Control module JAGUAR XFR 2010 1.G Workshop Manual

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 2010, Model line: XFR, Model: JAGUAR XFR 2010 1.GPages: 3039, PDF Size: 58.49 MB

Page 1791 of 3039

Instrument Cluster - Instrument Cluster

Diagnosis and Testing

Principles of Operation Published: 22-Mar-2013

For a detailed description of the Instrument Cluster, refer to the relevant Description and Operation sections in the workshop

manual. REFER to: (413-01 Instrument Cluster)

Instrument Cluster (Description and Operation), Instrument Cluster (Description and Operation), Instrument Cluster (Description and Operation).

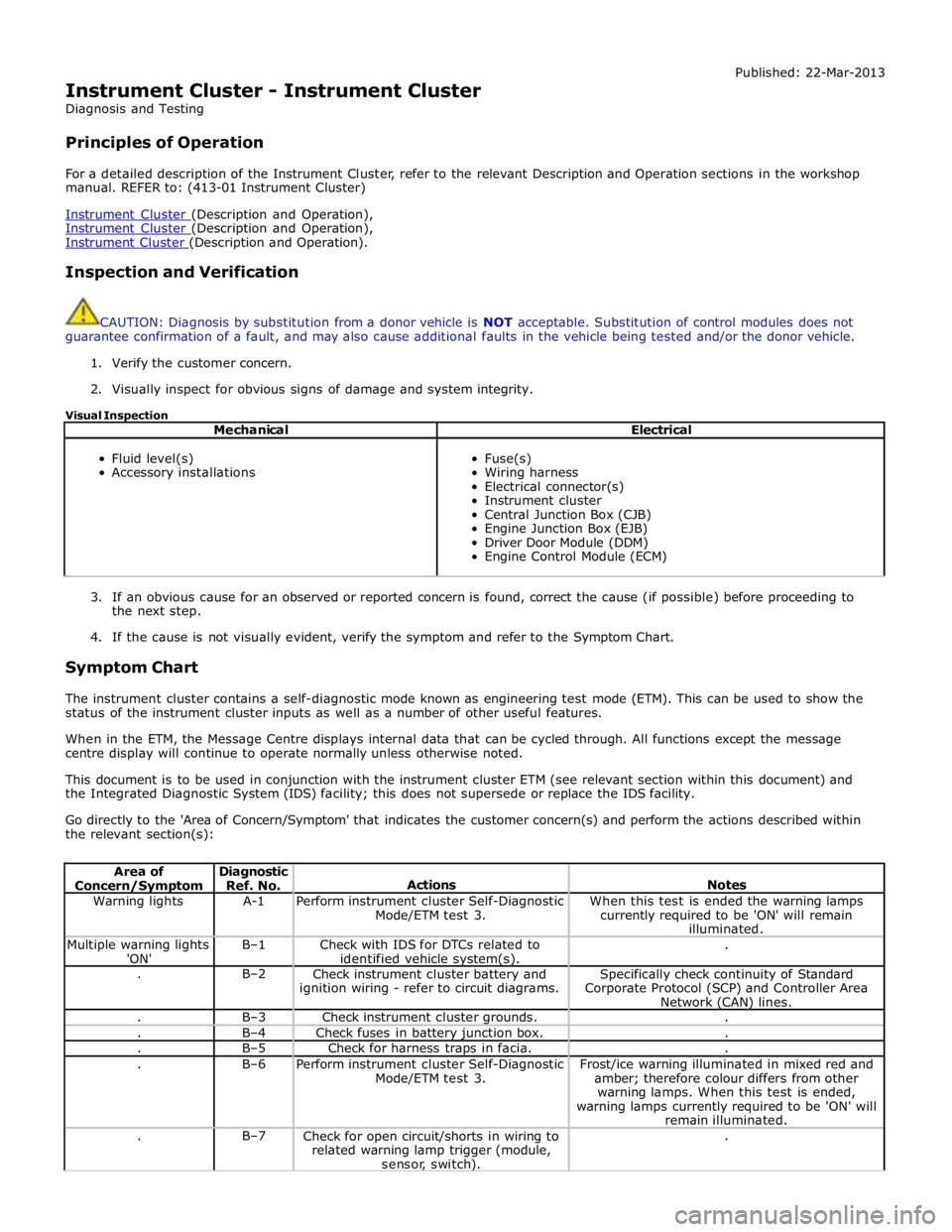

Inspection and Verification

CAUTION: Diagnosis by substitution from a donor vehicle is NOT acceptable. Substitution of control modules does not

guarantee confirmation of a fault, and may also cause additional faults in the vehicle being tested and/or the donor vehicle.

1. Verify the customer concern.

2. Visually inspect for obvious signs of damage and system integrity.

Visual Inspection

Mechanical Electrical

Fluid level(s)

Accessory installations

Fuse(s)

Wiring harness

Electrical connector(s)

Instrument cluster

Central Junction Box (CJB)

Engine Junction Box (EJB)

Driver Door Module (DDM)

Engine Control Module (ECM)

3. If an obvious cause for an observed or reported concern is found, correct the cause (if possible) before proceeding to

the next step.

4. If the cause is not visually evident, verify the symptom and refer to the Symptom Chart.

Symptom Chart

The instrument cluster contains a self-diagnostic mode known as engineering test mode (ETM). This can be used to show the

status of the instrument cluster inputs as well as a number of other useful features.

When in the ETM, the Message Centre displays internal data that can be cycled through. All functions except the message

centre display will continue to operate normally unless otherwise noted.

This document is to be used in conjunction with the instrument cluster ETM (see relevant section within this document) and

the Integrated Diagnostic System (IDS) facility; this does not supersede or replace the IDS facility.

Go directly to the 'Area of Concern/Symptom' that indicates the customer concern(s) and perform the actions described within

the relevant section(s):

Area of Concern/Symptom Diagnostic

Ref. No.

Actions

Notes Warning lights A-1

Perform instrument cluster Self-Diagnostic

Mode/ETM test 3. When this test is ended the warning lamps

currently required to be 'ON' will remain

illuminated. Multiple warning lights

'ON' B–1

Check with IDS for DTCs related to

identified vehicle system(s). . . B–2

Check instrument cluster battery and

ignition wiring - refer to circuit diagrams. Specifically check continuity of Standard

Corporate Protocol (SCP) and Controller Area

Network (CAN) lines. . B–3 Check instrument cluster grounds. . . B–4 Check fuses in battery junction box. . . B–5 Check for harness traps in facia. . . B–6

Perform instrument cluster Self-Diagnostic

Mode/ETM test 3. Frost/ice warning illuminated in mixed red and

amber; therefore colour differs from other

warning lamps. When this test is ended,

warning lamps currently required to be 'ON' will

remain illuminated. . B–7

Check for open circuit/shorts in wiring to

related warning lamp trigger (module,

sensor, switch). .

