battery monitoring module JAGUAR XFR 2010 1.G User Guide

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 2010, Model line: XFR, Model: JAGUAR XFR 2010 1.GPages: 3039, PDF Size: 58.49 MB

Page 259 of 3039

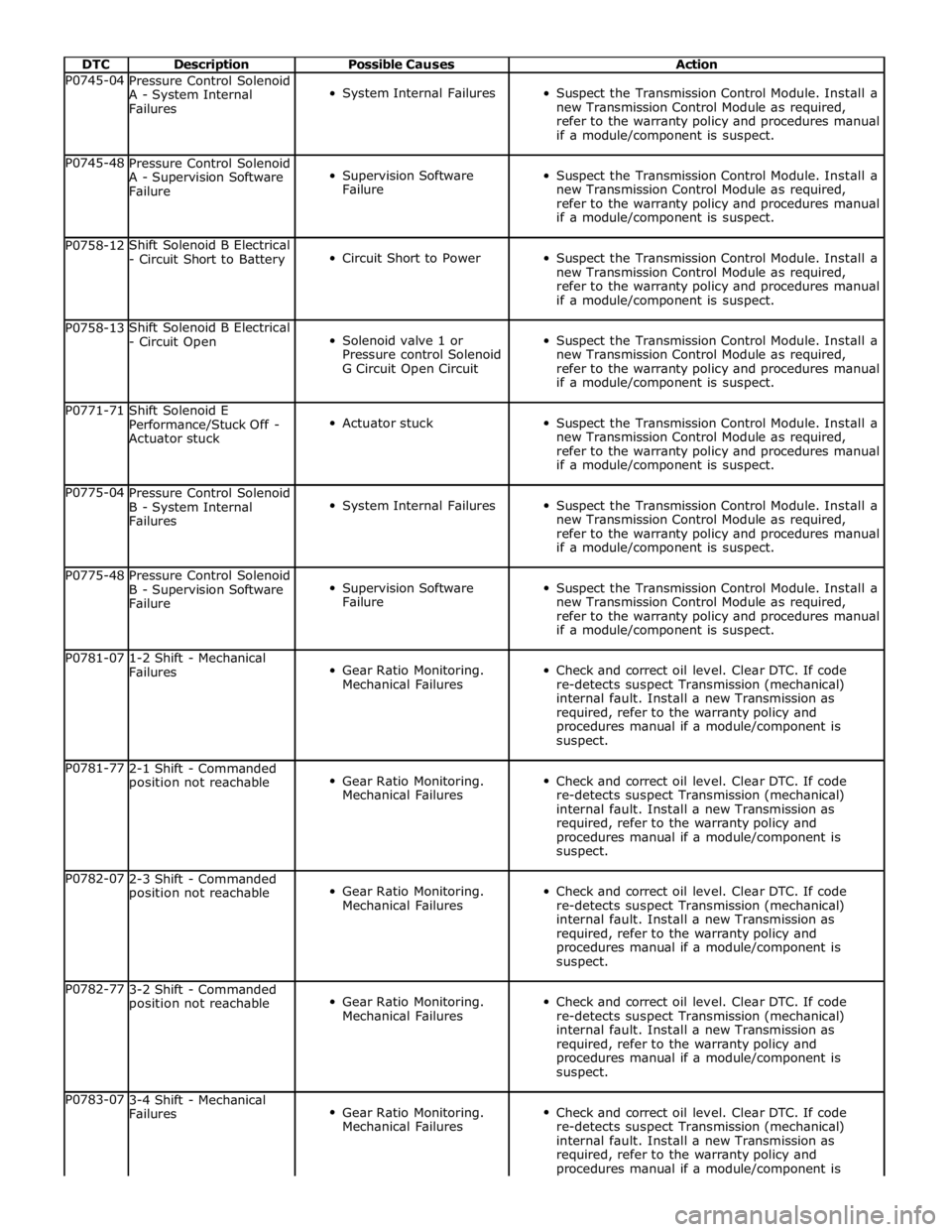

DTC Description Possible Causes Action P0745-04

Pressure Control Solenoid

A - System Internal

Failures

System Internal Failures

Suspect the Transmission Control Module. Install a

new Transmission Control Module as required,

refer to the warranty policy and procedures manual

if a module/component is suspect. P0745-48

Pressure Control Solenoid

A - Supervision Software

Failure

Supervision Software

Failure

Suspect the Transmission Control Module. Install a

new Transmission Control Module as required,

refer to the warranty policy and procedures manual

if a module/component is suspect. P0758-12 Shift Solenoid B Electrical

- Circuit Short to Battery

Circuit Short to Power

Suspect the Transmission Control Module. Install a

new Transmission Control Module as required,

refer to the warranty policy and procedures manual

if a module/component is suspect. P0758-13 Shift Solenoid B Electrical

- Circuit Open

Solenoid valve 1 or

Pressure control Solenoid

G Circuit Open Circuit

Suspect the Transmission Control Module. Install a

new Transmission Control Module as required,

refer to the warranty policy and procedures manual

if a module/component is suspect. P0771-71

Shift Solenoid E

Performance/Stuck Off -

Actuator stuck

Actuator stuck

Suspect the Transmission Control Module. Install a

new Transmission Control Module as required,

refer to the warranty policy and procedures manual

if a module/component is suspect. P0775-04

Pressure Control Solenoid

B - System Internal

Failures

System Internal Failures

Suspect the Transmission Control Module. Install a

new Transmission Control Module as required,

refer to the warranty policy and procedures manual

if a module/component is suspect. P0775-48

Pressure Control Solenoid

B - Supervision Software

Failure

Supervision Software

Failure

Suspect the Transmission Control Module. Install a

new Transmission Control Module as required,

refer to the warranty policy and procedures manual

if a module/component is suspect. P0781-07

1-2 Shift - Mechanical

Failures

Gear Ratio Monitoring.

Mechanical Failures

Check and correct oil level. Clear DTC. If code

re-detects suspect Transmission (mechanical)

internal fault. Install a new Transmission as

required, refer to the warranty policy and

procedures manual if a module/component is

suspect. P0781-77

2-1 Shift - Commanded

position not reachable

Gear Ratio Monitoring.

Mechanical Failures

Check and correct oil level. Clear DTC. If code

re-detects suspect Transmission (mechanical)

internal fault. Install a new Transmission as

required, refer to the warranty policy and

procedures manual if a module/component is

suspect. P0782-07

2-3 Shift - Commanded

position not reachable

Gear Ratio Monitoring.

Mechanical Failures

Check and correct oil level. Clear DTC. If code

re-detects suspect Transmission (mechanical)

internal fault. Install a new Transmission as

required, refer to the warranty policy and

procedures manual if a module/component is

suspect. P0782-77

3-2 Shift - Commanded

position not reachable

Gear Ratio Monitoring.

Mechanical Failures

Check and correct oil level. Clear DTC. If code

re-detects suspect Transmission (mechanical)

internal fault. Install a new Transmission as

required, refer to the warranty policy and

procedures manual if a module/component is

suspect. P0783-07

3-4 Shift - Mechanical

Failures

Gear Ratio Monitoring.

