Exhaust JAGUAR XFR 2010 1.G Owner's Manual

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 2010, Model line: XFR, Model: JAGUAR XFR 2010 1.GPages: 3039, PDF Size: 58.49 MB

Page 303 of 3039

PINPOINT TEST B : TIP-IN MOAN TEST

CONDITIONS DETAILS/RESULTS/ACTIONS B1: CHECK THE AIR CLEANER 1 Check the air cleaner.

Check the air cleaner, inlet tube, outlet tube, resonators and all other components associated with

the air induction system for correct installation and tightness of all connections. Are the components OK? Yes

GO to B2. No

Correct the condition. Repeat the Road Test as outlined. B2: CHECK THE EXHAUST SYSTEM 1 Carry out the exhaust system neutralizing procedure in this section. Is the exhaust system OK? Yes

GO to B3. No

Repair as necessary. Restore vehicle. Repeat the Road Test as outlined. B3: CHECK THE POWER STEERING 1 Remove the auxiliary drive belt and test for tip-in moan. Is the tip-in moan OK? Yes

Repair the power steering as necessary. For additional information, refer to Section 211-00.

No

Check and install new engine/transmission mounts as necessary. Repeat Road Test as outlined.

PINPOINT TEST C : IDLE BOOM/SHAKE/VIBRATION/SHUDDER TEST

CONDITIONS DETAILS/RESULTS/ACTIONS C1: CHECK CABLE/HOSES 1 Check the engine compartment for any component that may be grounding between the engine and body or chassis. Example: air conditioning (A/C) hoses. Are the components OK? Yes

GO to C2. No

Correct the condition. Repeat the Road Test as outlined. C2: CHECK THE COOLING RADIATOR 1 Check the engine cooling radiator mountings and bushings for security and condition. Check the radiator installation for any component that may have a touch condition. Are the installation and bushings OK? Yes

GO to C3. No

Correct the condition. Repeat the Road Test as outlined. C3: CHECK THE EXHAUST SYSTEM 1 Carry out the exhaust system neutralizing procedure in this section. Is the exhaust system OK? Yes

Check and install new engine/transmission mounts as necessary. Repeat Road Test as outlined.

No

Repair as necessary. Repeat Road Test.

PINPOINT TEST D : WHEEL END VIBRATION ANALYSIS TEST CONDITIONS DETAILS/RESULTS/ACTIONS D1: INSPECT THE TIRES 1 Inspect the tires.

Raise and support the vehicle. REFER to: (100-02 Jacking and Lifting)

Jacking (Description and Operation), Lifting (Description and Operation).

Inspect the tires for:

Correct tire size

Tire/wheel compatibility

Wear or damage

Page 305 of 3039

Noise, Vibration and Harshness - Exhaust System Neutralizing

General Procedures Published: 11-May-2011

1. Loosen the muffler inlet pipe and resonator pipe to exhaust manifold

fasteners at the flanges and the muffler inlet connection.

2. Place a stand to support the muffler parallel to the vehicle frame with

the muffler pipe bracket free of stress.

3. Tighten the muffler connection.

4. Position the exhaust pipes to the manifolds and tighten. Make sure that

the catalytic converter and heat shield do not contact the frame rails.

5. With the complete exhaust system tight (and cooled) the rear hanger

insulator should be angled forward, to allow the system to expand

rearward when heated during normal running

Page 412 of 3039

Rear Suspension - Rear Stabilizer Bar

Removal and Installation Published: 06-Jun-2013

Removal

1. Disconnect the battery ground cable.

For additional information, refer to: Battery Disconnect and Connect (414-01 Battery, Mounting and Cables, General Procedures).

2. WARNING: Make sure to support the vehicle with axle stands.

Raise and support the vehicle.

3. Remove both rear wheels and tires.

For additional information, refer to: Wheel and Tire (204-04 Wheels and Tires, Removal and Installation).

4. Drain the fuel tank.

For additional information, refer to: Fuel Tank Draining (310-00 Fuel System - General Information, General Procedures).

