roof JAGUAR XFR 2010 1.G Workshop Manual

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 2010, Model line: XFR, Model: JAGUAR XFR 2010 1.GPages: 3039, PDF Size: 58.49 MB

Page 28 of 3039

Instrument Panel Console

Instrument Panel Lower Trim Panel

Overhead Console501-14: Handles, Locks, Latches and Entry SystemsSpecificationDescription and OperationComponent Location

Overview

System Operation and Component DescriptionDiagnosis and TestingLocks, Latches and Entry SystemsRemoval and InstallationDoor Lock Cylinder Cover

Exterior Front Door Handle

Exterior Luggage Compartment Lid Release Switch

Exterior Rear Door Handle

Front Door Latch

Front Door Lock Cylinder

Interior Front Door Handle

Luggage Compartment Lid Latch Actuator

Luggage Compartment Lid Lock Cylinder

Rear Door Latch501-16: Wipers and WashersSpecificationDescription and OperationComponent Location

Overview

System Operation and Component DescriptionDiagnosis and TestingWipers and WashersRemoval and InstallationHeadlamp Washer Jet

Headlamp Washer Pump

Rain Sensor

Windshield Washer Reservoir

Windshield Wiper Motor

Windshield Wiper Pivot Arm

Windshield Washer Pump501-17: Roof Opening PanelSpecificationDescription and OperationComponent Location

Page 29 of 3039

Overview

System Operation and Component DescriptionDiagnosis and TestingRoof Opening PanelGeneral ProceduresRoof Opening Panel Alignment

Motor Synchronization (76.82.48)Removal and InstallationRoof Opening Panel Front Drain Hose

Roof Opening Panel Frame

Roof Opening Panel Glass

Roof Opening Panel Motor

Roof Opening Panel Rear Drain Hose

Roof Opening Panel Weatherstrip501-19: BumpersSpecificationRemoval and InstallationFront Bumper (76.22.08)

Front Bumper Cover

Front Bumper Cover Insert

Rear Bumper Cover

Rear Bumper501-20A: Safety Belt SystemSpecificationDescription and OperationComponent Location

Overview

System Operation and Component DescriptionDiagnosis and TestingSafety Belt SystemRemoval and InstallationFront Safety Belt Buckle

Front Safety Belt Retractor

Rear Center Safety Belt Retractor

Rear Safety Belt Buckle

Rear Safety Belt Retractor

Safety Belt Shoulder Height Adjuster501-20B: Supplemental Restraint SystemSpecificationDescription and OperationComponent Location

Overview

Page 31 of 3039

Removal and InstallationFender Apron Closing Panel Front Section

Fender Apron Panel

Fender Apron Panel Closing Panel

Fender Apron Panel Front Extension

Fender Apron Panel Front Section

Front Bumper Mounting

Front Fender

Front Fender Support Bracket

Front Side Member

Front Side Member and Suspension Top Mount Assembly

Front Side Member Closing Panel

Front Side Member Closing Panel Section

Front Side Member Section

Front Wheelhouse Section

Hood Latch Panel

Hood Latch Panel Mounting Bracket501-28: Roof Sheet Metal Repairs

Description and OperationRoofRemoval and InstallationRoof Panel - Vehicles With: Sliding Roof Opening Panel

Roof Panel - Vehicles Without: Sliding Roof Opening Panel501-29: Side Panel Sheet Metal Repairs

Description and OperationSide Panel Sheet MetalRemoval and InstallationA-Pillar Outer Panel

A-Pillar Reinforcement

B-Pillar Inner Panel

B-Pillar Reinforcement

Front Door Skin Panel

Rear Door Skin Panel

Rocker Panel

Rocker Panel and B-Pillar Outer Panel

Rocker Panel Front Section

Rocker Panel Inner Reinforcement

Rocker Panel Rear Section501-30: Rear End Sheet Metal Repairs

Description and OperationRear End Sheet Metal

Page 51 of 3039

Always reduce the engine speed to idle before disconnecting the jump leads.

Before removing the jump leads, switch on the heater blower (high) or the heated rear screen, to reduce the voltage peak

when the leads are removed.

Always disconnect the jump leads in the reverse order to the connecting sequence and take great care not to short the ends of

the leads.

