Engine JAGUAR XFR 2010 1.G Workshop Manual

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 2010, Model line: XFR, Model: JAGUAR XFR 2010 1.GPages: 3039, PDF Size: 58.49 MB

Page 1262 of 3039

When the ECM receives a crank request, it energizes the starter relay in the EJB (engine junction box). The energized starter relay supplies 12 V power (fed via the 250 A megafuse in the BJB (battery junction box)) to energize the pull-in coil of the

starter solenoid. Once activated, the pull-in coil engages the solenoid plunger, which engages the pinion with the ring gear.

The plunger then closes the solenoid circuit, feeding power from the 400 A megafuse in the BJB to the starter motor.

Page 1263 of 3039

Published: 11-May-2011

Starting System - V8 5.0L Petrol/V8 S/C 5.0L Petrol - Starting System

Diagnosis and Testing

Principles of Operation

For a detailed description of the starting system and operation, refer to the relevant Description and Operation section of the

workshop manual. REFER to: (303-06C Starting System - V8 5.0L Petrol/V8 S/C 5.0L Petrol)

Starting System (Description and Operation), Starting System (Description and Operation), Starting System (Description and Operation).

Inspection and Verification

CAUTION: Diagnosis by substitution from a donor vehicle is NOT acceptable. Substitution of control modules does not

guarantee confirmation of a fault and may also cause additional faults in the vehicle being checked and/or the donor vehicle.

NOTE: Check and rectify basic faults before beginning diagnostic routines involving pinpoint tests.