Page 1792 of 3039

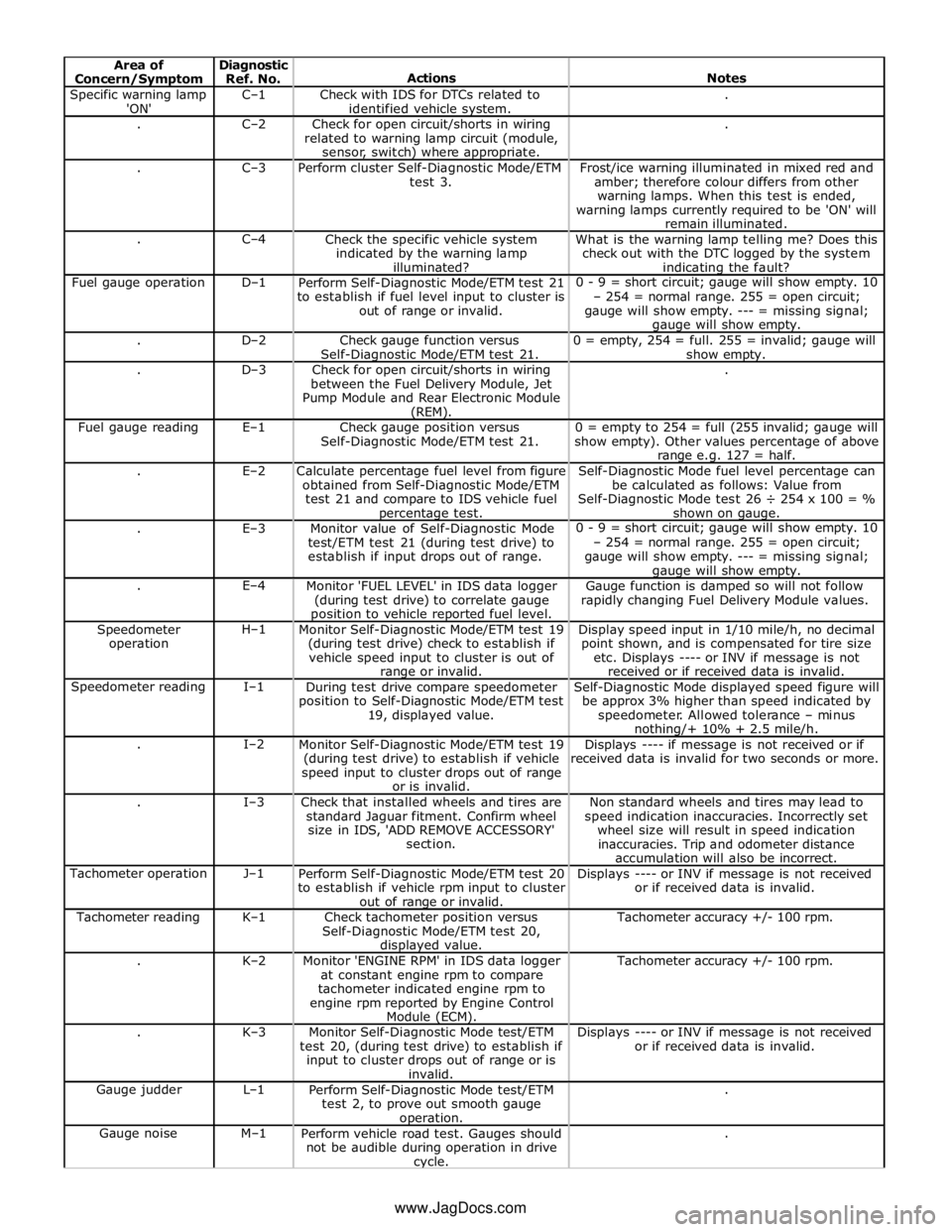

Specific warning lamp

'ON' C–1

Check with IDS for DTCs related to

identified vehicle system. . . C–2

Check for open circuit/shorts in wiring

related to warning lamp circuit (module,

sensor, switch) where appropriate. . . C–3

Perform cluster Self-Diagnostic Mode/ETM

test 3. Frost/ice warning illuminated in mixed red and

amber; therefore colour differs from other

warning lamps. When this test is ended,

warning lamps currently required to be 'ON' will

remain illuminated. . C–4

Check the specific vehicle system

indicated by the warning lamp

illuminated? What is the warning lamp telling me? Does this

check out with the DTC logged by the system indicating the fault? Fuel gauge operation D–1

Perform Self-Diagnostic Mode/ETM test 21

to establish if fuel level input to cluster is

out of range or invalid. 0 - 9 = short circuit; gauge will show empty. 10

– 254 = normal range. 255 = open circuit;

gauge will show empty. --- = missing signal; gauge will show empty. . D–2

Check gauge function versus

Self-Diagnostic Mode/ETM test 21. 0 = empty, 254 = full. 255 = invalid; gauge will

show empty. . D–3

Check for open circuit/shorts in wiring

between the Fuel Delivery Module, Jet

Pump Module and Rear Electronic Module (REM). . Fuel gauge reading E–1

Check gauge position versus

Self-Diagnostic Mode/ETM test 21. 0 = empty to 254 = full (255 invalid; gauge will

show empty). Other values percentage of above range e.g. 127 = half. . E–2

Calculate percentage fuel level from figure

obtained from Self-Diagnostic Mode/ETM

test 21 and compare to IDS vehicle fuel percentage test. Self-Diagnostic Mode fuel level percentage can

be calculated as follows: Value from

Self-Diagnostic Mode test 26 ÷ 254 x 100 = %

shown on gauge. . E–3

Monitor value of Self-Diagnostic Mode

test/ETM test 21 (during test drive) to

establish if input drops out of range. 0 - 9 = short circuit; gauge will show empty. 10

– 254 = normal range. 255 = open circuit;

gauge will show empty. --- = missing signal; gauge will show empty. . E–4

Monitor 'FUEL LEVEL' in IDS data logger

(during test drive) to correlate gauge position to vehicle reported fuel level. Gauge function is damped so will not follow

rapidly changing Fuel Delivery Module values. Speedometer

operation H–1

Monitor Self-Diagnostic Mode/ETM test 19

(during test drive) check to establish if

vehicle speed input to cluster is out of range or invalid. Display speed input in 1/10 mile/h, no decimal

point shown, and is compensated for tire size

etc. Displays ---- or INV if message is not

received or if received data is invalid. Speedometer reading I–1

During test drive compare speedometer

position to Self-Diagnostic Mode/ETM test

19, displayed value. Self-Diagnostic Mode displayed speed figure will

be approx 3% higher than speed indicated by

speedometer. Allowed tolerance – minus nothing/+ 10% + 2.5 mile/h. . I–2

Monitor Self-Diagnostic Mode/ETM test 19

(during test drive) to establish if vehicle

speed input to cluster drops out of range

or is invalid. Displays ---- if message is not received or if

received data is invalid for two seconds or more. . I–3

Check that installed wheels and tires are

standard Jaguar fitment. Confirm wheel

size in IDS, 'ADD REMOVE ACCESSORY'

section. Non standard wheels and tires may lead to

speed indication inaccuracies. Incorrectly set

wheel size will result in speed indication

inaccuracies. Trip and odometer distance

accumulation will also be incorrect. Tachometer operation J–1

Perform Self-Diagnostic Mode/ETM test 20

to establish if vehicle rpm input to cluster

out of range or invalid. Displays ---- or INV if message is not received

or if received data is invalid. Tachometer reading K–1

Check tachometer position versus

Self-Diagnostic Mode/ETM test 20, displayed value. Tachometer accuracy +/- 100 rpm. . K–2

Monitor 'ENGINE RPM' in IDS data logger

at constant engine rpm to compare

tachometer indicated engine rpm to

engine rpm reported by Engine Control

Module (ECM). Tachometer accuracy +/- 100 rpm. . K–3

Monitor Self-Diagnostic Mode test/ETM

test 20, (during test drive) to establish if

input to cluster drops out of range or is

invalid. Displays ---- or INV if message is not received

or if received data is invalid. Gauge judder L–1

Perform Self-Diagnostic Mode test/ETM

test 2, to prove out smooth gauge operation. . Gauge noise M–1

Perform vehicle road test. Gauges should

not be audible during operation in drive cycle. . www.JagDocs.com

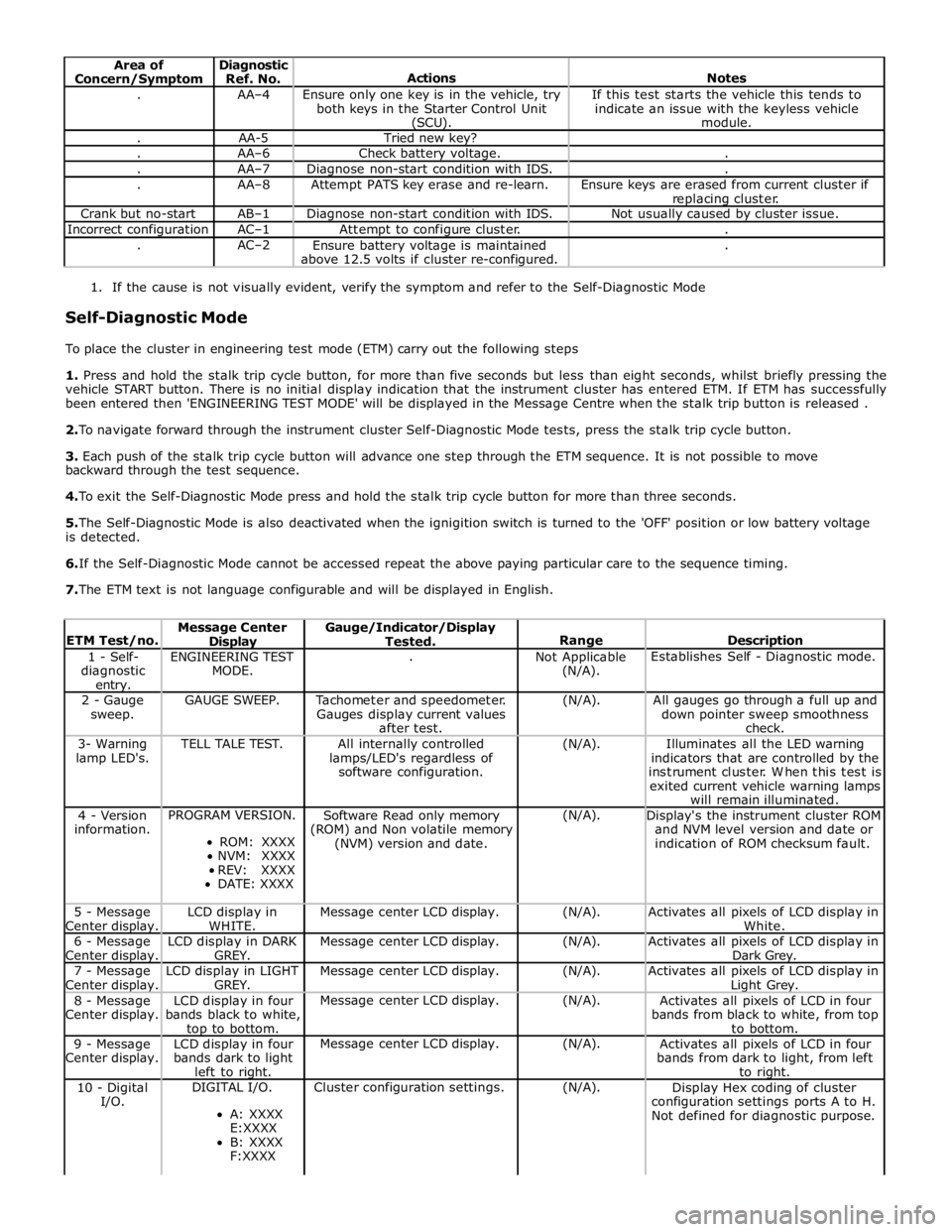

Page 1794 of 3039

Area of

Concern/Symptom Diagnostic

Ref. No.

