battery monitoring module JAGUAR XFR 2010 1.G Owner's Manual

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 2010, Model line: XFR, Model: JAGUAR XFR 2010 1.GPages: 3039, PDF Size: 58.49 MB

Page 460 of 3039

Measure the resistance between: C4MC42, harness side Battery Pin 1 Positive terminal Is the resistance less than 10,000 ohms?

Yes

GO to D8. No

GO to D9. D5: CHECK WHETHER THE SHORT CIRCUIT IS IN THE HARNESS OR THE MODULE 1 Disconnect the Tire Pressure Monitoring System module connector, C3MC39A.

2 Measure the resistance between: C4MC42, harness side Battery Pin 2 Negative terminal Is the resistance less than 10,000 ohms?

Yes

REPAIR the short circuit. This circuit contains intermediate

connector, C44-W. For additional information, refer to the wiring

diagram. Clear the DTC and run an On Demand Self Test (ODST)

using the manufacturer approved diagnostic system to confirm

rectification.

No

INSTALL a new Tire Pressure Monitoring System module. REFER to:

Tire Pressure Monitoring System (TPMS) Module (204-04 Wheels and Tires, Removal and Installation). D6: CHECK WHETHER THE SHORT CIRCUIT IS IN THE HARNESS OR THE MODULE 1 Disconnect the Tire Pressure Monitoring System module connector, C3MC39A. 2 Measure the resistance between: C4MC42, harness side Battery Pin 2 Positive terminal Is the resistance less than 10,000 ohms?

Yes

REPAIR the short circuit. This circuit contains intermediate

connector, C44-W. For additional information, refer to the wiring

diagram. Clear the DTC and run an On Demand Self Test (ODST)

using the manufacturer approved diagnostic system to confirm

rectification.

No

INSTALL a new Tire Pressure Monitoring System module. REFER to:

Tire Pressure Monitoring System (TPMS) Module (204-04 Wheels and Tires, Removal and Installation). D7: CHECK WHETHER THE SHORT CIRCUIT IS IN THE HARNESS OR THE MODULE 1 Disconnect the Tire Pressure Monitoring System module connector, C3MC39A.

Page 461 of 3039

Measure the resistance between: C4MC42, harness side Battery Pin 1 Negative terminal Is the resistance less than 10,000 ohms?

Yes

REPAIR the short circuit. This circuit contains intermediate

connector, C44-W. For additional information, refer to the wiring

diagram. Clear the DTC and run an On Demand Self Test (ODST)

using the manufacturer approved diagnostic system to confirm

rectification.

No

INSTALL a new Tire Pressure Monitoring System module. REFER to:

Tire Pressure Monitoring System (TPMS) Module (204-04 Wheels and Tires, Removal and Installation). D8: CHECK WHETHER THE SHORT CIRCUIT IS IN THE HARNESS OR THE MODULE 1 Disconnect the Tire Pressure Monitoring System module connector, C3MC39A.

2 Measure the resistance between: C4MC42, harness side Battery Pin 1 Positive terminal Is the resistance less than 10,000 ohms?

Yes

REPAIR the short circuit. This circuit contains intermediate

connector, C44-W. For additional information, refer to the wiring

diagram. Clear the DTC and run an On Demand Self Test (ODST)

using the manufacturer approved diagnostic system to confirm

rectification.

No

INSTALL a new Tire Pressure Monitoring System module. REFER to:

Tire Pressure Monitoring System (TPMS) Module (204-04 Wheels and Tires, Removal and Installation). D9: CHECK THE INITIATOR RETURN CIRCUIT FOR HIGH RESISTANCE 1 Measure the resistance between: C3MC39A, harness side C4MC42, harness side Pin 6 Pin 2 Is the resistance greater than 5 ohms?

Yes

REPAIR the high resistance circuit. This circuit contains

intermediate connector, C44-W. For additional information, refer to

the wiring diagram. Clear the DTC and run an On Demand Self Test

(ODST) using the manufacturer approved diagnostic system to

confirm rectification.

No

GO to E1. D10: CHECK THE INITIATOR CIRCUIT FOR HIGH RESISTANCE

Page 463 of 3039

No

GO to E9. E5: CHECK WHETHER THE SHORT CIRCUIT IS IN THE HARNESS OR THE MODULE 1 Disconnect the Tire Pressure Monitoring System module connector, C3MC39A.

2 Measure the resistance between: C4MC43, harness side Battery Pin 2 Negative terminal Is the resistance less than 10,000 ohms?

Yes

REPAIR the short circuit. This circuit contains intermediate

connector, C44-Y. For additional information, refer to the wiring

diagram. Clear the DTC and run an On Demand Self Test (ODST)

using the manufacturer approved diagnostic system to confirm

rectification.

No

INSTALL a new Tire Pressure Monitoring System module. REFER to:

Tire Pressure Monitoring System (TPMS) Module (204-04 Wheels and Tires, Removal and Installation). E6: CHECK WHETHER THE SHORT CIRCUIT IS IN THE HARNESS OR THE MODULE 1 Disconnect the Tire Pressure Monitoring System module connector, C3MC39A.

2 Measure the resistance between: C4MC43, harness side Battery Pin 2 Positive terminal Is the resistance less than 10,000 ohms?

Yes

REPAIR the short circuit. This circuit contains intermediate

connector, C44-Y. For additional information, refer to the wiring

diagram. Clear the DTC and run an On Demand Self Test (ODST)

using the manufacturer approved diagnostic system to confirm

rectification.

No

INSTALL a new Tire Pressure Monitoring System module. REFER to:

Tire Pressure Monitoring System (TPMS) Module (204-04 Wheels and Tires, Removal and Installation). E7: CHECK WHETHER THE SHORT CIRCUIT IS IN THE HARNESS OR THE MODULE 1 Disconnect the Tire Pressure Monitoring System module connector, C3MC39A.

