Pump JAGUAR XFR 2010 1.G Owner's Manual

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 2010, Model line: XFR, Model: JAGUAR XFR 2010 1.GPages: 3039, PDF Size: 58.49 MB

Page 590 of 3039

Does the brake pedal return to its original position? Yes

No action required, vehicle is OK.

No

GO to K2. K2: CHECK FOR BRAKE PEDAL BINDING 1 Disconnect the brake booster from the brake pedal. Check the brake pedal to ensure free operation. Is the brake pedal operating freely? Yes

Install a new brake booster as required. REFER to:

Brake Booster (206-07 Power Brake Actuation, Removal and Installation), Brake Booster - RHD (206-07, Removal and Installation).

Re-test the system for normal operation.

No

Repair or install new brake pedal. Re-test the system for normal operation. Component Tests

Brake Booster

1. Check all hoses and connections. All unused vacuum connectors should be capped. Hoses and their connections should

be correctly secured and in good condition with no holes and no collapsed areas. Inspect the valve on the brake booster

for damage.

2. Check the hydraulic brake system for leaks or low fluid.

3. With the automatic transmission in PARK, stop the engine and apply the parking brake. Pump the brake pedal several

times to exhaust all vacuum in the system. With the engine switched off and all vacuum in the system exhausted,

apply the brake pedal and hold it down. Start the engine. If the vacuum system is operating, the brake pedal will tend

to move downward under constant foot pressure. If no motion is felt, the vacuum booster system is not functioning.

4. Remove the vacuum hose from the brake booster. Manifold vacuum should be available at the brake booster end of the

hose with the engine at idle speed and the automatic transmission in PARK. Make sure that all unused vacuum outlets

are correctly capped, hose connectors are correctly secured and vacuum hoses are in good condition. When it is

established that manifold vacuum is available to the brake booster, connect the vacuum hose to the brake booster and

repeat Step 3. If no downward movement of the brake pedal is felt, install a new brake booster.

5. Operate the engine for a minimum of 10 seconds at a fast idle. Stop the engine and allow the vehicle to stand for 10

minutes. Then, apply the brake pedal with approximately 89 N (20lb) of force. The pedal feel (brake application) should

be the same as that noted with the engine running. If the brake pedal feels hard (no power assist), install a new valve

and then repeat the test. If the brake pedal still feels hard, install a new brake booster. If the brake pedal movement

feels spongy, bleed the brake system.

REFER to: Brake System Bleeding (206-00 Brake System - General Information, General Procedures). Brake Master Cylinder

Usually, the first and strongest indicator of anything wrong in the brake system is a feeling through the brake pedal. In

diagnosing the condition of the brake master cylinder, check pedal feel as evidence of a brake concern. Check for brake warning

lamp illumination and the brake fluid level in the brake master cylinder reservoir.

Normal Conditions

The following conditions are considered normal and are not indications that the brake master cylinder is in need of repair.

Modern brake systems are designed to produce a pedal effort that is not as hard as in the past. Complaints of light

pedal efforts should be compared to the pedal efforts of another vehicle of the same model and year.

The fluid level will fall with brake pad wear.

Abnormal Conditions

Changes in the brake pedal feel or brake pedal travel are indicators that something could be wrong in the brake system. The

diagnostic procedure and techniques use brake pedal feel, warning indicator illumination and low brake fluid level as indicators

to diagnosing brake system concerns. The following conditions are considered abnormal and indicate that the brake master

cylinder is in need of repair:

NOTE: Prior to carrying out any diagnosis, make sure the brake system warning indicator is functional.

Brake pedal goes down fast. This could be caused by an external or internal leak.

Brake pedal goes down slowly. This could be caused by an internal or external leak.

Brake pedal is low or feels spongy. This condition may be caused by no fluid in the brake master cylinder, reservoir cap

vent holes clogged or air in the hydraulic system.

Brake pedal effort is excessive. This may be caused by a bind or obstruction in the pedal/linkage, a faulty non-return

valve, booster or insufficient booster vacuum.

