air filter JAGUAR XFR 2010 1.G Owner's Guide

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 2010, Model line: XFR, Model: JAGUAR XFR 2010 1.GPages: 3039, PDF Size: 58.49 MB

Page 1188 of 3039

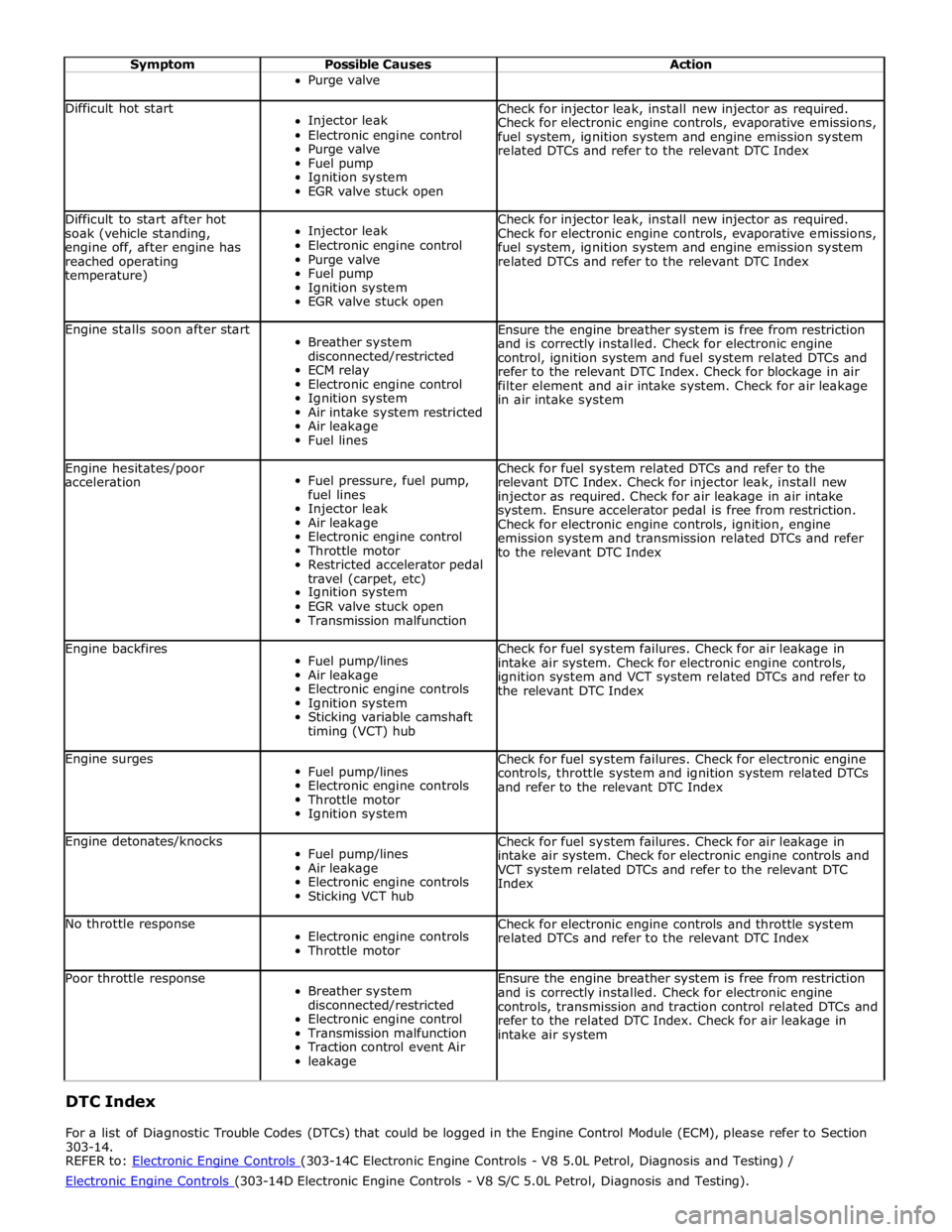

Symptom Possible Causes Action Purge valve

Difficult hot start

Injector leak

Electronic engine control

Purge valve

Fuel pump

Ignition system

EGR valve stuck open Check for injector leak, install new injector as required.

