Engine JAGUAR XFR 2010 1.G Workshop Manual

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 2010, Model line: XFR, Model: JAGUAR XFR 2010 1.GPages: 3039, PDF Size: 58.49 MB

Page 1293 of 3039

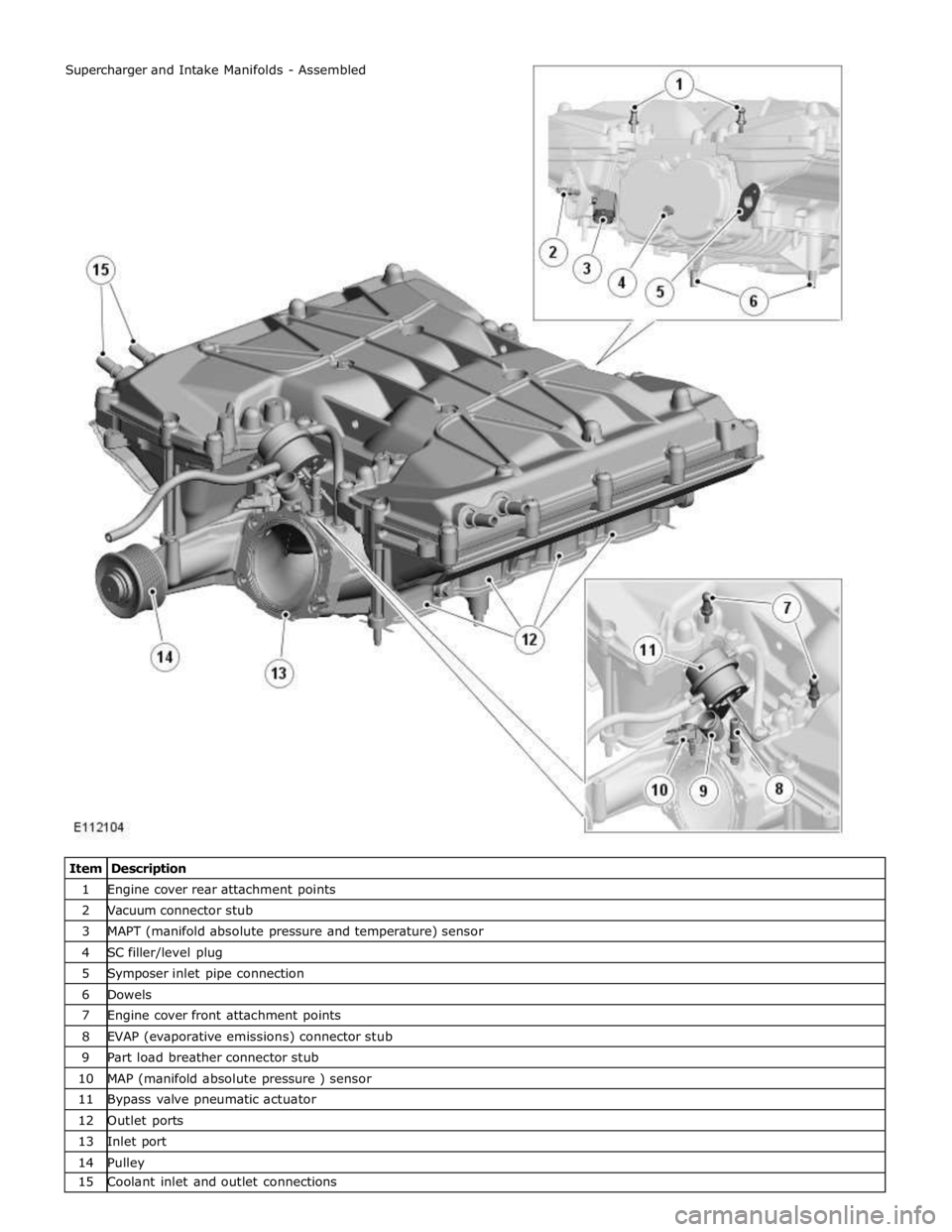

1 Engine cover rear attachment points 2 Vacuum connector stub 3 MAPT (manifold absolute pressure and temperature) sensor 4 SC filler/level plug 5 Symposer inlet pipe connection 6 Dowels 7 Engine cover front attachment points 8 EVAP (evaporative emissions) connector stub 9 Part load breather connector stub 10 MAP (manifold absolute pressure ) sensor 11 Bypass valve pneumatic actuator 12 Outlet ports 13 Inlet port 14 Pulley 15 Coolant inlet and outlet connections Supercharger and Intake Manifolds - Assembled