5. Remove the exhaust system.

For additional information, refer to: Front Muffler (309-00B Exhaust System - V6 3.0L Petrol, Removal and Installation).

6. CAUTION: Always plug any open connections to

prevent contamination.

NOTES:

To prevent the loss of brake fluid, using the special

tool apply the brake pedal and set to 40mm ( 1.6 in ) below

the rest position.

RH illustration shown, LH is similar.

Disconnect the brake hose from the brake caliper.

Using the special tool, press and hold the brake

pedal.

Remove and discard the two sealing washers. Powertrain Assembly Jack, HTJ

1200-2 Special Tool(s)

Page 494 of 3039

Published: 11-May-2011

Ride and Handling Optimization - Ride and Handling Optimization - Overview

Description and Operation

OVERVIEW

JaguarDrive Control is a selectable vehicle optimisation system, designed to fine-tune the driving characteristics of the vehicle

by accommodating different driving conditions or driving styles. The system allows the performance envelope of the vehicle to

be stretched and prevents the necessity for a single, compromised configuration for all conditions. JaguarDrive Control

increases the vehicle's abilities by changing the characteristics of engine mapping, transmission shifts and stability and

traction interventions. The software for the JaguarDrive control is incorporated in the JaguarDrive selector module.

NOTE: The JaguarDrive Control system is a co-ordinating system only. It CANNOT generate a fault in one of the

participating sub-systems. All participating subsystems should be FULLY diagnosed before assuming a fault with JaguarDrive

Control. Replacing the JaguarDrive selector module should not be done until all other options have been exhausted.

