battery monitoring module JAGUAR XFR 2010 1.G Repair Manual

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 2010, Model line: XFR, Model: JAGUAR XFR 2010 1.GPages: 3039, PDF Size: 58.49 MB

Page 2097 of 3039

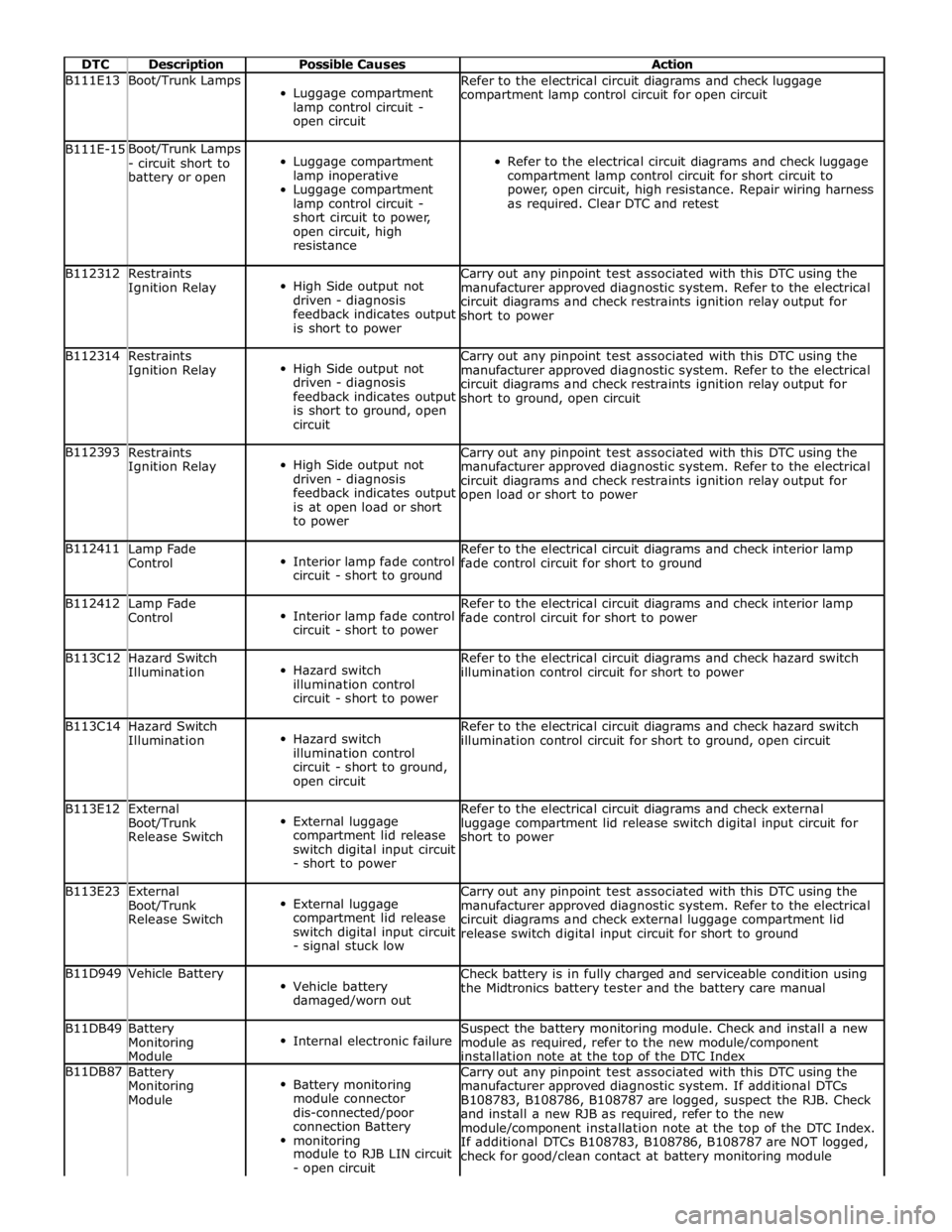

DTC Description Possible Causes Action B111E13 Boot/Trunk Lamps

Luggage compartment

lamp control circuit -

open circuit Refer to the electrical circuit diagrams and check luggage

compartment lamp control circuit for open circuit B111E-15 Boot/Trunk Lamps

- circuit short to

battery or open

Luggage compartment

lamp inoperative

Luggage compartment

lamp control circuit -

short circuit to power,

open circuit, high

resistance

Refer to the electrical circuit diagrams and check luggage

compartment lamp control circuit for short circuit to

power, open circuit, high resistance. Repair wiring harness

as required. Clear DTC and retest B112312

Restraints

Ignition Relay

High Side output not

driven - diagnosis

feedback indicates output

is short to power Carry out any pinpoint test associated with this DTC using the

manufacturer approved diagnostic system. Refer to the electrical

circuit diagrams and check restraints ignition relay output for

short to power B112314

Restraints

Ignition Relay

High Side output not

driven - diagnosis

feedback indicates output

is short to ground, open

circuit Carry out any pinpoint test associated with this DTC using the

manufacturer approved diagnostic system. Refer to the electrical

circuit diagrams and check restraints ignition relay output for

short to ground, open circuit B112393

Restraints

Ignition Relay

High Side output not

driven - diagnosis

feedback indicates output

is at open load or short

to power Carry out any pinpoint test associated with this DTC using the

manufacturer approved diagnostic system. Refer to the electrical

circuit diagrams and check restraints ignition relay output for

open load or short to power B112411

Lamp Fade

Control

Interior lamp fade control

circuit - short to ground Refer to the electrical circuit diagrams and check interior lamp

