

the manufacturer approved diagnostic system. Check DSM for

DTCs and refer to the relevant DTC Index U021400

Lost

Communication

with Remote

Function

Actuation

Loss of CAN communication

with keyless vehicle module

(KVM) Carry out any pinpoint tests associated with this DTC using

the manufacturer approved diagnostic system. Check KVM for

DTCs and refer to the relevant DTC Index U024100

Lost

Communication

with Headlamp

Control Module 'A'

Loss of CAN communication

with headlamp control module Carry out any pinpoint tests associated with this DTC using

the manufacturer approved diagnostic system. Check

headlamp control module for DTCs and refer to the relevant

DTC Index U025000

Lost

Communication

with Impact

Classification System Module

Loss of CAN communication

with pedestrian protection

module Carry out any pinpoint tests associated with this DTC using

the manufacturer approved diagnostic system. Check

pedestrian protection module for DTCs and refer to the

relevant DTC Index U025600

Lost

Communication

with Front

Controls Interface

Module 'A'

Loss of CAN communication

with integrated control panel Carry out any pinpoint tests associated with this DTC using

the manufacturer approved diagnostic system. Check

integrated control panel for DTCs and refer to the relevant

DTC Index U030000

Internal Control

Module Software

Incompatibility

Invalid configuration message

is received Re-configure the RJB using the manufacturer approved

diagnostic system. Clear the DTC and retest. If the DTC is

still logged suspect the instrument cluster, refer to the new

module/component installation note at the top of the DTC

Index U040268

Invalid data

received from

TCM

Algorithm based failures -

events information Check TCM for DTCs and refer to the relevant DTC Index U200411

Auxiliary Switch

Pack

Auxiliary switch signal circuit -

short to ground Refer to the electrical circuit diagrams and check auxiliary

switch signal circuit for short to ground U200415

Auxiliary Switch

Pack

Auxiliary switch signal circuit -

short to power, open circuit Carry out any pinpoint tests associated with this DTC using

the manufacturer approved diagnostic system. Refer to the

electrical circuit diagrams and check auxiliary switch signal

circuit for short to power, open circuit

Page 1806 of 3039

DTC Description Possible Cause Action U300046 Control Module

Calibration/parameter memory

failure Suspect the instrument cluster, check and install a new

instrument cluster as required, refer to the new

module/component installation note at the top of the DTC

Index U300049 Control Module

Internal electronic failure Suspect the instrument cluster, check and install a new

instrument cluster as required, refer to the new

module/component installation note at the top of the DTC

Index U300055 Control Module

Incorrect car configuration

data received Re-configure the RJB using the manufacturer approved

diagnostic system. Clear DTC and re-test. If the DTC remains

suspect the instrument cluster. Check and install a new

instrument cluster as required, refer to the new

module/component installation note at the top of the DTC

Index U300087 Control Module

Missing message Re-configure the RJB using the manufacturer approved

diagnostic system. Check instrument cluster for additional

DTCs and refer to the DTC Index. Carry out CAN network

integrity tests using the manufacturer approved diagnostic

system. If DTC remains suspect the instrument cluster.

Check and install a new instrument cluster as required, refer

to the new module/component installation note at the top of

the DTC Index U300281

Vehicle

Identification

Number

Vehicle/component mis-match.

Corrupt VIN data being

transmitted, instrument

cluster previously installed to

other vehicle Check and install original/new instrument cluster as required,

refer to the new module/component installation note at the

top of the DTC Index U300316 Battery Voltage

Instrument cluster logic power

supply circuit - voltage below

threshold Carry out any pinpoint tests associated with this DTC using

the manufacturer approved diagnostic system. Refer to the

electrical circuit diagrams and check instrument cluster logic

power supply circuit for short to ground, open circuit U300317 Battery Voltage

Instrument cluster logic power

supply circuit - circuit voltage

above threshold Carry out any pinpoint tests associated with this DTC using

the manufacturer approved diagnostic system. Check

charging system for over charging condition U300362 Battery Voltage

Mis-match in battery voltage,

of 2 volts or more, between

instrument cluster and RJB Carry out any pinpoint tests associated with this DTC using