1. Verify the customer concern.

2. Visually inspect for obvious signs of mechanical and electrical damage.

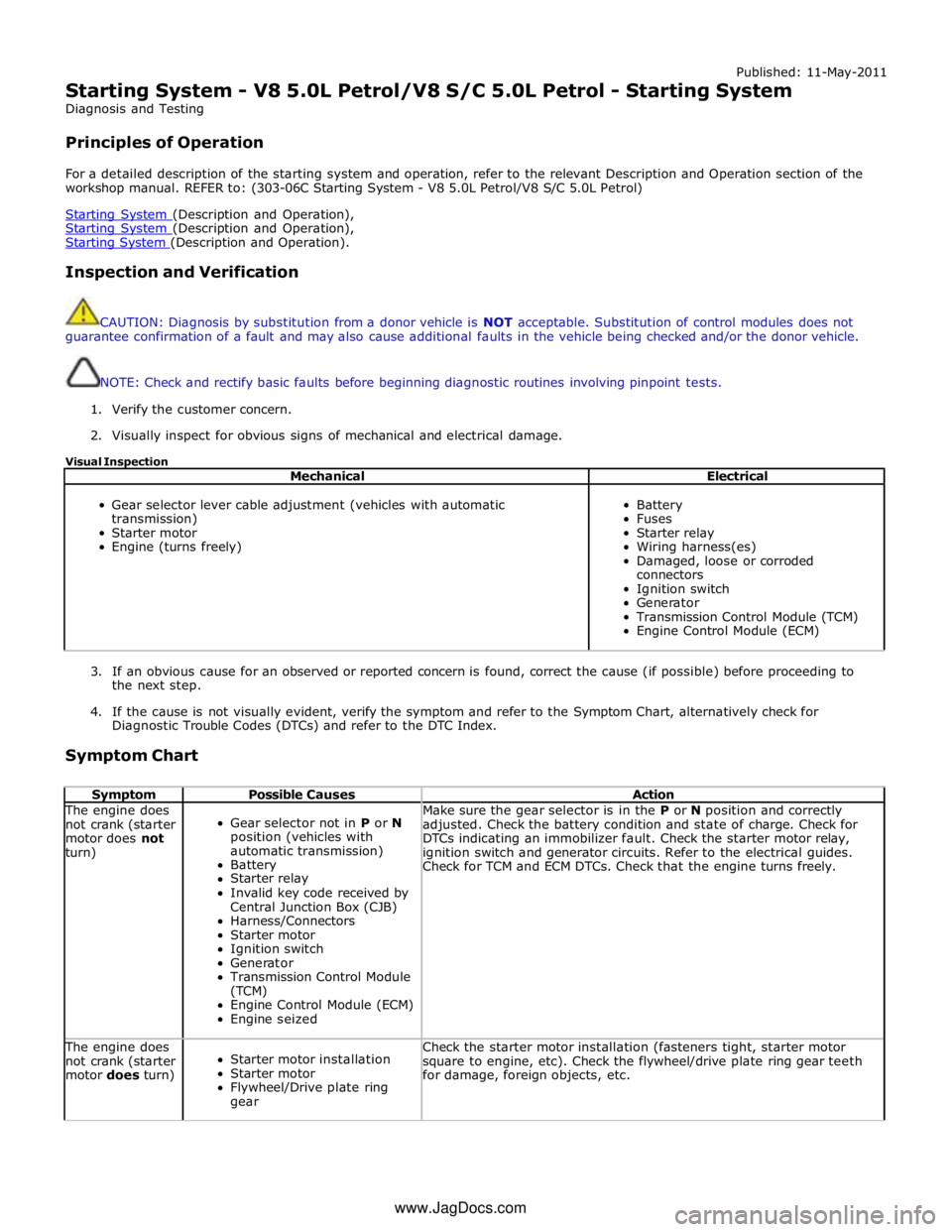

Visual Inspection

Mechanical Electrical

Gear selector lever cable adjustment (vehicles with automatic

transmission)

Starter motor

Engine (turns freely)

Battery

Fuses

Starter relay

Wiring harness(es)

Damaged, loose or corroded

connectors

Ignition switch

Generator

Transmission Control Module (TCM)

Engine Control Module (ECM)

3. If an obvious cause for an observed or reported concern is found, correct the cause (if possible) before proceeding to

the next step.

4. If the cause is not visually evident, verify the symptom and refer to the Symptom Chart, alternatively check for

Diagnostic Trouble Codes (DTCs) and refer to the DTC Index.

Symptom Chart

Symptom Possible Causes Action The engine does

not crank (starter

motor does not

turn)

Gear selector not in P or N

position (vehicles with

automatic transmission)

Battery

Starter relay

Invalid key code received by

Central Junction Box (CJB)

Harness/Connectors

Starter motor

Ignition switch

Generator

Transmission Control Module

(TCM)

Engine Control Module (ECM)

Engine seized Make sure the gear selector is in the P or N position and correctly

adjusted. Check the battery condition and state of charge. Check for

DTCs indicating an immobilizer fault. Check the starter motor relay,

ignition switch and generator circuits. Refer to the electrical guides.

Check for TCM and ECM DTCs. Check that the engine turns freely. The engine does

not crank (starter

motor does turn)

Starter motor installation

Starter motor

Flywheel/Drive plate ring

gear Check the starter motor installation (fasteners tight, starter motor

square to engine, etc). Check the flywheel/drive plate ring gear teeth

for damage, foreign objects, etc. www.JagDocs.com

Page 1264 of 3039

Symptom Possible Causes Action Engine cranks too

slowly

Battery

Harness/Connectors

Starter motor

Oil grade Check the battery condition and state of charge. Check the starter

motor circuits. Refer to the electrical guides. Check the engine oil

grade and condition. Engine cranks too

fast

Low engine compression Check the engine compressions. Excessive starter

motor noise

Starter motor

Flywheel/Drive plate ring

gear

Starter motor

installation/casing Check the starter motor installation (fasteners tight, motor square to

engine, etc). Check the starter motor casing condition. Check the

flywheel/drive plate ring gear teeth for damage, foreign objects, etc. DTC Index

For a list of Diagnostic Trouble Codes (DTCs) that could be logged in the Engine Control Module (ECM), please refer to Section

303-14. REFER to:

Electronic Engine Controls (303-14C Electronic Engine Controls - V8 5.0L Petrol, Diagnosis and Testing), Electronic Engine Controls (303-14D Electronic Engine Controls - V8 S/C 5.0L Petrol, Diagnosis and Testing).

Page 1265 of 3039

Starting System - V8 5.0L Petrol/V8 S/C 5.0L Petrol - Starting

System Vehicles With: Smart Key

Diagnosis and Testing

Principles of Operation Published: 06-Apr-2013

For a detailed description of the starting system, refer to the relevant Description and Operation section in the workshop

manual.