Rear brakes lock up during light pedal force. This may be caused by damaged brake pads, a partially applied parking

brake, a damaged ABS sensor or bearing failure.

Brake pedal effort erratic. This condition could be caused by the brake booster or incorrectly installed brake pads.

Brake warning indicator is on. This may be caused by low fluid level or float assembly damaged. www.JagDocs.com

Page 675 of 3039

6 Pulsation damper 7 Separation valve 8 Damping chambers 9 Separation valve 10 Shuttle valve 11 Hydraulic pumps 12 Motor 13 Shuttle valve 14 Pressure sensor - all vehicles 15 Low pressure accumulator 16 Check valve 17 Low pressure accumulator 18 Inlet valve 19 Inlet valve 20 Inlet valve 21 Inlet valve 22 Outlet valve 23 Outlet valve 24 Outlet valve 25 Outlet valve 26 Pressure sensors - vehicles fitted with adaptive speed control only 27 RH front brake 28 LH rear brake 29 RH rear brake 30 LH front brake www.JagDocs.com

Page 679 of 3039

Hydraulic Brake Actuation - Brake Master Cylinder

Removal and Installation

Removal Published: 11-May-2011

1. WARNING: Make sure to support the vehicle with axle stands.

Raise and support the vehicle.

2. Remove the cowl vent screen.

For additional information, refer to: Cowl Vent Screen (501-02 Front End Body Panels, Removal and Installation).

3. CAUTION: Brake fluid will damage paint finished surfaces. If spilled,

immediately remove the fluid and clean the area with water.

Remove the brake fluid reservoir.

For additional information, refer to: Brake Fluid Reservoir (206-06 Hydraulic Brake Actuation, Removal and Installation).

4. Remove the brake booster vacuum line from the brake vacuum

pump.