fade control circuit for short to ground B112412

Lamp Fade

Control

Interior lamp fade control

circuit - short to power Refer to the electrical circuit diagrams and check interior lamp

fade control circuit for short to power B113C12

Hazard Switch

Illumination

Hazard switch

illumination control

circuit - short to power Refer to the electrical circuit diagrams and check hazard switch

illumination control circuit for short to power B113C14

Hazard Switch

Illumination

Hazard switch

illumination control

circuit - short to ground,

open circuit Refer to the electrical circuit diagrams and check hazard switch

illumination control circuit for short to ground, open circuit B113E12

External

Boot/Trunk

Release Switch

External luggage

compartment lid release

switch digital input circuit

- short to power Refer to the electrical circuit diagrams and check external

luggage compartment lid release switch digital input circuit for

short to power B113E23

External

Boot/Trunk

Release Switch

External luggage

compartment lid release

switch digital input circuit

- signal stuck low Carry out any pinpoint test associated with this DTC using the

manufacturer approved diagnostic system. Refer to the electrical

circuit diagrams and check external luggage compartment lid

release switch digital input circuit for short to ground B11D949 Vehicle Battery

Vehicle battery

damaged/worn out Check battery is in fully charged and serviceable condition using

the Midtronics battery tester and the battery care manual B11DB49

Battery

Monitoring

Module

Internal electronic failure Suspect the battery monitoring module. Check and install a new

module as required, refer to the new module/component

installation note at the top of the DTC Index B11DB87

Battery

Monitoring

Module

Battery monitoring

module connector

dis-connected/poor

connection Battery

monitoring

module to RJB LIN circuit

- open circuit Carry out any pinpoint test associated with this DTC using the

manufacturer approved diagnostic system. If additional DTCs

B108783, B108786, B108787 are logged, suspect the RJB. Check

and install a new RJB as required, refer to the new

module/component installation note at the top of the DTC Index.

If additional DTCs B108783, B108786, B108787 are NOT logged,

check for good/clean contact at battery monitoring module

Page 2098 of 3039

DTC Description Possible Causes Action Battery monitoring

module to battery

positive monitor circuit -

open circuit

Battery monitoring

module/RJB failure connector, refer to electrical circuit diagrams and check battery

monitoring module to RJB LIN circuit and battery monitoring

module to battery positive monitor circuit for open circuit. Clear

DTC and repeat automated diagnostic procedure using

manufacturer approved diagnostic system. If DTC remains

suspect the battery monitoring module, check and install a new

battery monitoring module as required, refer to the new

module/component installation note at the top of the DTC Index B123A11

Left Front Turn

Indicator

Left front turn signal

lamp control circuit -

short to ground Refer to the electrical circuit diagrams and check left front turn

signal lamp control circuit for short to ground B123A12

Left Front Turn

Indicator

Left front turn signal

lamp control circuit -

short to power Refer to the electrical circuit diagrams and check left front turn

signal lamp control circuit for short to power B123A13

Left Front Turn

Indicator

Left front turn signal

lamp control circuit -

open circuit Refer to the electrical circuit diagrams and check left front turn

signal lamp control circuit for open circuit B123A-15

Left Front Turn

Indicator - circuit

short to battery

or open

Left front turn signal

lamp control circuit -

short circuit to power,

open circuit, high

resistance

Refer to electrical circuit diagrams and check left front

turn signal lamp control circuit for short circuit to power,

open circuit, high resistance. Repair wiring harness as

required. Clear DTC and retest B123B11

Right Front Turn

Indicator

Right front turn signal

lamp control circuit -

short to ground Refer to the electrical circuit diagrams and check right front turn

signal lamp control circuit for short to ground B123B12

Right Front Turn

Indicator

Right front turn signal

lamp control circuit -

short to power Refer to the electrical circuit diagrams and check right front turn

signal lamp control circuit for short to power B123B13

Right Front Turn

Indicator

Right front turn signal

lamp control circuit -

open circuit Refer to the electrical circuit diagrams and check right front turn

signal lamp control circuit for open circuit B123B-15

Right Front Turn

Indicator - circuit

short to battery

or open

Right front turn signal

lamp control circuit -

short circuit to power,

open circuit, high

resistance

Refer to electrical circuit diagrams and check right front

turn signal lamp control circuit for short circuit to power,

open circuit, high resistance. Repair wiring harness as

required. Clear DTC and retest B124711

Left Rear Turn

Indicator

Left rear turn signal lamp

control circuit - short to

ground Refer to the electrical circuit diagrams and check left rear turn

signal lamp control circuit for short to ground B124712

Left Rear Turn

Indicator

Left rear turn signal lamp

control circuit - short to

power Refer to the electrical circuit diagrams and check left rear turn

signal lamp control circuit for short to power B124713

Left Rear Turn

Indicator

Left rear turn signal lamp

control circuit - short to

power, open circuit Refer to the electrical circuit diagrams and check left rear turn

signal lamp control circuit for open circuit B1247-15

Left Rear Turn

Indicator - circuit

short to battery

or open

Left rear turn signal lamp

control circuit - short

circuit to power, open

circuit, high resistance

Refer to electrical circuit diagrams and check left rear turn

signal lamp control circuit for short circuit to power, open

circuit, high resistance. Repair wiring harness as required.

