battery monitoring module JAGUAR XFR 2010 1.G Owner's Guide

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 2010, Model line: XFR, Model: JAGUAR XFR 2010 1.GPages: 3039, PDF Size: 58.49 MB

Page 1444 of 3039

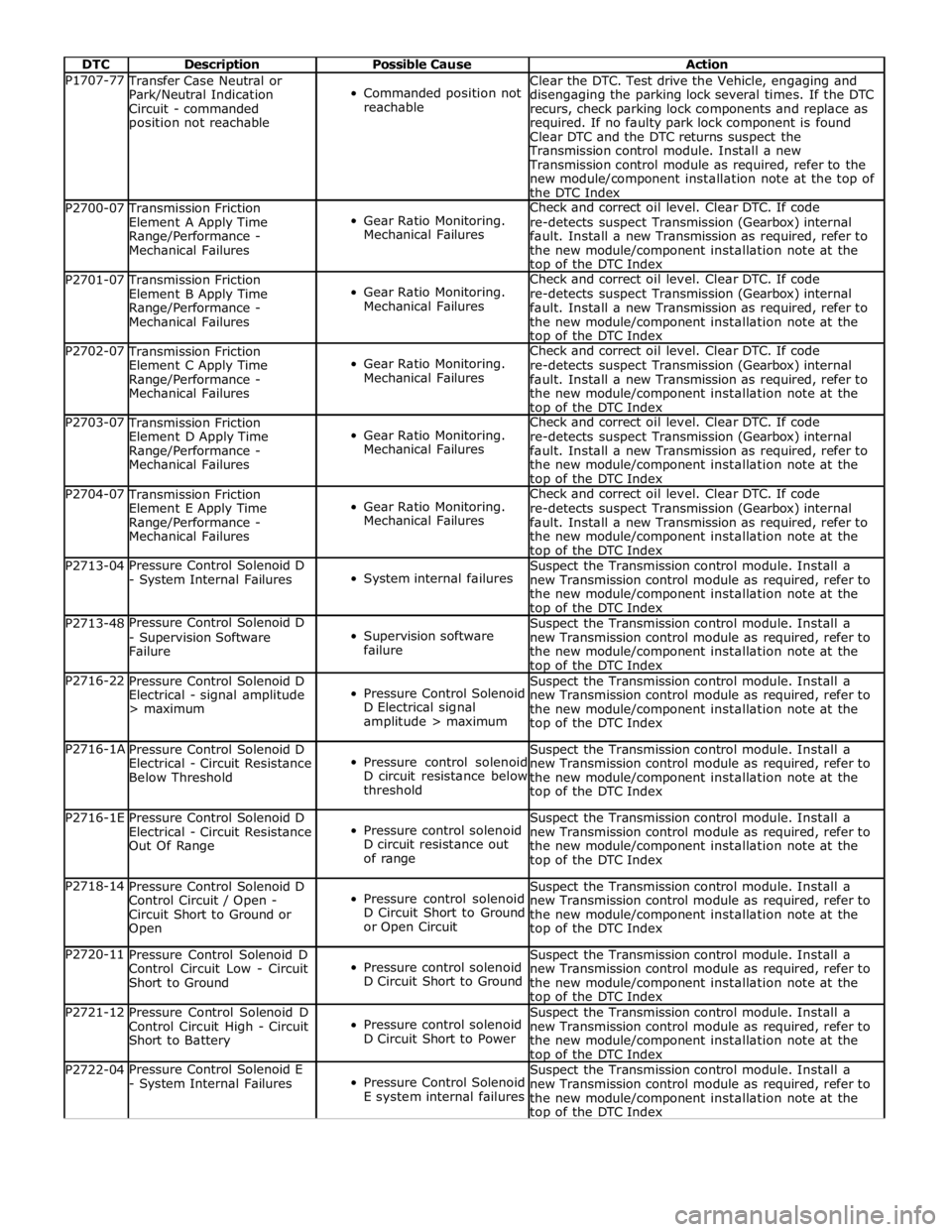

DTC Description Possible Cause Action P1707-77 Transfer Case Neutral or

Park/Neutral Indication

Circuit - commanded

position not reachable

Commanded position not

reachable Clear the DTC. Test drive the Vehicle, engaging and

disengaging the parking lock several times. If the DTC

recurs, check parking lock components and replace as

required. If no faulty park lock component is found

Clear DTC and the DTC returns suspect the

Transmission control module. Install a new

Transmission control module as required, refer to the

new module/component installation note at the top of

the DTC Index P2700-07 Transmission Friction

Element A Apply Time

Range/Performance -

Mechanical Failures

Gear Ratio Monitoring.

Mechanical Failures Check and correct oil level. Clear DTC. If code

re-detects suspect Transmission (Gearbox) internal

fault. Install a new Transmission as required, refer to

the new module/component installation note at the top of the DTC Index P2701-07 Transmission Friction

Element B Apply Time

Range/Performance -

Mechanical Failures

Gear Ratio Monitoring.

Mechanical Failures Check and correct oil level. Clear DTC. If code

re-detects suspect Transmission (Gearbox) internal

fault. Install a new Transmission as required, refer to

the new module/component installation note at the top of the DTC Index P2702-07 Transmission Friction

Element C Apply Time

Range/Performance -

Mechanical Failures

Gear Ratio Monitoring.

Mechanical Failures Check and correct oil level. Clear DTC. If code

re-detects suspect Transmission (Gearbox) internal

fault. Install a new Transmission as required, refer to

the new module/component installation note at the top of the DTC Index P2703-07 Transmission Friction

Element D Apply Time

Range/Performance -

Mechanical Failures

Gear Ratio Monitoring.

Mechanical Failures Check and correct oil level. Clear DTC. If code

re-detects suspect Transmission (Gearbox) internal

fault. Install a new Transmission as required, refer to

the new module/component installation note at the top of the DTC Index P2704-07 Transmission Friction

Element E Apply Time

Range/Performance -

Mechanical Failures

Gear Ratio Monitoring.

Mechanical Failures Check and correct oil level. Clear DTC. If code

re-detects suspect Transmission (Gearbox) internal

fault. Install a new Transmission as required, refer to

the new module/component installation note at the top of the DTC Index P2713-04 Pressure Control Solenoid D

- System Internal Failures

System internal failures Suspect the Transmission control module. Install a

new Transmission control module as required, refer to

the new module/component installation note at the top of the DTC Index P2713-48 Pressure Control Solenoid D

- Supervision Software

Failure

Supervision software

failure Suspect the Transmission control module. Install a

new Transmission control module as required, refer to

the new module/component installation note at the top of the DTC Index P2716-22

Pressure Control Solenoid D

Electrical - signal amplitude

> maximum

Pressure Control Solenoid

D Electrical signal

amplitude > maximum Suspect the Transmission control module. Install a

new Transmission control module as required, refer to

the new module/component installation note at the

top of the DTC Index P2716-1A

Pressure Control Solenoid D

Electrical - Circuit Resistance

Below Threshold

Pressure control solenoid

D circuit resistance below

threshold Suspect the Transmission control module. Install a

new Transmission control module as required, refer to

the new module/component installation note at the

top of the DTC Index P2716-1E

Pressure Control Solenoid D

Electrical - Circuit Resistance

Out Of Range

Pressure control solenoid

D circuit resistance out

of range Suspect the Transmission control module. Install a

new Transmission control module as required, refer to

the new module/component installation note at the

top of the DTC Index P2718-14

Pressure Control Solenoid D

Control Circuit / Open -

Circuit Short to Ground or

Open

Pressure control solenoid

D Circuit Short to Ground

or Open Circuit Suspect the Transmission control module. Install a

new Transmission control module as required, refer to

the new module/component installation note at the

top of the DTC Index P2720-11

Pressure Control Solenoid D

Control Circuit Low - Circuit

Short to Ground

Pressure control solenoid

D Circuit Short to Ground Suspect the Transmission control module. Install a

new Transmission control module as required, refer to

the new module/component installation note at the top of the DTC Index P2721-12

Pressure Control Solenoid D

Control Circuit High - Circuit

Short to Battery

Pressure control solenoid

D Circuit Short to Power Suspect the Transmission control module. Install a

new Transmission control module as required, refer to

the new module/component installation note at the top of the DTC Index P2722-04 Pressure Control Solenoid E

