clock JAGUAR XFR 2010 1.G Repair Manual

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 2010, Model line: XFR, Model: JAGUAR XFR 2010 1.GPages: 3039, PDF Size: 58.49 MB

Page 2172 of 3039

Module Network System Function Vehicle Location

Steering wheel

clockspring LIN Passes digital messages from the steering wheel

audio switches to the instrument cluster. Behind the steering wheel,

on the upper steering

column.

Instrument cluster LIN Receives digital signals from other vehicle systems. On the driver's side of the

instrument panel.

Battery backed sounder LIN Activated by CJB when alarm trigger is received. In the LH side of the engine compartment, near the

bulkhead.

CJB LIN Controls body functions and power distribution. On the RH 'A' pillar.

RJB LIN Controls body functions and power distribution. On the RH of the luggage compartment.

Battery monitoring

system module

Intrusion detection

module LIN Monitors the condition and charge of the vehicle

battery.

LIN Detects movement in the vehicle interior and

activates the anti-theft system. On the vehicle battery

positive terminal in the

luggage compartment.

In the front overhead

console.

Rain/light sensor LIN Detects ambient light levels and moisture on the

windscreen for operation of the automatic

headlamps and wiper systems.

Start control module LIN Used to identify the Smart Key - component of the

keyless start system.

Rear view camera LIN Passes digital images data from the rear view

camera to the RJB On the inside of the

windshield behind the interior

rear view mirror.

In the lower instrument panel

on the driver's side.

In the luggage compartment

lid trim finisher.

Driver's window switch LIN Controls operation of the driver's window. In the driver's door trim

panel.

Electronic transmission

selector LIN Sends selector position to the TCM. In the floor console. TCM LIN Receives selector position information to control the Inside the transmission and

Information control

module

Media Oriented

System Transport

(MOST) transmission.

Contains controls for the entertainment system and

gateway between audio system and other vehicle

systems. accessible by removal of the

fluid pan.

In the instrument panel

below the integrated control

panel.

Integrated control

panel MOST Contains controls for the entertainment system. In the instrument panel.

Digital Audio Broadcast MOST Receives digital radio broadcasts. In the LH side of the luggage (DAB) receiver (SDARS

NAS only)

Bluetooth® phone

module compartment, above the

keyless vehicle module.

MOST Controls operation of the Bluetooth® phone system. Below the LH front seat, adjacent to the portable

audio module.

Amplifier/tuner MOST Provides amplification for the entertainment systems In the LH side of the luggage and reception of radio RF broadcasts.

Navigation computer MOST Reads map data from a DVD (digital versatile disc)

to calculate and display visual route guidance

information via the TSD and audible guidance via the

amplifier to the driver. compartment.

In the LH side of the luggage compartment.

Touch Screen Display

(TSD) MOST Provides the driver interface to the entertainment,

navigation and driver personalization functions. In the center of the

instrument panel.

TV tuner MOST Controls the reception of television signals and

audio/visual inputs.

Portable Audio Module MOST Controls the auxiliary inputs for additional audio

inputs via the portable audio interface. In the LH side of the luggage compartment.

Below the LH front seat, adjacent to the Bluetooth®

phone module.

MOST diagnostic

connector MOST Allows for diagnostic fault detection of the MOST

ring. Below the air ducting in the

floor console.

Refer to Communications Network section for further details.

Refer to: Communications Network (418-00 Module Communications Network, Description and Operation).

Page 2542 of 3039

On vehicles with headlamp powerwash, each headlamp assembly is fitted with a headlamp powerwasher. The powerwasher is

located on the underside of the headlamp assembly. The powerwasher is located in a clip at the front of the headlamp and

secured with 2 self tapping screws to the headlamp body.

The powerwasher is a telescopic unit which extends forwards from the headlamp assembly under washer fluid pressure

supplied by the headlamp powerwash pump. When the pump pressure decreases the powerwasher is automatically retracted

back into the housing. The outer end of the powerwasher is fitted with a trim which blends the powerwasher into the headlamp

when it is not operating. The powerwasher has two washer jets which direct washer fluid under high pressure onto the

headlamp lens when the powerwasher is extended.