Page 1295 of 3039

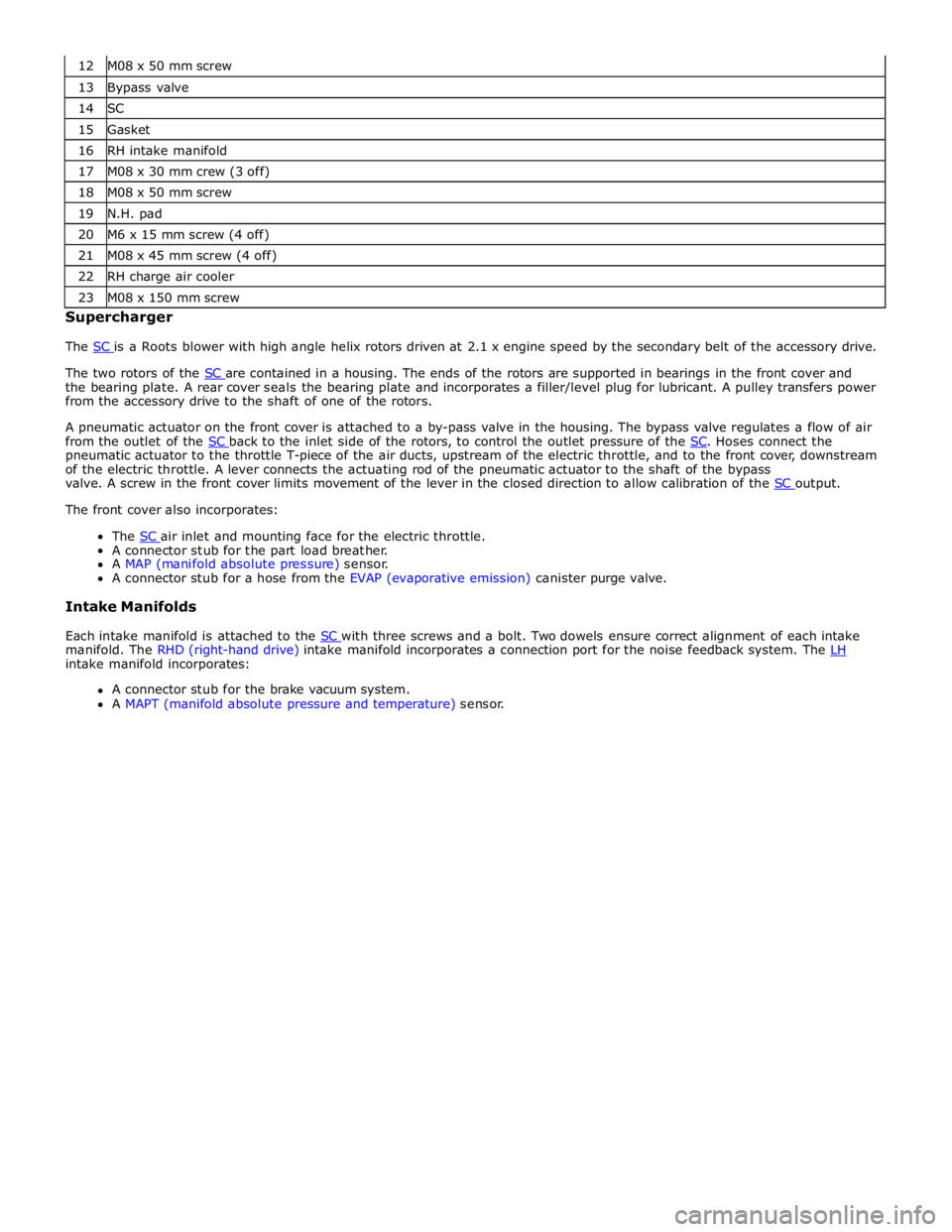

13 Bypass valve 14 SC 15 Gasket 16 RH intake manifold 17 M08 x 30 mm crew (3 off) 18 M08 x 50 mm screw 19 N.H. pad 20 M6 x 15 mm screw (4 off) 21 M08 x 45 mm screw (4 off) 22 RH charge air cooler 23 M08 x 150 mm screw Supercharger

The SC is a Roots blower with high angle helix rotors driven at 2.1 x engine speed by the secondary belt of the accessory drive.