- System Internal Failures

Pressure Control Solenoid

E system internal failures Suspect the Transmission control module. Install a

new Transmission control module as required, refer to

the new module/component installation note at the top of the DTC Index

Page 1824 of 3039

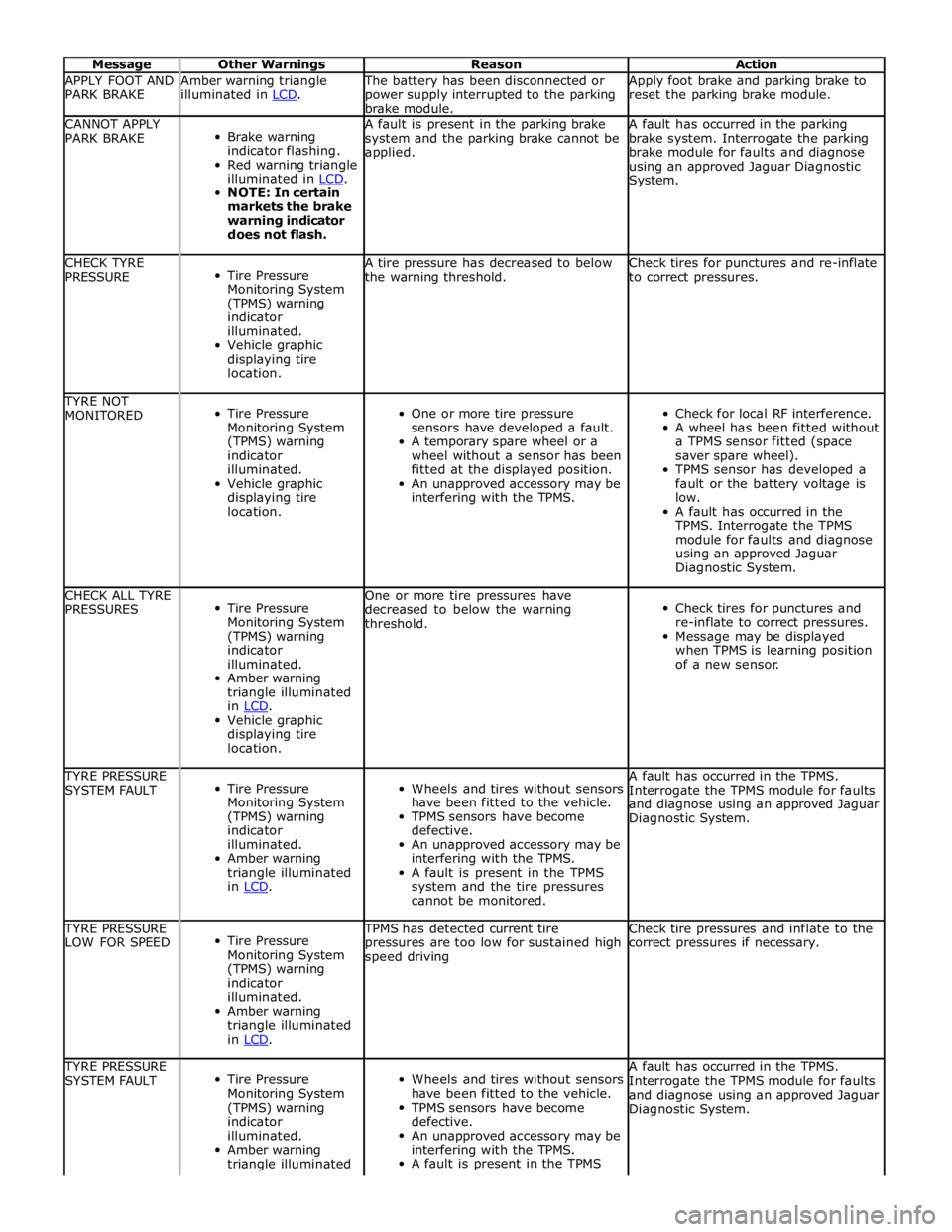

Message Other Warnings Reason Action APPLY FOOT AND

PARK BRAKE Amber warning triangle

illuminated in LCD. The battery has been disconnected or

power supply interrupted to the parking

brake module. Apply foot brake and parking brake to

reset the parking brake module. CANNOT APPLY

PARK BRAKE

Brake warning

indicator flashing.

Red warning triangle

illuminated in LCD. NOTE: In certain

markets the brake

warning indicator

does not flash. A fault is present in the parking brake

system and the parking brake cannot be

applied. A fault has occurred in the parking

brake system. Interrogate the parking

brake module for faults and diagnose

using an approved Jaguar Diagnostic

System. CHECK TYRE

PRESSURE

Tire Pressure

Monitoring System

(TPMS) warning

indicator

illuminated.

Vehicle graphic

displaying tire

location. A tire pressure has decreased to below

the warning threshold. Check tires for punctures and re-inflate

to correct pressures. TYRE NOT

MONITORED

Tire Pressure

Monitoring System

(TPMS) warning

indicator

illuminated.

Vehicle graphic

displaying tire

location.

One or more tire pressure

sensors have developed a fault.

A temporary spare wheel or a

wheel without a sensor has been

fitted at the displayed position.

An unapproved accessory may be

interfering with the TPMS.

Check for local RF interference.

A wheel has been fitted without

a TPMS sensor fitted (space

saver spare wheel).

TPMS sensor has developed a

fault or the battery voltage is

low.

A fault has occurred in the

TPMS. Interrogate the TPMS

module for faults and diagnose

using an approved Jaguar

Diagnostic System. CHECK ALL TYRE

PRESSURES

Tire Pressure

Monitoring System

(TPMS) warning

indicator

illuminated.

Amber warning

triangle illuminated

in LCD. Vehicle graphic

displaying tire

location. One or more tire pressures have

decreased to below the warning

threshold.

Check tires for punctures and

re-inflate to correct pressures.

Message may be displayed

when TPMS is learning position

of a new sensor. TYRE PRESSURE

SYSTEM FAULT

Tire Pressure

Monitoring System

(TPMS) warning

indicator

illuminated.

Amber warning

triangle illuminated

in LCD.

Wheels and tires without sensors

have been fitted to the vehicle.

TPMS sensors have become

defective.

An unapproved accessory may be

interfering with the TPMS.

A fault is present in the TPMS

system and the tire pressures

cannot be monitored. A fault has occurred in the TPMS.

