air conditioning JAGUAR XFR 2010 1.G Owner's Manual

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 2010, Model line: XFR, Model: JAGUAR XFR 2010 1.GPages: 3039, PDF Size: 58.49 MB

Page 1149 of 3039

Published: 19-Nov-2013

Engine Cooling - V8 5.0L Petrol/V8 S/C 5.0L Petrol - Cooling Module Vehicles

With: Supercharger

Removal and Installation

Removal

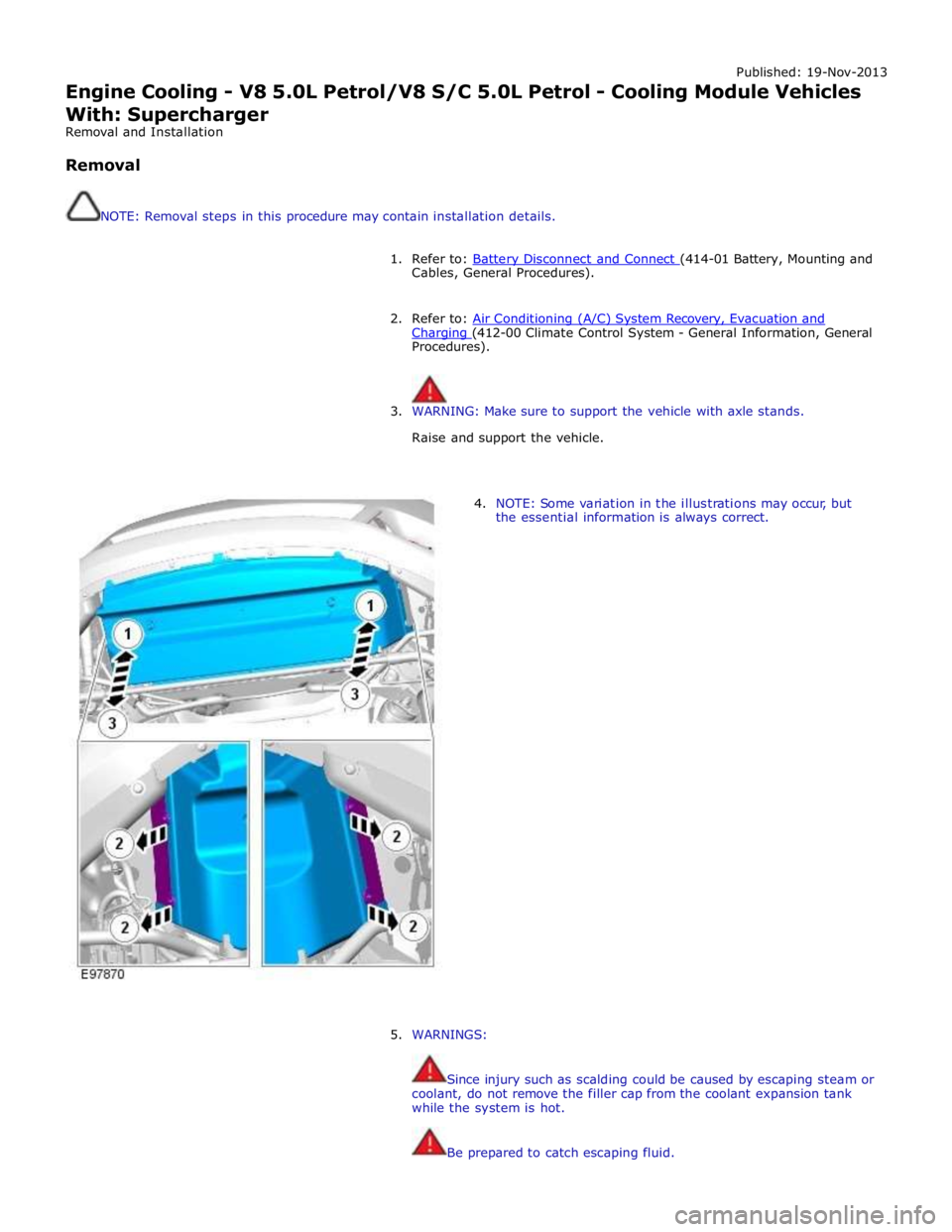

NOTE: Removal steps in this procedure may contain installation details.

1. Refer to: Battery Disconnect and Connect (414-01 Battery, Mounting and Cables, General Procedures).

2. Refer to: Air Conditioning (A/C) System Recovery, Evacuation and Charging (412-00 Climate Control System - General Information, General Procedures).

3. WARNING: Make sure to support the vehicle with axle stands.

Raise and support the vehicle.

4. NOTE: Some variation in the illustrations may occur, but

the essential information is always correct.

5. WARNINGS:

Since injury such as scalding could be caused by escaping steam or

coolant, do not remove the filler cap from the coolant expansion tank

while the system is hot.

Be prepared to catch escaping fluid.

