diagram JAGUAR XFR 2010 1.G Workshop Manual

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 2010, Model line: XFR, Model: JAGUAR XFR 2010 1.GPages: 3039, PDF Size: 58.49 MB

Page 1962 of 3039

11

12

1

2

3

4

5

6

7

8

9

10

11

12

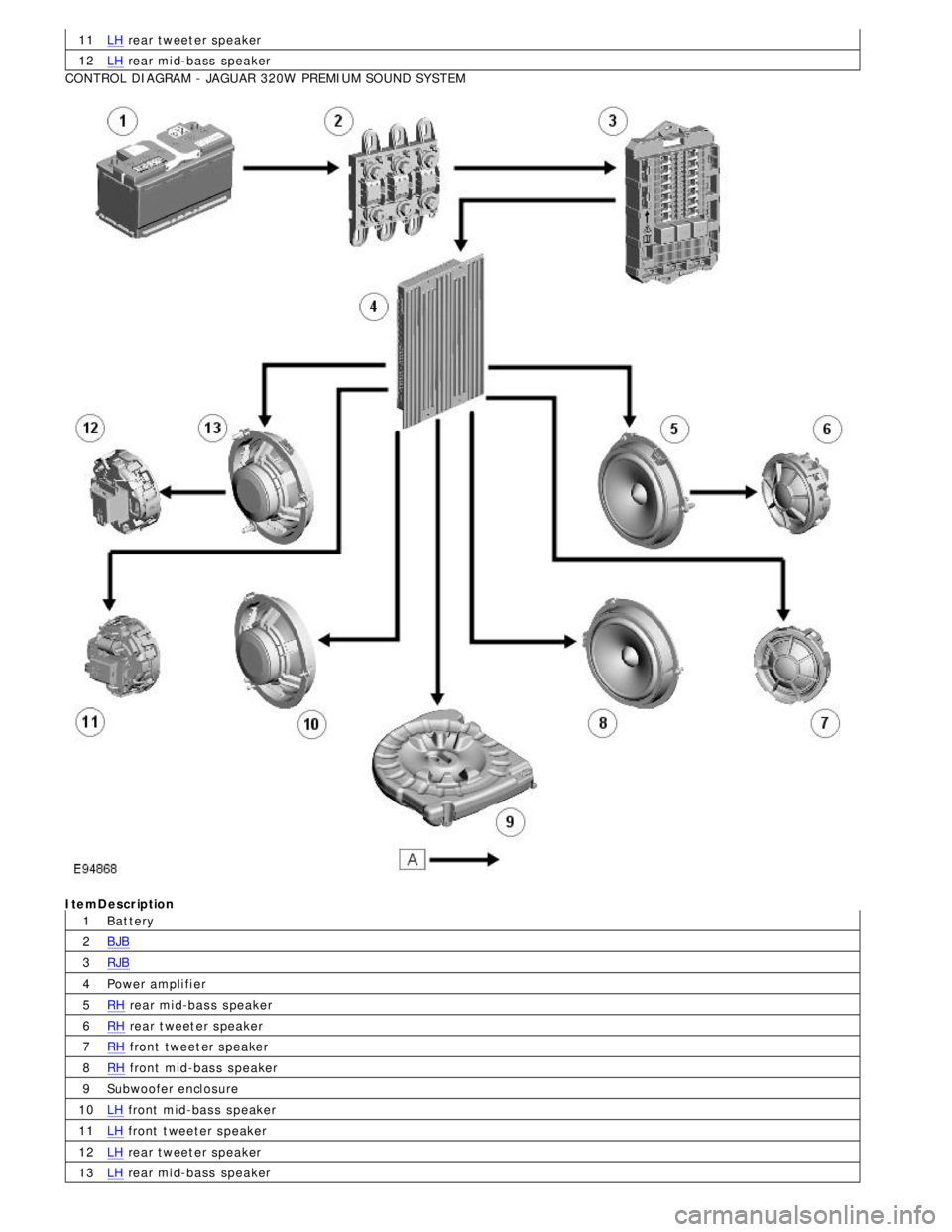

13LH rear tweet er speakerLH rear mi d-bass speaker

CONTROL DIAGRAM - JAGUAR 320W PREMIUM SOUND SY STEMItemDescription

Bat teryBJBRJB

Power ampli fi erRH rear mi d-bas s s peakerRH rear t weet er s peakerRH front tweet er s peakerRH front mid-bas s s peaker