Actions

Notes . AA–4

Ensure only one key is in the vehicle, try

both keys in the Starter Control Unit (SCU). If this test starts the vehicle this tends to

indicate an issue with the keyless vehicle

module. . AA-5 Tried new key? . AA–6 Check battery voltage. . . AA–7 Diagnose non-start condition with IDS. . . AA–8 Attempt PATS key erase and re-learn.

Ensure keys are erased from current cluster if

replacing cluster. Crank but no-start AB–1 Diagnose non-start condition with IDS. Not usually caused by cluster issue. Incorrect configuration AC–1 Attempt to configure cluster. . . AC–2

Ensure battery voltage is maintained

above 12.5 volts if cluster re-configured. .

1. If the cause is not visually evident, verify the symptom and refer to the Self-Diagnostic Mode

Self-Diagnostic Mode

To place the cluster in engineering test mode (ETM) carry out the following steps

1. Press and hold the stalk trip cycle button, for more than five seconds but less than eight seconds, whilst briefly pressing the

vehicle START button. There is no initial display indication that the instrument cluster has entered ETM. If ETM has successfully

been entered then 'ENGINEERING TEST MODE' will be displayed in the Message Centre when the stalk trip button is released .

2. To navigate forward through the instrument cluster Self-Diagnostic Mode tests, press the stalk trip cycle button.

3. Each push of the stalk trip cycle button will advance one step through the ETM sequence. It is not possible to move

backward through the test sequence.

4. To exit the Self-Diagnostic Mode press and hold the stalk trip cycle button for more than three seconds.

5. The Self-Diagnostic Mode is also deactivated when the ignigition switch is turned to the 'OFF' position or low battery voltage

is detected.

6. If the Self-Diagnostic Mode cannot be accessed repeat the above paying particular care to the sequence timing.

7. The ETM text is not language configurable and will be displayed in English.

ETM Test/no. Message Center Display Gauge/Indicator/Display

Tested.

Range

Description 1 - Self-

diagnostic entry. ENGINEERING TEST

MODE. .

Not Applicable

(N/A). Establishes Self - Diagnostic mode. 2 - Gauge

sweep. GAUGE SWEEP.

Tachometer and speedometer.

Gauges display current values

after test. (N/A).

All gauges go through a full up and

down pointer sweep smoothness

check. 3- Warning

lamp LED's. TELL TALE TEST.

All internally controlled

lamps/LED's regardless of

software configuration. (N/A).

Illuminates all the LED warning

indicators that are controlled by the

instrument cluster. When this test is

exited current vehicle warning lamps

will remain illuminated. 4 - Version

information. PROGRAM VERSION.

ROM: XXXX

NVM: XXXX

REV: XXXX

DATE: XXXX Software Read only memory

(ROM) and Non volatile memory

(NVM) version and date. (N/A).

Display's the instrument cluster ROM

and NVM level version and date or

indication of ROM checksum fault. 5 - Message

Center display. LCD display in

WHITE. Message center LCD display. (N/A).

Activates all pixels of LCD display in

White. 6 - Message

Center display. LCD display in DARK

GREY. Message center LCD display. (N/A).

Activates all pixels of LCD display in

Dark Grey. 7 - Message

Center display. LCD display in LIGHT

GREY. Message center LCD display. (N/A).

Activates all pixels of LCD display in Light Grey. 8 - Message

Center display. LCD display in four

bands black to white, top to bottom. Message center LCD display. (N/A).

Activates all pixels of LCD in four

bands from black to white, from top

to bottom. 9 - Message

Center display. LCD display in four

bands dark to light

left to right. Message center LCD display. (N/A).

Activates all pixels of LCD in four

bands from dark to light, from left

to right. 10 - Digital

I/O. DIGITAL I/O.

A: XXXX

E:XXXX

B: XXXX

F:XXXX Cluster configuration settings. (N/A).

Display Hex coding of cluster

configuration settings ports A to H.

Not defined for diagnostic purpose.

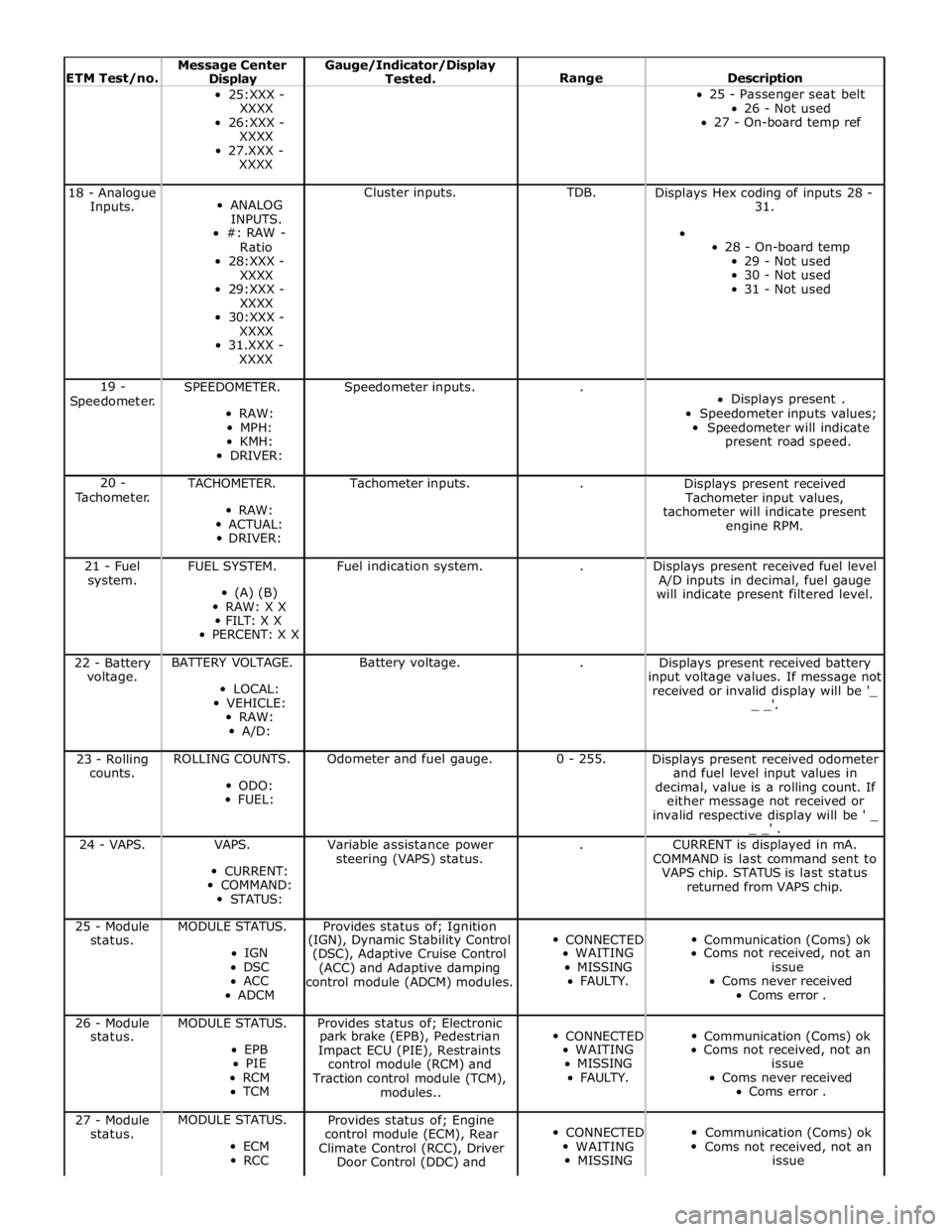

Page 1796 of 3039

ETM Test/no. Message Center Display Gauge/Indicator/Display

Tested.

