wiper JAGUAR XFR 2010 1.G Owner's Manual

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 2010, Model line: XFR, Model: JAGUAR XFR 2010 1.GPages: 3039, PDF Size: 58.49 MB

Page 2089 of 3039

DTC Description Possible Cause Action B115B11 Driver Seat Heater

Driver seat heater supply circuit

- short to ground Carry out any pinpoint tests associated with this DTC

using the manufacturer approved diagnostic system.

Refer to the electrical circuit diagrams and check driver

seat heater supply circuit for short to ground B115B15 Driver Seat Heater

Driver seat heater supply circuit

- short to power, open circuit Carry out any pinpoint tests associated with this DTC

using the manufacturer approved diagnostic system.

Refer to the electrical circuit diagrams and check driver

seat heater supply circuit for short to power, open circuit B117513

Driver Door Ajar

Switch

Driver door ajar switch signal

circuit - open circuit Refer to the electrical circuit diagrams and check driver

door ajar switch signal circuit for open circuit B117613

Passenger Door

Ajar Switch

Passenger door ajar switch

signal circuit - open circuit Refer to the electrical circuit diagrams and check

passenger door ajar switch signal circuit for open circuit B117712

Screenwash Level

Switch

Screenwash level switch signal

circuit - short to power Refer to the electrical circuit diagrams and check

screenwash level switch signal circuit for short to power B11C013

Driver Side Rear

Door Ajar Switch

Left rear door ajar switch signal

circuit - open circuit Refer to the electrical circuit diagrams and check left rear

door ajar switch signal circuit for open circuit B11C113

Passenger Side

Rear Door Ajar

Switch

Right rear door ajar switch

signal circuit - open circuit Refer to the electrical circuit diagrams and check right

rear door ajar switch signal circuit for open circuit B122223

Master Lock/Unlock

Switch

Master lock or unlock switch

digital input circuit - signal

stuck low Refer to the electrical circuit diagrams and check master

lock and unlock switch digital input circuits for short to

ground, open circuit B123711

Gear Shift Module

Early Wake-up

Transmission shift module

wake-up control circuit - short

to ground Carry out any pinpoint tests associated with this DTC

using the manufacturer approved diagnostic system.

Refer to the electrical circuit diagrams and check

transmission shift module wake-up control circuit for

short to ground B123712

Gear Shift Module

Early Wake-up

Transmission shift module

wake-up control circuit - short

to power Refer to the electrical circuit diagrams and check

transmission shift module wake-up control circuit for

short to power B123713

Gear Shift Module

Early Wake-up

Transmission shift module

wake-up control circuit - open

circuit Refer to the electrical circuit diagrams and check

transmission shift module wake-up control circuit for

open circuit B123E13 Crank Enable

OK to crank signal circuit -

open circuit Refer to the electrical circuit diagrams and check OK to

crank signal circuit for open circuit B1A8596

Ambient Light

Sensor

Light sensor internal electronic

failure Check and install a new sensor as required B1C4513

Front Wiper Park

Position Switch

Windshield wiper motor park

switch signal circuit - open

circuit Refer to the electrical circuit diagrams and check

windshield wiper motor park switch signal circuit for open

circuit B1C4523

Front Wiper Park

Position Switch

Signal stuck low Refer to the electrical circuit diagrams and check front

wiper park position switch input circuit for short, open

circuit B1C7812 Powerwash Relay

Powerwash relay control circuit

- short to power Refer to the electrical circuit diagrams and check

powerwash relay control circuit for short to power B1C7814 Powerwash Relay

Powerwash relay control circuit

- short to ground, open circuit Refer to the electrical circuit diagrams and check