Mechanical Failures

Check and correct oil level. Clear DTC. If code

re-detects suspect Transmission (mechanical)

internal fault. Install a new Transmission as

required, refer to the warranty policy and

procedures manual if a module/component is

Page 261 of 3039

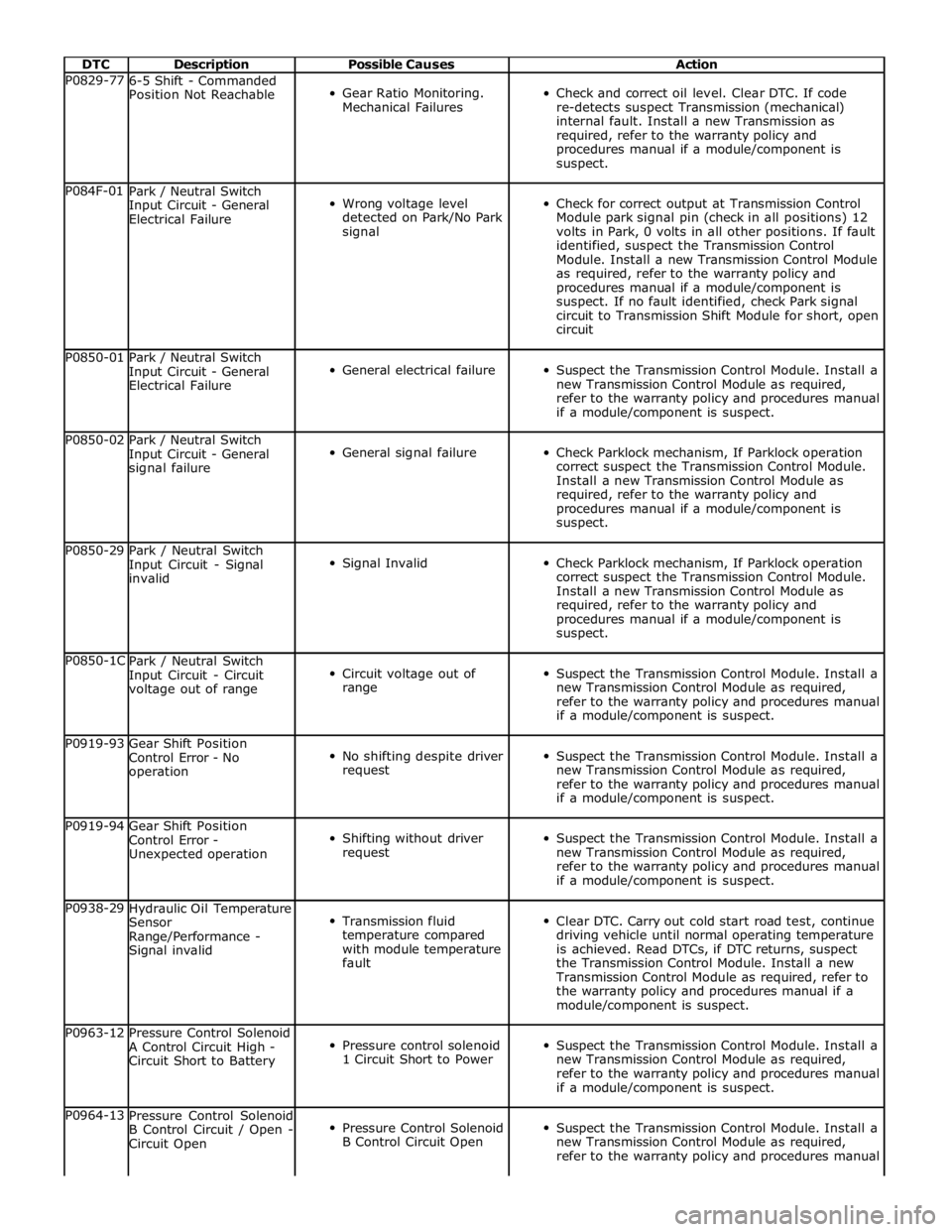

DTC Description Possible Causes Action P0829-77

6-5 Shift - Commanded

Position Not Reachable

Gear Ratio Monitoring.

Mechanical Failures

Check and correct oil level. Clear DTC. If code

re-detects suspect Transmission (mechanical)

internal fault. Install a new Transmission as

required, refer to the warranty policy and

procedures manual if a module/component is

suspect. P084F-01

Park / Neutral Switch

Input Circuit - General

Electrical Failure

Wrong voltage level

detected on Park/No Park

signal

Check for correct output at Transmission Control

Module park signal pin (check in all positions) 12

volts in Park, 0 volts in all other positions. If fault

identified, suspect the Transmission Control

Module. Install a new Transmission Control Module

as required, refer to the warranty policy and

procedures manual if a module/component is

suspect. If no fault identified, check Park signal

circuit to Transmission Shift Module for short, open

circuit P0850-01

Park / Neutral Switch

Input Circuit - General

Electrical Failure

General electrical failure

Suspect the Transmission Control Module. Install a

new Transmission Control Module as required,

refer to the warranty policy and procedures manual

if a module/component is suspect. P0850-02

Park / Neutral Switch

Input Circuit - General

signal failure

General signal failure

Check Parklock mechanism, If Parklock operation

correct suspect the Transmission Control Module.

Install a new Transmission Control Module as

required, refer to the warranty policy and

procedures manual if a module/component is

suspect. P0850-29

Park / Neutral Switch

Input Circuit - Signal

invalid

Signal Invalid

Check Parklock mechanism, If Parklock operation

correct suspect the Transmission Control Module.