the manufacturer approved diagnostic system. Refer to the

electrical circuit diagrams and check instrument cluster logic

power supply circuit for short, open circuit

Page 1836 of 3039

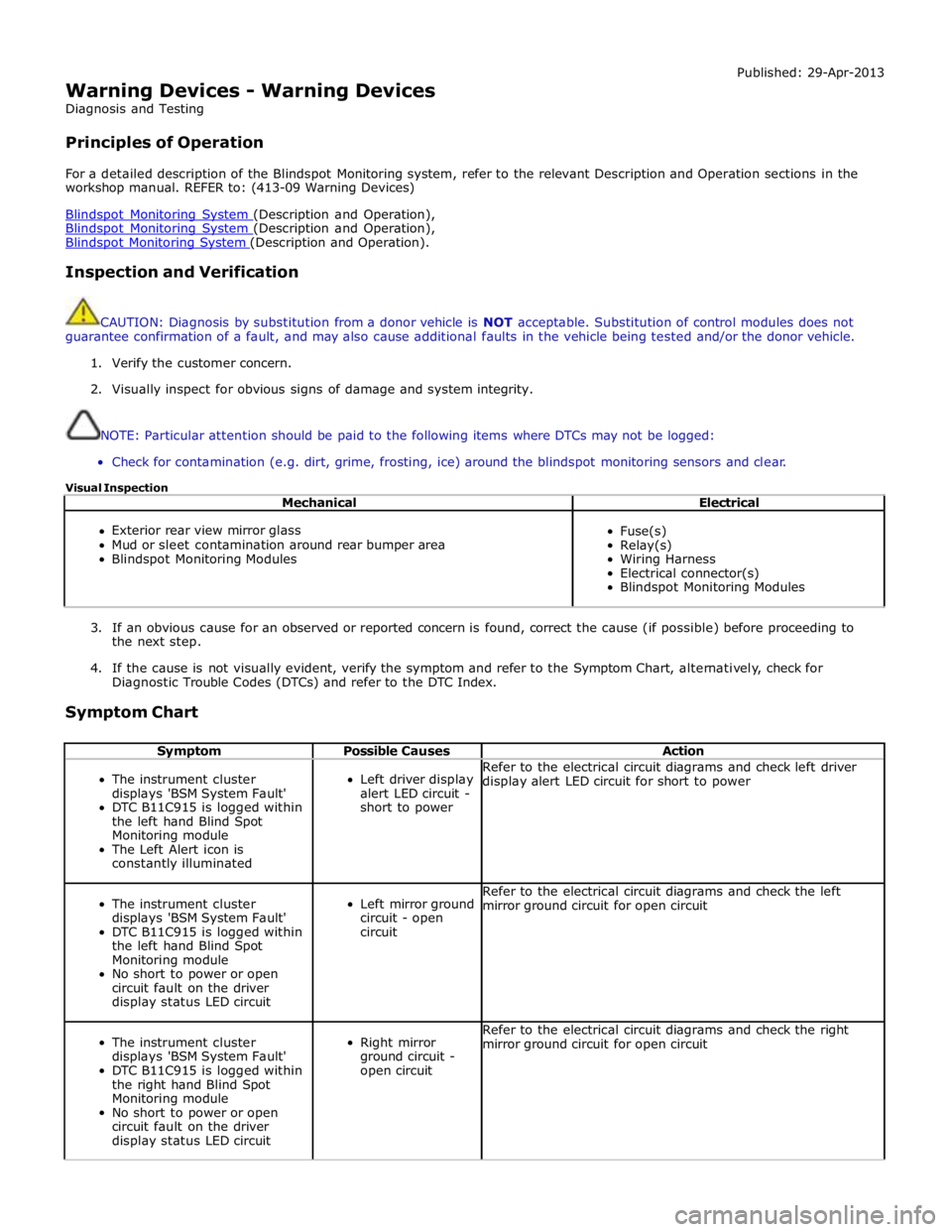

Warning Devices - Warning Devices

Diagnosis and Testing

Principles of Operation Published: 29-Apr-2013

For a detailed description of the Blindspot Monitoring system, refer to the relevant Description and Operation sections in the

workshop manual. REFER to: (413-09 Warning Devices)

Blindspot Monitoring System (Description and Operation), Blindspot Monitoring System (Description and Operation), Blindspot Monitoring System (Description and Operation).

Inspection and Verification

CAUTION: Diagnosis by substitution from a donor vehicle is NOT acceptable. Substitution of control modules does not

guarantee confirmation of a fault, and may also cause additional faults in the vehicle being tested and/or the donor vehicle.

1. Verify the customer concern.

2. Visually inspect for obvious signs of damage and system integrity.

NOTE: Particular attention should be paid to the following items where DTCs may not be logged:

Check for contamination (e.g. dirt, grime, frosting, ice) around the blindspot monitoring sensors and clear.