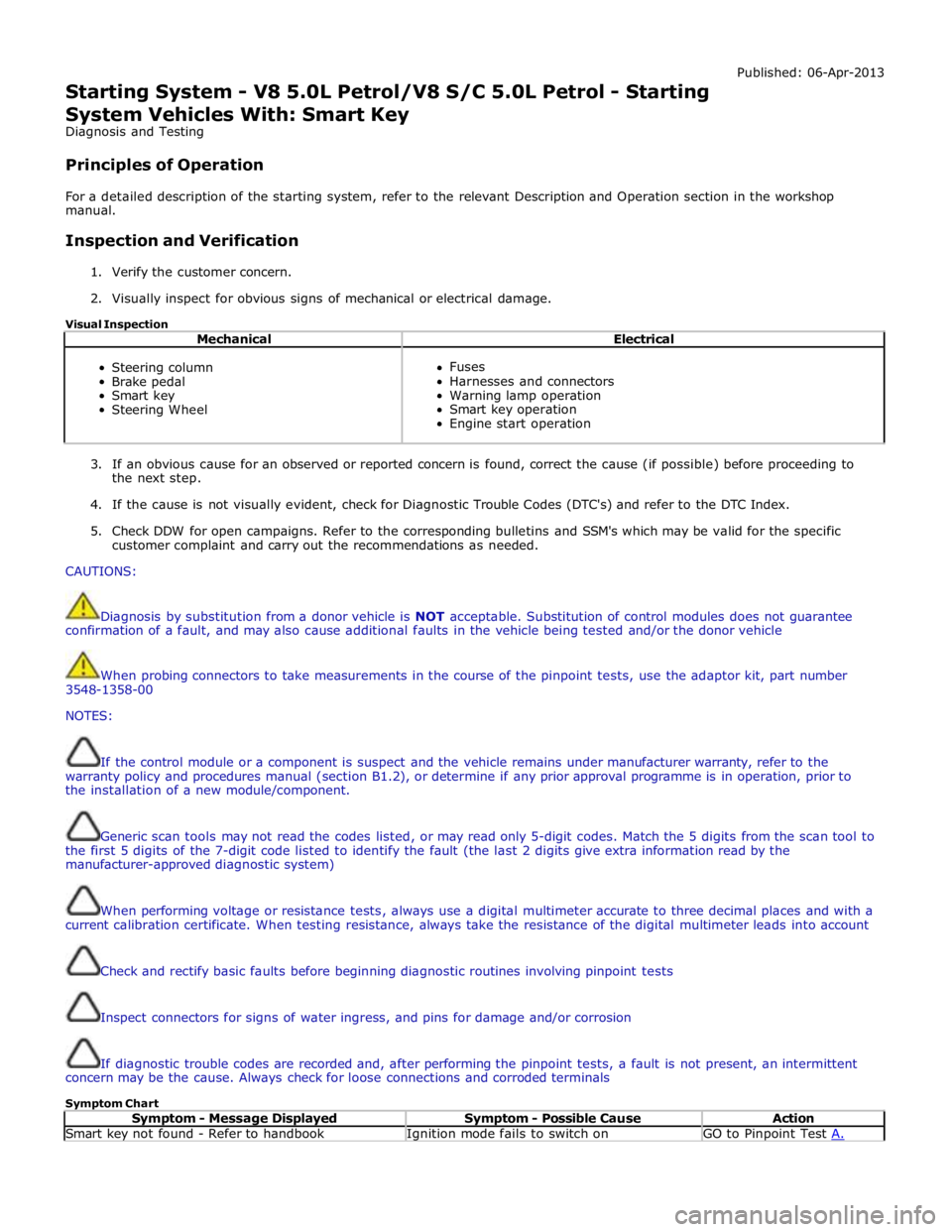

Inspection and Verification

1. Verify the customer concern.

2. Visually inspect for obvious signs of mechanical or electrical damage.

Visual Inspection

Mechanical Electrical

Steering column

Brake pedal

Smart key

Steering Wheel

Fuses

Harnesses and connectors

Warning lamp operation

Smart key operation

Engine start operation

3. If an obvious cause for an observed or reported concern is found, correct the cause (if possible) before proceeding to

the next step.

4. If the cause is not visually evident, check for Diagnostic Trouble Codes (DTC's) and refer to the DTC Index.

5. Check DDW for open campaigns. Refer to the corresponding bulletins and SSM's which may be valid for the specific

customer complaint and carry out the recommendations as needed.

CAUTIONS:

Diagnosis by substitution from a donor vehicle is NOT acceptable. Substitution of control modules does not guarantee

confirmation of a fault, and may also cause additional faults in the vehicle being tested and/or the donor vehicle

When probing connectors to take measurements in the course of the pinpoint tests, use the adaptor kit, part number

3548-1358-00

NOTES:

If the control module or a component is suspect and the vehicle remains under manufacturer warranty, refer to the

warranty policy and procedures manual (section B1.2), or determine if any prior approval programme is in operation, prior to

the installation of a new module/component.