www.JagDocs.com

Page 497 of 3039

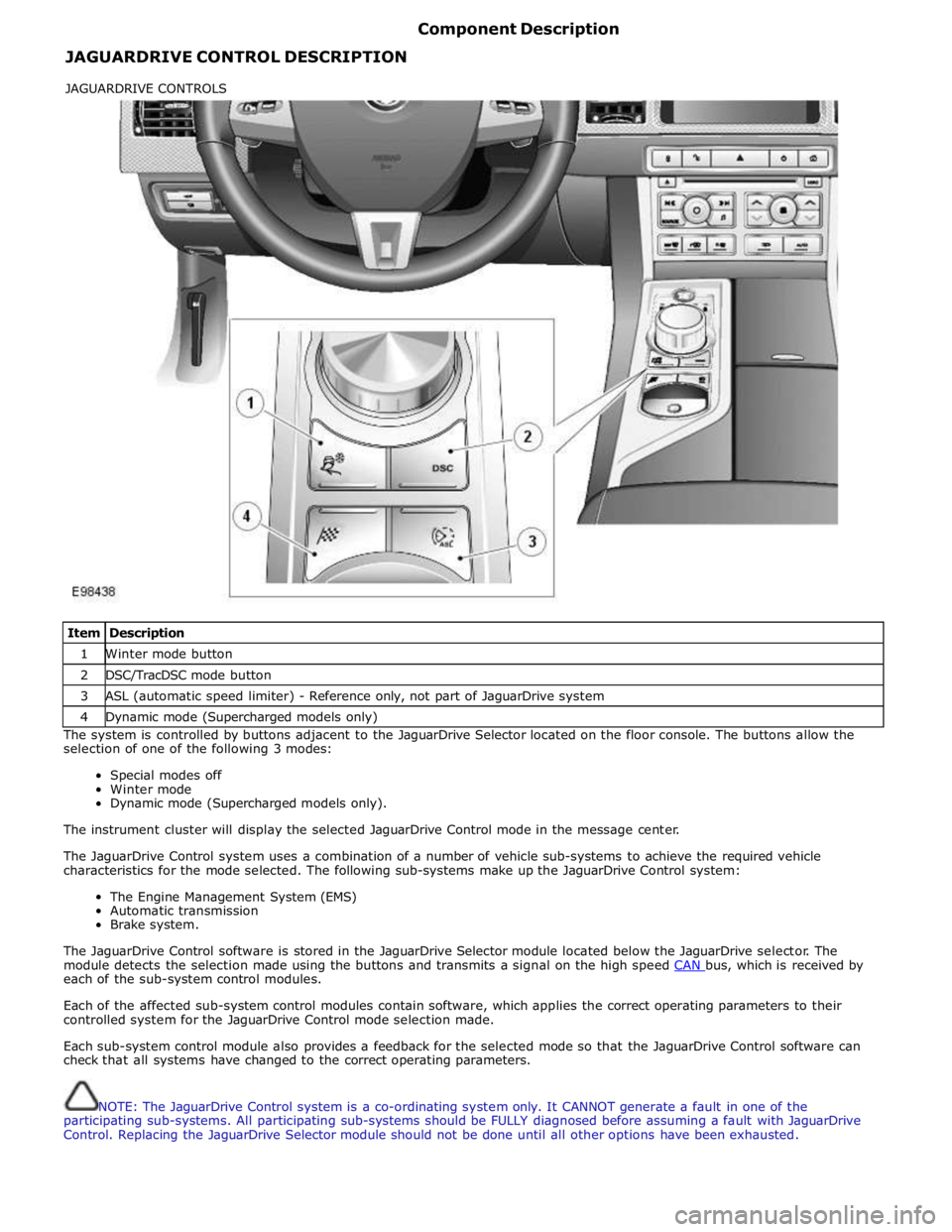

JAGUARDRIVE CONTROL DESCRIPTION Component Description

Item Description 1 Winter mode button 2 DSC/TracDSC mode button 3 ASL (automatic speed limiter) - Reference only, not part of JaguarDrive system 4 Dynamic mode (Supercharged models only) The system is controlled by buttons adjacent to the JaguarDrive Selector located on the floor console. The buttons allow the

selection of one of the following 3 modes:

Special modes off

Winter mode

Dynamic mode (Supercharged models only).

The instrument cluster will display the selected JaguarDrive Control mode in the message center.

The JaguarDrive Control system uses a combination of a number of vehicle sub-systems to achieve the required vehicle

characteristics for the mode selected. The following sub-systems make up the JaguarDrive Control system:

The Engine Management System (EMS)

Automatic transmission

Brake system.

The JaguarDrive Control software is stored in the JaguarDrive Selector module located below the JaguarDrive selector. The

module detects the selection made using the buttons and transmits a signal on the high speed CAN bus, which is received by each of the sub-system control modules.

Each of the affected sub-system control modules contain software, which applies the correct operating parameters to their

controlled system for the JaguarDrive Control mode selection made.

Each sub-system control module also provides a feedback for the selected mode so that the JaguarDrive Control software can

check that all systems have changed to the correct operating parameters.

NOTE: The JaguarDrive Control system is a co-ordinating system only. It CANNOT generate a fault in one of the

participating sub-systems. All participating sub-systems should be FULLY diagnosed before assuming a fault with JaguarDrive

Control. Replacing the JaguarDrive Selector module should not be done until all other options have been exhausted. JAGUARDRIVE CONTROLS