Page 464 of 3039

Measure the resistance between: C4MC43, harness side Battery Pin 1 Negative terminal Is the resistance less than 10,000 ohms?

Yes

REPAIR the short circuit. This circuit contains intermediate

connector, C44-Y. For additional information, refer to the wiring

diagram. Clear the DTC and run an On Demand Self Test (ODST)

using the manufacturer approved diagnostic system to confirm

rectification.

No

INSTALL a new Tire Pressure Monitoring System module. REFER to:

Tire Pressure Monitoring System (TPMS) Module (204-04 Wheels and Tires, Removal and Installation). E8: CHECK WHETHER THE SHORT CIRCUIT IS IN THE HARNESS OR THE MODULE 1 Disconnect the Tire Pressure Monitoring System module connector, C3MC39A.

2 Measure the resistance between: C4MC43, harness side Battery Pin 1 Positive terminal Is the resistance less than 10,000 ohms?

Yes

REPAIR the short circuit. This circuit contains intermediate

connector, C44-Y. For additional information, refer to the wiring

diagram. Clear the DTC and run an On Demand Self Test (ODST)

using the manufacturer approved diagnostic system to confirm

rectification.

No

INSTALL a new Tire Pressure Monitoring System module. REFER to:

Tire Pressure Monitoring System (TPMS) Module (204-04 Wheels and Tires, Removal and Installation). E9: CHECK THE INITIATOR CIRCUIT FOR HIGH RESISTANCE 1 Measure the resistance between: C3MC39A, harness side C4MC43, harness side Pin 8 Pin 2 Is the resistance greater than 5 ohms?

Yes

REPAIR the high resistance circuit. This circuit contains

intermediate connector, C44-Y. For additional information, refer to

the wiring diagram. Clear the DTC and run an On Demand Self Test

(ODST) using the manufacturer approved diagnostic system to

confirm rectification.

No

GO to E10. E10: CHECK THE INITIATOR CIRCUIT FOR HIGH RESISTANCE www.JagDocs.com

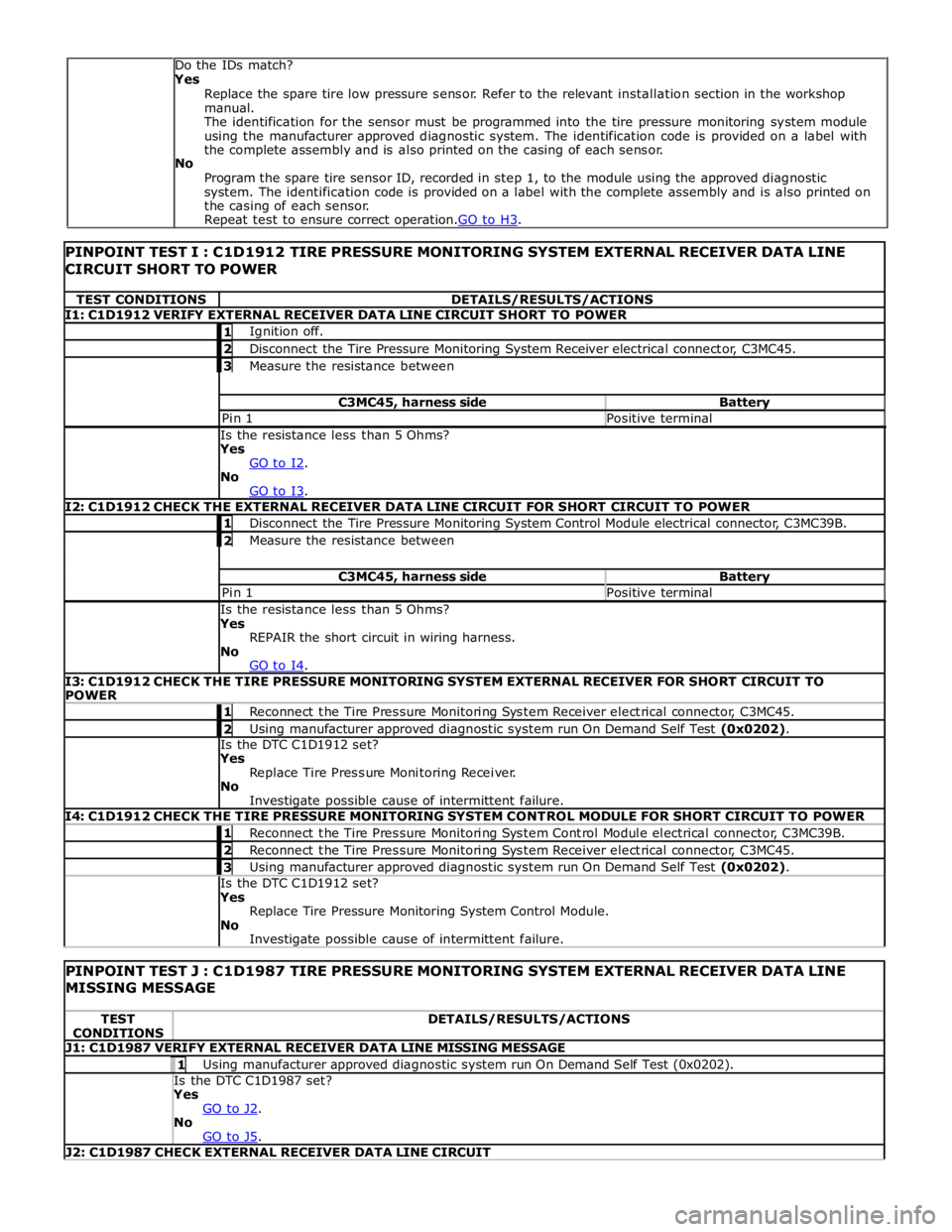

Page 467 of 3039

TEST CONDITIONS DETAILS/RESULTS/ACTIONS I1: C1D1912 VERIFY EXTERNAL RECEIVER DATA LINE CIRCUIT SHORT TO POWER 1 Ignition off. 2 Disconnect the Tire Pressure Monitoring System Receiver electrical connector, C3MC45. 3 Measure the resistance between C3MC45, harness side Battery Pin 1 Positive terminal Is the resistance less than 5 Ohms?