powerwash relay control circuit for short to ground, open

circuit B1C7911 Front Washer Pump

Screenwash pump control

circuit - short to ground Refer to the electrical circuit diagrams and check

screenwash pump control circuit for short to ground

Page 2172 of 3039

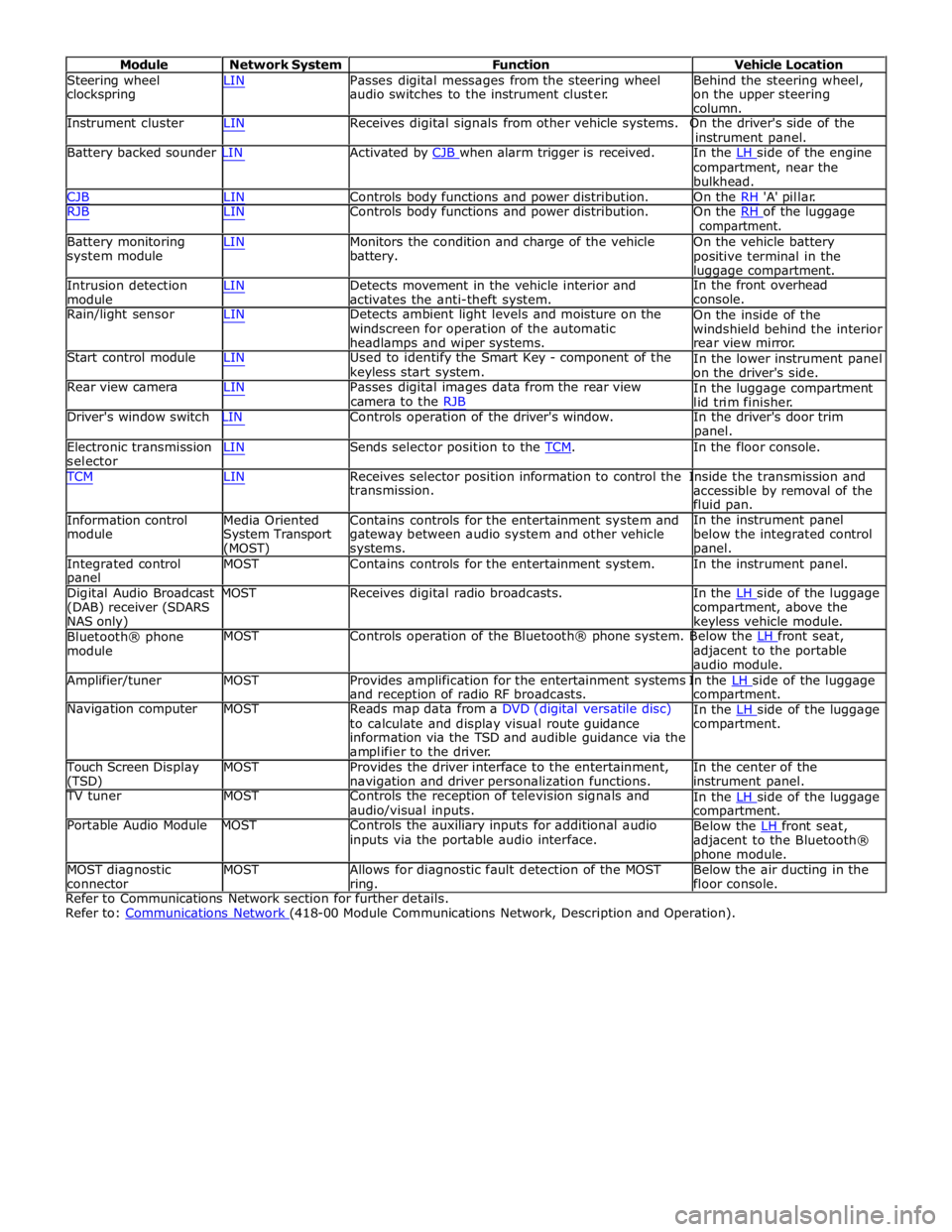

Module Network System Function Vehicle Location

Steering wheel

clockspring LIN Passes digital messages from the steering wheel

audio switches to the instrument cluster. Behind the steering wheel,

on the upper steering

column.

Instrument cluster LIN Receives digital signals from other vehicle systems. On the driver's side of the

instrument panel.

Battery backed sounder LIN Activated by CJB when alarm trigger is received. In the LH side of the engine compartment, near the

bulkhead.

CJB LIN Controls body functions and power distribution. On the RH 'A' pillar.

RJB LIN Controls body functions and power distribution. On the RH of the luggage compartment.

Battery monitoring

system module

Intrusion detection

module LIN Monitors the condition and charge of the vehicle

battery.

LIN Detects movement in the vehicle interior and

activates the anti-theft system. On the vehicle battery

positive terminal in the

luggage compartment.

In the front overhead

console.

Rain/light sensor LIN Detects ambient light levels and moisture on the

windscreen for operation of the automatic

headlamps and wiper systems.

Start control module LIN Used to identify the Smart Key - component of the

keyless start system.

Rear view camera LIN Passes digital images data from the rear view

camera to the RJB On the inside of the

windshield behind the interior

rear view mirror.

In the lower instrument panel

on the driver's side.

In the luggage compartment

lid trim finisher.

Driver's window switch LIN Controls operation of the driver's window. In the driver's door trim

panel.

Electronic transmission

selector LIN Sends selector position to the TCM. In the floor console. TCM LIN Receives selector position information to control the Inside the transmission and

Information control

module

Media Oriented

System Transport

(MOST) transmission.

Contains controls for the entertainment system and

gateway between audio system and other vehicle

systems. accessible by removal of the

fluid pan.

In the instrument panel

below the integrated control

panel.

Integrated control

panel MOST Contains controls for the entertainment system. In the instrument panel.

Digital Audio Broadcast MOST Receives digital radio broadcasts. In the LH side of the luggage (DAB) receiver (SDARS

NAS only)

Bluetooth® phone

module compartment, above the

keyless vehicle module.

MOST Controls operation of the Bluetooth® phone system. Below the LH front seat, adjacent to the portable

audio module.

Amplifier/tuner MOST Provides amplification for the entertainment systems In the LH side of the luggage and reception of radio RF broadcasts.

Navigation computer MOST Reads map data from a DVD (digital versatile disc)

to calculate and display visual route guidance

information via the TSD and audible guidance via the

amplifier to the driver. compartment.

In the LH side of the luggage compartment.

Touch Screen Display

(TSD) MOST Provides the driver interface to the entertainment,

navigation and driver personalization functions. In the center of the

instrument panel.

TV tuner MOST Controls the reception of television signals and

audio/visual inputs.

Portable Audio Module MOST Controls the auxiliary inputs for additional audio

inputs via the portable audio interface. In the LH side of the luggage compartment.

Below the LH front seat, adjacent to the Bluetooth®

phone module.

MOST diagnostic

connector MOST Allows for diagnostic fault detection of the MOST

ring. Below the air ducting in the

floor console.

Refer to Communications Network section for further details.

Refer to: Communications Network (418-00 Module Communications Network, Description and Operation).

