torque JAGUAR XFR 2010 1.G Workshop Manual

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 2010, Model line: XFR, Model: JAGUAR XFR 2010 1.GPages: 3039, PDF Size: 58.49 MB

Page 1446 of 3039

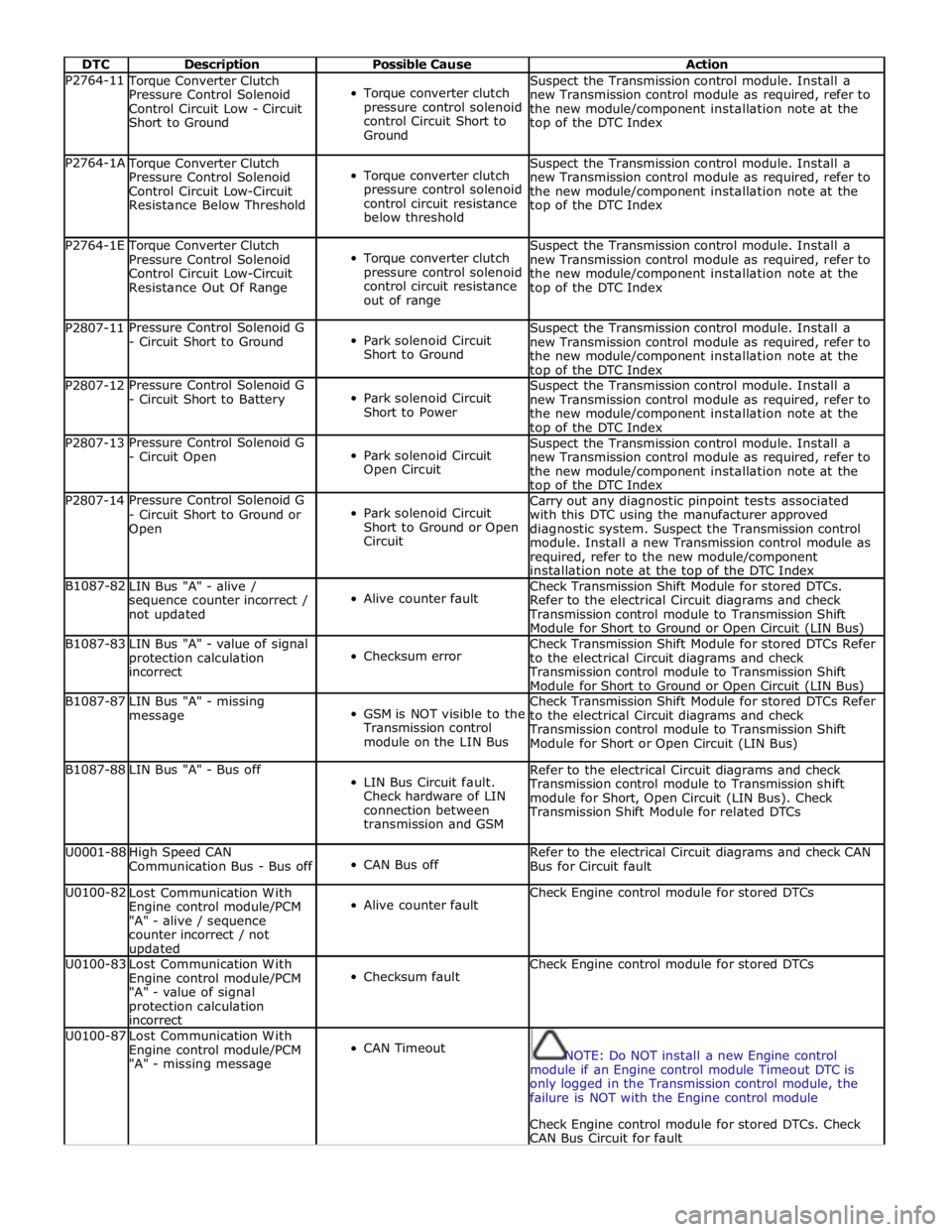

DTC Description Possible Cause Action P2764-11 Torque Converter Clutch

Pressure Control Solenoid

Control Circuit Low - Circuit

Short to Ground

Torque converter clutch

pressure control solenoid

control Circuit Short to

Ground Suspect the Transmission control module. Install a

new Transmission control module as required, refer to

the new module/component installation note at the

top of the DTC Index P2764-1A Torque Converter Clutch

Pressure Control Solenoid

Control Circuit Low-Circuit

Resistance Below Threshold

Torque converter clutch

pressure control solenoid

control circuit resistance

below threshold Suspect the Transmission control module. Install a

new Transmission control module as required, refer to

the new module/component installation note at the

top of the DTC Index P2764-1E Torque Converter Clutch

Pressure Control Solenoid

Control Circuit Low-Circuit

Resistance Out Of Range

Torque converter clutch

pressure control solenoid

control circuit resistance

out of range Suspect the Transmission control module. Install a

new Transmission control module as required, refer to

the new module/component installation note at the

top of the DTC Index P2807-11 Pressure Control Solenoid G

- Circuit Short to Ground

Park solenoid Circuit

Short to Ground Suspect the Transmission control module. Install a

new Transmission control module as required, refer to

the new module/component installation note at the top of the DTC Index P2807-12 Pressure Control Solenoid G

- Circuit Short to Battery

Park solenoid Circuit

Short to Power Suspect the Transmission control module. Install a

new Transmission control module as required, refer to

the new module/component installation note at the top of the DTC Index P2807-13 Pressure Control Solenoid G

- Circuit Open

Park solenoid Circuit

Open Circuit Suspect the Transmission control module. Install a

new Transmission control module as required, refer to

the new module/component installation note at the top of the DTC Index P2807-14 Pressure Control Solenoid G

- Circuit Short to Ground or

Open

Park solenoid Circuit

Short to Ground or Open

Circuit Carry out any diagnostic pinpoint tests associated

with this DTC using the manufacturer approved

diagnostic system. Suspect the Transmission control

module. Install a new Transmission control module as

required, refer to the new module/component

installation note at the top of the DTC Index B1087-82

LIN Bus "A" - alive /

sequence counter incorrect /

not updated

Alive counter fault Check Transmission Shift Module for stored DTCs.