Interrogate the TPMS module for faults

and diagnose using an approved Jaguar

Diagnostic System. TYRE PRESSURE

LOW FOR SPEED

Tire Pressure

Monitoring System

(TPMS) warning

indicator

illuminated.

Amber warning

triangle illuminated

in LCD. TPMS has detected current tire

pressures are too low for sustained high

speed driving Check tire pressures and inflate to the

correct pressures if necessary. TYRE PRESSURE

SYSTEM FAULT

Tire Pressure

Monitoring System

(TPMS) warning

indicator

illuminated.

Amber warning

triangle illuminated

Wheels and tires without sensors

have been fitted to the vehicle.

TPMS sensors have become

defective.

An unapproved accessory may be

interfering with the TPMS.

A fault is present in the TPMS A fault has occurred in the TPMS.

Interrogate the TPMS module for faults

and diagnose using an approved Jaguar

Diagnostic System.

Page 1825 of 3039

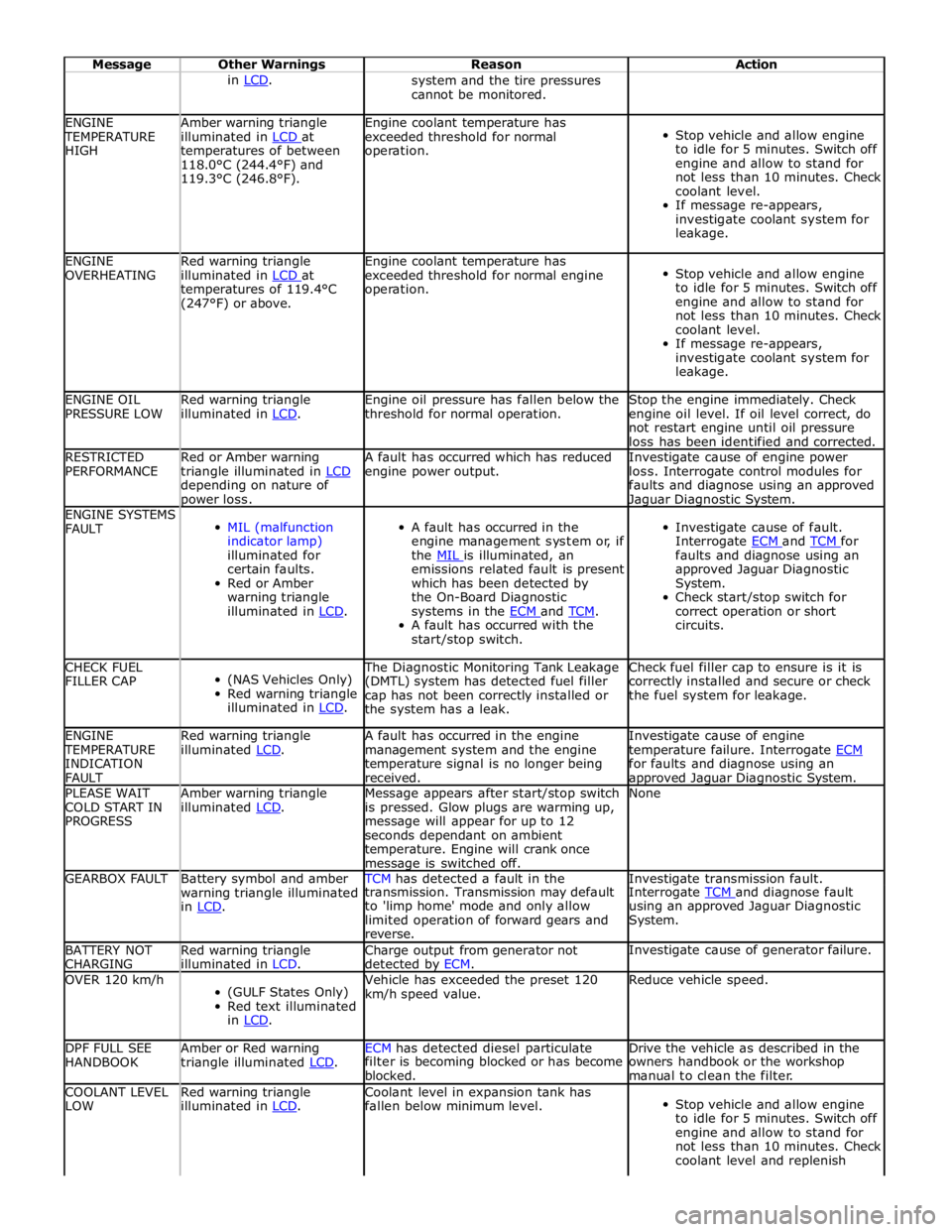

Message Other Warnings Reason Action in LCD. system and the tire pressures

cannot be monitored. ENGINE TEMPERATURE

HIGH Amber warning triangle

illuminated in LCD at temperatures of between

118.0°C (244.4°F) and

119.3°C (246.8°F). Engine coolant temperature has

exceeded threshold for normal

operation.

Stop vehicle and allow engine

to idle for 5 minutes. Switch off

engine and allow to stand for

not less than 10 minutes. Check

coolant level.

If message re-appears,

investigate coolant system for

leakage. ENGINE

OVERHEATING Red warning triangle

illuminated in LCD at temperatures of 119.4°C

(247°F) or above. Engine coolant temperature has

exceeded threshold for normal engine

operation.

Stop vehicle and allow engine

to idle for 5 minutes. Switch off

engine and allow to stand for

not less than 10 minutes. Check

coolant level.

If message re-appears,

investigate coolant system for

leakage. ENGINE OIL

PRESSURE LOW Red warning triangle

illuminated in LCD. Engine oil pressure has fallen below the

threshold for normal operation. Stop the engine immediately. Check

engine oil level. If oil level correct, do

not restart engine until oil pressure

loss has been identified and corrected. RESTRICTED

PERFORMANCE Red or Amber warning

triangle illuminated in LCD depending on nature of power loss. A fault has occurred which has reduced

engine power output. Investigate cause of engine power

loss. Interrogate control modules for

faults and diagnose using an approved Jaguar Diagnostic System. ENGINE SYSTEMS

FAULT

MIL (malfunction

indicator lamp)

illuminated for

certain faults.

Red or Amber

warning triangle

illuminated in LCD.

A fault has occurred in the

engine management system or, if

the MIL is illuminated, an emissions related fault is present

which has been detected by

the On-Board Diagnostic

systems in the ECM and TCM. A fault has occurred with the

start/stop switch.

Investigate cause of fault.

Interrogate ECM and TCM for faults and diagnose using an

approved Jaguar Diagnostic

System.

