Pump JAGUAR XFR 2010 1.G Owner's Guide

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 2010, Model line: XFR, Model: JAGUAR XFR 2010 1.GPages: 3039, PDF Size: 58.49 MB

Page 726 of 3039

Hum

Continuous sound of varying frequencies, like a wire humming in the wind.

Knock

Heavy, loud repeating sound like a knock on a door.

Ping

Similar to knock, except at higher frequency.

Rattle

A sound suggesting looseness, such as marbles rolling around in a can.

Roar

Deep, long, prolonged sound like an animal, or winds and ocean waves.

Rumble

Low, heavy continuous sound like that made by wagons or thunder.

Scrape

Grating noise like one hard plastic part rubbing against another.

Squeak

High-pitched sound like rubbing a clean window.

Squeal

Continuous, high-pitched sound like running finger nails across a chalkboard.

Tap

Light, hammering sound like tapping pencil on edge of table. May be rhythmic or intermittent.

Whirr/Whine

High-pitched buzzing sound, like an electric motor or drill.

Whistle

Sharp, shrill sound, like wind passing a small opening.

Specific Steering System Noise Types

Belt Squeal

Belt squeal is a high frequency air-borne noise generated by slippage of the ribbed Vee belt on the power steering pump

pulley. Squeal increases with system loading and at full lock.

Clonk

Clonk is a structure-borne noise heard as a loose-sounding rattle or vibration coming from the steering column. Clonk can be

identified by driving and turning over cobblestones, rough roads, or high frequency bumps such as 25-50 mm tall tar strips.

Clonk requires a tie-rod load impact.

Column Knock

Column knock is a loose-sounding rattle or vibration generated by the steering column shaft contacting other portions of the

column assembly. The noise is both audible and tactile. Column knock is generated by driving over cobblestones or rough

pavement. It is not necessary to turn the steering wheel to create this noise.

Column Rattle

Column rattle is a metallic sounding noise created when applying a highly impulsive force to the steering wheel. Column rattle

is often used to combine the more general group of column noises including clonk and column knock. Column rattle noises can

be caused by clonk, knock, loose column components, bonus parts etc. A series of parked, straight-line driving, and cornering

tests should be carried out to isolate the source/sources.

Grinding/Scrape

Grinding is a low frequency noise in the column when the steering wheel is turned. It is generally caused by interference

Page 727 of 3039

between moving components such as the steering wheel to steering column shroud.

Grunt (Squawk/Whoop)

Grunt is a 'honking' sound elicited when coming off one of the steering stops. Grunt is generally excited during parking

manoeuvres with a low to medium speed steering input.

Hiss (Swish)

Hiss or Valve Hiss is a high-frequency sound coming from the steering gear when the system is loaded. It is a rushing or

'swish' noise that doesn't change frequency with RPM. Hiss is the general noise generated by the flow of hydraulic fluid through

restrictions in the steering system. Restrictions include the rotary steering valve, power steering tubes, connectors, tuning

orifices, etc. Hiss can be air-borne and structure-borne, but the structure-borne path through the steering intermediate shaft is

usually dominant.

Moan (Groan)

Moan is the general structure-borne noise of the steering system. Moan is primarily transmitted to the driver via the body

structure through the pump mount, engine mounts, power steering lines and power steering brackets. On some vehicles, moan

is a loud humming noise, often present when the wheel is turned and the system is loaded. It may change frequency with

engine RPM and if the system is loaded or unloaded.

Steering Gear Knock (Steering Gear Slap)

CAUTION: DO NOT attempt to adjust the steering gear yoke. Failure to follow this instruction will invalidate the steering

gear warranty.

Steering gear knock is a rattle sound and steering wheel vibration caused by separation of the steering gear and pinion while

driving over bumps. It is a structure-borne noise transmitted through the intermediate shaft and column. Steering gear knock

can also be heard as a 'thump' or impact noise that occurs with the vehicle stationary when the steering wheel is released

from a loaded position and allowed to return to rest. Noise occurs with the engine on or off.

Rattles

Rattles are noises caused by knocking or hitting of components in the steering system. Steering rattles can occur in the engine

compartment, the suspension, or the passenger compartment. Rattles can be caused by loose components, movable and

flexible components, and improper clearances.

Squeaks/Scrapes

Squeaks/Scrapes are noises due to friction or component rubbing anywhere in the steering system. Squeaks/Scrapes have

appeared in steering linkages and joints, in column components and in column and steering wheel trim.

Weep

Weep is an air-borne noise, occasionally generated when turning the steering across lock at a constant rate. When present on

a vehicle the noise, once initiated can often be maintained across a large proportion of the available steering movement.

Whistle

Whistle is similar to hiss but is louder and of a higher frequency. It is also more of a pure tone noise than hiss. Whistle is

air-borne and is generated by a high flow rate of hydraulic fluid through a small restriction.

Zip

Zip noise is the air-borne noise generated by power steering pump cavitation when power steering fluid does not flow freely

through the suction hose from the reservoir to the pump. Zip primarily occurs during cold weather at start-up.

Steering System Vibrations and Harshness

Buzz

Buzz is a tactile rotary vibration felt in the steering wheel when steering inputs are slow. Buzz can also be called a grinding

feel and it is closely related to grunt and is caused by high system gain with low damping. Buzz is generally excited during

parking manoeuvres with low to medium speed steering input.

Buzz (Electrical)

A different steering buzz can be caused by pulse width modulated (PWM) electric actuators used in variable assist steering

systems. This buzz is felt by turning the ignition key to run without starting the engine and holding onto the steering wheel.

In extreme cases, the buzz can be felt with the engine running also.

Column/Steering Wheel Shake

Column shake is a low frequency vertical vibration excited by primary engine vibrations.