Clear DTC and retest B124811

Right Rear Turn

Indicator

Right rear turn signal

lamp control circuit -

short to ground Refer to the electrical circuit diagrams and check right rear turn

signal lamp control circuit for short to ground

Page 2123 of 3039

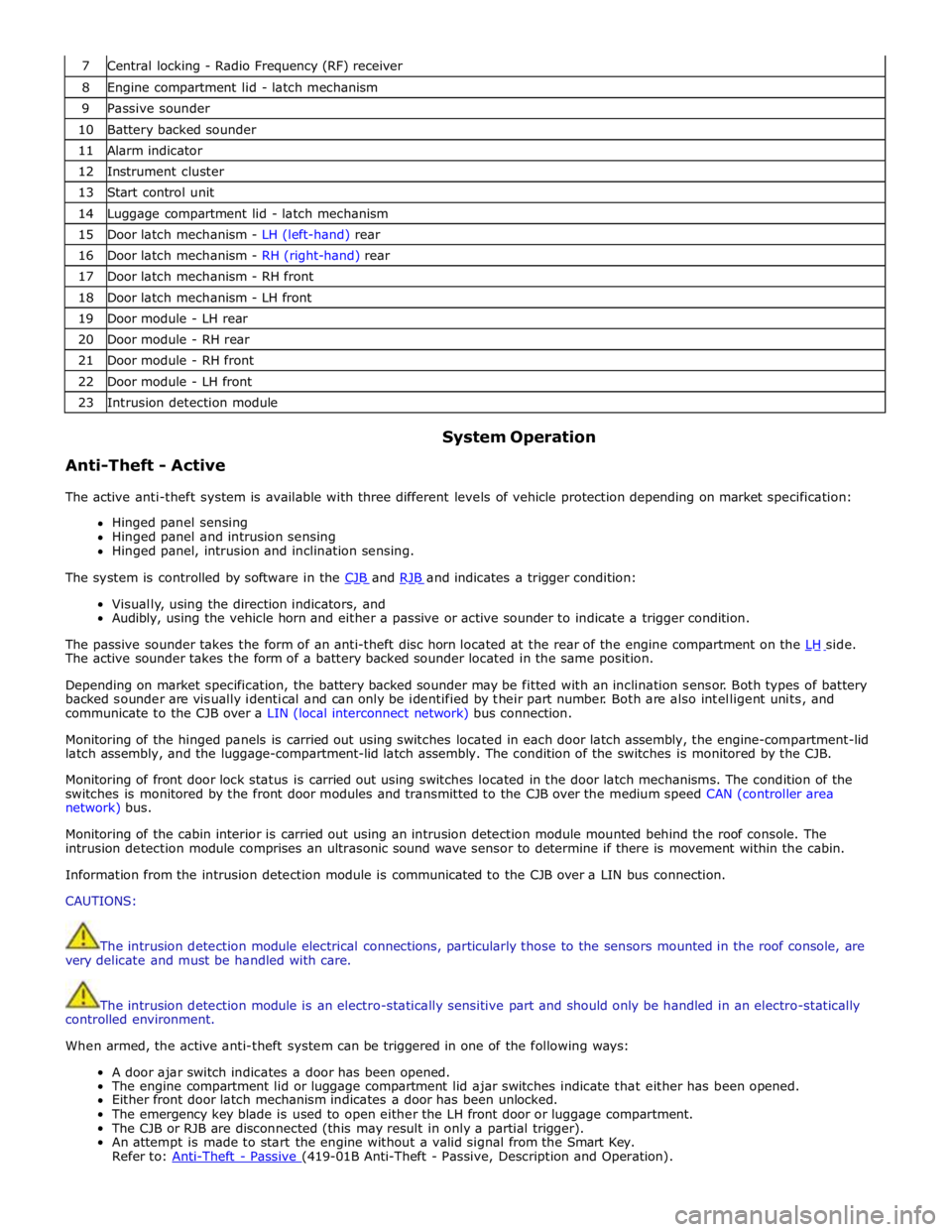

7 Central locking - Radio Frequency (RF) receiver 8 Engine compartment lid - latch mechanism 9 Passive sounder 10 Battery backed sounder 11 Alarm indicator 12 Instrument cluster 13 Start control unit 14 Luggage compartment lid - latch mechanism 15 Door latch mechanism - LH (left-hand) rear 16 Door latch mechanism - RH (right-hand) rear 17 Door latch mechanism - RH front 18 Door latch mechanism - LH front 19 Door module - LH rear 20 Door module - RH rear 21 Door module - RH front 22 Door module - LH front 23 Intrusion detection module

Anti-Theft - Active System Operation

The active anti-theft system is available with three different levels of vehicle protection depending on market specification:

Hinged panel sensing

Hinged panel and intrusion sensing

Hinged panel, intrusion and inclination sensing.