Do not rely on the generator to restore a discharged battery. For a generator to recharge a battery, it would take in excess of 8

hours continuous driving with no additional loads placed on the battery.

Component Cleaning

To prevent ingress of dirt, accumulations of loose dirt and greasy deposits should be removed before disconnecting or

dismantling components or assemblies.

Components should be thoroughly cleaned before inspection prior to reassembly.

Cleaning Methods:

Dry Cleaning

Removal of loose dirt with soft or wire brushes

Scraping dirt off with a piece of metal or wood

Wiping off with a rag

CAUTION: Compressed air is sometimes wet so use with caution, especially on hydraulic systems.

Blowing dirt off with compressed air (Eye protection should be worn when using this method)

Removal of dry dust using vacuum equipment. This method should always be used to remove friction lining material

dust (asbestos particles)

Steam Cleaning

Calibration of Essential Measuring Equipment

WARNING: Failure to comply may result in personal injury or damage to components.

It is of fundamental importance that certain essential equipment e.g. torque wrenches, multimeters, exhaust gas analysers,

rolling roads etc., are regularly calibrated in accordance with the manufacturers instructions.

Use of Control Modules

Control modules may only be used on the vehicle to which they were originally installed. Do not attempt to use or test a

control module on any other vehicle.

Functional Test

On completion of a maintenance procedure, a thorough test should be carried out, to ensure the relevant vehicle systems are

working correctly.

Preparation

Before disassembly, clean the surrounding area as thoroughly as possible. When components have been removed, blank off

any exposed openings using grease-proof paper and masking tape. Immediately seal fuel, oil and hydraulic lines when

separated, using plastic caps or plugs, to prevent loss of fluid and the entry of dirt. Close the open ends of oil ways, exposed

by component removal, with tapered hardwood plugs or readily visible plastic plugs. Immediately a component is removed,

place it in a suitable container; use a separate container for each component and its associated parts. Before dismantling a

component, clean it thoroughly with a recommended cleaning agent; check that the agent will not damage any of the materials

within the component. Clean the bench and obtain marking materials, labels, containers and locking wire before dismantling a

component.

Dismantling

Observe scrupulous cleanliness when dismantling components, particularly when parts of the brake, fuel or hydraulic systems

are being worked on. A particle of dirt or a fragment of cloth could cause a dangerous malfunction if trapped in these systems.

Clean all tapped holes, crevices, oil ways and fluid passages with compressed air.

WARNING: Do not permit compressed air to enter an open wound. Always use eye protection when using compressed air.

Make sure that any O-rings used for sealing are correctly reinstalled or renewed if disturbed. Mark mating parts to make sure

that they are replaced as dismantled. Whenever possible use marking materials which avoid the possibilities of causing

distortion or the initiation of cracks, which could occur if a center punch or scriber were used. Wire together mating parts where

necessary to prevent accidental interchange (e.g roller bearing components). Tie labels on to all parts to be renewed and to

parts requiring further inspection before being passed for reassembly. Place labelled parts and other parts for rebuild in

separate containers. Do not discard a part which is due for renewal until it has been compared with the new part, to make sure

Page 66 of 3039

4. Components or assemblies displaying this symbol give warning that the component contains a corrosive substance. See

Acids and Alkalis in this subsection.

5. Vehicles displaying the caution circle with a deleted lighted match symbol, caution against the use of naked lights or

flames within the immediate vicinity due to the presence of highly flammable or explosive liquids or vapors. See Fire in

this subsection.

6. All vehicles with the passenger air bag installed from the factory have a warning sticker attached to the instrument

panel, prohibiting the use of rear facing child seats in the front seating position. Failure to follow this instruction may

result in personal injury.

White Spirit

See Solvents.