Nibble (Shimmy)

Page 736 of 3039

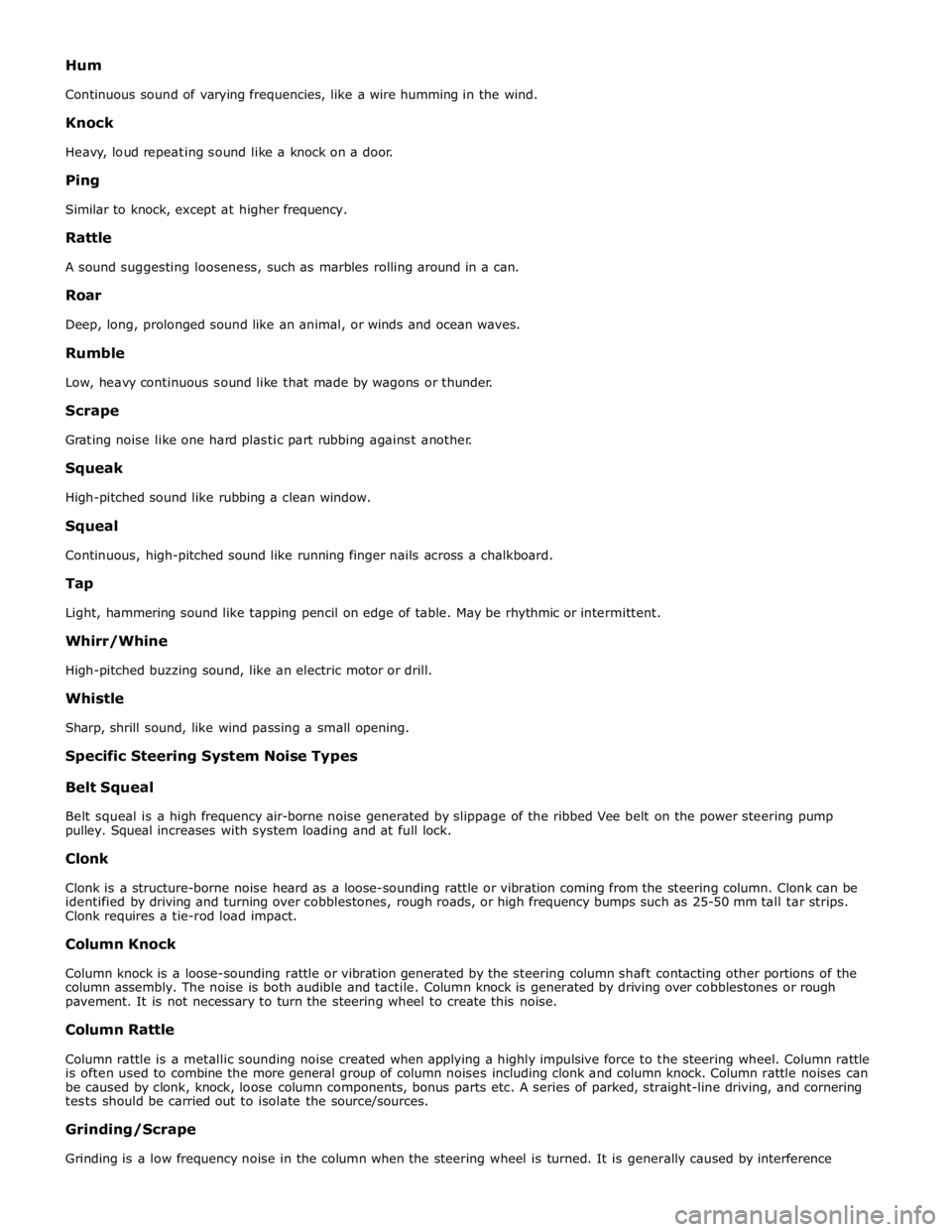

4. CAUTION: Fluid must always be present in the

reservoir during bleeding.

Fill the power steering reservoir.

5. Install the vacuum hand pump to the power steering fluid reservoir.

6. NOTE: Apply the maximum vacuum possible on the reservoir for 1

minute.

Apply a vacuum to the power steering fluid reservoir.