Subwoofer encl osureLH front mid-bas s s peakerLH front t weeter s peakerLH rear tweet er speakerLH rear mi d-bass speaker

Page 1963 of 3039

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

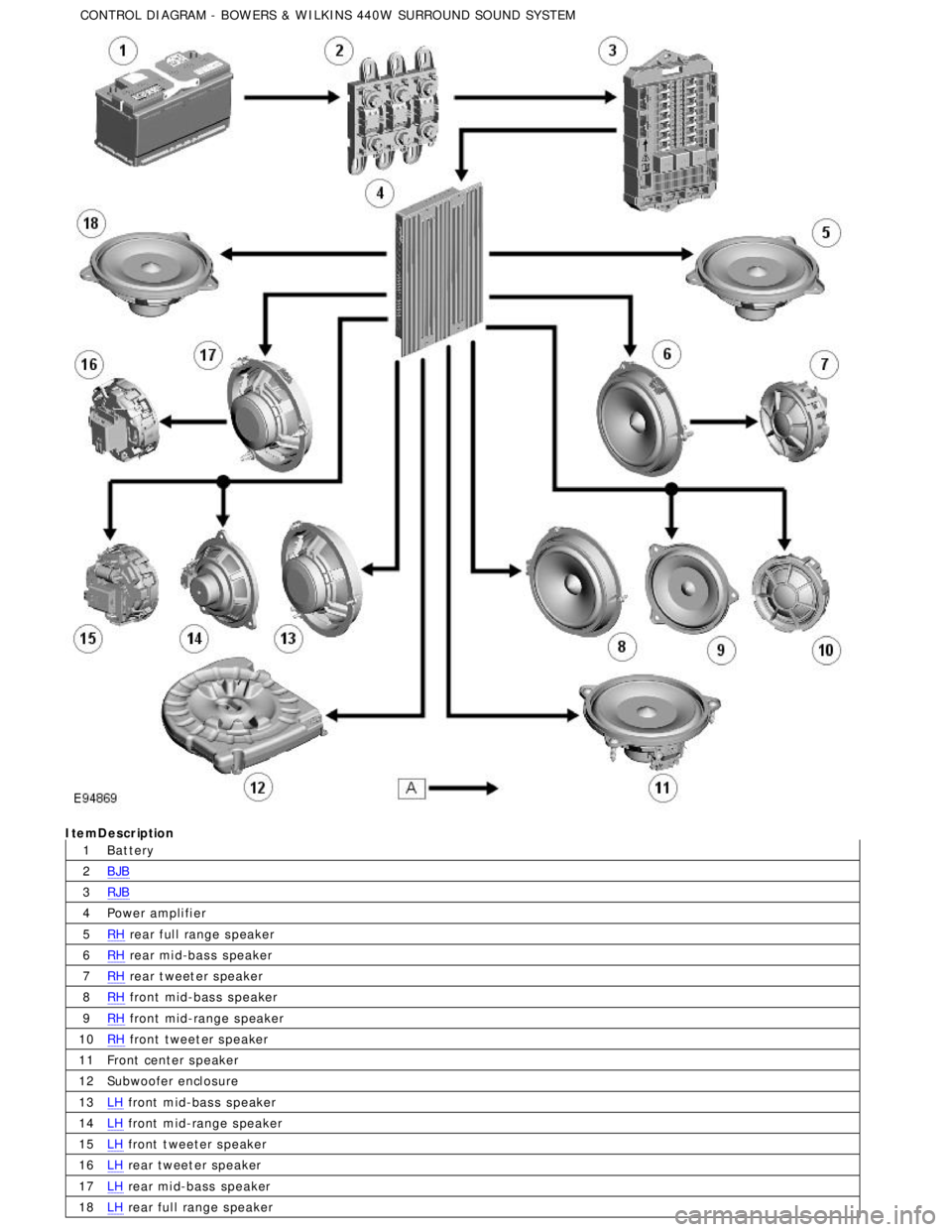

18ItemDescription

Bat teryBJBRJB

Power ampli fi erRH rear ful l range s peakerRH rear mi d-bas s s peakerRH rear t weet er s peakerRH front mid-bas s s peakerRH front mid-range s peakerRH front tweet er s peaker