Page 2193 of 3039

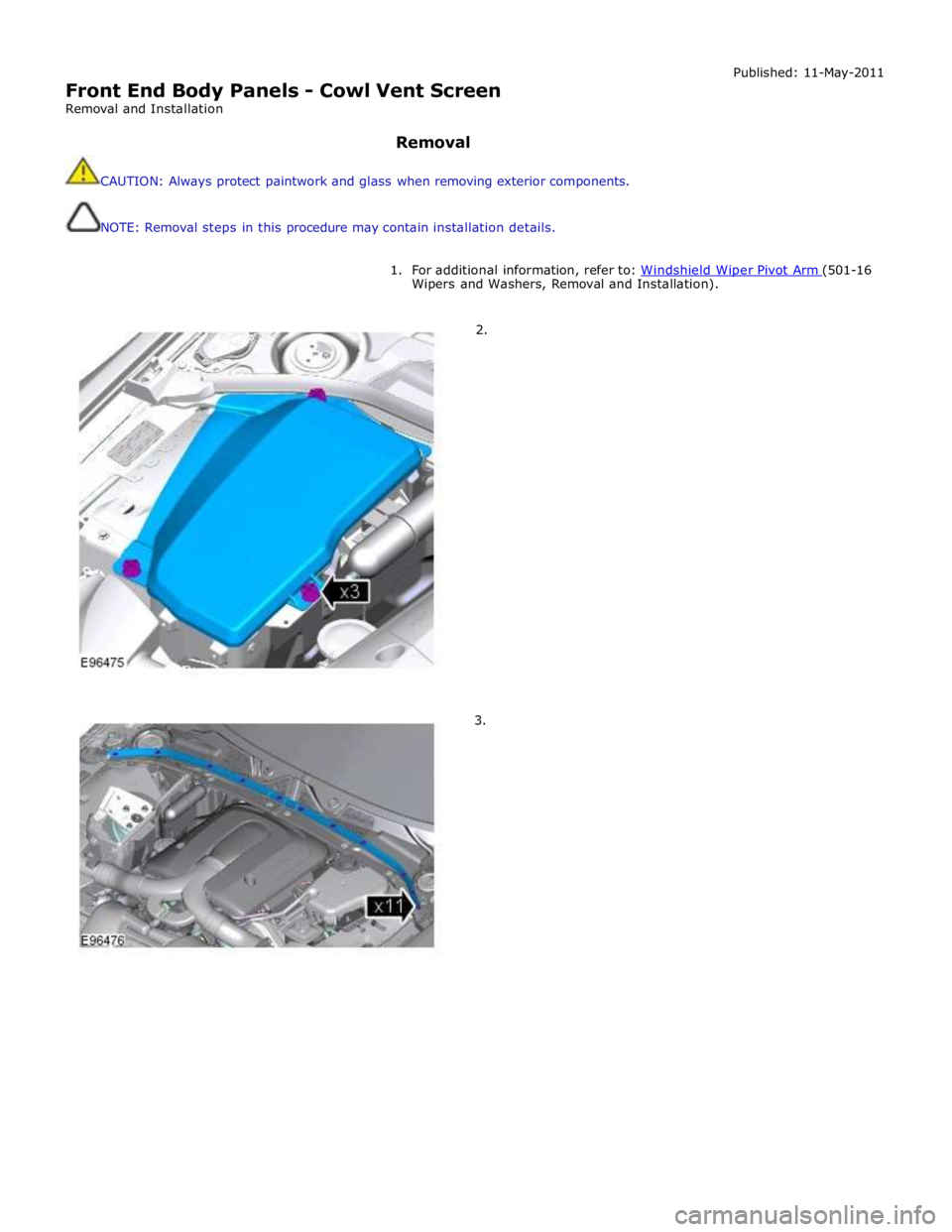

Front End Body Panels - Cowl Vent Screen

Removal and Installation

Removal

CAUTION: Always protect paintwork and glass when removing exterior components.

NOTE: Removal steps in this procedure may contain installation details. Published: 11-May-2011

1. For additional information, refer to: Windshield Wiper Pivot Arm (501-16 Wipers and Washers, Removal and Installation).

2.

3.

