clock JAGUAR XFR 2010 1.G Service Manual

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 2010, Model line: XFR, Model: JAGUAR XFR 2010 1.GPages: 3039, PDF Size: 58.49 MB

Page 1639 of 3039

Published: 11-May-2011

Speed Control - V8 5.0L Petrol/V8 S/C 5.0L Petrol - Speed Control - Overview

Description and Operation

OVERVIEW

Speed Control

The speed control system is integrated with the engine management system and uses fueling intervention to automatically

maintain a set vehicle speed. Once engaged, the system can also be used to accelerate the vehicle without using the

accelerator pedal.

The speed control system comprises the following components:

On/Off/Suspend switch

'+' and '-' (set/accelerate and decelerate) steering wheel switches

Resume switch

Clock spring

Speed control warning indicator.

Adaptive Speed Control

The adaptive speed control system uses a forward looking radar sensor to scan the road ahead, looking for objects that are

moving at a different rate to itself. When a target is identified the adaptive speed control system will monitor the time gap

between it and the target vehicle. When that gap falls below a set driver selected level the adaptive speed control system will

intervene slowing the vehicle by backing off the throttle and/ or applying the brakes, until the correct gap is attained.

The adaptive speed control system comprises the following components:

Adaptive speed control sensor

Adaptive speed control module

Steering wheel control switches

ECM (engine control module)

Electric throttle actuator

ABS (anti-lock brake system) module and pump

Adaptive speed control warning indicator (in the instrument cluster).

Page 1641 of 3039

6 Clockspring 7 APP (accelerator pedal position) sensor 8 Electric throttle actuator 9 Brake lamp/brake test switch 10 Adaptive speed control radar sensor 11 Diagnostic socket 12 Instrument cluster 13 TCM (transmission control module) 14 Adaptive speed control module

SPEED CONTROL System Operation

The speed control system uses inputs from the brake lamp/brake test switch, the APP sensor, the ECM and the ABS module.

Speed control is operated by the driver using only the steering wheel switches. When speed control is active, the ECM regulates the PWM (pulse width modulation) signals to the fuel injectors to adjust the fuel supply as required to maintain the

set speed.

During speed control operation, the ECM controls vehicle speed by adjusting fuel injection duration and timing. When the accelerator pedal is pressed with speed control active, the ECM outputs a calculated throttle angle signal in place of the actual throttle angle signals produced by the APP sensor. The calculated throttle angle is derived from fuel demand.

The minimum set speed for speed control is 18 mph (30 (km/h). Speed control is automatically suspended if the following

conditions apply:

Vehicle speed falls below 18 mph (30 km/h)

The brake pedal is pressed

The cancel button is pressed

Neutral, park or reverse gear is selected

The difference between actual speed and the set speed is too great

If the engine speed becomes near to the red line (maximum engine speed)

If the accelerator pedal is used to accelerate beyond the set speed for too long.

ADAPTIVE SPEED CONTROL

The adaptive speed control system comprises the following components:

Adaptive speed control sensor

Adaptive speed control module

Steering wheel control switches

ECM

Electric throttle actuator

ABS module and pump Adaptive speed control warning indicator.

The adaptive speed control system uses a forward looking radar sensor to scan the road ahead, looking for objects that are

moving at a different rate to itself. When a target is identified the adaptive speed control system will monitor the time gap

between it and the target vehicle. When that gap falls below a set driver selected level the adaptive speed control system will

intervene slowing the vehicle by backing off the throttle and/ or applying the brakes, until the correct gap is attained. The

driver can chose between four gap settings, 1, 1.4, 1.8 and 2.2 seconds.

The system will detect but not react to the following:

Vehicles in the oncoming lane

Stationary vehicles

Pedestrians

Vehicles not in the same lane.

Adaptive speed control is active when the vehicle is moving. Adaptive Speed Control only functions when a set speed is

entered in normal speed control mode. The adaptive speed control system only intervenes with the set speed when it detects

a target vehicle, and then only if the minimum time gap is breached.

It is important to note that the system is intended for use in limited driving situations, does not remove control and

responsibility from the driver, and at all times can be quickly overridden. The adaptive speed control system is not a collision

warning system and will not react to stationary objects. The system does not operate below a minimum speed of

approximately 30 km/h (20 mph) since it is unsuitable for use in cities or congested traffic. The system is best suited to main

roads/ highways with gradual bends.

The ECM, throttle body and throttle control are unchanged from those used for non adaptive speed control variants.

The adaptive speed control system is based on the use of a front mounted radar sensor. The sensor transmits a 1.5° wide

beam forward of the vehicle and detects the returning signals reflected off other vehicles and objects ahead.

The 1.5° wide radar beam is mechanically scanned at a rate of 10 sweeps/second across a total arc of 15° centered on the

Page 1644 of 3039

1 Set speed adjustment switch 2 Time gap switch (only on vehicles with adaptive speed control fitted) 3 Cancel switch 4 Resume switch The speed control switches are located on the RH (right-hand)side of the steering wheel. The switches are connected via fly

leads to the clock spring. The speed control switches are resistive ladder type switches which vary the resistance of a 5 volt

signal sent to them. The signal is returned along a LIN bus to the instrument cluster. The instrument cluster routes the control signals to the ECM on the medium speed CAN

Speed control is engaged by rotating the speed adjustment switch to the + or - positions. Once engaged the speed can be

varied by the speed adjustment switches. Each press of the speed adjustment switch will increase or decrease the set speed

in steps of 1 mph (2 kph).