Page 505 of 3039

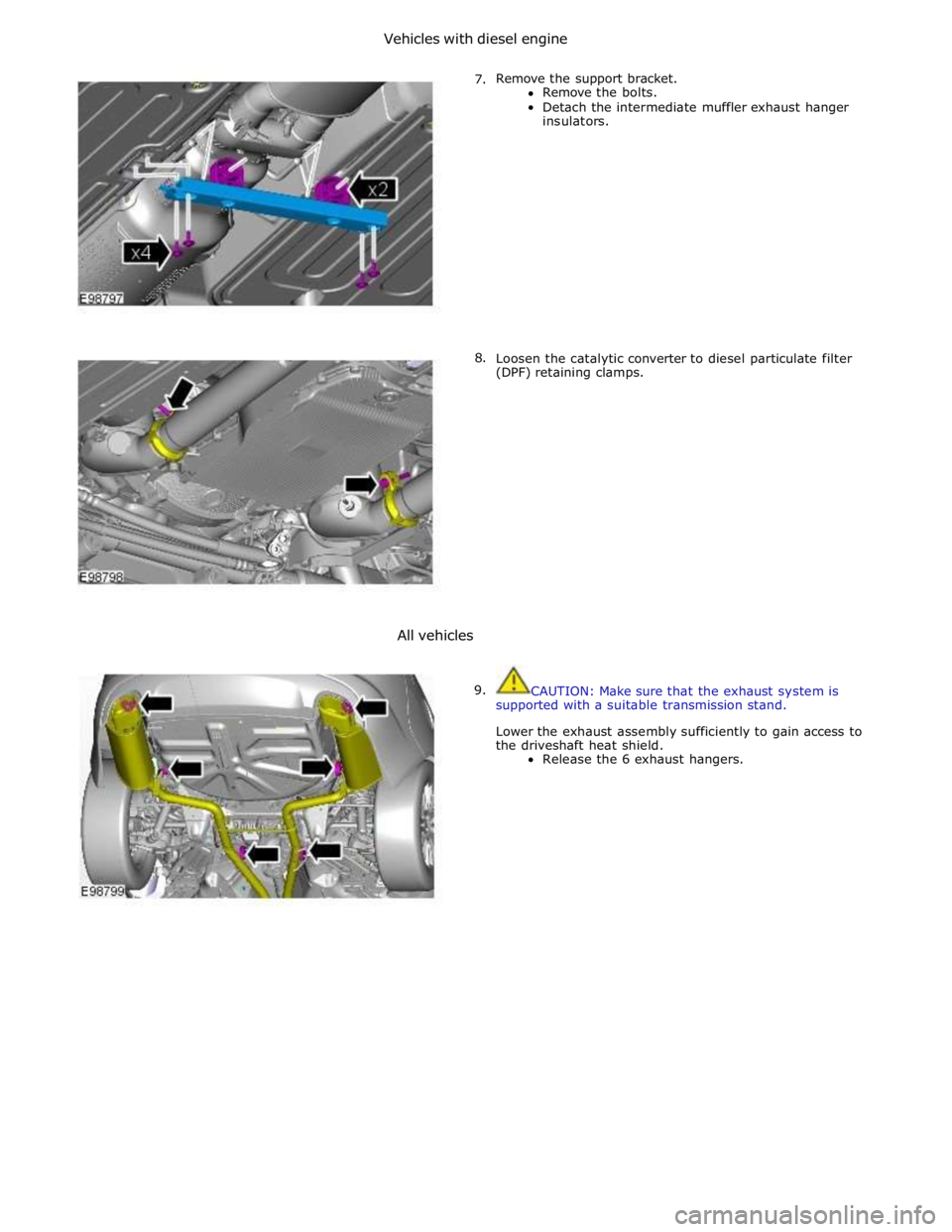

Vehicles with diesel engine

7.

8.

All vehicles

9.

Remove the support bracket.

Remove the bolts.

Detach the intermediate muffler exhaust hanger

insulators.

Loosen the catalytic converter to diesel particulate filter

(DPF) retaining clamps.

CAUTION: Make sure that the exhaust system is

supported with a suitable transmission stand.

Lower the exhaust assembly sufficiently to gain access to

the driveshaft heat shield.

Release the 6 exhaust hangers.