Page 2295 of 3039

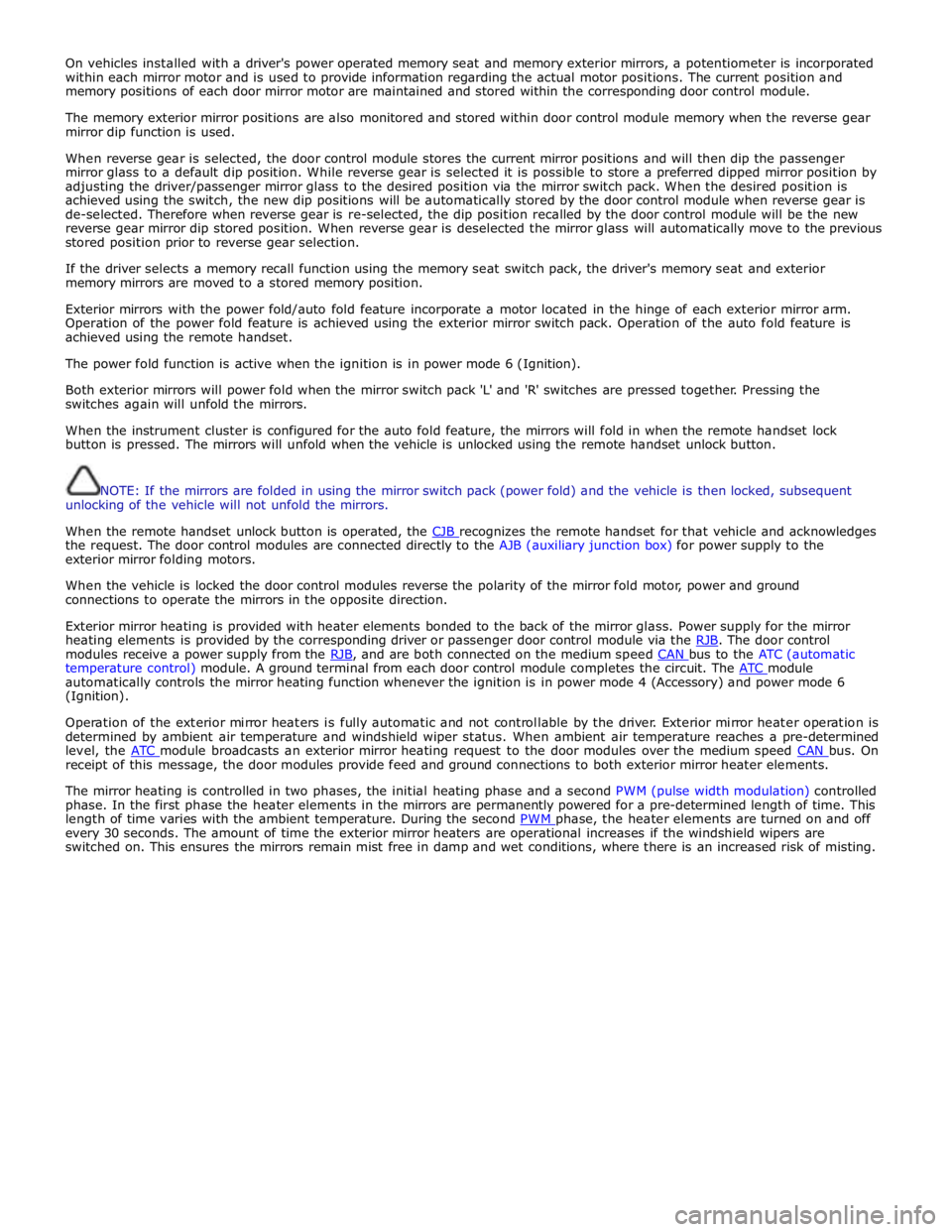

On vehicles installed with a driver's power operated memory seat and memory exterior mirrors, a potentiometer is incorporated

within each mirror motor and is used to provide information regarding the actual motor positions. The current position and

memory positions of each door mirror motor are maintained and stored within the corresponding door control module.

The memory exterior mirror positions are also monitored and stored within door control module memory when the reverse gear

mirror dip function is used.

When reverse gear is selected, the door control module stores the current mirror positions and will then dip the passenger

mirror glass to a default dip position. While reverse gear is selected it is possible to store a preferred dipped mirror position by

adjusting the driver/passenger mirror glass to the desired position via the mirror switch pack. When the desired position is

achieved using the switch, the new dip positions will be automatically stored by the door control module when reverse gear is

de-selected. Therefore when reverse gear is re-selected, the dip position recalled by the door control module will be the new

reverse gear mirror dip stored position. When reverse gear is deselected the mirror glass will automatically move to the previous

stored position prior to reverse gear selection.

If the driver selects a memory recall function using the memory seat switch pack, the driver's memory seat and exterior

memory mirrors are moved to a stored memory position.

Exterior mirrors with the power fold/auto fold feature incorporate a motor located in the hinge of each exterior mirror arm.

Operation of the power fold feature is achieved using the exterior mirror switch pack. Operation of the auto fold feature is

achieved using the remote handset.

The power fold function is active when the ignition is in power mode 6 (Ignition).

Both exterior mirrors will power fold when the mirror switch pack 'L' and 'R' switches are pressed together. Pressing the

switches again will unfold the mirrors.

When the instrument cluster is configured for the auto fold feature, the mirrors will fold in when the remote handset lock

button is pressed. The mirrors will unfold when the vehicle is unlocked using the remote handset unlock button.

NOTE: If the mirrors are folded in using the mirror switch pack (power fold) and the vehicle is then locked, subsequent

unlocking of the vehicle will not unfold the mirrors.

When the remote handset unlock button is operated, the CJB recognizes the remote handset for that vehicle and acknowledges the request. The door control modules are connected directly to the AJB (auxiliary junction box) for power supply to the

exterior mirror folding motors.

When the vehicle is locked the door control modules reverse the polarity of the mirror fold motor, power and ground

connections to operate the mirrors in the opposite direction.

Exterior mirror heating is provided with heater elements bonded to the back of the mirror glass. Power supply for the mirror

heating elements is provided by the corresponding driver or passenger door control module via the RJB. The door control modules receive a power supply from the RJB, and are both connected on the medium speed CAN bus to the ATC (automatic temperature control) module. A ground terminal from each door control module completes the circuit. The ATC module automatically controls the mirror heating function whenever the ignition is in power mode 4 (Accessory) and power mode 6

(Ignition).

Operation of the exterior mirror heaters is fully automatic and not controllable by the driver. Exterior mirror heater operation is

determined by ambient air temperature and windshield wiper status. When ambient air temperature reaches a pre-determined

level, the ATC module broadcasts an exterior mirror heating request to the door modules over the medium speed CAN bus. On receipt of this message, the door modules provide feed and ground connections to both exterior mirror heater elements.

The mirror heating is controlled in two phases, the initial heating phase and a second PWM (pulse width modulation) controlled

phase. In the first phase the heater elements in the mirrors are permanently powered for a pre-determined length of time. This

length of time varies with the ambient temperature. During the second PWM phase, the heater elements are turned on and off every 30 seconds. The amount of time the exterior mirror heaters are operational increases if the windshield wipers are

switched on. This ensures the mirrors remain mist free in damp and wet conditions, where there is an increased risk of misting.