Generic scan tools may not read the codes listed, or may read only 5-digit codes. Match the 5 digits from the scan tool to

the first 5 digits of the 7-digit code listed to identify the fault (the last 2 digits give extra information read by the

manufacturer-approved diagnostic system)

When performing voltage or resistance tests, always use a digital multimeter accurate to three decimal places and with a

current calibration certificate. When testing resistance, always take the resistance of the digital multimeter leads into account

Check and rectify basic faults before beginning diagnostic routines involving pinpoint tests

Inspect connectors for signs of water ingress, and pins for damage and/or corrosion

If diagnostic trouble codes are recorded and, after performing the pinpoint tests, a fault is not present, an intermittent

concern may be the cause. Always check for loose connections and corroded terminals

Symptom Chart

Symptom - Message Displayed Symptom - Possible Cause Action Smart key not found - Refer to handbook Ignition mode fails to switch on GO to Pinpoint Test A.

Page 1266 of 3039

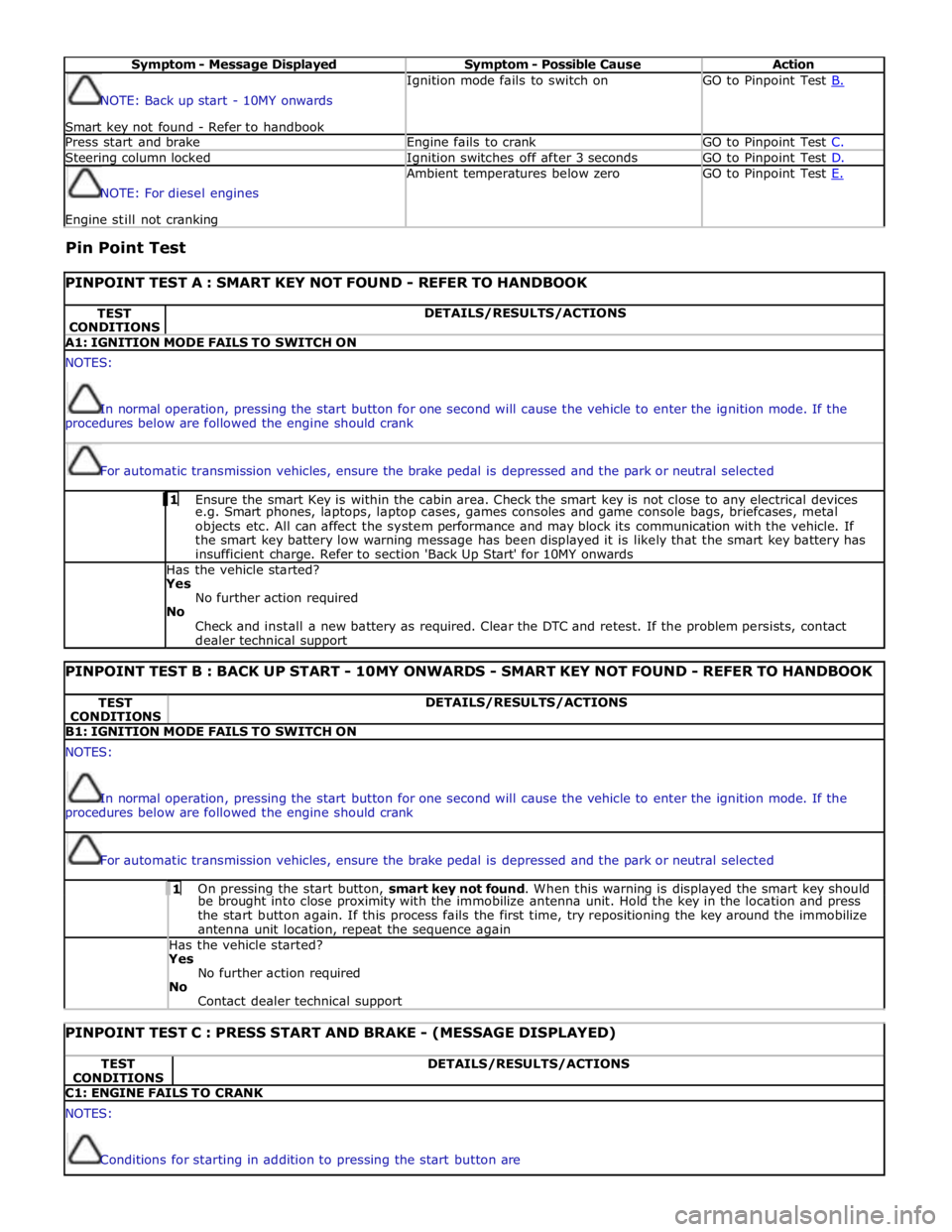

Symptom - Message Displayed Symptom - Possible Cause Action NOTE: Back up start - 10MY onwards

Smart key not found - Refer to handbook Ignition mode fails to switch on GO to Pinpoint Test B. Press start and brake Engine fails to crank GO to Pinpoint Test C. Steering column locked Ignition switches off after 3 seconds GO to Pinpoint Test D. NOTE: For diesel engines Engine still not cranking Ambient temperatures below zero GO to Pinpoint Test E.