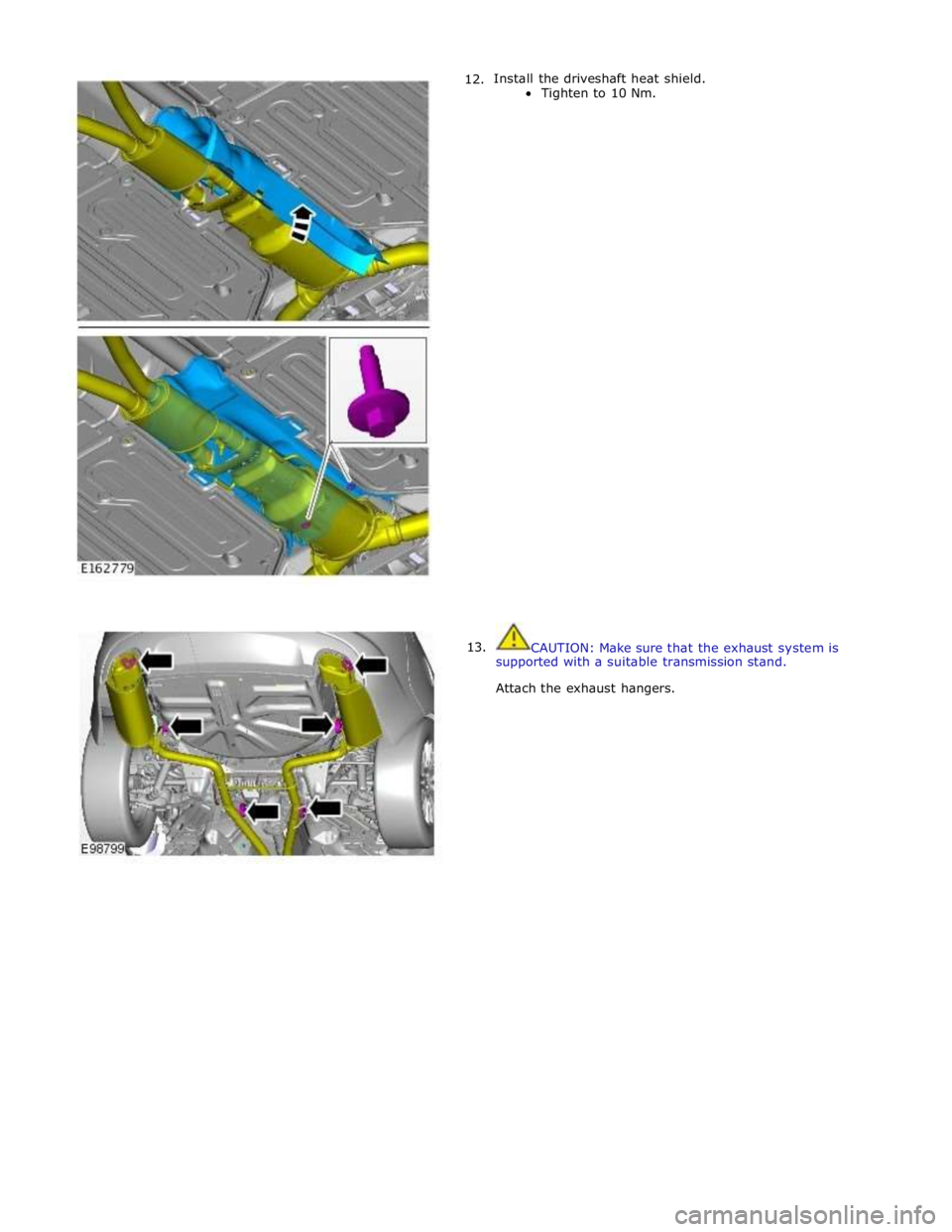

Page 507 of 3039

12.

13. Install the driveshaft heat shield.

Tighten to 10 Nm.

CAUTION: Make sure that the exhaust system is

supported with a suitable transmission stand.

Attach the exhaust hangers.

