Engine JAGUAR XFR 2010 1.G Workshop Manual

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 2010, Model line: XFR, Model: JAGUAR XFR 2010 1.GPages: 3039, PDF Size: 58.49 MB

Page 1276 of 3039

Published: 11-May-2011

Engine Ignition - V8 5.0L Petrol/V8 S/C 5.0L Petrol - Engine Ignition

Diagnosis and Testing

Principles of Operation

For a detailed description of the engine ignition system and operation, refer to the relevant Description and Operation section

of the workshop manual. REFER to: (303-07B Engine Ignition - V8 5.0L Petrol/V8 S/C 5.0L Petrol)

Engine Ignition (Description and Operation), Engine Ignition (Description and Operation), Engine Ignition (Description and Operation).

Inspection and Verification

CAUTION: Diagnosis by substitution from a donor vehicle is NOT acceptable. Substitution of control modules does not

guarantee confirmation of a fault and may also cause additional faults in the vehicle being checked and/or the donor vehicle.

NOTE: Check and rectify basic faults before beginning diagnostic routines involving pinpoint tests.

1. Verify the customer concern.

2. Visually inspect for obvious signs of mechanical and electrical damage.

Visual Inspection

Mechanical Electrical

Engine oil level

Cooling system coolant level

Fuel level

Fuel contamination/grade/quality

Exhaust gas recirculation (EGR) valves

Fuses

Wiring harness

Loose or corroded electrical connectors

Ignition coils

Sensor(s)

Engine Control Module (ECM)

Transmission Control Module (TCM)

3. If an obvious cause for an observed or reported concern is found, correct the cause (if possible) before proceeding to

the next step.

4. If the cause is not visually evident, verify the symptom and refer to the Symptom Chart, alternatively check for

Diagnostic Trouble Codes (DTCs) and refer to the DTC Index.

Symptom Chart

Symptom Possible Causes Action Engine cranks, but does not

fire

Engine breather system

disconnected/restricted

Ignition system

Fuel system

Electronic engine control Ensure the engine breather system is free from restriction

and is correctly installed. Check for ignition system, fuel

system and electronic engine control DTCs and refer to the

relevant DTC Index Engine cranks and fires, but

will not start

Evaporative emissions purge

valve

Fuel pump

Spark plugs

HT short to ground (tracking)

check rubber boots for

cracks/damage

Ignition system Check for evaporative emissions, fuel system and ignition

system related DTCs and refer to the relevant DTC Index Difficult cold start

Engine coolant level/anti-

freeze content

Battery

Electronic engine controls

Exhaust Gas Recirculation

(EGR) valve stuck open

Fuel pump

Purge valve Check the engine coolant level and condition. Ensure the

battery is in a fully charged and serviceable condition.

Check for electronic engine controls, engine emissions, fuel

system and evaporative emissions system related DTCs

and refer to the relevant DTC Index

Page 1277 of 3039

Symptom Possible Causes Action Difficult hot start

Injector leak

Electronic engine control

Purge valve

Fuel pump

Ignition system

EGR valve stuck open Check for injector leak, install new injector as required.

Check for electronic engine controls, evaporative emissions,

fuel system, ignition system and engine emission system

related DTCs and refer to the relevant DTC Index Difficult to start after hot

soak (vehicle standing,

engine off, after engine has

reached operating

temperature)

Injector leak

Electronic engine control

Purge valve

Fuel pump

Ignition system

EGR valve stuck open Check for injector leak, install new injector as required.

