Control module JAGUAR XFR 2010 1.G Workshop Manual

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 2010, Model line: XFR, Model: JAGUAR XFR 2010 1.GPages: 3039, PDF Size: 58.49 MB

Page 1850 of 3039

Parking Aid - Parking Aid

Diagnosis and Testing

Principles of Operation Published: 24-Feb-2014

For a detailed description of the parking aid system, characteristics and limitations refer to the relevant description and

operation section in the workshop manual.

REFER to: Parking Aid (413-13 Parking Aid, Description and Operation).

Parking Aid System On-Board Self-Test

As part of the strategy of the system if any DTCs are detected, a long high-pitched tone approx 3 seconds will sound and the

parking aid switch (where fitted) indicator LED will flash 6 times at ignition on

If a fault is present when the parking aid system is activated then the parking aid switch (where fitted) status LED will

flash 6 times indicating an issue with front or rear parking aid sensors, wiring switch, parking aid control module or hard

wired sounders

The rear parking aid sounder/rear audio system will emit an error tone for approx 3 seconds at ignition on if a fault is

detected with the front or rear sensors, the switch, or if there is a controller area network (CAN) bus error

(Only applicable to vehicles fitted with front parking aid and a hard wired rear parking aid sounder). If there is a fault

with the rear parking aid sounder the error tone will come from the front parking aid sounder unit (integral with the

instrument cluster)

Audible and Visual Warnings when Parking Aid System is in Error State

Rear Parking Aid

System Fitted and

No Parking Aid

System Switch

Fitted

Rear Parking Aid System Fitted and Parking Aid System Switch Fitted

Front and Rear Parking Aid System Fitted with Parking Aid System Switch Fitted A long high-pitched

error tone will

sound at Ignition

On for approx 3

seconds

A long high-pitched error tone will sound at

ignition on for approx 3 seconds and the

parking aid switch indicator LED will flash 6

times at ignition on. Every time the parking

aid system is activated within the same

ignition cycle, parking aid switch indicator

LED will flash 6 times

A long high-pitched error tone will sound at

ignition on for approximately 3 seconds and

the parking aid switch indicator LED will flash 6

times at ignition on. Every time the parking aid

system is activated within the same ignition

cycle the parking aid switch indicator LED will

flash 6 times Inspection and Verification

CAUTIONS:

If the control module or a component is suspect and the vehicle remains under manufacturer warranty, refer to the

warranty policy and procedures manual (section B1.2), or determine if any prior approval programme is in operation, prior to

the installation of a new module/component.

Diagnosis by substitution from a donor vehicle is NOT acceptable. Substitution of control modules does not guarantee

confirmation of a fault, and may also cause additional faults in the vehicle being tested and/or the donor vehicle

Do not apply any grease based products to any parking aid system connector or pins

NOTE: Check DDW for open campaigns. Refer to the corresponding bulletins and SSMs which may be valid for the specific

customer complaint and carry out the recommendations as required.

1. Verify the customer concern

2. Visually inspect for obvious signs of mechanical or electrical damage

3. Ensure that the parking aid sensor face is clear of contamination that could affect the performance of the sensor

Visual Inspection

Mechanical Electrical

Parking aid sensor condition/damaged

Parking aid sensor installation and holder

Parking aid sensor alignment

Parking aid sensor contamination

Bumper cover(s)

Vehicle ride height

Non standard/non manufacturer approved accessories fitted

Battery

Fuse(s)

Relays

Wiring harness

Electrical connector(s)

Front parking aid sensor(s)

Rear parking aid sensor(s)

Parking aid switch and LED

Page 1851 of 3039

Mechanical Electrical Parking aid control module

Parking aid sounder

Audio system

4. If an obvious cause for an observed or reported concern is found, correct the cause (if possible) before proceeding to

the next step

5. If the cause is not visually evident, check for diagnostic trouble codes (DTCs) and refer to the DTC index

Symptom Chart

CAUTION: Do not apply any grease based products to any parking aid system connector or pins

NOTES:

Please note if this diagnosis is being carried out on a vehicle without a hard wired parking aid speaker, ensure the in car

infotainment system is fully functional and configured correctly

Parking aid sensors that are painted incorrectly and not to the manufacturer standards, will not be considered in any

warranty claim

Symptom Possible Causes Action

NOTE:

Permanent/Intermittent fault

Parking aid system not

functioning correctly. (No

DTCs displayed)

Front or rear parking aid

sensors dirty

Front or rear parking aid

sensor position incorrect

Front or rear parking aid

sensor incorrectly installed

Front or rear parking aid

sensor coupling rings not

installed/incorrectly installed

Parking aid control module or

parking aid sensor connector

not fully latched

Parking aid sensors painted

without being removed from

the bumper assembly or not

painted to the manufacturer

specification

Clean front or rear parking aid sensors

Check the front or parking aid rear sensor position

Check the front or rear parking aid sensor are

correctly installed

Check front or rear parking aid sensor coupling

rings are installed/installed correctly

Ensure all parking aid system connectors are

correctly latched

Remove parking aid sensor and ensure correctly

painted parking aid sensor is installed

- Parking aid sensors that are painted

incorrectly and not to the manufacturer

standards, will not be considered in any

warranty claim

NOTE:

Permanent/Intermittent fault

Parking aid system not

functioning correctly. (No

DTCs displayed). System

characteristics or

environmental effects

Parking aid sensors incorrectly

mounted

Incorrect vehicle ride height

Dirty parking aid sensor face.

Ice/snow covered sensor.

Debris trapped between

parking aid sensor and

parking aid sensor body.

Heavy rain or water splash

from the ground

Non standard, bumper,

exhausts/tailpipes, tow bar or

external spare wheel

mounting

Area around vehicle is not

clear of obstacles such as

channels, gutters or other

items on the ground

Exhaust gas and warm air

clouds creating ghost echoes

Vehicle not on level ground or

next to a gradient

Parking aid sensors painted

without being removed from

the bumper assembly or not

painted to the manufacturer

specification

Ensure the sensors are a tight fit in the holder and

locked. Ensure the sensors are central in the holder

and bumper and at the correct angle

Ensure vehicle ride height is within the specified

limits. Rectify as required

Clean the sensor face as required. Defrost the

sensor and dry as required. Clear any debris from

the sensor and holder as required. Water flowing

over the sensor is a system limitation. (no action

required)

Check for non standard, bumper, exhausts/tailpipe,

tow bar or external spare wheel mounting that may

be being detected by the parking aid system.

Rectify as required

Ensure the area around the vehicle is clear of any

obstacles, move the vehicle to a suitable area

before continuing diagnosis

Ensure no exhaust gas or warm area clouds are in

the area around the parking aid sensor detection

range

Ensure the vehicle is on level ground and clear of

any ramps, potholes or speed bumps, move the

vehicle to a suitable area before continuing

diagnosis

Remove parking aid sensor and ensure correctly

painted parking aid sensor is installed

- Parking aid sensors that are painted

incorrectly and not to the manufacturer

standards, will not be considered in any

warranty claim

Page 1852 of 3039

Symptom Possible Causes Action Parking aid sensors are being

returned with no faults found

or signs of water

ingress/corrosion Possible issue with sensor connectors

not latched correctly

When either no/intermittent operation has been

reported the following action should be taken

1. Using Datalogger, identify the position of the

suspect parking aid sensor within the bumper

2. Visually locate the position of the suspect

parking aid sensor. Inspect and provide details in

claim if the sensor has any sign of physical

damage

3. Remove the bumper. Disconnect the wiring at

the main harness connector. Inspect the main

harness connectors and terminals for signs of

damage, backed out pins, corrosion and water

ingress, or damage to the seals. Provide details in

claim if any of the above symptoms are present

4. Attempt to remove the harness connector from

the suspect parking aid sensor without using the

connector latch i.e. lightly pull back on ALL wires

together, ensuring the harness is held close to the

back of the connector, not elsewhere on the wiring

harness. DO NOT apply excessive force. If the

connector can be removed without using the latch,

provide details in claim if connector is loose. If the

connector is fully latched, disconnect it from the

sensor

5. Inspect and provide details in claim if the

suspect sensor harness connector has any sign of

water ingress/corrosion

6. Inspect and provide details in claim if the

suspect parking aid sensor harness connector

shows any sign that the terminals have backed-out

of the connector or for any damage to the terminal

seals. Replace/repair the harness as required and

proceed

7. Remove the suspect parking aid sensor from the

bumper. Inspect the parking aid sensor connector

for signs of water ingress/corrosion. Provide details

in claim if corrosion/water ingress is present

8. Exchange the suspect parking aid sensor with

another parking aid sensor within the bumper that

is performing correctly. Reconnect all sensors and

reconnect the bumper main harness connector.