The system is controlled by software in the CJB and RJB and indicates a trigger condition: Visually, using the direction indicators, and

Audibly, using the vehicle horn and either a passive or active sounder to indicate a trigger condition.

The passive sounder takes the form of an anti-theft disc horn located at the rear of the engine compartment on the LH side. The active sounder takes the form of a battery backed sounder located in the same position.

Depending on market specification, the battery backed sounder may be fitted with an inclination sensor. Both types of battery

backed sounder are visually identical and can only be identified by their part number. Both are also intelligent units, and

communicate to the CJB over a LIN (local interconnect network) bus connection.

Monitoring of the hinged panels is carried out using switches located in each door latch assembly, the engine-compartment-lid

latch assembly, and the luggage-compartment-lid latch assembly. The condition of the switches is monitored by the CJB.

Monitoring of front door lock status is carried out using switches located in the door latch mechanisms. The condition of the

switches is monitored by the front door modules and transmitted to the CJB over the medium speed CAN (controller area

network) bus.

Monitoring of the cabin interior is carried out using an intrusion detection module mounted behind the roof console. The

intrusion detection module comprises an ultrasonic sound wave sensor to determine if there is movement within the cabin.

Information from the intrusion detection module is communicated to the CJB over a LIN bus connection.

CAUTIONS:

The intrusion detection module electrical connections, particularly those to the sensors mounted in the roof console, are

very delicate and must be handled with care.

The intrusion detection module is an electro-statically sensitive part and should only be handled in an electro-statically

controlled environment.

When armed, the active anti-theft system can be triggered in one of the following ways:

A door ajar switch indicates a door has been opened.

The engine compartment lid or luggage compartment lid ajar switches indicate that either has been opened.

Either front door latch mechanism indicates a door has been unlocked.

The emergency key blade is used to open either the LH front door or luggage compartment.

The CJB or RJB are disconnected (this may result in only a partial trigger).

An attempt is made to start the engine without a valid signal from the Smart Key.

Refer to: Anti-Theft - Passive (419-01B Anti-Theft - Passive, Description and Operation).