Check for electronic engine controls, evaporative emissions,

fuel system, ignition system and engine emission system

related DTCs and refer to the relevant DTC Index Difficult to start after hot

soak (vehicle standing,

engine off, after engine has

reached operating

temperature)

Injector leak

Electronic engine control

Purge valve

Fuel pump

Ignition system

EGR valve stuck open Check for injector leak, install new injector as required.

Check for electronic engine controls, evaporative emissions,

fuel system, ignition system and engine emission system

related DTCs and refer to the relevant DTC Index Engine stalls soon after start

Breather system

disconnected/restricted

ECM relay

Electronic engine control

Ignition system

Air intake system restricted

Air leakage

Fuel lines Ensure the engine breather system is free from restriction

and is correctly installed. Check for electronic engine

control, ignition system and fuel system related DTCs and

refer to the relevant DTC Index. Check for blockage in air

filter element and air intake system. Check for air leakage

in air intake system Engine hesitates/poor

acceleration

Fuel pressure, fuel pump,

fuel lines

Injector leak

Air leakage

Electronic engine control

Throttle motor

Restricted accelerator pedal

travel (carpet, etc)

Ignition system

EGR valve stuck open

Transmission malfunction Check for fuel system related DTCs and refer to the

relevant DTC Index. Check for injector leak, install new

injector as required. Check for air leakage in air intake

system. Ensure accelerator pedal is free from restriction.

Check for electronic engine controls, ignition, engine

emission system and transmission related DTCs and refer

to the relevant DTC Index Engine backfires

Fuel pump/lines

Air leakage

Electronic engine controls

Ignition system

Sticking variable camshaft

timing (VCT) hub Check for fuel system failures. Check for air leakage in

intake air system. Check for electronic engine controls,

ignition system and VCT system related DTCs and refer to

the relevant DTC Index Engine surges

Fuel pump/lines

Electronic engine controls

Throttle motor

Ignition system Check for fuel system failures. Check for electronic engine

controls, throttle system and ignition system related DTCs

and refer to the relevant DTC Index Engine detonates/knocks

Fuel pump/lines

Air leakage

Electronic engine controls

Sticking VCT hub Check for fuel system failures. Check for air leakage in

intake air system. Check for electronic engine controls and

VCT system related DTCs and refer to the relevant DTC

Index No throttle response

Electronic engine controls

Throttle motor Check for electronic engine controls and throttle system

related DTCs and refer to the relevant DTC Index Poor throttle response

Breather system

disconnected/restricted

Electronic engine control

Transmission malfunction

Traction control event Air

leakage Ensure the engine breather system is free from restriction

and is correctly installed. Check for electronic engine

controls, transmission and traction control related DTCs and

refer to the related DTC Index. Check for air leakage in

intake air system DTC Index

For a list of Diagnostic Trouble Codes (DTCs) that could be logged in the Engine Control Module (ECM), please refer to Section

303-14.

REFER to: Electronic Engine Controls (303-14C Electronic Engine Controls - V8 5.0L Petrol, Diagnosis and Testing) / Electronic Engine Controls (303-14D Electronic Engine Controls - V8 S/C 5.0L Petrol, Diagnosis and Testing).