Repeat step 1. Confirm if the original fault now

appears at the new position of the suspect parking

aid sensor, if so, proceed to step 10

9. If not, carry out the appropriate open circuit and

short circuit checks between the original suspect

parking aid sensor harness connector and the

parking aid control module

10. Refit the parking aid sensors to their original

position in the bumper

11. Reconnect the parking aid sensor to the

bumper harness connector. Reconnect main harness

connector and refit the bumper

12. Repeat Step 1. If fault is still present, replace

only the faulty sensor

PINPOINT TEST A : PARKING AID SYSTEM NOT FUNCTIONING CORRECTLY WITH NO DTCS LOGGED TEST

CONDITIONS DETAILS/RESULTS/ACTIONS A1: PERMANENT FAULT 1 When the parking aid system is activated, there is a vibration on the parking aid sensor membrane. This can be verified by touching the parking aid sensor face with a hard item such as a pencil, ball-pen, small

screwdriver, or fingernail. Ensure no damage is caused to sensor painted surface Are the parking aid sensor(s) vibrating? Yes

GO to A2. No

GO to A5. A2: SENSORS VIBRATING WITH PARKING AID FAULT 1 Clean the parking aid sensor face Parking aid system functioning correctly? Yes

No further action required

No www.JagDocs.com

Page 1853 of 3039

A3: SENSORS VIBRATING WITH PARKING AID FAULT 1 Check parking aid sensors correctly mounted. Parking aid sensor holder correctly mounted. Parking aid sensor decoupler ring fitted or fitted correctly. Parking aid sensor positioning correct. Parking aid sensor

painted without being removed from the bumper assembly or not painted to manufacturer specification.

Rectify as required Parking aid system functioning correctly? Yes

No further action required

No

GO to A4. A4: SENSORS VIBRATING WITH PARKING AID FAULT 1 Carry out speaker test. Only applicable to vehicles with rear hard wired parking aid speakers. Check the parking aid speaker wiring circuit and connector. Rectify as required. Check and install a new parking aid

speaker as required. Vehicles with audio parking aid system. Confirm audio system is functioning

correctly. Refer to the relevant section of the workshop manual Parking aid system functioning correctly Yes

No further action required A5: SENSORS NOT VIBRATING WITH PARKING AID FAULT 1 Isolate the fault to front or rear parking aid sensors Are all rear parking aid sensors vibrating? Yes

GO to A6. No

GO to A10. A6: FRONT SENSORS NOT VIBRATING WITH PARKING AID FAULT 1 Check the parking aid control module is correctly configured. Check and update the car configuration file as required Parking aid system functioning correctly? Yes

No further action required

No

GO to A7. A7: FRONT SENSORS NOT VIBRATING WITH PARKING AID FAULT 1 Check the correct parking aid control module is installed to the vehicle Parking aid system functioning correctly? Yes

No further action required

No

GO to A8. A8: FRONT SENSORS NOT VIBRATING WITH PARKING AID FAULT 1 If all 4 front parking aid sensors are not vibrating, carry out harness test on common ground, power supply. Check main parking aid harness connector to bumper harness connector. Rectify as required Parking aid system functioning correctly? Yes

No further action required

No

GO to A9. A9: FRONT SENSORS NOT VIBRATING WITH PARKING AID FAULT 1 Check and install a new parking aid control module as required. Refer to the warranty policy and procedures manual, or determine if any prior approval programme is in operation, prior to the installation

of a new module/component Parking aid system functioning correctly Yes

No further action required A10: REAR SENSORS NOT VIBRATING WITH PARKING AID FAULT 1 Check the parking aid control module is correctly configured. Check and update the car configuration file as required Parking aid system functioning correctly? Yes