The two rotors of the SC are contained in a housing. The ends of the rotors are supported in bearings in the front cover and the bearing plate. A rear cover seals the bearing plate and incorporates a filler/level plug for lubricant. A pulley transfers power

from the accessory drive to the shaft of one of the rotors.

A pneumatic actuator on the front cover is attached to a by-pass valve in the housing. The bypass valve regulates a flow of air

from the outlet of the SC back to the inlet side of the rotors, to control the outlet pressure of the SC. Hoses connect the pneumatic actuator to the throttle T-piece of the air ducts, upstream of the electric throttle, and to the front cover, downstream

of the electric throttle. A lever connects the actuating rod of the pneumatic actuator to the shaft of the bypass

valve. A screw in the front cover limits movement of the lever in the closed direction to allow calibration of the SC output. The front cover also incorporates:

The SC air inlet and mounting face for the electric throttle. A connector stub for the part load breather.

A MAP (manifold absolute pressure) sensor.

A connector stub for a hose from the EVAP (evaporative emission) canister purge valve.

Intake Manifolds

Each intake manifold is attached to the SC with three screws and a bolt. Two dowels ensure correct alignment of each intake manifold. The RHD (right-hand drive) intake manifold incorporates a connection port for the noise feedback system. The LH intake manifold incorporates:

A connector stub for the brake vacuum system.

A MAPT (manifold absolute pressure and temperature) sensor.

Page 1297 of 3039

Symposer System

The symposer system modifies induction sound waves of a specific frequency range, at given engine settings, to produce the

required engine sound. The symposer system consists of:

An inlet pipe and flange.

A symposer and pneumatic valve assembly. A

tuning valve and associated vacuum tubes.

An outlet pipe.

An outlet adapter.

The inlet pipe and flange transfer induction noise from the RH intake manifold to the symposer. The pipe is a push fit on the symposer and the flange, which is attached to the rear face of the RH intake manifold.

The symposer contains two pairs of chambers, one pair on the inlet side and one pair on the outlet side. The inlet pipe

connects to one of the chambers on the inlet side of the symposer, and the pneumatic valve connects to one of the chambers

on the outlet side of the symposer. A calibrated orifice in the inlet pipe connection on the symposer limits the range of sound

waves that pass through it. A 'paddle' installed in a diaphragm forms the separating wall in each pair of chambers. The paddle

is able to pivot about its lateral axis where it passes through the wall that separates the two pairs of chambers.

Symposer

Item Description 1 Diaphragm 2 Paddle 3 Isolator 4 Inlet chamber (sealed) 5 Outlet chamber (open to pneumatic valve) 6 Screw (8 off) 7 Pneumatic valve 8 Outlet chamber 9 Inlet chamber (open to inlet pipe) 10 Inlet pipe connection

Page 1298 of 3039

The tuning valve controls the application of vacuum pressure to the pneumatic valve. Two screws attach the tuning valve to the

same bracket as the symposer and pneumatic valve. The tuning valve is a normally-closed solenoid-operated valve installed in

the vacuum line between a T-connection in the brake vacuum system and the pneumatic valve. A vent cap on the tuning valve

allows atmospheric pressure into the vacuum line to the pneumatic valve when the tuning valve is closed.

The outlet pipe carries sound from the pneumatic valve to the feedback tube via the outlet adapter. The outlet pipe is a push

fit on the pneumatic valve and in the outlet adapter. A screw attaches the outlet adapter to an engine harness bracket

installed between the two intake manifolds.

Feedback Tube

The feedback tube transfers the sound from the symposer system to the resonator. Clips secure the feedback tube to the

outlet adapter of the symposer system and to the resonator.

Resonator

The resonator directs the sound from the feedback tube into the passenger compartment. The resonator is installed in the

passenger compartment side of the engine bulkhead, on two mounting grommets each consisting of an isolator and a

compression limiter. A hose seal isolates the resonator where it passes through the secondary bulkhead.