Page 1162 of 3039

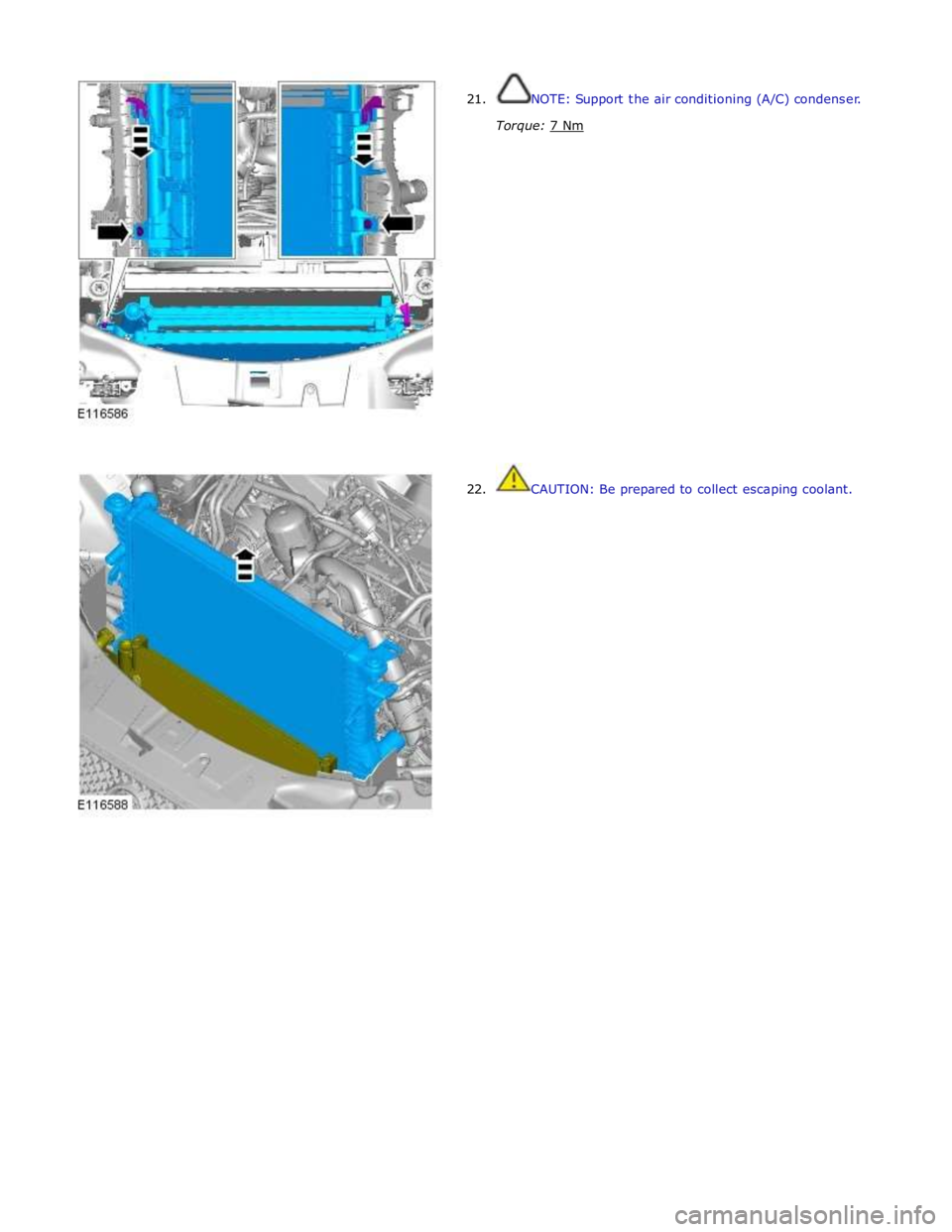

21.

22. NOTE: Support the air conditioning (A/C) condenser.

Torque: 7 Nm

CAUTION: Be prepared to collect escaping coolant.