Page 2163 of 3039

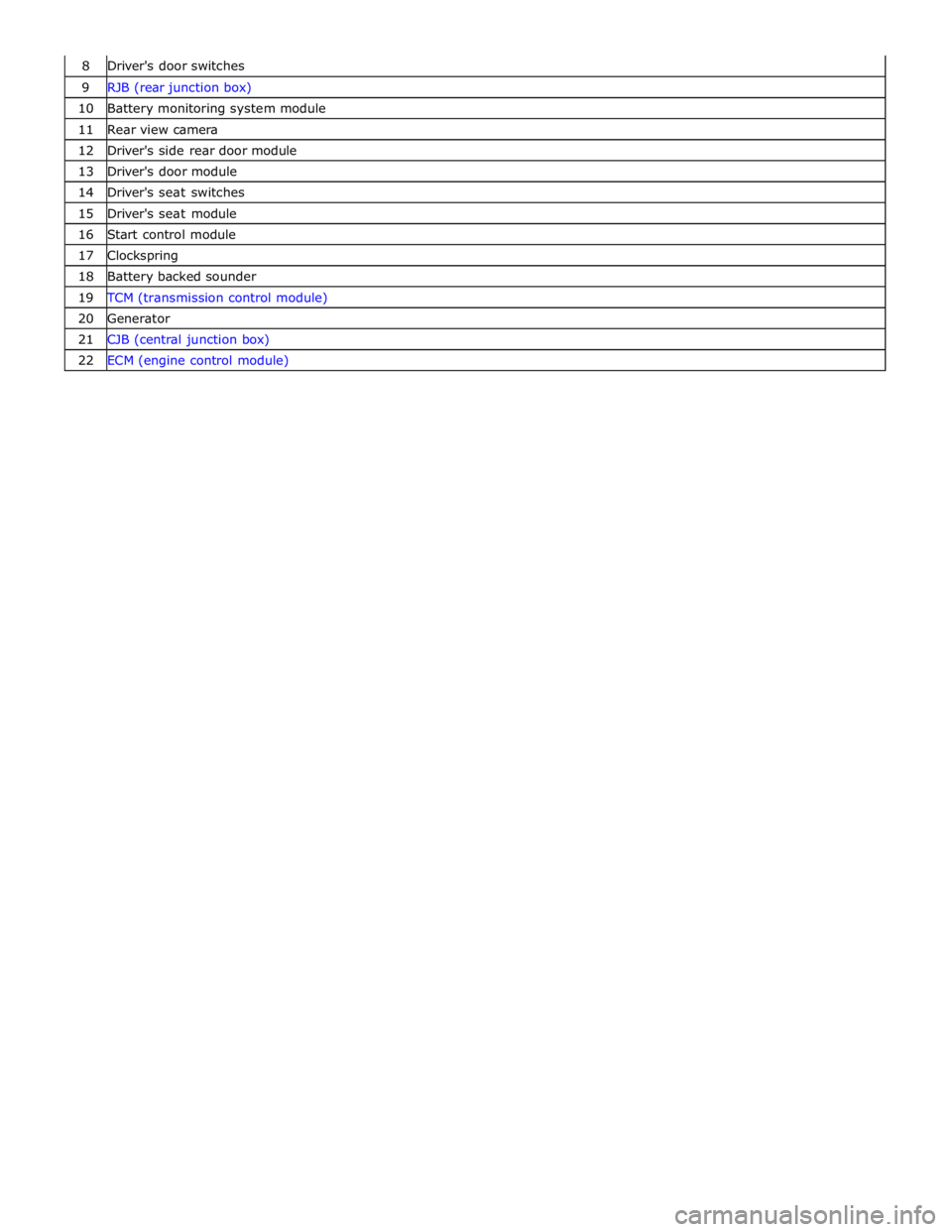

9 RJB (rear junction box) 10 Battery monitoring system module 11 Rear view camera 12 Driver's side rear door module 13 Driver's door module 14 Driver's seat switches 15 Driver's seat module 16 Start control module 17 Clockspring 18 Battery backed sounder 19 TCM (transmission control module) 20 Generator 21 CJB (central junction box) 22 ECM (engine control module)

Page 2172 of 3039

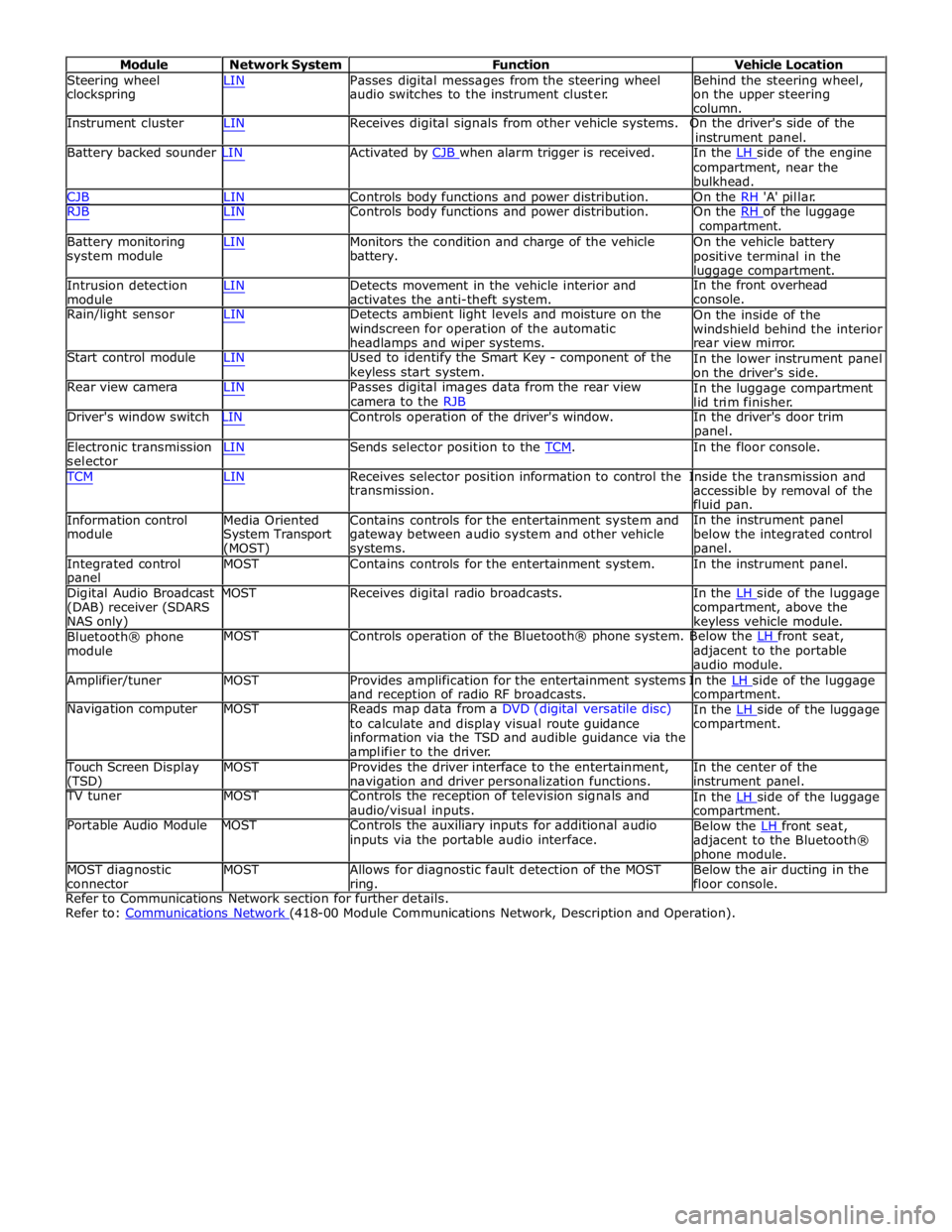

Module Network System Function Vehicle Location

Steering wheel

clockspring LIN Passes digital messages from the steering wheel

audio switches to the instrument cluster. Behind the steering wheel,

on the upper steering

column.