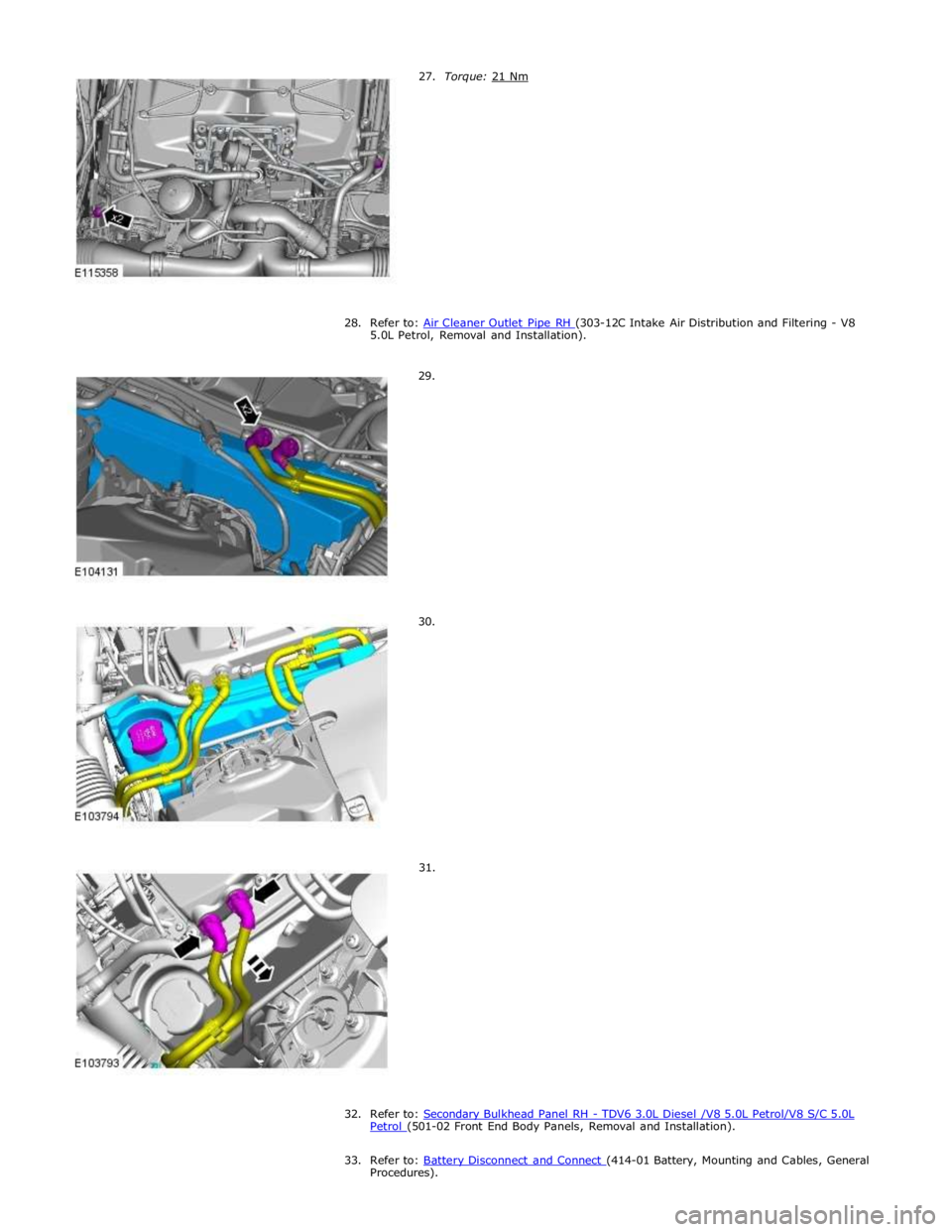

Page 1193 of 3039

9. CAUTION: Be prepared to collect escaping fluids.

10.

Refer to: Air Cleaner Outlet Pipe RH (303-12C Intake Air Distribution and Filtering - V8 5.0L Petrol, Removal and Installation).

12.

11.

CAUTIONS:

Be

prepared to

collect

escaping

fluids.

Make

sure that all

openings

are sealed.

Use new

blanking

caps.

Page 1200 of 3039

14.

15. NOTES:

Lubricate

the union

threads with

clean engine

oil.