Visual Inspection

Mechanical Electrical

Exterior rear view mirror glass

Mud or sleet contamination around rear bumper area

Blindspot Monitoring Modules

Fuse(s)

Relay(s)

Wiring Harness

Electrical connector(s)

Blindspot Monitoring Modules

3. If an obvious cause for an observed or reported concern is found, correct the cause (if possible) before proceeding to

the next step.

4. If the cause is not visually evident, verify the symptom and refer to the Symptom Chart, alternatively, check for

Diagnostic Trouble Codes (DTCs) and refer to the DTC Index.

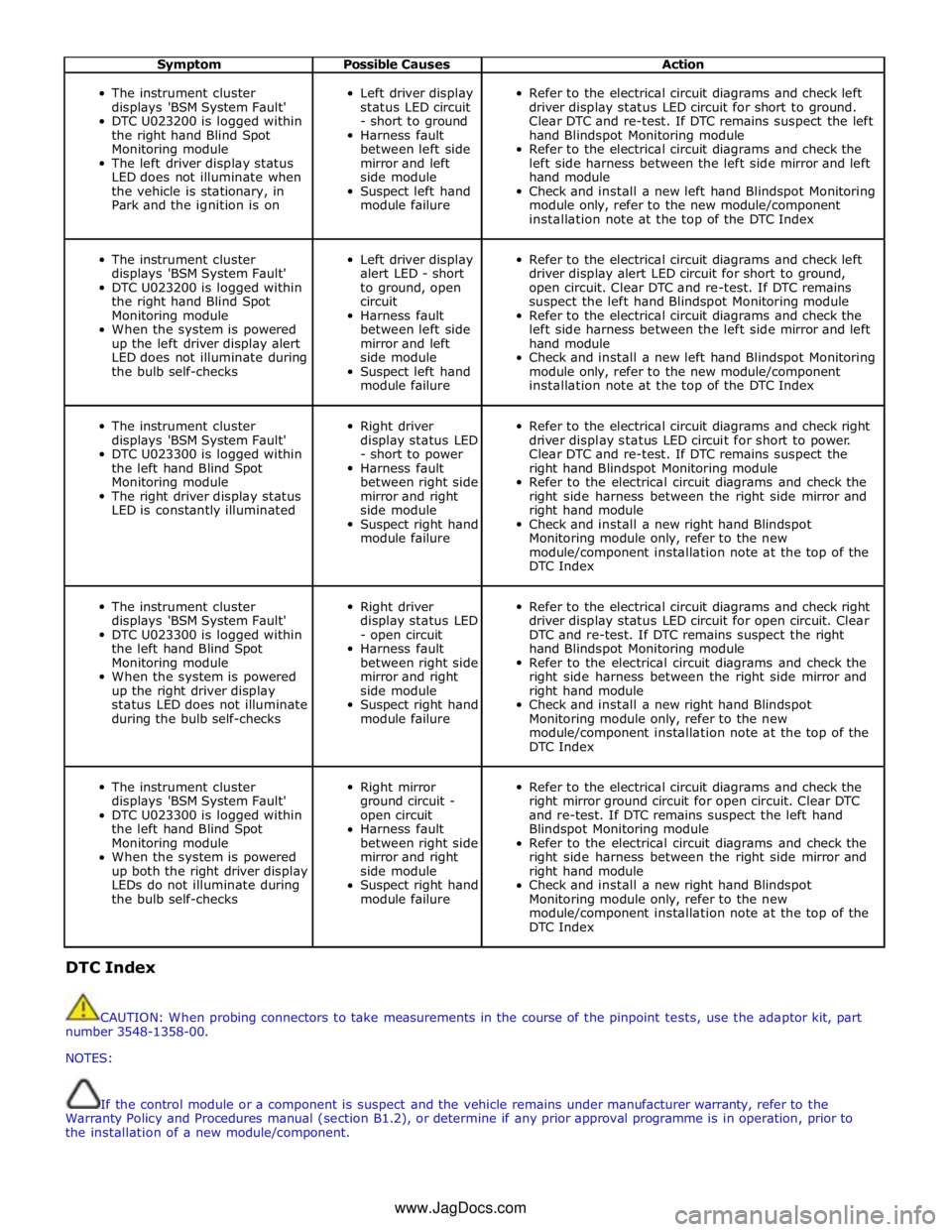

Symptom Chart

Symptom Possible Causes Action

The instrument cluster

displays 'BSM System Fault'

DTC B11C915 is logged within

the left hand Blind Spot

Monitoring module

The Left Alert icon is

constantly illuminated

Left driver display

alert LED circuit -

short to power Refer to the electrical circuit diagrams and check left driver

display alert LED circuit for short to power

The instrument cluster

displays 'BSM System Fault'