Pin Point Test

PINPOINT TEST A : SMART KEY NOT FOUND - REFER TO HANDBOOK TEST

CONDITIONS DETAILS/RESULTS/ACTIONS A1: IGNITION MODE FAILS TO SWITCH ON NOTES:

In normal operation, pressing the start button for one second will cause the vehicle to enter the ignition mode. If the

procedures below are followed the engine should crank

For automatic transmission vehicles, ensure the brake pedal is depressed and the park or neutral selected 1 Ensure the smart Key is within the cabin area. Check the smart key is not close to any electrical devices e.g. Smart phones, laptops, laptop cases, games consoles and game console bags, briefcases, metal

objects etc. All can affect the system performance and may block its communication with the vehicle. If

the smart key battery low warning message has been displayed it is likely that the smart key battery has

insufficient charge. Refer to section 'Back Up Start' for 10MY onwards Has the vehicle started? Yes

No further action required

No

Check and install a new battery as required. Clear the DTC and retest. If the problem persists, contact

dealer technical support

PINPOINT TEST B : BACK UP START - 10MY ONWARDS - SMART KEY NOT FOUND - REFER TO HANDBOOK TEST

CONDITIONS DETAILS/RESULTS/ACTIONS B1: IGNITION MODE FAILS TO SWITCH ON NOTES:

In normal operation, pressing the start button for one second will cause the vehicle to enter the ignition mode. If the

procedures below are followed the engine should crank

For automatic transmission vehicles, ensure the brake pedal is depressed and the park or neutral selected 1 On pressing the start button, smart key not found. When this warning is displayed the smart key should be brought into close proximity with the immobilize antenna unit. Hold the key in the location and press

the start button again. If this process fails the first time, try repositioning the key around the immobilize

antenna unit location, repeat the sequence again Has the vehicle started? Yes

No further action required

No

Contact dealer technical support

PINPOINT TEST C : PRESS START AND BRAKE - (MESSAGE DISPLAYED) TEST

CONDITIONS DETAILS/RESULTS/ACTIONS C1: ENGINE FAILS TO CRANK NOTES:

Conditions for starting in addition to pressing the start button are

Page 1267 of 3039

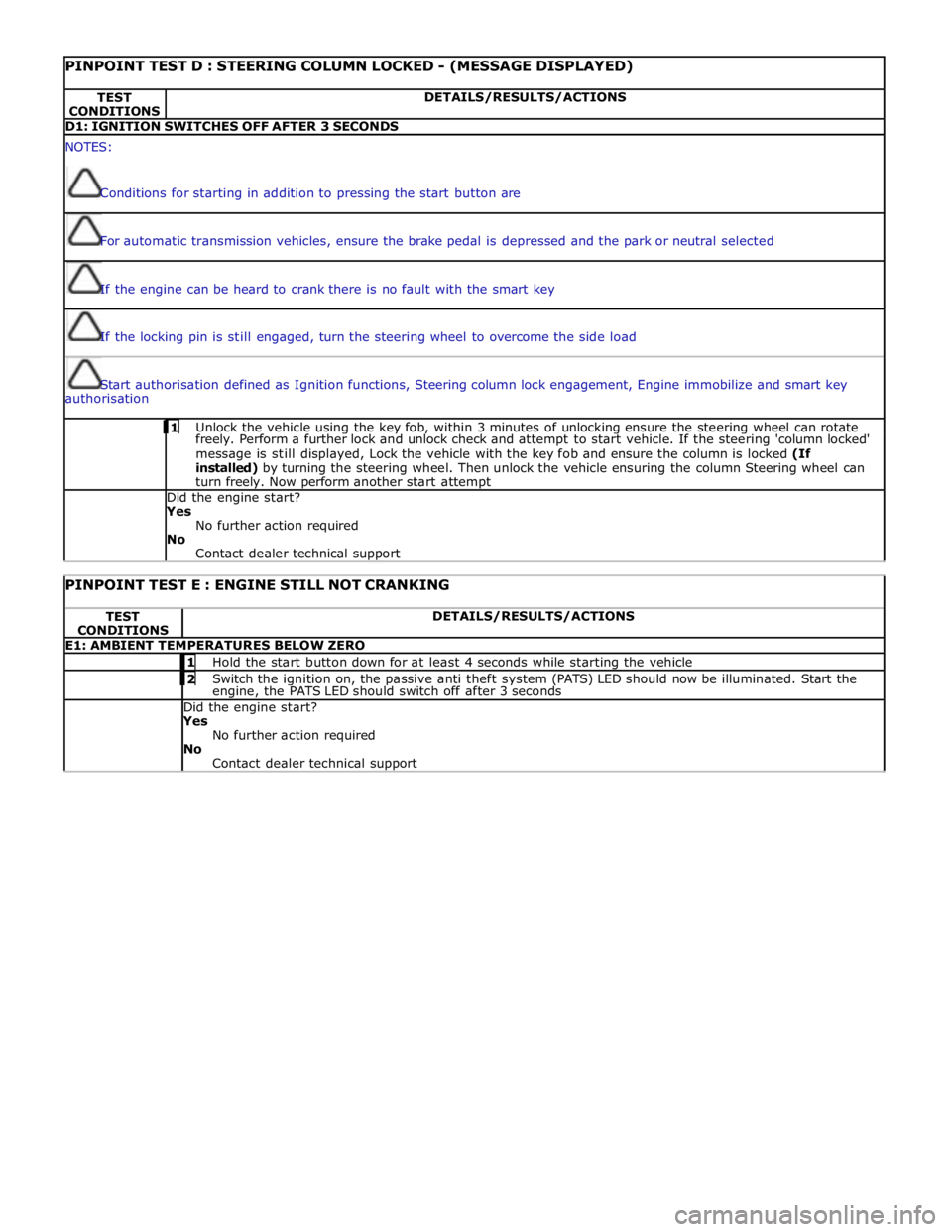

PINPOINT TEST D : STEERING COLUMN LOCKED - (MESSAGE DISPLAYED) TEST

CONDITIONS DETAILS/RESULTS/ACTIONS D1: IGNITION SWITCHES OFF AFTER 3 SECONDS NOTES:

Conditions for starting in addition to pressing the start button are

For automatic transmission vehicles, ensure the brake pedal is depressed and the park or neutral selected

If the engine can be heard to crank there is no fault with the smart key

If the locking pin is still engaged, turn the steering wheel to overcome the side load

Start authorisation defined as Ignition functions, Steering column lock engagement, Engine immobilize and smart key

authorisation 1 Unlock the vehicle using the key fob, within 3 minutes of unlocking ensure the steering wheel can rotate freely. Perform a further lock and unlock check and attempt to start vehicle. If the steering 'column locked'

message is still displayed, Lock the vehicle with the key fob and ensure the column is locked (If

installed) by turning the steering wheel. Then unlock the vehicle ensuring the column Steering wheel can

turn freely. Now perform another start attempt Did the engine start?

Yes

No further action required

No

Contact dealer technical support

PINPOINT TEST E : ENGINE STILL NOT CRANKING TEST

CONDITIONS DETAILS/RESULTS/ACTIONS E1: AMBIENT TEMPERATURES BELOW ZERO 1 Hold the start button down for at least 4 seconds while starting the vehicle 2 Switch the ignition on, the passive anti theft system (PATS) LED should now be illuminated. Start the engine, the PATS LED should switch off after 3 seconds Did the engine start? Yes