Page 1172 of 3039

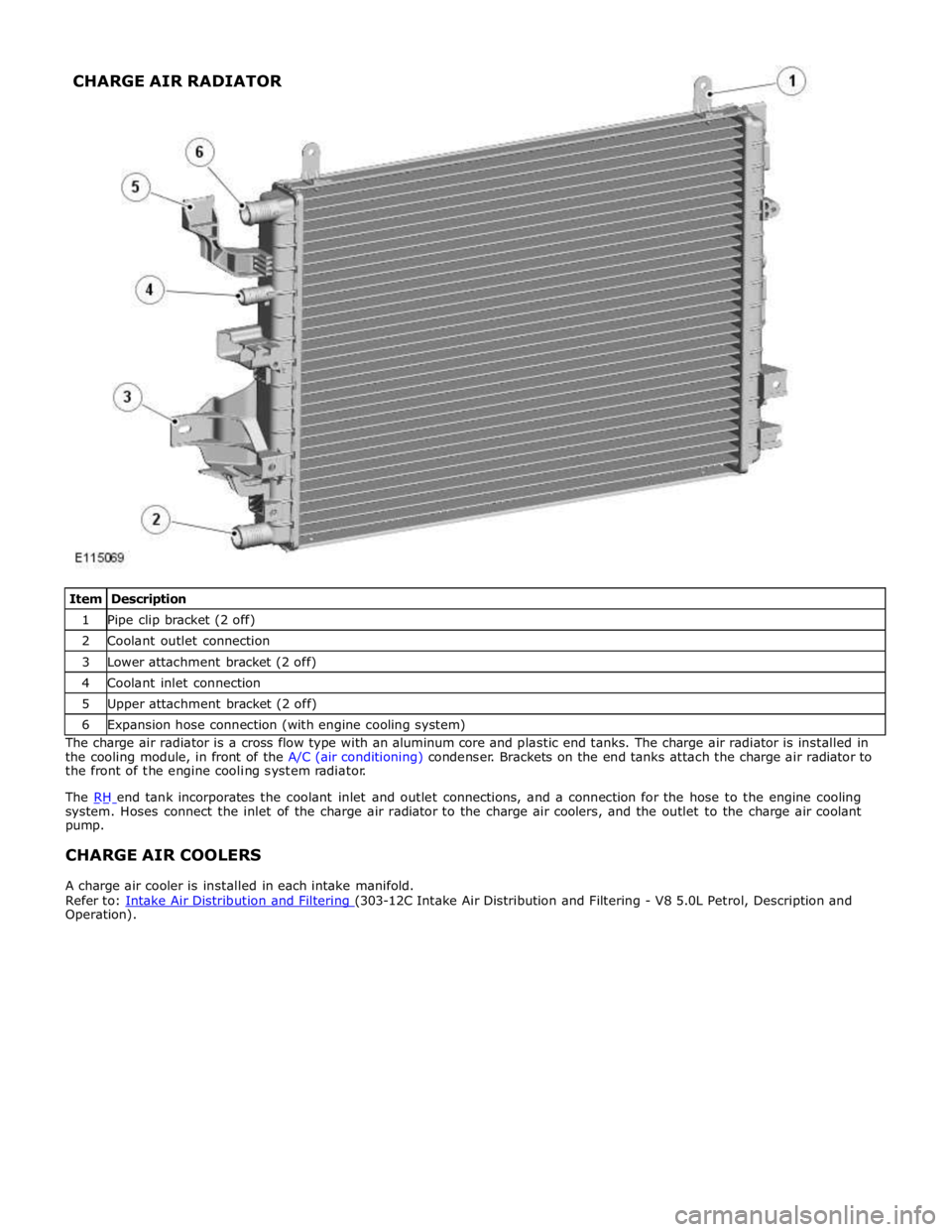

1 Pipe clip bracket (2 off) 2 Coolant outlet connection 3 Lower attachment bracket (2 off) 4 Coolant inlet connection 5 Upper attachment bracket (2 off) 6 Expansion hose connection (with engine cooling system) The charge air radiator is a cross flow type with an aluminum core and plastic end tanks. The charge air radiator is installed in

the cooling module, in front of the A/C (air conditioning) condenser. Brackets on the end tanks attach the charge air radiator to

the front of the engine cooling system radiator.

The RH end tank incorporates the coolant inlet and outlet connections, and a connection for the hose to the engine cooling system. Hoses connect the inlet of the charge air radiator to the charge air coolers, and the outlet to the charge air coolant

pump.

CHARGE AIR COOLERS

A charge air cooler is installed in each intake manifold.

Refer to: Intake Air Distribution and Filtering (303-12C Intake Air Distribution and Filtering - V8 5.0L Petrol, Description and Operation). CHARGE AIR RADIATOR

Page 1176 of 3039

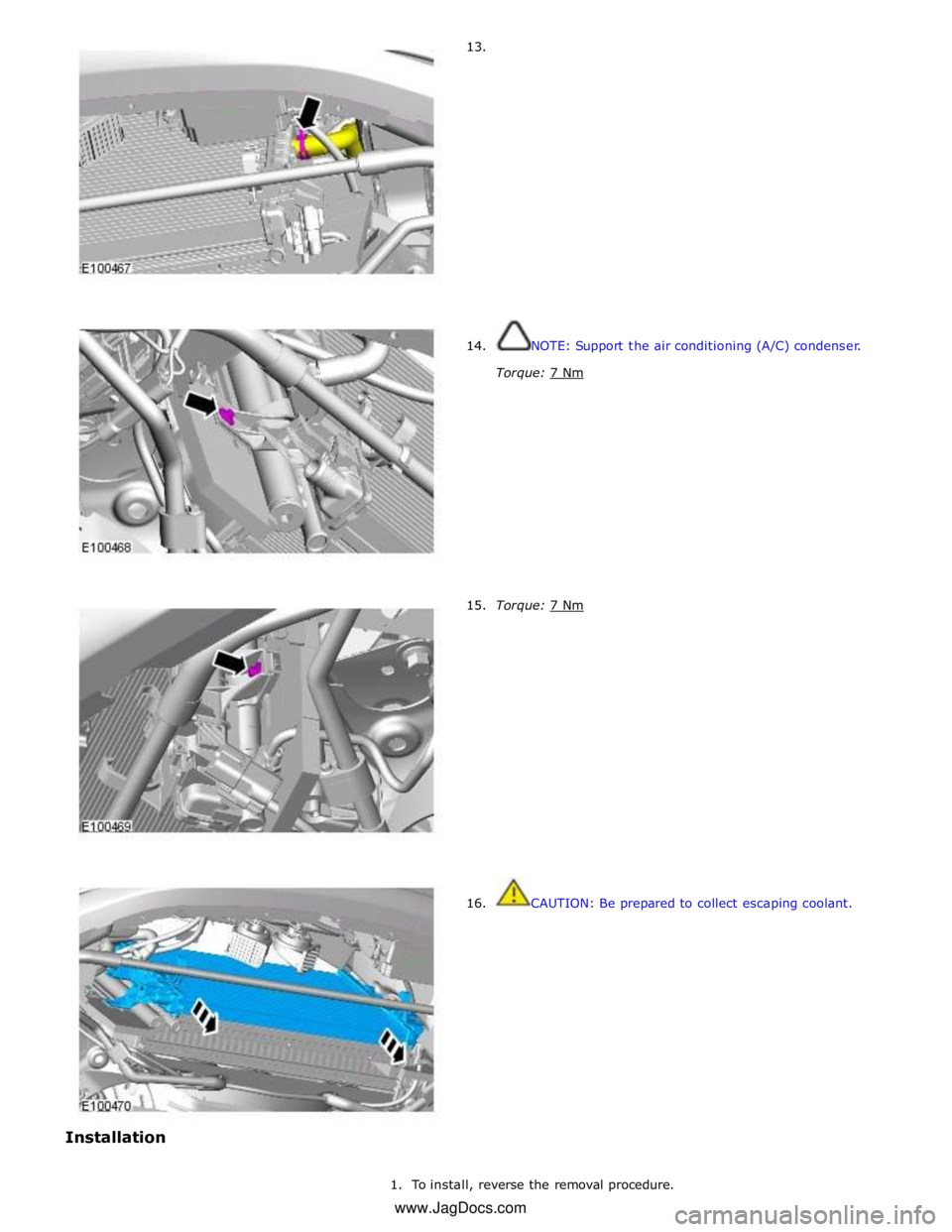

Installation 13.

14.

15.

16.

NOTE: Support the air conditioning (A/C) condenser.

Torque: 7 Nm

Torque: 7 Nm

CAUTION: Be prepared to collect escaping coolant.