No further action required

No

GO to A11. A11: REAR SENSORS NOT VIBRATING WITH PARKING AID FAULT 1 If all 4 rear parking aid sensors are not vibrating, carry out harness test on common ground, power supply. Check main parking aid harness connector to bumper harness connector. Rectify as required Parking aid system functioning correctly Yes

No further action required

No

GO to A12. A12: REAR SENSORS NOT VIBRATING WITH PARKING AID FAULT 1 Check and install a new parking aid control module as required. Refer to the warranty policy and procedures manual, or determine if any prior approval programme is in operation, prior to the installation

of a new module/component

Page 1854 of 3039

PINPOINT TEST B : PARKING AID SYSTEM NOT FUNCTIONING CORRECTLY WITH NO DTCS LOGGED TEST

CONDITIONS DETAILS/RESULTS/ACTIONS B1: PARKING AID SYSTEM GIVES WARNING SIGNAL WITHOUT OBSTACLE 1 Clean the parking aid sensor face. Check for any damage to the parking aid sensor face. Rectify as required. Snow, water or ice on sensor face. Parking aid sensor face has been repainted to the incorrect

thickness. Rectify as required Parking aid system functioning correctly? Yes

No further action required

No

GO to B2. B2: PARKING AID SYSTEM GIVES WARNING SIGNAL WITHOUT OBSTACLE 1 Ensure the vehicle ride height is within manufacturer specified limits. Rectify as required Parking aid system functioning correctly? Yes

No further action required

No

GO to B3. B3: PARKING AID SYSTEM GIVES WARNING SIGNAL WITHOUT OBSTACLE 1 Check for any non standard accessories are not fitted, such as tow bar, bike rack, body kit, modified exhaust, lighting or licence plate holder Parking aid system functioning correctly? Yes

No further action required

No

GO to B4. B4: PARKING AID SYSTEM GIVES WARNING SIGNAL WITHOUT OBSTACLE 1 Limitations or characteristics of the parking aid system such as vehicle on a gradient, exhaust gas vapour, signal reflection Parking aid system functioning correctly? Yes

No further action required

No

For a detailed description of the parking aid system, refer to the relevant description and operation

section in the workshop manual.

REFER to: Parking Aid (413-13 Parking Aid, Description and Operation). DTC Index

CAUTION: Diagnosis by substitution from a donor vehicle is NOT acceptable. Substitution of control modules does not

guarantee confirmation of a fault, and may also cause additional faults in the vehicle being tested and/or the donor vehicle.

NOTES:

If the control module is suspect and the vehicle remains under manufacturer warranty, refer to the Warranty Policy and

Procedures manual (section B1.2), or determine if any prior approval programme is in operation, prior to the installation of a

new module.

Generic scan tools may not read the codes listed, or may read only five digit codes. Match the five digits from the scan

tool to the first five digits of the seven digit code listed to identify the fault (the last two digits give additional information

read by the manufacturer approved diagnostic system).

When performing voltage or resistance tests, always use a digital multimeter (DMM) accurate to three decimal places,

and with an up-to-date calibration certificate. When testing resistance always take the resistance of the DMM leads into

account.

Check and rectify basic faults before beginning diagnostic routines involving pinpoint tests.

Inspect connectors for signs of water ingress, and pins for damage and/or corrosion.

If DTCs are recorded and, after performing the pinpoint tests, a fault is not present, an intermittent concern may be the

cause. Always check for loose connections and corroded terminals. Parking aid system functioning correctly

Yes

No further action required

Page 1856 of 3039

Parking Aid - Proximity Camera

Diagnosis and Testing

Principles of Operation Published: 30-Apr-2014

For a detailed description of the rear view camera system, refer to the relevant Description and Operation section of the

workshop manual.

Inspection and Verification

CAUTION: Diagnosis by substitution from a donor vehicle is NOT acceptable. Substitution of control modules does not

guarantee confirmation of a fault, and may also cause additional faults in the vehicle being tested and/or the donor vehicle.

NOTES:

If a control module or a component is suspect and the vehicle remains under manufacturer warranty, refer to the Warranty

Policy and Procedures manual, or determine if any prior approval programme is in operation, prior to the installation of a new

module/component.