Install a new Transmission Control Module as

required, refer to the warranty policy and

procedures manual if a module/component is

suspect. P0850-1C

Park / Neutral Switch

Input Circuit - Circuit

voltage out of range

Circuit voltage out of

range

Suspect the Transmission Control Module. Install a

new Transmission Control Module as required,

refer to the warranty policy and procedures manual

if a module/component is suspect. P0919-93

Gear Shift Position

Control Error - No

operation

No shifting despite driver

request

Suspect the Transmission Control Module. Install a

new Transmission Control Module as required,

refer to the warranty policy and procedures manual

if a module/component is suspect. P0919-94

Gear Shift Position

Control Error -

Unexpected operation

Shifting without driver

request

Suspect the Transmission Control Module. Install a

new Transmission Control Module as required,

refer to the warranty policy and procedures manual

if a module/component is suspect. P0938-29

Hydraulic Oil Temperature

Sensor

Range/Performance -

Signal invalid

Transmission fluid

temperature compared

with module temperature

fault

Clear DTC. Carry out cold start road test, continue

driving vehicle until normal operating temperature

is achieved. Read DTCs, if DTC returns, suspect

the Transmission Control Module. Install a new

Transmission Control Module as required, refer to

the warranty policy and procedures manual if a

module/component is suspect. P0963-12

Pressure Control Solenoid

A Control Circuit High -

Circuit Short to Battery

Pressure control solenoid

1 Circuit Short to Power

Suspect the Transmission Control Module. Install a

new Transmission Control Module as required,

refer to the warranty policy and procedures manual

if a module/component is suspect. P0964-13

Pressure Control Solenoid

B Control Circuit / Open -

Circuit Open

Pressure Control Solenoid

B Control Circuit Open

Suspect the Transmission Control Module. Install a

new Transmission Control Module as required,

refer to the warranty policy and procedures manual

Page 264 of 3039

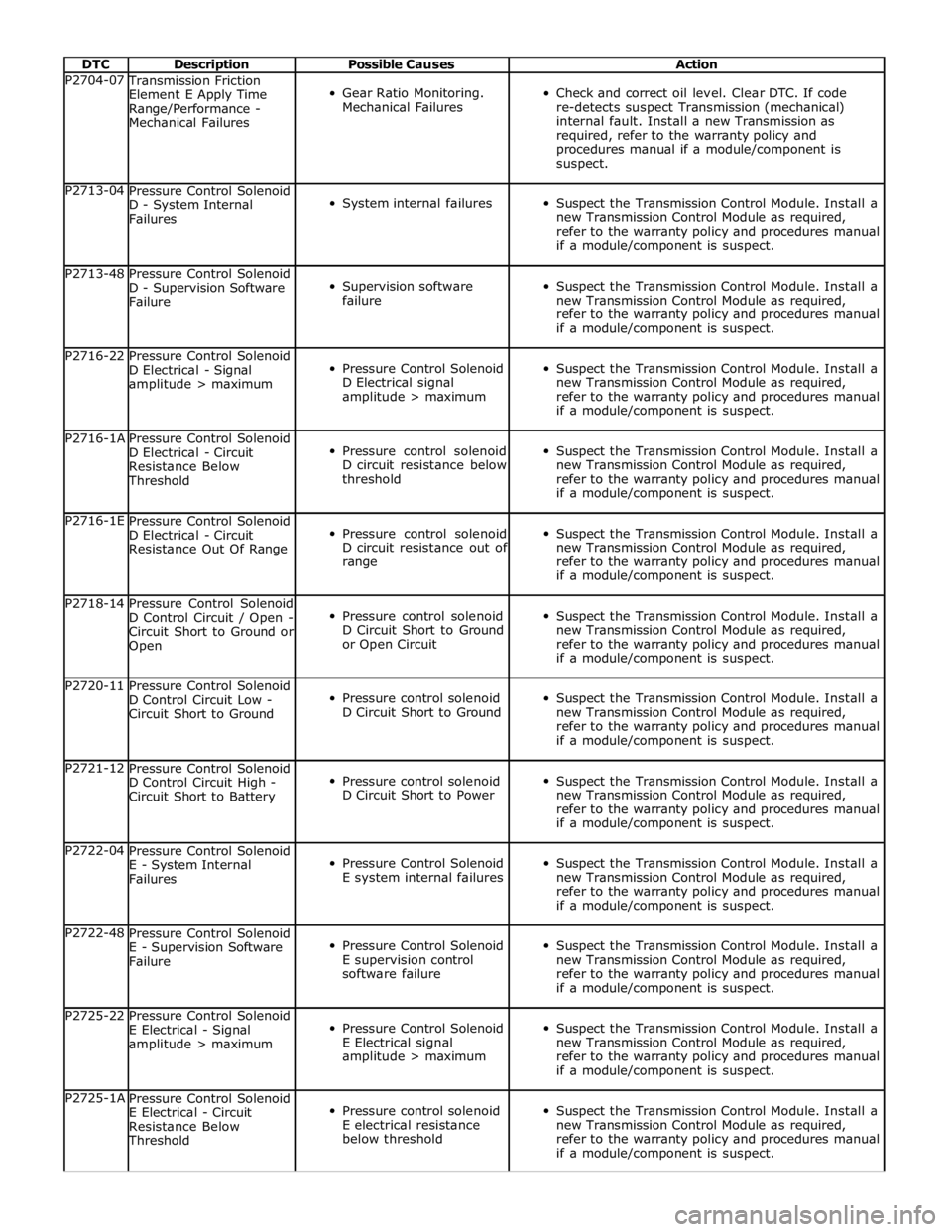

DTC Description Possible Causes Action P2704-07 Transmission Friction

Element E Apply Time

Range/Performance -

Mechanical Failures

Gear Ratio Monitoring.

Mechanical Failures

Check and correct oil level. Clear DTC. If code

re-detects suspect Transmission (mechanical)

internal fault. Install a new Transmission as

required, refer to the warranty policy and

procedures manual if a module/component is

suspect. P2713-04

Pressure Control Solenoid

D - System Internal

Failures

System internal failures

Suspect the Transmission Control Module. Install a

new Transmission Control Module as required,

refer to the warranty policy and procedures manual

if a module/component is suspect. P2713-48

Pressure Control Solenoid

D - Supervision Software

Failure

Supervision software

failure

Suspect the Transmission Control Module. Install a

new Transmission Control Module as required,

refer to the warranty policy and procedures manual

if a module/component is suspect. P2716-22

Pressure Control Solenoid

D Electrical - Signal

amplitude > maximum

Pressure Control Solenoid

D Electrical signal

amplitude > maximum

Suspect the Transmission Control Module. Install a

new Transmission Control Module as required,

refer to the warranty policy and procedures manual

if a module/component is suspect. P2716-1A

Pressure Control Solenoid

D Electrical - Circuit

Resistance Below Threshold

Pressure control solenoid

D circuit resistance below

threshold

Suspect the Transmission Control Module. Install a

new Transmission Control Module as required,

refer to the warranty policy and procedures manual

if a module/component is suspect. P2716-1E

Pressure Control Solenoid

D Electrical - Circuit

Resistance Out Of Range

Pressure control solenoid

D circuit resistance out of

range

Suspect the Transmission Control Module. Install a

new Transmission Control Module as required,

refer to the warranty policy and procedures manual

if a module/component is suspect. P2718-14

Pressure Control Solenoid

D Control Circuit / Open -

Circuit Short to Ground or

Open

Pressure control solenoid

D Circuit Short to Ground

or Open Circuit

Suspect the Transmission Control Module. Install a

new Transmission Control Module as required,

refer to the warranty policy and procedures manual

if a module/component is suspect. P2720-11

Pressure Control Solenoid

D Control Circuit Low -

Circuit Short to Ground

Pressure control solenoid

D Circuit Short to Ground

Suspect the Transmission Control Module. Install a

new Transmission Control Module as required,

refer to the warranty policy and procedures manual

if a module/component is suspect. P2721-12

Pressure Control Solenoid

D Control Circuit High -

Circuit Short to Battery

Pressure control solenoid

D Circuit Short to Power

Suspect the Transmission Control Module. Install a

new Transmission Control Module as required,

refer to the warranty policy and procedures manual

if a module/component is suspect. P2722-04

Pressure Control Solenoid

E - System Internal

Failures

Pressure Control Solenoid

E system internal failures

Suspect the Transmission Control Module. Install a

new Transmission Control Module as required,

refer to the warranty policy and procedures manual

if a module/component is suspect. P2722-48

Pressure Control Solenoid

E - Supervision Software

Failure

Pressure Control Solenoid

E supervision control

software failure

Suspect the Transmission Control Module. Install a

new Transmission Control Module as required,

refer to the warranty policy and procedures manual

if a module/component is suspect. P2725-22

Pressure Control Solenoid

E Electrical - Signal

amplitude > maximum

Pressure Control Solenoid

E Electrical signal

amplitude > maximum

Suspect the Transmission Control Module. Install a

new Transmission Control Module as required,

refer to the warranty policy and procedures manual

if a module/component is suspect. P2725-1A

Pressure Control Solenoid

E Electrical - Circuit

Resistance Below Threshold

Pressure control solenoid

E electrical resistance

below threshold

Suspect the Transmission Control Module. Install a

new Transmission Control Module as required,

refer to the warranty policy and procedures manual

if a module/component is suspect.