Yes

GO to I2. No

GO to I3. I2: C1D1912 CHECK THE EXTERNAL RECEIVER DATA LINE CIRCUIT FOR SHORT CIRCUIT TO POWER 1 Disconnect the Tire Pressure Monitoring System Control Module electrical connector, C3MC39B. 2 Measure the resistance between C3MC45, harness side Battery Pin 1 Positive terminal Is the resistance less than 5 Ohms?

Yes

REPAIR the short circuit in wiring harness.

No

GO to I4. I3: C1D1912 CHECK THE TIRE PRESSURE MONITORING SYSTEM EXTERNAL RECEIVER FOR SHORT CIRCUIT TO

POWER 1 Reconnect the Tire Pressure Monitoring System Receiver electrical connector, C3MC45. 2 Using manufacturer approved diagnostic system run On Demand Self Test (0x0202). Is the DTC C1D1912 set?

Yes

Replace Tire Pressure Monitoring Receiver.

No

Investigate possible cause of intermittent failure. I4: C1D1912 CHECK THE TIRE PRESSURE MONITORING SYSTEM CONTROL MODULE FOR SHORT CIRCUIT TO POWER 1 Reconnect the Tire Pressure Monitoring System Control Module electrical connector, C3MC39B. 2 Reconnect the Tire Pressure Monitoring System Receiver electrical connector, C3MC45. 3 Using manufacturer approved diagnostic system run On Demand Self Test (0x0202). Is the DTC C1D1912 set?

Yes

Replace Tire Pressure Monitoring System Control Module.

No

Investigate possible cause of intermittent failure.

PINPOINT TEST J : C1D1987 TIRE PRESSURE MONITORING SYSTEM EXTERNAL RECEIVER DATA LINE

MISSING MESSAGE TEST

CONDITIONS DETAILS/RESULTS/ACTIONS J1: C1D1987 VERIFY EXTERNAL RECEIVER DATA LINE MISSING MESSAGE 1 Using manufacturer approved diagnostic system run On Demand Self Test (0x0202). Is the DTC C1D1987 set? Yes

GO to J2. No

GO to J5. J2: C1D1987 CHECK EXTERNAL RECEIVER DATA LINE CIRCUIT Do the IDs match?

Yes

Replace the spare tire low pressure sensor. Refer to the relevant installation section in the workshop

manual.

The identification for the sensor must be programmed into the tire pressure monitoring system module

using the manufacturer approved diagnostic system. The identification code is provided on a label with

the complete assembly and is also printed on the casing of each sensor.

No

Program the spare tire sensor ID, recorded in step 1, to the module using the approved diagnostic

system. The identification code is provided on a label with the complete assembly and is also printed on

the casing of each sensor.

Repeat test to ensure correct operation.GO to H3.