Check for electronic engine controls, evaporative emissions,

fuel system, ignition system and engine emission system

related DTCs and refer to the relevant DTC Index Engine stalls soon after start

Breather system

disconnected/restricted

ECM relay

Electronic engine control

Ignition system

Air intake system restricted

Air leakage

Fuel lines Ensure the engine breather system is free from restriction

and is correctly installed. Check for electronic engine

control, ignition system and fuel system related DTCs and

refer to the relevant DTC Index. Check for blockage in air

filter element and air intake system. Check for air leakage

in air intake system Engine hesitates/poor

acceleration

Fuel pressure, fuel pump,

fuel lines

Injector leak

Air leakage

Electronic engine control

Throttle motor

Restricted accelerator pedal

travel (carpet, etc)

Ignition system

EGR valve stuck open

Transmission malfunction Check for fuel system related DTCs and refer to the

relevant DTC Index. Check for injector leak, install new

injector as required. Check for air leakage in air intake

system. Ensure accelerator pedal is free from restriction.

Check for electronic engine controls, ignition, engine

emission system and transmission related DTCs and refer

to the relevant DTC Index Engine backfires

Fuel pump/lines

Air leakage

Electronic engine controls

Ignition system

Sticking variable camshaft

timing (VCT) hub Check for fuel system failures. Check for air leakage in

intake air system. Check for electronic engine controls,

ignition system and VCT system related DTCs and refer to

the relevant DTC Index Engine surges

Fuel pump/lines

Electronic engine controls

Throttle motor

Ignition system Check for fuel system failures. Check for electronic engine

controls, throttle system and ignition system related DTCs

and refer to the relevant DTC Index Engine detonates/knocks

Fuel pump/lines

Air leakage

Electronic engine controls

Sticking VCT hub Check for fuel system failures. Check for air leakage in

intake air system. Check for electronic engine controls and

VCT system related DTCs and refer to the relevant DTC

Index No throttle response

Electronic engine controls

Throttle motor Check for electronic engine controls and throttle system

related DTCs and refer to the relevant DTC Index Poor throttle response

Breather system

disconnected/restricted

Electronic engine control

Transmission malfunction

Traction control event Air

leakage Ensure the engine breather system is free from restriction

and is correctly installed. Check for electronic engine

controls, transmission and traction control related DTCs and

refer to the related DTC Index. Check for air leakage in

intake air system DTC Index

For a list of Diagnostic Trouble Codes (DTCs) that could be logged in the Engine Control Module (ECM), please refer to Section

303-14. REFER to:

Electronic Engine Controls (303-14C Electronic Engine Controls - V8 5.0L Petrol, Diagnosis and Testing), Electronic Engine Controls (303-14D Electronic Engine Controls - V8 S/C 5.0L Petrol, Diagnosis and Testing).