Safety Precautions

WARNINGS:

Working on the fuel system results in fuel and fuel vapor being present in the atmosphere. Fuel vapor is extremely

flammable, hence great care must be taken whilst working on the fuel system. Adhere strictly to the following precautions:

Do not smoke in the work area

Display 'no smoking' signs around the area

Disconnect the battery before working on the fuel system

Do not connect/disconnect electrical circuits, use electrical equipment or other tools or engage in working practices

which in any way may result in the production of sparks

Ensure that a CO² fire extinguisher is close at hand

Ensure that dry sand is available to soak up any fuel spillage

Empty fuel using suitable fire proof equipment into an authorized explosion proof container

Page 135 of 3039

DTC Description Possible Causes Action error following

re-programming

Noise/EMC related error network for interference/EMC related issues B1009-63 Ignition Authorisation

- Circuit/component

protection time-out

CJB fault

Low speed CAN fault

Instrument cluster fault

Low battery voltage <9V

Check Power and Ground supplies to CJB and

instrument cluster. Check CAN communications

between CJB and instrument cluster. Check

battery is in fully charged and serviceable

condition, refer to the battery care manual B1009-64 Ignition Authorisation

- Signal plausibility

failure

CJB fault

Low speed CAN fault

Instrument cluster fault

Check power and ground supplies to CJB and

instrument cluster. Check CAN communications

between CJB and instrument cluster B102B-67

Passive Key - Signal

incorrect after event

CJB fault

Low speed CAN fault

Remote Keyless Entry (RKE)

module fault

Write target SID

synchronisation error

following re-programming

Check power and ground supplies to CJB and RKE

module. Check CAN communications between CJB

and RKE module. Re-synchronise ID by

re-configuring the RKE module as a new module B102B-87

Passive Key - Missing

message

CJB fault

Low speed CAN fault

RKE module fault

Key fob battery low/battery

contact issue

Interference from other RF

signal

EMC/noise

Receiver fault

Receiver not programmed

correctly

Serial communications fault

(between receiver and RKE

module)