Instrument cluster LIN Receives digital signals from other vehicle systems. On the driver's side of the

instrument panel.

Battery backed sounder LIN Activated by CJB when alarm trigger is received. In the LH side of the engine compartment, near the

bulkhead.

CJB LIN Controls body functions and power distribution. On the RH 'A' pillar.

RJB LIN Controls body functions and power distribution. On the RH of the luggage compartment.

Battery monitoring

system module

Intrusion detection

module LIN Monitors the condition and charge of the vehicle

battery.

LIN Detects movement in the vehicle interior and

activates the anti-theft system. On the vehicle battery

positive terminal in the

luggage compartment.

In the front overhead

console.

Rain/light sensor LIN Detects ambient light levels and moisture on the

windscreen for operation of the automatic

headlamps and wiper systems.

Start control module LIN Used to identify the Smart Key - component of the

keyless start system.

Rear view camera LIN Passes digital images data from the rear view

camera to the RJB On the inside of the

windshield behind the interior

rear view mirror.

In the lower instrument panel

on the driver's side.

In the luggage compartment

lid trim finisher.

Driver's window switch LIN Controls operation of the driver's window. In the driver's door trim

panel.

Electronic transmission

selector LIN Sends selector position to the TCM. In the floor console. TCM LIN Receives selector position information to control the Inside the transmission and

Information control

module

Media Oriented

System Transport

(MOST) transmission.

Contains controls for the entertainment system and

gateway between audio system and other vehicle

systems. accessible by removal of the

fluid pan.

In the instrument panel

below the integrated control

panel.

Integrated control

panel MOST Contains controls for the entertainment system. In the instrument panel.

Digital Audio Broadcast MOST Receives digital radio broadcasts. In the LH side of the luggage (DAB) receiver (SDARS

NAS only)

Bluetooth® phone

module compartment, above the

keyless vehicle module.

MOST Controls operation of the Bluetooth® phone system. Below the LH front seat, adjacent to the portable

audio module.

Amplifier/tuner MOST Provides amplification for the entertainment systems In the LH side of the luggage and reception of radio RF broadcasts.

Navigation computer MOST Reads map data from a DVD (digital versatile disc)

to calculate and display visual route guidance

information via the TSD and audible guidance via the

amplifier to the driver. compartment.

In the LH side of the luggage compartment.

Touch Screen Display

(TSD) MOST Provides the driver interface to the entertainment,

navigation and driver personalization functions. In the center of the

instrument panel.

TV tuner MOST Controls the reception of television signals and

audio/visual inputs.

Portable Audio Module MOST Controls the auxiliary inputs for additional audio

inputs via the portable audio interface. In the LH side of the luggage compartment.

Below the LH front seat, adjacent to the Bluetooth®

phone module.

MOST diagnostic

connector MOST Allows for diagnostic fault detection of the MOST

ring. Below the air ducting in the

floor console.

Refer to Communications Network section for further details.

Refer to: Communications Network (418-00 Module Communications Network, Description and Operation).

Page 2415 of 3039

7 Window regulator motor – driver's door 8 Door module – LH (left-hand) rear passenger 9 Window control switch - LH rear passenger 10 Window regulator motor – LH rear passenger 11 Door module – front passenger 12 Window control switches - front passenger 13 Window regulator motor – front passenger 14 Door module – RH (right-hand) rear passenger 15 Window control switch - RH rear passenger 16 Window regulator motor – RH rear passenger

Door Windows System Operation

All windows can be operated individually, or by the driver’s window control switch. The operation of the windows is proportional

to the switch activation. All windows can be controlled by ‘one touch’ in an upward or downward direction. When the ‘one

touch’ operation is activated in the upwards direction ‘pinch protection‘ is enabled. If a pinch condition is detected the window

will automatically stop and travel downwards to a pre-determined position.

When the rear window ‘one touch’ operation is activated in the downward direction, the window will drop a limited way down.

This is the comfort setting to achieve optimum noise levels when vehicle is in motion with rear windows open. Further ‘one

touch’ operation will drop the window all the way down. (Only applies to vehicles post VIN R99740) The ‘one touch’ operation

to activate the upward direction will fully close the window.

Electric window operation is enabled while the ignition is in power mode 4 and 6. When the switches in the driver's door are

used to operate the passenger windows, the driver's door module outputs a related message on the LIN (local interconnect

network) bus and medium speed CAN (controller area network) bus. The passenger door module responds to the message by

operating the appropriate window. When the child lock is engaged, the rear door modules ignore inputs from the rear window

switches.

End of travel shut off

End of travel shut-off for the window motors is determined by monitoring the current draw of the motors. Each time it switches

on a window motor, the door module measures the window motor current for a preset time. The maximum value measured

within that time is stored as the switch-on current. When the window motor current next exceeds the switch-on current, the

door module assumes the window has reached the end of its travel and switches off the power supply to the window motor

even if a window switch is still being activated.

Anti-trap

The anti-trap function is enabled for window closing in both the inching and one-shot modes. If the anti-trap feature is

activated while a window is closing, the window motor is reversed for a preset period.

A Hall sensor, located in the window regulator motor, monitors the speed of the motor and if the speed decreases below a set

threshold, indicating an obstruction, the power feed to the motor is reversed so the window goes back down for preset time.