ADAPTIVE SPEED CONTROL MODULE

The adaptive speed control module, located on the drivers side at the bottom of the 'A' post. The control module is connected

to the other vehicle systems via the high speed CAN bus. Signals from the adaptive speed control forward looking radar sensor are received on a dedicated CAN bus between the two modules.

ADAPTIVE SPEED CONTROL RADAR SENSOR

The adaptive speed control radar sensor is located in the front bumper, on the RH side above the radiator grill behind the bumper cover. The sensor is connected to the adaptive speed control, module via a private CAN bus. If the unit is replaced in service the unit must be re-aligned vertically. Horizontal alignment is achieved by putting the sensor in service mode using an

approved Jaguar diagnostic system.

Page 1784 of 3039

7 Instrument cluster 8 Steering column motor 9 High speed CAN bus connection to other vehicle systems 10 Engine oil pressure switch 11 Steering column adjustment switch 12 Brake fluid level switch 13 LH (left-hand) steering column multifunction switch 14 Start control module 15 Clockspring 16 RH (right-hand) steering column multifunction switch 17 Engine coolant level sensor 18 Auxiliary lighting switch

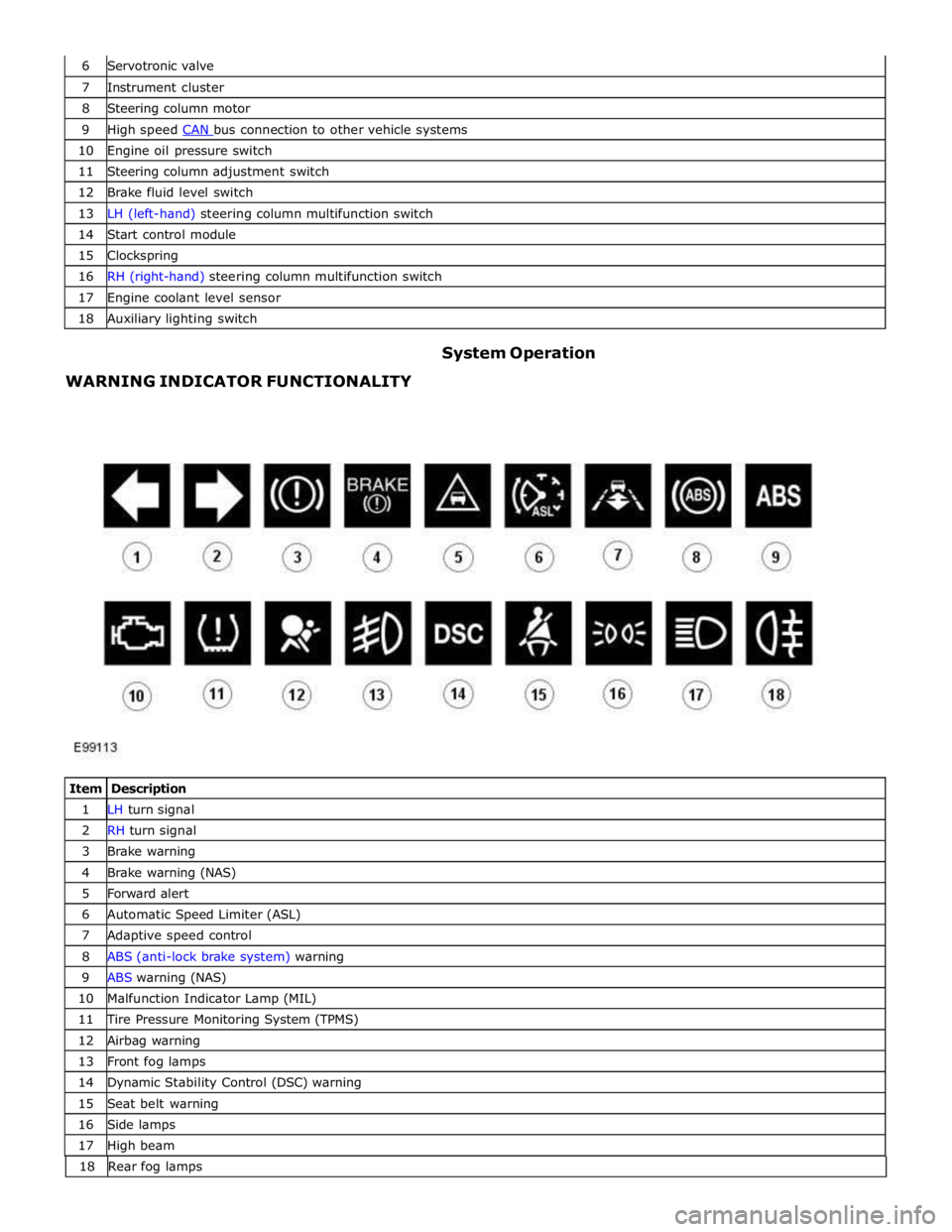

WARNING INDICATOR FUNCTIONALITY System Operation

Item Description 1 LH turn signal 2 RH turn signal 3 Brake warning 4 Brake warning (NAS) 5 Forward alert 6 Automatic Speed Limiter (ASL) 7 Adaptive speed control 8 ABS (anti-lock brake system) warning 9 ABS warning (NAS) 10 Malfunction Indicator Lamp (MIL) 11 Tire Pressure Monitoring System (TPMS) 12 Airbag warning 13 Front fog lamps 14 Dynamic Stability Control (DSC) warning 15 Seat belt warning 16 Side lamps 17 High beam 18 Rearfoglamps