Page 1278 of 3039

Published: 11-May-2011

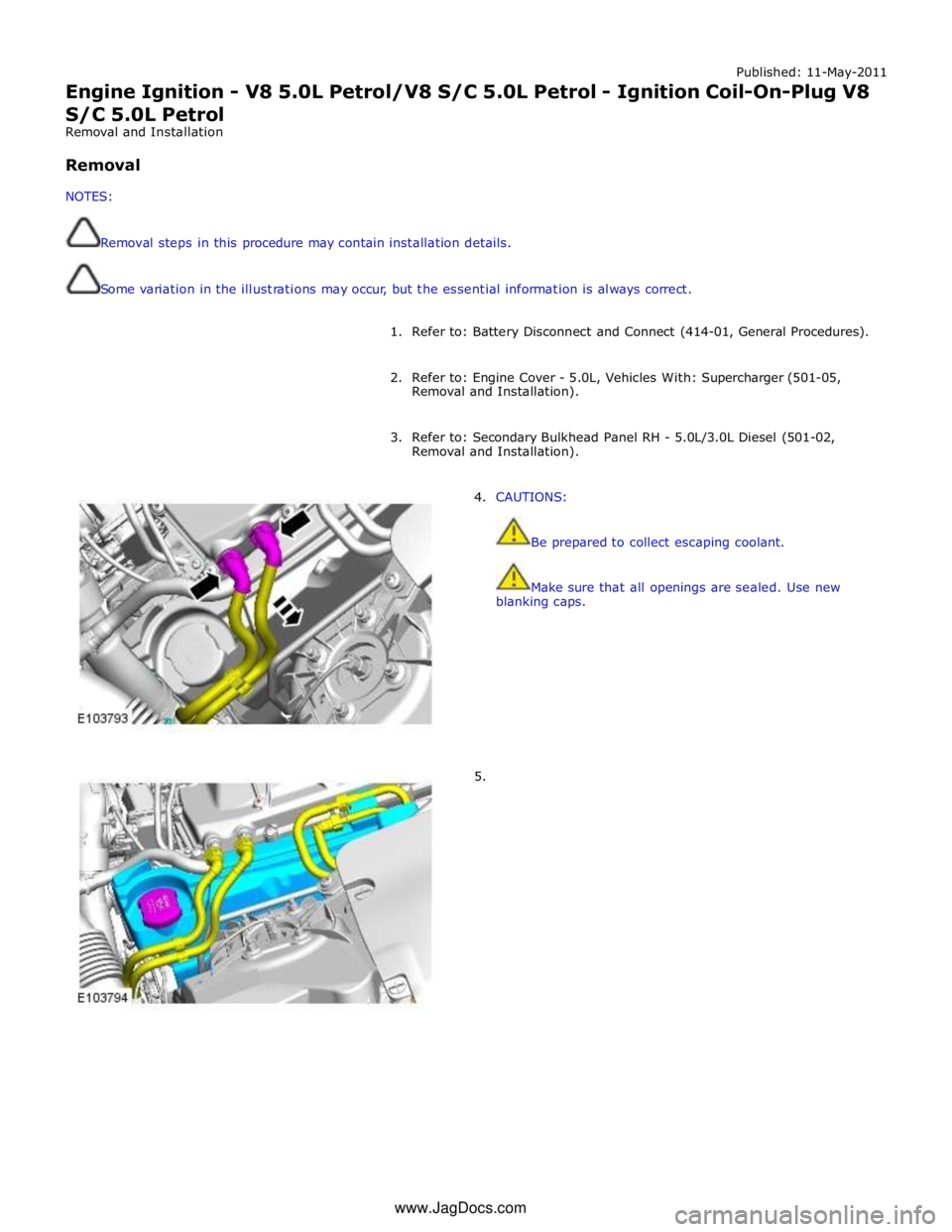

Engine Ignition - V8 5.0L Petrol/V8 S/C 5.0L Petrol - Ignition Coil-On-Plug V8 S/C 5.0L Petrol

Removal and Installation

Removal

NOTES:

Removal steps in this procedure may contain installation details.

Some variation in the illustrations may occur, but the essential information is always correct.

1. Refer to: Battery Disconnect and Connect (414-01, General Procedures).

2. Refer to: Engine Cover - 5.0L, Vehicles With: Supercharger (501-05,

Removal and Installation).

3. Refer to: Secondary Bulkhead Panel RH - 5.0L/3.0L Diesel (501-02,

Removal and Installation).

4. CAUTIONS:

Be prepared to collect escaping coolant.

Make sure that all openings are sealed. Use new

blanking caps.

5. www.JagDocs.com

Page 1280 of 3039

Published: 11-May-2011

Engine Emission Control - V8 5.0L Petrol/V8 S/C 5.0L Petrol - Engine Emission Control - Component Location

Description and Operation

www.JagDocs.com ItemDescription1Partloadbreather2FullloadbreatherCOMPONENTLOCATION-SUPERCHARGERVEHICLES

Page 1283 of 3039

Published: 11-May-2011

Engine Emission Control - V8 5.0L Petrol/V8 S/C 5.0L Petrol - Engine Emission

Control

Diagnosis and Testing

Principles of Operation

For a detailed description of the engine emission control system and operation, refer to the relevant Description and Operation

section of the workshop manual. REFER to: (303-08C Engine Emission Control - V8 5.0L Petrol/V8 S/C 5.0L Petrol)

Engine Emission Control (Description and Operation), Engine Emission Control (Description and Operation), Engine Emission Control (Description and Operation).