1. To install, reverse the removal procedure. www.JagDocs.com

Page 1247 of 3039

Published: 11-May-2011

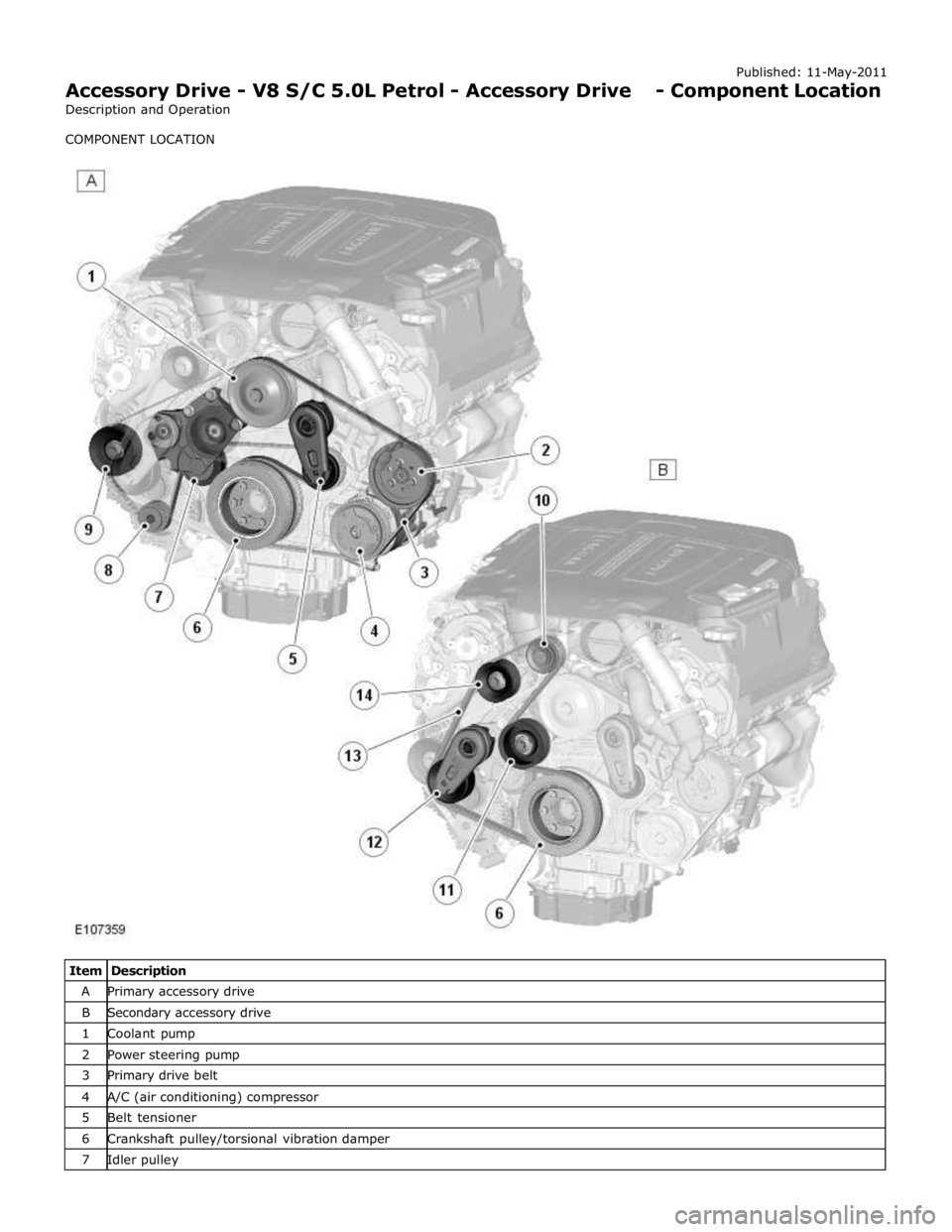

Accessory Drive - V8 S/C 5.0L Petrol - Accessory Drive - Component Location

Description and Operation

COMPONENT LOCATION

Item Description A Primary accessory drive B Secondary accessory drive 1 Coolant pump 2 Power steering pump 3 Primary drive belt 4 A/C (air conditioning) compressor 5 Belt tensioner 6 Crankshaft pulley/torsional vibration damper 7 Idler pulley

Page 1249 of 3039

Published: 11-May-2011

Accessory Drive - V8 S/C 5.0L Petrol - Accessory Drive - Overview

Description and Operation

OVERVIEW

The accessory drive is a belt system powered by a pulley attached to the front of the crankshaft. The crankshaft pulley, which

incorporates a torsional vibration damper, drives two drive belts. An automatic belt tensioner in each belt run maintains the

drive belt at the correct tension. Together with idler pulleys, the belt tensioners also guide the drive belts clear of obstructions

and set the correct 'wrap-around' of the accessory component drive pulleys to ensure a slip-free drive.

PRIMARY DRIVE BELT

The primary drive belt is a six-ribbed poly-V belt that drives the:

Coolant pump

Power steering pump

A/C (air conditioning) compressor

Generator.

SECONDARY DRIVE BELT

The secondary drive belt is an eight-ribbed poly-V belt that drives the SC (supercharger).

BELT TENSIONERS

Each belt tensioner consists of an idler pulley on the end of a spring loaded pivot arm. The pivot arms can be turned manually

for removal and installation of the drive belts.

Each belt tensioners is calibrated to automatically maintain the correct tension in the related drive belt.