7. Remove the vacuum hand pump from the power steering fluid reservoir.

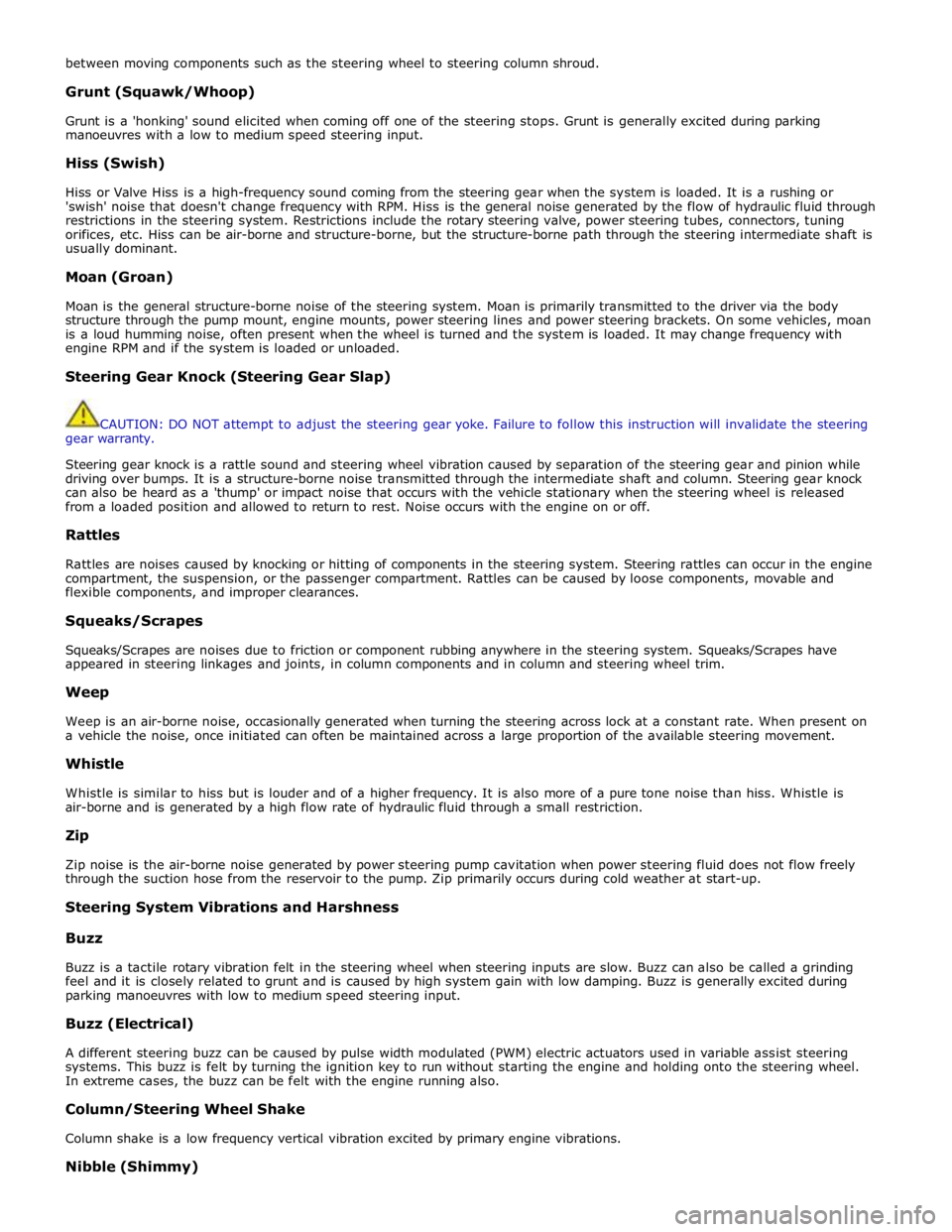

8. CAUTION: Fluid must always be present in the

reservoir during bleeding.

Fill the power steering reservoir.

9.

Run the engine for 30 seconds.

Turn the steering fully lock-to-lock, stop the engine.

10. Install the vacuum hand pump to the power steering fluid reservoir.

11. NOTE: Apply the maximum vacuum possible on the reservoir for 1

minute.

Apply a vacuum to the power steering fluid reservoir.

12. Remove the vacuum hand pump from the power steering fluid reservoir.

Page 737 of 3039

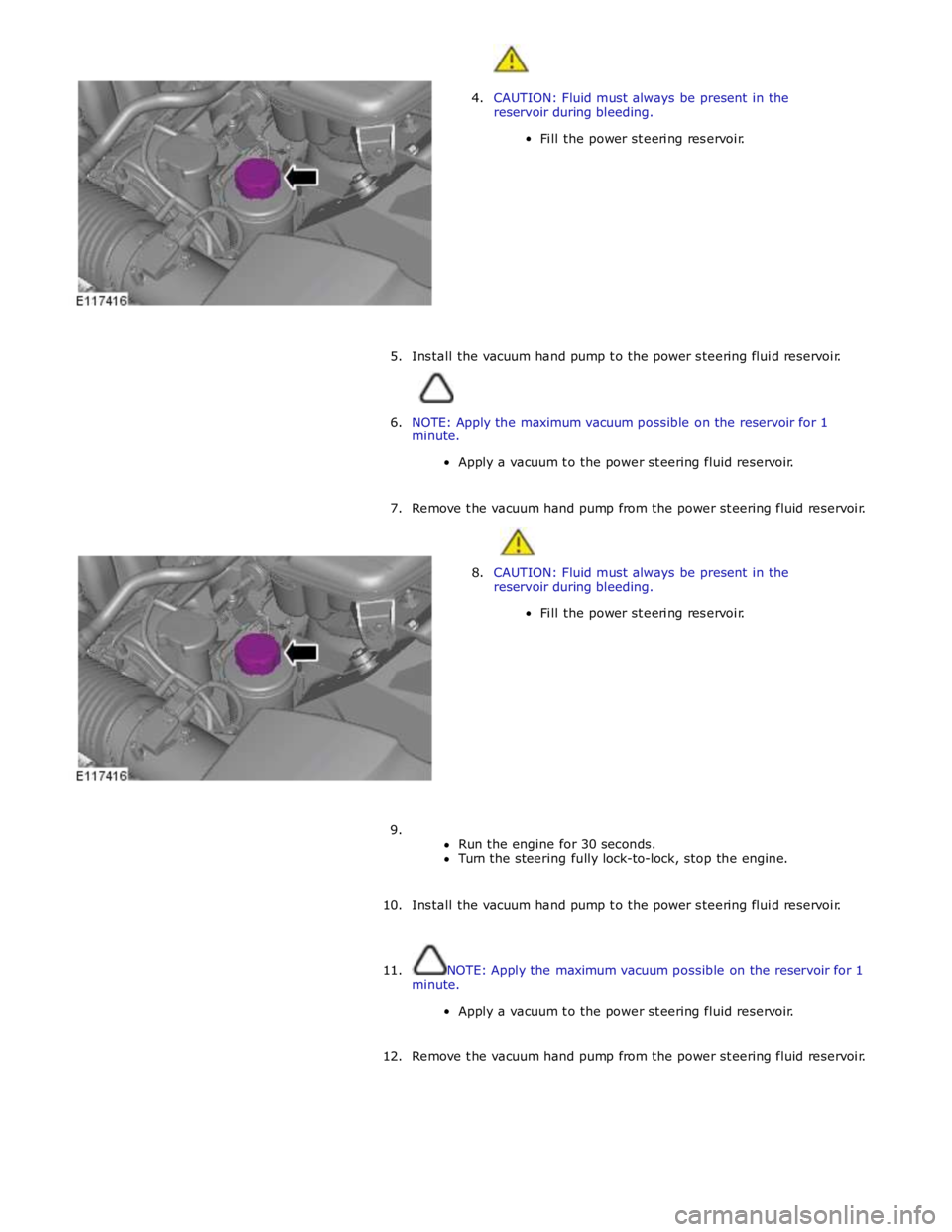

13. CAUTION: Fluid must always be present in the

reservoir during bleeding.

Fill the power steering reservoir.

14.

Run the engine for 30 seconds.

Turn the steering fully lock-to-lock, stop the engine.

15. Install the vacuum hand pump to the power steering fluid reservoir.

16. NOTE: Apply the maximum vacuum possible on the reservoir for 1

minute.

Apply a vacuum to the power steering fluid reservoir.