Refer to the electrical Circuit diagrams and check

Transmission control module to Transmission Shift

Module for Short to Ground or Open Circuit (LIN Bus) B1087-83

LIN Bus "A" - value of signal

protection calculation

incorrect

Checksum error Check Transmission Shift Module for stored DTCs Refer

to the electrical Circuit diagrams and check

Transmission control module to Transmission Shift

Module for Short to Ground or Open Circuit (LIN Bus) B1087-87

LIN Bus "A" - missing

message

GSM is NOT visible to the

Transmission control

module on the LIN Bus Check Transmission Shift Module for stored DTCs Refer

to the electrical Circuit diagrams and check

Transmission control module to Transmission Shift

Module for Short or Open Circuit (LIN Bus) B1087-88 LIN Bus "A" - Bus off

LIN Bus Circuit fault.

Check hardware of LIN

connection between

transmission and GSM Refer to the electrical Circuit diagrams and check

Transmission control module to Transmission shift

module for Short, Open Circuit (LIN Bus). Check

Transmission Shift Module for related DTCs U0001-88

High Speed CAN

Communication Bus - Bus off

CAN Bus off Refer to the electrical Circuit diagrams and check CAN

Bus for Circuit fault U0100-82

Lost Communication With

Engine control module/PCM

"A" - alive / sequence

counter incorrect / not updated

Alive counter fault Check Engine control module for stored DTCs U0100-83

Lost Communication With

Engine control module/PCM

"A" - value of signal

protection calculation

incorrect

Checksum fault Check Engine control module for stored DTCs U0100-87

Lost Communication With

Engine control module/PCM

"A" - missing message

CAN Timeout

NOTE: Do NOT install a new Engine control

module if an Engine control module Timeout DTC is

only logged in the Transmission control module, the

failure is NOT with the Engine control module

Check Engine control module for stored DTCs. Check

CAN Bus Circuit for fault

Page 1447 of 3039

DTC Description Possible Cause Action U0103-82

Lost Communication With

Gear Shift Control Module

A-alive / sequence counter

incorrect / not updated

Alive counter fault Check Transmission shift module for stored DTCs.

Check CAN Bus Circuit for fault U0103-83

Lost Communication With

Gear Shift Control Module A

- value of signal protection

calculation incorrect

Checksum fault Check Transmission shift module for stored DTCs.

Check CAN Bus Circuit for fault U0103-87

Lost Communication With

Gear Shift Control Module A

- missing message

CAN Timeout Check Transmission shift module for stored DTCs.

Check CAN Bus Circuit for fault U0122-82

Lost Communication With

Vehicle Dynamics Control

Module - alive / sequence

counter incorrect / not updated

Alive counter fault Check Anti-lock braking system for stored DTCs. Check

CAN Bus Circuit for fault U0122-83

Lost Communication With

Vehicle Dynamics Control

Module - value of signal

protection calculation

incorrect

Checksum fault Check Anti-lock braking system for stored DTCs. Check

CAN Bus Circuit for fault U0122-87

Lost Communication With

Vehicle Dynamics Control

Module - missing message

CAN Timeout Check Anti-lock braking system for stored DTCs. Check

CAN Bus Circuit for fault U0126-00

Lost Communication With

Steering Angle Sensor

Module - no sub type

information

Lost Communication

With Steering Angle

Sensor Module Check Steering angle sensor for stored DTCs. Check

CAN Bus Circuit for fault U0128-87

Lost Communication With

Park Brake Control Module -

missing message

CAN timeout electronic

parking brake module Check Electronic Parking Brake Module for stored DTCs.

Check CAN Bus Circuit for fault U0140-82

Lost Communication With

Body Control Module - alive / sequence counter incorrect / not updated

Alive counter fault Check Central junction box for stored DTCs. Check CAN

Bus Circuit for fault U0140-83

Lost Communication With

Body Control Module - value

of signal protection

calculation incorrect

Checksum fault Check Central junction box for stored DTCs. Check CAN

Bus Circuit for fault U0140-87

Lost Communication With

Body Control Module - missing message

CAN Timeout Check Central junction box for stored DTCs. Check CAN

Bus Circuit for fault U0155-87

Lost Communication With

Instrument Panel Cluster

(Instrument cluster) Control

Module - missing message

CAN timeout instrument

cluster Check Instrument cluster for stored DTCs. Check CAN

Bus Circuit for fault U0300-68

Control Module - event

information

Transmission software

does not match vehicle

network Check Central junction box software level, Check

Transmission control module Software level, Update

software as required using the manufacturer approved

process U0401-08

Invalid Data Received From

Engine control module/PCM

A - Bus Signal Message

Failures

Inaccurate engine speed,

torque information Check Engine control module for stored DTCs, Check

CAN Bus circuit for faults U0401-68

Invalid Data Received from

Engine control module/PCM

A - event information

Inaccurate engine speed,

torque information Check Engine control module for stored DTCs. Check

CAN Bus Circuit for fault U0401-86

Invalid Data Received from

Engine control module/PCM

A - Signal Invalid

Inaccurate engine speed,

torque information Check Engine control module for stored DTCs. Check

CAN Bus Circuit for fault U0404-68

Invalid Data Received from

Gear Shift Control Module A

- event information

Incorrect CAN data

received from

Transmission shift

module Check Transmission Shift Module for stored DTCs.