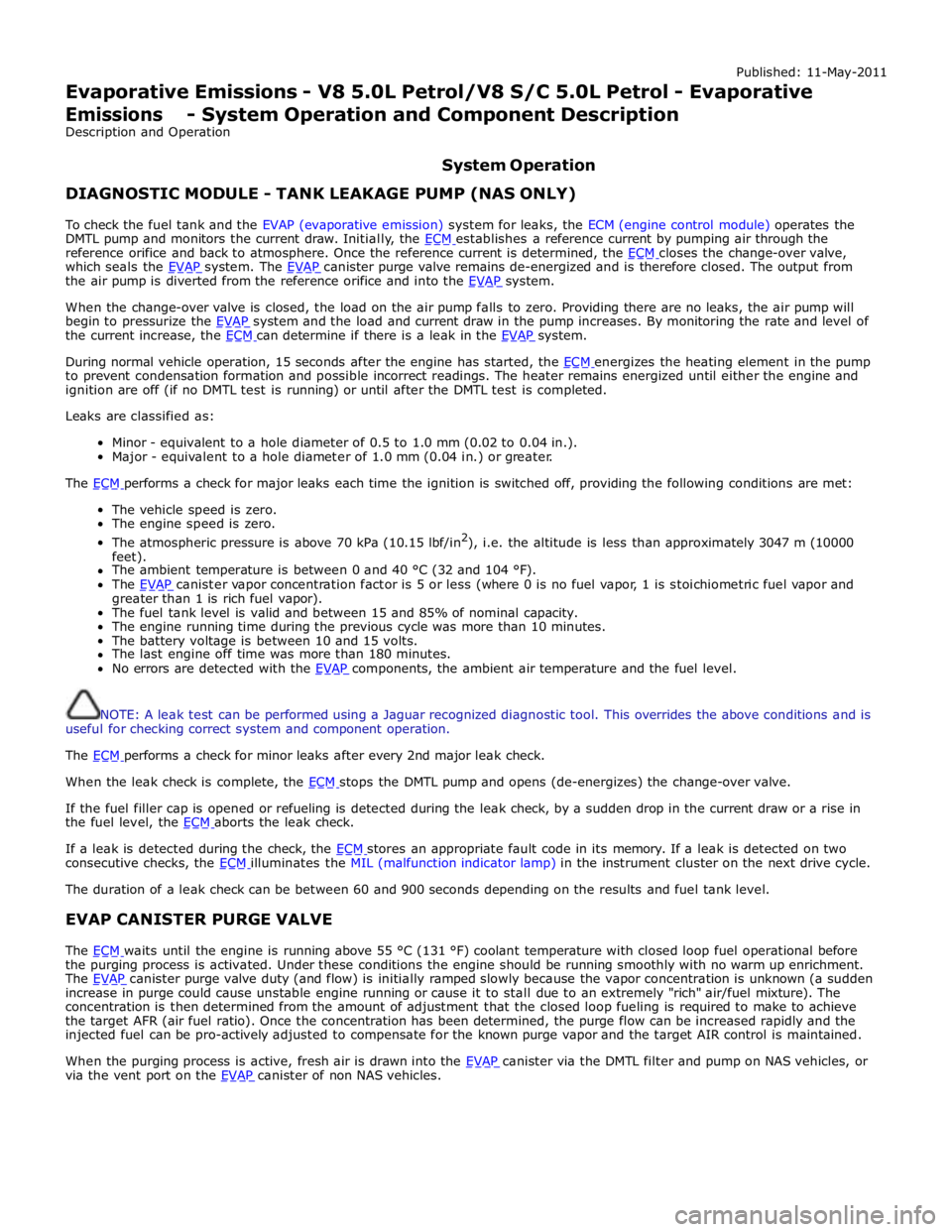

Page 1344 of 3039

Published: 11-May-2011

Evaporative Emissions - V8 5.0L Petrol/V8 S/C 5.0L Petrol - Evaporative Emissions - System Operation and Component Description

Description and Operation

System Operation DIAGNOSTIC MODULE - TANK LEAKAGE PUMP (NAS ONLY)

To check the fuel tank and the EVAP (evaporative emission) system for leaks, the ECM (engine control module) operates the

DMTL pump and monitors the current draw. Initially, the ECM establishes a reference current by pumping air through the reference orifice and back to atmosphere. Once the reference current is determined, the ECM closes the change-over valve, which seals the EVAP system. The EVAP canister purge valve remains de-energized and is therefore closed. The output from the air pump is diverted from the reference orifice and into the EVAP system.

When the change-over valve is closed, the load on the air pump falls to zero. Providing there are no leaks, the air pump will

begin to pressurize the EVAP system and the load and current draw in the pump increases. By monitoring the rate and level of the current increase, the ECM can determine if there is a leak in the EVAP system.

During normal vehicle operation, 15 seconds after the engine has started, the ECM energizes the heating element in the pump to prevent condensation formation and possible incorrect readings. The heater remains energized until either the engine and

ignition are off (if no DMTL test is running) or until after the DMTL test is completed.

Leaks are classified as:

Minor - equivalent to a hole diameter of 0.5 to 1.0 mm (0.02 to 0.04 in.).

Major - equivalent to a hole diameter of 1.0 mm (0.04 in.) or greater.

The ECM performs a check for major leaks each time the ignition is switched off, providing the following conditions are met: The vehicle speed is zero.

The engine speed is zero.

The atmospheric pressure is above 70 kPa (10.15 lbf/in2

), i.e. the altitude is less than approximately 3047 m (10000

feet).

The ambient temperature is between 0 and 40 °C (32 and 104 °F).

The EVAP canister vapor concentration factor is 5 or less (where 0 is no fuel vapor, 1 is stoichiometric fuel vapor and greater than 1 is rich fuel vapor).

The fuel tank level is valid and between 15 and 85% of nominal capacity.

The engine running time during the previous cycle was more than 10 minutes.

The battery voltage is between 10 and 15 volts.

The last engine off time was more than 180 minutes.

No errors are detected with the EVAP components, the ambient air temperature and the fuel level.

NOTE: A leak test can be performed using a Jaguar recognized diagnostic tool. This overrides the above conditions and is

useful for checking correct system and component operation.

The ECM performs a check for minor leaks after every 2nd major leak check.

When the leak check is complete, the ECM stops the DMTL pump and opens (de-energizes) the change-over valve.

If the fuel filler cap is opened or refueling is detected during the leak check, by a sudden drop in the current draw or a rise in

the fuel level, the ECM aborts the leak check.

If a leak is detected during the check, the ECM stores an appropriate fault code in its memory. If a leak is detected on two consecutive checks, the ECM illuminates the MIL (malfunction indicator lamp) in the instrument cluster on the next drive cycle. The duration of a leak check can be between 60 and 900 seconds depending on the results and fuel tank level.

EVAP CANISTER PURGE VALVE

The ECM waits until the engine is running above 55 °C (131 °F) coolant temperature with closed loop fuel operational before the purging process is activated. Under these conditions the engine should be running smoothly with no warm up enrichment.

The EVAP canister purge valve duty (and flow) is initially ramped slowly because the vapor concentration is unknown (a sudden increase in purge could cause unstable engine running or cause it to stall due to an extremely "rich" air/fuel mixture). The

concentration is then determined from the amount of adjustment that the closed loop fueling is required to make to achieve

the target AFR (air fuel ratio). Once the concentration has been determined, the purge flow can be increased rapidly and the

injected fuel can be pro-actively adjusted to compensate for the known purge vapor and the target AIR control is maintained.

When the purging process is active, fresh air is drawn into the EVAP canister via the DMTL filter and pump on NAS vehicles, or via the vent port on the EVAP canister of non NAS vehicles.