When performing voltage or resistance tests, always use a digital multimeter accurate to three decimal places, and with

an up-to-date calibration certificate. When testing resistance always take the resistance of the digital multimeter leads into

account.

Check and rectify basic faults before beginning diagnostic routines involving pinpoint tests.

1. Verify the customer concern

2. Visually inspect for obvious signs of damage and system integrity

Visual Inspection

Mechanical Electrical

Touch screen

Rear view camera

Fuses

Wiring harnesses and connectors

Touch screen

Rear view camera

3. If an obvious cause for an observed or reported concern is found, correct the cause (if possible) before proceeding to

the next step

4. If the cause is not visually evident, verify the symptom and refer to the Symptom Chart, alternatively check for

Diagnostic Trouble Codes (DTCs) and refer to the DTC Index

5. Check DDW for open campaigns. Refer to the corresponding bulletins and SSMs which may be valid for the specific

customer complaint and carry out the recommendations as required

Symptom Chart

Symptom Possible Cause Action Rear view camera

image slow to react

System operation within

specification

NOTE: After selecting reverse, it may take up to 20 seconds for the

image to be displayed.

No further action necessary Blank screen

Rear view camera not

functioning

GO to Pinpoint Test A. Blue screen

Video in signal absent

GO to Pinpoint Test B. No tracking lines

Missing/invalid reverse

gear signal

LIN fault

Using the manufacturer approved diagnostic system, check the

central junction box for related DTCs and refer to the relevant

DTC index

GO to Pinpoint Test C.

Page 1866 of 3039

Published: 07-Aug-2014

Battery and Charging System - General Information - Battery Care

Requirements

Description and Operation

1. INTRODUCTION

This document defines the requirements for care and maintenance of batteries, and the standard of battery care at dealers and

retailers for new vehicles.

This applies to all types of 12 Volt Lead Acid Batteries used in Jaguar and Land Rover vehicles whether they are conventional

flooded technology or Absorbed Glass Mat (AGM – also known as Valve Regulated Lead Acid (VRLA)) technology and also

applies to both Primary, Secondary and Auxiliary Batteries. AGM batteries offer improved resistance to cycling as seen in stop

start applications.

In order to prevent damage to the battery and ensure a satisfactory service life, all processes detailed within this document

must be rigorously adhered to.

It is equally important therefore to note the following key points:

All new vehicles leave the factory with either a transit relay installed and/or have a transit mode programmed into the

vehicle control modules. The transit relay must be removed and the transit mode disabled (where applicable) using an

approved diagnostic system, NOT MORE THAN 72 HOURS before the customer takes delivery.

The battery can be discharged by the following mechanisms:

- Self Discharge: - A lead acid battery will very slowly discharge itself due to its own internal chemical processes

whether it is connected to a vehicle or not.

- Quiescent Discharge: - The vehicle electrical systems when connected to the battery will draw charge from the

battery.

12 Volt Lead Acid Batteries rely on internal chemical processes to create a voltage and deliver current. These processes and

the internal chemical structure of the battery can be damaged if the battery is allowed to discharge over a number of weeks /

months, or is left in a discharged state for a lengthy time period.

On vehicles with conventional ignition keys, these must not be left in the ignition lock barrel when the transit relay

has been removed, otherwise quiescent current will increase and the battery will discharge more rapidly.

For keyless vehicles, the Smart Key must be stored at least 5m (16 ft) away from the vehicle when the vehicle is

parked or stored.

AGM Batteries are fully sealed and cannot have the electrolyte level topped up.

NOTE: Dealers and retailers involved in the storage / handling of vehicles and replacement batteries have a responsibility

to ensure that only a fully charged battery may be processed through the distribution selling chain.

2. GENERAL RULES FOR BATTERY CARE

2.1 Dealer Demonstration Vehicles

Vehicles used as dealer demonstrator(s), in a showroom, must be connected to a JLR approved showroom conditioner capable

of delivering 50 Amps. This will prevent the battery from being damaged.

2.2 Software Reflash, SDD work or Ignition On related workshop activities

Due to the high electrical current demand and high depth of discharge that can occur during vehicle software re-flash activities,

SDD work or ignition on (power mode 6) related work in the workshop, vehicles that are undergoing such activities MUST have a

JLR approved power supply capable of delivering 50 Amps or more.