Refer to Circuit diagrams and check CAN and LIN Bus

for Circuit fault U0404-81

Invalid Data Received from

Gear Shift Control Module A

- Invalid Serial Data

Received

Incorrect LIN data

received from

Transmission shift

module Check Transmission Shift Module for stored DTCs.

Refer to Circuit diagrams and check CAN and LIN Bus

for Circuit fault www.JagDocs.com

Page 1451 of 3039

9.

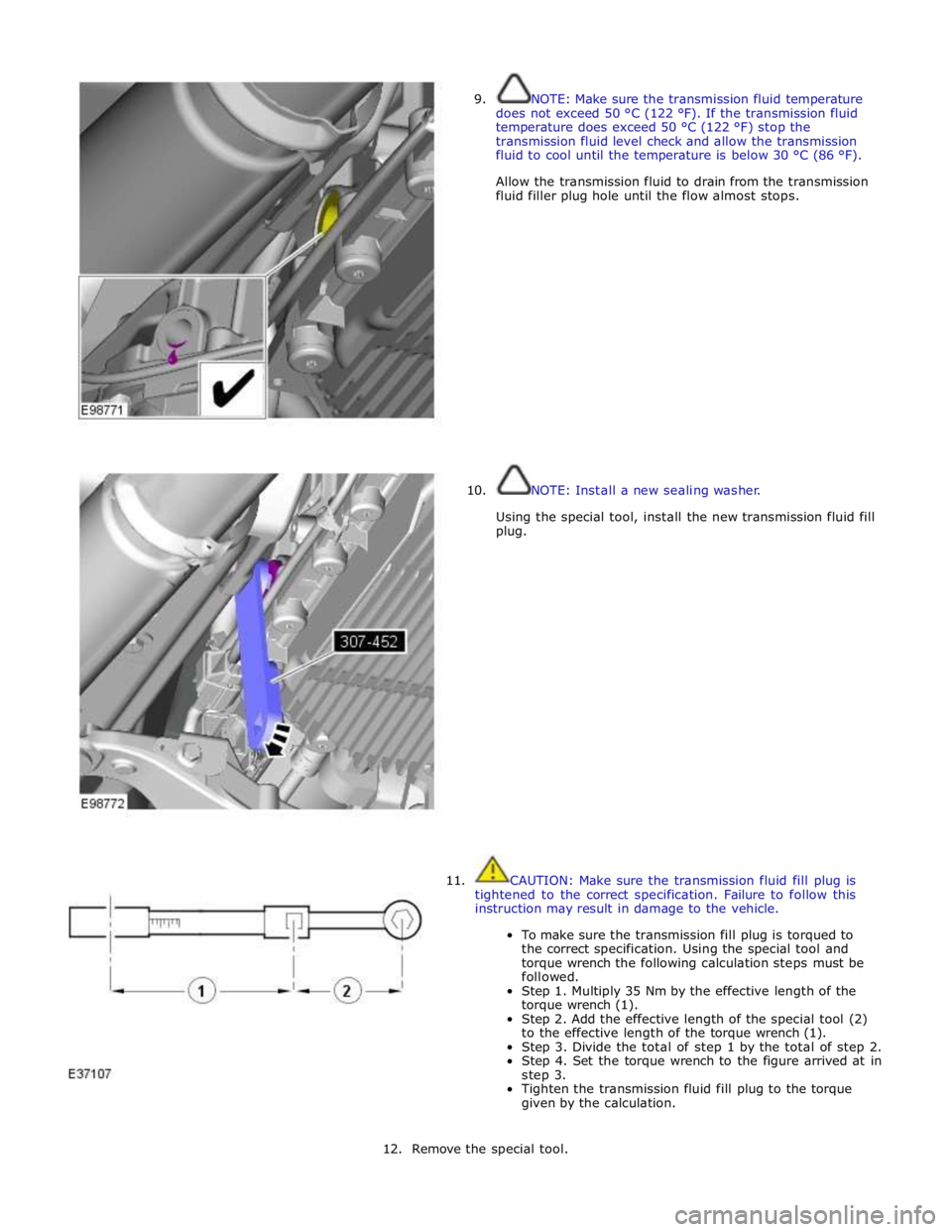

10. NOTE: Make sure the transmission fluid temperature

does not exceed 50 °C (122 °F). If the transmission fluid

temperature does exceed 50 °C (122 °F) stop the

transmission fluid level check and allow the transmission

fluid to cool until the temperature is below 30 °C (86 °F).

Allow the transmission fluid to drain from the transmission

fluid filler plug hole until the flow almost stops.

NOTE: Install a new sealing washer.

Using the special tool, install the new transmission fluid fill

plug.

11. CAUTION: Make sure the transmission fluid fill plug is

tightened to the correct specification. Failure to follow this

instruction may result in damage to the vehicle.

To make sure the transmission fill plug is torqued to

the correct specification. Using the special tool and

torque wrench the following calculation steps must be

followed.

Step 1. Multiply 35 Nm by the effective length of the

torque wrench (1).

Step 2. Add the effective length of the special tool (2)

to the effective length of the torque wrench (1).

Step 3. Divide the total of step 1 by the total of step 2.

Step 4. Set the torque wrench to the figure arrived at in

step 3.

Tighten the transmission fluid fill plug to the torque

given by the calculation.