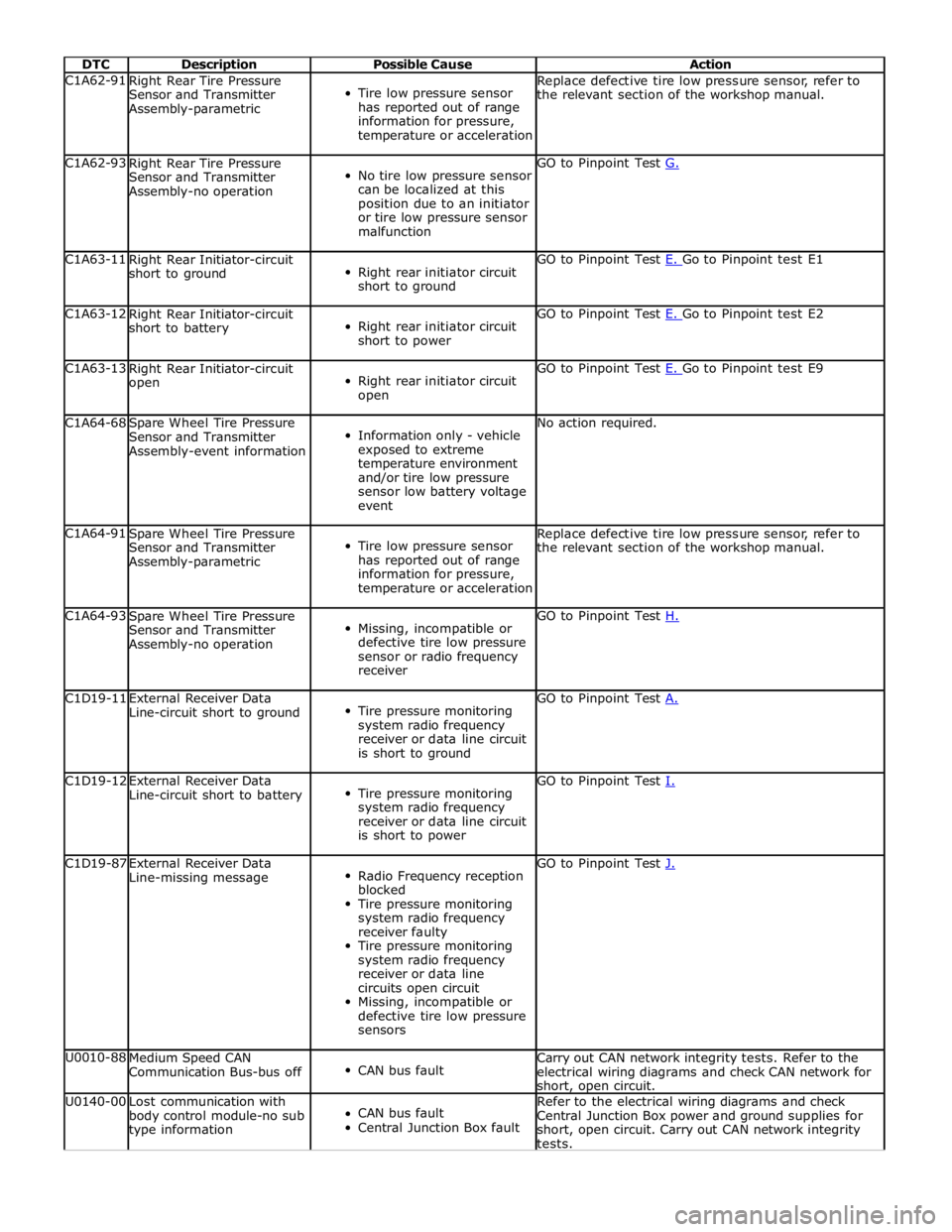

Page 450 of 3039

DTC Description Possible Cause Action C1A62-91

Right Rear Tire Pressure

Sensor and Transmitter

Assembly-parametric

Tire low pressure sensor

has reported out of range

information for pressure,

temperature or acceleration Replace defective tire low pressure sensor, refer to

the relevant section of the workshop manual. C1A62-93

Right Rear Tire Pressure

Sensor and Transmitter

Assembly-no operation

No tire low pressure sensor

can be localized at this

position due to an initiator

or tire low pressure sensor

malfunction GO to Pinpoint Test G. C1A63-11

Right Rear Initiator-circuit

short to ground

Right rear initiator circuit

short to ground GO to Pinpoint Test E. Go to Pinpoint test E1 C1A63-12

Right Rear Initiator-circuit

short to battery

Right rear initiator circuit

short to power GO to Pinpoint Test E. Go to Pinpoint test E2 C1A63-13

Right Rear Initiator-circuit

open

Right rear initiator circuit

open GO to Pinpoint Test E. Go to Pinpoint test E9 C1A64-68

Spare Wheel Tire Pressure

Sensor and Transmitter

Assembly-event information

Information only - vehicle

exposed to extreme

temperature environment

and/or tire low pressure

sensor low battery voltage

event No action required. C1A64-91

Spare Wheel Tire Pressure

Sensor and Transmitter

Assembly-parametric

Tire low pressure sensor

has reported out of range

information for pressure,

temperature or acceleration Replace defective tire low pressure sensor, refer to

the relevant section of the workshop manual. C1A64-93

Spare Wheel Tire Pressure

Sensor and Transmitter

Assembly-no operation

Missing, incompatible or

defective tire low pressure

sensor or radio frequency

receiver GO to Pinpoint Test H. C1D19-11

External Receiver Data

Line-circuit short to ground

Tire pressure monitoring

system radio frequency

receiver or data line circuit

is short to ground GO to Pinpoint Test A. C1D19-12

External Receiver Data

Line-circuit short to battery

Tire pressure monitoring

system radio frequency

receiver or data line circuit

is short to power GO to Pinpoint Test I. C1D19-87

External Receiver Data

Line-missing message

Radio Frequency reception

blocked

Tire pressure monitoring

system radio frequency

receiver faulty

Tire pressure monitoring

system radio frequency

receiver or data line

circuits open circuit

Missing, incompatible or

defective tire low pressure

sensors GO to Pinpoint Test J. U0010-88

Medium Speed CAN

Communication Bus-bus off

CAN bus fault Carry out CAN network integrity tests. Refer to the

electrical wiring diagrams and check CAN network for

short, open circuit. U0140-00

Lost communication with

body control module-no sub

type information

CAN bus fault

Central Junction Box fault Refer to the electrical wiring diagrams and check

Central Junction Box power and ground supplies for

short, open circuit. Carry out CAN network integrity

tests.

Page 452 of 3039

TEST CONDITIONS DETAILS/RESULTS/ACTIONS A1: C1D1911 VERIFY EXTERNAL RECEIVER DATA LINE CIRCUIT SHORT TO GROUND 1 Ignition off. 2 Disconnect the Tire Pressure Monitoring System Receiver electrical connector, C3MC45. 3 Measure the resistance between C3MC45, harness side Battery Pin 1 Negative terminal Is the resistance less than 5 Ohms?