Page 1800 of 3039

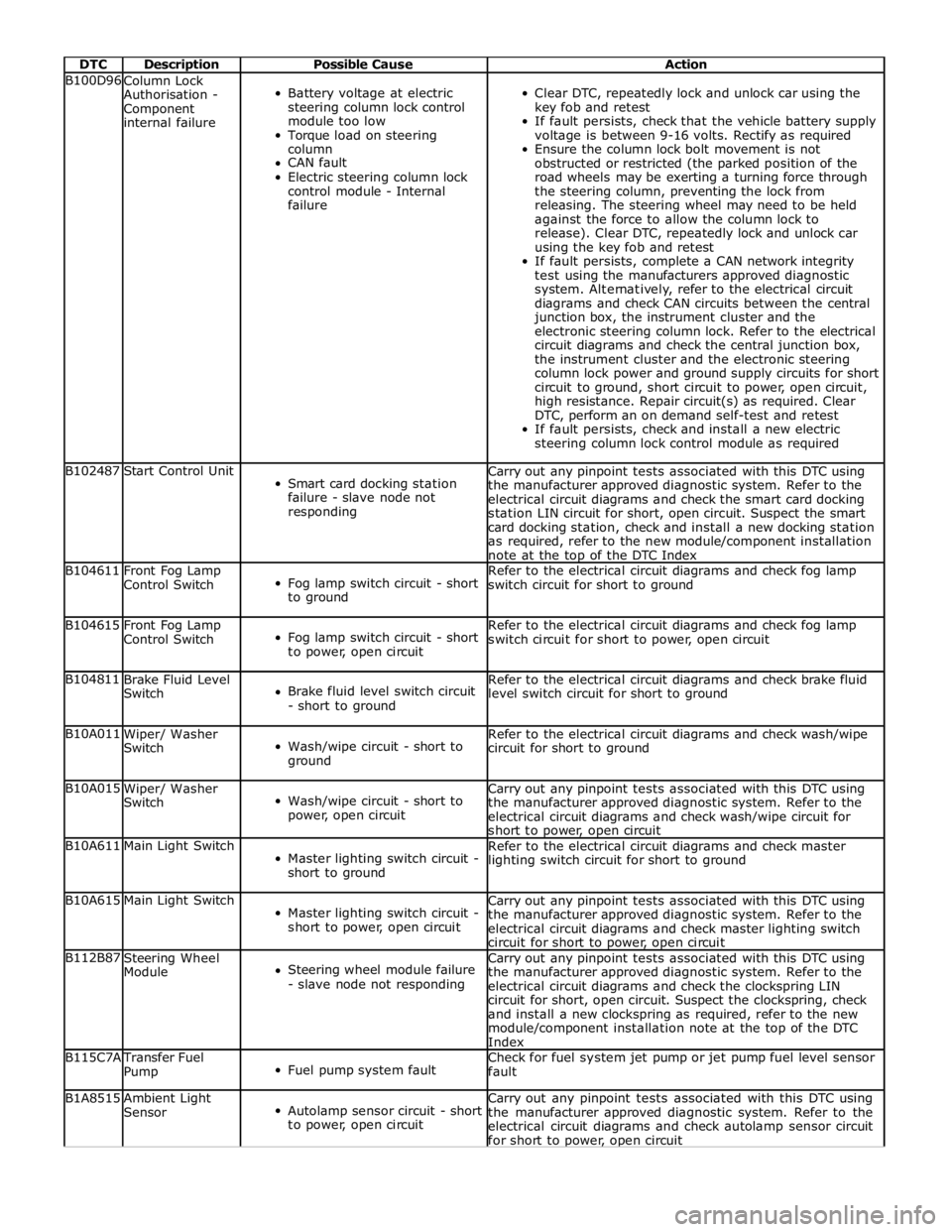

DTC Description Possible Cause Action B100D96

Column Lock

Authorisation -

Component

internal failure

Battery voltage at electric

steering column lock control

module too low

Torque load on steering

column

CAN fault

Electric steering column lock

control module - Internal

failure

Clear DTC, repeatedly lock and unlock car using the

key fob and retest

If fault persists, check that the vehicle battery supply

voltage is between 9-16 volts. Rectify as required

Ensure the column lock bolt movement is not

obstructed or restricted (the parked position of the

road wheels may be exerting a turning force through

the steering column, preventing the lock from

releasing. The steering wheel may need to be held

against the force to allow the column lock to

release). Clear DTC, repeatedly lock and unlock car

using the key fob and retest

If fault persists, complete a CAN network integrity

test using the manufacturers approved diagnostic

system. Alternatively, refer to the electrical circuit

diagrams and check CAN circuits between the central

junction box, the instrument cluster and the

electronic steering column lock. Refer to the electrical

circuit diagrams and check the central junction box,

the instrument cluster and the electronic steering

column lock power and ground supply circuits for short

circuit to ground, short circuit to power, open circuit,

high resistance. Repair circuit(s) as required. Clear

DTC, perform an on demand self-test and retest

If fault persists, check and install a new electric

steering column lock control module as required B102487 Start Control Unit

Smart card docking station

failure - slave node not

responding Carry out any pinpoint tests associated with this DTC using

the manufacturer approved diagnostic system. Refer to the

electrical circuit diagrams and check the smart card docking

station LIN circuit for short, open circuit. Suspect the smart

card docking station, check and install a new docking station

as required, refer to the new module/component installation

note at the top of the DTC Index B104611

Front Fog Lamp

Control Switch

Fog lamp switch circuit - short

to ground Refer to the electrical circuit diagrams and check fog lamp

switch circuit for short to ground B104615

Front Fog Lamp

Control Switch

Fog lamp switch circuit - short

to power, open circuit Refer to the electrical circuit diagrams and check fog lamp