12. Remove the special tool.

Page 1454 of 3039

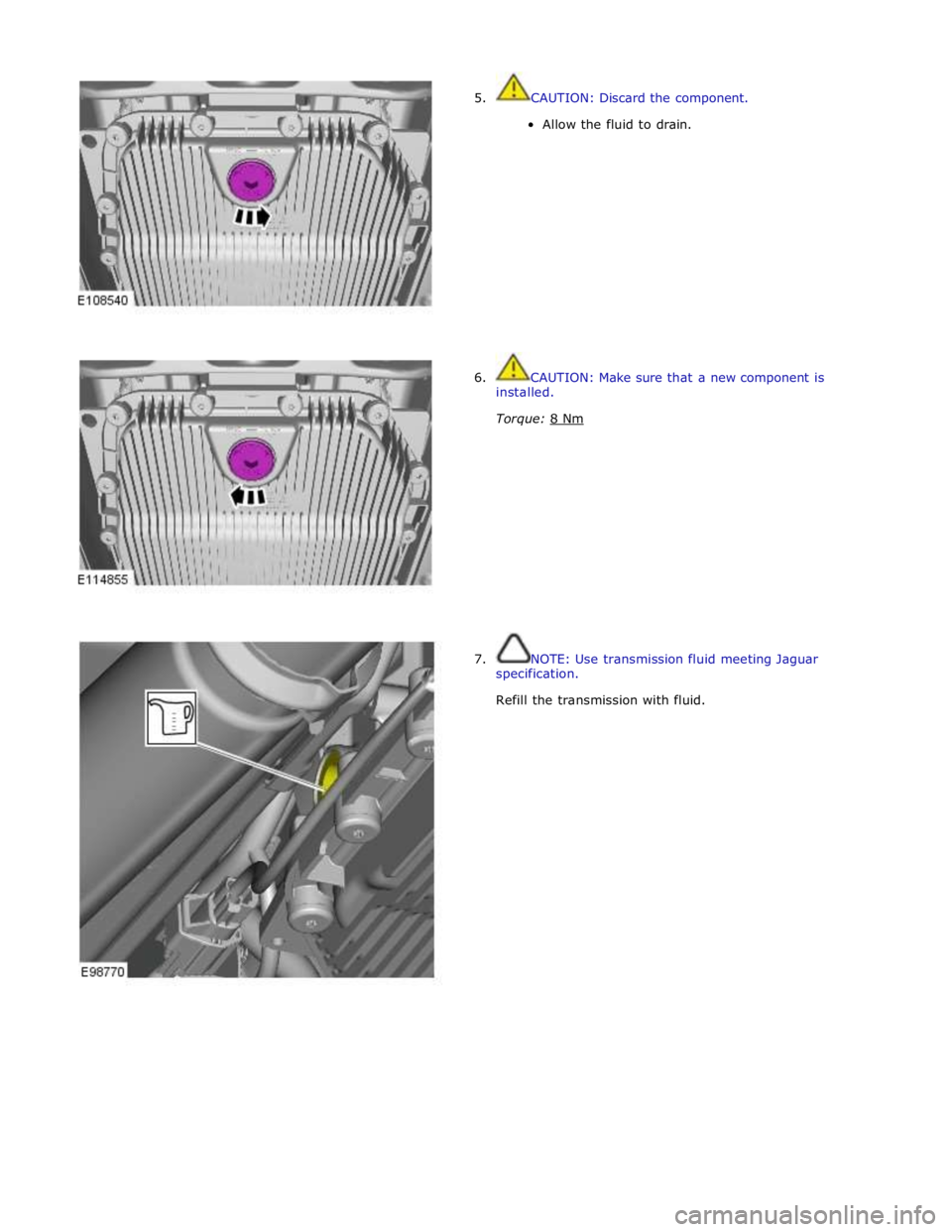

5. CAUTION: Discard the component.

Allow the fluid to drain.

6. CAUTION: Make sure that a new component is

installed.

Torque: 8 Nm

7. NOTE: Use transmission fluid meeting Jaguar

specification.

Refill the transmission with fluid.