Page 1311 of 3039

Published: 11-May-2011

Intake Air Distribution and Filtering - V8 S/C 5.0L Petrol - Air Cleaner Outlet Pipe T-Connector

Removal and Installation

Removal

NOTE: Removal steps in this procedure may contain installation details.

1. Refer to: Engine Cover - V8 5.0L Petrol/V8 S/C 5.0L Petrol (501-05 Interior Trim and Ornamentation, Removal and Installation).

Installation

2. Torque: 10 Nm

1. To install, reverse the removal procedure. www.JagDocs.com

Page 1312 of 3039

Published: 08-Nov-2013

Intake Air Distribution and Filtering - V8 S/C 5.0L Petrol - Charge Air Cooler

Removal and Installation

Removal

NOTE: Removal steps in this procedure may contain installation details.

1. WARNING: Make sure to support the vehicle with axle stands.

Raise and support the vehicle.

2. Refer to: Battery Disconnect and Connect (414-01 Battery, Mounting and Cables, General Procedures).

3. Refer to: Engine Cover - V8 5.0L Petrol/V8 S/C 5.0L Petrol (501-05 Interior Trim and Ornamentation, Removal and Installation).

4. Refer to: Secondary Bulkhead Center Panel (501-02 Front End Body Panels, Removal and Installation).

5. Refer to: Fuel Injection Component Cleaning (303-04D Fuel Charging and Controls - V8 5.0L Petrol, General Procedures).

6. Refer to: Cooling System Partial Draining, Filling and Bleeding - V8 S/C 5.0L Petrol (303-03C Engine Cooling - V8 5.0L Petrol/V8 S/C 5.0L Petrol, General Procedures).

7. Refer to: Fuel System Pressure Release - V8 5.0L Petrol/V8 S/C 5.0L Petrol (310-00 Fuel System - General Information, General Procedures).

8. NOTE: Some variation in the illustrations may occur, but the essential

information is always correct.

Torque: 25 Nm

9.