Yes

GO to A2.GO to A2. No

GO to A3.GO to A3. A2: C1D1911 CHECK THE EXTERNAL RECEIVER DATA LINE CIRCUIT FOR SHORT CIRCUIT TO GROUND 1 Disconnect the Tire Pressure Monitoring System Control Module electrical connector, C3MC39B. 2 Measure the resistance between C3MC45, harness side Battery Pin 1 Negative terminal Is the resistance less than 5 Ohms?

Yes

REPAIR the short circuit in wiring harness.

No

GO to A4.GO to A4. A3: C1D1911 CHECK THE TIRE PRESSURE MONITORING SYSTEM EXTERNAL RECEIVER FOR SHORT CIRCUIT TO

GROUND 1 Reconnect the Tire Pressure Monitoring System Receiver electrical connector, C3MC45. 2 Using manufacturer approved diagnostic system run On Demand Self Test (0x0202). Is the DTC C1D1911 set?

Yes

Replace Tire Pressure Monitoring Receiver.

No

Investigate possible cause of intermittent failure. A4: C1D1911 CHECK THE TIRE PRESSURE MONITORING SYSTEM CONTROL MODULE FOR SHORT CIRCUIT TO

GROUND 1 Reconnect the Tire Pressure Monitoring System Control Module electrical connector, C3MC39B. 2 Reconnect the Tire Pressure Monitoring System Receiver electrical connector, C3MC45.

Page 453 of 3039

3 Using manufacturer approved diagnostic system run On Demand Self Test (0x0202). Is the DTC C1D1911 set?

Yes

Replace Tire Pressure Monitoring System Control Module.

No

Investigate possible cause of intermittent failure.

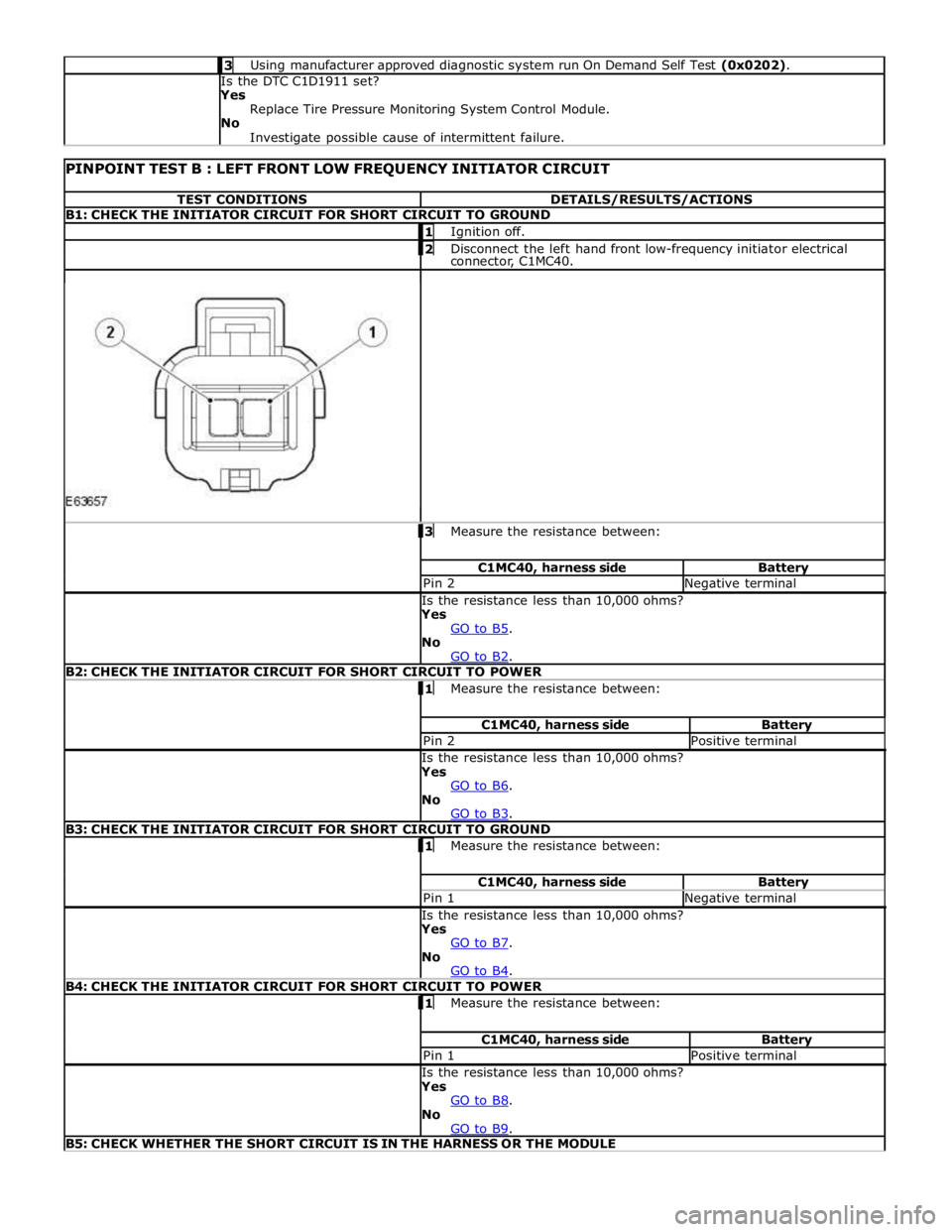

PINPOINT TEST B : LEFT FRONT LOW FREQUENCY INITIATOR CIRCUIT TEST CONDITIONS DETAILS/RESULTS/ACTIONS B1: CHECK THE INITIATOR CIRCUIT FOR SHORT CIRCUIT TO GROUND 1 Ignition off. 2 Disconnect the left hand front low-frequency initiator electrical connector, C1MC40. 3 Measure the resistance between: C1MC40, harness side Battery Pin 2 Negative terminal Is the resistance less than 10,000 ohms?

Yes

GO to B5. No

GO to B2. B2: CHECK THE INITIATOR CIRCUIT FOR SHORT CIRCUIT TO POWER 1 Measure the resistance between: C1MC40, harness side Battery Pin 2 Positive terminal Is the resistance less than 10,000 ohms?

Yes

GO to B6. No

GO to B3. B3: CHECK THE INITIATOR CIRCUIT FOR SHORT CIRCUIT TO GROUND 1 Measure the resistance between: C1MC40, harness side Battery Pin 1 Negative terminal Is the resistance less than 10,000 ohms?

Yes

GO to B7. No

GO to B4. B4: CHECK THE INITIATOR CIRCUIT FOR SHORT CIRCUIT TO POWER 1 Measure the resistance between: C1MC40, harness side Battery Pin 1 Positive terminal Is the resistance less than 10,000 ohms?