Page 1455 of 3039

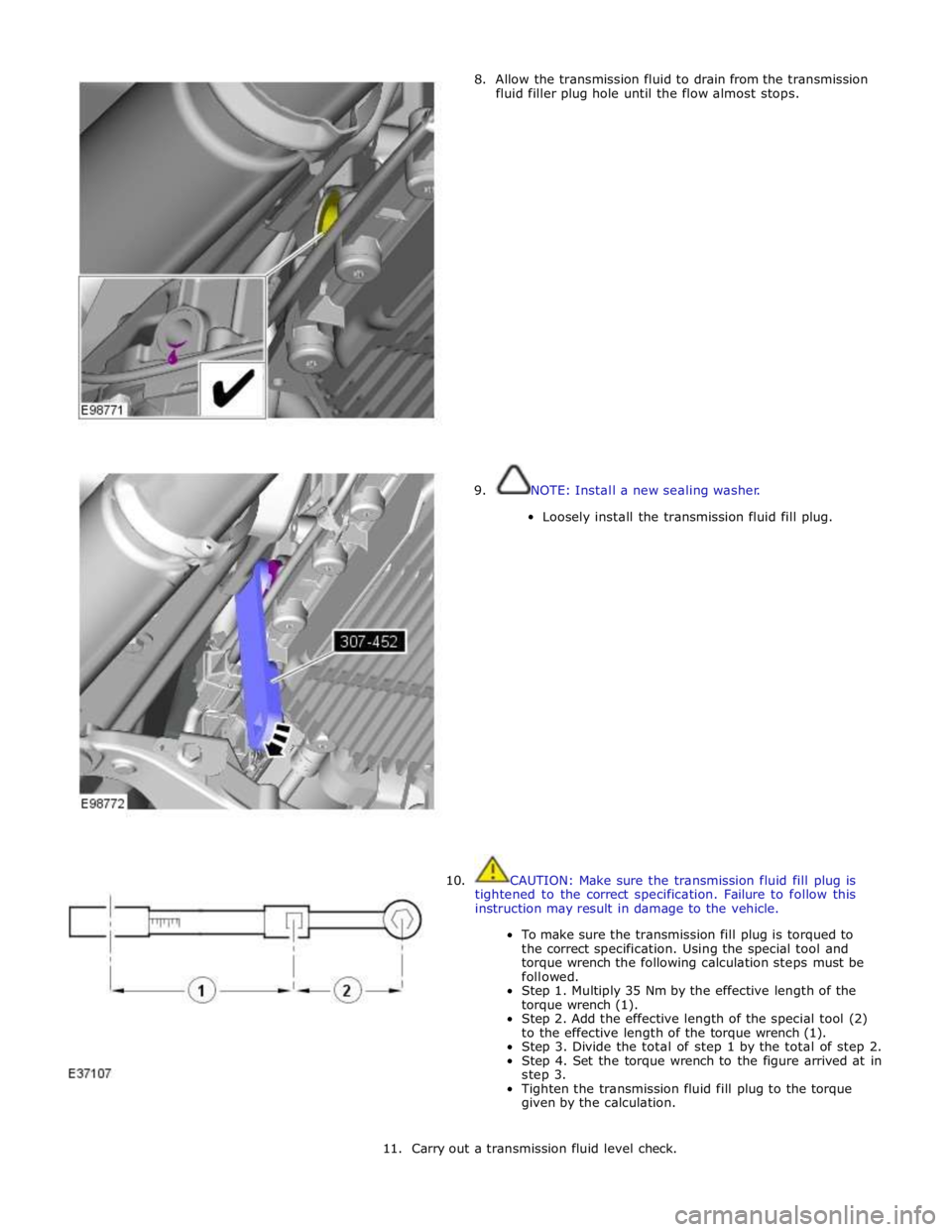

8. Allow the transmission fluid to drain from the transmission

fluid filler plug hole until the flow almost stops.

9. NOTE: Install a new sealing washer.

Loosely install the transmission fluid fill plug.

10. CAUTION: Make sure the transmission fluid fill plug is

tightened to the correct specification. Failure to follow this

instruction may result in damage to the vehicle.

To make sure the transmission fill plug is torqued to

the correct specification. Using the special tool and

torque wrench the following calculation steps must be

followed.

Step 1. Multiply 35 Nm by the effective length of the

torque wrench (1).

Step 2. Add the effective length of the special tool (2)

to the effective length of the torque wrench (1).

Step 3. Divide the total of step 1 by the total of step 2.

Step 4. Set the torque wrench to the figure arrived at in

step 3.

Tighten the transmission fluid fill plug to the torque

given by the calculation.

11. Carry out a transmission fluid level check.

Page 1457 of 3039

Published: 11-May-2011

Automatic Transmission/Transaxle - TDV6 3.0L Diesel /V8 5.0L Petrol/V8 S/C 5.0L Petrol - Input Shaft Seal

Removal and Installation

Special Tool(s)