Front center s peaker

Subwoofer encl osureLH front mid-bas s s peakerLH front mid-range s peakerLH front t weeter s peakerLH rear tweet er speakerLH rear mi d-bass speakerLH rear ful l range s peaker CONTROL DIAGRAM - BOW ERS & W ILKINS 440W SURROUND SOUND SY STEM

Page 1967 of 3039

1

2

3

4

5

6

7

8

9

10

11Publi s hed: 11-May-2011

Information and Entertainment System - Cellular Phone - System Operation

and Component Description

Des cript ion and Operat ion

Control Diagram

• NOTE: A = Hardwi red; N = Medium Speed CAN (controller area net work) bus ; O = LIN bus ; P = MOST ringItemDescription

Touch-s creen

Power ampli fi er

Speakers

IAM (i nt egrat ed audi o module)

Microphone

Tel ephone cont rol module

Cl ock spring

St eering wheel cont rol s

ICM (i nformat ion control modul e)

Ins trument cl us t er

Navigat ion computer

Page 1974 of 3039

Published: 11-May-2011

Information and Entertainment System - Navigation System - System

Operation and Component Description

Description and Operation

Control Diagram

NOTE: A = Hardwired; D = High Speed CAN bus; N = Medium Speed CAN bus; O = LIN bus; P = MOST ring; Q = GVIF; T

= CoAxial

Item Description 1 ABS (anti-lock brake system) module 2 Steering wheel remote audio controls 3 Touch-screen 4 Power amplifier 5 Speakers

Page 1985 of 3039

1

2

3

4

5

6

7

8

9

10Publi s hed: 11-May-2011

Information and Entertainment System - Video System - System Operation

and Component Description

Des cript ion and Operat ion

Control Diagram

• NOTE: A = Hardwi red; N = Medium Speed CAN (controller area net work) bus ; O = LIN bus ; P = MOST ring; T = CoAxial; I

= Compos it e video s i gnalItemDescription

Triple TV (televis i on) ant enna modul e

TV (t elevis ion) t uner

Touch-s creen

Microphone

IAM (i nt egrat ed audi o module)

Speakers

Power ampli fi er

Cl ock spring

St eering wheel remote controls

ICM (i nformat ion control modul e)11

12ICP (int egrated control panel)