switch circuit for short to power, open circuit B104811

Brake Fluid Level

Switch

Brake fluid level switch circuit

- short to ground Refer to the electrical circuit diagrams and check brake fluid

level switch circuit for short to ground B10A011

Wiper/ Washer

Switch

Wash/wipe circuit - short to

ground Refer to the electrical circuit diagrams and check wash/wipe

circuit for short to ground B10A015

Wiper/ Washer

Switch

Wash/wipe circuit - short to

power, open circuit Carry out any pinpoint tests associated with this DTC using

the manufacturer approved diagnostic system. Refer to the

electrical circuit diagrams and check wash/wipe circuit for

short to power, open circuit B10A611 Main Light Switch

Master lighting switch circuit -

short to ground Refer to the electrical circuit diagrams and check master

lighting switch circuit for short to ground B10A615 Main Light Switch

Master lighting switch circuit -

short to power, open circuit Carry out any pinpoint tests associated with this DTC using

the manufacturer approved diagnostic system. Refer to the

electrical circuit diagrams and check master lighting switch

circuit for short to power, open circuit B112B87

Steering Wheel

Module

Steering wheel module failure

- slave node not responding Carry out any pinpoint tests associated with this DTC using

the manufacturer approved diagnostic system. Refer to the

electrical circuit diagrams and check the clockspring LIN

circuit for short, open circuit. Suspect the clockspring, check

and install a new clockspring as required, refer to the new

module/component installation note at the top of the DTC

Index B115C7A

Transfer Fuel

Pump

Fuel pump system fault Check for fuel system jet pump or jet pump fuel level sensor

fault B1A8515

Ambient Light

Sensor

Autolamp sensor circuit - short

to power, open circuit Carry out any pinpoint tests associated with this DTC using

the manufacturer approved diagnostic system. Refer to the

electrical circuit diagrams and check autolamp sensor circuit

for short to power, open circuit

Page 1820 of 3039

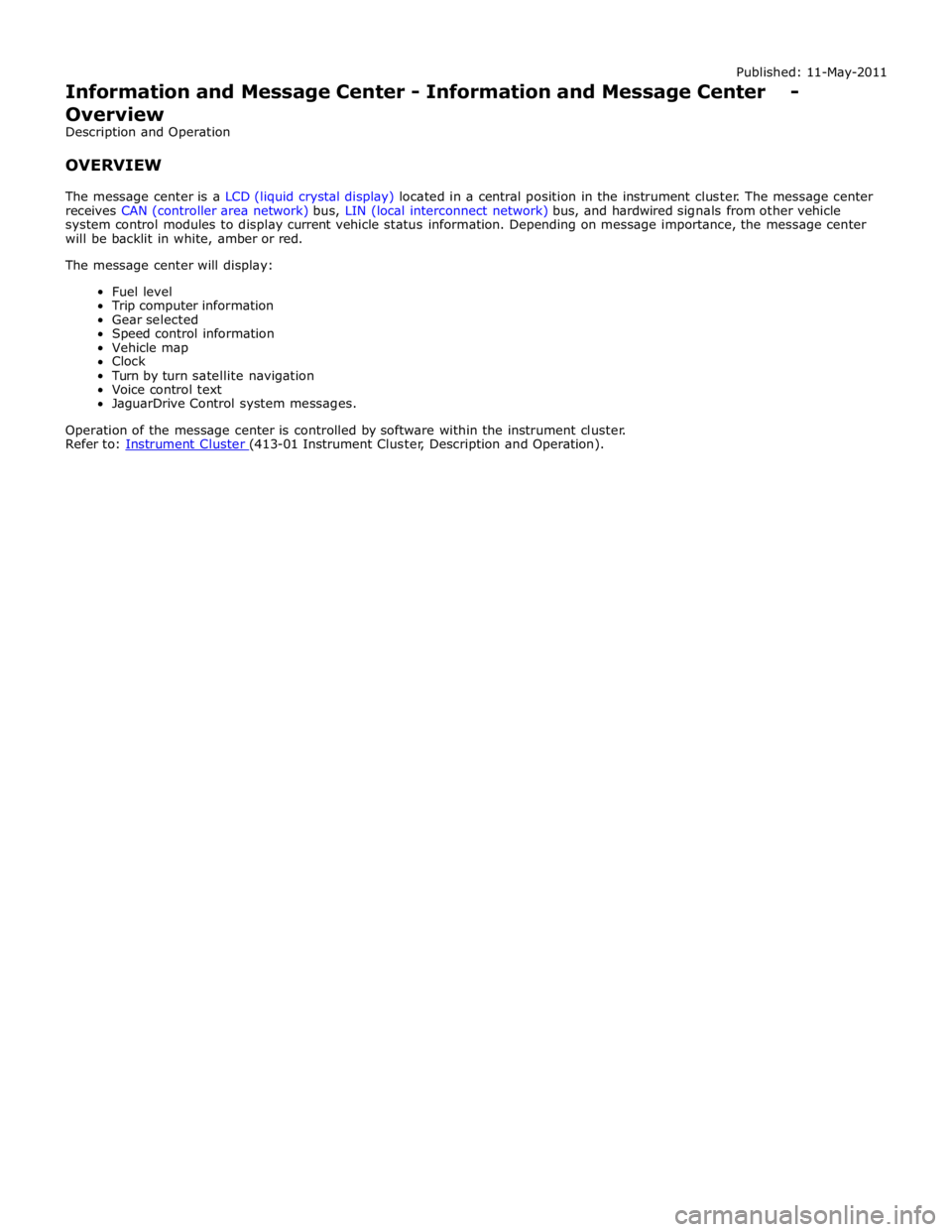

Published: 11-May-2011

Information and Message Center - Information and Message Center - Overview

Description and Operation

OVERVIEW

The message center is a LCD (liquid crystal display) located in a central position in the instrument cluster. The message center