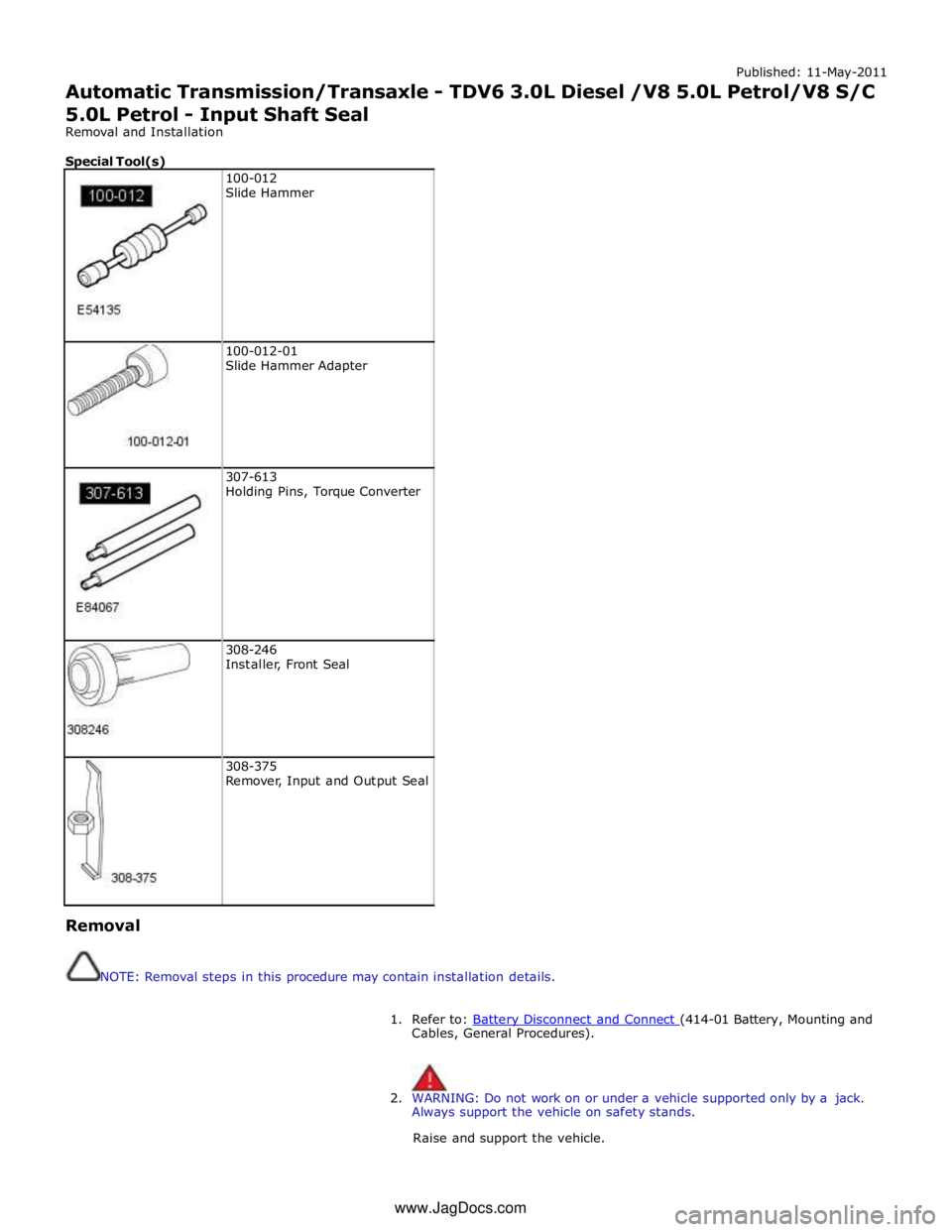

100-012

Slide Hammer

100-012-01

Slide Hammer Adapter

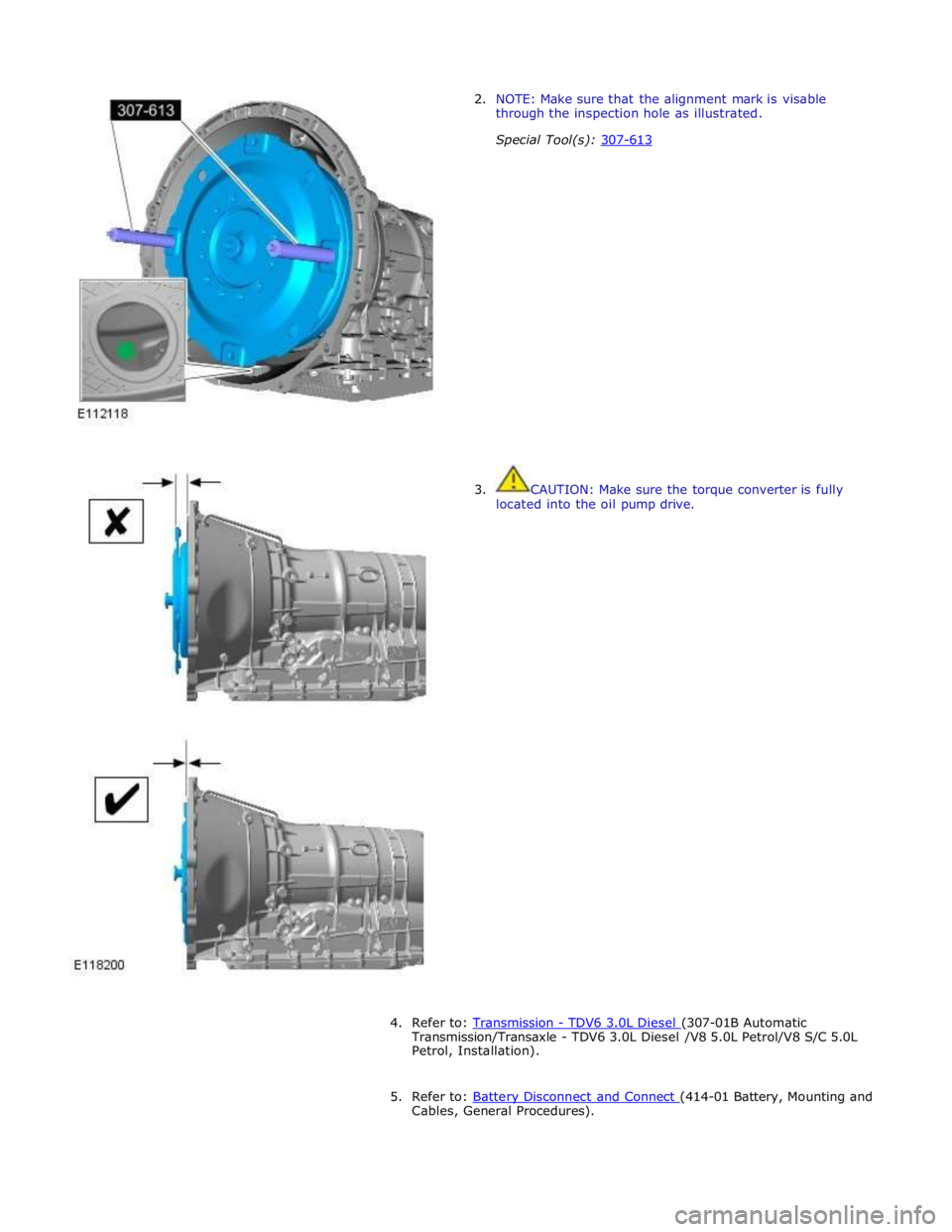

307-613

Holding Pins, Torque Converter

308-246

Installer, Front Seal

308-375

Remover, Input and Output Seal Removal

NOTE: Removal steps in this procedure may contain installation details.

1. Refer to: Battery Disconnect and Connect (414-01 Battery, Mounting and Cables, General Procedures).

2. WARNING: Do not work on or under a vehicle supported only by a jack.

Always support the vehicle on safety stands.

Raise and support the vehicle. www.JagDocs.com

Page 1459 of 3039

3. CAUTION: Make sure the torque converter is fully

located into the oil pump drive.

4. Refer to: Transmission - TDV6 3.0L Diesel (307-01B Automatic Transmission/Transaxle - TDV6 3.0L Diesel /V8 5.0L Petrol/V8 S/C 5.0L

Petrol, Installation).