Page 1317 of 3039

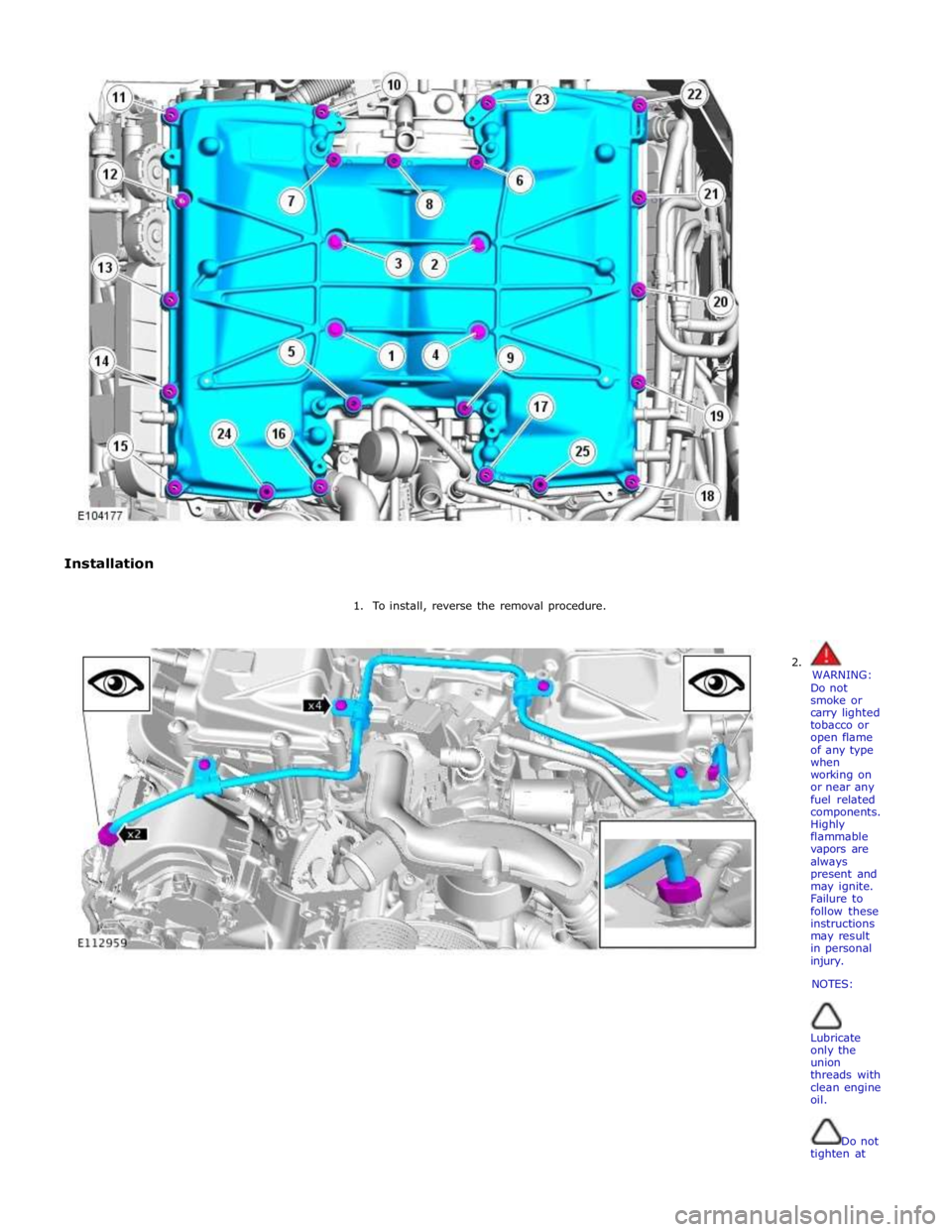

Installation

1. To install, reverse the removal procedure.

2.

WARNING:

Do not

smoke or

carry lighted

tobacco or

open flame

of any type

when

working on

or near any

fuel related

components.

Highly

flammable

vapors are

always

present and

may ignite.

Failure to

follow these

instructions

may result

in personal

injury.

NOTES:

Lubricate

only the

union

threads with

clean engine

oil.