Inspection and Verification

CAUTION: Diagnosis by substitution from a donor vehicle is NOT acceptable. Substitution of control modules does not

guarantee confirmation of a fault and may also cause additional faults in the vehicle being checked and/or the donor vehicle.

NOTE: Check and rectify basic faults before beginning diagnostic routines involving pinpoint tests.

1. Verify the customer concern.

2. Visually inspect for obvious signs of mechanical or electrical damage.

Visual Inspection

Mechanical Electrical

Exhaust gas recirculation system

Breather hoses

Positive crankcase ventilation valve

Fuel level

Fuel contamination/grade/quality

Throttle body

Fuses

Loose or corroded electrical connectors

Exhaust Gas Recirculation (EGR) valve

Engine Control Module (ECM)

3. If an obvious cause for an observed or reported concern is found, correct the cause (if possible) before proceeding to

the next step.

4. If the cause is not visually evident, verify the symptom and refer to the Symptom Chart, alternatively check for

Diagnostic Trouble Codes (DTCs) and refer to the DTC Index.

Symptom Chart

Symptom Possible Causes Action Difficult to

start cold

Battery

Crankshaft Position (CKP)

sensor

Exhaust Gas Recirculation

(EGR) valve stuck open

Fuel system

Evaporative emissions purge

valve For battery information, CKP sensor, fuel system and purge valve tests,

refer to relevant workshop manual section. Check the EGR valve. Engine stalls

soon after

start

Breather system

disconnected/restricted

Engine Control Module (ECM)

relay

MAF sensor

Ignition system

Air filter restricted

Air leakage

Fuel lines Check the engine breather hoses, PCV, etc. Check the Engine Control

Module (ECM) relay operation. For MAF sensor, ignition system tests, air

intake and fuel line information, refer to relevant workshop manual

section. Poor throttle

response

APP sensor malfunction

TP sensors

ECT sensor

MAF sensor

Transmission malfunction

Traction control event Air

leakage For APP, TP, ECT, MAF sensor tests, intake system checks and

transmission information, refer to relevant workshop manual section.

Check the breather system hoses, PCV, etc.

Page 1284 of 3039

Symptom Possible Causes Action Breather system

disconnected/restricted DTC Index

For a list of Diagnostic Trouble Codes (DTCs) that could be logged in the Engine Control Module (ECM), please refer to Section

303-14. REFER to:

Electronic Engine Controls (303-14C Electronic Engine Controls - V8 5.0L Petrol, Diagnosis and Testing), Electronic Engine Controls (303-14D Electronic Engine Controls - V8 S/C 5.0L Petrol, Diagnosis and Testing).

Page 1288 of 3039

Published: 11-May-2011

Intake Air Distribution and Filtering - V8 S/C 5.0L Petrol - Intake Air

Distribution and Filtering - System Operation and Component Description

Description and Operation

Control Diagram

NOTE: A = Hardwired

Item Description 1 Battery 2 BJB (battery junction box) (250 A megafuse) 3 EJB (engine junction box) (EMS high current relay) 4 Tuning valve 5 ECM (engine control module)

Page 1289 of 3039

SUPERCHARGER System Operation

At closed or partially open throttle positions, the bypass valve is fully open, allowing a flow of air from the SC (supercharger)

outlet back to the inlet side. This results in little or no pressure increase across the SC. Progressive opening of the throttle reduces the depression downstream of the electric throttle. This is sensed by the pneumatic actuator, which moves to close

the bypass valve. As the bypass valve closes there is a corresponding increase in the outlet pressure from the SC, which increases engine power output.

NOISE FEEDBACK SYSTEM

Sound waves from the RH (right-hand) intake manifold are filtered by the calibrated orifice in the inlet pipe connection on the

symposer. The sound waves make the paddle oscillate and generate pulsations in the outlet chambers. When the pneumatic

valve is open, the pulsations are transmitted through the outlet pipe and feedback tube to the resonator in the passenger

compartment.