2.3 Extended Vehicle Rework

For any extended vehicle rework that results in consuming vehicle power, either the battery should be disconnected or a JLR

approved power supply connected.

2.4 Jump Starting New vehicles before they have been delivered to the customer

It is the dealer / retailers responsibility to make sure the battery is not allowed to discharge by following the

instructions and processes defined in this manual.

However, if circumstances dictate that a new vehicle must be jump started due to a discharged battery whilst the

vehicle is in the dealer / retailers care, the battery on this vehicle must be replaced with a new one prior to delivery

to the customer at the dealer / retailers liability.

The vehicle should also undergo investigation as to why the battery became discharged.

Do not connect the jump starting cable to the negative (-) terminal of the battery. Always connect to the recommended

earth point. As defined in the owners handbook or service documentation for that vehicle. 2.5 AGM Batteries

AGM batteries must not be charged above 14.8 Volts. Doing so will damage them.

AGM Batteries must be tested with a capable battery tester as detailed in the Equipment section (Section 5) of this

Page 1869 of 3039

5. EQUIPMENT

All equipment used must be functionally capable of meeting the compliance requirements. Please refer to the approved

equipment document (JLR 000015).

In the case of batteries fitted to a new vehicle at the dealership, battery condition should be measured using the appropriate

hand-held Midtronics tester as follows:

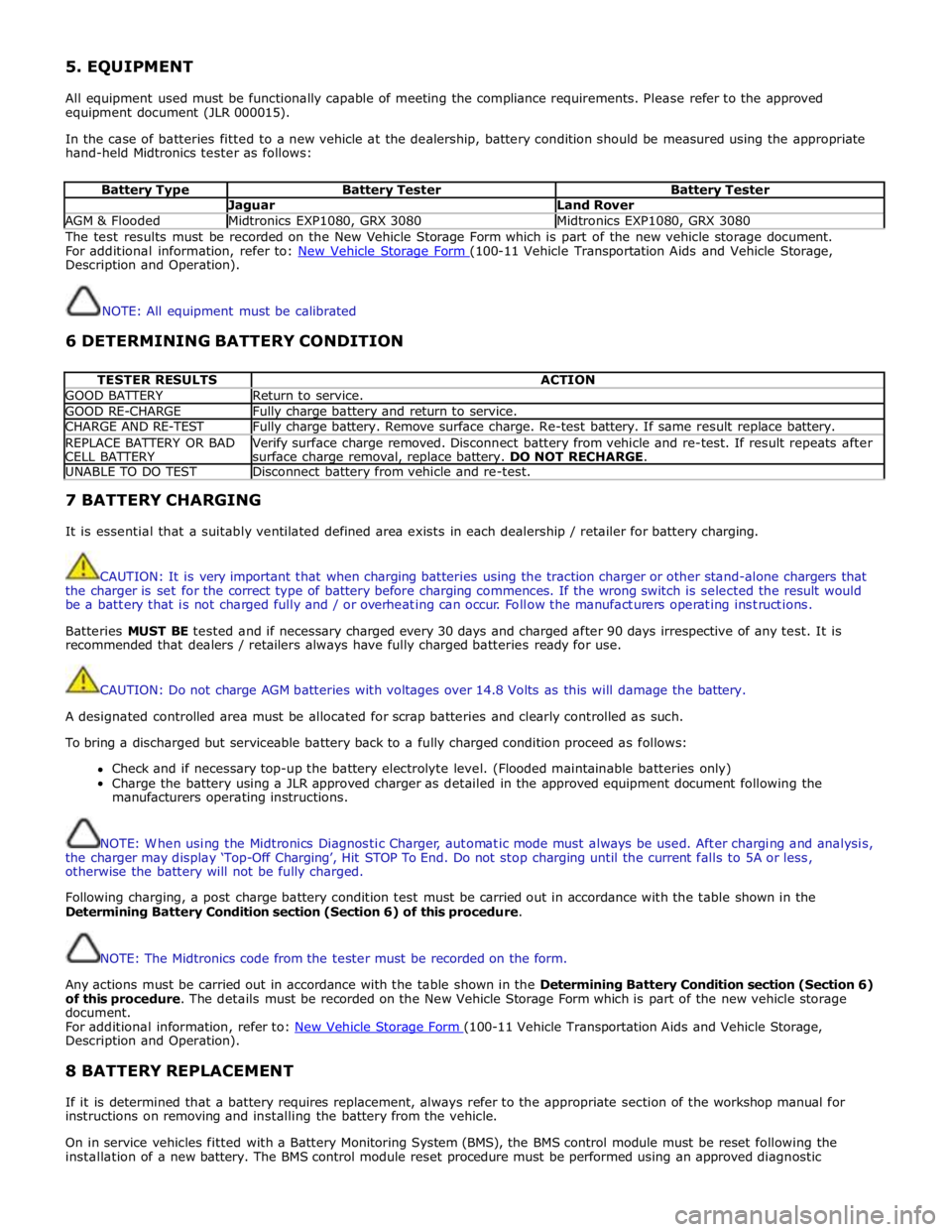

Battery Type Battery Tester Battery Tester Jaguar Land Rover AGM & Flooded Midtronics EXP1080, GRX 3080 Midtronics EXP1080, GRX 3080 The test results must be recorded on the New Vehicle Storage Form which is part of the new vehicle storage document.

For additional information, refer to: New Vehicle Storage Form (100-11 Vehicle Transportation Aids and Vehicle Storage, Description and Operation).

NOTE: All equipment must be calibrated

6 DETERMINING BATTERY CONDITION

TESTER RESULTS ACTION GOOD BATTERY Return to service. GOOD RE-CHARGE Fully charge battery and return to service. CHARGE AND RE-TEST Fully charge battery. Remove surface charge. Re-test battery. If same result replace battery. REPLACE BATTERY OR BAD

CELL BATTERY Verify surface charge removed. Disconnect battery from vehicle and re-test. If result repeats after

surface charge removal, replace battery. DO NOT RECHARGE. UNABLE TO DO TEST Disconnect battery from vehicle and re-test. 7 BATTERY CHARGING

It is essential that a suitably ventilated defined area exists in each dealership / retailer for battery charging.

CAUTION: It is very important that when charging batteries using the traction charger or other stand-alone chargers that

the charger is set for the correct type of battery before charging commences. If the wrong switch is selected the result would

be a battery that is not charged fully and / or overheating can occur. Follow the manufacturers operating instructions.

Batteries MUST BE tested and if necessary charged every 30 days and charged after 90 days irrespective of any test. It is

recommended that dealers / retailers always have fully charged batteries ready for use.

CAUTION: Do not charge AGM batteries with voltages over 14.8 Volts as this will damage the battery.

A designated controlled area must be allocated for scrap batteries and clearly controlled as such.

To bring a discharged but serviceable battery back to a fully charged condition proceed as follows:

Check and if necessary top-up the battery electrolyte level. (Flooded maintainable batteries only)

Charge the battery using a JLR approved charger as detailed in the approved equipment document following the

manufacturers operating instructions.

NOTE: When using the Midtronics Diagnostic Charger, automatic mode must always be used. After charging and analysis,

the charger may display ‘Top-Off Charging’, Hit STOP To End. Do not stop charging until the current falls to 5A or less,

otherwise the battery will not be fully charged.

Following charging, a post charge battery condition test must be carried out in accordance with the table shown in the

Determining Battery Condition section (Section 6) of this procedure.

NOTE: The Midtronics code from the tester must be recorded on the form.

Any actions must be carried out in accordance with the table shown in the Determining Battery Condition section (Section 6)

of this procedure. The details must be recorded on the New Vehicle Storage Form which is part of the new vehicle storage

document.

For additional information, refer to: New Vehicle Storage Form (100-11 Vehicle Transportation Aids and Vehicle Storage, Description and Operation).

8 BATTERY REPLACEMENT

If it is determined that a battery requires replacement, always refer to the appropriate section of the workshop manual for

instructions on removing and installing the battery from the vehicle.