In an emergency the anti-trap function can be overridden by holding the window switch in the one-shot closed position.

After the battery has been disconnected it is necessary to initialize the door window motors to be able to operate the one-shot

up function.

Windshield Component Description

The windshield, manufactured from 5mm laminated green-tinted glass is positioned to the vehicle's body by two locator pins,

one in each top corner of the windshield. This allows for centralizing movement of the windshield across the car upon fitment.

The base of the windshield carries a leaf-screen retainer. The windshield is bonded and sealed to the vehicle body aperture

using Polyurethane (PU) adhesive. The windshield finisher is a three-sided extruded flip, taped onto the inner surface of the

glass; this helps to centralize the glass in the aperture.

Two variants of windshield are available:

standard, and

heated.

Refer to: Control Components (412-01 Climate Control, Description and Operation).

Interior Mirror and Rain Sensor

The interior mirror and rain sensor mounting positions are located at the top of the windshield.

Refer to: Wipers and Washers (501-16 Wipers and Washers, Description and Operation).

Page 2615 of 3039

Driver Passenger Applicable Pretensioner Driver airbag Passenger airbag Fastened - -

Fired at pretensioner

threshold Fired at belt fastened

threshold - Unfastened - - Not fired

Fired at belt unfastened

threshold - - Fastened Occupied allow

Fired at pretensioner

threshold -

Fired at belt fastened

threshold - Fastened

Unoccupied inhibit/empty Fired at pretensioner

threshold - Not fired - Unfastened Occupied allow Not fired -

Fired at belt unfastened

threshold Unfastened

Unoccupied inhibit/empty Not fired - Not fired The battery disconnect unit is fired:

At driver and passenger airbag belt fastened threshold in a frontal impact

At the driver and passenger side impact threshold in a side impact

At the rear impact threshold in a rear impact.

Crash Signal

When the RCM outputs any of the fire signals it also outputs a crash signal to the RJB and the ECM (engine control module) on the high speed CAN. The crash signal is also hardwired to the ECM and the RJB. The instrument cluster picks up the crash signal from the high speed CAN and gateways it to the LCM (lighting control module). On receipt of the crash signal, the RJB goes into a crash mode and the ECM cuts the power supply to the fuel pump relay. In the crash mode, the RJB: Activates all of the unlock signals of the vehicle locking system, even if the vehicle is already unlocked.

Ignores all locking/superlocking inputs until it receives an unlock input, when it returns the locking system to normal

operation.

Activates the interior lamps. The interior lamps remain on permanently until they are manually switched off at the lamp

unit, or the RJB crash mode is switched off and they return to normal operation. Disables the rear window child lock input until the crash mode is switched off.

Sends a crash message to the LCM, to activate the hazard flashers. The hazard flashers remain on until cancelled by the hazard warning switch or the crash mode is switched off.

The RJB crash mode is switched off by a valid locking and unlocking cycle of the locking system.

Restraints Control Module Component Description

The RCM is installed on the top of the transmission tunnel, in line with the B pillars, and controls operation of the SRS (supplemental restraint system). The main functions of the RCM include:

Crash detection and recording

airbag and pre-tensioner firing

Self-test and system monitoring, with status indication via the airbag warning lamp and non-volatile storage of fault

information.

The RCM determines which elements of the SRS are to be deployed by using two internal areas:

Page 2616 of 3039

and the safety belt buckle sensor. Based on this data, the RCM decides which level of airbag module deployment is required and forwards the information to the second area, the deployment handler.

The deployment handler evaluates the status of the seat track position sensor and safety belt buckle sensors before a decision

is made about which restraints should finally be deployed.

Data from the side crash sensors is used by the RCM in conjunction with acceleration data from the RCM internal accelerometer to make a deployment decision. The RCM processes the acceleration data and subject to an impact being of high enough severity, decides whether the side airbag module should be deployed.

On board testing of the airbag modules, front safety belt pretensioner firing circuits, warning indicator circuits and module

status (the crash and side impact sensors perform basic self-tests) is performed by the RCM together with the storing of fault codes.

The RCM drives the SRS indicator on the instrument pack via a CAN signal. If the warning lamp fails, a fault code is recorded and a warning tone is sounded in place of the lamp if a further fault occurs. It also provides a temporary back-up power supply

to operate the airbag modules in the event that in crash conditions, the battery supply is lost. In the event of a crash, it

records certain data which can be accessed via the diagnostic connector.

A safing sensor in the RCM provides confirmation of an impact to verify if airbag and pretensioner activation is necessary. A roll-over sensor monitors the lateral attitude of the vehicle. Various firing strategies are employed by the RCM to ensure that during an accident only the appropriate airbags and pretensioners are fired. The firing strategy used also depends on the

inputs from the safety belt switches and the occupant monitoring system.

An energy reserve in the RCM ensures there is always a minimum of 150 milliseconds of stored energy available if the power supply from the ignition switch is disrupted during a crash. The stored energy is sufficient to produce firing signals for the

driver airbag, the passenger airbag and the safety belt pretensioners.