Key fault

Passive antenna fault

Confirm placement of key

within vehicle

Check power and ground supplies to CJB, RKE

module and receiver. Check CAN communications

between CJB and instrument cluster. Check key

fob battery. Confirm vehicle surroundings, move

vehicle. Check CAN network for interference/EMC

related issues. Disconnect battery, then

re-connect - confirm operation by re-programming

keys. Check serial circuit between receiver and

RKE module. Confirm spare key works. Refer to

the electrical circuit diagrams and test circuits to

all 3 antennas. Check whereabouts of key B1084-13

Boot/Trunk Motor

Close Switch - Circuit

open

Trunk latch open signal

circuit - open circuit

Refer to the electrical circuit diagrams and check

trunk latch open signal circuit for open circuit B1087-83

LIN Bus "A" - Value of

signal protection

calculation incorrect

Checksum of the received

LIN frame from battery

backed sounder, roof header

console, and/or rain/light

sensor is incorrect

Check operation of rain/light sensor by covering

sensor or applying water to screen, install a new

sensor as required B1087-88 LIN Bus "A" - Bus off

Bus off. Battery backed

sounder, roof header

console, and/or rain/light

sensor LIN circuit - short to

ground, power

Carry out any pinpoint tests associated with this

DTC using the manufacturer approved diagnostic

system. Refer to the electrical circuit diagrams

and check battery backed sounder, roof header

console, and rain/light sensor LIN circuit for short

to ground, power B108A-11

Start Button - Circuit

short to ground

Start/Stop switch analogue

input circuits 1 or 2 - short

to ground

Refer to the electrical circuit diagrams and check

Start/Stop switch analogue input circuits 1 and 2

for short to ground B108A-12

Start Button - Circuit

short to battery

Start/Stop switch analogue

input circuits 1 or 2 - short

to power

Refer to the electrical circuit diagrams and check

Start/Stop switch analogue input circuits 1 and 2

for short to power B1095-12

Wiper On/Off Relay -

Circuit short to battery

Wiper On/Off relay control

circuit - short to power

Carry out any pinpoint tests associated with this

DTC using the manufacturer approved diagnostic

system. Refer to the electrical circuit diagrams

and check wiper On/Off relay control circuit for www.JagDocs.com

Page 136 of 3039

DTC Description Possible Causes Action short to power B1095-14

Wiper On/Off Relay -

Circuit short to ground

or open

Wiper On/Off relay control

circuit - short to ground,

open circuit

Refer to the electrical circuit diagrams and check

wiper On/Off relay control circuit for short to

ground, open circuit B1096-12 Wiper High/Low Relay

- Circuit short to

battery

Wiper Fast/Slow relay

control circuit - short to

power

Carry out any pinpoint tests associated with this

DTC using the manufacturer approved diagnostic

system. Refer to the electrical circuit diagrams

and check wiper Fast/Slow relay control circuit for

short to power B1096-14 Wiper High/Low Relay

- Circuit short to

ground or open

Wiper Fast/Slow relay

control circuit - short to

ground, open circuit

Refer to the electrical circuit diagrams and check

wiper Fast/Slow relay control circuit for short to

ground, open circuit B1097-12