17. Remove the vacuum hand pump from the power steering fluid reservoir.

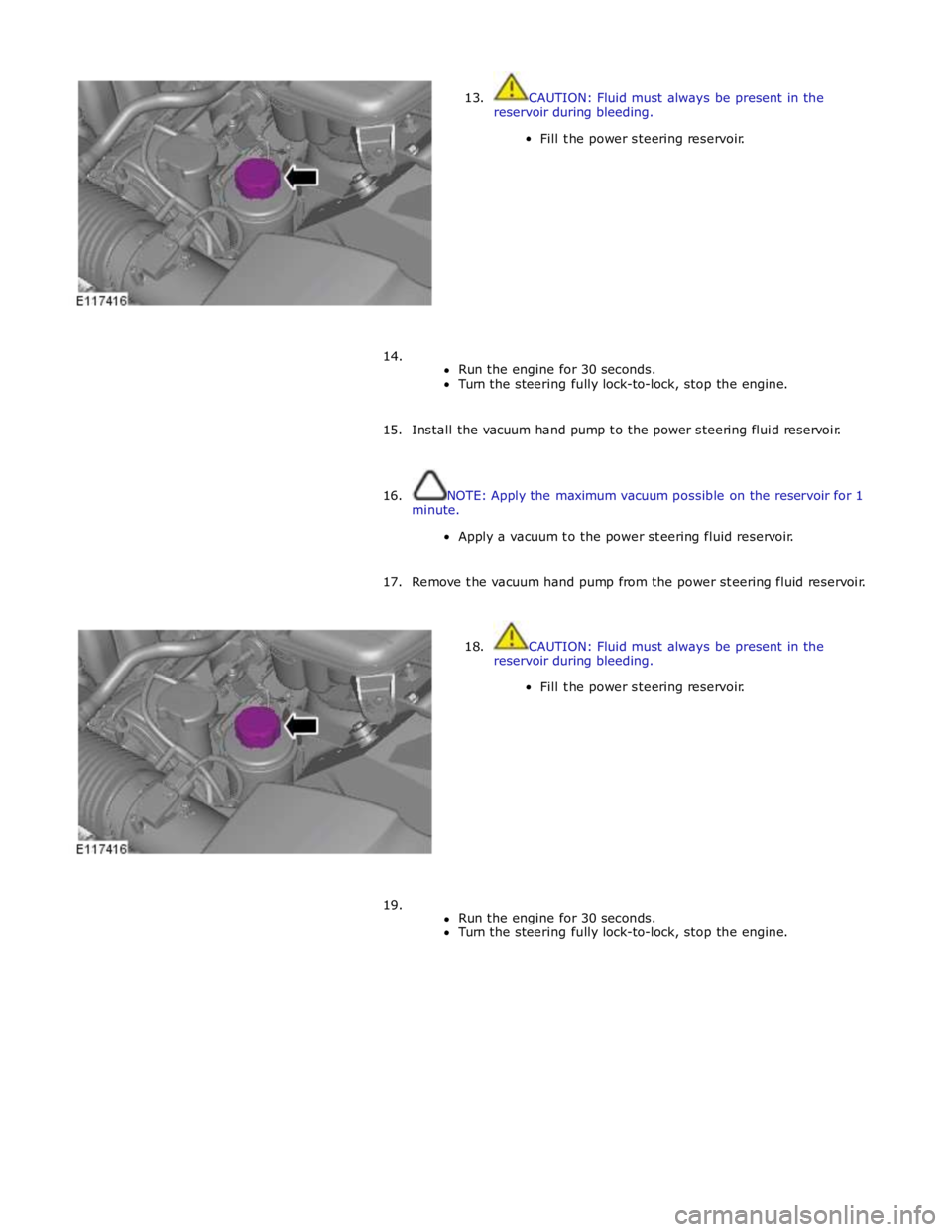

18. CAUTION: Fluid must always be present in the

reservoir during bleeding.

Fill the power steering reservoir.

19.

Run the engine for 30 seconds.

Turn the steering fully lock-to-lock, stop the engine.