DTC B11C915 is logged within

the left hand Blind Spot

Monitoring module

No short to power or open

circuit fault on the driver

display status LED circuit

Left mirror ground

circuit - open

circuit Refer to the electrical circuit diagrams and check the left

mirror ground circuit for open circuit

The instrument cluster

displays 'BSM System Fault'

DTC B11C915 is logged within

the right hand Blind Spot

Monitoring module

No short to power or open

circuit fault on the driver

display status LED circuit

Right mirror

ground circuit -

open circuit Refer to the electrical circuit diagrams and check the right

mirror ground circuit for open circuit

Page 1837 of 3039

Symptom Possible Causes Action

The instrument cluster

displays 'BSM System Fault'

DTC U023200 is logged within

the right hand Blind Spot

Monitoring module

The left driver display status

LED does not illuminate when

the vehicle is stationary, in

Park and the ignition is on

Left driver display

status LED circuit

- short to ground

Harness fault

between left side

mirror and left

side module

Suspect left hand

module failure

Refer to the electrical circuit diagrams and check left

driver display status LED circuit for short to ground.

Clear DTC and re-test. If DTC remains suspect the left

hand Blindspot Monitoring module

Refer to the electrical circuit diagrams and check the

left side harness between the left side mirror and left

hand module

Check and install a new left hand Blindspot Monitoring

module only, refer to the new module/component

installation note at the top of the DTC Index

The instrument cluster

displays 'BSM System Fault'

DTC U023200 is logged within

the right hand Blind Spot

Monitoring module

When the system is powered

up the left driver display alert

LED does not illuminate during

the bulb self-checks

Left driver display

alert LED - short

to ground, open

circuit

Harness fault

between left side

mirror and left

side module

Suspect left hand

module failure

Refer to the electrical circuit diagrams and check left

driver display alert LED circuit for short to ground,

open circuit. Clear DTC and re-test. If DTC remains

suspect the left hand Blindspot Monitoring module

Refer to the electrical circuit diagrams and check the

left side harness between the left side mirror and left

hand module

Check and install a new left hand Blindspot Monitoring

module only, refer to the new module/component

installation note at the top of the DTC Index

The instrument cluster

displays 'BSM System Fault'

DTC U023300 is logged within

the left hand Blind Spot

Monitoring module

The right driver display status

LED is constantly illuminated

Right driver

display status LED

- short to power

Harness fault

between right side

mirror and right

side module

Suspect right hand

module failure

Refer to the electrical circuit diagrams and check right

driver display status LED circuit for short to power.

Clear DTC and re-test. If DTC remains suspect the

right hand Blindspot Monitoring module

Refer to the electrical circuit diagrams and check the

right side harness between the right side mirror and

right hand module

Check and install a new right hand Blindspot

Monitoring module only, refer to the new

module/component installation note at the top of the

DTC Index

The instrument cluster

displays 'BSM System Fault'

DTC U023300 is logged within

the left hand Blind Spot

Monitoring module

When the system is powered

up the right driver display

status LED does not illuminate

during the bulb self-checks

Right driver

display status LED

- open circuit

Harness fault

between right side

mirror and right

side module

Suspect right hand

module failure

Refer to the electrical circuit diagrams and check right

driver display status LED circuit for open circuit. Clear

DTC and re-test. If DTC remains suspect the right

hand Blindspot Monitoring module

Refer to the electrical circuit diagrams and check the

right side harness between the right side mirror and

right hand module

Check and install a new right hand Blindspot

Monitoring module only, refer to the new

module/component installation note at the top of the

DTC Index

The instrument cluster

displays 'BSM System Fault'