Heated Windshield

Relay - Circuit short to

battery

Heated windshield relay

control circuit - short to

power

Carry out any pinpoint tests associated with this

DTC using the manufacturer approved diagnostic

system. Refer to the electrical circuit diagrams

and check heated windshield relay control circuit

for short to power B1097-14

Heated Windshield

Relay - Circuit short to

ground or open

Heated windshield relay

control circuit - short to

ground, open circuit

Refer to the electrical circuit diagrams and check

heated windshield relay control circuit for short to

ground, open circuit B10A6-12

Main Light Switch -

Circuit short to battery

Master light switch signal

from roof header console

circuit - short to power

Refer to the electrical circuit diagrams and check

master light switch signal from roof header

console circuit for short to power B10A6-23

Main Light Switch -

Signal stuck low

Master light switch signal

from roof header console

signal stuck low. Switch is

read as ON for too long a

time

Carry out any pinpoint tests associated with this

DTC using the manufacturer approved diagnostic

system. Refer to the electrical circuit diagrams

and check master light switch signal from roof

header console for short to ground B10AD-09

Rain Sensor -

Component failures

Component failures

Carry out any pinpoint tests associated with this

DTC using the manufacturer approved diagnostic

system. Suspect the rain/light sensor, check and

install a new sensor as required B10AD-11

Rain Sensor - Circuit

short to ground

Rain/light sensor power

circuit - short to ground

Carry out any pinpoint tests associated with this

DTC using the manufacturer approved diagnostic

system. Refer to the electrical circuit diagrams

and check rain/light sensor power circuit for short

to ground B10AD-96

Rain Sensor -

Component internal

failure

Component internal failure

Suspect the rain/light sensor, check and install a

new sensor as required B10E5-11

PCM Wake-up Signal -

Circuit short to ground

ECM wake-up signal circuit -

short to ground

Refer to the electrical circuit diagrams and check

ECM wake-up signal circuit for short to ground B10E5-12

PCM Wake-up Signal -

Circuit short to battery

ECM wake-up signal circuit -

short to power

Refer to the electrical circuit diagrams and check

ECM wake-up signal circuit for short to power B10E5-13

PCM Wake-up Signal -

Circuit open

ECM wake-up signal circuit -

open circuit

Refer to the electrical circuit diagrams and check

ECM wake-up signal circuit for open circuit B10F1-11

Key In Switch - Circuit

short to ground

Keyless vehicle module, key

IN status circuit - short to

ground

Carry out any pinpoint tests associated with this

DTC using the manufacturer approved diagnostic

system. Refer to the electrical circuit diagrams

and check keyless vehicle module, key IN status

circuit for short to ground

Page 137 of 3039

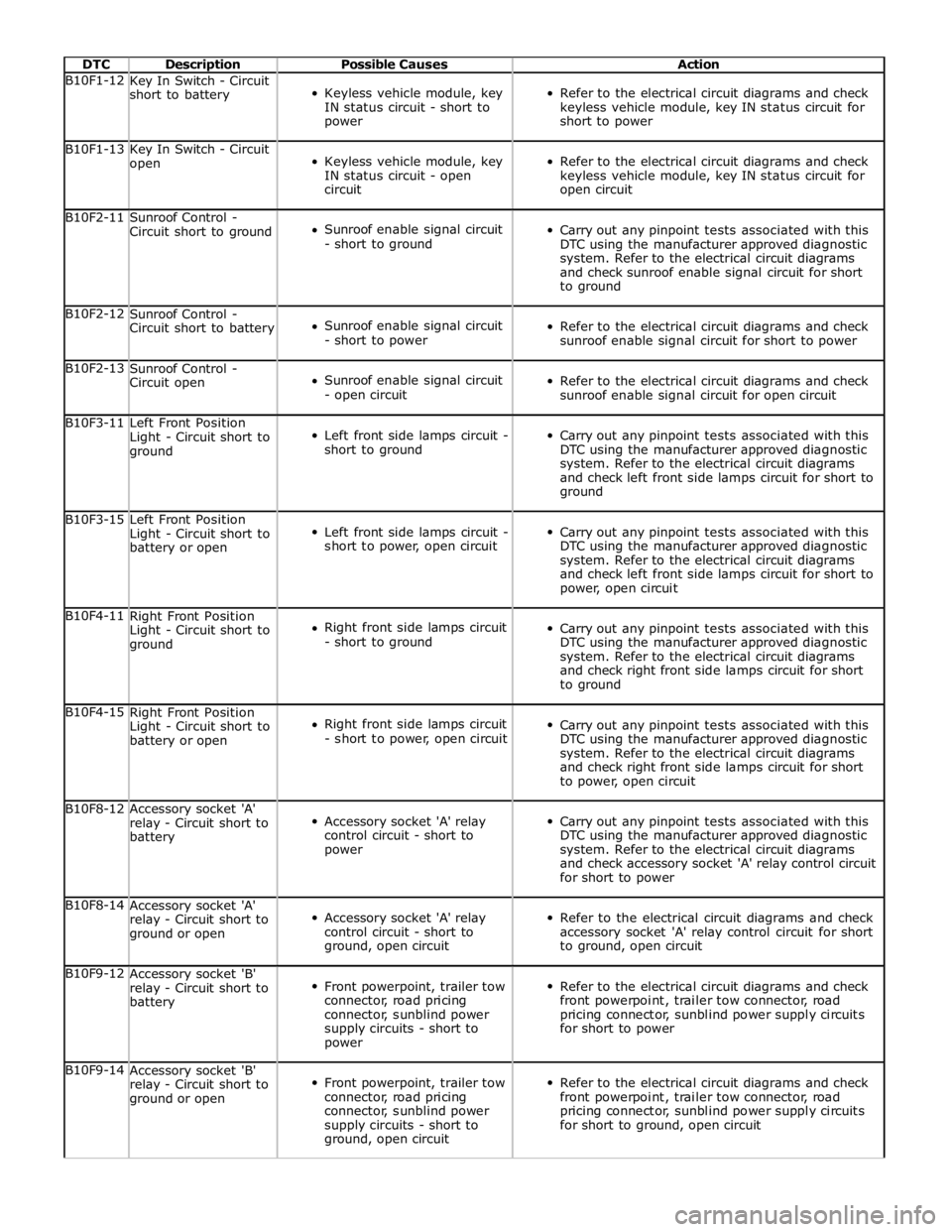

DTC Description Possible Causes Action B10F1-12

Key In Switch - Circuit

short to battery

Keyless vehicle module, key

IN status circuit - short to

power

Refer to the electrical circuit diagrams and check

keyless vehicle module, key IN status circuit for

short to power B10F1-13

Key In Switch - Circuit