Page 2415 of 3039

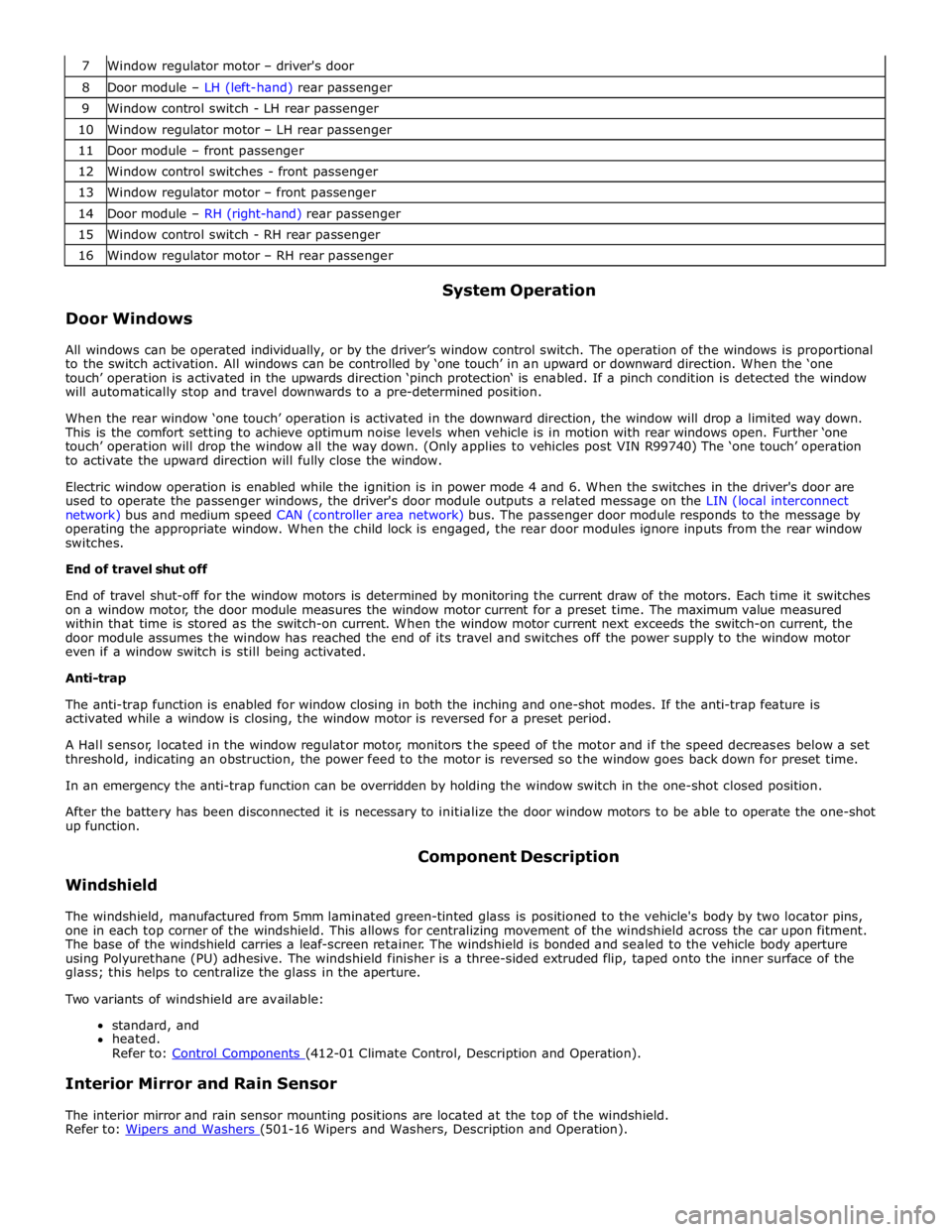

7 Window regulator motor – driver's door 8 Door module – LH (left-hand) rear passenger 9 Window control switch - LH rear passenger 10 Window regulator motor – LH rear passenger 11 Door module – front passenger 12 Window control switches - front passenger 13 Window regulator motor – front passenger 14 Door module – RH (right-hand) rear passenger 15 Window control switch - RH rear passenger 16 Window regulator motor – RH rear passenger

Door Windows System Operation

All windows can be operated individually, or by the driver’s window control switch. The operation of the windows is proportional

to the switch activation. All windows can be controlled by ‘one touch’ in an upward or downward direction. When the ‘one

touch’ operation is activated in the upwards direction ‘pinch protection‘ is enabled. If a pinch condition is detected the window

will automatically stop and travel downwards to a pre-determined position.

When the rear window ‘one touch’ operation is activated in the downward direction, the window will drop a limited way down.

This is the comfort setting to achieve optimum noise levels when vehicle is in motion with rear windows open. Further ‘one

touch’ operation will drop the window all the way down. (Only applies to vehicles post VIN R99740) The ‘one touch’ operation

to activate the upward direction will fully close the window.

Electric window operation is enabled while the ignition is in power mode 4 and 6. When the switches in the driver's door are

used to operate the passenger windows, the driver's door module outputs a related message on the LIN (local interconnect

network) bus and medium speed CAN (controller area network) bus. The passenger door module responds to the message by

operating the appropriate window. When the child lock is engaged, the rear door modules ignore inputs from the rear window

switches.

End of travel shut off

End of travel shut-off for the window motors is determined by monitoring the current draw of the motors. Each time it switches

on a window motor, the door module measures the window motor current for a preset time. The maximum value measured

within that time is stored as the switch-on current. When the window motor current next exceeds the switch-on current, the

door module assumes the window has reached the end of its travel and switches off the power supply to the window motor

even if a window switch is still being activated.

Anti-trap

The anti-trap function is enabled for window closing in both the inching and one-shot modes. If the anti-trap feature is

activated while a window is closing, the window motor is reversed for a preset period.