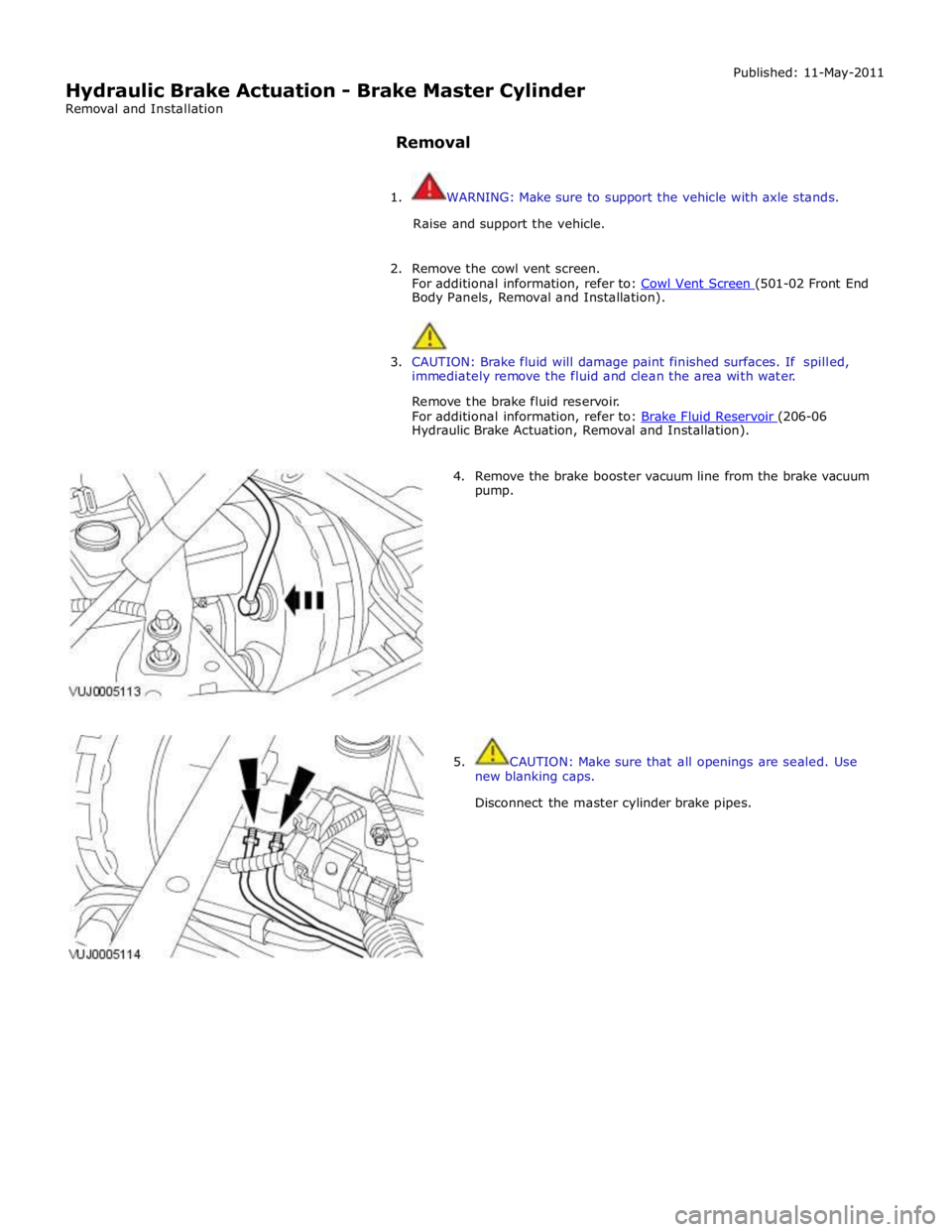

5. CAUTION: Make sure that all openings are sealed. Use

new blanking caps.

Disconnect the master cylinder brake pipes.