Range

Description 25:XXX -

XXXX

26:XXX -

XXXX

27.XXX -

XXXX 25 - Passenger seat belt

26 - Not used

27 - On-board temp ref 18 - Analogue

Inputs.

ANALOG

INPUTS.

#: RAW -

Ratio

28:XXX -

XXXX

29:XXX -

XXXX

30:XXX -

XXXX

31.XXX -

XXXX Cluster inputs. TDB.

Displays Hex coding of inputs 28 -

31.

28 - On-board temp

29 - Not used

30 - Not used

31 - Not used 19 -

Speedometer. SPEEDOMETER.

RAW:

MPH:

KMH:

DRIVER: Speedometer inputs. .

Displays present .

Speedometer inputs values;

Speedometer will indicate

present road speed. 20 -

Tachometer. TACHOMETER.

RAW:

ACTUAL:

DRIVER: Tachometer inputs. .

Displays present received

Tachometer input values,

tachometer will indicate present

engine RPM. 21 - Fuel

system. FUEL SYSTEM.

(A) (B)

RAW: X X

FILT: X X

PERCENT: X X Fuel indication system. .

Displays present received fuel level

A/D inputs in decimal, fuel gauge

will indicate present filtered level. 22 - Battery

voltage. BATTERY VOLTAGE.

LOCAL:

VEHICLE:

RAW:

A/D: Battery voltage. .

Displays present received battery

input voltage values. If message not

received or invalid display will be '_

_ _'. 23 - Rolling

counts. ROLLING COUNTS.

ODO:

FUEL: Odometer and fuel gauge. 0 - 255.

Displays present received odometer

and fuel level input values in

decimal, value is a rolling count. If

either message not received or

invalid respective display will be ' _

_ _' . 24 - VAPS. VAPS.

CURRENT:

COMMAND:

STATUS: Variable assistance power

steering (VAPS) status. .

CURRENT is displayed in mA.

COMMAND is last command sent to

VAPS chip. STATUS is last status

returned from VAPS chip. 25 - Module MODULE STATUS. Provides status of; Ignition

CONNECTED

Communication (Coms) ok status. (IGN), Dynamic Stability Control IGN

(DSC), Adaptive Cruise Control WAITING Coms not received, not an DSC

(ACC) and Adaptive damping MISSING issue ACC

control module (ADCM) modules. FAULTY. Coms never received ADCM Coms error . 26 - Module MODULE STATUS. Provides status of; Electronic

CONNECTED

Communication (Coms) ok status. park brake (EPB), Pedestrian EPB

Impact ECU (PIE), Restraints WAITING Coms not received, not an PIE

control module (RCM) and MISSING issue RCM

Traction control module (TCM), FAULTY. Coms never received TCM

modules.. Coms error . 27 - Module

status. MODULE STATUS.

ECM

RCC Provides status of; Engine

control module (ECM), Rear

Climate Control (RCC), Driver

Door Control (DDC) and

CONNECTED

WAITING

MISSING

Communication (Coms) ok

Coms not received, not an

issue

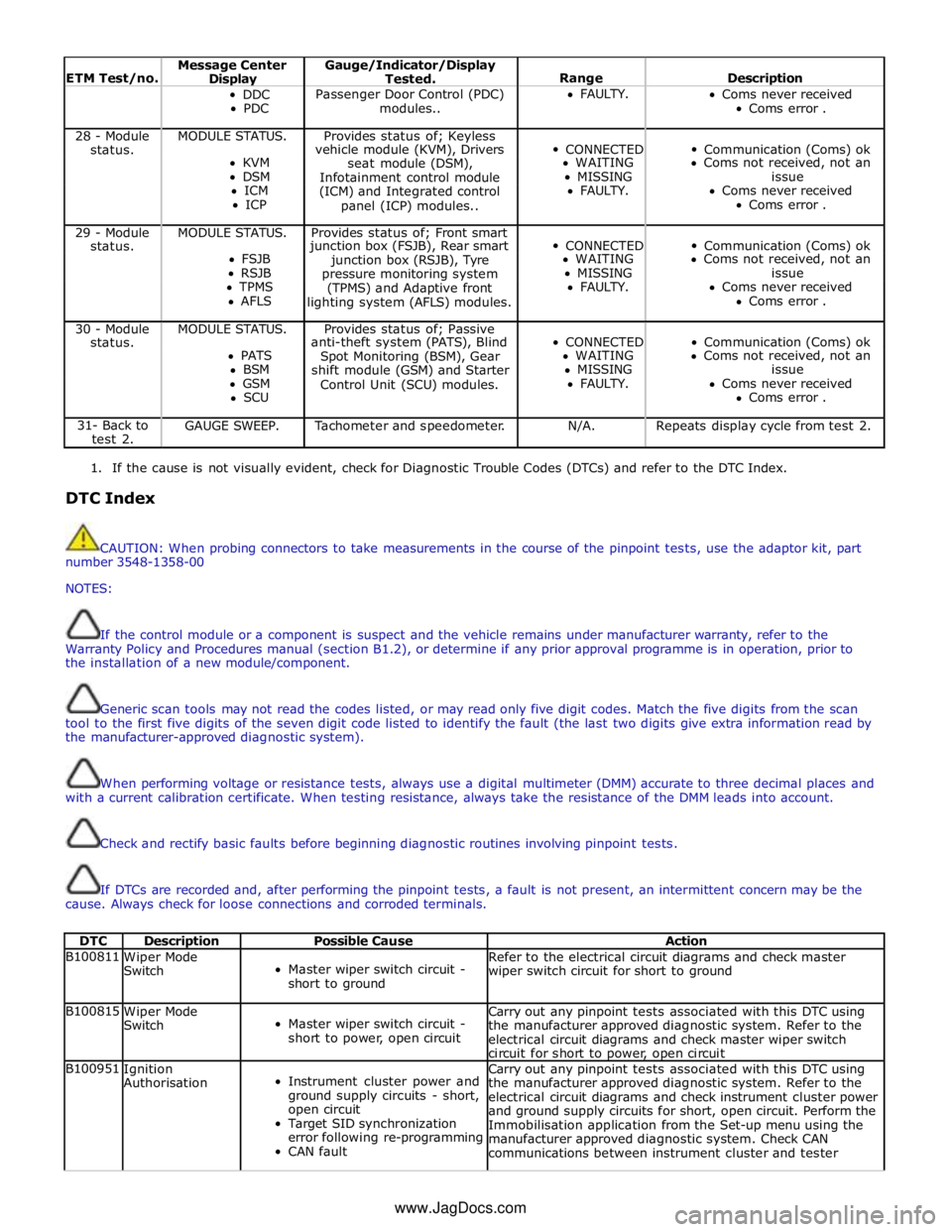

Page 1797 of 3039

ETM Test/no. Message Center Display Gauge/Indicator/Display

Tested.

Range

Description DDC

PDC Passenger Door Control (PDC)

modules.. FAULTY.

Coms never received

Coms error . 28 - Module MODULE STATUS. Provides status of; Keyless

CONNECTED

Communication (Coms) ok status. vehicle module (KVM), Drivers KVM

seat module (DSM), WAITING Coms not received, not an DSM

Infotainment control module MISSING issue ICM

(ICM) and Integrated control FAULTY. Coms never received ICP

panel (ICP) modules.. Coms error . 29 - Module MODULE STATUS. Provides status of; Front smart

CONNECTED

Communication (Coms) ok status. junction box (FSJB), Rear smart FSJB

junction box (RSJB), Tyre WAITING Coms not received, not an RSJB

pressure monitoring system MISSING issue TPMS

(TPMS) and Adaptive front FAULTY. Coms never received AFLS

lighting system (AFLS) modules. Coms error . 30 - Module MODULE STATUS. Provides status of; Passive

CONNECTED

Communication (Coms) ok status. anti-theft system (PATS), Blind PATS

Spot Monitoring (BSM), Gear WAITING Coms not received, not an BSM

shift module (GSM) and Starter MISSING issue GSM

Control Unit (SCU) modules. FAULTY. Coms never received SCU Coms error . 31- Back to

test 2. GAUGE SWEEP. Tachometer and speedometer. N/A. Repeats display cycle from test 2.

1. If the cause is not visually evident, check for Diagnostic Trouble Codes (DTCs) and refer to the DTC Index.

DTC Index

CAUTION: When probing connectors to take measurements in the course of the pinpoint tests, use the adaptor kit, part

number 3548-1358-00

NOTES:

If the control module or a component is suspect and the vehicle remains under manufacturer warranty, refer to the

Warranty Policy and Procedures manual (section B1.2), or determine if any prior approval programme is in operation, prior to

the installation of a new module/component.