A Hall sensor, located in the window regulator motor, monitors the speed of the motor and if the speed decreases below a set

threshold, indicating an obstruction, the power feed to the motor is reversed so the window goes back down for preset time.

In an emergency the anti-trap function can be overridden by holding the window switch in the one-shot closed position.

After the battery has been disconnected it is necessary to initialize the door window motors to be able to operate the one-shot

up function.

Windshield Component Description

The windshield, manufactured from 5mm laminated green-tinted glass is positioned to the vehicle's body by two locator pins,

one in each top corner of the windshield. This allows for centralizing movement of the windshield across the car upon fitment.

The base of the windshield carries a leaf-screen retainer. The windshield is bonded and sealed to the vehicle body aperture

using Polyurethane (PU) adhesive. The windshield finisher is a three-sided extruded flip, taped onto the inner surface of the

glass; this helps to centralize the glass in the aperture.

Two variants of windshield are available:

standard, and

heated.

Refer to: Control Components (412-01 Climate Control, Description and Operation).

Interior Mirror and Rain Sensor

The interior mirror and rain sensor mounting positions are located at the top of the windshield.

Refer to: Wipers and Washers (501-16 Wipers and Washers, Description and Operation).

Page 2419 of 3039

Glass, Frames and Mechanisms - Fixed Window Glass

Diagnosis and Testing

Principles of Operation Published: 09-Apr-2014

For a detailed description of the Glass, Frames and Mechanisms, refer to the relevant Description and Operation section in the

workshop manual.

Inspection and Verification

CAUTION: Diagnosis by substitution from a donor vehicle is NOT acceptable. Substitution of control modules does not

guarantee confirmation of a fault, and may also cause additional faults in the vehicle being tested and/or the donor vehicle.

NOTES:

If a control module or a component is suspect and the vehicle remains under manufacturer warranty, refer to the Warranty

Policy and Procedures manual, or determine if any prior approval programme is in operation, prior to the installation of a new

module/component.

When performing voltage or resistance tests, always use a digital multimeter accurate to three decimal places, and with

an up-to-date calibration certificate. When testing resistance always take the resistance of the digital multimeter leads into

account.

Check and rectify basic faults before beginning diagnostic routines involving pinpoint tests.

Refer to Section 100-00 General Information for window glass health and safety precautions.

1. Verify the customer concern

2. Visually inspect for obvious signs of damage and system integrity

Visual Inspection

3. If an obvious cause for an observed or reported concern is found, correct the cause (if possible) before proceeding to

the next step

4. If the cause is not visually evident, verify the symptom and refer to the Symptom Chart, alternatively check for

Diagnostic Trouble Codes (DTCs) and refer to the DTC Index

5. Check DDW for open campaigns. Refer to the corresponding bulletins and SSMs which may be valid for the specific

customer complaint and carry out the recommendations as required

Warranty Repairs

NOTES:

The warranty period for the windshield is twelve months with the exception of delamination and electrical faults.

Warranty repairs should be completed using genuine parts, in accordance with the Warranty Policy and Procedures

Manual.

1. Draw a line around the windshield damage using a marker pen.

2. Photograph the entire windshield. If the damage extends behind any trim, remove the trim and take further

photographs.