Page 682 of 3039

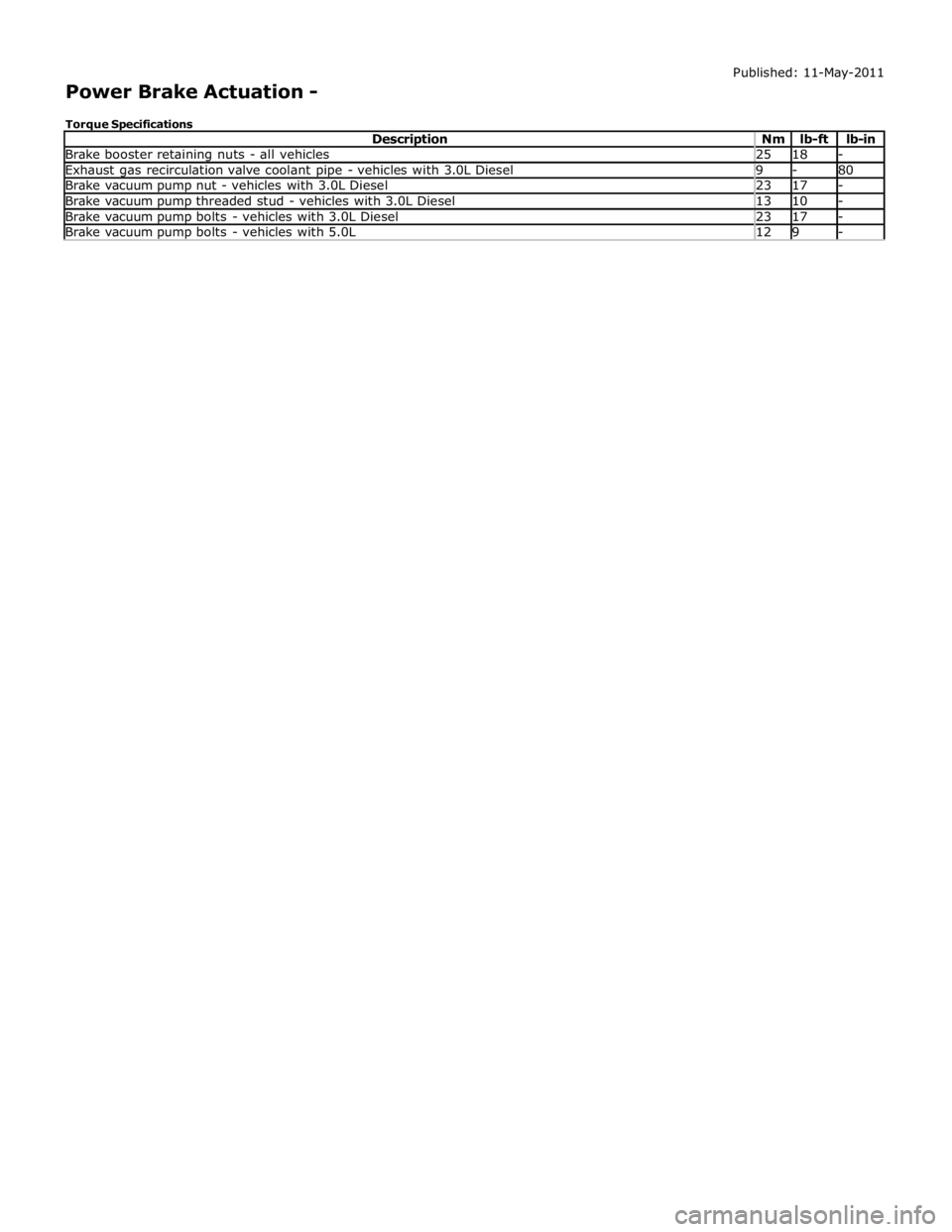

Brake booster retaining nuts - all vehicles 25 18 - Exhaust gas recirculation valve coolant pipe - vehicles with 3.0L Diesel 9 - 80 Brake vacuum pump nut - vehicles with 3.0L Diesel 23 17 - Brake vacuum pump threaded stud - vehicles with 3.0L Diesel 13 10 - Brake vacuum pump bolts - vehicles with 3.0L Diesel 23 17 - Brake vacuum pump bolts - vehicles with 5.0L 12 9 -

Page 688 of 3039

Published: 08-Oct-2012

Power Brake Actuation - Brake Vacuum Pump V8 5.0L Petrol/V8 S/C 5.0L

Petrol

Removal and Installation

Removal

CAUTION: Make sure that all openings are sealed. Use new blanking caps.

NOTE: Removal steps in this procedure may contain installation details.

1. WARNING: Make sure to support the vehicle with axle stands.

Raise and support the vehicle.

2. Refer to: Engine Oil Draining and Filling (303-01, General Procedures).

3.