Si ngl e TV (t el evi s ion) ant enna module

www.JagDocs.com

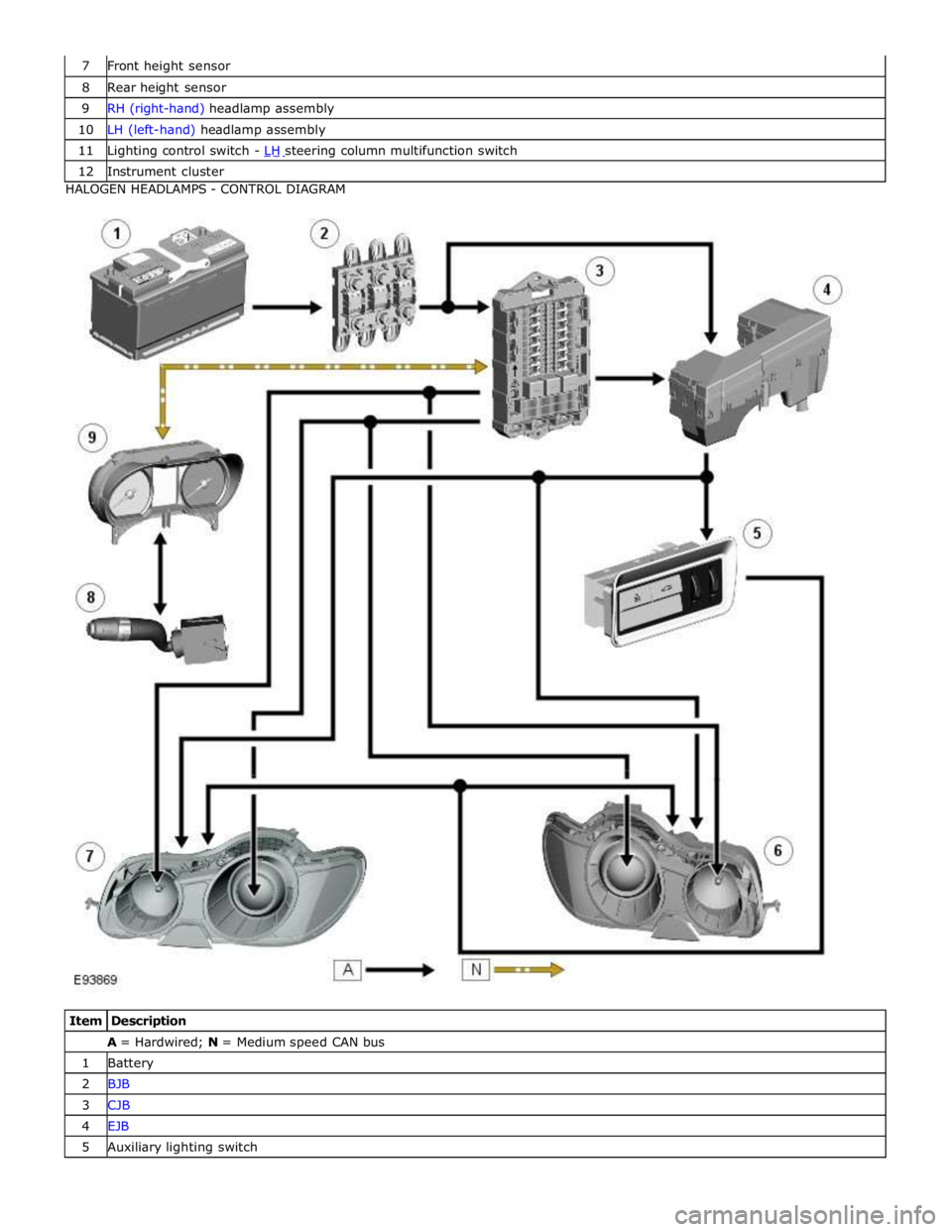

Page 2024 of 3039

8 Rear height sensor 9 RH (right-hand) headlamp assembly 10 LH (left-hand) headlamp assembly 11 Lighting control switch - LH steering column multifunction switch 12 Instrument cluster HALOGEN HEADLAMPS - CONTROL DIAGRAM

Item Description A = Hardwired; N = Medium speed CAN bus 1 Battery 2 BJB 3 CJB 4 EJB 5 Auxiliary lighting switch