open

Keyless vehicle module, key

IN status circuit - open

circuit

Refer to the electrical circuit diagrams and check

keyless vehicle module, key IN status circuit for

open circuit B10F2-11

Sunroof Control -

Circuit short to ground

Sunroof enable signal circuit

- short to ground

Carry out any pinpoint tests associated with this

DTC using the manufacturer approved diagnostic

system. Refer to the electrical circuit diagrams

and check sunroof enable signal circuit for short

to ground B10F2-12

Sunroof Control -

Circuit short to battery

Sunroof enable signal circuit

- short to power

Refer to the electrical circuit diagrams and check

sunroof enable signal circuit for short to power B10F2-13

Sunroof Control -

Circuit open

Sunroof enable signal circuit

- open circuit

Refer to the electrical circuit diagrams and check

sunroof enable signal circuit for open circuit B10F3-11

Left Front Position

Light - Circuit short to

ground

Left front side lamps circuit -

short to ground

Carry out any pinpoint tests associated with this

DTC using the manufacturer approved diagnostic

system. Refer to the electrical circuit diagrams

and check left front side lamps circuit for short to

ground B10F3-15

Left Front Position

Light - Circuit short to

battery or open

Left front side lamps circuit -

short to power, open circuit

Carry out any pinpoint tests associated with this

DTC using the manufacturer approved diagnostic

system. Refer to the electrical circuit diagrams

and check left front side lamps circuit for short to

power, open circuit B10F4-11

Right Front Position

Light - Circuit short to

ground

Right front side lamps circuit

- short to ground

Carry out any pinpoint tests associated with this

DTC using the manufacturer approved diagnostic

system. Refer to the electrical circuit diagrams

and check right front side lamps circuit for short

to ground B10F4-15

Right Front Position

Light - Circuit short to

battery or open

Right front side lamps circuit

- short to power, open circuit

Carry out any pinpoint tests associated with this

DTC using the manufacturer approved diagnostic

system. Refer to the electrical circuit diagrams

and check right front side lamps circuit for short

to power, open circuit B10F8-12

Accessory socket 'A'

relay - Circuit short to

battery

Accessory socket 'A' relay

control circuit - short to

power

Carry out any pinpoint tests associated with this

DTC using the manufacturer approved diagnostic

system. Refer to the electrical circuit diagrams

and check accessory socket 'A' relay control circuit

for short to power B10F8-14

Accessory socket 'A'

relay - Circuit short to

ground or open

Accessory socket 'A' relay

control circuit - short to

ground, open circuit

Refer to the electrical circuit diagrams and check

accessory socket 'A' relay control circuit for short

to ground, open circuit B10F9-12

Accessory socket 'B'

relay - Circuit short to

battery

Front powerpoint, trailer tow

connector, road pricing

connector, sunblind power

supply circuits - short to

power

Refer to the electrical circuit diagrams and check

front powerpoint, trailer tow connector, road

pricing connector, sunblind power supply circuits

for short to power B10F9-14

Accessory socket 'B'