4. CAUTION: Be prepared to collect escaping oil.

Torque: 12 Nm

Page 717 of 3039

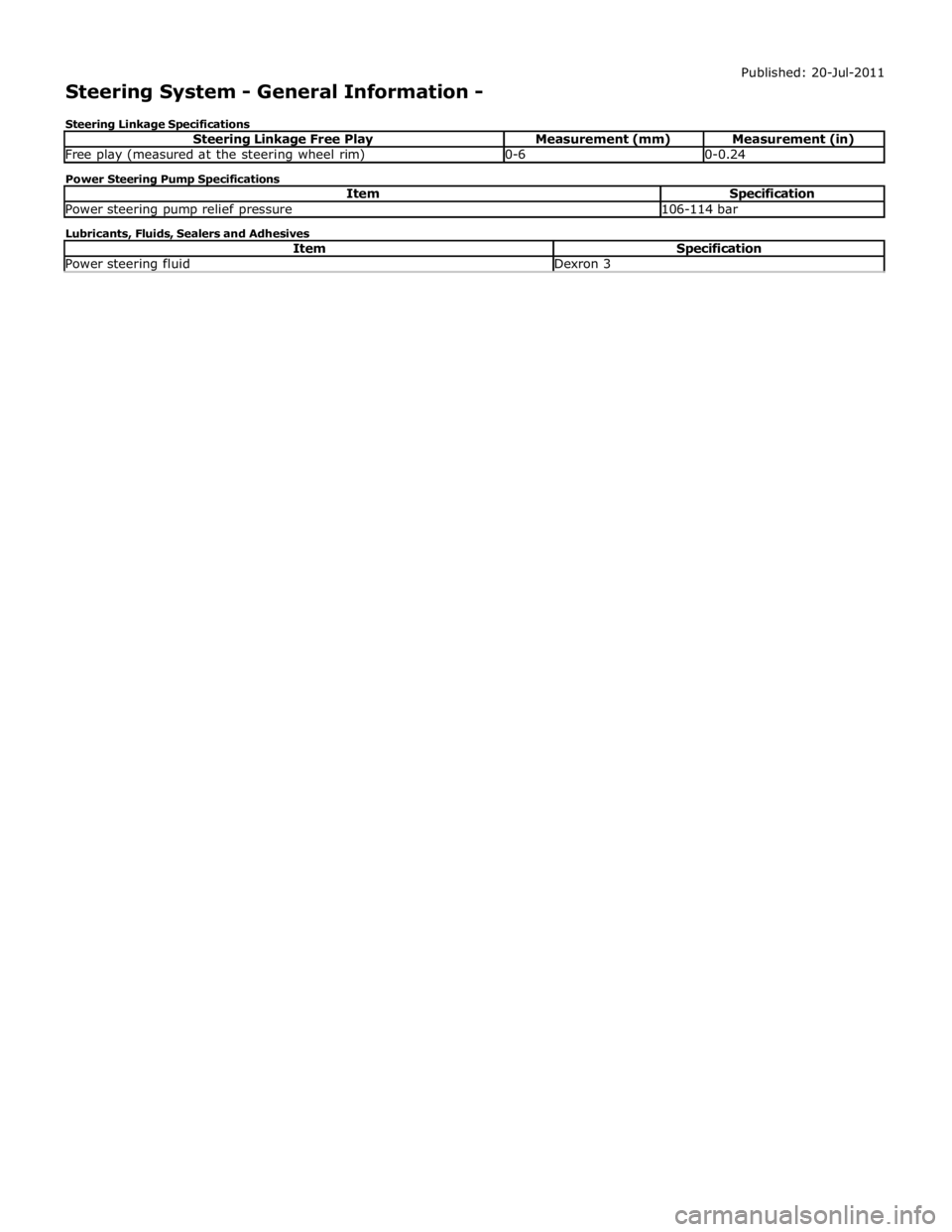

Free play (measured at the steering wheel rim) 0-6 0-0.24 Power Steering Pump Specifications

Item Specification Power steering pump relief pressure 106-114 bar Lubricants, Fluids, Sealers and Adhesives

Item Specification Power steering fluid Dexron 3

Page 719 of 3039

Symptom Possible Causes Action

Damaged fluid

cap/reservoir

Check and install a new fluid cap/reservoir as required

Loose or damaged

hoses and fittings

O-ring or Dowty seals

Tighten the hose connection or latch plate fixing to the

recommended torque.

REFER to: Specifications (211-00 Steering System - General Information, Specifications).

Check and install new components as required

Install new O-ring or Dowty seals as required

Fluid cooler

Check and install a new fluid cooler as required, refer to the new

module/component installation note at the top of the Symptom

Charts

Power steering pump

Check and install a new power steering pump as required, refer to

the new module/component installation note at the top of the

Symptom Charts Functional

Symptom Possible Causes Action

Steering wheel

misalignment

Steering not correctly centred

Check the steering alignment.

REFER to: Specifications (204-00 Suspension System - General

Information, Specifications).

Excessive free play at

steering wheel (refer to

the Steering Linkage

Inspection and Backlash

(Free play) Check in this

section)

Steering wheel loose

Check and tighten the steering

wheel retaining bolt as required.

REFER to: Specifications (211-00 Steering System - General

Information, Specifications).