RAIN/LIGHT SENSOR

The rain/light sensor is located at the upper edge of the windshield, behind the interior rear view mirror. Contact between the

rain sensor and windscreen is provided via a silicon pad which is compressed during the assembly process by two locking

retaining clips either side of the sensor.

The rain/light sensor unit attaches to the windshield via two clips, which latch onto formed tags on the windshield bracket.

The sensor provides information to the CJB for the optimum wiper operation for the prevailing conditions to maintain the shield in a clear condition at all times. The rain/light sensor is an optical unit, which operates on an infrared waveband. The sensor

uses the principle of the laws of reflection on interfacing surfaces between materials with differing refraction properties.

The rain/light sensor is connected to the CJB via a LIN bus. The sensor also receives a hardwired power and ground from the CJB. The 'auto' wipers are activated when the column stalk is moved to position 1 (first position from off in the upward direction). The sensitivity of the sensor can be adjusted by rotating the sensitivity collar on the wiper column stalk in the

clockwise or counterclockwise direction. Clockwise rotation will decrease sensitivity, while counterclockwise adjustment will

increase sensitivity. An increase in sensitivity adjustment results in a single wipe of the front wiper motor.

NOTE: The rain sensor also contains a light sensor. The light sensor is used to control operation of the automatic

headlamps function.

Refer to: Exterior Lighting (417-01 Exterior Lighting, Description and Operation).

WIPER CONTROL SWITCH

The wiper control switch is located on the RH steering column multifunction switch. The switch allows selection of the following functions:

Slow wipe

Fast wipe

Auto

Flick wipe

Windshield wash and headlamp powerwash (if fitted).

All wiper functions are connected to the instrument cluster by a resistor or series of resistors within the switch. The instrument

cluster uses the returned current to determine the selected function.

WIPER SERVICE POSITION

The wiper service position allows the wipers to be parked in a position to allow easy access to the wiper blades for

replacement. The service position is initiated by pulling the RH steering column multifunction switch towards the steering wheel and pressing the start/stop button to switch on the ignition. The wipers will move and stop in a vertical position on the

windshield. The RH steering column multifunction switch can be released and the ignition switched off. The service position is terminated at the next ignition on cycle and the wipers return to their normal park position.

Page 2608 of 3039

Passenger air bag module retaining nuts 6 - 55 Passenger air bag earth lead retaining bolt 9 - 80 Restraints control module (RCM) retaining nuts 10 - 89 Side air curtain module inflator retaining bolts 9 - 80 Side air curtain module tether straps retaining bolts 9 - 80 Side air bag module retaining nuts 7 - 62 Side impact sensor retaining bolt 10 - 89 Front crash sensor retaining bolt 10 - 89 Clock spring retaining screws 5 - 44

Page 2614 of 3039

Item Description 1 Battery 2 BJB 3 RJB 4 Front passenger airbag 5 Clockspring 6 Driver's airbag 7 Front passenger seat safety belt switch 8 Driver's seat safety belt switch 9 LH curtain airbag 10 Driver's seat thorax airbag 11 Front passenger seat thorax airbag 12 RH curtain airbag 13 RCM

System Operation System Operation

In a collision, the sudden deceleration or acceleration is measured by the impact sensors and the accelerometers in the

restraints control module. The restraints control module evaluates the readings to determine the impact point on the vehicle

and whether the deceleration/acceleration readings exceed the limits for firing any of the airbags, pretensioners, and battery

disconnect unit. During a collision, the restraints control module only fires the airbags and pretensioners if the safing function

confirms that the data from the impact sensor(s) indicates an impact limit has been exceeded.

The RCM incorporates the following impact thresholds to cater for different accident scenarios: Front impact, pretensioners

Front impact, driver and passenger airbags stage 1, belt unfastened

Front impact, driver and passenger airbags stage 1, belt fastened

Front impact, driver and passenger airbags stage 2, belt unfastened

Front impact, driver and passenger airbags stage 2, belt fastened

Rear impact

Driver side impact

Passenger side impact.

The front impact thresholds increase in severity from pretensioners to driver and passenger airbag stage 2, belt fastened (refer

to list above).