Generic scan tools may not read the codes listed, or may read only five digit codes. Match the five digits from the scan

tool to the first five digits of the seven digit code listed to identify the fault (the last two digits give extra information read by

the manufacturer-approved diagnostic system).

When performing voltage or resistance tests, always use a digital multimeter (DMM) accurate to three decimal places and

with a current calibration certificate. When testing resistance, always take the resistance of the DMM leads into account.

Check and rectify basic faults before beginning diagnostic routines involving pinpoint tests.

If DTCs are recorded and, after performing the pinpoint tests, a fault is not present, an intermittent concern may be the

cause. Always check for loose connections and corroded terminals.

DTC Description Possible Cause Action B100811

Wiper Mode

Switch

Master wiper switch circuit -

short to ground Refer to the electrical circuit diagrams and check master

wiper switch circuit for short to ground B100815

Wiper Mode

Switch

Master wiper switch circuit -

short to power, open circuit Carry out any pinpoint tests associated with this DTC using

the manufacturer approved diagnostic system. Refer to the

electrical circuit diagrams and check master wiper switch

circuit for short to power, open circuit B100951

Ignition

Authorisation

Instrument cluster power and

ground supply circuits - short,

open circuit

Target SID synchronization

error following re-programming

CAN fault Carry out any pinpoint tests associated with this DTC using

the manufacturer approved diagnostic system. Refer to the

electrical circuit diagrams and check instrument cluster power

and ground supply circuits for short, open circuit. Perform the

Immobilisation application from the Set-up menu using the

manufacturer approved diagnostic system. Check CAN

communications between instrument cluster and tester www.JagDocs.com

Page 1799 of 3039

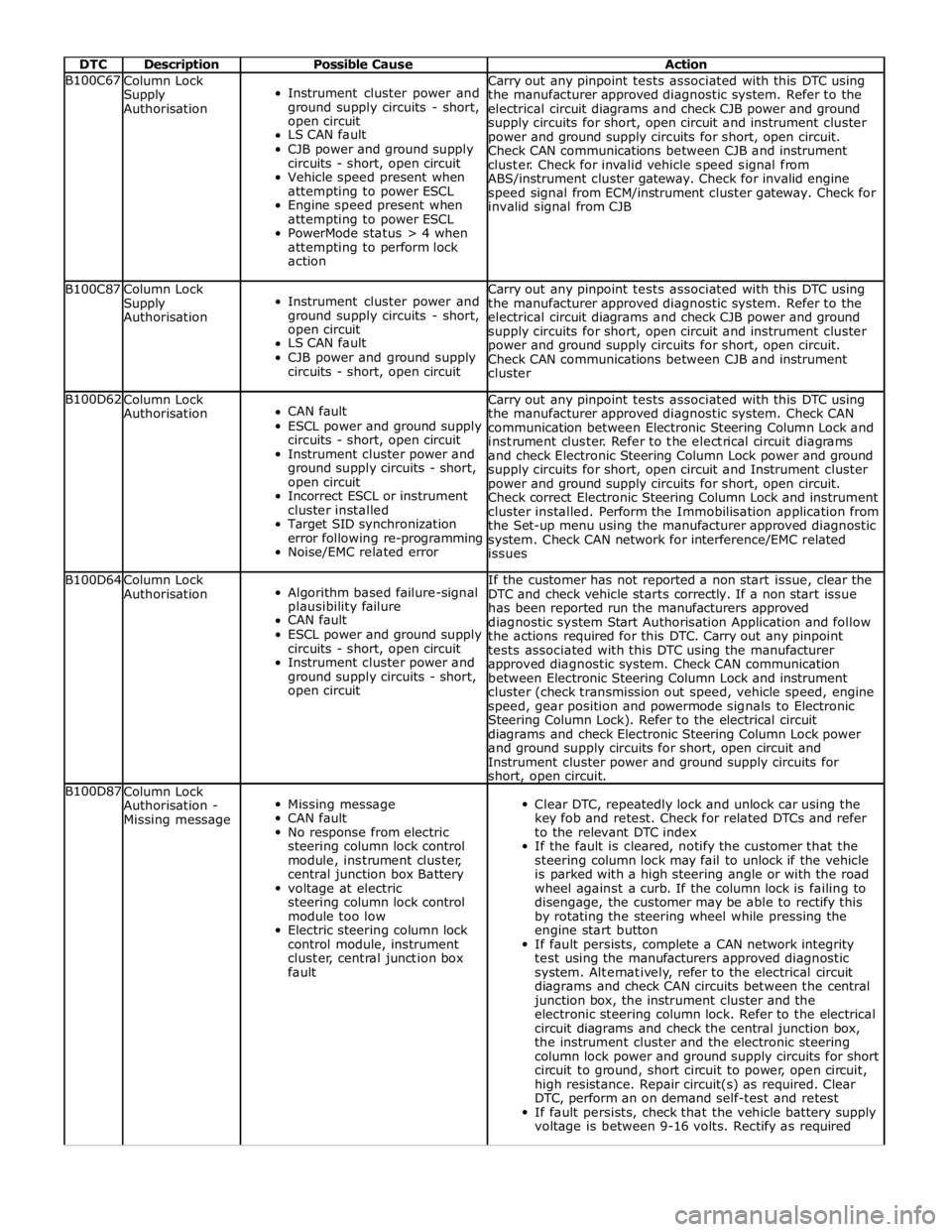

DTC Description Possible Cause Action B100C67

Column Lock

Supply

Authorisation

Instrument cluster power and

ground supply circuits - short,

open circuit

LS CAN fault

CJB power and ground supply

circuits - short, open circuit

Vehicle speed present when

attempting to power ESCL

Engine speed present when

attempting to power ESCL

PowerMode status > 4 when

attempting to perform lock

action Carry out any pinpoint tests associated with this DTC using

the manufacturer approved diagnostic system. Refer to the

electrical circuit diagrams and check CJB power and ground

supply circuits for short, open circuit and instrument cluster

power and ground supply circuits for short, open circuit.

Check CAN communications between CJB and instrument

cluster. Check for invalid vehicle speed signal from

ABS/instrument cluster gateway. Check for invalid engine

speed signal from ECM/instrument cluster gateway. Check for

invalid signal from CJB B100C87

Column Lock

Supply

Authorisation

Instrument cluster power and

ground supply circuits - short,

open circuit

LS CAN fault

CJB power and ground supply

circuits - short, open circuit Carry out any pinpoint tests associated with this DTC using

the manufacturer approved diagnostic system. Refer to the

electrical circuit diagrams and check CJB power and ground

supply circuits for short, open circuit and instrument cluster

power and ground supply circuits for short, open circuit.

Check CAN communications between CJB and instrument

cluster B100D62

Column Lock

Authorisation

CAN fault

ESCL power and ground supply

circuits - short, open circuit

Instrument cluster power and

ground supply circuits - short,

open circuit

Incorrect ESCL or instrument

cluster installed

Target SID synchronization

error following re-programming

Noise/EMC related error Carry out any pinpoint tests associated with this DTC using

the manufacturer approved diagnostic system. Check CAN

communication between Electronic Steering Column Lock and

instrument cluster. Refer to the electrical circuit diagrams

and check Electronic Steering Column Lock power and ground

supply circuits for short, open circuit and Instrument cluster

power and ground supply circuits for short, open circuit.