The tuning valve of the noise feedback system receives a power feed from the power distribution box and is connected to

ground through the ECM (engine control module). At lower engine loads and speeds the ECM keeps the ground open circuit and the tuning valve is de-energized closed. Atmospheric pressure is sensed at the pneumatic valve through the vent cap on the

tuning valve, which keeps the pneumatic valve closed and prevents sound from the symposer entering the feedback system.

At higher engine loads and speeds the ECM connects the tuning valve to ground. The tuning valve energizes, blanks off the atmospheric vent and opens the vacuum line between the brake vacuum system and the pneumatic valve. The depression in

the brake vacuum system is sensed at the pneumatic valve, which opens and allows sound from the symposer into the

feedback system.

The status of the pneumatic valve at various engine loads and speeds is given below:

Pneumatic Valve Status

NOTE: Values are for valve opening with increasing engine load and speed. Deduct 0.05 g/rev and 50 rev/min for valve

closing with decreasing engine load and speed.

Engine Load: g/rev Engine Speed: rev/min 0 500 1000 2500 3000 4000 5800 6500 1.30 Closed Closed Closed Closed Closed Closed Closed Closed 1.35 Closed Closed Closed Closed Closed Closed Closed Closed 1.40 Closed Closed Closed Closed Closed Closed Closed Open 1.60 Closed Closed Closed Closed Closed Closed Closed Open 1.80 Closed Closed Closed Closed Closed Closed Closed Open 2.50 Closed Closed Closed Closed Closed Open Open Open 3.00 Closed Closed Closed Closed Closed Open Open Open 3.50 Closed Closed Closed Open Open Open Open Open