Page 739 of 3039

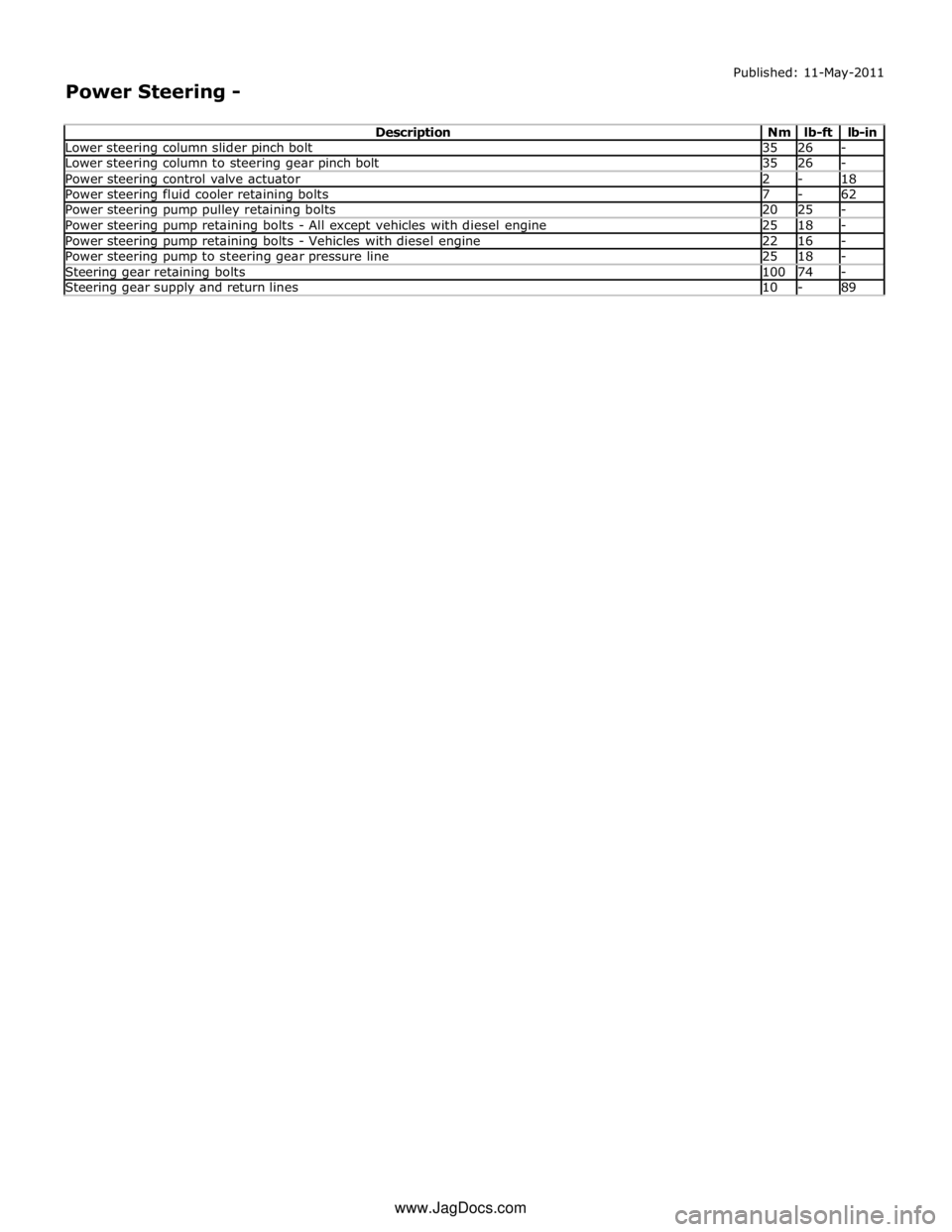

Lower steering column slider pinch bolt 35 26 - Lower steering column to steering gear pinch bolt 35 26 - Power steering control valve actuator 2 - 18 Power steering fluid cooler retaining bolts 7 - 62 Power steering pump pulley retaining bolts 20 25 - Power steering pump retaining bolts - All except vehicles with diesel engine 25 18 - Power steering pump retaining bolts - Vehicles with diesel engine 22 16 - Power steering pump to steering gear pressure line 25 18 - Steering gear retaining bolts 100 74 - Steering gear supply and return lines 10 - 89 www.JagDocs.com

Page 740 of 3039

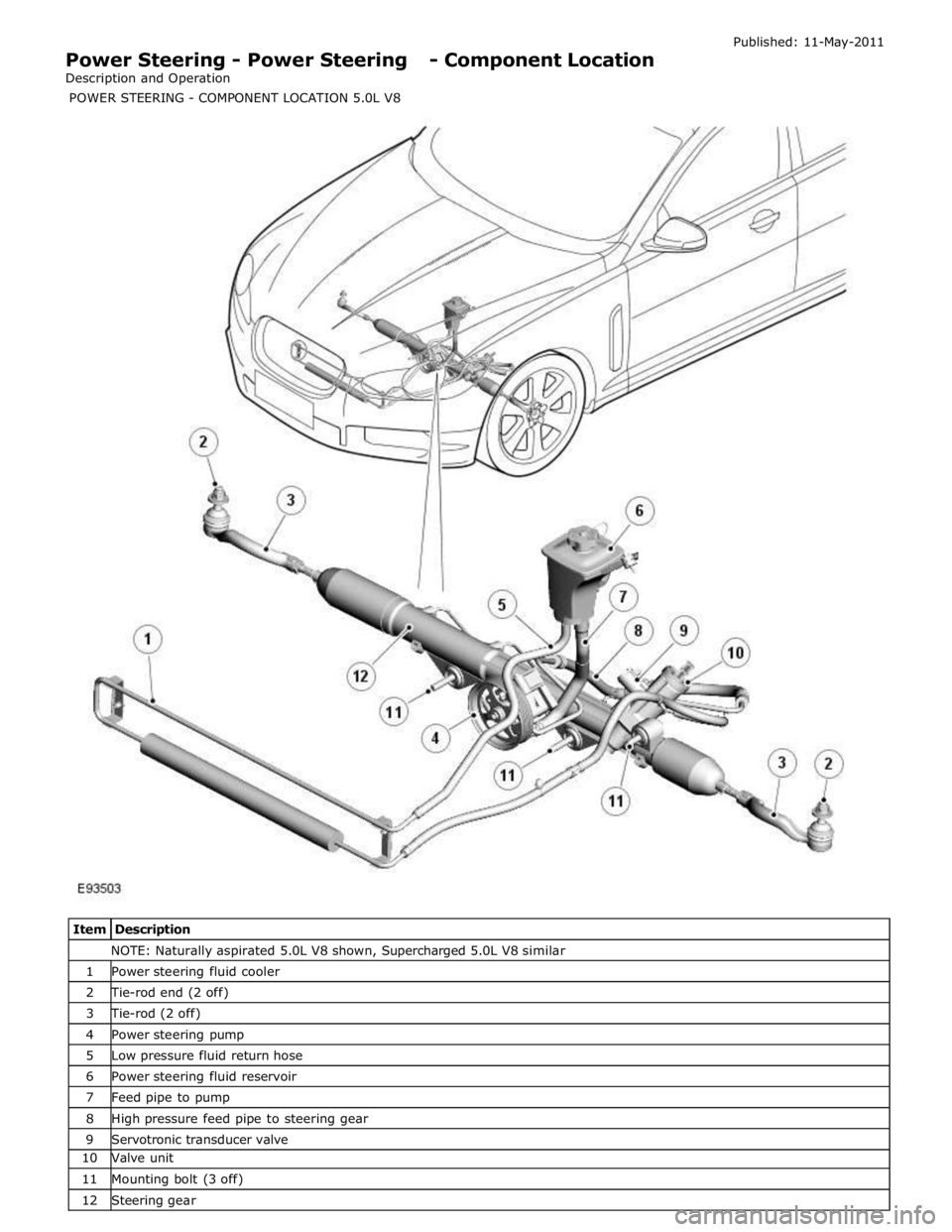

Power Steering - Power Steering - Component Location

Description and Operation

Published: 11-May-2011

POWER STEERING-COMPONENTLOCATION5.0LV8

ItemDescriptionNOTE:Naturallyaspirated5.0LV8shown,Supercharged5.0LV8similar1Powersteeringfluidcooler2Tie-rodend(2off)3Tie-rod(2off)4Powersteeringpump5Lowpressurefluidreturnhose6Powersteeringfluidreservoir7Feedpipetopump8Highpressurefeedpipetosteeringgear9Servotronictransducervalve10Valveunit11Mountingbolt(3off)12Steeringgear