Page 1371 of 3039

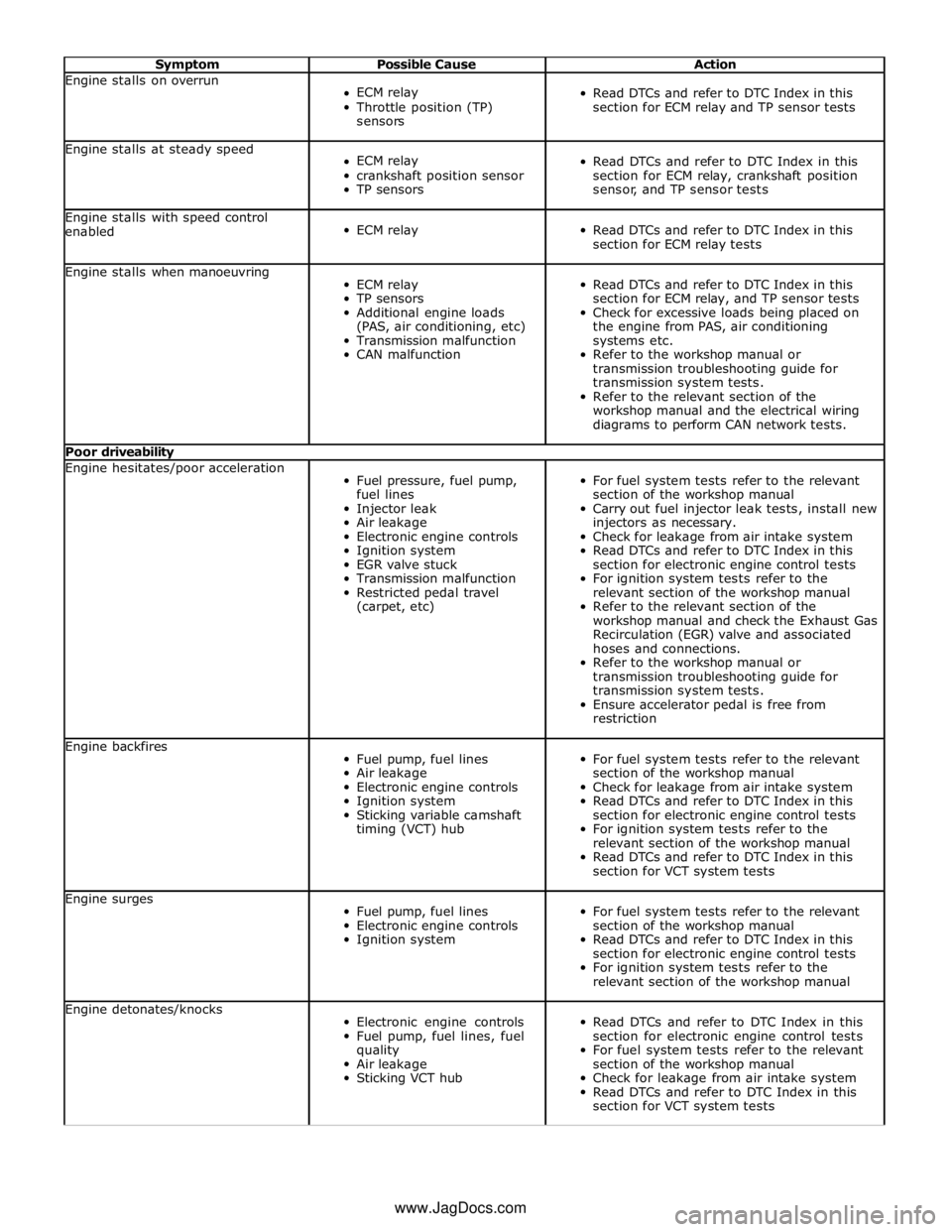

Symptom Possible Cause Action Engine stalls on overrun

ECM relay

Throttle position (TP)

sensors

Read DTCs and refer to DTC Index in this

section for ECM relay and TP sensor tests Engine stalls at steady speed

ECM relay

crankshaft position sensor

TP sensors

Read DTCs and refer to DTC Index in this

section for ECM relay, crankshaft position

sensor, and TP sensor tests Engine stalls with speed control

enabled

ECM relay

Read DTCs and refer to DTC Index in this

section for ECM relay tests Engine stalls when manoeuvring

ECM relay

TP sensors

Additional engine loads

(PAS, air conditioning, etc)

Transmission malfunction

CAN malfunction

Read DTCs and refer to DTC Index in this

section for ECM relay, and TP sensor tests

Check for excessive loads being placed on

the engine from PAS, air conditioning

systems etc.

Refer to the workshop manual or

transmission troubleshooting guide for

transmission system tests.

Refer to the relevant section of the

workshop manual and the electrical wiring

diagrams to perform CAN network tests. Poor driveability Engine hesitates/poor acceleration

Fuel pressure, fuel pump,

fuel lines

Injector leak

Air leakage

Electronic engine controls

Ignition system

EGR valve stuck

Transmission malfunction

Restricted pedal travel

(carpet, etc)

For fuel system tests refer to the relevant

section of the workshop manual

Carry out fuel injector leak tests, install new

injectors as necessary.

Check for leakage from air intake system

Read DTCs and refer to DTC Index in this

section for electronic engine control tests

For ignition system tests refer to the

relevant section of the workshop manual

Refer to the relevant section of the

workshop manual and check the Exhaust Gas

Recirculation (EGR) valve and associated

hoses and connections.

Refer to the workshop manual or

transmission troubleshooting guide for

transmission system tests.