receives CAN (controller area network) bus, LIN (local interconnect network) bus, and hardwired signals from other vehicle

system control modules to display current vehicle status information. Depending on message importance, the message center

will be backlit in white, amber or red.

The message center will display:

Fuel level

Trip computer information

Gear selected

Speed control information

Vehicle map

Clock

Turn by turn satellite navigation

Voice control text

JaguarDrive Control system messages.

Operation of the message center is controlled by software within the instrument cluster.

Refer to: Instrument Cluster (413-01 Instrument Cluster, Description and Operation).

Page 1823 of 3039

Message Other Warnings Reason Action CRUISE NOT

AVAILABLE None Speed control cannot be engaged.

A fault has occurred in the speed

control system. Diagnose fault

using an approved Jaguar Diagnostic System. RADAR SENSOR

BLOCKED None

The adaptive speed control radar

sensor has become dirty or obstructed. Remove obstruction or clean the

radar sensor. FORWARD ALERT

OFF None

Forward alert has been switched off.

No warning will be given for objects in

the vehicles forward direction. None FORWARD ALERT None

Forward alert has been switched on or

the gap settings have changed. None FORWARD ALERT

UNAVAILABLE None

Forward Alert and Emergency Brake

Assist are not available. Use an approved Jaguar

Diagnostic System to diagnose

fault.. Warning/Message Display

Warning and information messages are displayed in the central area of the LCD. When no messages are required, an analogue clock is present on the display. The message display language can be changed by the driver using a selection menu on the

Touch Screen Display (TSD). The following table shows the possible messages which can be displayed, other visual or audible

warnings and a description of the message.

Message Other Warnings Reason Action DSC ON

DSC warning indicator

flashes for a short time. Displayed for a short time when the DSC

switch is operated to activate the DSC system. None DSC OFF

DSC warning indicator

illuminated. Displayed for a short time when the DSC

switch is operated to de-activate the

DSC system. None TRAC DSC

DSC warning indicator

illuminated. Displayed for a short time when the DSC

switch is operated to activate the TRAC

DSC system. None DSC NOT

AVAILABLE DSC warning indicator

illuminated. A fault is present in the DSC system.

A fault has occurred in the DSC

system. Interrogate ABS (anti-lock

brake system) module for faults and

diagnose fault using an approved Jaguar Diagnostic System. BRAKE FLUID

LOW

Brake warning

indicator

illuminated.

Red warning triangle

illuminated in LCD. Brake fluid level has become low and

activated low level switch. Investigate fluid loss and check brake

system for leaks. Repair system as

required and replenish brake fluid

reservoir. ABS FAULT

ABS warning indicator

illuminated.

Amber warning

triangle illuminated

in LCD. A fault is present in the ABS system. Braking system will operate but ABS will not be available. A fault has occurred in the ABS system. Interrogate ABS module for faults and diagnose fault using an approved

Jaguar Diagnostic System. BRAKE ASSIST

FAULT Amber warning triangle

illuminated in LCD. A fault is present in the braking system

preventing brake assist operation.

Braking system will operate but brake

assist will not be available and

increased effort on the brake pedal may

be required. A fault has occurred in the brake assist

system. Interrogate ABS module for faults and diagnose fault using an

approved Jaguar Diagnostic System. EBD FAULT

Red warning triangle

illuminated in LCD. A fault is present in the braking system

preventing EBD operation. Braking

system will operate but EBD will not be

available. A fault has occurred in the EBD

system. Interrogate ABS module for faults and diagnose fault using an approved Jaguar Diagnostic System. ADAPTIVE

DYNAMICS FAULT Amber warning triangle

illuminated in LCD. A fault is present in the Computer

Active Technology Suspension (CATS) or

the Adaptive Dynamic Suspension

system. Suspension will default to the

'hard' setting. A fault has occurred in the CATS

system. Interrogate the CATS or

adaptive damping module for faults

and diagnose using an approved Jaguar Diagnostic System. PARK BRAKE

APPLIED None

Parking brake has been applied when

the vehicle moving at a speed 5 km/h (3 mph) or above. None PARK BRAKE

FAULT

Brake warning

indicator

illuminated.

Red warning triangle

illuminated in LCD. A fault is present in the parking brake

system. A fault has occurred in the parking

brake system. Interrogate the parking

brake module for faults and diagnose

using an approved Jaguar Diagnostic

System.