Page 743 of 3039

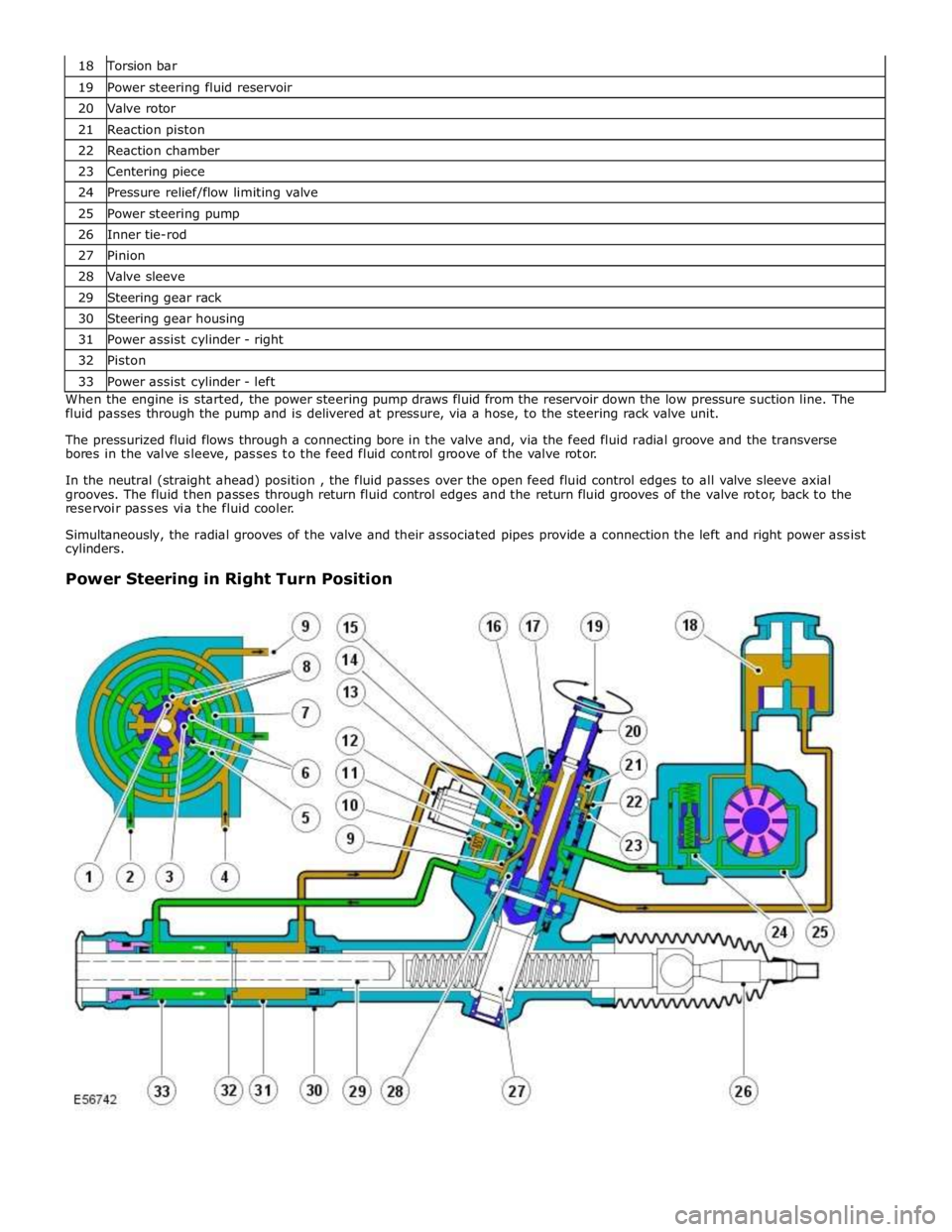

Torsion bar 19 Power steering fluid reservoir 20 Valve rotor 21 Reaction piston 22 Reaction chamber 23 Centering piece 24 Pressure relief/flow limiting valve 25 Power steering pump 26 Inner tie-rod 27 Pinion 28 Valve sleeve 29 Steering gear rack 30 Steering gear housing 31 Power assist cylinder - right 32 Piston 33 Power assist cylinder - left When the engine is started, the power steering pump draws fluid from the reservoir down the low pressure suction line. The

fluid passes through the pump and is delivered at pressure, via a hose, to the steering rack valve unit.

The pressurized fluid flows through a connecting bore in the valve and, via the feed fluid radial groove and the transverse

bores in the valve sleeve, passes to the feed fluid control groove of the valve rotor.

In the neutral (straight ahead) position , the fluid passes over the open feed fluid control edges to all valve sleeve axial

grooves. The fluid then passes through return fluid control edges and the return fluid grooves of the valve rotor, back to the

reservoir passes via the fluid cooler.

Simultaneously, the radial grooves of the valve and their associated pipes provide a connection the left and right power assist

cylinders.