No further action required

No

Contact dealer technical support

Page 1271 of 3039

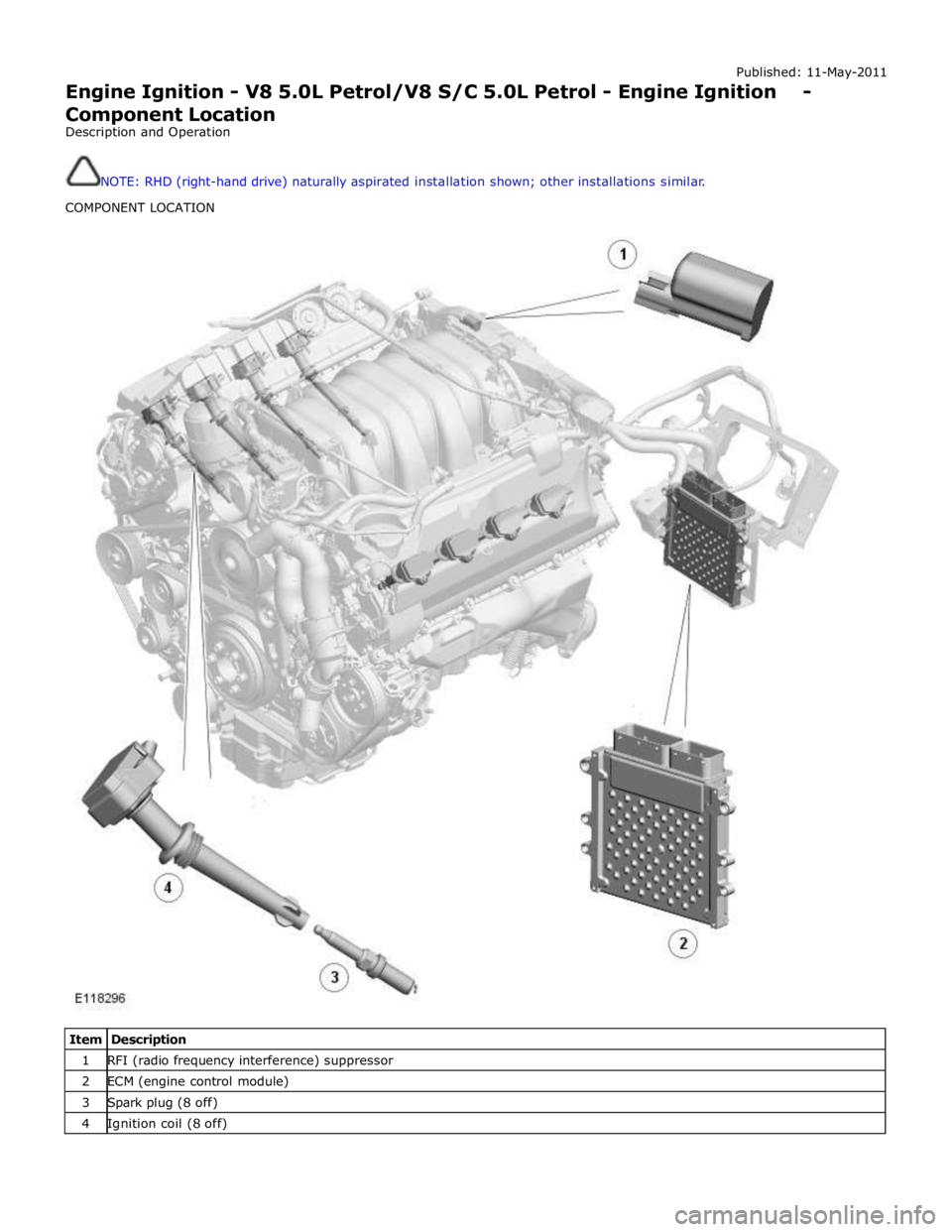

Published: 11-May-2011

Engine Ignition - V8 5.0L Petrol/V8 S/C 5.0L Petrol - Engine Ignition - Component Location

Description and Operation

NOTE: RHD (right-hand drive) naturally aspirated installation shown; other installations similar.

COMPONENT LOCATION

Item Description 1 RFI (radio frequency interference) suppressor 2 ECM (engine control module) 3 Spark plug (8 off) 4 Ignition coil (8 off)

Page 1272 of 3039

Published: 11-May-2011

Engine Ignition - V8 5.0L Petrol/V8 S/C 5.0L Petrol - Engine Ignition - Overview

Description and Operation

OVERVIEW

The engine ignition system is a coil-on-plug, single spark system controlled by the ECM (engine control module). An iridium

tipped spark plug is installed in each combustion chamber, between the inlet and exhaust valves, and an ignition coil is

installed on each spark plug. A RFI (radio frequency interference) suppressor is connected to the power feed to the ignition

coils.