relay - Circuit short to

ground or open

Front powerpoint, trailer tow

connector, road pricing

connector, sunblind power

supply circuits - short to

ground, open circuit

Refer to the electrical circuit diagrams and check

front powerpoint, trailer tow connector, road

pricing connector, sunblind power supply circuits

for short to ground, open circuit

Page 138 of 3039

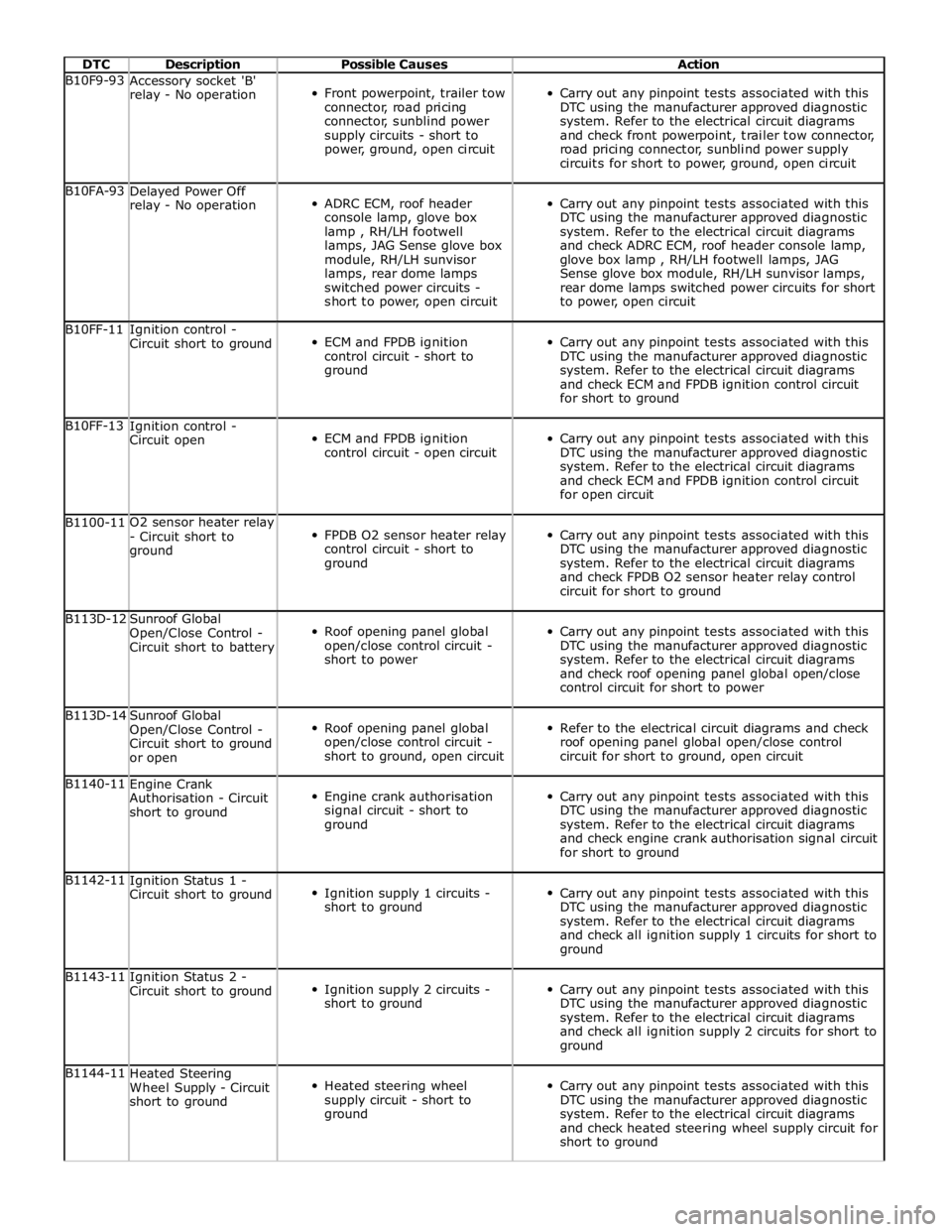

DTC Description Possible Causes Action B10F9-93

Accessory socket 'B'