Ensure accelerator pedal is free from

restriction Engine backfires

Fuel pump, fuel lines

Air leakage

Electronic engine controls

Ignition system

Sticking variable camshaft

timing (VCT) hub

For fuel system tests refer to the relevant

section of the workshop manual

Check for leakage from air intake system

Read DTCs and refer to DTC Index in this

section for electronic engine control tests

For ignition system tests refer to the

relevant section of the workshop manual

Read DTCs and refer to DTC Index in this

section for VCT system tests Engine surges

Fuel pump, fuel lines

Electronic engine controls

Ignition system

For fuel system tests refer to the relevant

section of the workshop manual

Read DTCs and refer to DTC Index in this

section for electronic engine control tests

For ignition system tests refer to the

relevant section of the workshop manual Engine detonates/knocks

Electronic engine controls

Fuel pump, fuel lines, fuel

quality

Air leakage

Sticking VCT hub

Read DTCs and refer to DTC Index in this

section for electronic engine control tests

For fuel system tests refer to the relevant

section of the workshop manual

Check for leakage from air intake system

Read DTCs and refer to DTC Index in this

section for VCT system tests www.JagDocs.com

Page 1663 of 3039

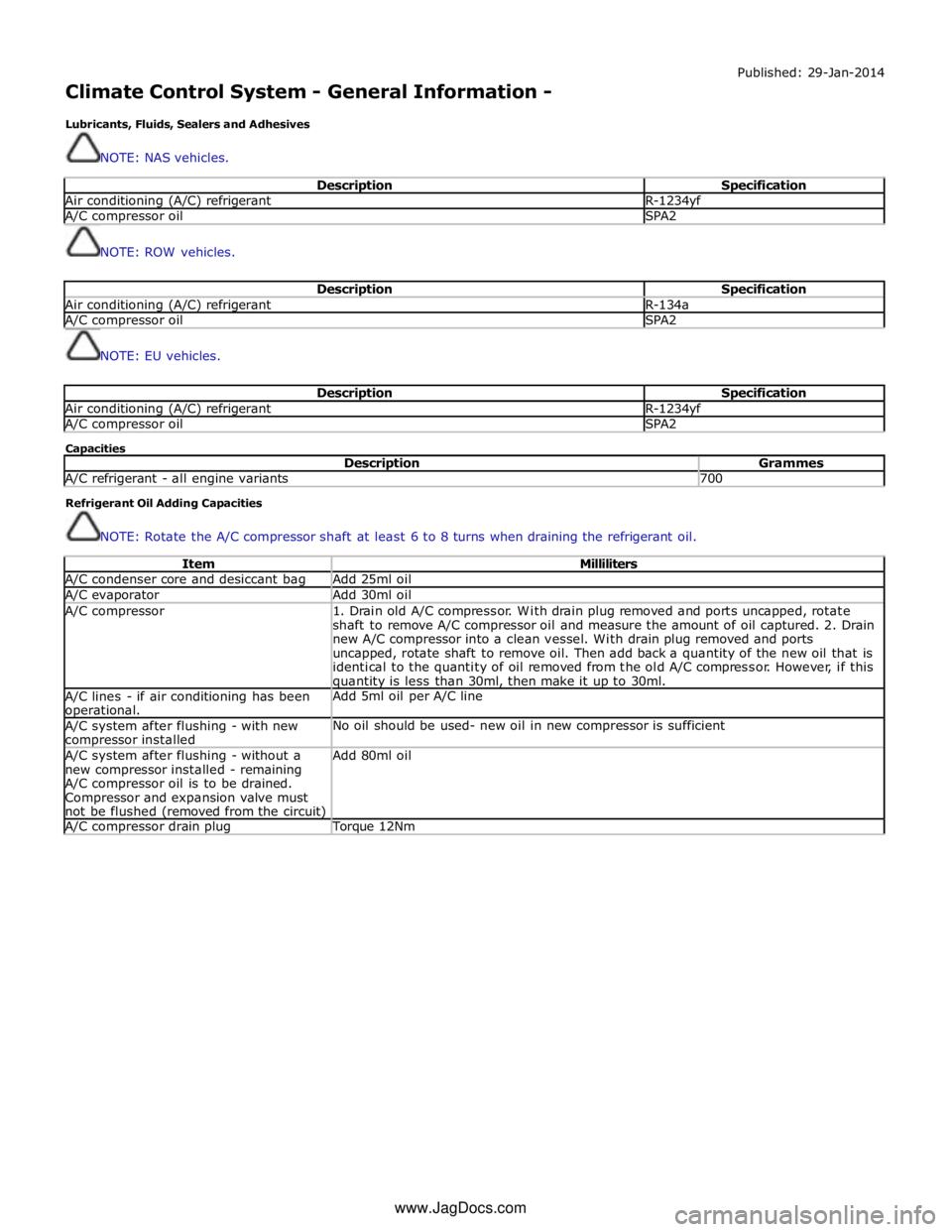

Climate Control System - General Information -

Lubricants, Fluids, Sealers and Adhesives

NOTE: NAS vehicles. Published: 29-Jan-2014

Description Specification Air conditioning (A/C) refrigerant R-1234yf A/C compressor oil SPA2

NOTE: ROW vehicles.

Description Specification Air conditioning (A/C) refrigerant R-134a A/C compressor oil SPA2

NOTE: EU vehicles.

Description Specification Air conditioning (A/C) refrigerant R-1234yf A/C compressor oil SPA2 Capacities

Description Grammes A/C refrigerant - all engine variants 700 Refrigerant Oil Adding Capacities

NOTE: Rotate the A/C compressor shaft at least 6 to 8 turns when draining the refrigerant oil.

Item Milliliters A/C condenser core and desiccant bag Add 25ml oil A/C evaporator Add 30ml oil A/C compressor

1. Drain old A/C compressor. With drain plug removed and ports uncapped, rotate

shaft to remove A/C compressor oil and measure the amount of oil captured. 2. Drain

new A/C compressor into a clean vessel. With drain plug removed and ports

uncapped, rotate shaft to remove oil. Then add back a quantity of the new oil that is

identical to the quantity of oil removed from the old A/C compressor. However, if this quantity is less than 30ml, then make it up to 30ml. A/C lines - if air conditioning has been operational. Add 5ml oil per A/C line A/C system after flushing - with new compressor installed No oil should be used- new oil in new compressor is sufficient A/C system after flushing - without a

new compressor installed - remaining

A/C compressor oil is to be drained.

Compressor and expansion valve must

not be flushed (removed from the circuit) Add 80ml oil A/C compressor drain plug Torque 12Nm www.JagDocs.com

Page 1664 of 3039

Published: 11-Jul-2014

Climate Control System - General Information - Climate Control System

Diagnosis and Testing

Principles of Operation

For a detailed description of the Climate Control System, refer to the relevant Description and Operation sections in the

Workshop Manual. REFER to:

Air Distribution and Filtering (412-01 Climate Control, Description and Operation), Air Distribution and Filtering (412-01 Climate Control, Description and Operation), Air Distribution and Filtering (412-01 Climate Control, Description and Operation), Heating and Ventilation (412-01 Climate Control, Description and Operation), Heating and Ventilation (412-01 Climate Control, Description and Operation), Heating and Ventilation (412-01 Climate Control, Description and Operation), Air Conditioning (412-01 Climate Control, Description and Operation), Air Conditioning (412-01 Climate Control, Description and Operation), Air Conditioning (412-01 Climate Control, Description and Operation), Control Components (412-01 Climate Control, Description and Operation), Control Components (412-01 Climate Control, Description and Operation), Control Components (412-01 Climate Control, Description and Operation), Electric Booster Heater (412-02 Auxiliary Climate Control, Description and Operation), Electric Booster Heater (412-02 Auxiliary Climate Control, Description and Operation), Electric Booster Heater (412-02 Auxiliary Climate Control, Description and Operation).