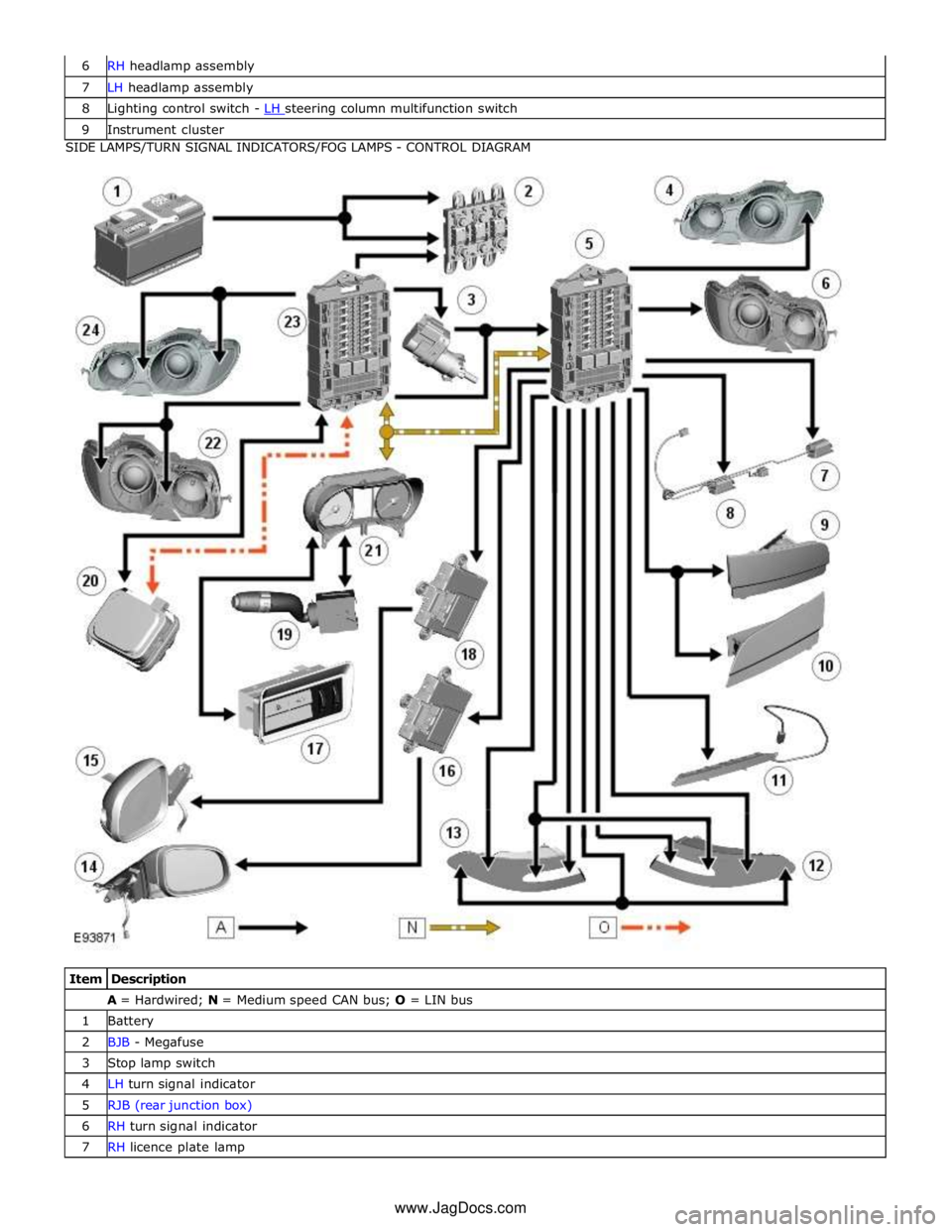

Page 2025 of 3039

7 LH headlamp assembly 8 Lighting control switch - LH steering column multifunction switch 9 Instrument cluster SIDE LAMPS/TURN SIGNAL INDICATORS/FOG LAMPS - CONTROL DIAGRAM

Item Description A = Hardwired; N = Medium speed CAN bus; O = LIN bus 1 Battery 2 BJB - Megafuse 3 Stop lamp switch 4 LH turn signal indicator 5 RJB (rear junction box) 6 RH turn signal indicator 7 RH licence plate lamp www.JagDocs.com

Page 2057 of 3039

8 Passenger door module 9 LH (left-hand) rear door latch 10 RH (right-hand) rear door latch 11 LH front door latch 12 RH front door latch 13 CJB (central junction box) 14 LH front door handle LED (light emitting diode) illumination 15 RH front door handle LED illumination CONTROL DIAGRAM (SHEET 2 OF 2)

Item Description A = Hardwired 1 Battery 2 BJB - Megafuse

Page 2063 of 3039

Interior Lighting - Interior Lighting

Diagnosis and Testing

Principles of Operation Published: 11-May-2011

For a detailed description of the interior lighting system, refer to the relevant Description and Operation sections in the

workshop manual. REFER to: (417-02 Interior Lighting)

Interior Lighting (Description and Operation), Interior Lighting (Description and Operation), Interior Lighting (Description and Operation).

Inspection and Verification

CAUTION: Diagnosis by substitution from a donor vehicle is NOT acceptable. Substitution of control modules does not

guarantee confirmation of a fault, and may also cause additional faults in the vehicle being tested and/or the donor vehicle.