relay - No operation

Front powerpoint, trailer tow

connector, road pricing

connector, sunblind power

supply circuits - short to

power, ground, open circuit

Carry out any pinpoint tests associated with this

DTC using the manufacturer approved diagnostic

system. Refer to the electrical circuit diagrams

and check front powerpoint, trailer tow connector,

road pricing connector, sunblind power supply

circuits for short to power, ground, open circuit B10FA-93

Delayed Power Off

relay - No operation

ADRC ECM, roof header

console lamp, glove box

lamp , RH/LH footwell

lamps, JAG Sense glove box

module, RH/LH sunvisor

lamps, rear dome lamps

switched power circuits -

short to power, open circuit

Carry out any pinpoint tests associated with this

DTC using the manufacturer approved diagnostic

system. Refer to the electrical circuit diagrams

and check ADRC ECM, roof header console lamp,

glove box lamp , RH/LH footwell lamps, JAG

Sense glove box module, RH/LH sunvisor lamps,

rear dome lamps switched power circuits for short

to power, open circuit B10FF-11

Ignition control -

Circuit short to ground

ECM and FPDB ignition

control circuit - short to

ground

Carry out any pinpoint tests associated with this

DTC using the manufacturer approved diagnostic

system. Refer to the electrical circuit diagrams

and check ECM and FPDB ignition control circuit

for short to ground B10FF-13

Ignition control -

Circuit open

ECM and FPDB ignition

control circuit - open circuit

Carry out any pinpoint tests associated with this

DTC using the manufacturer approved diagnostic

system. Refer to the electrical circuit diagrams

and check ECM and FPDB ignition control circuit

for open circuit B1100-11 O2 sensor heater relay

- Circuit short to

ground

FPDB O2 sensor heater relay

control circuit - short to

ground

Carry out any pinpoint tests associated with this

DTC using the manufacturer approved diagnostic

system. Refer to the electrical circuit diagrams

and check FPDB O2 sensor heater relay control

circuit for short to ground B113D-12

Sunroof Global

Open/Close Control -

Circuit short to battery

Roof opening panel global

open/close control circuit -

short to power

Carry out any pinpoint tests associated with this

DTC using the manufacturer approved diagnostic

system. Refer to the electrical circuit diagrams

and check roof opening panel global open/close

control circuit for short to power B113D-14

Sunroof Global

Open/Close Control -

Circuit short to ground

or open

Roof opening panel global

open/close control circuit -

short to ground, open circuit

Refer to the electrical circuit diagrams and check

roof opening panel global open/close control

circuit for short to ground, open circuit B1140-11

Engine Crank

Authorisation - Circuit

short to ground

Engine crank authorisation

signal circuit - short to

ground

Carry out any pinpoint tests associated with this

DTC using the manufacturer approved diagnostic

system. Refer to the electrical circuit diagrams

and check engine crank authorisation signal circuit

for short to ground B1142-11

Ignition Status 1 -

Circuit short to ground

Ignition supply 1 circuits -

short to ground

Carry out any pinpoint tests associated with this

DTC using the manufacturer approved diagnostic

system. Refer to the electrical circuit diagrams

and check all ignition supply 1 circuits for short to

ground B1143-11

Ignition Status 2 -

Circuit short to ground

Ignition supply 2 circuits -

short to ground

Carry out any pinpoint tests associated with this

DTC using the manufacturer approved diagnostic

system. Refer to the electrical circuit diagrams

and check all ignition supply 2 circuits for short to

ground B1144-11

Heated Steering

Wheel Supply - Circuit

short to ground

Heated steering wheel

supply circuit - short to

ground

Carry out any pinpoint tests associated with this

DTC using the manufacturer approved diagnostic

system. Refer to the electrical circuit diagrams

and check heated steering wheel supply circuit for

short to ground

Page 299 of 3039

Published: 16-Sep-2013

Noise, Vibration and Harshness - Noise, Vibration and Harshness (NVH)

Diagnosis and Testing

Principle of Operation

For a detailed description of Noise, Vibration and Harshness issues, refer to the Description and Operation section of the

workshop manual.

REFER to: Noise, Vibration and Harshness (NVH) (100-04 Noise, Vibration and Harshness, Description and Operation).

Inspection and Verification

1. Verify the customer's concerns by operating the vehicle to duplicate the condition.

2. Visually inspect the vehicle to determine any obvious cause(s) of the concern(s).

3. If the inspection reveals obvious causes that can be readily identified, repair as necessary.

4. If the concern(s) remains after the inspection, determine the symptom(s) and refer to the Symptom Chart.

How To Use This Diagnostic Procedure Section

Noise, vibration and harshness (NVH) concerns have become more important as vehicles have become more sensitive to

these vibrations. This section is designed as an aid to identifying these situations

The section provides diagnostic procedures based on symptoms. If the condition occurs at high speed, for instance, the

most likely place to start is under High Speed Shake

The road test procedure will tell how to sort the conditions into categories and how to tell a vibration from a shake

A series of Road Test Quick Checks is provided to make sure that a cause is either pinpointed or eliminated

Name the condition, proceed to the appropriate section and locate the correct diagnosis. When the condition is

identified, the job is partly done

Follow the diagnostic procedure as outlined

Quick Checks are described within the step, while more involved tests and adjustments are outlined in General

Procedures

Always follow each step exactly and make notes to recall important findings later

Customer Interview

The road test and customer interview (if available) provide information that will help identify the concerns and will provide

direction to the correct starting point for diagnosis.

Identify the Condition

NVH problems usually occur in a number of areas:

tires

engine accessories

suspension

driveline

air leakage (wind noise)

squeaks and rattles

heating ventilation and air conditioning (HVAC)

electrical (e.g. motor noise)

transmission

engine

It is important, therefore, that an NVH concern be isolated into its specific area(s) as soon as possible. The easiest and

quickest way to do this is to carry out the Road Test as outlined.

Noise Diagnostic Procedure

Non-Axle Noise

The five most important sources of non-axle noise are exhaust, tires, roof racks, trim and mouldings, and transmission.

Therefore, make sure that none of the following conditions are the cause of the noise before proceeding with a driveline tear

down and diagnosis.

Under certain conditions, the pitch of the exhaust may sound very much like gear noise. At other times, it can be

mistaken for a wheel bearing rumble

Tires, especially snow tires, can have a high pitched tread whine or roar, similar to gear noise. Radial tires, to some

degree, have this characteristic. Also, any non-standard tire with an unusual tread construction may emit a roar or

whine type noise

Trim and mouldings can also cause whistling or a whining noise

Clunk may be a metallic noise heard when the automatic transmission is engaged in reverse or drive, or it may occur

when the throttle is applied or released. It is caused by backlash somewhere in the driveline

Bearing rumble sounds like marbles being tumbled. This condition is usually caused by a damaged wheel bearing