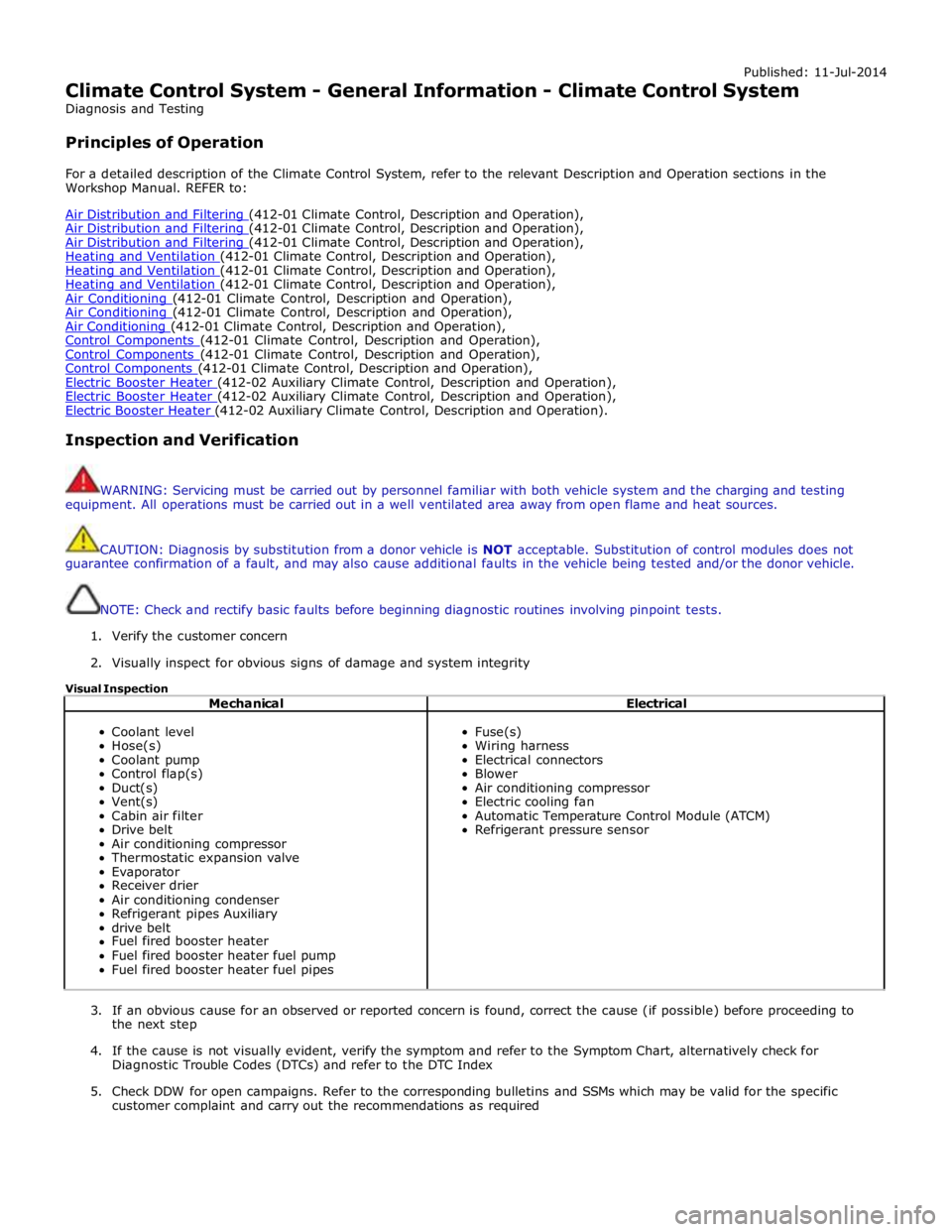

Inspection and Verification

WARNING: Servicing must be carried out by personnel familiar with both vehicle system and the charging and testing

equipment. All operations must be carried out in a well ventilated area away from open flame and heat sources.

CAUTION: Diagnosis by substitution from a donor vehicle is NOT acceptable. Substitution of control modules does not

guarantee confirmation of a fault, and may also cause additional faults in the vehicle being tested and/or the donor vehicle.

NOTE: Check and rectify basic faults before beginning diagnostic routines involving pinpoint tests.

1. Verify the customer concern

2. Visually inspect for obvious signs of damage and system integrity

Visual Inspection

Mechanical Electrical

Coolant level

Hose(s)

Coolant pump

Control flap(s)

Duct(s)

Vent(s)

Cabin air filter

Drive belt

Air conditioning compressor

Thermostatic expansion valve

Evaporator

Receiver drier

Air conditioning condenser

Refrigerant pipes Auxiliary

drive belt

Fuel fired booster heater

Fuel fired booster heater fuel pump

Fuel fired booster heater fuel pipes

Fuse(s)

Wiring harness

Electrical connectors

Blower

Air conditioning compressor

Electric cooling fan

Automatic Temperature Control Module (ATCM)