Excess play in the steering linkage

Check and install new

components as required

Steering gear not correctly adjusted (causing

excessive backlash)

CAUTION: DO NOT attempt to

adjust the steering gear yoke. Failure to

follow this instruction will invalidate the

steering gear warranty

Check and install a new steering

gear as required, refer to the

new module/component

installation note at the top of

the Symptom Charts

Lower steering column universal joint pinch

bolts loose

Check and tighten the lower

steering column pinch bolts as

required.

REFER to: Specifications (211-00 Steering System - General

Information, Specifications).

Excessive wear in steering column universal

joints

Check and install a new steering

column or steering column lower

shaft as required, refer to the

new module/component

installation note at the top of

the Symptom Charts

Steering gear mounting bolts loose or

damaged

Check/tighten and install new

steering gear mounting bolts as

required.

REFER to: Specifications (211-00 Steering System - General

Information, Specifications). www.JagDocs.com

Page 722 of 3039

Noise

Symptom Possible Causes Action

Continuous noise

Low power steering fluid level

Check for leaks and rectify as required. For further

information refer to the symptom charts for

leakage in this section. Fill power steering fluid

reservoir to correct level

NOTE: Look for small air bubbles

visible in the fluid, air may also get

trapped in the hydraulic system

Air in hydraulic system

Bleed the power steering system.

REFER to: Power Steering System Bleeding (211-00 Steering System - General Information,

General Procedures).

Power steering pipe/hose in

contact with the vehicle body

Check and reposition, or install new IF

damaged/deformed, power steering pipe/hose

Power steering pipe/hose

restricted or twisted

Check and clear restriction to pipe/hose

Reposition power steering pipe/hose. Install new

pipe/hose IF permanently damaged/deformed

Power steering pump mounting

bolts loose

Tighten the power steering pump mounting bolts

to the correct torque.

REFER to: Specifications (211-00 Steering System - General Information, Specifications).

Noise gets worse

when system is

loaded

NOTE: Refer to the power

steering pressure check in this section

Low power steering fluid level

Aerated fluid

Low power steering pump

pressure

Check and fill power steering fluid reservoir to

correct level

Bleed the power steering system.

REFER to: Power Steering System Bleeding (211-00 Steering System - General Information,

General Procedures).

Check power steering pump pressure. If the pump

pressure is low, install a new power steering

pump

Front End Accessory

Drive (FEAD) belt

squeal

FEAD belt incorrectly tensioned

or glazed

Check FEAD belt tension

Check FEAD belt condition and install a new belt

as required

Chirp noise from the

steering pump when a

load is applied

Loose or worn FEAD belt

Check FEAD belt tension

Check FEAD belt condition and install a new belt

as required

Scrape/grind noise

from behind steering

wheel while steering

Steering column shroud foul

condition or clockspring

Correctly install the steering column shroud to

eliminate the foul condition

Install a new clockspring as required

Foreign objects

Remove foreign objects from between steering

column shroud and steering wheel/steering

column rotating components

Click

Clockspring or steering column

multifunction switch LH

Correctly install and install new components as

required

Loose universal joint pinch bolt

Install a new universal joint pinch bolt and

tighten to correct specification.

REFER to: Specifications (211-00 Steering System - General Information, Specifications).

Squeak

Steering column shroud joints

Apply Krytox spray to steering column shroud

joints

Clockspring

Install new clockspring as required

Page 724 of 3039

2. Free play should be between 0 and 6 mm (0 and 0.24 in) at the steering wheel rim. If the free play exceeds this limit,

either the ball joints are worn, the lower steering column joints are worn or the backlash of the steering gear is

excessive.

CAUTION: DO NOT attempt to adjust the steering gear yoke. Failure to follow this instruction will invalidate the steering

gear warranty.

3. The backlash of the steering gear cannot be adjusted, install a new steering gear if excessive backlash is diagnosed.

4. Grasp the steering wheel firmly and move it up and down and to the left and right without turning the wheel to check

for column bearing wear, steering wheel or steering column.