Check start/stop switch for

correct operation or short

circuits. CHECK FUEL

FILLER CAP

(NAS Vehicles Only)

Red warning triangle

illuminated in LCD. The Diagnostic Monitoring Tank Leakage

(DMTL) system has detected fuel filler

cap has not been correctly installed or

the system has a leak. Check fuel filler cap to ensure is it is

correctly installed and secure or check

the fuel system for leakage. ENGINE TEMPERATURE

INDICATION

FAULT Red warning triangle

illuminated LCD. A fault has occurred in the engine

management system and the engine

temperature signal is no longer being

received. Investigate cause of engine

temperature failure. Interrogate ECM for faults and diagnose using an approved Jaguar Diagnostic System. PLEASE WAIT

COLD START IN

PROGRESS Amber warning triangle

illuminated LCD. Message appears after start/stop switch

is pressed. Glow plugs are warming up,

message will appear for up to 12

seconds dependant on ambient

temperature. Engine will crank once message is switched off. None GEARBOX FAULT

Battery symbol and amber

warning triangle illuminated

in LCD. TCM has detected a fault in the Investigate transmission fault. transmission. Transmission may default

to 'limp home' mode and only allow

limited operation of forward gears and

reverse. Interrogate TCM and diagnose fault using an approved Jaguar Diagnostic

System. BATTERY NOT

CHARGING Red warning triangle

illuminated in LCD. Charge output from generator not

detected by ECM. Investigate cause of generator failure. OVER 120 km/h

(GULF States Only)

Red text illuminated

in LCD. Vehicle has exceeded the preset 120

km/h speed value. Reduce vehicle speed. DPF FULL SEE

HANDBOOK Amber or Red warning

triangle illuminated LCD. ECM has detected diesel particulate Drive the vehicle as described in the filter is becoming blocked or has become

blocked. owners handbook or the workshop

manual to clean the filter. COOLANT LEVEL

LOW Red warning triangle

illuminated in LCD. Coolant level in expansion tank has

fallen below minimum level.

Stop vehicle and allow engine

to idle for 5 minutes. Switch off

engine and allow to stand for

not less than 10 minutes. Check

coolant level and replenish

Page 1828 of 3039

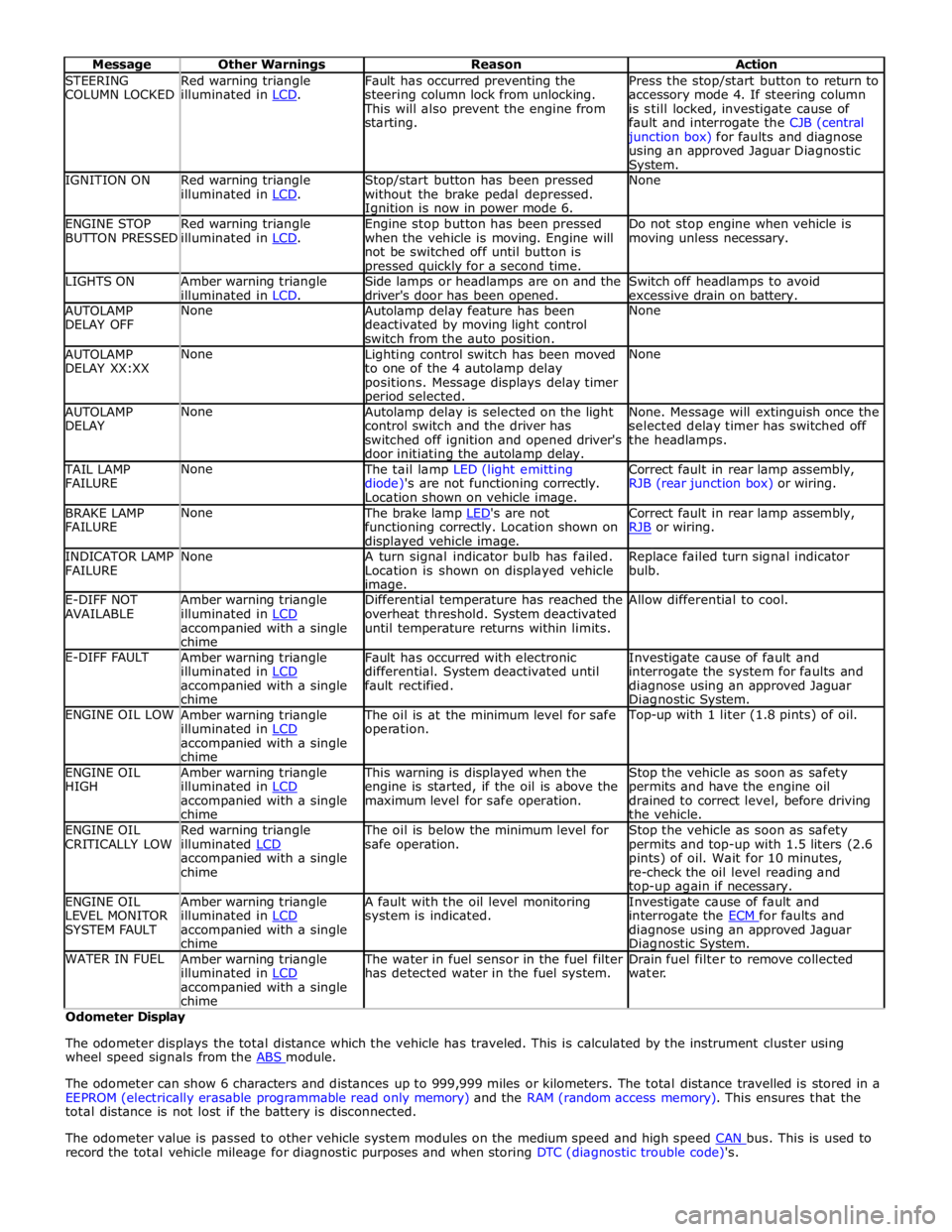

STEERING

COLUMN LOCKED Red warning triangle

illuminated in LCD. Fault has occurred preventing the

steering column lock from unlocking. This will also prevent the engine from

starting. Press the stop/start button to return to

accessory mode 4. If steering column

is still locked, investigate cause of

fault and interrogate the CJB (central junction box) for faults and diagnose

using an approved Jaguar Diagnostic System. IGNITION ON

Red warning triangle

illuminated in LCD. Stop/start button has been pressed

without the brake pedal depressed. Ignition is now in power mode 6. None ENGINE STOP

BUTTON PRESSED Red warning triangle

illuminated in LCD. Engine stop button has been pressed

when the vehicle is moving. Engine will

not be switched off until button is pressed quickly for a second time. Do not stop engine when vehicle is

moving unless necessary. LIGHTS ON

Amber warning triangle

illuminated in LCD. Side lamps or headlamps are on and the

driver's door has been opened. Switch off headlamps to avoid

excessive drain on battery. AUTOLAMP

DELAY OFF None

Autolamp delay feature has been

deactivated by moving light control

switch from the auto position. None AUTOLAMP

DELAY XX:XX None

Lighting control switch has been moved

to one of the 4 autolamp delay

positions. Message displays delay timer period selected. None AUTOLAMP

DELAY None

Autolamp delay is selected on the light

control switch and the driver has

switched off ignition and opened driver's

door initiating the autolamp delay. None. Message will extinguish once the

selected delay timer has switched off

the headlamps. TAIL LAMP

FAILURE None The tail lamp LED (light emitting

diode)'s are not functioning correctly.

Location shown on vehicle image. Correct fault in rear lamp assembly,

RJB (rear junction box) or wiring. BRAKE LAMP

FAILURE None The brake lamp LED's are not functioning correctly. Location shown on displayed vehicle image. Correct fault in rear lamp assembly,

RJB or wiring. INDICATOR LAMP

FAILURE None

A turn signal indicator bulb has failed.