Refrigerant pressure sensor

3. If an obvious cause for an observed or reported concern is found, correct the cause (if possible) before proceeding to

the next step

4. If the cause is not visually evident, verify the symptom and refer to the Symptom Chart, alternatively check for

Diagnostic Trouble Codes (DTCs) and refer to the DTC Index

5. Check DDW for open campaigns. Refer to the corresponding bulletins and SSMs which may be valid for the specific

customer complaint and carry out the recommendations as required

Page 1665 of 3039

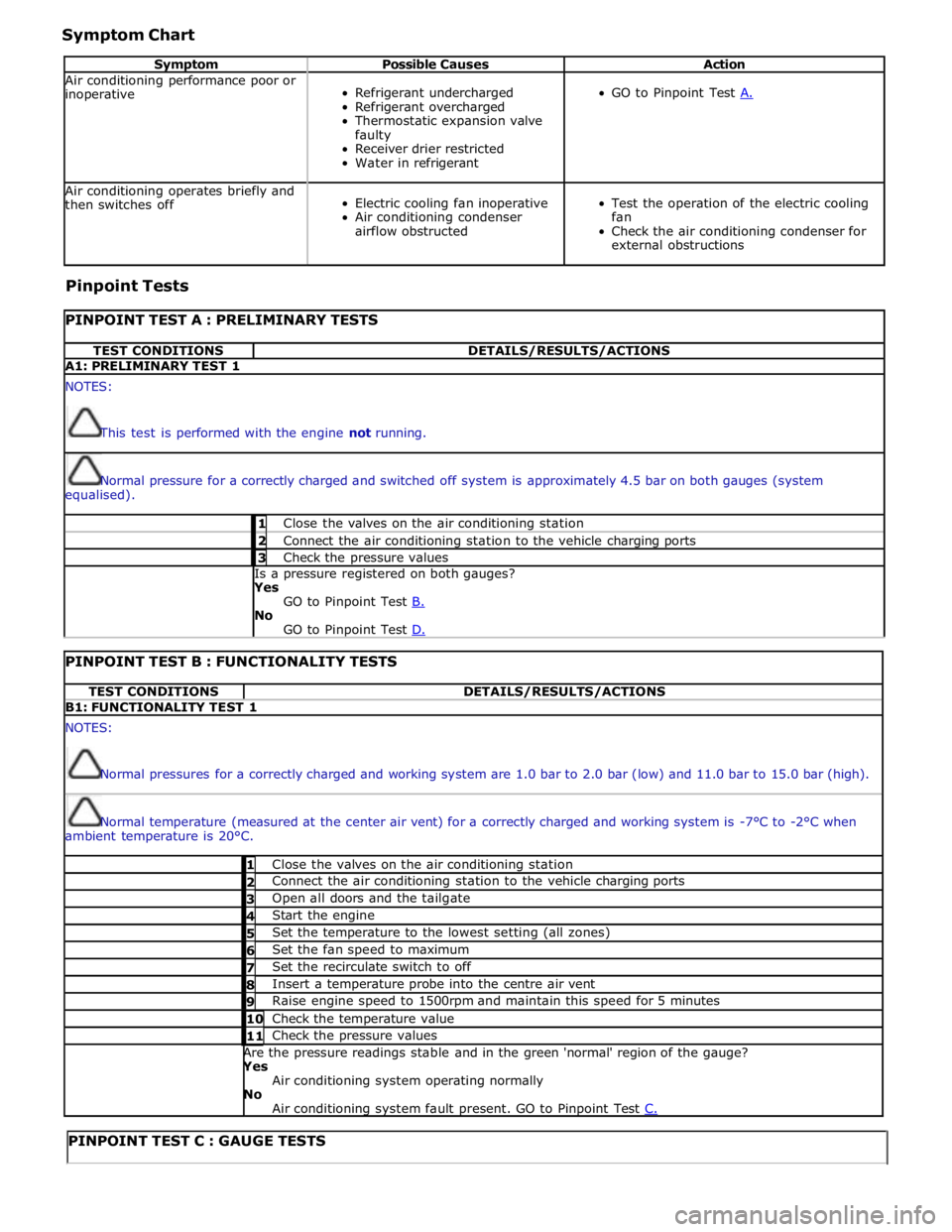

Symptom Chart

Symptom Possible Causes Action Air conditioning performance poor or

inoperative

Refrigerant undercharged

Refrigerant overcharged

Thermostatic expansion valve

faulty

Receiver drier restricted

Water in refrigerant

GO to Pinpoint Test A. Air conditioning operates briefly and

then switches off

Electric cooling fan inoperative

Air conditioning condenser

airflow obstructed

Test the operation of the electric cooling

fan

Check the air conditioning condenser for

external obstructions Pinpoint Tests

PINPOINT TEST A : PRELIMINARY TESTS TEST CONDITIONS DETAILS/RESULTS/ACTIONS A1: PRELIMINARY TEST 1 NOTES:

This test is performed with the engine not running.

Normal pressure for a correctly charged and switched off system is approximately 4.5 bar on both gauges (system

equalised). 1 Close the valves on the air conditioning station 2 Connect the air conditioning station to the vehicle charging ports 3 Check the pressure values Is a pressure registered on both gauges? Yes

GO to Pinpoint Test B. No

GO to Pinpoint Test D.

PINPOINT TEST B : FUNCTIONALITY TESTS TEST CONDITIONS DETAILS/RESULTS/ACTIONS B1: FUNCTIONALITY TEST 1 NOTES:

Normal pressures for a correctly charged and working system are 1.0 bar to 2.0 bar (low) and 11.0 bar to 15.0 bar (high).

Normal temperature (measured at the center air vent) for a correctly charged and working system is -7°C to -2°C when

ambient temperature is 20°C. 1 Close the valves on the air conditioning station 2 Connect the air conditioning station to the vehicle charging ports 3 Open all doors and the tailgate 4 Start the engine 5 Set the temperature to the lowest setting (all zones) 6 Set the fan speed to maximum 7 Set the recirculate switch to off 8 Insert a temperature probe into the centre air vent 9 Raise engine speed to 1500rpm and maintain this speed for 5 minutes 10 Check the temperature value 11 Check the pressure values Are the pressure readings stable and in the green 'normal' region of the gauge? Yes

Air conditioning system operating normally No

Air conditioning system fault present. GO to Pinpoint Test C.

PINPOINT TEST C : GAUGE TESTS