Do not

tighten at

Page 1319 of 3039

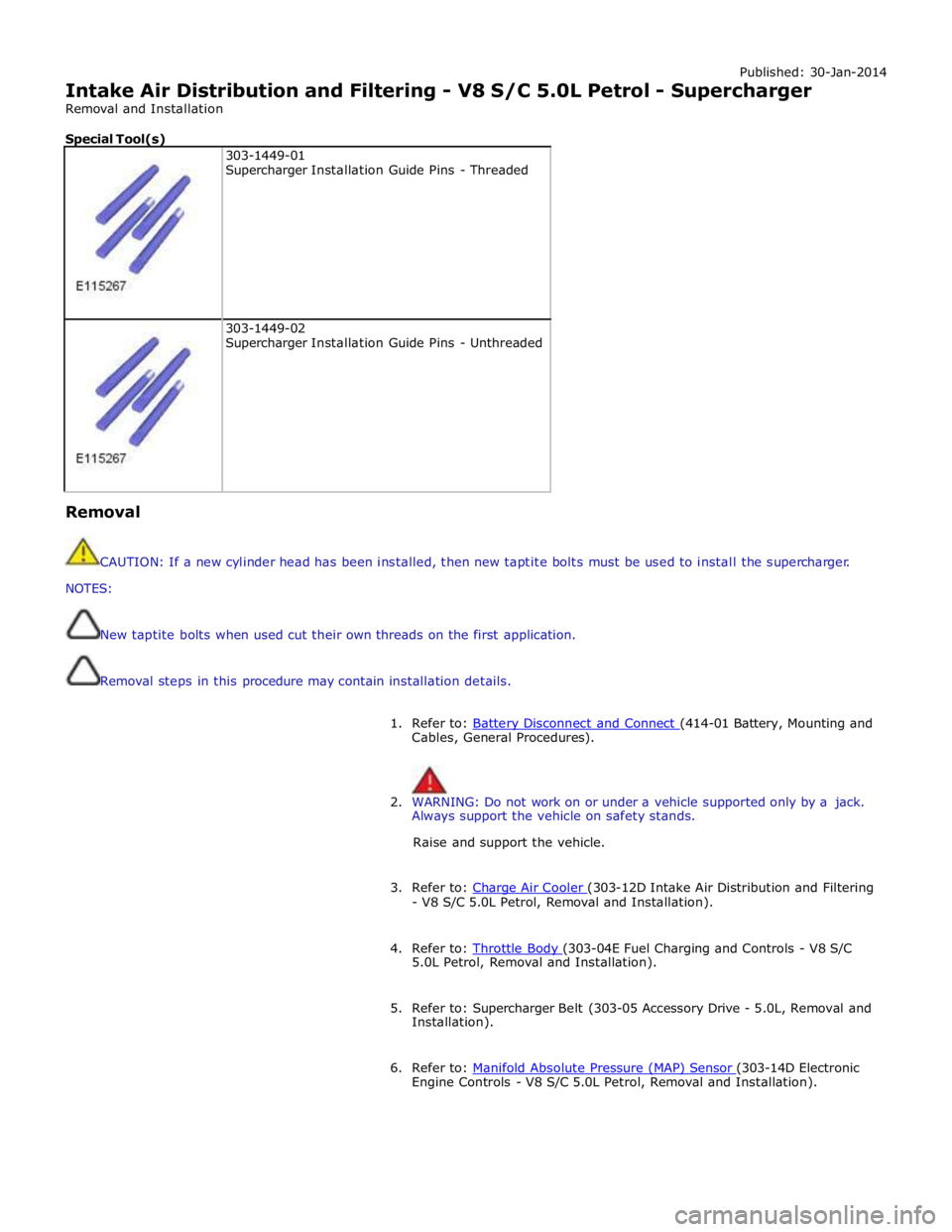

Published: 30-Jan-2014

Intake Air Distribution and Filtering - V8 S/C 5.0L Petrol - Supercharger

Removal and Installation

Special Tool(s)

303-1449-01

Supercharger Installation Guide Pins - Threaded

303-1449-02

Supercharger Installation Guide Pins - Unthreaded Removal

CAUTION: If a new cylinder head has been installed, then new taptite bolts must be used to install the supercharger.

NOTES:

New taptite bolts when used cut their own threads on the first application.

Removal steps in this procedure may contain installation details.

1. Refer to: Battery Disconnect and Connect (414-01 Battery, Mounting and Cables, General Procedures).

2. WARNING: Do not work on or under a vehicle supported only by a jack.

Always support the vehicle on safety stands.

Raise and support the vehicle.

3. Refer to: Charge Air Cooler (303-12D Intake Air Distribution and Filtering - V8 S/C 5.0L Petrol, Removal and Installation).

4. Refer to: Throttle Body (303-04E Fuel Charging and Controls - V8 S/C 5.0L Petrol, Removal and Installation).

5. Refer to: Supercharger Belt (303-05 Accessory Drive - 5.0L, Removal and

Installation).

6. Refer to: Manifold Absolute Pressure (MAP) Sensor (303-14D Electronic Engine Controls - V8 S/C 5.0L Petrol, Removal and Installation).

Page 1326 of 3039

Engine Controls - V8 S/C 5.0L Petrol, Removal and Installation).

14. Refer to: Supercharger Belt (303-05 Accessory Drive - 5.0L, Removal and

Installation).

15. Refer to: Throttle Body (303-04E Fuel Charging and Controls - V8 S/C 5.0L Petrol, Removal and Installation).

16. Refer to: Charge Air Cooler (303-12D Intake Air Distribution and Filtering - V8 S/C 5.0L Petrol, Removal and Installation).

17. Refer to: Battery Disconnect and Connect (414-01 Battery, Mounting and Cables, General Procedures). www.JagDocs.com

Page 1343 of 3039

vehicles, a DMTL pump and filter. The vapor pipes are connected to the system components using quick release connectors.

Fuel vapor is generated by the fuel in the tank and the amount of vapor produced increases as the fuel heats up. Fuel vapor

can flow freely to the EVAP canister via the tank venting system. On NAS vehicles the vapor generated in the fuel tank during refueling flows without restriction to the EVAP canister.

On all vehicles except NAS, the vapor is restricted in its path to the EVAP canister, but can flow freely during the refueling operation to atmosphere via the fuel filler pipe opening.

The vapor passes into the EVAP canister where it is absorbed and stored by the charcoal. Because there is a limit to the amount of vapor the canister can contain, the fuel vapor is purged from the canister when the engine is running and burned in

the engine.