Check correct Electronic Steering Column Lock and instrument

cluster installed. Perform the Immobilisation application from

the Set-up menu using the manufacturer approved diagnostic

system. Check CAN network for interference/EMC related

issues B100D64

Column Lock

Authorisation

Algorithm based failure-signal

plausibility failure

CAN fault

ESCL power and ground supply

circuits - short, open circuit

Instrument cluster power and

ground supply circuits - short,

open circuit If the customer has not reported a non start issue, clear the

DTC and check vehicle starts correctly. If a non start issue

has been reported run the manufacturers approved

diagnostic system Start Authorisation Application and follow

the actions required for this DTC. Carry out any pinpoint

tests associated with this DTC using the manufacturer

approved diagnostic system. Check CAN communication

between Electronic Steering Column Lock and instrument

cluster (check transmission out speed, vehicle speed, engine

speed, gear position and powermode signals to Electronic

Steering Column Lock). Refer to the electrical circuit

diagrams and check Electronic Steering Column Lock power

and ground supply circuits for short, open circuit and

Instrument cluster power and ground supply circuits for

short, open circuit. B100D87

Column Lock

Authorisation -

Missing message

Missing message

CAN fault

No response from electric

steering column lock control

module, instrument cluster,

central junction box Battery

voltage at electric

steering column lock control

module too low

Electric steering column lock

control module, instrument

cluster, central junction box

fault

Clear DTC, repeatedly lock and unlock car using the

key fob and retest. Check for related DTCs and refer

to the relevant DTC index

If the fault is cleared, notify the customer that the

steering column lock may fail to unlock if the vehicle

is parked with a high steering angle or with the road

wheel against a curb. If the column lock is failing to

disengage, the customer may be able to rectify this

by rotating the steering wheel while pressing the

engine start button

If fault persists, complete a CAN network integrity

test using the manufacturers approved diagnostic

system. Alternatively, refer to the electrical circuit

diagrams and check CAN circuits between the central

junction box, the instrument cluster and the

electronic steering column lock. Refer to the electrical

circuit diagrams and check the central junction box,

the instrument cluster and the electronic steering

column lock power and ground supply circuits for short

circuit to ground, short circuit to power, open circuit,

high resistance. Repair circuit(s) as required. Clear

DTC, perform an on demand self-test and retest

If fault persists, check that the vehicle battery supply

voltage is between 9-16 volts. Rectify as required

Page 1800 of 3039

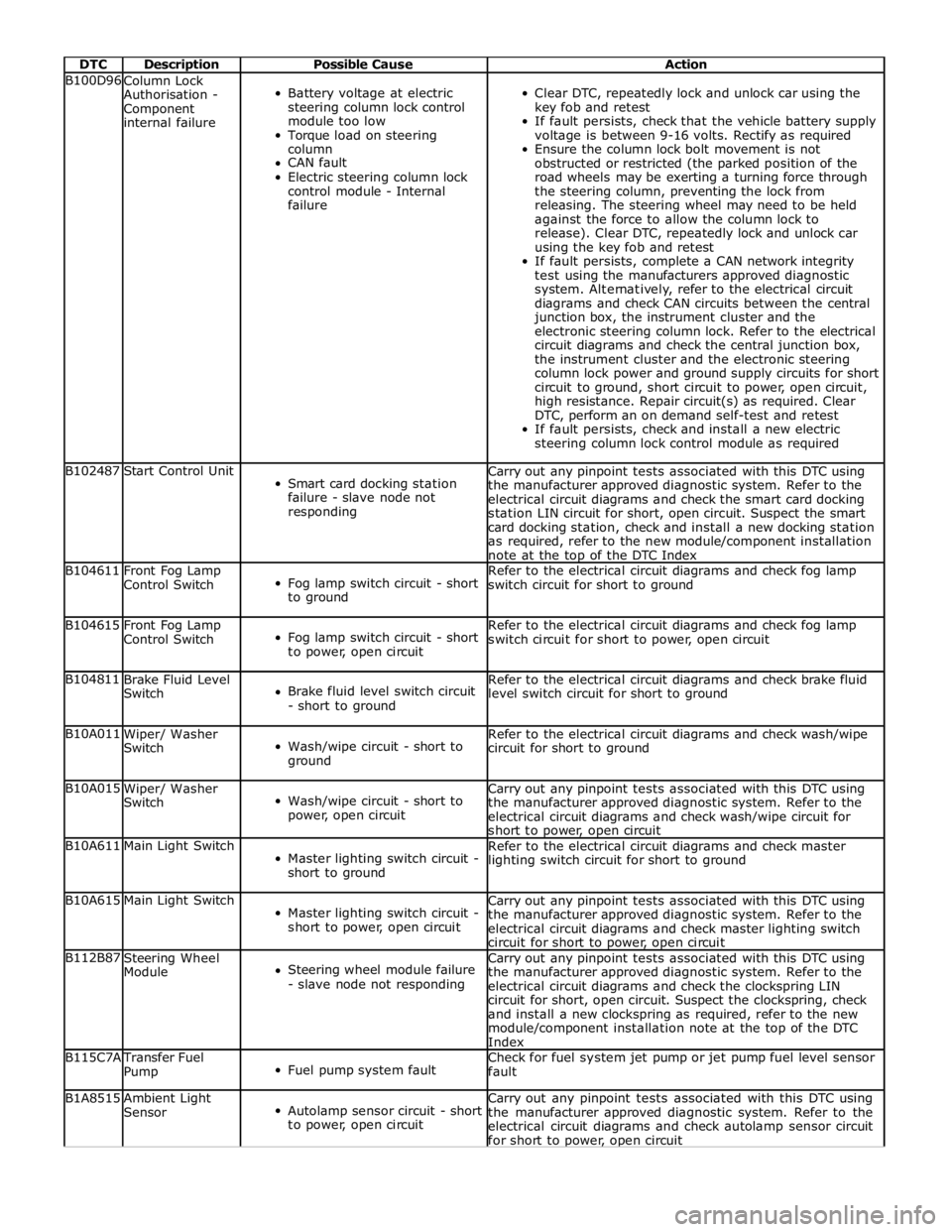

DTC Description Possible Cause Action B100D96

Column Lock

Authorisation -

Component

internal failure

Battery voltage at electric

steering column lock control

module too low

Torque load on steering

column

CAN fault

Electric steering column lock

control module - Internal

failure

Clear DTC, repeatedly lock and unlock car using the

key fob and retest

If fault persists, check that the vehicle battery supply

voltage is between 9-16 volts. Rectify as required

Ensure the column lock bolt movement is not

obstructed or restricted (the parked position of the

road wheels may be exerting a turning force through

the steering column, preventing the lock from

releasing. The steering wheel may need to be held

against the force to allow the column lock to

release). Clear DTC, repeatedly lock and unlock car

using the key fob and retest

If fault persists, complete a CAN network integrity

test using the manufacturers approved diagnostic

system. Alternatively, refer to the electrical circuit

diagrams and check CAN circuits between the central

junction box, the instrument cluster and the

electronic steering column lock. Refer to the electrical

circuit diagrams and check the central junction box,

the instrument cluster and the electronic steering

column lock power and ground supply circuits for short

circuit to ground, short circuit to power, open circuit,

high resistance. Repair circuit(s) as required. Clear

DTC, perform an on demand self-test and retest

If fault persists, check and install a new electric

steering column lock control module as required B102487 Start Control Unit

Smart card docking station

failure - slave node not

responding Carry out any pinpoint tests associated with this DTC using

the manufacturer approved diagnostic system. Refer to the

electrical circuit diagrams and check the smart card docking

station LIN circuit for short, open circuit. Suspect the smart

card docking station, check and install a new docking station

as required, refer to the new module/component installation

note at the top of the DTC Index B104611

Front Fog Lamp

Control Switch

Fog lamp switch circuit - short

to ground Refer to the electrical circuit diagrams and check fog lamp

switch circuit for short to ground B104615

Front Fog Lamp

Control Switch

Fog lamp switch circuit - short

to power, open circuit Refer to the electrical circuit diagrams and check fog lamp

switch circuit for short to power, open circuit B104811

Brake Fluid Level

Switch

Brake fluid level switch circuit

- short to ground Refer to the electrical circuit diagrams and check brake fluid

level switch circuit for short to ground B10A011

Wiper/ Washer

Switch

Wash/wipe circuit - short to

ground Refer to the electrical circuit diagrams and check wash/wipe

circuit for short to ground B10A015

Wiper/ Washer

Switch

Wash/wipe circuit - short to

power, open circuit Carry out any pinpoint tests associated with this DTC using

the manufacturer approved diagnostic system. Refer to the

electrical circuit diagrams and check wash/wipe circuit for

short to power, open circuit B10A611 Main Light Switch

Master lighting switch circuit -

short to ground Refer to the electrical circuit diagrams and check master

lighting switch circuit for short to ground B10A615 Main Light Switch

Master lighting switch circuit -

short to power, open circuit Carry out any pinpoint tests associated with this DTC using

the manufacturer approved diagnostic system. Refer to the

electrical circuit diagrams and check master lighting switch

circuit for short to power, open circuit B112B87

Steering Wheel

Module

Steering wheel module failure

- slave node not responding Carry out any pinpoint tests associated with this DTC using

the manufacturer approved diagnostic system. Refer to the

electrical circuit diagrams and check the clockspring LIN

circuit for short, open circuit. Suspect the clockspring, check

and install a new clockspring as required, refer to the new

module/component installation note at the top of the DTC

Index B115C7A

Transfer Fuel

Pump

Fuel pump system fault Check for fuel system jet pump or jet pump fuel level sensor

fault B1A8515

Ambient Light

Sensor

Autolamp sensor circuit - short

to power, open circuit Carry out any pinpoint tests associated with this DTC using