Location is shown on displayed vehicle image. Replace failed turn signal indicator

bulb. E-DIFF NOT

AVAILABLE Amber warning triangle

illuminated in LCD accompanied with a single

chime Differential temperature has reached the

overheat threshold. System deactivated

until temperature returns within limits. Allow differential to cool. E-DIFF FAULT

Amber warning triangle

illuminated in LCD accompanied with a single

chime Fault has occurred with electronic

differential. System deactivated until

fault rectified. Investigate cause of fault and

interrogate the system for faults and

diagnose using an approved Jaguar Diagnostic System. ENGINE OIL LOW

Amber warning triangle

illuminated in LCD accompanied with a single

chime The oil is at the minimum level for safe

operation. Top-up with 1 liter (1.8 pints) of oil. ENGINE OIL

HIGH Amber warning triangle

illuminated in LCD accompanied with a single

chime This warning is displayed when the

engine is started, if the oil is above the

maximum level for safe operation. Stop the vehicle as soon as safety

permits and have the engine oil

drained to correct level, before driving

the vehicle. ENGINE OIL

CRITICALLY LOW Red warning triangle

illuminated LCD accompanied with a single

chime The oil is below the minimum level for

safe operation. Stop the vehicle as soon as safety

permits and top-up with 1.5 liters (2.6

pints) of oil. Wait for 10 minutes,

re-check the oil level reading and top-up again if necessary. ENGINE OIL

LEVEL MONITOR

SYSTEM FAULT Amber warning triangle

illuminated in LCD accompanied with a single

chime A fault with the oil level monitoring

system is indicated. Investigate cause of fault and

interrogate the ECM for faults and diagnose using an approved Jaguar Diagnostic System. WATER IN FUEL

Amber warning triangle

illuminated in LCD accompanied with a single

chime The water in fuel sensor in the fuel filter

has detected water in the fuel system. Drain fuel filter to remove collected

water. Odometer Display

The odometer displays the total distance which the vehicle has traveled. This is calculated by the instrument cluster using

wheel speed signals from the ABS module.

The odometer can show 6 characters and distances up to 999,999 miles or kilometers. The total distance travelled is stored in a

EEPROM (electrically erasable programmable read only memory) and the RAM (random access memory). This ensures that the

total distance is not lost if the battery is disconnected.

The odometer value is passed to other vehicle system modules on the medium speed and high speed CAN bus. This is used to record the total vehicle mileage for diagnostic purposes and when storing DTC (diagnostic trouble code)'s.

Page 1833 of 3039

1 Battery 2 LH (left-hand) door mirror 3 RH (right-hand) door mirror 4 RH blind spot monitoring module 5 LH blind spot monitoring module 6 RJB (rear junction box)

Page 1839 of 3039

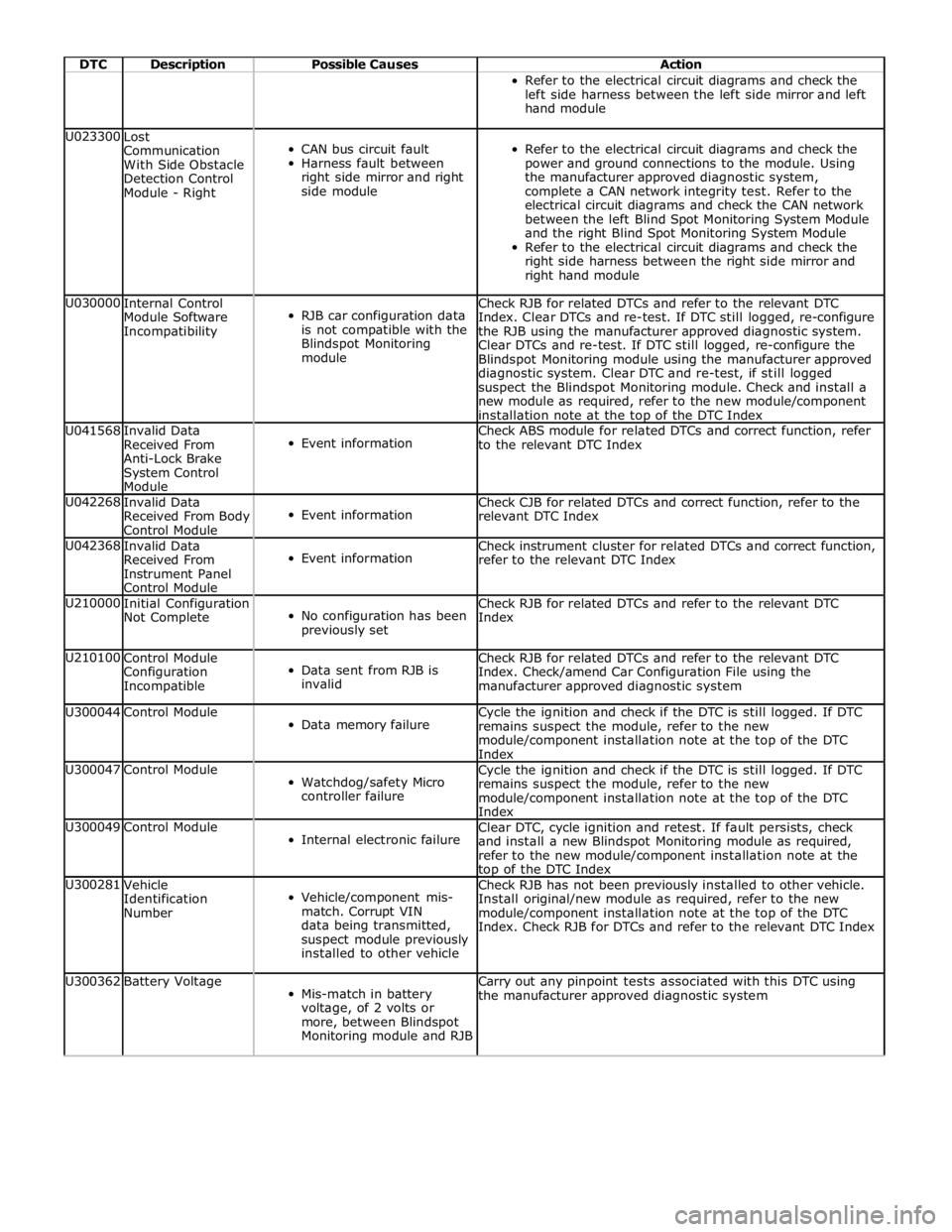

DTC Description Possible Causes Action Refer to the electrical circuit diagrams and check the

left side harness between the left side mirror and left

hand module U023300

Lost

Communication

With Side Obstacle

Detection Control

Module - Right

CAN bus circuit fault

Harness fault between

right side mirror and right

side module

Refer to the electrical circuit diagrams and check the

power and ground connections to the module. Using

the manufacturer approved diagnostic system,

complete a CAN network integrity test. Refer to the

electrical circuit diagrams and check the CAN network

between the left Blind Spot Monitoring System Module

and the right Blind Spot Monitoring System Module

Refer to the electrical circuit diagrams and check the

right side harness between the right side mirror and

right hand module U030000

Internal Control

Module Software

Incompatibility

RJB car configuration data

is not compatible with the

Blindspot Monitoring

module Check RJB for related DTCs and refer to the relevant DTC

Index. Clear DTCs and re-test. If DTC still logged, re-configure

the RJB using the manufacturer approved diagnostic system.