DTC U023300 is logged within

the left hand Blind Spot

Monitoring module

When the system is powered

up both the right driver display

LEDs do not illuminate during

the bulb self-checks

Right mirror

ground circuit -

open circuit

Harness fault

between right side

mirror and right

side module

Suspect right hand

module failure

Refer to the electrical circuit diagrams and check the

right mirror ground circuit for open circuit. Clear DTC

and re-test. If DTC remains suspect the left hand

Blindspot Monitoring module

Refer to the electrical circuit diagrams and check the

right side harness between the right side mirror and

right hand module

Check and install a new right hand Blindspot

Monitoring module only, refer to the new

module/component installation note at the top of the

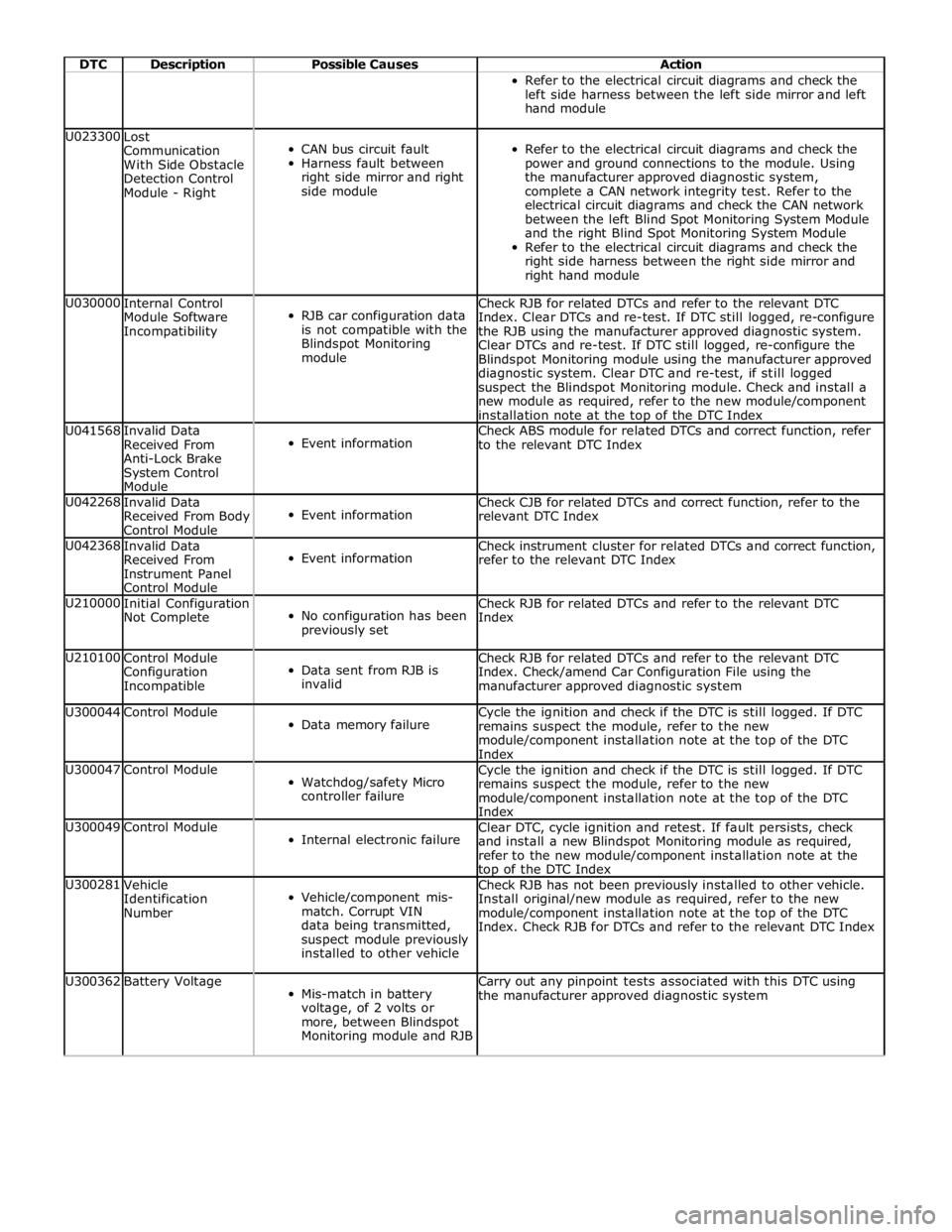

DTC Index DTC Index

CAUTION: When probing connectors to take measurements in the course of the pinpoint tests, use the adaptor kit, part

number 3548-1358-00.

NOTES:

If the control module or a component is suspect and the vehicle remains under manufacturer warranty, refer to the

Warranty Policy and Procedures manual (section B1.2), or determine if any prior approval programme is in operation, prior to

the installation of a new module/component.

www.JagDocs.com

Page 1838 of 3039

Generic scan tools may not read the codes listed, or may read only five digit codes. Match the five digits from the scan

tool to the first five digits of the seven digit code listed to identify the fault (the last two digits give additional information

read by the manufacturer approved diagnostic system).

When performing voltage or resistance tests, always use a digital multimeter (DMM) accurate to three decimal places,

and with an up-to-date calibration certificate. When testing resistance always take the resistance of the DMM leads into

account.

Check and rectify basic faults before beginning diagnostic routines involving pinpoint tests.

Inspect connectors for signs of water ingress, and pins for damage and/or corrosion.

If DTCs are recorded and, after performing the pinpoint tests, a fault is not present, an intermittent concern may be the

cause. Always check for loose connections and corroded terminals.