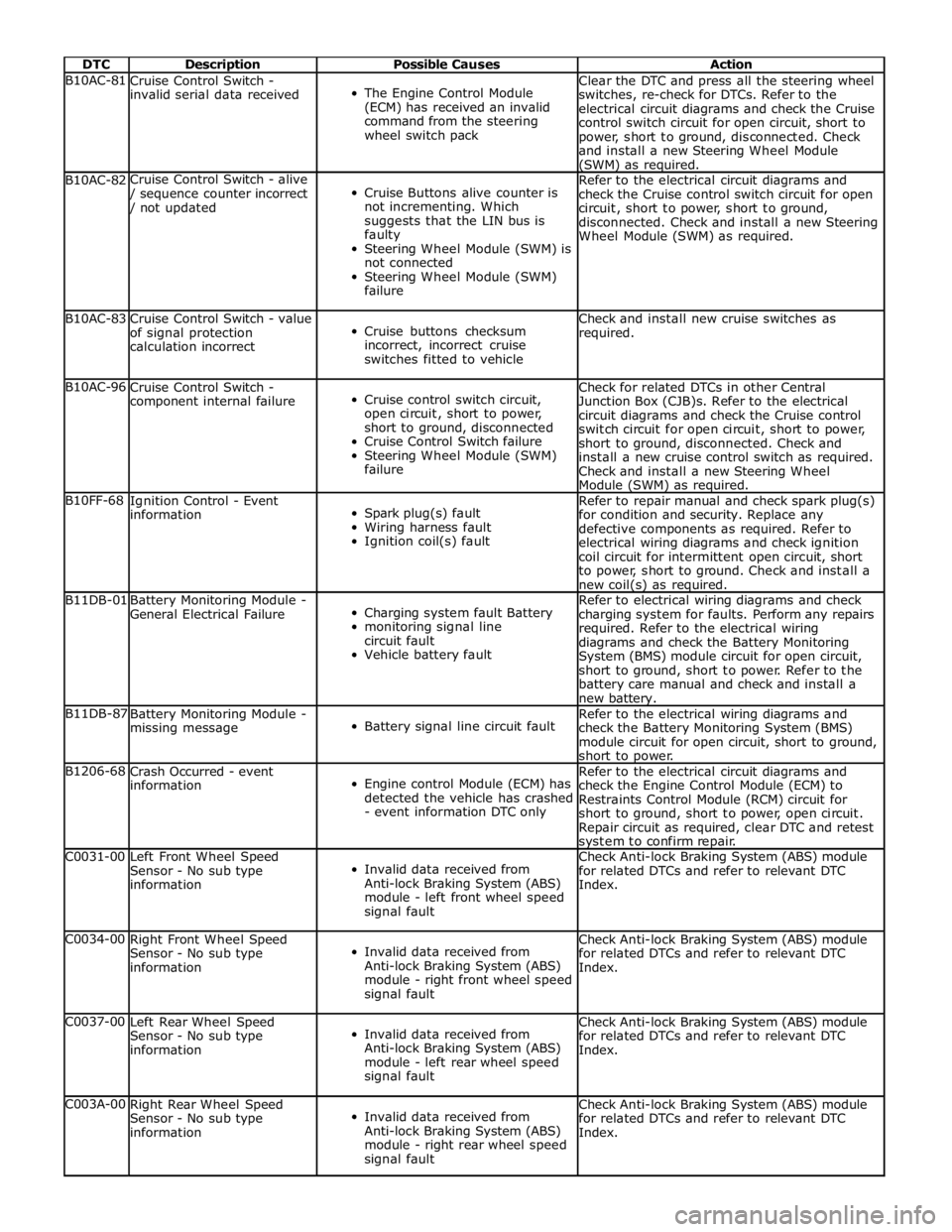

Page 1373 of 3039

DTC Description Possible Causes Action B10AC-81

Cruise Control Switch -

invalid serial data received

The Engine Control Module

(ECM) has received an invalid

command from the steering

wheel switch pack Clear the DTC and press all the steering wheel

switches, re-check for DTCs. Refer to the

electrical circuit diagrams and check the Cruise

control switch circuit for open circuit, short to

power, short to ground, disconnected. Check

and install a new Steering Wheel Module (SWM) as required. B10AC-82 Cruise Control Switch - alive / sequence counter incorrect / not updated

Cruise Buttons alive counter is

not incrementing. Which

suggests that the LIN bus is

faulty

Steering Wheel Module (SWM) is

not connected

Steering Wheel Module (SWM)

failure Refer to the electrical circuit diagrams and

check the Cruise control switch circuit for open

circuit, short to power, short to ground,

disconnected. Check and install a new Steering

Wheel Module (SWM) as required. B10AC-83

Cruise Control Switch - value

of signal protection

calculation incorrect

Cruise buttons checksum

incorrect, incorrect cruise

switches fitted to vehicle Check and install new cruise switches as

required. B10AC-96

Cruise Control Switch -

component internal failure

Cruise control switch circuit,

open circuit, short to power,

short to ground, disconnected

Cruise Control Switch failure

Steering Wheel Module (SWM)

failure Check for related DTCs in other Central

Junction Box (CJB)s. Refer to the electrical

circuit diagrams and check the Cruise control

switch circuit for open circuit, short to power,

short to ground, disconnected. Check and

install a new cruise control switch as required.

Check and install a new Steering Wheel

Module (SWM) as required. B10FF-68

Ignition Control - Event

information

Spark plug(s) fault

Wiring harness fault

Ignition coil(s) fault Refer to repair manual and check spark plug(s)

for condition and security. Replace any

defective components as required. Refer to

electrical wiring diagrams and check ignition

coil circuit for intermittent open circuit, short

to power, short to ground. Check and install a

new coil(s) as required. B11DB-01

Battery Monitoring Module -

General Electrical Failure

Charging system fault Battery

monitoring signal line

circuit fault

Vehicle battery fault Refer to electrical wiring diagrams and check

charging system for faults. Perform any repairs

required. Refer to the electrical wiring

diagrams and check the Battery Monitoring

System (BMS) module circuit for open circuit,

short to ground, short to power. Refer to the

battery care manual and check and install a

new battery. B11DB-87

Battery Monitoring Module -

missing message

Battery signal line circuit fault Refer to the electrical wiring diagrams and

check the Battery Monitoring System (BMS)

module circuit for open circuit, short to ground,

short to power. B1206-68

Crash Occurred - event

information

Engine control Module (ECM) has

detected the vehicle has crashed

- event information DTC only Refer to the electrical circuit diagrams and

check the Engine Control Module (ECM) to

Restraints Control Module (RCM) circuit for

short to ground, short to power, open circuit.