5. Refer to: Battery Disconnect and Connect (414-01 Battery, Mounting and Cables, General Procedures).

Page 1462 of 3039

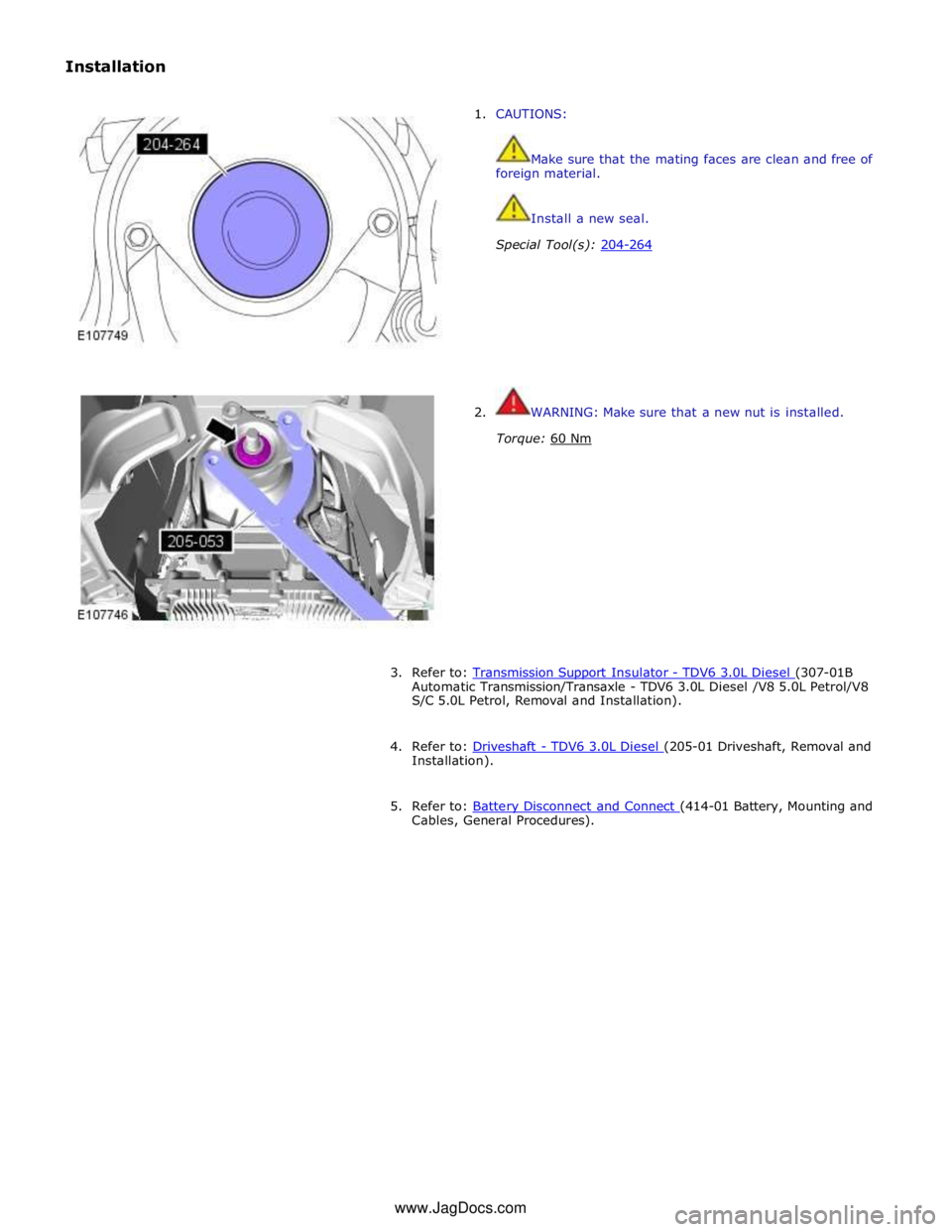

Installation

1. CAUTIONS:

Make sure that the mating faces are clean and free of

foreign material.

Install a new seal.

Special Tool(s): 204-264

2. WARNING: Make sure that a new nut is installed.

Torque: 60 Nm

3. Refer to: Transmission Support Insulator - TDV6 3.0L Diesel (307-01B Automatic Transmission/Transaxle - TDV6 3.0L Diesel /V8 5.0L Petrol/V8

S/C 5.0L Petrol, Removal and Installation).