Page 508 of 3039

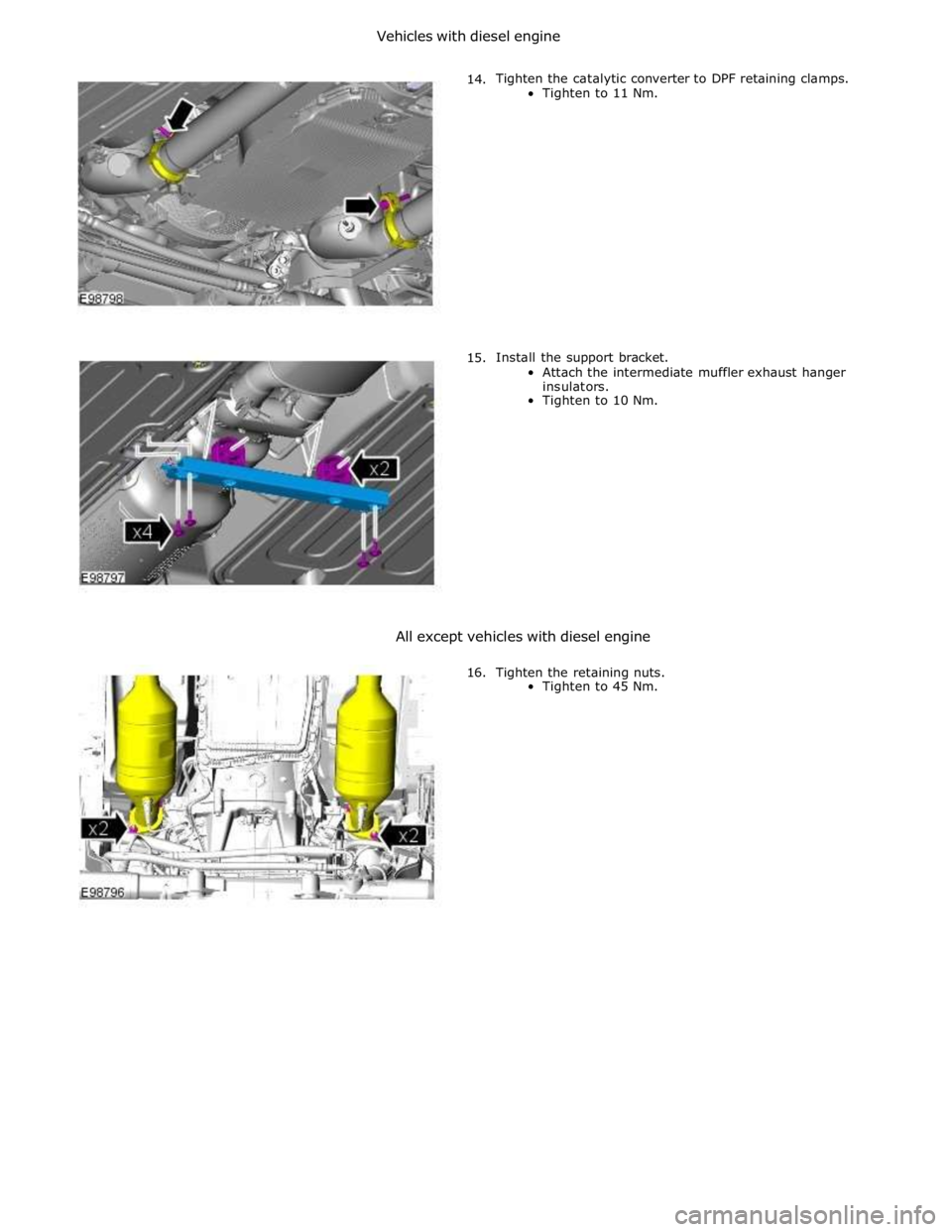

Vehicles with diesel engine

14.

15. Tighten the catalytic converter to DPF retaining clamps.

Tighten to 11 Nm.

Install the support bracket.

Attach the intermediate muffler exhaust hanger

insulators.

Tighten to 10 Nm.

All except vehicles with diesel engine

16. Tighten the retaining nuts.

Tighten to 45 Nm.