1. Verify the customer concern.

2. Visually inspect for obvious signs of damage and system integrity.

Visual Inspection

Mechanical Electrical

Bulbs

Fuses/relays (refer to electrical guide)

Wiring harness

Correct engagement of electrical connectors

Loose or corroded connections

3. If an obvious cause for an observed or reported concern is found, correct the cause (if possible) before proceeding to

the next step.

4. If the cause is not visually evident, check for Diagnostic Trouble Codes (DTCs) and refer to the DTC Index.

DTC Index

CAUTION: When probing connectors to take measurements in the course of the pinpoint tests, use the adaptor kit, part

number 3548-1358-00

NOTES:

If the control module or a component is suspect and the vehicle remains under manufacturer warranty, refer to the

Warranty Policy and Procedures manual (section B1.2), or determine if any prior approval programme is in operation, prior to

the installation of a new module/component.

Generic scan tools may not read the codes listed, or may read only five digit codes. Match the five digits from the scan

tool to the first five digits of the seven digit code listed to identify the fault (the last two digits give extra information read by

the manufacturer-approved diagnostic system).

When performing voltage or resistance tests, always use a digital multimeter (DMM) accurate to three decimal places and

with a current calibration certificate. When testing resistance, always take the resistance of the DMM leads into account.

Check and rectify basic faults before beginning diagnostic routines involving pinpoint tests.

If DTCs are recorded and, after performing the pinpoint tests, a fault is not present, an intermittent concern may be the

cause. Always check for loose connections and corroded terminals.

DTC Description Possible Cause Action B116511

Left Front

Puddle Lamp

Output

Left front puddle lamp

control circuit - short to

ground Refer to the electrical circuit diagrams and test left front puddle

lamp control circuit for short to ground

Page 2064 of 3039

DTC Description Possible Cause Action B116515

Left Front

Puddle Lamp

Output

Left front puddle lamp

control circuit - short to

power, open circuit Carry out any pinpoint tests associated with this DTC using the

manufacturer approved diagnostic system. Refer to the electrical

circuit diagrams and test left front puddle lamp control circuit

for short to power, open circuit B116611

Right Front

Puddle Lamp

Output

Right front puddle lamp

control circuit - short to

ground Refer to the electrical circuit diagrams and test right front

puddle lamp control circuit for short to ground B116615

Right Front

Puddle Lamp

Output

Right front puddle lamp

control circuit - short to

power, open circuit Carry out any pinpoint tests associated with this DTC using the

manufacturer approved diagnostic system. Refer to the electrical

circuit diagrams and test right front puddle lamp control circuit

for short to power, open circuit B111E11

Boot/Trunk

Lamps

Luggage compartment lamp

control circuit - short to

ground Carry out any pinpoint test associated with this DTC using the

manufacturer approved diagnostic system. Refer to the electrical

circuit diagrams and check luggage compartment lamp control

circuit for short to ground B111E15

Boot/Trunk

Lamps

Luggage compartment lamp

control circuit - short to

power, open circuit Carry out any pinpoint test associated with this DTC using the

manufacturer approved diagnostic system. Refer to the electrical

circuit diagrams and check luggage compartment lamp control

circuit for short to power, open circuit B112412

Lamp Fade

Control

Interior lamp fade control

circuit - short to power Refer to the electrical circuit diagrams and check interior lamp

fade control circuit for short to power B113C12

Hazard Switch

Illumination

Hazard switch illumination

control circuit - short to

power Refer to the electrical circuit diagrams and check hazard switch

illumination control circuit for short to power B1A8596

Ambient Light

Sensor

Light sensor internal

electronic failure Check and install a new sensor as required U201012

Switch

Illumination

Switch/interior illumination

PWM supply circuit - short to

power Refer to the electrical circuit diagrams and check switch/interior

illumination PWM supply circuit for short to power U201014

Switch

Illumination

Switch/interior illumination

PWM supply circuit - short to

ground, open circuit Refer to the electrical circuit diagrams and check switch/interior

illumination PWM supply circuit for short to ground, open circuit