the manufacturer approved diagnostic system. Refer to the

electrical circuit diagrams and check autolamp sensor circuit

for short to power, open circuit

Page 1804 of 3039

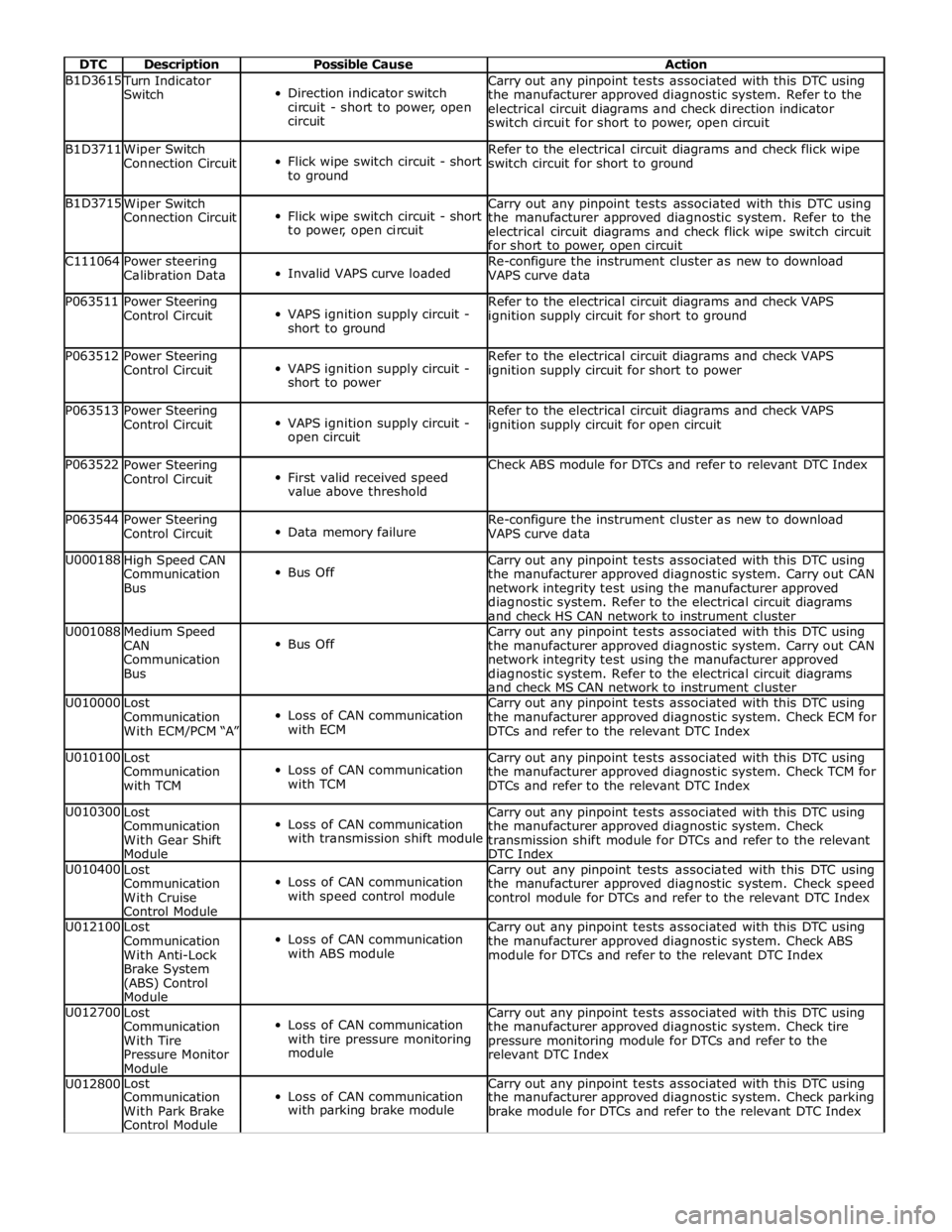

DTC Description Possible Cause Action B1D3615

Turn Indicator

Switch

Direction indicator switch

circuit - short to power, open

circuit Carry out any pinpoint tests associated with this DTC using

the manufacturer approved diagnostic system. Refer to the

electrical circuit diagrams and check direction indicator

switch circuit for short to power, open circuit B1D3711

Wiper Switch

Connection Circuit

Flick wipe switch circuit - short

to ground Refer to the electrical circuit diagrams and check flick wipe

switch circuit for short to ground B1D3715

Wiper Switch

Connection Circuit

Flick wipe switch circuit - short

to power, open circuit Carry out any pinpoint tests associated with this DTC using

the manufacturer approved diagnostic system. Refer to the

electrical circuit diagrams and check flick wipe switch circuit

for short to power, open circuit C111064

Power steering

Calibration Data

Invalid VAPS curve loaded Re-configure the instrument cluster as new to download

VAPS curve data P063511

Power Steering

Control Circuit

VAPS ignition supply circuit -

short to ground Refer to the electrical circuit diagrams and check VAPS

ignition supply circuit for short to ground P063512

Power Steering

Control Circuit

VAPS ignition supply circuit -

short to power Refer to the electrical circuit diagrams and check VAPS

ignition supply circuit for short to power P063513

Power Steering

Control Circuit

VAPS ignition supply circuit -

open circuit Refer to the electrical circuit diagrams and check VAPS

ignition supply circuit for open circuit P063522

Power Steering

Control Circuit

First valid received speed

value above threshold Check ABS module for DTCs and refer to relevant DTC Index P063544

Power Steering

Control Circuit

Data memory failure Re-configure the instrument cluster as new to download

VAPS curve data U000188

High Speed CAN

Communication

Bus

Bus Off Carry out any pinpoint tests associated with this DTC using

the manufacturer approved diagnostic system. Carry out CAN

network integrity test using the manufacturer approved

diagnostic system. Refer to the electrical circuit diagrams

and check HS CAN network to instrument cluster U001088

Medium Speed

CAN

Communication

Bus

Bus Off Carry out any pinpoint tests associated with this DTC using

the manufacturer approved diagnostic system. Carry out CAN

network integrity test using the manufacturer approved

diagnostic system. Refer to the electrical circuit diagrams

and check MS CAN network to instrument cluster U010000

Lost

Communication

With ECM/PCM “A”

Loss of CAN communication

with ECM Carry out any pinpoint tests associated with this DTC using

the manufacturer approved diagnostic system. Check ECM for

DTCs and refer to the relevant DTC Index U010100

Lost

Communication

with TCM

Loss of CAN communication

with TCM Carry out any pinpoint tests associated with this DTC using

the manufacturer approved diagnostic system. Check TCM for

DTCs and refer to the relevant DTC Index U010300

Lost

Communication

With Gear Shift

Module

Loss of CAN communication

with transmission shift module Carry out any pinpoint tests associated with this DTC using

the manufacturer approved diagnostic system. Check

transmission shift module for DTCs and refer to the relevant

DTC Index U010400

Lost

Communication

With Cruise

Control Module

Loss of CAN communication

with speed control module Carry out any pinpoint tests associated with this DTC using

the manufacturer approved diagnostic system. Check speed

control module for DTCs and refer to the relevant DTC Index U012100

Lost

Communication

With Anti-Lock

Brake System

(ABS) Control

Module

Loss of CAN communication

with ABS module Carry out any pinpoint tests associated with this DTC using

the manufacturer approved diagnostic system. Check ABS

module for DTCs and refer to the relevant DTC Index U012700

Lost

Communication

With Tire

Pressure Monitor

Module

Loss of CAN communication

with tire pressure monitoring

module Carry out any pinpoint tests associated with this DTC using

the manufacturer approved diagnostic system. Check tire

pressure monitoring module for DTCs and refer to the

relevant DTC Index U012800 Lost

Loss of CAN communication Carry out any pinpoint tests associated with this DTC using Communication the manufacturer approved diagnostic system. Check parking With Park Brake with parking brake module