When carrying out repair/diagnosis of the system, on removal of the front or rear bumper inspect the sensor connectors

to ensure they were correctly latched and check fly leads for signs of chaffing or trapped wires.

Check DDW for open campaigns. Refer to the corresponding bulletins and SSMs which may be valid for the specific

customer complaint and carry out the recommendations as required

DTC Description Possible Causes Action B11C911

Driver Display

Status LED

Driver Display Status LED

circuit - short to ground Refer to the electrical circuit diagrams and check driver display

status LED circuit for short to ground B11C915

Driver Display

Status LED

Driver Display Status LED

circuit - short to power,

open circuit Refer to the electrical circuit diagrams and check driver display

status LED circuit for short to power, open circuit B11D611

Driver Display Alert

LED

Driver Display Alert LED

circuit - short to ground Refer to the electrical circuit diagrams and check driver display

alert LED circuit for short to ground B11D615

Driver Display Alert

LED

Driver Display Alert LED

circuit - short to power,

open circuit Refer to the electrical circuit diagrams and check driver display

alert LED circuit for short to power, open circuit U001000

Medium Speed CAN

Communication Bus

No sub type information Carry out any pinpoint tests associated with this DTC using

the manufacturer approved diagnostic system. Check MS CAN

bus state, carry out CAN network integrity tests using the

manufacturer approved diagnostic system U014000

Lost

Communication

With Body Control

Module

Lost communication with

CJB Carry out any pinpoint tests associated with this DTC using

the manufacturer approved diagnostic system. Check CJB for

related DTCs and correct function, refer to the relevant DTC

Index U014200

Lost

Communication

With Body Control

Module "B"

Lost communication with

RJB Carry out any pinpoint tests associated with this DTC using

the manufacturer approved diagnostic system. Check RJB for

related DTCs and correct function, refer to the relevant DTC

Index U014600

Lost

Communication

With Gateway "A"

Lost communication with

information and

entertainment module Carry out any pinpoint tests associated with this DTC using

the manufacturer approved diagnostic system. Check

information and entertainment module for related DTCs and

correct function, refer to the relevant DTC Index U015500

Lost

Communication

With Instrument

Panel Cluster (IPC)

Control Module

Lost communication with

instrument cluster Carry out any pinpoint tests associated with this DTC using

the manufacturer approved diagnostic system. Check

instrument cluster for related DTCs and correct function, refer

to the relevant DTC Index U023200

Lost

Communication

With Side Obstacle

Detection Control

Module - Left

CAN bus circuit fault

Harness fault between left

side mirror and left side

module

Refer to the electrical circuit diagrams and check the

power and ground connections to the module. Using

the manufacturer approved diagnostic system,

complete a CAN network integrity test. Refer to the

electrical circuit diagrams and check the CAN network

between the left Blind Spot Monitoring System Module

and the right Blind Spot Monitoring System Module

Page 1839 of 3039

DTC Description Possible Causes Action Refer to the electrical circuit diagrams and check the

left side harness between the left side mirror and left

hand module U023300

Lost

Communication

With Side Obstacle

Detection Control

Module - Right

CAN bus circuit fault

Harness fault between

right side mirror and right

side module

Refer to the electrical circuit diagrams and check the

power and ground connections to the module. Using

the manufacturer approved diagnostic system,

complete a CAN network integrity test. Refer to the

electrical circuit diagrams and check the CAN network

between the left Blind Spot Monitoring System Module

and the right Blind Spot Monitoring System Module

Refer to the electrical circuit diagrams and check the

right side harness between the right side mirror and

right hand module U030000

Internal Control

Module Software

Incompatibility

RJB car configuration data

is not compatible with the

Blindspot Monitoring

module Check RJB for related DTCs and refer to the relevant DTC

Index. Clear DTCs and re-test. If DTC still logged, re-configure

the RJB using the manufacturer approved diagnostic system.

Clear DTCs and re-test. If DTC still logged, re-configure the

Blindspot Monitoring module using the manufacturer approved

diagnostic system. Clear DTC and re-test, if still logged

suspect the Blindspot Monitoring module. Check and install a

new module as required, refer to the new module/component

installation note at the top of the DTC Index U041568

Invalid Data

Received From

Anti-Lock Brake

System Control

Module

Event information Check ABS module for related DTCs and correct function, refer

to the relevant DTC Index U042268

Invalid Data

Received From Body

Control Module

Event information Check CJB for related DTCs and correct function, refer to the

relevant DTC Index U042368

Invalid Data

Received From

Instrument Panel

Control Module

Event information Check instrument cluster for related DTCs and correct function,