Page 520 of 3039

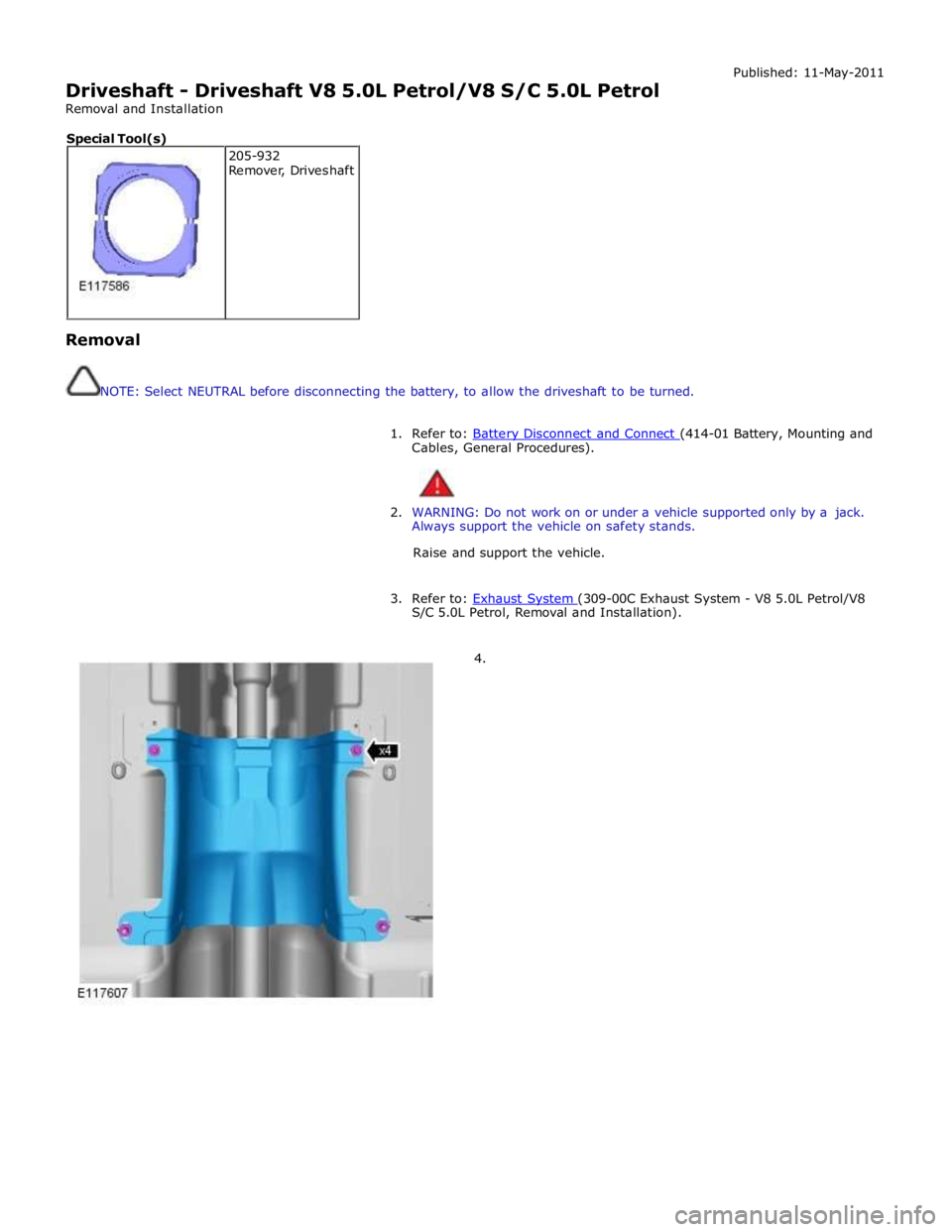

Driveshaft - Driveshaft V8 5.0L Petrol/V8 S/C 5.0L Petrol

Removal and Installation Published: 11-May-2011

Removal

NOTE: Select NEUTRAL before disconnecting the battery, to allow the driveshaft to be turned.

1. Refer to: Battery Disconnect and Connect (414-01 Battery, Mounting and Cables, General Procedures).

2. WARNING: Do not work on or under a vehicle supported only by a jack.

Always support the vehicle on safety stands.

Raise and support the vehicle.