brake module for DTCs and refer to the relevant DTC Index Control Module

Page 1805 of 3039

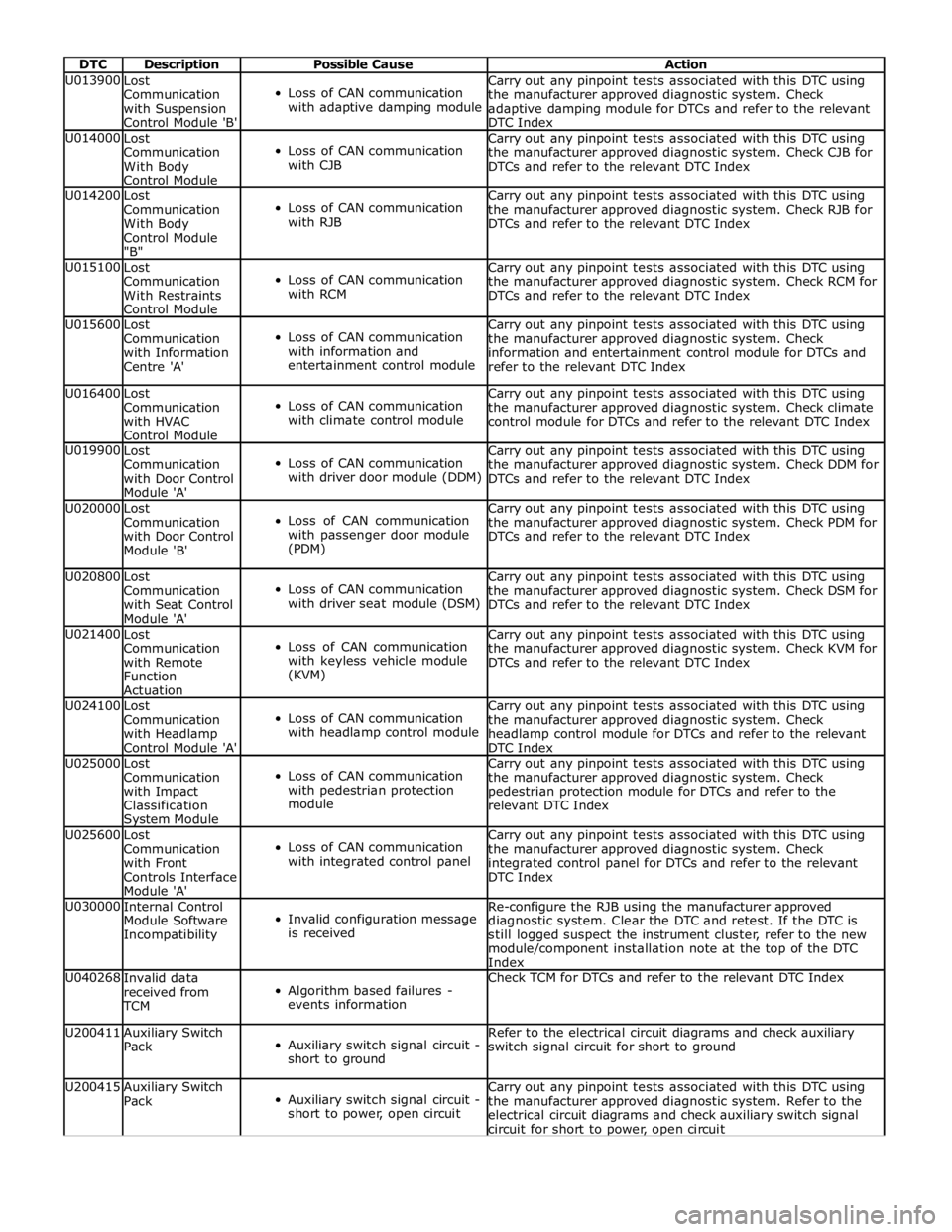

DTC Description Possible Cause Action U013900

Lost

Communication

with Suspension

Control Module 'B'

Loss of CAN communication

with adaptive damping module Carry out any pinpoint tests associated with this DTC using

the manufacturer approved diagnostic system. Check

adaptive damping module for DTCs and refer to the relevant

DTC Index U014000

Lost

Communication

With Body

Control Module

Loss of CAN communication

with CJB Carry out any pinpoint tests associated with this DTC using

the manufacturer approved diagnostic system. Check CJB for

DTCs and refer to the relevant DTC Index U014200

Lost

Communication

With Body

Control Module

"B"

Loss of CAN communication

with RJB Carry out any pinpoint tests associated with this DTC using

the manufacturer approved diagnostic system. Check RJB for

DTCs and refer to the relevant DTC Index U015100

Lost

Communication

With Restraints

Control Module

Loss of CAN communication

with RCM Carry out any pinpoint tests associated with this DTC using

the manufacturer approved diagnostic system. Check RCM for

DTCs and refer to the relevant DTC Index U015600

Lost

Communication

with Information

Centre 'A'

Loss of CAN communication

with information and

entertainment control module Carry out any pinpoint tests associated with this DTC using

the manufacturer approved diagnostic system. Check

information and entertainment control module for DTCs and

refer to the relevant DTC Index U016400

Lost

Communication

with HVAC

Control Module

Loss of CAN communication

with climate control module Carry out any pinpoint tests associated with this DTC using

the manufacturer approved diagnostic system. Check climate

control module for DTCs and refer to the relevant DTC Index U019900

Lost

Communication

with Door Control

Module 'A'

Loss of CAN communication

with driver door module (DDM) Carry out any pinpoint tests associated with this DTC using

the manufacturer approved diagnostic system. Check DDM for

DTCs and refer to the relevant DTC Index U020000

Lost

Communication

with Door Control

Module 'B'

Loss of CAN communication

with passenger door module

(PDM) Carry out any pinpoint tests associated with this DTC using

the manufacturer approved diagnostic system. Check PDM for

DTCs and refer to the relevant DTC Index U020800

Lost

Communication

with Seat Control

Module 'A'

Loss of CAN communication

with driver seat module (DSM) Carry out any pinpoint tests associated with this DTC using

the manufacturer approved diagnostic system. Check DSM for

DTCs and refer to the relevant DTC Index U021400

Lost

Communication

with Remote

Function

Actuation

Loss of CAN communication

with keyless vehicle module

(KVM) Carry out any pinpoint tests associated with this DTC using

the manufacturer approved diagnostic system. Check KVM for

DTCs and refer to the relevant DTC Index U024100

Lost

Communication

with Headlamp

Control Module 'A'

Loss of CAN communication

with headlamp control module Carry out any pinpoint tests associated with this DTC using

the manufacturer approved diagnostic system. Check

headlamp control module for DTCs and refer to the relevant

DTC Index U025000

Lost

Communication

with Impact

Classification System Module

Loss of CAN communication

with pedestrian protection

module Carry out any pinpoint tests associated with this DTC using

the manufacturer approved diagnostic system. Check

pedestrian protection module for DTCs and refer to the

relevant DTC Index U025600

Lost

Communication

with Front

Controls Interface

Module 'A'

Loss of CAN communication

with integrated control panel Carry out any pinpoint tests associated with this DTC using

the manufacturer approved diagnostic system. Check

integrated control panel for DTCs and refer to the relevant

DTC Index U030000

Internal Control

Module Software

Incompatibility

Invalid configuration message

is received Re-configure the RJB using the manufacturer approved

diagnostic system. Clear the DTC and retest. If the DTC is

still logged suspect the instrument cluster, refer to the new

module/component installation note at the top of the DTC

Index U040268

Invalid data

received from

TCM

Algorithm based failures -

events information Check TCM for DTCs and refer to the relevant DTC Index U200411

Auxiliary Switch

Pack

Auxiliary switch signal circuit -

short to ground Refer to the electrical circuit diagrams and check auxiliary

switch signal circuit for short to ground U200415

Auxiliary Switch

Pack

Auxiliary switch signal circuit -

short to power, open circuit Carry out any pinpoint tests associated with this DTC using

the manufacturer approved diagnostic system. Refer to the

electrical circuit diagrams and check auxiliary switch signal

circuit for short to power, open circuit

Page 1806 of 3039

DTC Description Possible Cause Action U300046 Control Module

Calibration/parameter memory

failure Suspect the instrument cluster, check and install a new

instrument cluster as required, refer to the new

module/component installation note at the top of the DTC

Index U300049 Control Module

Internal electronic failure Suspect the instrument cluster, check and install a new

instrument cluster as required, refer to the new

module/component installation note at the top of the DTC

Index U300055 Control Module

Incorrect car configuration

data received Re-configure the RJB using the manufacturer approved

diagnostic system. Clear DTC and re-test. If the DTC remains

suspect the instrument cluster. Check and install a new

instrument cluster as required, refer to the new

module/component installation note at the top of the DTC

Index U300087 Control Module

Missing message Re-configure the RJB using the manufacturer approved

diagnostic system. Check instrument cluster for additional

DTCs and refer to the DTC Index. Carry out CAN network

integrity tests using the manufacturer approved diagnostic

system. If DTC remains suspect the instrument cluster.

Check and install a new instrument cluster as required, refer

to the new module/component installation note at the top of

the DTC Index U300281

Vehicle

Identification

Number

Vehicle/component mis-match.

Corrupt VIN data being

transmitted, instrument

cluster previously installed to

other vehicle Check and install original/new instrument cluster as required,

refer to the new module/component installation note at the

top of the DTC Index U300316 Battery Voltage

Instrument cluster logic power

supply circuit - voltage below

threshold Carry out any pinpoint tests associated with this DTC using

the manufacturer approved diagnostic system. Refer to the

electrical circuit diagrams and check instrument cluster logic

power supply circuit for short to ground, open circuit U300317 Battery Voltage

Instrument cluster logic power

supply circuit - circuit voltage

above threshold Carry out any pinpoint tests associated with this DTC using

the manufacturer approved diagnostic system. Check

charging system for over charging condition U300362 Battery Voltage

Mis-match in battery voltage,

of 2 volts or more, between

instrument cluster and RJB Carry out any pinpoint tests associated with this DTC using

the manufacturer approved diagnostic system. Refer to the

electrical circuit diagrams and check instrument cluster logic

power supply circuit for short, open circuit