Repair circuit as required, clear DTC and retest

system to confirm repair. C0031-00

Left Front Wheel Speed

Sensor - No sub type

information

Invalid data received from

Anti-lock Braking System (ABS)

module - left front wheel speed

signal fault Check Anti-lock Braking System (ABS) module

for related DTCs and refer to relevant DTC

Index. C0034-00

Right Front Wheel Speed

Sensor - No sub type

information

Invalid data received from

Anti-lock Braking System (ABS)

module - right front wheel speed

signal fault Check Anti-lock Braking System (ABS) module

for related DTCs and refer to relevant DTC

Index. C0037-00

Left Rear Wheel Speed

Sensor - No sub type

information

Invalid data received from

Anti-lock Braking System (ABS)

module - left rear wheel speed

signal fault Check Anti-lock Braking System (ABS) module

for related DTCs and refer to relevant DTC

Index. C003A-00

Right Rear Wheel Speed

Sensor - No sub type

information

Invalid data received from

Anti-lock Braking System (ABS)

module - right rear wheel speed

signal fault Check Anti-lock Braking System (ABS) module

for related DTCs and refer to relevant DTC

Index.

Page 1438 of 3039

DTC Description Possible Cause Action P061B-02

Internal Control Module Torque Calculation

Performance - general signal

failure

Transmission control

module - positive torque

signal not valid Suspect the Transmission control module. Install a

new Transmission control module as required, refer to

the new module/component installation note at the

top of the DTC Index P061B-26

Internal Control Module Torque Calculation

Performance - signal rate of

change below threshold

Transmission control

module positive torque

signal not valid Suspect the Transmission control module. Install a

new Transmission control module as required, refer to

the new module/component installation note at the

top of the DTC Index P062F-04

Internal Control Module

EEPROM Error - System

Internal Failures

EEPROM communication

error Suspect the Transmission control module. Install a

new Transmission control module as required, refer to

the new module/component installation note at the top of the DTC Index P0642-21

Sensor Reference Voltage A

Circuit Low - signal

amplitude < minimum

Sensor supply voltage

fault low Suspect the Transmission control module. Install a

new Transmission control module as required, refer to

the new module/component installation note at the top of the DTC Index P0643-22

Sensor Reference Voltage A

Circuit High - signal

amplitude > maximum

Sensor supply voltage

fault high Suspect the Transmission control module. Install a

new Transmission control module as required, refer to

the new module/component installation note at the top of the DTC Index P0657-13

Actuator Supply Voltage A

Circuit / Open - Circuit Open

Actuator supply (pressure

control valves etc) Open

Circuit Suspect the Transmission control module. Install a

new Transmission control module as required, refer to

the new module/component installation note at the

top of the DTC Index P0657-1C

Actuator Supply Voltage A

Circuit / Open - Circuit

voltage out of range

Actuator supply (pressure

control valves etc)

voltage plausibility fault Refer to electrical Circuit diagrams and check

Transmission control module connector for signs of

water ingress or damage, check pin 7 for Short to

Power or Ground (should NOT be connected and

harness terminal should have a bung fitted). If no

fault identified, suspect the Transmission control

module. Check and install a new Transmission control

module as required, refer to the new

module/component installation note at the top of the

DTC Index P0658-11

Actuator Supply Voltage A

Circuit Low - Circuit Short to

Ground

Actuator supply (pressure

control valves etc)

voltage Short to Ground Suspect the Transmission control module. Install a

new Transmission control module as required, refer to

the new module/component installation note at the

top of the DTC Index P0659-12

Actuator Supply Voltage A

Circuit High - Circuit Short to

Battery

Actuator supply (pressure

control valves etc)

voltage Short to Power Suspect the Transmission control module. Install a

new Transmission control module as required, refer to

the new module/component installation note at the

top of the DTC Index P0667-01 PCM / Engine control module / Transmission control

module Internal Temperature

Sensor A Range/Performance

- General Electrical Failure

General electrical failure Suspect the Transmission control module. Install a

new Transmission control module as required, refer to

the new module/component installation note at the

top of the DTC Index P0667-04 PCM / Engine control module / Transmission control

module Internal Temperature

Sensor A Range/Performance

- System Internal Failures

Internal Electronic Failure Suspect the Transmission control module. Install a

new Transmission control module as required, refer to

the new module/component installation note at the

top of the DTC Index P0667-49 PCM / Engine control module / Transmission control

module Internal Temperature

Sensor A Range/Performance

- internal electronic failure

Internal electronic failure Suspect the Transmission control module. Install a

new Transmission control module as required, refer to

the new module/component installation note at the

top of the DTC Index P0700-02 Transmission Control System

(MIL Request) - General signal failure

General Signal failure Clear DTC, Road test and re-test, Read DTCs and

Investigate as required P0700-22 Transmission Control System

(MIL Request) - signal

amplitude > maximum

Double fault from

monitoring of internal

power supply and

pressure

regulator/solenoid

control software If any of the following DTCs are also present;