Yes

GO to B8. No

GO to B9. B5: CHECK WHETHER THE SHORT CIRCUIT IS IN THE HARNESS OR THE MODULE

Page 454 of 3039

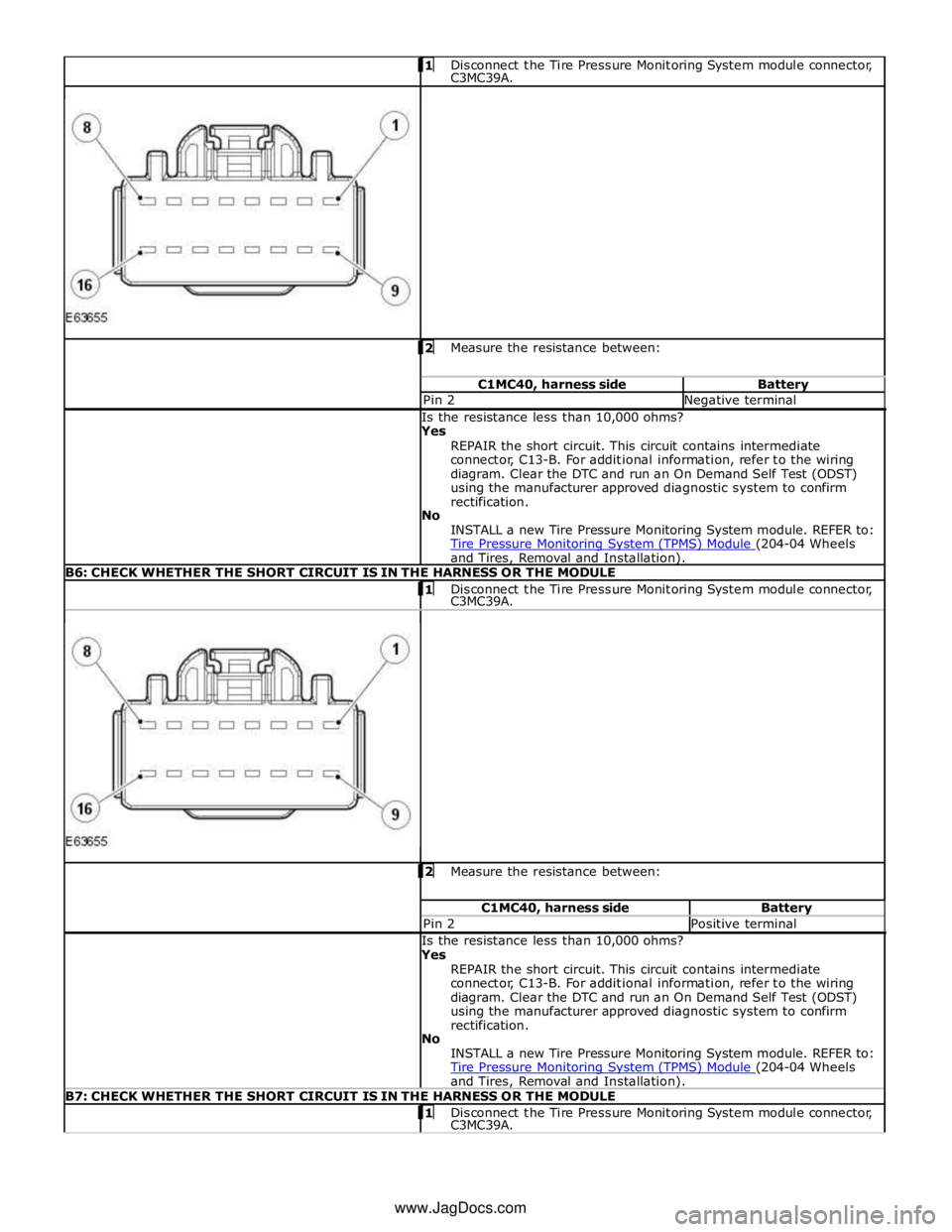

Disconnect the Tire Pressure Monitoring System module connector, C3MC39A.

2 Measure the resistance between: C1MC40, harness side Battery Pin 2 Negative terminal Is the resistance less than 10,000 ohms?

Yes

REPAIR the short circuit. This circuit contains intermediate

connector, C13-B. For additional information, refer to the wiring

diagram. Clear the DTC and run an On Demand Self Test (ODST)

using the manufacturer approved diagnostic system to confirm

rectification.

No

INSTALL a new Tire Pressure Monitoring System module. REFER to:

Tire Pressure Monitoring System (TPMS) Module (204-04 Wheels and Tires, Removal and Installation). B6: CHECK WHETHER THE SHORT CIRCUIT IS IN THE HARNESS OR THE MODULE 1 Disconnect the Tire Pressure Monitoring System module connector, C3MC39A. 2 Measure the resistance between: C1MC40, harness side Battery Pin 2 Positive terminal Is the resistance less than 10,000 ohms?

Yes

REPAIR the short circuit. This circuit contains intermediate

connector, C13-B. For additional information, refer to the wiring

diagram. Clear the DTC and run an On Demand Self Test (ODST)

using the manufacturer approved diagnostic system to confirm

rectification.

No

INSTALL a new Tire Pressure Monitoring System module. REFER to:

Tire Pressure Monitoring System (TPMS) Module (204-04 Wheels and Tires, Removal and Installation). B7: CHECK WHETHER THE SHORT CIRCUIT IS IN THE HARNESS OR THE MODULE 1 Disconnect the Tire Pressure Monitoring System module connector, C3MC39A. www.JagDocs.com