Do not

tighten at

this stage.

Remove and

discard the

blanking

caps.

Torque:

union 21 Nm bolts 8 Nm

16.

Torque: 21 Nm

17.

Refer to: Air Cleaner Outlet Pipe RH (303-12C Intake Air Distribution and Filtering - V8 5.0L Petrol, Removal and Installation).

Page 1203 of 3039

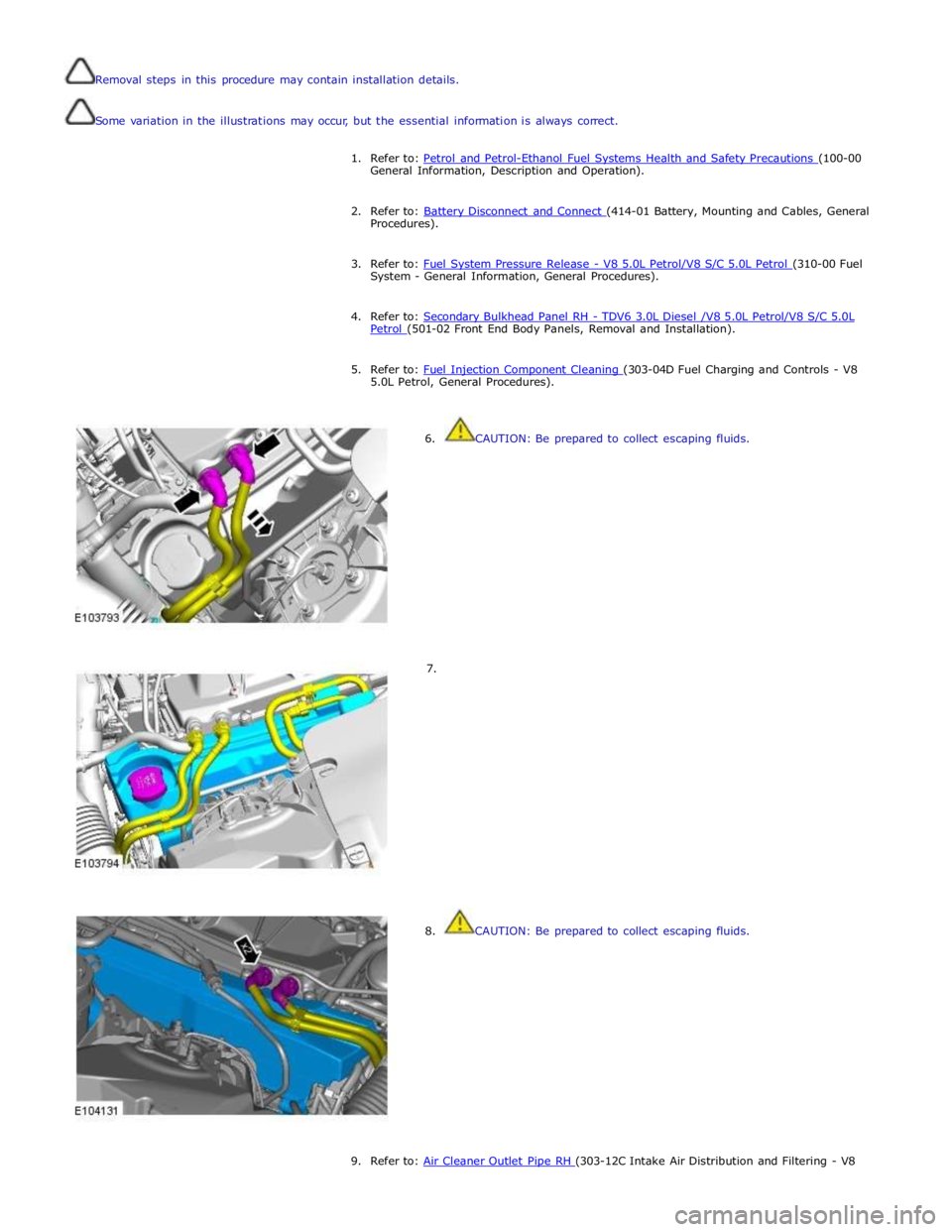

Removal steps in this procedure may contain installation details.