When the ignition is switched on, the RCM performs a self-test and then performs cyclical monitoring of the system. If a fault is detected the RCM stores a related fault code and illuminates the airbag warning indicator. The faults can be retrieved by the recommended Jaguar diagnostic tool over the CAN bus. If a fault that could cause a false fire signal is detected, the RCM disables the respective firing circuit, and keeps it disabled during a crash event.

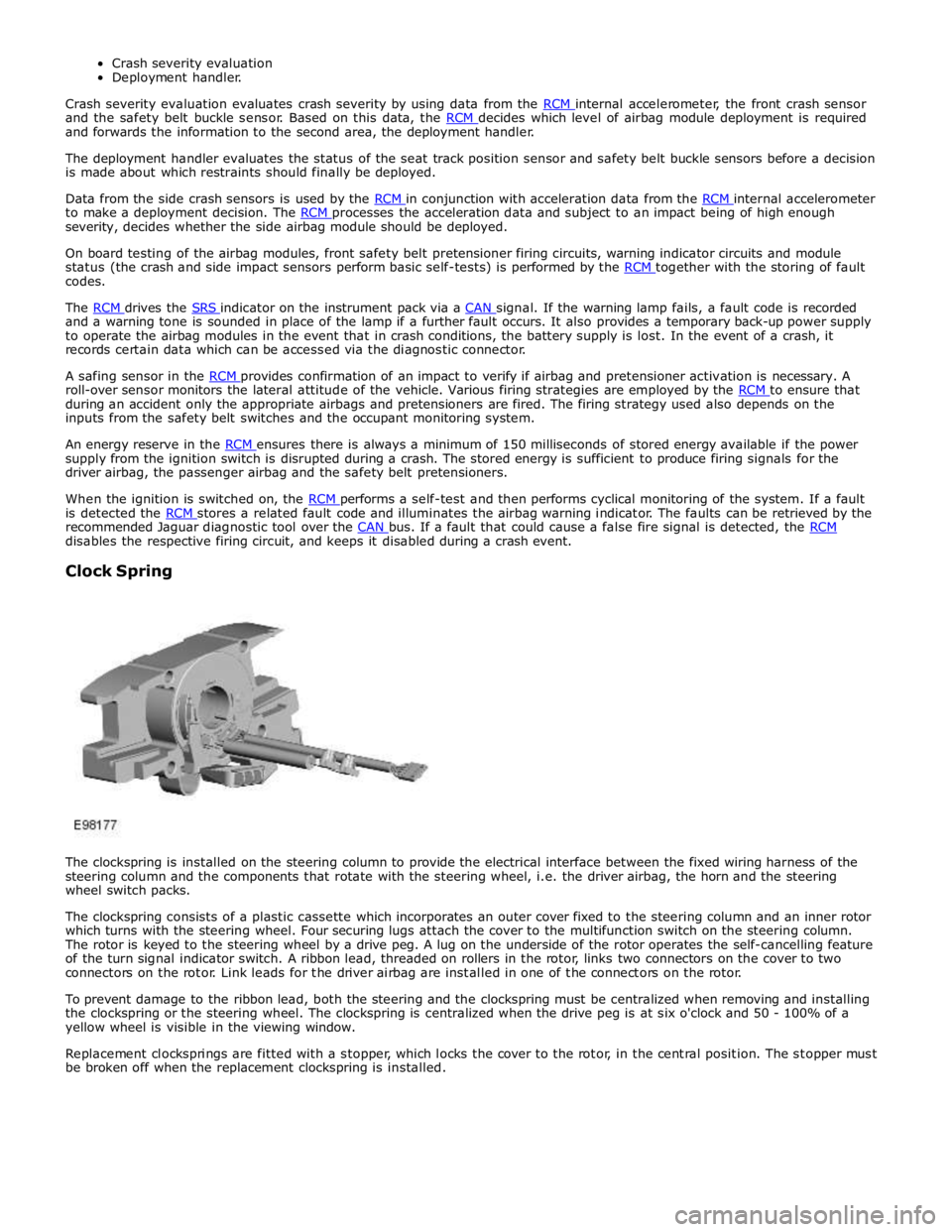

Clock Spring

The clockspring is installed on the steering column to provide the electrical interface between the fixed wiring harness of the

steering column and the components that rotate with the steering wheel, i.e. the driver airbag, the horn and the steering

wheel switch packs.

The clockspring consists of a plastic cassette which incorporates an outer cover fixed to the steering column and an inner rotor

which turns with the steering wheel. Four securing lugs attach the cover to the multifunction switch on the steering column.

The rotor is keyed to the steering wheel by a drive peg. A lug on the underside of the rotor operates the self-cancelling feature

of the turn signal indicator switch. A ribbon lead, threaded on rollers in the rotor, links two connectors on the cover to two

connectors on the rotor. Link leads for the driver airbag are installed in one of the connectors on the rotor.

To prevent damage to the ribbon lead, both the steering and the clockspring must be centralized when removing and installing

the clockspring or the steering wheel. The clockspring is centralized when the drive peg is at six o'clock and 50 - 100% of a

yellow wheel is visible in the viewing window.

Replacement clocksprings are fitted with a stopper, which locks the cover to the rotor, in the central position. The stopper must

be broken off when the replacement clockspring is installed.