3. Photograph the trademark logo and code to validate the windshield as factory fitment.

Symptom Chart

Symptom Possible Causes Action Scratches

Debris trapped under a wiper blade

GO to Pinpoint Test A. Electrical

Physical damage to the windshield

www.JagDocs.com

Page 2440 of 3039

Glass, Frames and Mechanisms - Windshield Glass

Removal and Installation

Removal

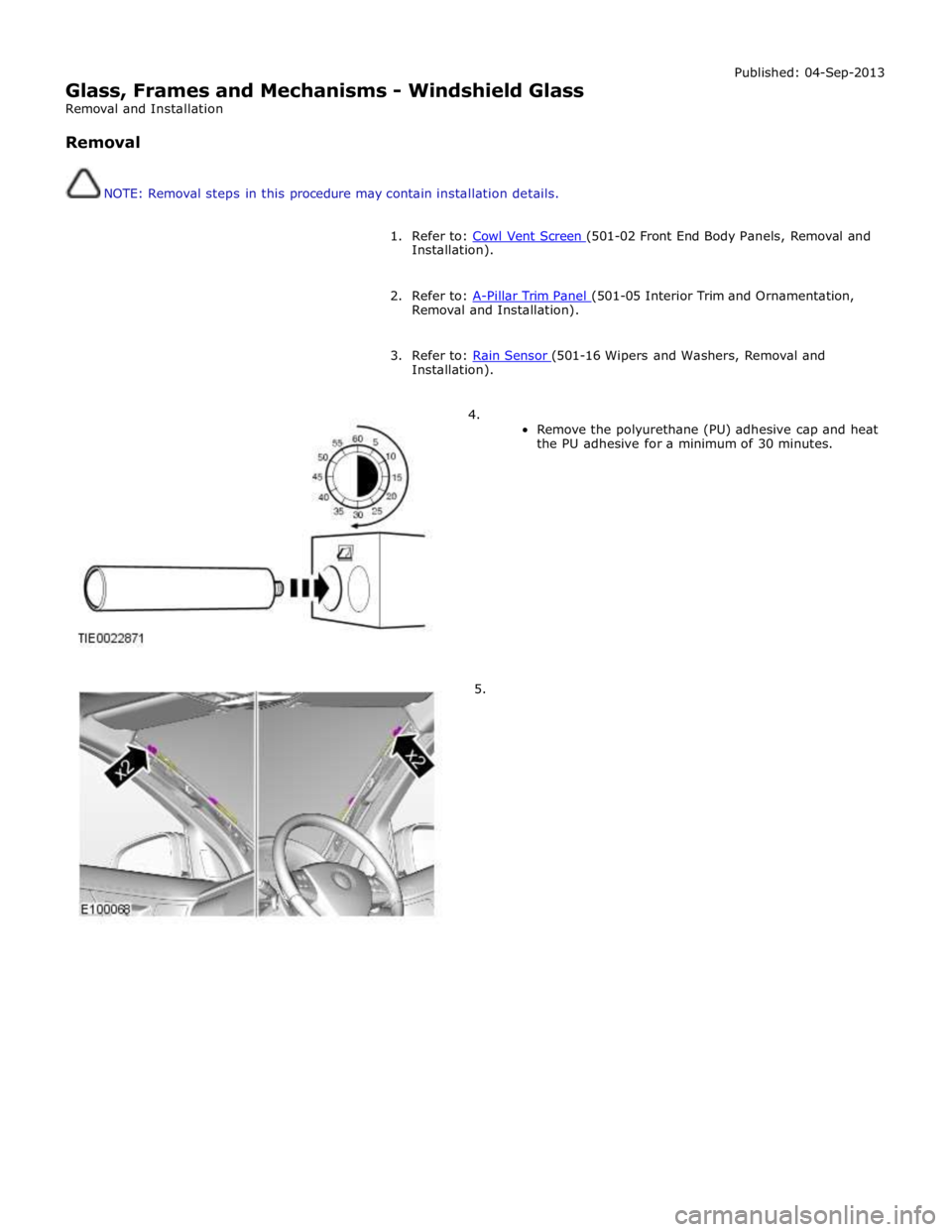

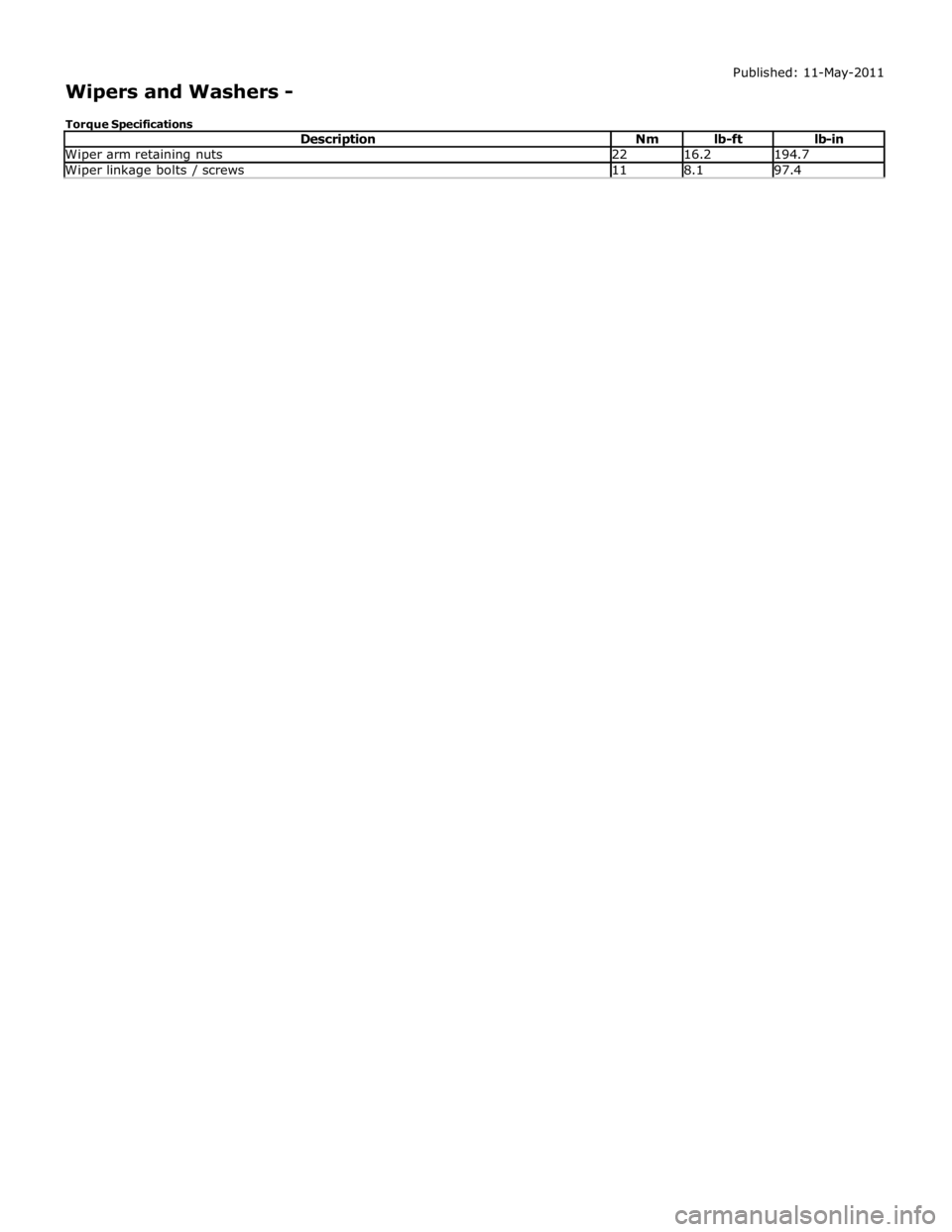

NOTE: Removal steps in this procedure may contain installation details. Published: 04-Sep-2013

1. Refer to: Cowl Vent Screen (501-02 Front End Body Panels, Removal and Installation).

2. Refer to: A-Pillar Trim Panel (501-05 Interior Trim and Ornamentation, Removal and Installation).

3. Refer to: Rain Sensor (501-16 Wipers and Washers, Removal and Installation).

4.