refer to the relevant DTC Index U210000

Initial Configuration

Not Complete

No configuration has been

previously set Check RJB for related DTCs and refer to the relevant DTC

Index U210100

Control Module

Configuration

Incompatible

Data sent from RJB is

invalid Check RJB for related DTCs and refer to the relevant DTC

Index. Check/amend Car Configuration File using the

manufacturer approved diagnostic system U300044 Control Module

Data memory failure Cycle the ignition and check if the DTC is still logged. If DTC

remains suspect the module, refer to the new

module/component installation note at the top of the DTC

Index U300047 Control Module

Watchdog/safety Micro

controller failure Cycle the ignition and check if the DTC is still logged. If DTC

remains suspect the module, refer to the new

module/component installation note at the top of the DTC

Index U300049 Control Module

Internal electronic failure Clear DTC, cycle ignition and retest. If fault persists, check

and install a new Blindspot Monitoring module as required,

refer to the new module/component installation note at the top of the DTC Index U300281

Vehicle

Identification

Number

Vehicle/component mis-

match. Corrupt VIN

data being transmitted,

suspect module previously

installed to other vehicle Check RJB has not been previously installed to other vehicle.

Install original/new module as required, refer to the new

module/component installation note at the top of the DTC

Index. Check RJB for DTCs and refer to the relevant DTC Index U300362 Battery Voltage

Mis-match in battery

voltage, of 2 volts or

more, between Blindspot

Monitoring module and RJB Carry out any pinpoint tests associated with this DTC using

the manufacturer approved diagnostic system

Page 1844 of 3039

9 RH inner rear sensor 10 LH (left-hand) inner rear sensor 11 LH outer rear sensor 12 LH outer front sensor 13 LH inner front sensor 14 RH inner front sensor 15 RH outer front sensor 16 Parking aid module 17 Parking aid switch CONTROL DIAGRAM - PARKING AID CAMERA

A = Hardwired; N = Medium speed CAN bus; O = LIN bus; P = MOST ring; T = Co-axial cable