Some variation in the illustrations may occur, but the essential information is always correct.

1. Refer to: Petrol and Petrol-Ethanol Fuel Systems Health and Safety Precautions (100-00 General Information, Description and Operation).

2. Refer to: Battery Disconnect and Connect (414-01 Battery, Mounting and Cables, General Procedures).

3. Refer to: Fuel System Pressure Release - V8 5.0L Petrol/V8 S/C 5.0L Petrol (310-00 Fuel System - General Information, General Procedures).

4. Refer to: Secondary Bulkhead Panel RH - TDV6 3.0L Diesel /V8 5.0L Petrol/V8 S/C 5.0L Petrol (501-02 Front End Body Panels, Removal and Installation).

5. Refer to: Fuel Injection Component Cleaning (303-04D Fuel Charging and Controls - V8 5.0L Petrol, General Procedures).

6. CAUTION: Be prepared to collect escaping fluids.

7.

8. CAUTION: Be prepared to collect escaping fluids.

9. Refer to: Air Cleaner Outlet Pipe RH (303-12C Intake Air Distribution and Filtering - V8

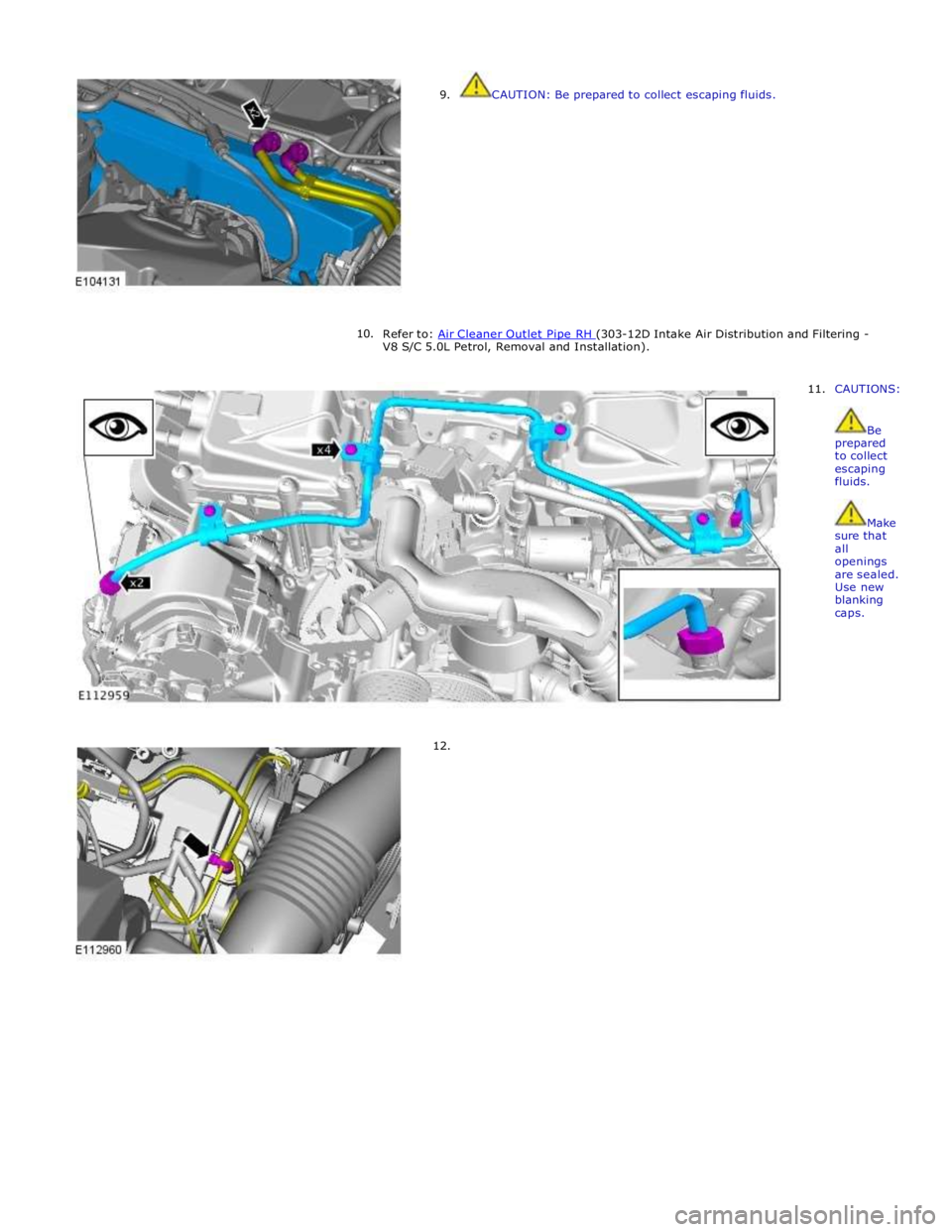

Page 1216 of 3039