On in service vehicles fitted with a Battery Monitoring System (BMS), the BMS control module must be reset following the

installation of a new battery. The BMS control module reset procedure must be performed using an approved diagnostic

Page 1876 of 3039

1 EJB (engine junction box) 2 CJB (central junction box) 3 BJB (battery junction box) 4 RJB (rear junction box) 5 BMS (battery monitoring system) 6 Battery 7 ECM (engine control module) 8 Generator

Page 1878 of 3039

Battery, Mounting and Cables - Battery and Cables - Overview

Description and Operation

OVERVIEW

Single Battery Vehicles Published: 18-Jun-2014

Mounted on the battery negative terminal is a BMS (battery monitoring system) module. The BMS module is integral with the

battery negative cable and is controlled by the ECM (engine control module).

CAUTION: To avoid damaging the battery monitoring system module, always use a suitable body ground point rather than

the battery negative terminal when connecting a slave power supply to the vehicle.

If a new battery is fitted to the vehicle, the BMS module will require re-calibrating using the Jaguar approved diagnostic

system.

Fitted on the battery positive terminal is a transit relay. The transit relay must be removed from the vehicle during the

Pre-Delivery Inspection (PDI). For additional information, refer to the PDI Manual.

The vehicle battery provides power to the BJB (battery junction box). The BJB contains 3 megafuses, delivering power to the RJB (rear junction box), the CJB (central junction box) and the EJB (engine junction box). In addition to containing fuses and

relays, the RJB and RJB contain software to control a number of vehicle systems. These functions are covered in the appropriate sections of this manual.

Dual Battery System Vehicles - TD42.2L Engine Variants Only

Two batteries are fitted to accommodate the dual battery system used for the Stop/Start system.

A primary battery is located in the luggage compartment floor in a plastic molded tray and secured with a metal rod. The

secondary battery is located in the DBJB (dual battery junction box).

The primary battery is a 90Ahr, 850A CCA AGM Battery.

The secondary battery is a 14Ahr, 200A CCA Absorbed Glass Mat (AGM) Battery.

A BMS (battery monitoring system) control module is mounted on the primary battery negative terminal. The BMS control

module is integral with the battery negative cable and is controlled by the GWM (gateway module).

CAUTION: To avoid damaging the BMS control module, always use the ground (negative (-)) terminal stud point on the

right side top mount. Never connect directly to the primary battery negative terminal when connecting a slave power supply to

the vehicle, the BMS control module can be damaged.

If a new primary battery is fitted to the vehicle, the BMS control module will require re-calibrating using a Jaguar approved

diagnostic system.

When the vehicle leaves the factory, a transit relay is fitted to the battery positive terminal. The transit relay is connected to

the CJB which limits the electrical functions to essential items only, to reduce loads on the primary battery. The transit relay must be removed from the vehicle during the PDI (Pre-Delivery Inspection). For additional information, refer to the PDI.

The primary battery provides power to the BJB. The BJB contains three megafuses, delivering power to the RJB, the EJB and the starter motor and generator. In addition to containing fuses and relays, the RJB and CJB contain software to control a number of vehicle systems. These functions are covered in the appropriate sections of this manual.

A jump start terminal is located adjacent to the EJB. A cover protects the terminal when not in use. If jump starting is

required, the cover must be removed and the positive (+) jump lead attached securely. The negative (-) jump lead is attached

to a stud located on the right side top mount in the engine compartment. The cover must be fitted to the positive terminal

when not in use.

Dual Battery System

The dual battery system is used on vehicles with the stop/start system. The dual battery system prevents the vehicle

electrical systems being subjected to undesirably low voltages during repeated engine restarts. If the electrical systems are

subject to low voltages the customer may notice degraded performance of components and systems and incorrect fault DTC

(diagnostic trouble code)'s may be stored.

The dual battery system isolates all electrical components and systems sensitive to low supply voltage from the primary

battery while an engine start is in progress, and supplies them from the secondary battery. Without the dual battery system,

the electrical power required by the TSS (Tandem Solenoid Starter) motor to crank the engine for each start would cause a

voltage drop across the entire vehicle electrical network, and cause control modules to function incorrectly and in some cases

reset and/or record DTC's.

If the dual battery system is unable to prevent electrical supplies to the vehicle systems being subjected to low voltage levels

during engine stop/start operations, due to the condition of the primary and/or secondary batteries or a system fault, the

stop/start feature is disabled.