3. Refer to: Exhaust System (309-00C Exhaust System - V8 5.0L Petrol/V8 S/C 5.0L Petrol, Removal and Installation).

4. 205-932

Remover, Driveshaft Special Tool(s)

Page 526 of 3039

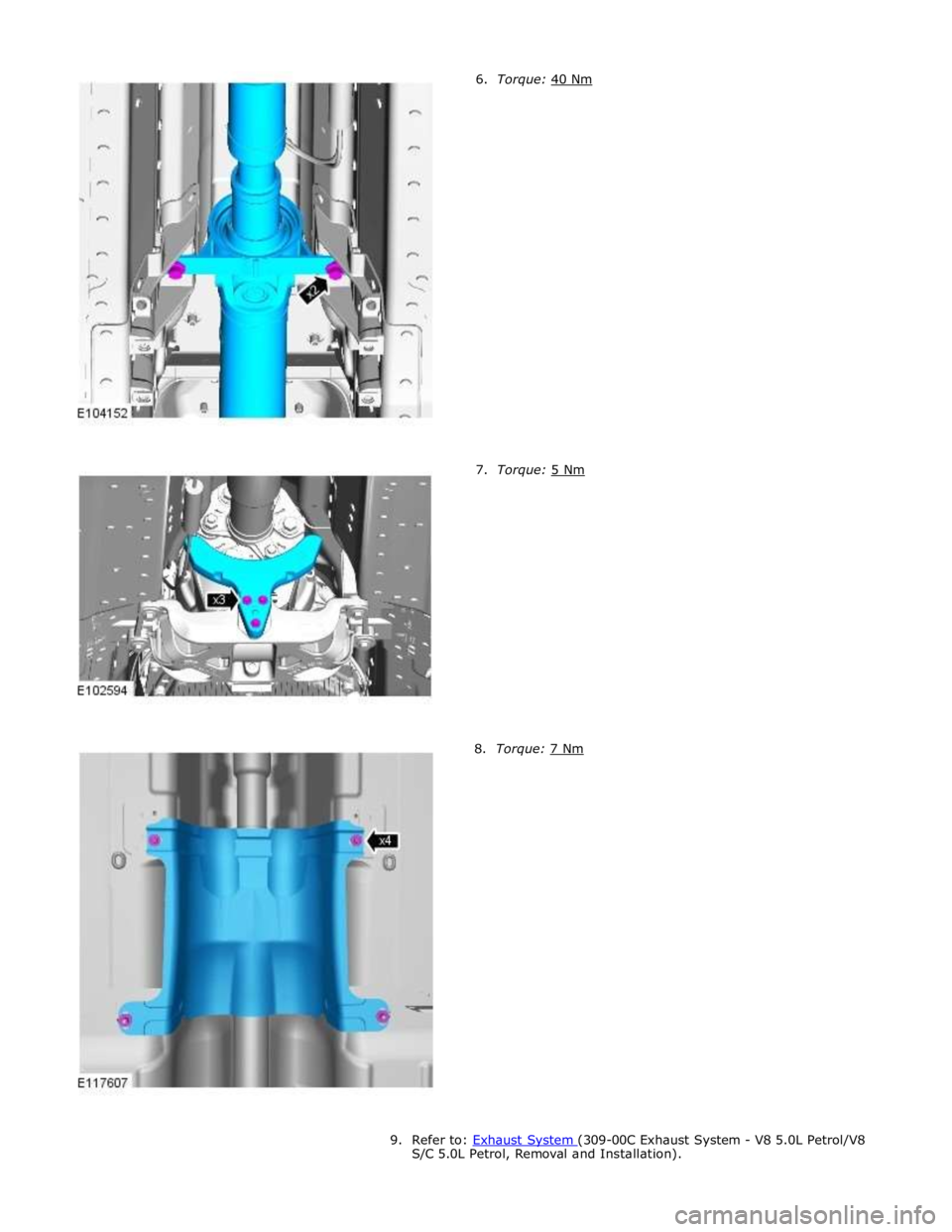

7. Torque: 5 Nm 8. Torque: 7 Nm

9. Refer to: Exhaust System (309-00C Exhaust System - V8 5.0L Petrol/V8 S/C 5.0L Petrol, Removal and Installation).