28. Refer to: Air Cleaner Outlet Pipe RH (303-12C Intake Air Distribution and Filtering - V8 5.0L Petrol, Removal and Installation).

29.

30.

31.

32. Refer to: Secondary Bulkhead Panel RH - TDV6 3.0L Diesel /V8 5.0L Petrol/V8 S/C 5.0L Petrol (501-02 Front End Body Panels, Removal and Installation).

33. Refer to: Battery Disconnect and Connect (414-01 Battery, Mounting and Cables, General Procedures).

Page 1218 of 3039

9. CAUTION: Be prepared to collect escaping fluids.

10. Refer to: Air Cleaner Outlet Pipe RH (303-12D Intake Air Distribution and Filtering - V8 S/C 5.0L Petrol, Removal and Installation).

12.

11.

CAUTIONS:

Be

prepared

to collect

escaping

fluids.

Make

sure that

all

openings

are sealed.

Use new

blanking

caps.

Page 1227 of 3039

21. NOTES:

Lubricate

the

union

threads

with

clean

engine

oil.

Do

not tighten

at this

stage.

Remove

and

discard

the

blanking

caps.

22. Torque: Unions 21 Nm Bolts 8 Nm

23. Refer to: Air Cleaner Outlet Pipe RH (303-12D Intake Air Distribution and Filtering - V8 S/C 5.0L Petrol, Removal and Installation).