Power Steering in Right Turn Position

Page 744 of 3039

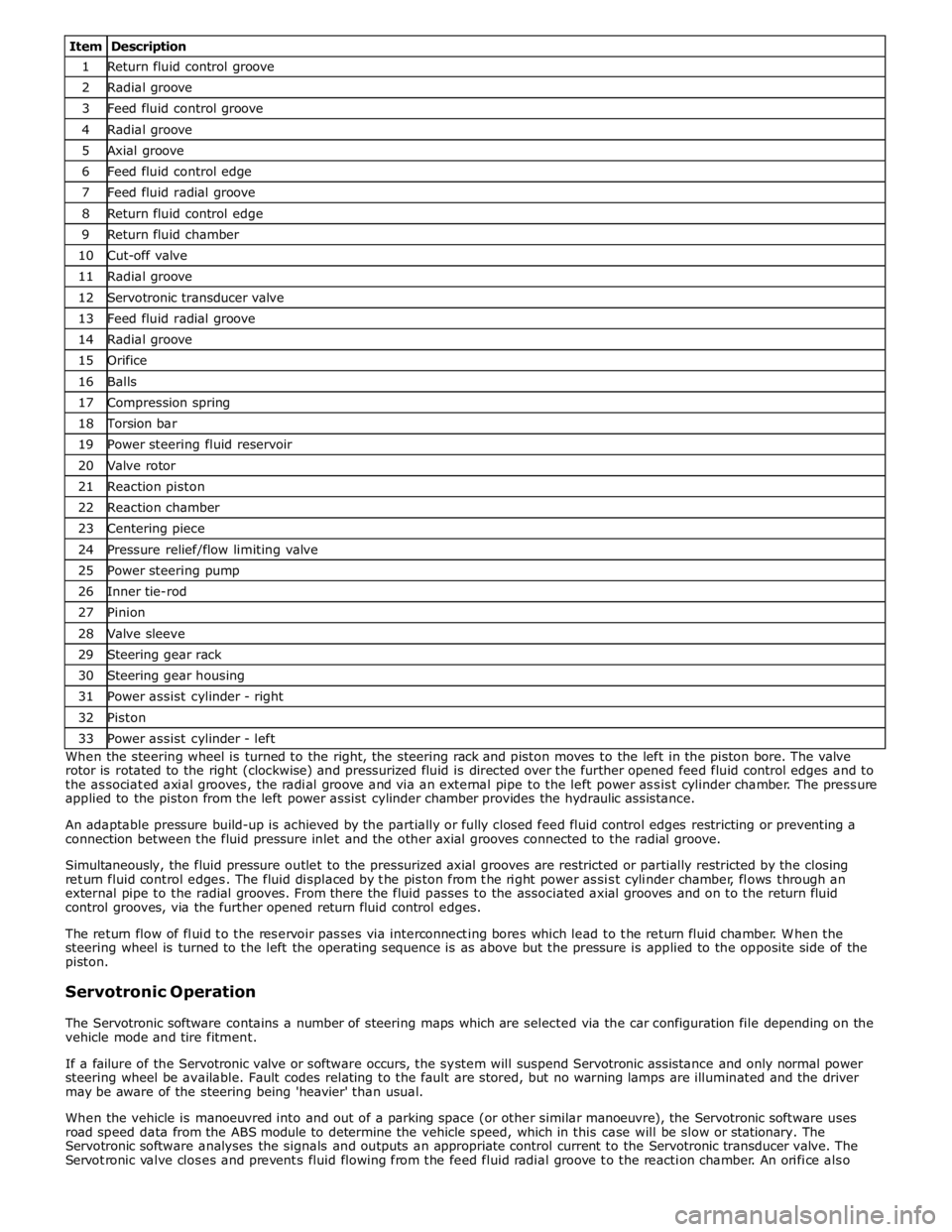

1 Return fluid control groove 2 Radial groove 3 Feed fluid control groove 4 Radial groove 5 Axial groove 6 Feed fluid control edge 7 Feed fluid radial groove 8 Return fluid control edge 9 Return fluid chamber 10 Cut-off valve 11 Radial groove 12 Servotronic transducer valve 13 Feed fluid radial groove 14 Radial groove 15 Orifice 16 Balls 17 Compression spring 18 Torsion bar 19 Power steering fluid reservoir 20 Valve rotor 21 Reaction piston 22 Reaction chamber 23 Centering piece 24 Pressure relief/flow limiting valve 25 Power steering pump 26 Inner tie-rod 27 Pinion 28 Valve sleeve 29 Steering gear rack 30 Steering gear housing 31 Power assist cylinder - right 32 Piston 33 Power assist cylinder - left When the steering wheel is turned to the right, the steering rack and piston moves to the left in the piston bore. The valve

rotor is rotated to the right (clockwise) and pressurized fluid is directed over the further opened feed fluid control edges and to

the associated axial grooves, the radial groove and via an external pipe to the left power assist cylinder chamber. The pressure

applied to the piston from the left power assist cylinder chamber provides the hydraulic assistance.

An adaptable pressure build-up is achieved by the partially or fully closed feed fluid control edges restricting or preventing a

connection between the fluid pressure inlet and the other axial grooves connected to the radial groove.

Simultaneously, the fluid pressure outlet to the pressurized axial grooves are restricted or partially restricted by the closing

return fluid control edges. The fluid displaced by the piston from the right power assist cylinder chamber, flows through an

external pipe to the radial grooves. From there the fluid passes to the associated axial grooves and on to the return fluid

control grooves, via the further opened return fluid control edges.

The return flow of fluid to the reservoir passes via interconnecting bores which lead to the return fluid chamber. When the

steering wheel is turned to the left the operating sequence is as above but the pressure is applied to the opposite side of the

piston.

Servotronic Operation

The Servotronic software contains a number of steering maps which are selected via the car configuration file depending on the

vehicle mode and tire fitment.

If a failure of the Servotronic valve or software occurs, the system will suspend Servotronic assistance and only normal power

steering wheel be available. Fault codes relating to the fault are stored, but no warning lamps are illuminated and the driver

may be aware of the steering being 'heavier' than usual.

When the vehicle is manoeuvred into and out of a parking space (or other similar manoeuvre), the Servotronic software uses

road speed data from the ABS module to determine the vehicle speed, which in this case will be slow or stationary. The

Servotronic software analyses the signals and outputs an appropriate control current to the Servotronic transducer valve. The

Servotronic valve closes and prevents fluid flowing from the feed fluid radial groove to the reaction chamber. An orifice also

Page 747 of 3039

18 Pinion 19 Steering gear rack bar 20 Valve sleeve The valve unit is an integral part of the steering gear. The principle function of the valve unit is to provide power assistance

(i.e. when parking) to optimize the effort required to turn the steering wheel.

The pinion housing of the valve is an integral part of the main steering gear casting. The pinion housing has four machined

ports which provide connections for pressure feed from the power steering pump, return fluid to the reservoir and pressure

feeds to each side of the cylinder piston.

The valve unit comprises an outer sleeve, an input shaft, a torsion bar and a pinion shaft. The valve unit is co-axial with the

pinion shaft which is connected to the steering column via the input shaft. The valve unit components are located in the

steering gear pinion housing which is sealed with a cap.

The outer sleeve is located in the main bore of the pinion housing. Three annular grooves are machined on its outer diameter.

PTFE (polytetrafluoroethylene) rings are located between the grooves and seal against the bore of the pinion housing. Holes

are drilled radially in each annular groove through the wall of the sleeve. The bore of the outer sleeve is machined to accept

the input shaft. Six equally spaced slots are machined in the bore of the sleeve. The ends of the slots are closed and do not

continue to the end of the outer sleeve. The radial holes in the outer sleeve are drilled into each slot.