Page 455 of 3039

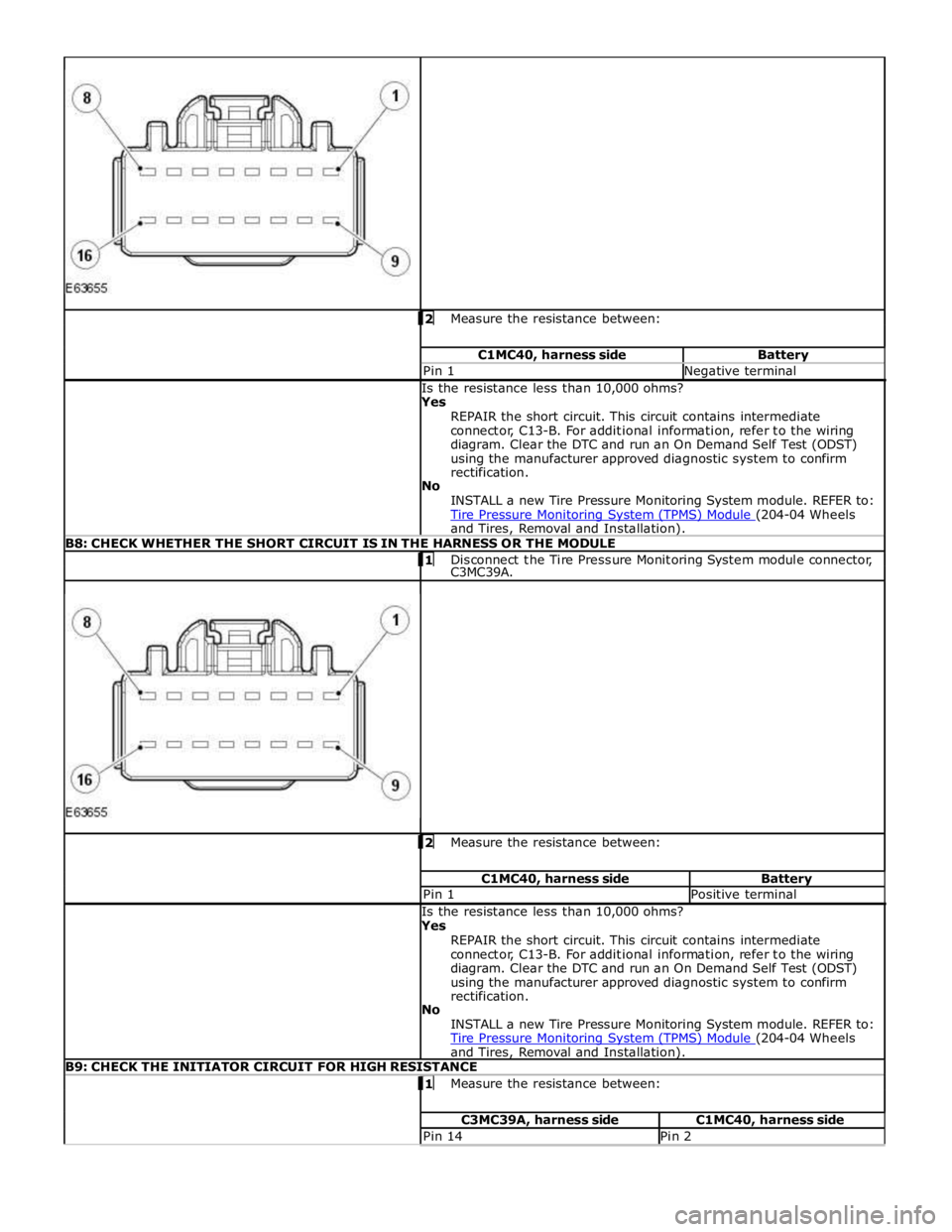

2 Measure the resistance between: C1MC40, harness side Battery Pin 1 Negative terminal Is the resistance less than 10,000 ohms?

Yes

REPAIR the short circuit. This circuit contains intermediate

connector, C13-B. For additional information, refer to the wiring

diagram. Clear the DTC and run an On Demand Self Test (ODST)

using the manufacturer approved diagnostic system to confirm

rectification.

No

INSTALL a new Tire Pressure Monitoring System module. REFER to:

Tire Pressure Monitoring System (TPMS) Module (204-04 Wheels and Tires, Removal and Installation). B8: CHECK WHETHER THE SHORT CIRCUIT IS IN THE HARNESS OR THE MODULE 1 Disconnect the Tire Pressure Monitoring System module connector, C3MC39A. 2 Measure the resistance between: C1MC40, harness side Battery Pin 1 Positive terminal Is the resistance less than 10,000 ohms?

Yes

REPAIR the short circuit. This circuit contains intermediate

connector, C13-B. For additional information, refer to the wiring

diagram. Clear the DTC and run an On Demand Self Test (ODST)

using the manufacturer approved diagnostic system to confirm

rectification.

No

INSTALL a new Tire Pressure Monitoring System module. REFER to:

Tire Pressure Monitoring System (TPMS) Module (204-04 Wheels and Tires, Removal and Installation). B9: CHECK THE INITIATOR CIRCUIT FOR HIGH RESISTANCE 1 Measure the resistance between: C3MC39A, harness side C1MC40, harness side Pin 14 Pin 2

Page 457 of 3039

No

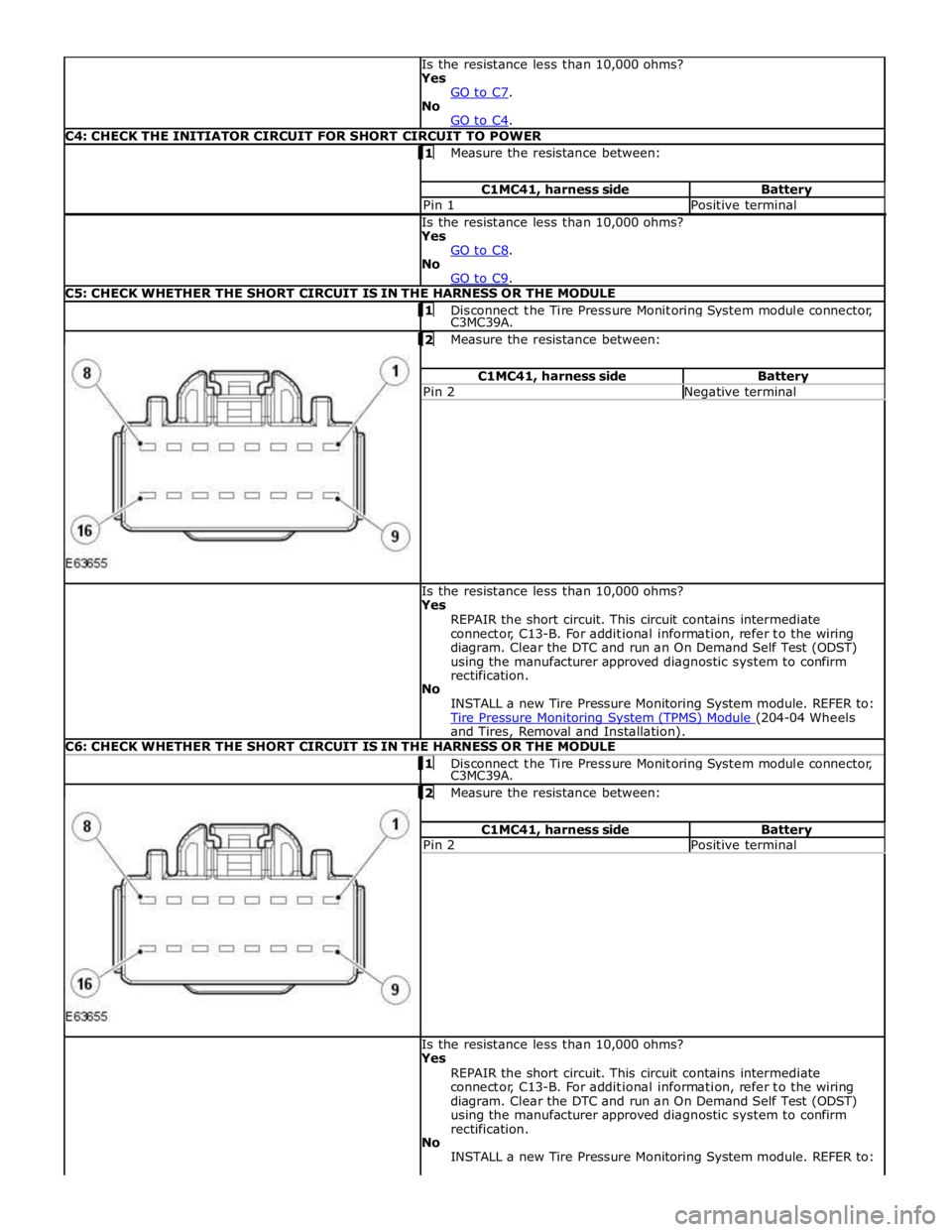

GO to C4. C4: CHECK THE INITIATOR CIRCUIT FOR SHORT CIRCUIT TO POWER 1 Measure the resistance between: C1MC41, harness side Battery Pin 1 Positive terminal Is the resistance less than 10,000 ohms?