Power Steering Fluid Condition Check

1. Run the engine for 2 minutes.

2. Check the power steering fluid system level.

3. Observe the color and the odor. The color under normal circumstances should be dark reddish, not brown or black.

4. Using a suitable clean syringe extract a suitable amount of fluid from the reservoir.

5. Allow the fluid to drip onto a facial tissue and examine the stain.

6. If evidence of solid material is found, the power steering fluid system should be drained for further inspection.

7. If fluid contamination or steering component failure is confirmed by the sediment in the power steering fluid system,

refer to Steering Fault Diagnosis by Symptom Charts in this section.

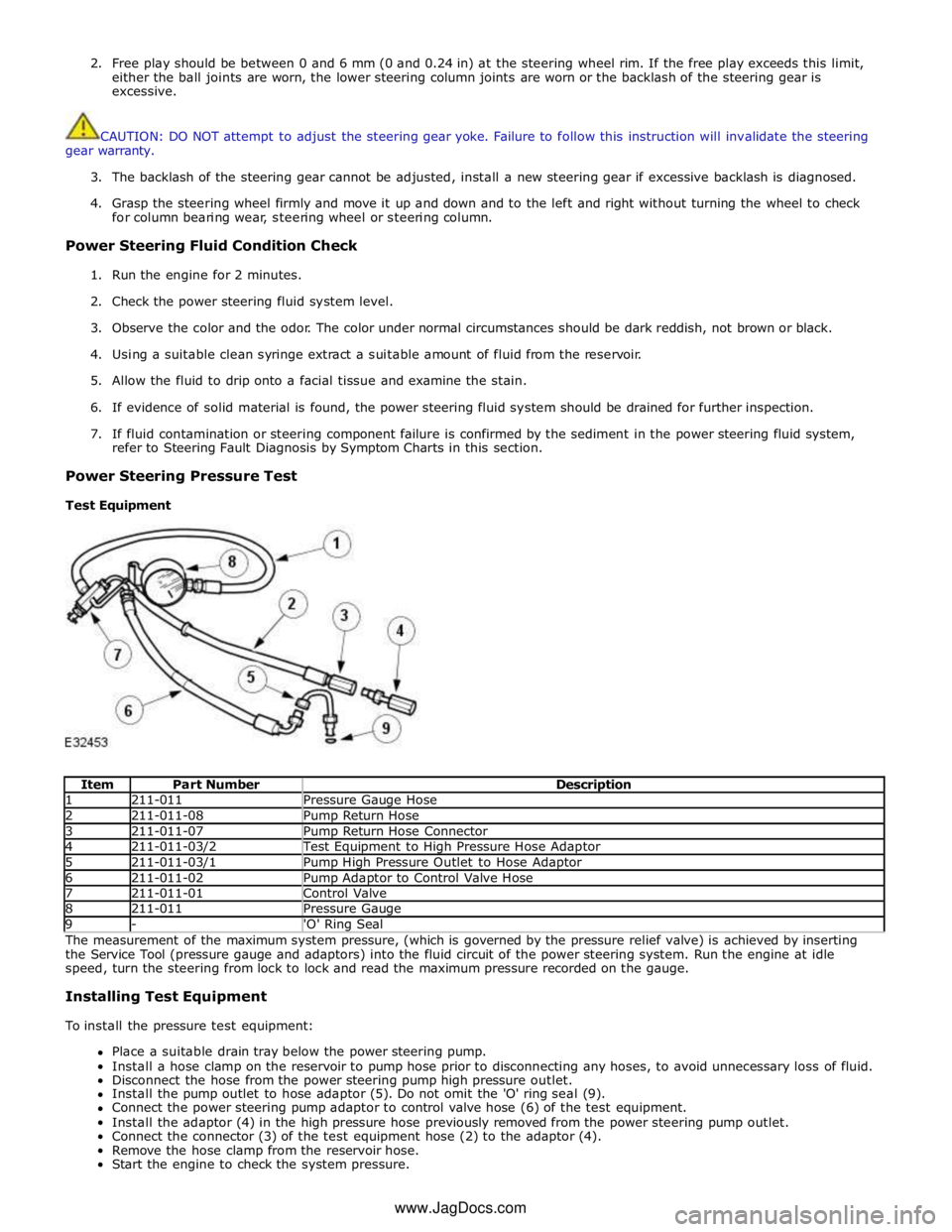

Power Steering Pressure Test

Test Equipment

Item Part Number Description 1 211-011 Pressure Gauge Hose 2 211-011-08 Pump Return Hose 3 211-011-07 Pump Return Hose Connector 4 211-011-03/2 Test Equipment to High Pressure Hose Adaptor 5 211-011-03/1 Pump High Pressure Outlet to Hose Adaptor 6 211-011-02 Pump Adaptor to Control Valve Hose 7 211-011-01 Control Valve 8 211-011 Pressure Gauge 9 - 'O' Ring Seal The measurement of the maximum system pressure, (which is governed by the pressure relief valve) is achieved by inserting

the Service Tool (pressure gauge and adaptors) into the fluid circuit of the power steering system. Run the engine at idle

speed, turn the steering from lock to lock and read the maximum pressure recorded on the gauge.

Installing Test Equipment

To install the pressure test equipment:

Place a suitable drain tray below the power steering pump.

Install a hose clamp on the reservoir to pump hose prior to disconnecting any hoses, to avoid unnecessary loss of fluid.

Disconnect the hose from the power steering pump high pressure outlet.

Install the pump outlet to hose adaptor (5). Do not omit the 'O' ring seal (9).

Connect the power steering pump adaptor to control valve hose (6) of the test equipment.

Install the adaptor (4) in the high pressure hose previously removed from the power steering pump outlet.

Connect the connector (3) of the test equipment hose (2) to the adaptor (4).