Page 1896 of 3039

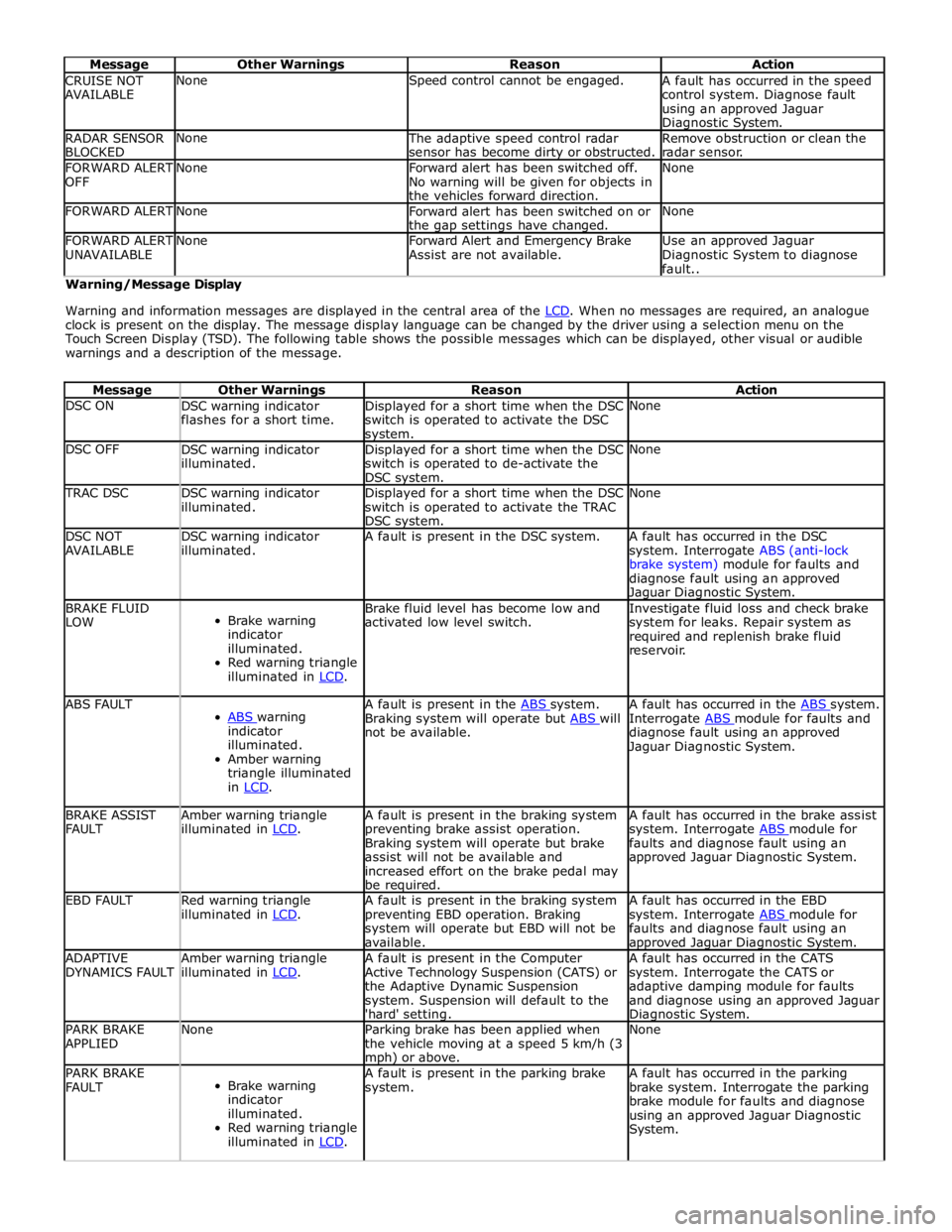

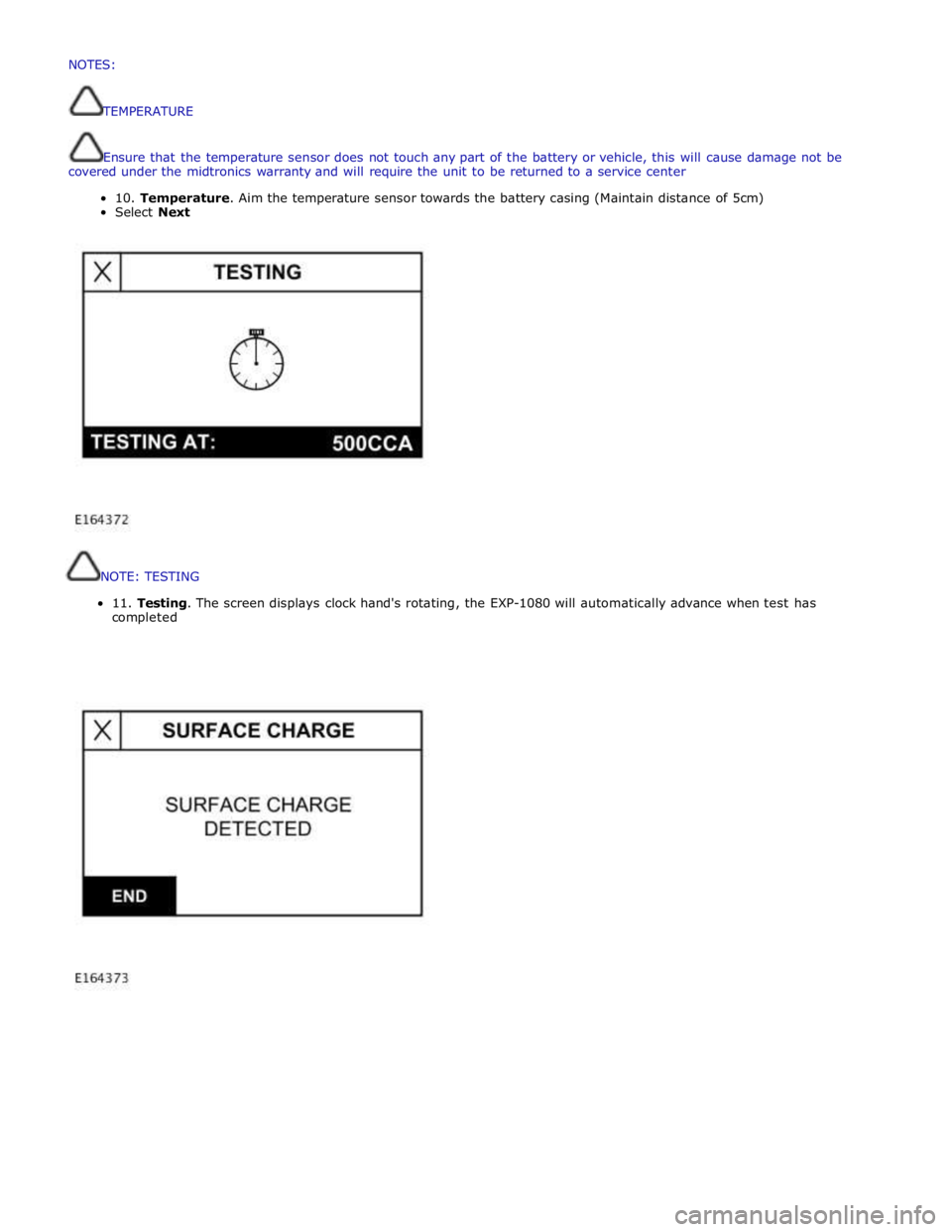

NOTE:

TESTING

11.

Testing.

The

screen

displays

clock

hand's

rotating,

the

EXP-1080

will

automatically

advance

when

test

has

completed

NOTES:

TEMPERATURE

Ensurethatthetemperaturesensordoesnottouchanypartofthebatteryorvehicle,thiswillcausedamagenotbe