24. www.JagDocs.com

Page 1230 of 3039

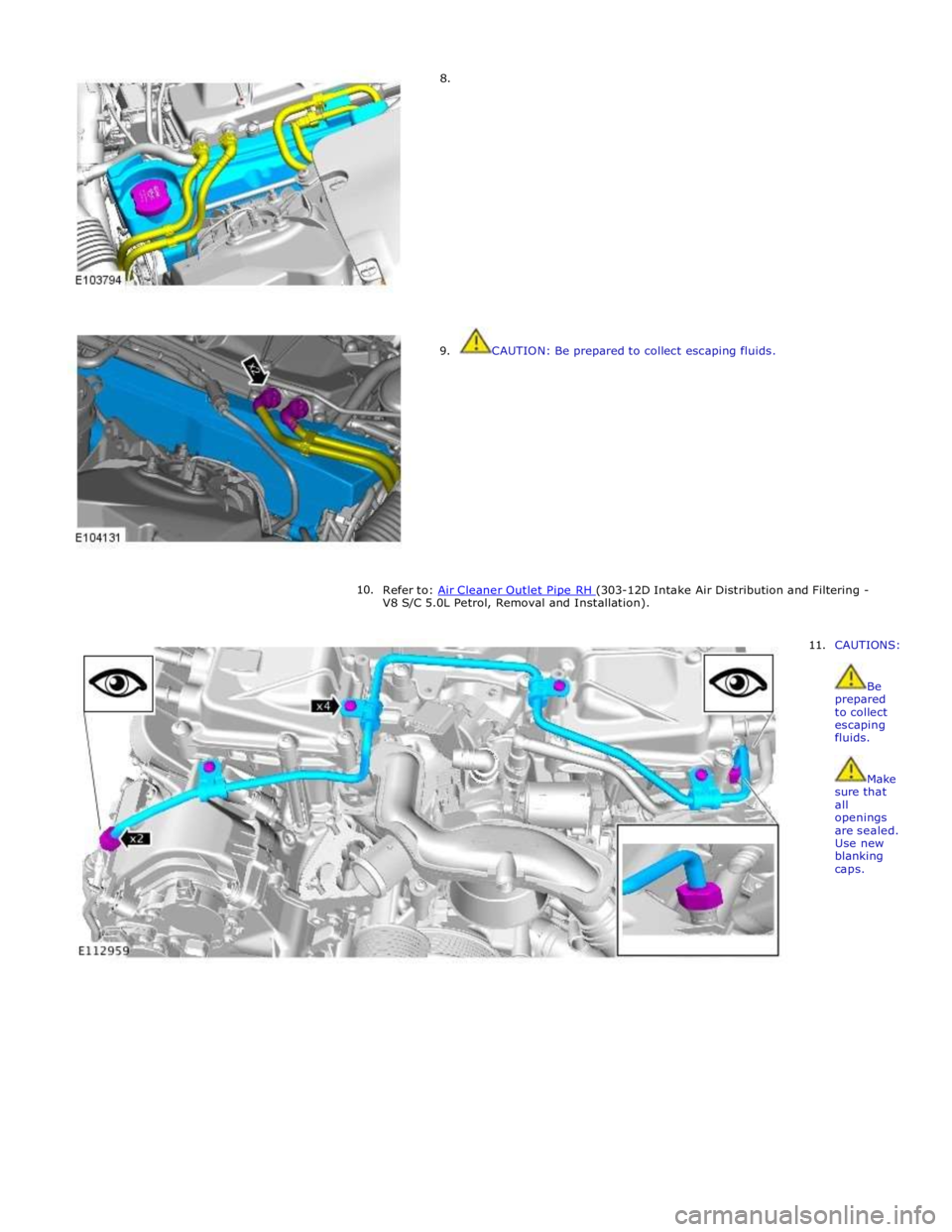

8.

9. CAUTION: Be prepared to collect escaping fluids.

10. Refer to: Air Cleaner Outlet Pipe RH (303-12D Intake Air Distribution and Filtering - V8 S/C 5.0L Petrol, Removal and Installation).

11. CAUTIONS:

Be

prepared

to collect

escaping

fluids.

Make

sure that

all

openings

are sealed.

Use new

blanking

caps.

Page 1241 of 3039

Bolts 8 Nm

25. Refer to: Air Cleaner Outlet Pipe RH (303-12D Intake Air Distribution and Filtering - V8 S/C 5.0L Petrol, Removal and Installation).

26.

27. 28.