Item Description 1 Battery

Page 1855 of 3039

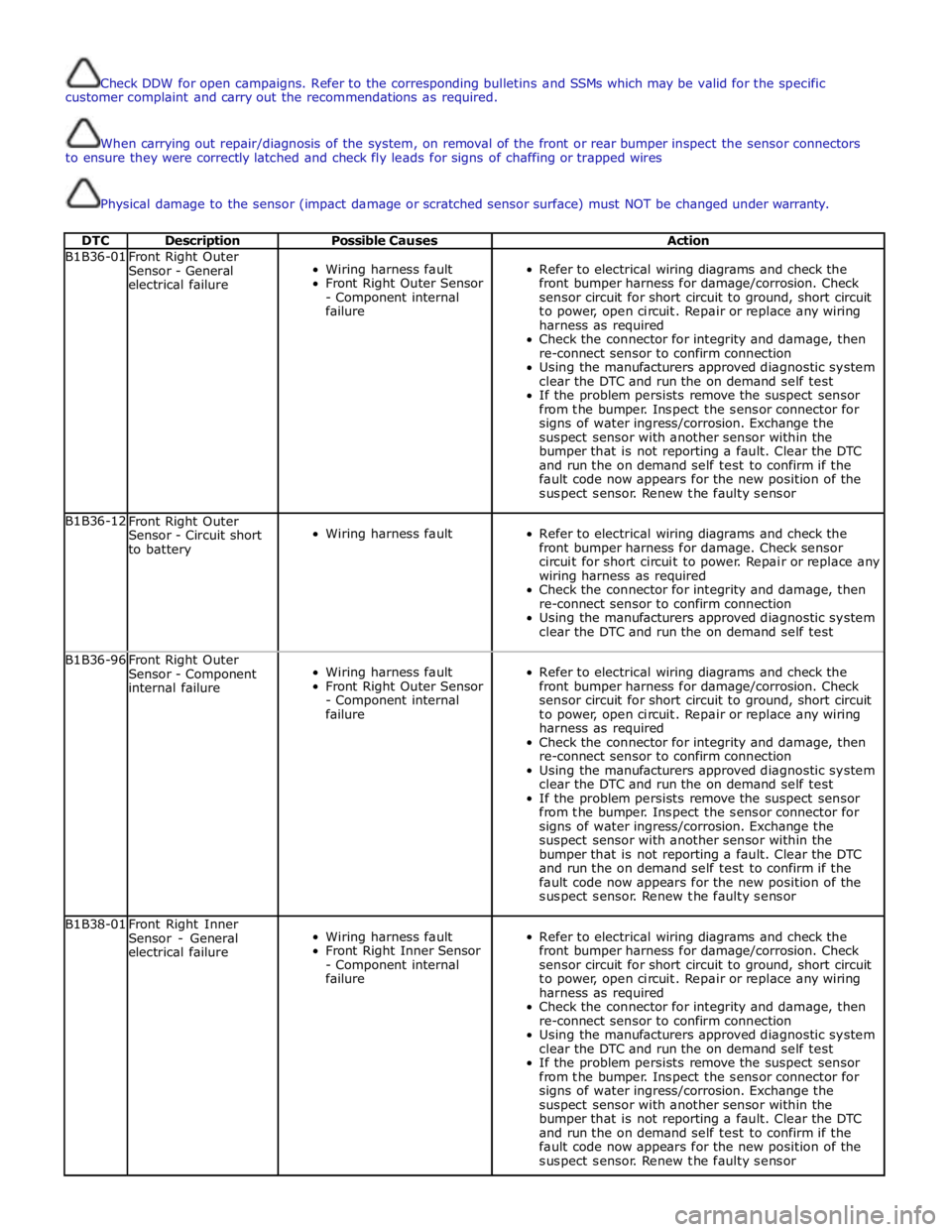

Check DDW for open campaigns. Refer to the corresponding bulletins and SSMs which may be valid for the specific

customer complaint and carry out the recommendations as required.

When carrying out repair/diagnosis of the system, on removal of the front or rear bumper inspect the sensor connectors

to ensure they were correctly latched and check fly leads for signs of chaffing or trapped wires

Physical damage to the sensor (impact damage or scratched sensor surface) must NOT be changed under warranty.

DTC Description Possible Causes Action B1B36-01

Front Right Outer

Sensor - General

electrical failure

Wiring harness fault

Front Right Outer Sensor

- Component internal

failure

Refer to electrical wiring diagrams and check the

front bumper harness for damage/corrosion. Check

sensor circuit for short circuit to ground, short circuit

to power, open circuit. Repair or replace any wiring

harness as required

Check the connector for integrity and damage, then

re-connect sensor to confirm connection

Using the manufacturers approved diagnostic system

clear the DTC and run the on demand self test

If the problem persists remove the suspect sensor

from the bumper. Inspect the sensor connector for

signs of water ingress/corrosion. Exchange the

suspect sensor with another sensor within the

bumper that is not reporting a fault. Clear the DTC

and run the on demand self test to confirm if the

fault code now appears for the new position of the

suspect sensor. Renew the faulty sensor B1B36-12

Front Right Outer

Sensor - Circuit short

to battery

Wiring harness fault

Refer to electrical wiring diagrams and check the

front bumper harness for damage. Check sensor

circuit for short circuit to power. Repair or replace any

wiring harness as required

Check the connector for integrity and damage, then

re-connect sensor to confirm connection

Using the manufacturers approved diagnostic system

clear the DTC and run the on demand self test B1B36-96

Front Right Outer

Sensor - Component

internal failure

Wiring harness fault

Front Right Outer Sensor

- Component internal

failure

Refer to electrical wiring diagrams and check the

front bumper harness for damage/corrosion. Check

sensor circuit for short circuit to ground, short circuit

to power, open circuit. Repair or replace any wiring

harness as required

Check the connector for integrity and damage, then

re-connect sensor to confirm connection

Using the manufacturers approved diagnostic system

clear the DTC and run the on demand self test

If the problem persists remove the suspect sensor

from the bumper. Inspect the sensor connector for

signs of water ingress/corrosion. Exchange the

suspect sensor with another sensor within the

bumper that is not reporting a fault. Clear the DTC

and run the on demand self test to confirm if the

fault code now appears for the new position of the

suspect sensor. Renew the faulty sensor B1B38-01

Front Right Inner

Sensor - General

electrical failure

Wiring harness fault

Front Right Inner Sensor

- Component internal

failure

Refer to electrical wiring diagrams and check the

front bumper harness for damage/corrosion. Check

sensor circuit for short circuit to ground, short circuit

to power, open circuit. Repair or replace any wiring

harness as required

Check the connector for integrity and damage, then

re-connect sensor to confirm connection

Using the manufacturers approved diagnostic system

clear the DTC and run the on demand self test

If the problem persists remove the suspect sensor

from the bumper. Inspect the sensor connector for

signs of water ingress/corrosion. Exchange the

suspect sensor with another sensor within the

bumper that is not reporting a fault. Clear the DTC

and run the on demand self test to confirm if the

fault code now appears for the new position of the

suspect sensor. Renew the faulty sensor