The input shaft has two machined flats at its outer end which allow for the attachment of the steering column intermediate

shaft yoke. The flats ensure that the intermediate shaft is fitted in the correct position. The inner end of the input shaft forms

a dog-tooth which mates with a slot in the pinion shaft. The fit of the dog-tooth in the slot allows a small amount of relative

rotation between the input shaft and the pinion shaft before the dog-tooth contacts the wall of the slot. This ensures that, if

the power assistance fails, the steering can be operated manually without over stressing the torsion bar. The central portion of

the input shaft has equally spaced longitudinal slots machined in its circumference. The slots are arranged alternately around

the input shaft.

The torsion bar is fitted inside the input shaft and is an interference fit in the pinion shaft. The torsion bar is connected to the

input shaft by a drive pin. The torsion bar is machined to a smaller diameter in its central section. The smaller diameter allows

the torsion bar to twist in response to torque applied from the steering wheel in relation to the grip of the tyres on the road

surface.

The pinion shaft has machined teeth on its central diameter which mate with teeth on the steering gear rack. A slot, machined

in the upper end of the pinion shaft mates with the dog-tooth on the input shaft. The pinion shaft locates in the pinion

housing and rotates on ball and roller bearings.

Servotronic Valve

The Servotronic transducer valve is located in a port in the side of the steering gear valve housing. The valve is sealed in the

housing with an O-ring seal and is secured with two long screws into threaded holes in the housing. The Servotronic valve is a

transducer controlled valve which responds to control signals supplied from Servotronic software in the instrument cluster.

The Servotronic valve determines the hydraulic reaction at the steering gear rotary valve and controls the input torque required

to turn the steering wheel. The Servotronic system allows the steering to be turned with the optimum effort when the vehicle

is stationary or manoeuvred at slow speed. The hydraulic reaction changes proportional to the vehicle speed, with the required

steering effort increasing as the vehicle moves faster. At high speeds, the Servotronic system provides the driver with a good

feedback through the steering providing precise steering and improved stability.

The instrument cluster receives road speed signals from the ABS module and calculates the correct controlling signal for the Servotronic valve. The Servotronic software within the instrument cluster has a diagnostic capability which allows a Jaguar

approved diagnostic system to check the tune of the steering and retrieve fault codes relating to the Servotronic valve. Two

fault codes are stored relating to the valve for positive connection short to ground or battery and negative connection short to

ground or battery.

The Servotronic software within the instrument cluster also contains a number of steering maps which are selected via the car

configuration file depending on the vehicle model and tire fitment.

If a failure of the Servotronic valve or software occurs, the system will suspend Servotronic assistance and only a default level

of assistance will be available. Fault codes relating to the fault are stored in the instrument cluster. No warning lamps are

illuminated and the driver may be aware of the steering being 'heavier' than usual.

www.JagDocs.com

Page 748 of 3039

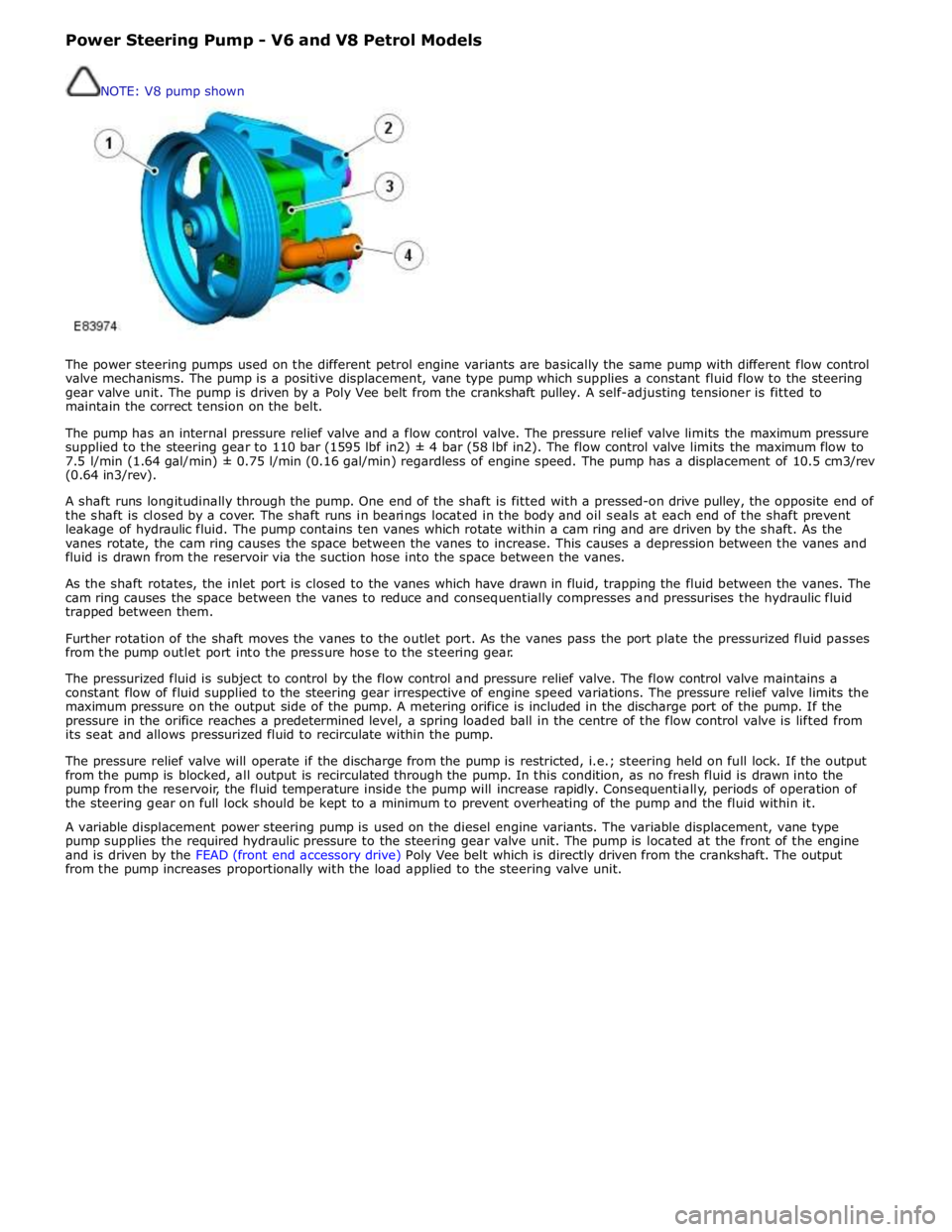

NOTE: V8 pump shown