4. Refer to: Driveshaft - TDV6 3.0L Diesel (205-01 Driveshaft, Removal and Installation).

5. Refer to: Battery Disconnect and Connect (414-01 Battery, Mounting and Cables, General Procedures). www.JagDocs.com

Page 1466 of 3039

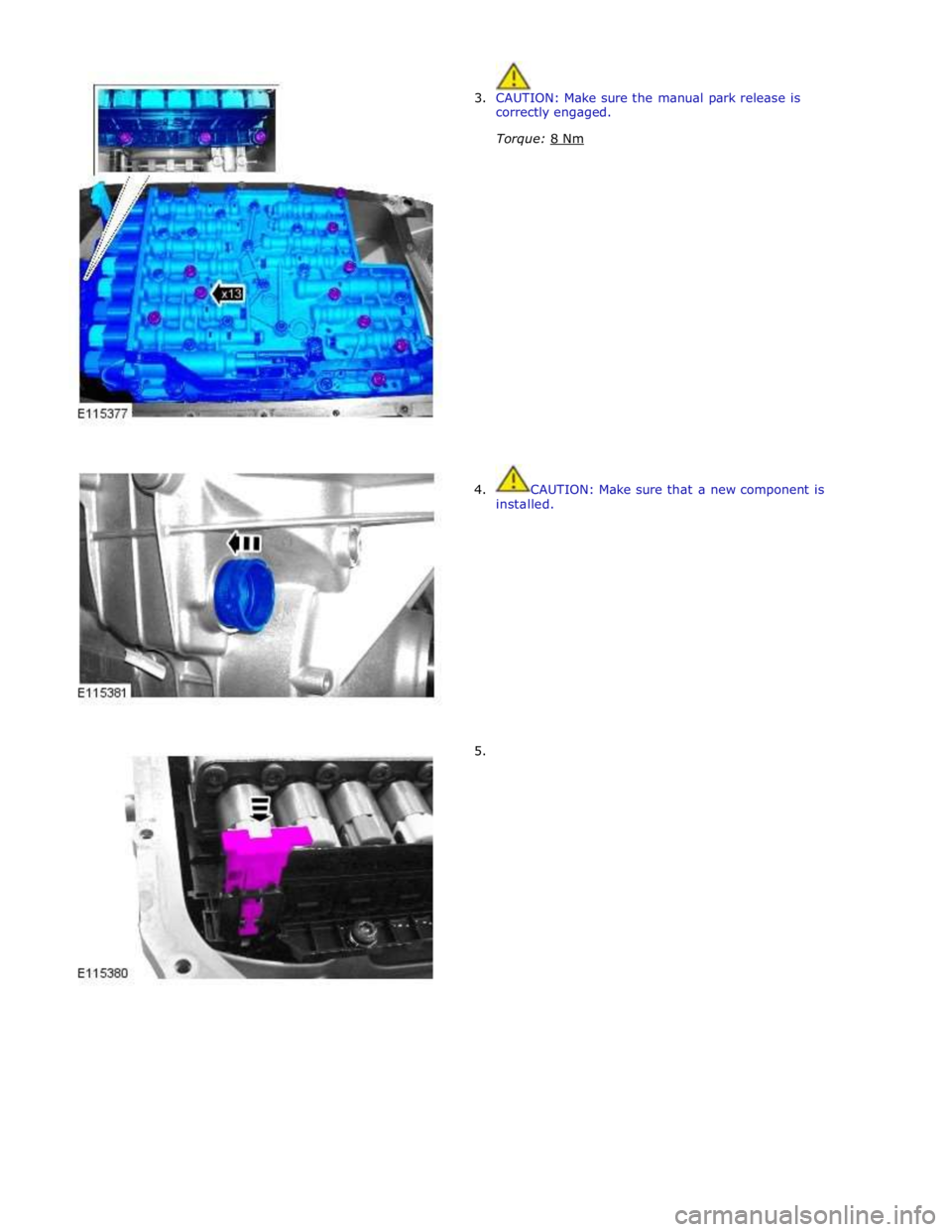

3. CAUTION: Make sure the manual park release is

correctly engaged.

Torque: 8 Nm

4. CAUTION: Make sure that a new component is

installed.

5.

Page 1469 of 3039

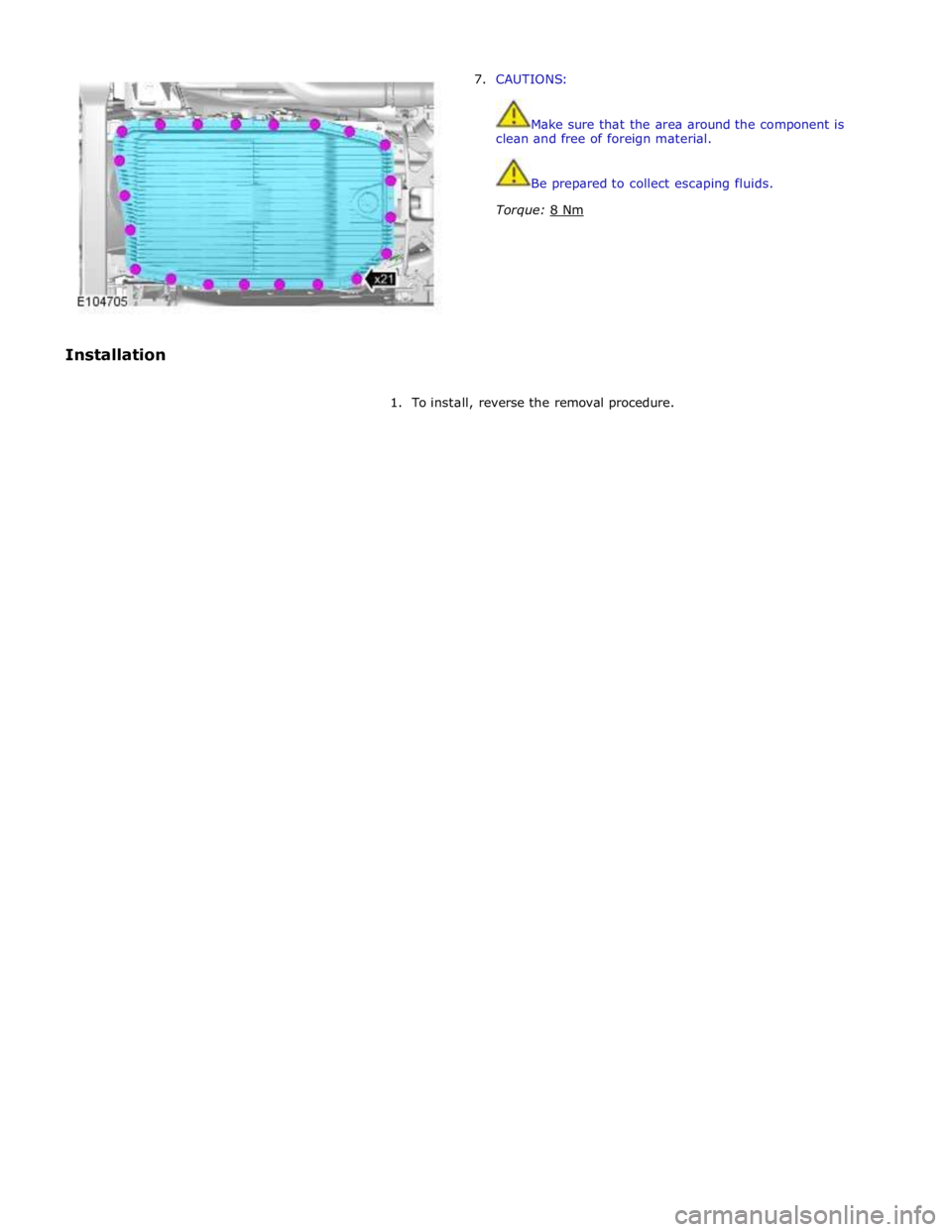

Installation 7. CAUTIONS:

Make sure that the area around the component is

clean and free of foreign material.

Be prepared to collect escaping fluids.

Torque: 8 Nm

1. To install, reverse the removal procedure.