Clear DTCs and re-test. If DTC still logged, re-configure the

Blindspot Monitoring module using the manufacturer approved

diagnostic system. Clear DTC and re-test, if still logged

suspect the Blindspot Monitoring module. Check and install a

new module as required, refer to the new module/component

installation note at the top of the DTC Index U041568

Invalid Data

Received From

Anti-Lock Brake

System Control

Module

Event information Check ABS module for related DTCs and correct function, refer

to the relevant DTC Index U042268

Invalid Data

Received From Body

Control Module

Event information Check CJB for related DTCs and correct function, refer to the

relevant DTC Index U042368

Invalid Data

Received From

Instrument Panel

Control Module

Event information Check instrument cluster for related DTCs and correct function,

refer to the relevant DTC Index U210000

Initial Configuration

Not Complete

No configuration has been

previously set Check RJB for related DTCs and refer to the relevant DTC

Index U210100

Control Module

Configuration

Incompatible

Data sent from RJB is

invalid Check RJB for related DTCs and refer to the relevant DTC

Index. Check/amend Car Configuration File using the

manufacturer approved diagnostic system U300044 Control Module

Data memory failure Cycle the ignition and check if the DTC is still logged. If DTC

remains suspect the module, refer to the new

module/component installation note at the top of the DTC

Index U300047 Control Module

Watchdog/safety Micro

controller failure Cycle the ignition and check if the DTC is still logged. If DTC

remains suspect the module, refer to the new

module/component installation note at the top of the DTC

Index U300049 Control Module

Internal electronic failure Clear DTC, cycle ignition and retest. If fault persists, check

and install a new Blindspot Monitoring module as required,

refer to the new module/component installation note at the top of the DTC Index U300281

Vehicle

Identification

Number

Vehicle/component mis-

match. Corrupt VIN

data being transmitted,

suspect module previously

installed to other vehicle Check RJB has not been previously installed to other vehicle.

Install original/new module as required, refer to the new

module/component installation note at the top of the DTC

Index. Check RJB for DTCs and refer to the relevant DTC Index U300362 Battery Voltage

Mis-match in battery

voltage, of 2 volts or

more, between Blindspot

Monitoring module and RJB Carry out any pinpoint tests associated with this DTC using

the manufacturer approved diagnostic system

Page 1869 of 3039

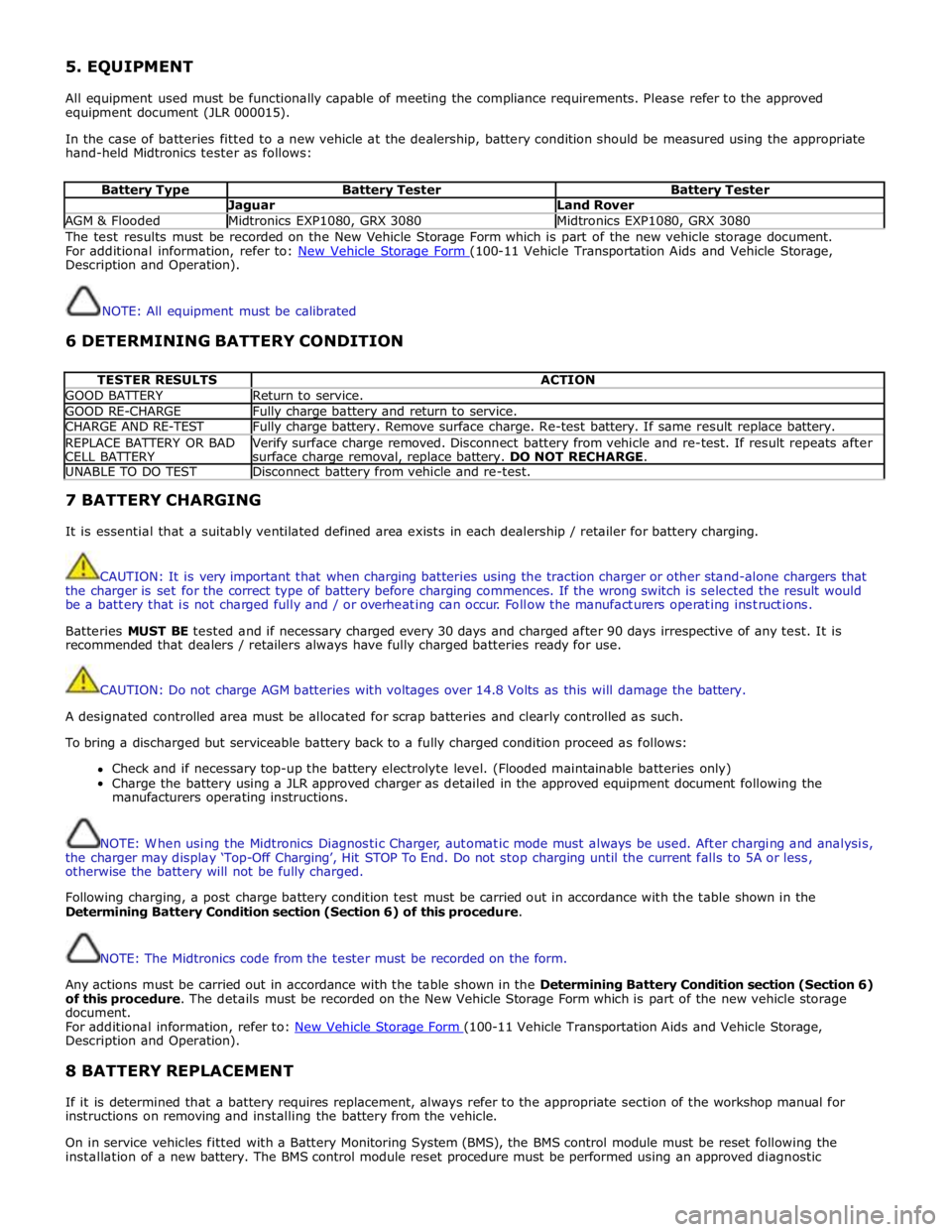

5. EQUIPMENT

All equipment used must be functionally capable of meeting the compliance requirements. Please refer to the approved

equipment document (JLR 000015).

In the case of batteries fitted to a new vehicle at the dealership, battery condition should be measured using the appropriate

hand-held Midtronics tester as follows:

Battery Type Battery Tester Battery Tester Jaguar Land Rover AGM & Flooded Midtronics EXP1080, GRX 3080 Midtronics EXP1080, GRX 3080 The test results must be recorded on the New Vehicle Storage Form which is part of the new vehicle storage document.

For additional information, refer to: New Vehicle Storage Form (100-11 Vehicle Transportation Aids and Vehicle Storage, Description and Operation).

NOTE: All equipment must be calibrated

6 DETERMINING BATTERY CONDITION

TESTER RESULTS ACTION GOOD BATTERY Return to service. GOOD RE-CHARGE Fully charge battery and return to service. CHARGE AND RE-TEST Fully charge battery. Remove surface charge. Re-test battery. If same result replace battery. REPLACE BATTERY OR BAD

CELL BATTERY Verify surface charge removed. Disconnect battery from vehicle and re-test. If result repeats after

surface charge removal, replace battery. DO NOT RECHARGE. UNABLE TO DO TEST Disconnect battery from vehicle and re-test. 7 BATTERY CHARGING

It is essential that a suitably ventilated defined area exists in each dealership / retailer for battery charging.

CAUTION: It is very important that when charging batteries using the traction charger or other stand-alone chargers that

the charger is set for the correct type of battery before charging commences. If the wrong switch is selected the result would

be a battery that is not charged fully and / or overheating can occur. Follow the manufacturers operating instructions.