P074013, P096712, P273912, P273012, P272112,

P096312, P276312, P097112, suspect the Transmission

control module, check and install a new Transmission

control module as required, refer to the new

module/component installation note at the top of the

DTC Index P0700-75 Transmission Control System

(MIL Request) - Emergency

Position Not Reachable

Emergency Position Not

Reachable Clear DTC, Road test and re-test, Read DTCs and

investigate as required

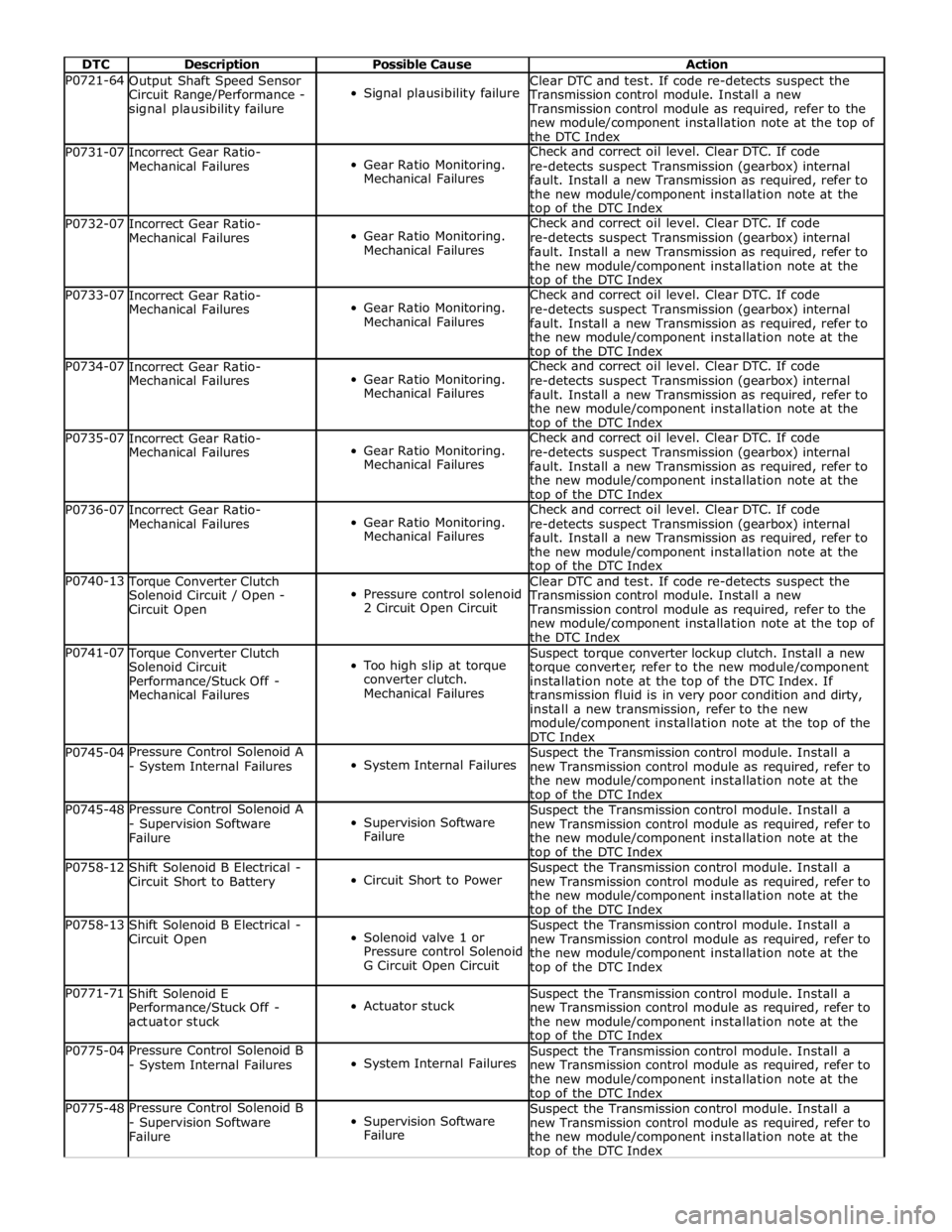

Page 1440 of 3039

DTC Description Possible Cause Action P0721-64

Output Shaft Speed Sensor

Circuit Range/Performance -

signal plausibility failure

Signal plausibility failure Clear DTC and test. If code re-detects suspect the

Transmission control module. Install a new

Transmission control module as required, refer to the

new module/component installation note at the top of

the DTC Index P0731-07

Incorrect Gear Ratio-

Mechanical Failures

Gear Ratio Monitoring.

Mechanical Failures Check and correct oil level. Clear DTC. If code

re-detects suspect Transmission (gearbox) internal

fault. Install a new Transmission as required, refer to

the new module/component installation note at the top of the DTC Index P0732-07

Incorrect Gear Ratio-

Mechanical Failures

Gear Ratio Monitoring.

Mechanical Failures Check and correct oil level. Clear DTC. If code

re-detects suspect Transmission (gearbox) internal

fault. Install a new Transmission as required, refer to

the new module/component installation note at the top of the DTC Index P0733-07

Incorrect Gear Ratio-

Mechanical Failures

Gear Ratio Monitoring.

Mechanical Failures Check and correct oil level. Clear DTC. If code

re-detects suspect Transmission (gearbox) internal

fault. Install a new Transmission as required, refer to

the new module/component installation note at the top of the DTC Index P0734-07

Incorrect Gear Ratio-

Mechanical Failures

Gear Ratio Monitoring.

Mechanical Failures Check and correct oil level. Clear DTC. If code

re-detects suspect Transmission (gearbox) internal

fault. Install a new Transmission as required, refer to

the new module/component installation note at the top of the DTC Index P0735-07

Incorrect Gear Ratio-

Mechanical Failures

Gear Ratio Monitoring.

Mechanical Failures Check and correct oil level. Clear DTC. If code

re-detects suspect Transmission (gearbox) internal

fault. Install a new Transmission as required, refer to

the new module/component installation note at the top of the DTC Index P0736-07

Incorrect Gear Ratio-

Mechanical Failures

Gear Ratio Monitoring.

Mechanical Failures Check and correct oil level. Clear DTC. If code

re-detects suspect Transmission (gearbox) internal

fault. Install a new Transmission as required, refer to

the new module/component installation note at the top of the DTC Index P0740-13 Torque Converter Clutch

Solenoid Circuit / Open -

Circuit Open

Pressure control solenoid

2 Circuit Open Circuit Clear DTC and test. If code re-detects suspect the

Transmission control module. Install a new

Transmission control module as required, refer to the

new module/component installation note at the top of

the DTC Index P0741-07 Torque Converter Clutch

Solenoid Circuit

Performance/Stuck Off -

Mechanical Failures

Too high slip at torque

converter clutch.