Page 1273 of 3039

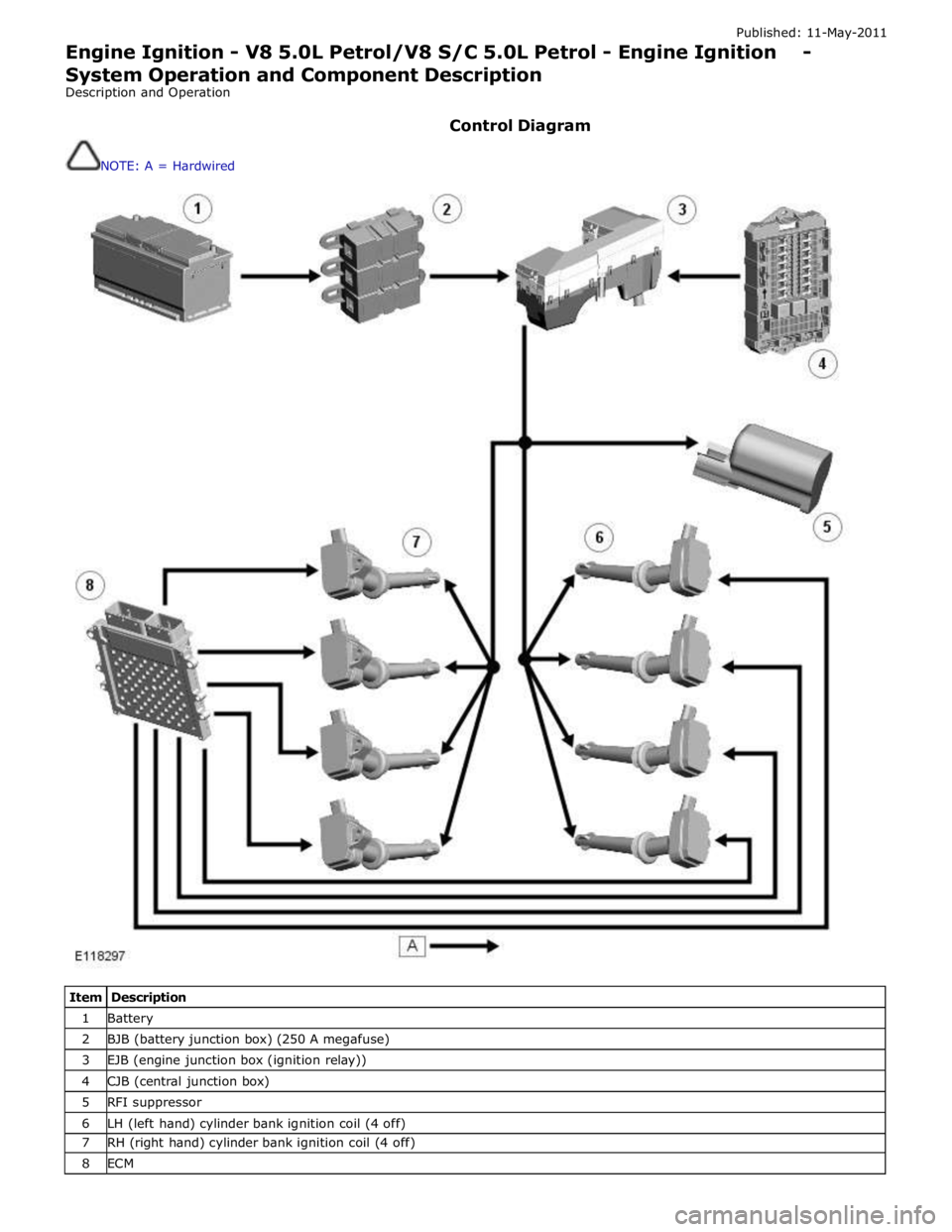

Published: 11-May-2011

Engine Ignition - V8 5.0L Petrol/V8 S/C 5.0L Petrol - Engine Ignition - System Operation and Component Description

Description and Operation

Control Diagram

NOTE: A = Hardwired

Item Description 1 Battery 2 BJB (battery junction box) (250 A megafuse) 3 EJB (engine junction box (ignition relay)) 4 CJB (central junction box) 5 RFI suppressor 6 LH (left hand) cylinder bank ignition coil (4 off) 7 RH (right hand) cylinder bank ignition coil (4 off) 8 ECM

Page 1274 of 3039

GENERAL System Operation

The ignition coils are supplied with electrical power from the battery via a 250 A megafuse in the BJB (battery junction box)

and the ignition relay in the EJB (engine junction box). The control signal for the ignition relay is supplied by the CJB (central

junction box).

The ECM (engine control module) sends a separate signal to each ignition coil to trigger the power stage switching. The ECM calculates the dwell time from the battery voltage and engine speed, to ensure a constant energy level is produced in the

secondary coil each time the power stage is switched. This ensures sufficient spark energy is available without excessive

primary current flow, which avoids overheating and damage to the ignition coils.

The ECM calculates the ignition timing for individual cylinders from: Engine speed

Camshaft position

Engine load

Engine temperature

The knock control function

The shift control function

The idle speed control function.

IGNITION COILS Component Description

The ignition coils are installed in the cylinder head covers, under the NVH (noise, vibration and harshness) covers. Each

ignition coil locates on a spark plug and is secured to the related cylinder head cover with a single screw. Each ignition coil

incorporates a three pin electrical connector for connection to the engine harness.

Each ignition coil contains a primary and a secondary winding. The primary winding receives electrical power from the ignition

relay in the power distribution box. A power stage in the primary winding allows the ECM to interrupt the power supply, to induce a voltage in the secondary winding and thus the spark plug. A diode in the ground side of the secondary winding

reduces any undesirable switch-on voltage, to prevent misfiring into the intake manifold. The power stage limits the maximum

voltage and current in the primary winding, to protect the power stage and limit the voltage in the secondary winding. www.JagDocs.com