Batteries MUST BE tested and if necessary charged every 30 days and charged after 90 days irrespective of any test. It is

recommended that dealers / retailers always have fully charged batteries ready for use.

CAUTION: Do not charge AGM batteries with voltages over 14.8 Volts as this will damage the battery.

A designated controlled area must be allocated for scrap batteries and clearly controlled as such.

To bring a discharged but serviceable battery back to a fully charged condition proceed as follows:

Check and if necessary top-up the battery electrolyte level. (Flooded maintainable batteries only)

Charge the battery using a JLR approved charger as detailed in the approved equipment document following the

manufacturers operating instructions.

NOTE: When using the Midtronics Diagnostic Charger, automatic mode must always be used. After charging and analysis,

the charger may display ‘Top-Off Charging’, Hit STOP To End. Do not stop charging until the current falls to 5A or less,

otherwise the battery will not be fully charged.

Following charging, a post charge battery condition test must be carried out in accordance with the table shown in the

Determining Battery Condition section (Section 6) of this procedure.

NOTE: The Midtronics code from the tester must be recorded on the form.

Any actions must be carried out in accordance with the table shown in the Determining Battery Condition section (Section 6)

of this procedure. The details must be recorded on the New Vehicle Storage Form which is part of the new vehicle storage

document.

For additional information, refer to: New Vehicle Storage Form (100-11 Vehicle Transportation Aids and Vehicle Storage, Description and Operation).

8 BATTERY REPLACEMENT

If it is determined that a battery requires replacement, always refer to the appropriate section of the workshop manual for

instructions on removing and installing the battery from the vehicle.

On in service vehicles fitted with a Battery Monitoring System (BMS), the BMS control module must be reset following the

installation of a new battery. The BMS control module reset procedure must be performed using an approved diagnostic

Page 1871 of 3039

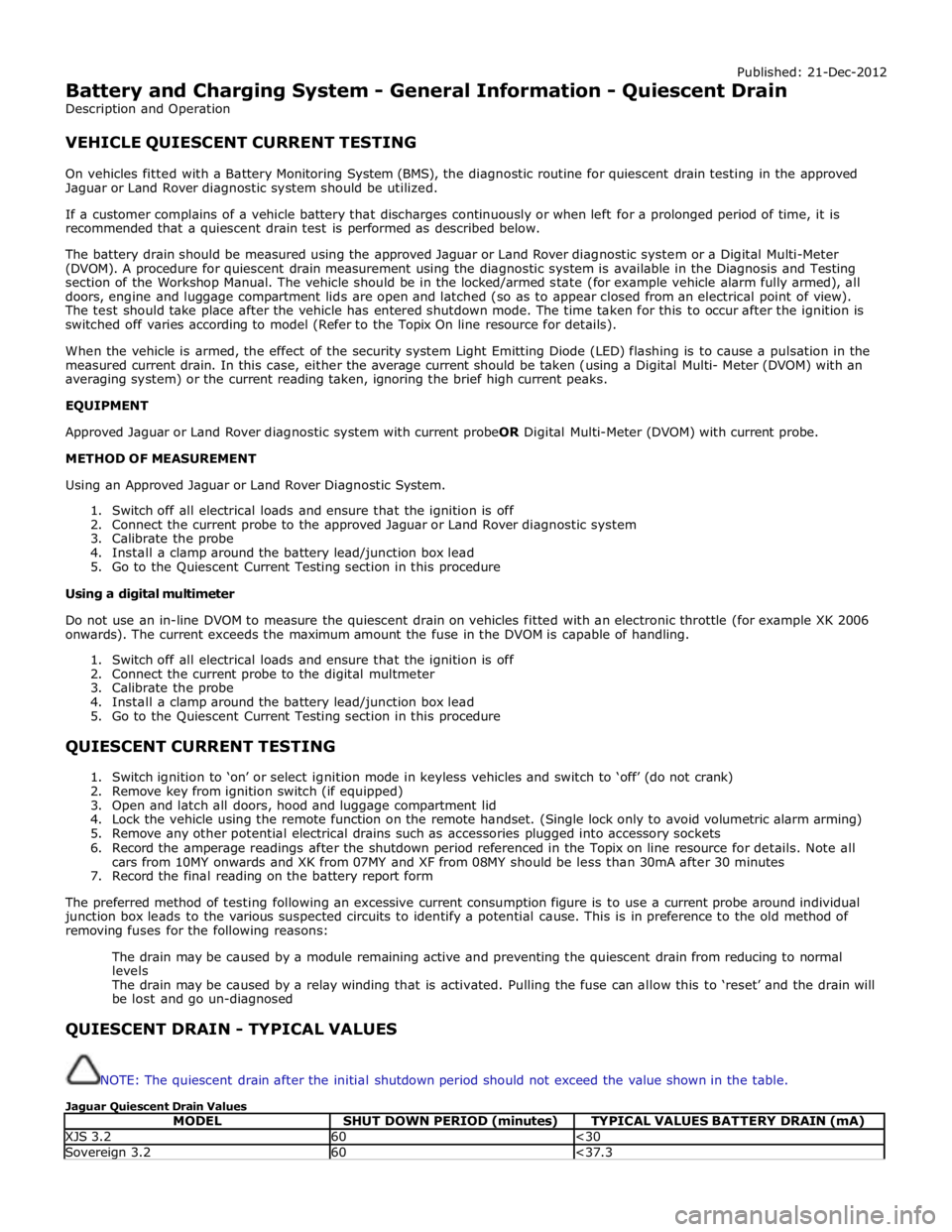

Published: 21-Dec-2012

Battery and Charging System - General Information - Quiescent Drain

Description and Operation

VEHICLE QUIESCENT CURRENT TESTING

On vehicles fitted with a Battery Monitoring System (BMS), the diagnostic routine for quiescent drain testing in the approved

Jaguar or Land Rover diagnostic system should be utilized.

If a customer complains of a vehicle battery that discharges continuously or when left for a prolonged period of time, it is

recommended that a quiescent drain test is performed as described below.

The battery drain should be measured using the approved Jaguar or Land Rover diagnostic system or a Digital Multi-Meter

(DVOM). A procedure for quiescent drain measurement using the diagnostic system is available in the Diagnosis and Testing

section of the Workshop Manual. The vehicle should be in the locked/armed state (for example vehicle alarm fully armed), all

doors, engine and luggage compartment lids are open and latched (so as to appear closed from an electrical point of view).

The test should take place after the vehicle has entered shutdown mode. The time taken for this to occur after the ignition is

switched off varies according to model (Refer to the Topix On line resource for details).

When the vehicle is armed, the effect of the security system Light Emitting Diode (LED) flashing is to cause a pulsation in the

measured current drain. In this case, either the average current should be taken (using a Digital Multi- Meter (DVOM) with an

averaging system) or the current reading taken, ignoring the brief high current peaks.

EQUIPMENT

Approved Jaguar or Land Rover diagnostic system with current probeOR Digital Multi-Meter (DVOM) with current probe.

METHOD OF MEASUREMENT

Using an Approved Jaguar or Land Rover Diagnostic System.

1. Switch off all electrical loads and ensure that the ignition is off

2. Connect the current probe to the approved Jaguar or Land Rover diagnostic system

3. Calibrate the probe

4. Install a clamp around the battery lead/junction box lead

5. Go to the Quiescent Current Testing section in this procedure

Using a digital multimeter

Do not use an in-line DVOM to measure the quiescent drain on vehicles fitted with an electronic throttle (for example XK 2006

onwards). The current exceeds the maximum amount the fuse in the DVOM is capable of handling.