Mechanical Failures Suspect torque converter lockup clutch. Install a new

torque converter, refer to the new module/component

installation note at the top of the DTC Index. If

transmission fluid is in very poor condition and dirty,

install a new transmission, refer to the new

module/component installation note at the top of the

DTC Index P0745-04 Pressure Control Solenoid A

- System Internal Failures

System Internal Failures Suspect the Transmission control module. Install a

new Transmission control module as required, refer to

the new module/component installation note at the top of the DTC Index P0745-48 Pressure Control Solenoid A

- Supervision Software

Failure

Supervision Software

Failure Suspect the Transmission control module. Install a

new Transmission control module as required, refer to

the new module/component installation note at the top of the DTC Index P0758-12

Shift Solenoid B Electrical -

Circuit Short to Battery

Circuit Short to Power Suspect the Transmission control module. Install a

new Transmission control module as required, refer to

the new module/component installation note at the top of the DTC Index P0758-13

Shift Solenoid B Electrical -

Circuit Open

Solenoid valve 1 or

Pressure control Solenoid

G Circuit Open Circuit Suspect the Transmission control module. Install a

new Transmission control module as required, refer to

the new module/component installation note at the

top of the DTC Index P0771-71

Shift Solenoid E

Performance/Stuck Off -

actuator stuck

Actuator stuck Suspect the Transmission control module. Install a

new Transmission control module as required, refer to

the new module/component installation note at the top of the DTC Index P0775-04 Pressure Control Solenoid B

- System Internal Failures

System Internal Failures Suspect the Transmission control module. Install a

new Transmission control module as required, refer to

the new module/component installation note at the top of the DTC Index P0775-48 Pressure Control Solenoid B

- Supervision Software

Failure

Supervision Software

Failure Suspect the Transmission control module. Install a

new Transmission control module as required, refer to

the new module/component installation note at the top of the DTC Index

Page 1442 of 3039

DTC Description Possible Cause Action P0829-07

5-6 Shift - Mechanical

Failures

Gear Ratio Monitoring.

Mechanical Failures Check and correct oil level. Clear DTC. If code

re-detects suspect Transmission internal fault. Install

a new Transmission as required, refer to the new

module/component installation note at the top of the

DTC Index P0829-77

6-5 Shift - Commanded

Position Not Reachable

Gear Ratio Monitoring.

Mechanical Failures Check and correct oil level. Clear DTC. If code

re-detects suspect Transmission internal fault. Install

a new Transmission as required, refer to the new

module/component installation note at the top of the

DTC Index P084F-01

Park / Neutral Switch Input

Circuit - General Electrical

Failure

Wrong voltage level

detected on Park/No Park

signal Check for correct output at Transmission control

module park signal pin (check in all positions) 12 volts

in Park, 0 volts in all other positions. If fault

identified, suspect the Transmission control module.

Install a new Transmission control module as required,

refer to the new module/component installation note

at the top of the DTC Index. If no fault identified,

check Park signal circuit to Transmission Shift Module

for short, open circuit. P0850-01

Park / Neutral Switch Input

Circuit - General Electrical

Failure

General electrical failure Suspect the Transmission control module. Install a

new Transmission control module as required, refer to

the new module/component installation note at the top of the DTC Index P0850-02

Park / Neutral Switch Input

Circuit - General signal

failure

General signal failure Check park lock mechanism. If park lock operation is

correct, suspect the transmission control module.

Check and install a new transmission control module

as required. Refer to the warranty policy and

procedures manual, or determine if any prior approval

programme is in operation, prior to the installation of

a new module/component P0850-29

Park / Neutral Switch Input

Circuit - signal invalid

Signal invalid Check park lock mechanism. If park lock operation is

correct, suspect the transmission control module.

Check and install a new transmission control module

as required. Refer to the warranty policy and

procedures manual, or determine if any prior approval

programme is in operation, prior to the installation of

a new module/component P850-1C

Park / Neutral Switch Input

Circuit - circuit voltage out

of range

Circuit voltage out of

range Check park lock mechanism, if park lock operation

correct suspect the Transmission control module.

Install a new Transmission control module as required,

refer to the new module/component installation note

at the top of the DTC Index P0919-93

Gear Shift Position Control

Error - no operation

No shifting despite driver

request Suspect the Transmission control module. Install a

new Transmission control module as required, refer to

the new module/component installation note at the top of the DTC Index P0919-94

Gear Shift Position Control

Error - unexpected operation

Shifting without driver

request Suspect the Transmission control module. Install a

new Transmission control module as required, refer to

the new module/component installation note at the top of the DTC Index P0938-29

Hydraulic Oil Temperature

Sensor Range/Performance -

signal invalid

Transmission fluid

temperature compared

with module temperature

fault Clear DTC. Carry out cold start road test, continue

driving vehicle until normal operating temperature is

achieved. Read DTCs, if DTC returns, suspect the

Transmission control module. Install a new

Transmission control module as required, refer to the

new module/component installation note at the top of

the DTC Index P0963-12

Pressure Control Solenoid A

Control Circuit High - Circuit

Short to Battery

Pressure control solenoid

1 Circuit Short to Power Suspect the Transmission control module. Install a

new Transmission control module as required, refer to

the new module/component installation note at the top of the DTC Index P0964-13

Pressure Control Solenoid B

Control Circuit / Open -

Circuit Open

Pressure Control Solenoid

B Control Circuit Open Suspect the Transmission control module. Install a

new Transmission control module as required, refer to

the new module/component installation note at the top of the DTC Index P0964-14

Pressure Control Solenoid B

Control Circuit / Open -

Circuit Short to Ground or

Open

Pressure Control Solenoid

B Control Circuit Short to

Ground or Open Suspect the Transmission control module. Install a

new Transmission control module as required, refer to

the new module/component installation note at the

top of the DTC Index P0966-11

Pressure Control Solenoid B

Control Circuit Low - Circuit

Short to Ground

Pressure control solenoid

2 Circuit Short to Ground Suspect the Transmission control module. Install a

new Transmission control module as required, refer to

the new module/component installation note at the top of the DTC Index www.JagDocs.com