Yes

GO to C8. No

GO to C9. C5: CHECK WHETHER THE SHORT CIRCUIT IS IN THE HARNESS OR THE MODULE 1 Disconnect the Tire Pressure Monitoring System module connector, C3MC39A.

2 Measure the resistance between: C1MC41, harness side Battery Pin 2 Negative terminal Is the resistance less than 10,000 ohms?

Yes

REPAIR the short circuit. This circuit contains intermediate

connector, C13-B. For additional information, refer to the wiring

diagram. Clear the DTC and run an On Demand Self Test (ODST)

using the manufacturer approved diagnostic system to confirm

rectification.

No

INSTALL a new Tire Pressure Monitoring System module. REFER to:

Tire Pressure Monitoring System (TPMS) Module (204-04 Wheels and Tires, Removal and Installation). C6: CHECK WHETHER THE SHORT CIRCUIT IS IN THE HARNESS OR THE MODULE 1 Disconnect the Tire Pressure Monitoring System module connector, C3MC39A.

2 Measure the resistance between: C1MC41, harness side Battery Pin 2 Positive terminal Is the resistance less than 10,000 ohms?

Yes

REPAIR the short circuit. This circuit contains intermediate

connector, C13-B. For additional information, refer to the wiring

diagram. Clear the DTC and run an On Demand Self Test (ODST)

using the manufacturer approved diagnostic system to confirm

rectification.

No

INSTALL a new Tire Pressure Monitoring System module. REFER to:

Page 458 of 3039

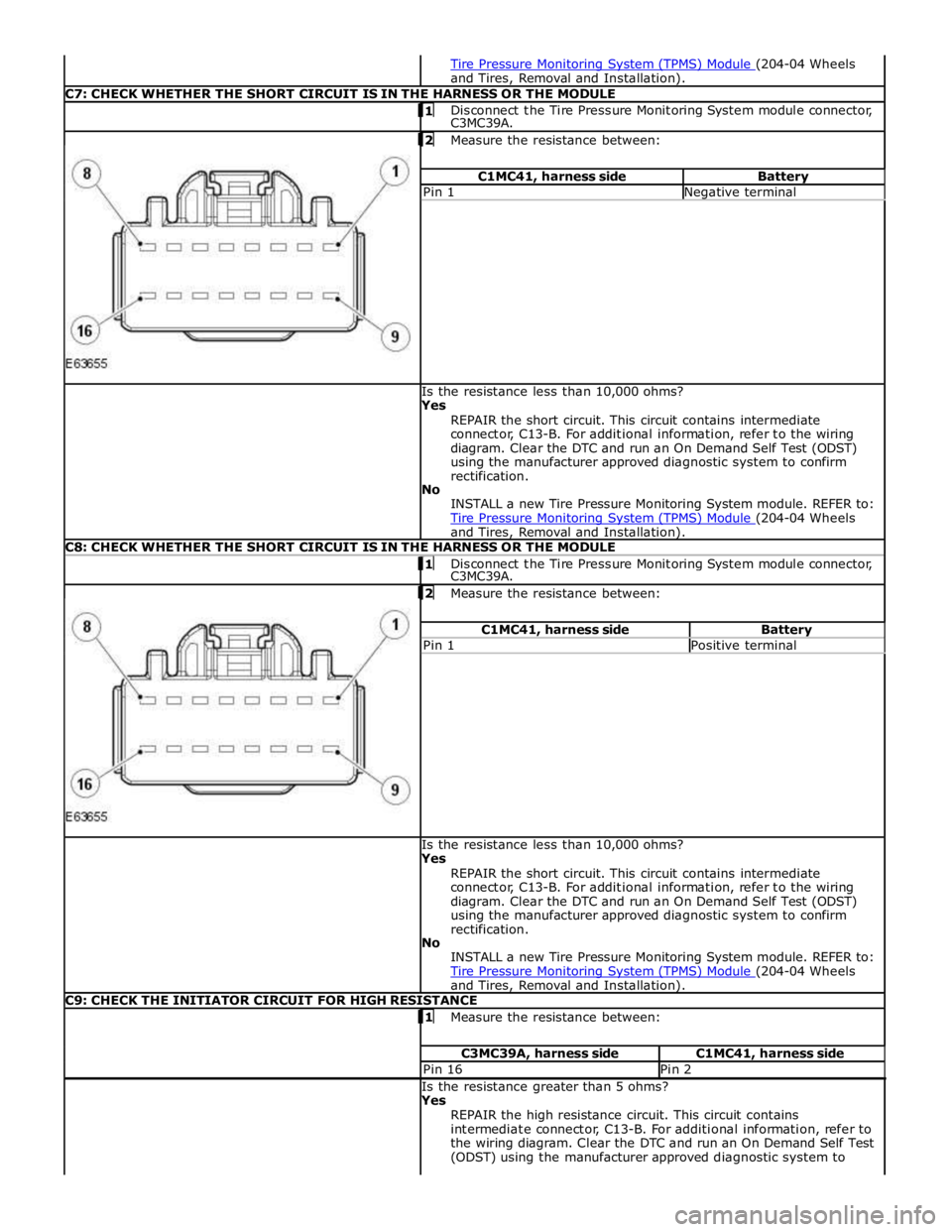

and Tires, Removal and Installation). C7: CHECK WHETHER THE SHORT CIRCUIT IS IN THE HARNESS OR THE MODULE 1 Disconnect the Tire Pressure Monitoring System module connector, C3MC39A.

2 Measure the resistance between: C1MC41, harness side Battery Pin 1 Negative terminal Is the resistance less than 10,000 ohms?

Yes

REPAIR the short circuit. This circuit contains intermediate

connector, C13-B. For additional information, refer to the wiring

diagram. Clear the DTC and run an On Demand Self Test (ODST)

using the manufacturer approved diagnostic system to confirm

rectification.

No

INSTALL a new Tire Pressure Monitoring System module. REFER to:

Tire Pressure Monitoring System (TPMS) Module (204-04 Wheels and Tires, Removal and Installation). C8: CHECK WHETHER THE SHORT CIRCUIT IS IN THE HARNESS OR THE MODULE 1 Disconnect the Tire Pressure Monitoring System module connector, C3MC39A.

2 Measure the resistance between: C1MC41, harness side Battery Pin 1 Positive terminal Is the resistance less than 10,000 ohms?

Yes

REPAIR the short circuit. This circuit contains intermediate

connector, C13-B. For additional information, refer to the wiring

diagram. Clear the DTC and run an On Demand Self Test (ODST)

using the manufacturer approved diagnostic system to confirm

rectification.

No

INSTALL a new Tire Pressure Monitoring System module. REFER to:

Tire Pressure Monitoring System (TPMS) Module (204-04 Wheels and Tires, Removal and Installation). C9: CHECK THE INITIATOR CIRCUIT FOR HIGH RESISTANCE 1 Measure the resistance between: C3MC39A, harness side C1MC41, harness side Pin 16 Pin 2 Is the resistance greater than 5 ohms?

Yes

REPAIR the high resistance circuit. This circuit contains

intermediate connector, C13-B. For additional information, refer to

the wiring diagram. Clear the DTC and run an On Demand Self Test

(ODST) using the manufacturer approved diagnostic system to