1. Switch off all electrical loads and ensure that the ignition is off

2. Connect the current probe to the digital multmeter

3. Calibrate the probe

4. Install a clamp around the battery lead/junction box lead

5. Go to the Quiescent Current Testing section in this procedure

QUIESCENT CURRENT TESTING

1. Switch ignition to ‘on’ or select ignition mode in keyless vehicles and switch to ‘off’ (do not crank)

2. Remove key from ignition switch (if equipped)

3. Open and latch all doors, hood and luggage compartment lid

4. Lock the vehicle using the remote function on the remote handset. (Single lock only to avoid volumetric alarm arming)

5. Remove any other potential electrical drains such as accessories plugged into accessory sockets

6. Record the amperage readings after the shutdown period referenced in the Topix on line resource for details. Note all

cars from 10MY onwards and XK from 07MY and XF from 08MY should be less than 30mA after 30 minutes

7. Record the final reading on the battery report form

The preferred method of testing following an excessive current consumption figure is to use a current probe around individual

junction box leads to the various suspected circuits to identify a potential cause. This is in preference to the old method of

removing fuses for the following reasons:

The drain may be caused by a module remaining active and preventing the quiescent drain from reducing to normal

levels

The drain may be caused by a relay winding that is activated. Pulling the fuse can allow this to ‘reset’ and the drain will

be lost and go un-diagnosed

QUIESCENT DRAIN - TYPICAL VALUES

NOTE: The quiescent drain after the initial shutdown period should not exceed the value shown in the table.

Jaguar Quiescent Drain Values

MODEL SHUT DOWN PERIOD (minutes) TYPICAL VALUES BATTERY DRAIN (mA) XJS 3.2 60 <30 Sovereign 3.2 60 <37.3

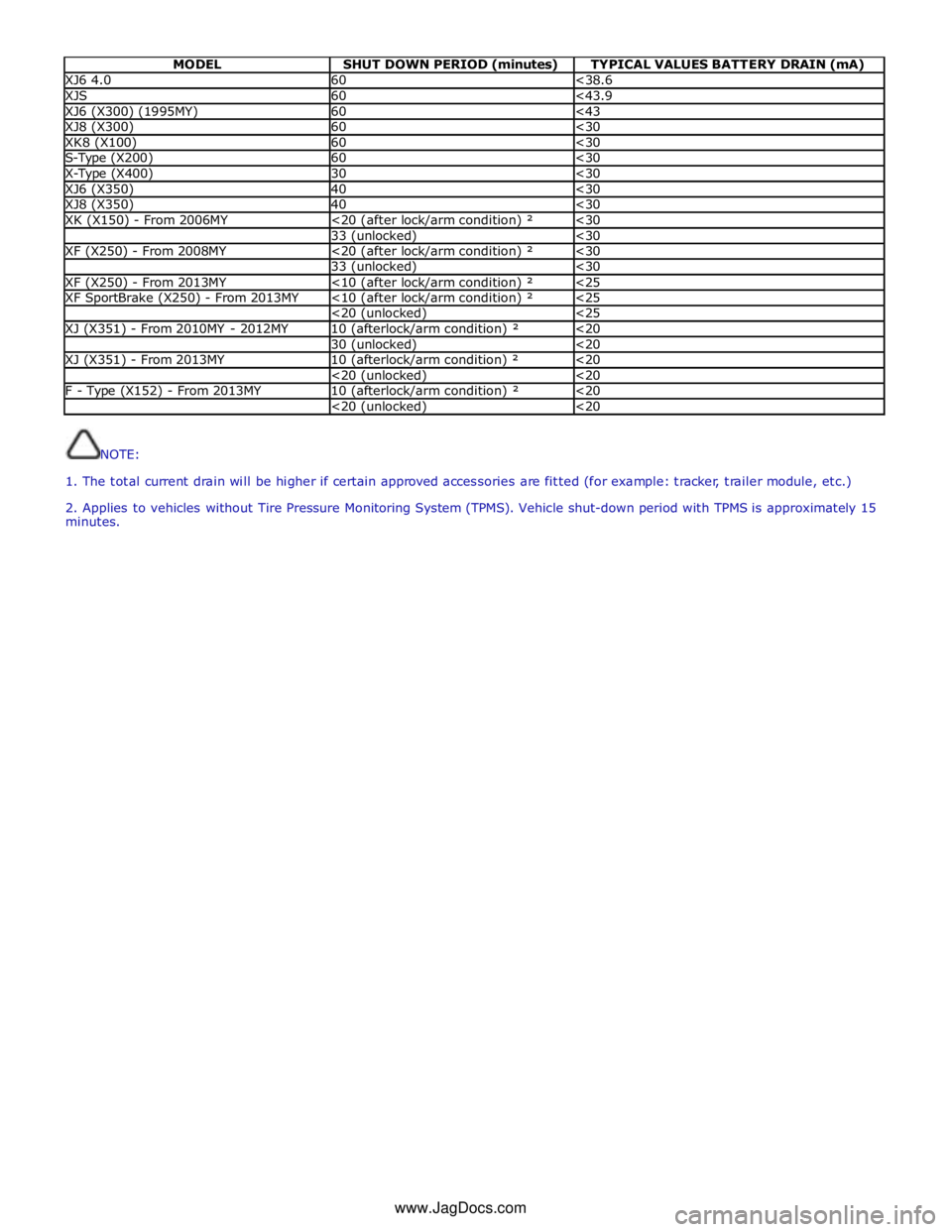

Page 1872 of 3039

MODEL SHUT DOWN PERIOD (minutes) TYPICAL VALUES BATTERY DRAIN (mA) XJ6 4.0 60 <38.6 XJS 60 <43.9 XJ6 (X300) (1995MY) 60 <43 XJ8 (X300) 60 <30 XK8 (X100) 60 <30 S-Type (X200) 60 <30 X-Type (X400) 30 <30 XJ6 (X350) 40 <30 XJ8 (X350) 40 <30 XK (X150) - From 2006MY <20 (after lock/arm condition) ² <30 33 (unlocked) <30 XF (X250) - From 2008MY <20 (after lock/arm condition) ² <30 33 (unlocked) <30 XF (X250) - From 2013MY <10 (after lock/arm condition) ² <25 XF SportBrake (X250) - From 2013MY <10 (after lock/arm condition) ² <25 <20 (unlocked) <25 XJ (X351) - From 2010MY - 2012MY 10 (afterlock/arm condition) ² <20 30 (unlocked) <20 XJ (X351) - From 2013MY 10 (afterlock/arm condition) ² <20 <20 (unlocked) <20 F - Type (X152) - From 2013MY 10 (afterlock/arm condition) ² <20 <20 (unlocked) <20

NOTE:

1. The total current drain will be higher if certain approved accessories are fitted (for example: tracker, trailer module, etc.)

2. Applies to vehicles without Tire Pressure Monitoring System (TPMS). Vehicle shut-down period with TPMS is approximately 15

minutes.

www.JagDocs.com

Page 1876 of 3039

1 EJB (engine junction box) 2 CJB (central junction box) 3 BJB (battery junction box) 4 RJB (rear junction box) 5 BMS (battery monitoring system) 6 Battery 7 ECM (engine control module) 8 Generator