Remove the hose clamp from the reservoir hose.

Start the engine to check the system pressure. www.JagDocs.com

Page 725 of 3039

With the control valve (7) OPEN and the engine idling, the following system pressures may be checked:

During turning when static (dry parking pressure).

When the steering is held on full lock (maximum system pressure or pressure relief).

With the steering at rest (idle pressure or back pressure).

CAUTIONS:

To avoid excessive heating of the power steering pump when checking the pressure, do not close the valve for more than

5 seconds maximum.

When checking the pump pressure DO NOT drive the vehicle with the test equipment installed.

With the control valve (7) CLOSED the power steering pump maximum output pressure can be checked.

Removing Test Equipment

To remove the test equipment:

Install a hose clamp on the reservoir to power steering pump hose.

Removing the test equipment is a reversal of the installation instructions.

Install a new 'O' ring seal (9) to the power steering pump high pressure outlet to hose connection.

Install the original hose to the power steering pump.

Remove the clamp from the reservoir to the power steering pump hose.

Top-up the reservoir fluid.

Bleed the power steering system.

REFER to: Power Steering System Bleeding (211-00 Steering System - General Information, General Procedures).

Description of Terms General Steering System Noises

Boom

Rhythmic sound like a drum roll or distant thunder. May cause pressure on the ear drum.

Buzz

Low-pitched sound, like a bee. Usually associated with vibrations.

Chatter

Rapidly repeating metallic sound.

Chuckle

Rapid noise that sounds like a stick against the spokes of a spinning bicycle wheel.

Chirp

High pitched rapidly repeating sound, like chirping birds.

Click

Light sound, like a ball point pen being clicked.

Click/Thump

Heavy metal-to-metal sound, like a hammer striking steel.

Grind

Abrasive sound, like a grinding wheel or sandpaper rubbing against wood.

Groan/Moan

Continuous, low-pitched humming sound.

Groan/Howl

Low, guttural sound, like an angry dog.

Hiss

Continuous sound like air escaping from a tire valve.