coveredunderthemidtronicswarrantyand willrequiretheunittobereturnedtoaservicecenter

10.Temperature.Aimthetemperaturesensortowardsthebatterycasing (Maintaindistanceof5cm)

SelectNext

Page 1903 of 3039

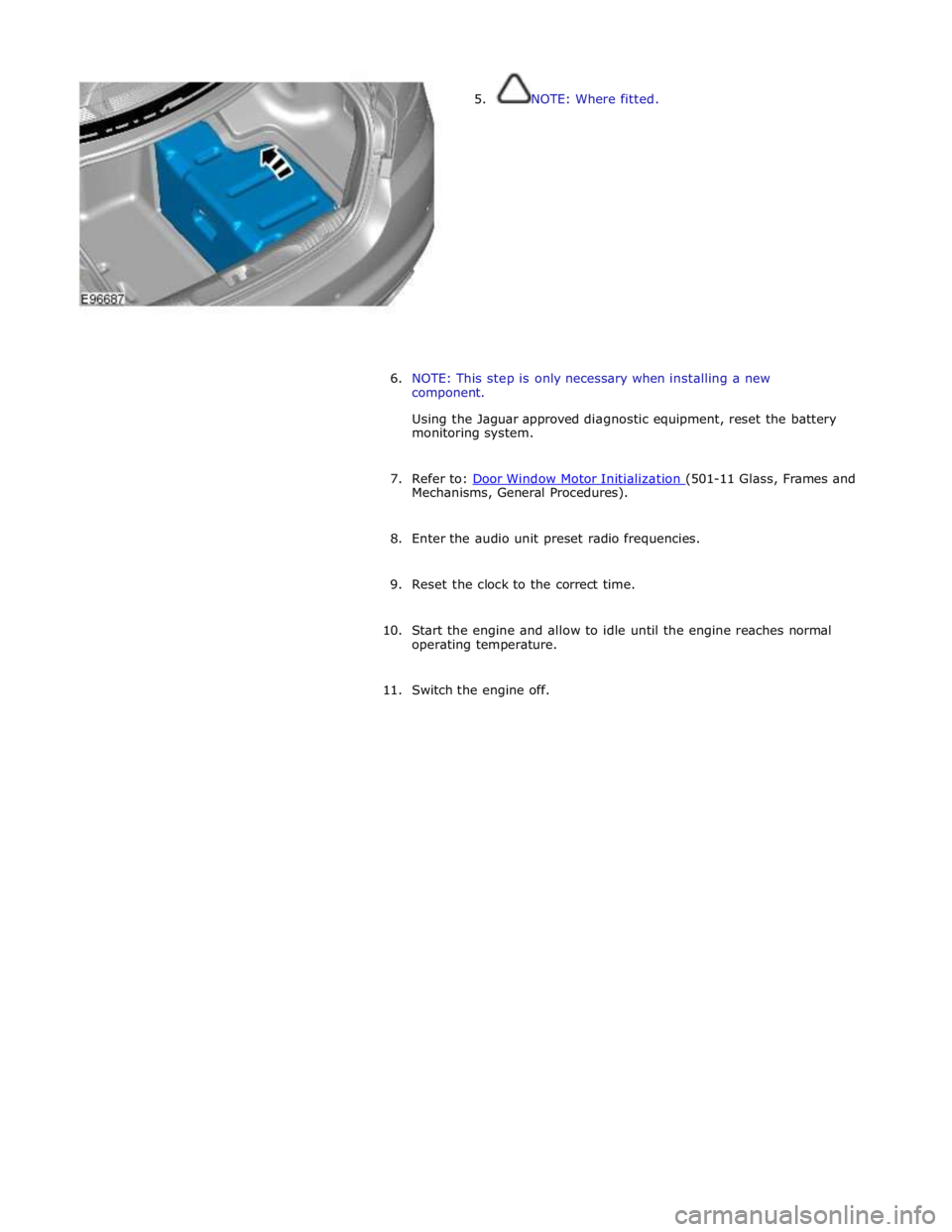

5. NOTE: Where fitted.

6. NOTE: This step is only necessary when installing a new

component.