Remove the polyurethane (PU) adhesive cap and heat

the PU adhesive for a minimum of 30 minutes.

5.

Page 2533 of 3039

Wiper arm retaining nuts 22 16.2 194.7 Wiper linkage bolts / screws 11 8.1 97.4

Page 2534 of 3039

Published: 11-May-2011

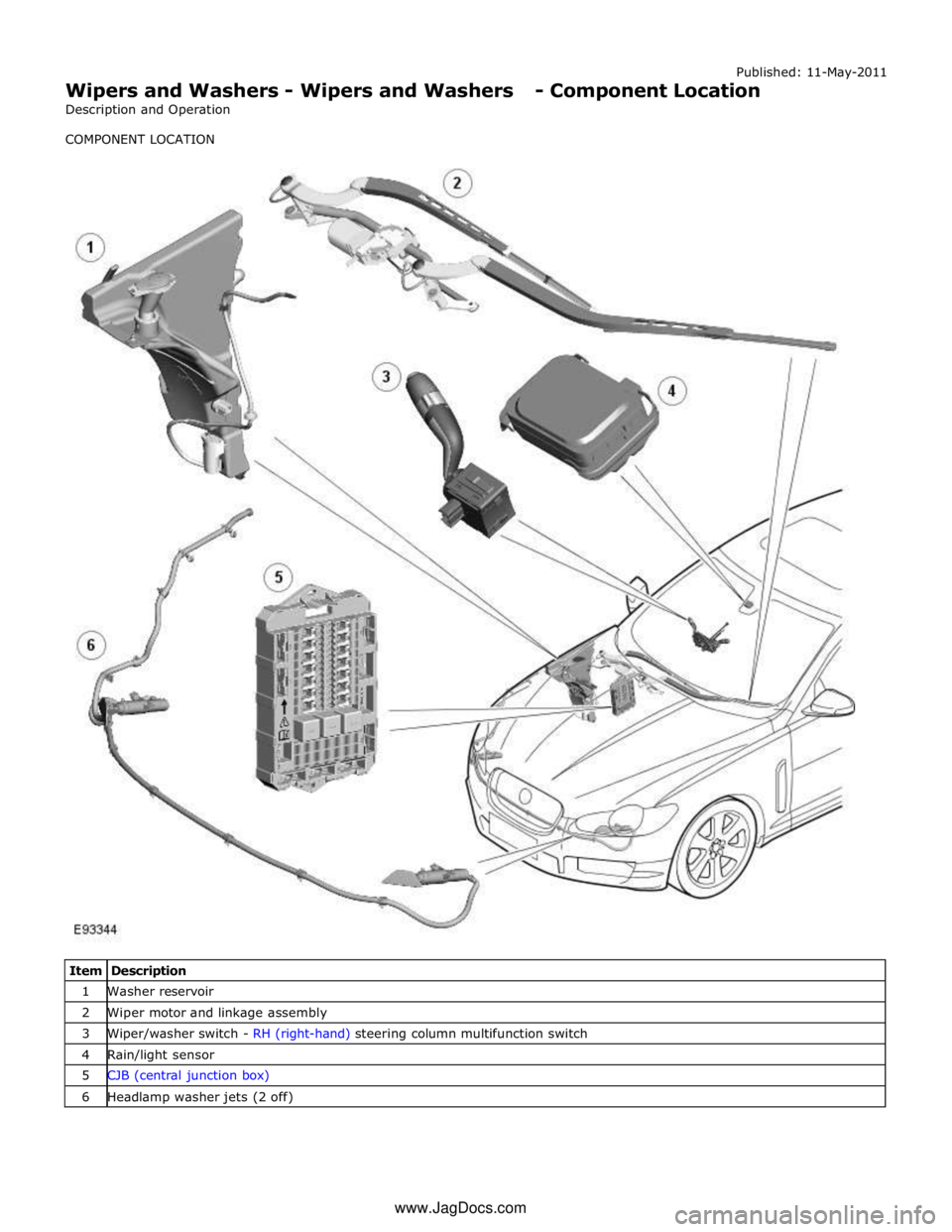

Wipers and Washers - Wipers and Washers - Component Location

Description and Operation

COMPONENT LOCATION

Item Description 1 Washer reservoir 2 Wiper motor and linkage assembly 3 Wiper/washer switch - RH (right-hand) steering column multifunction switch 4 Rain/light sensor 5 CJB (central junction box) 6 Headlamp washer jets (2 off) www.JagDocs.com

Page 2535 of 3039

Wipers and Washers - Wipers and Washers - Overview

Description and Operation

OVERVIEW Published: 11-May-2011

The wipers and washers comprise a windshield wiper system with a conventional wiper linkage and 2 wiper blades and a

windshield washer with jets located on the wiper arms. A headlamp powerwash is available on certain models.

The front wipers have 4 operational states:

Flick wipe

Auto

Slow wipe

Fast wipe.

Operation of the windshield wipers and washers and the headlamp powerwash is controlled by the CJB (central junction box) in

response to driver inputs and signals from the rain/light sensor. The instrument cluster monitors the condition of the

wiper/washer control switch and transmits driver requests to the CJB over the medium speed CAN (controller area network) bus.

The 'Auto' function requires an input from the rain sensor. The rain sensor is mounted on the inner surface of the windshield

and transmits an infra-red signal to determine the amount of water on the outer surface of the windshield. A value is then

transmitted to the CJB over the LIN (local interconnect network) bus.