Page 1290 of 3039

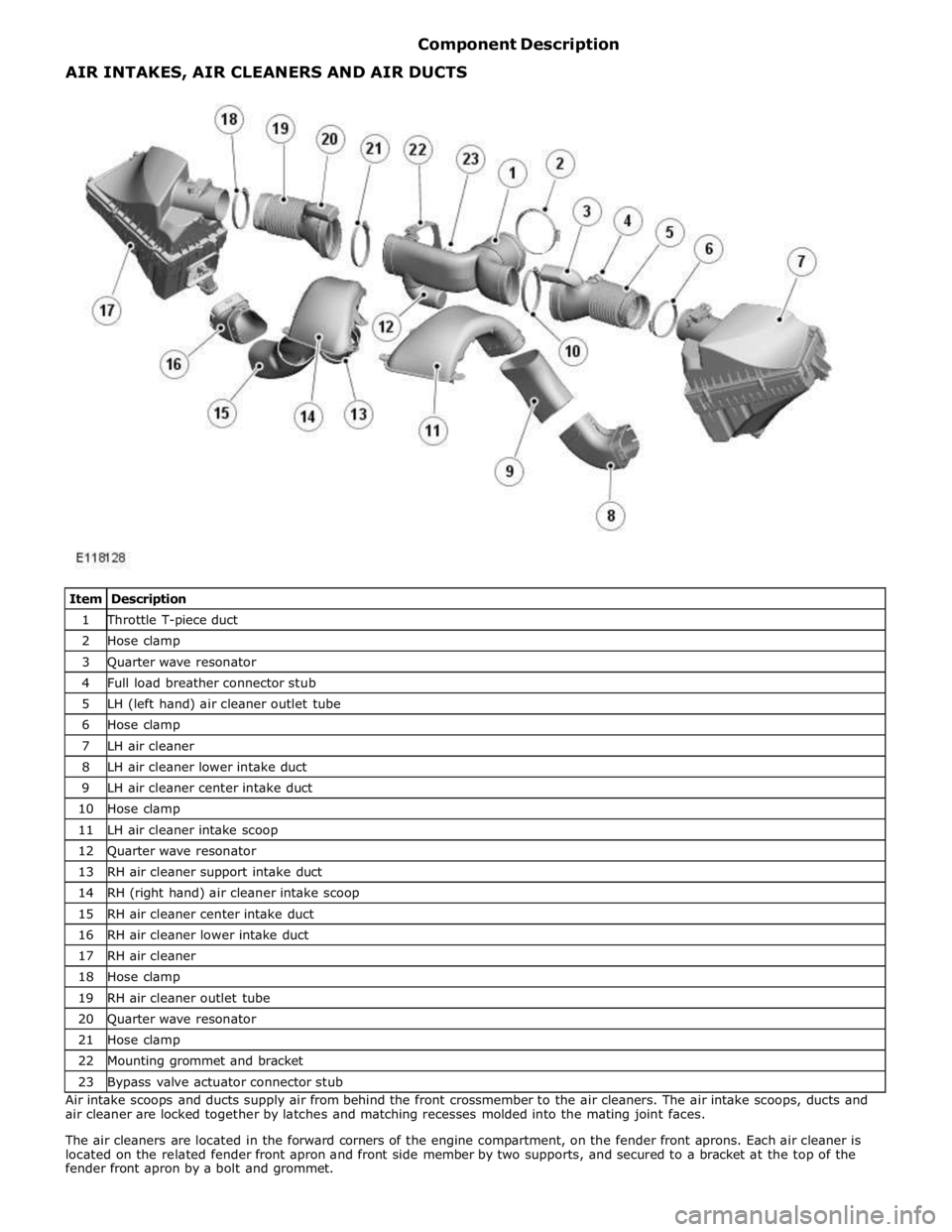

1 Throttle T-piece duct 2 Hose clamp 3 Quarter wave resonator 4 Full load breather connector stub 5 LH (left hand) air cleaner outlet tube 6 Hose clamp 7 LH air cleaner 8 LH air cleaner lower intake duct 9 LH air cleaner center intake duct 10 Hose clamp 11 LH air cleaner intake scoop 12 Quarter wave resonator 13 RH air cleaner support intake duct 14 RH (right hand) air cleaner intake scoop 15 RH air cleaner center intake duct 16 RH air cleaner lower intake duct 17 RH air cleaner 18 Hose clamp 19 RH air cleaner outlet tube 20 Quarter wave resonator 21 Hose clamp 22 Mounting grommet and bracket 23 Bypass valve actuator connector stub Air intake scoops and ducts supply air from behind the front crossmember to the air cleaners. The air intake scoops, ducts and

air cleaner are locked together by latches and matching recesses molded into the mating joint faces.

The air cleaners are located in the forward corners of the engine compartment, on the fender front aprons. Each air cleaner is

located on the related fender front apron and front side member by two supports, and secured to a bracket at the top of the

fender front apron by a bolt and grommet. AIR INTAKES, AIR CLEANERS AND AIR DUCTS

Page 1292 of 3039

9 Support 10 Inlet connection 11 Outlet connection 12 MAFT sensor The outlet tubes and T-piece duct direct the air from the air cleaners to the electric throttle. Hose clamps connect the outlet

tubes and T-piece duct together, and to the air cleaners and the electric throttle. A grommet and bracket attached the T-piece

duct to a bracket on the RH cylinder head. The two outlet tubes and the T-piece duct each incorporate a quarter wave resonator to reduce air induction noise.

The LH (left-hand) outlet tube incorporates a connector stub for the engine full load breather pipe.

The T-piece duct incorporates a connector stub for the vacuum tube of the bypass valve actuator on the supercharger.

SUPERCHARGER AND INTAKE MANIFOLDS

The SC increases the pressure, and thus mass, of the air supplied to the engine, to increase the engine's power output. Two separate intake manifolds direct air from the SC to the cylinder inlet ports.

The intake manifolds are attached to their related cylinder heads and the sides of the SC. Two dowels locate the SC in position on the cylinder block. A charge air cooler tank top is installed on top of the SC and intake manifolds to form the air duct from the SC outlet to the intake manifolds. A charge air cooler is installed in each intake manifold.

The charge air cooler tank top incorporates four studs for the attachment of the engine cover. A NVH (noise, vibration and

harshness) pad is attached to the side of each intake manifold.