Using the Jaguar approved diagnostic equipment, reset the battery

monitoring system.

7. Refer to: Door Window Motor Initialization (501-11 Glass, Frames and Mechanisms, General Procedures).

8. Enter the audio unit preset radio frequencies.

9. Reset the clock to the correct time.

10. Start the engine and allow to idle until the engine reaches normal

operating temperature.

11. Switch the engine off.

Page 1907 of 3039

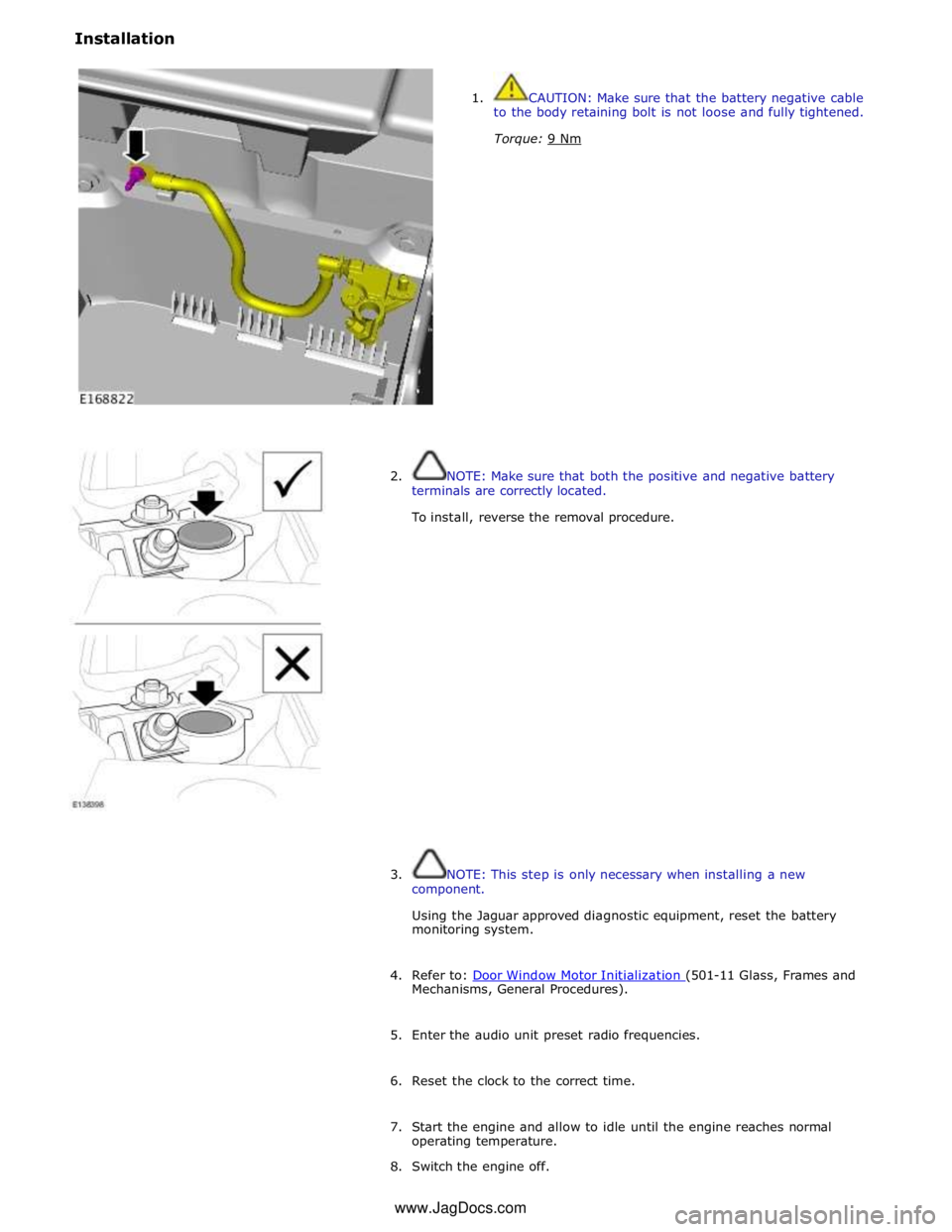

Installation

1. CAUTION: Make sure that the battery negative cable

to the body retaining bolt is not loose and fully tightened.

Torque: 9 Nm

2. NOTE: Make sure that both the positive and negative battery

terminals are correctly located.

To install, reverse the removal procedure.

3. NOTE: This step is only necessary when installing a new

component.

Using the Jaguar approved diagnostic equipment, reset the battery

monitoring system.

4. Refer to: Door Window Motor Initialization (501-11 Glass, Frames and Mechanisms, General Procedures).

5. Enter the audio unit preset radio frequencies.

6. Reset the clock to the correct time.

7. Start the engine and allow to idle until the engine reaches normal

operating temperature.

8. Switch the engine off. www.JagDocs.com