29. Refer to: Engine Cover - V8 5.0L Petrol/V8 S/C 5.0L Petrol (501-05 Interior Trim and

Page 1252 of 3039

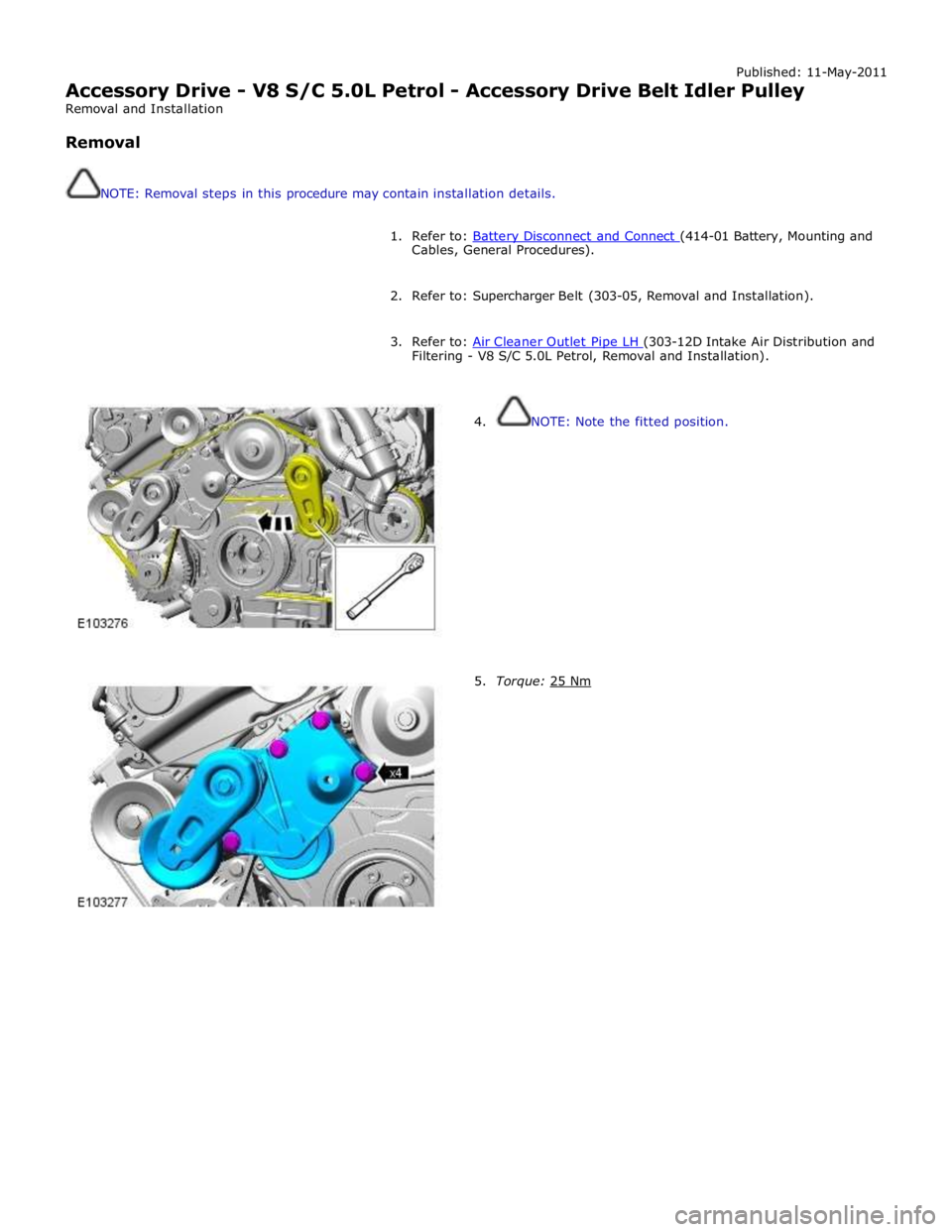

Published: 11-May-2011

Accessory Drive - V8 S/C 5.0L Petrol - Accessory Drive Belt Idler Pulley

Removal and Installation

Removal

NOTE: Removal steps in this procedure may contain installation details.

1. Refer to: Battery Disconnect and Connect (414-01 Battery, Mounting and Cables, General Procedures).

2. Refer to: Supercharger Belt (303-05, Removal and Installation).

3. Refer to: Air Cleaner Outlet Pipe LH (303-12D Intake Air Distribution and Filtering - V8 S/C 5.0L Petrol, Removal and Installation).

4. NOTE: Note the fitted position.

5. Torque: 25 Nm