Firing Strategies

The safety belt pretensioners are fired when the pretensioner impact limit is exceeded. The RCM only fires the pretensioners if the related safety belt is fastened.

The driver and passenger airbags are only fired in a frontal impact. If an impact exceeds a stage 1 limit, but is less than the

corresponding stage 2 limit, only one inflator in each airbag is fired (stage 2 is still fired for disposal after a delay of 100ms).

If an impact exceeds the stage 2 limit, the two inflators in each airbag are fired simultaneously.

The passenger airbag is disabled unless the front passenger seat is occupied by a large person (NAS only), or the passenger

airbag deactivation switch is on (all except NAS & AUS).

The stage 2 inflator of the driver airbag is disabled if the driver seat is forward of the switching point of the seat position

sensor.

If there is a fault with a safety belt buckle sensor, the RCM assumes the related safety belt is fastened for the pretensioner firing strategy and unfastened for the driver and passenger airbag firing strategies. If there is a fault with the occupant

classification sensor, the RCM disables the passenger airbag. If there is a fault with the passenger airbag deactivation switch, the RCM disables the passenger airbag.

If a side impact limit is exceeded, the RCM fires the side airbag and the side head airbag on that side of the vehicle. If the side impact limit on the front passenger side of the vehicle is exceeded, the RCM also evaluates the input from the occupant classification sensor, and fires the side airbag only if the front passenger seat is occupied by a large person (NAS only).

If multiple impacts occur during a crash event, after responding to the primary impact the RCM will output the appropriate fire signals in response to any further impacts if unfired units are available.

Front and Rear Impact Firing Strategy (All Except NAS)

Safety Belt Status Strategy Driver Passenger Applicable Pretensioner Driver airbag Passenger airbag Fastened - Fired at pretensioner threshold Fired at belt fastened threshold - Unfastened - Not fired Fired at belt unfastened threshold - - Fastened Fired at pretensioner threshold - Fired at belt fastened threshold - Unfastened Not fired - Fired at belt unfastened threshold www.JagDocs.com

Page 2616 of 3039

and the safety belt buckle sensor. Based on this data, the RCM decides which level of airbag module deployment is required and forwards the information to the second area, the deployment handler.

The deployment handler evaluates the status of the seat track position sensor and safety belt buckle sensors before a decision

is made about which restraints should finally be deployed.

Data from the side crash sensors is used by the RCM in conjunction with acceleration data from the RCM internal accelerometer to make a deployment decision. The RCM processes the acceleration data and subject to an impact being of high enough severity, decides whether the side airbag module should be deployed.

On board testing of the airbag modules, front safety belt pretensioner firing circuits, warning indicator circuits and module

status (the crash and side impact sensors perform basic self-tests) is performed by the RCM together with the storing of fault codes.

The RCM drives the SRS indicator on the instrument pack via a CAN signal. If the warning lamp fails, a fault code is recorded and a warning tone is sounded in place of the lamp if a further fault occurs. It also provides a temporary back-up power supply

to operate the airbag modules in the event that in crash conditions, the battery supply is lost. In the event of a crash, it

records certain data which can be accessed via the diagnostic connector.

A safing sensor in the RCM provides confirmation of an impact to verify if airbag and pretensioner activation is necessary. A roll-over sensor monitors the lateral attitude of the vehicle. Various firing strategies are employed by the RCM to ensure that during an accident only the appropriate airbags and pretensioners are fired. The firing strategy used also depends on the

inputs from the safety belt switches and the occupant monitoring system.

An energy reserve in the RCM ensures there is always a minimum of 150 milliseconds of stored energy available if the power supply from the ignition switch is disrupted during a crash. The stored energy is sufficient to produce firing signals for the

driver airbag, the passenger airbag and the safety belt pretensioners.

When the ignition is switched on, the RCM performs a self-test and then performs cyclical monitoring of the system. If a fault is detected the RCM stores a related fault code and illuminates the airbag warning indicator. The faults can be retrieved by the recommended Jaguar diagnostic tool over the CAN bus. If a fault that could cause a false fire signal is detected, the RCM disables the respective firing circuit, and keeps it disabled during a crash event.

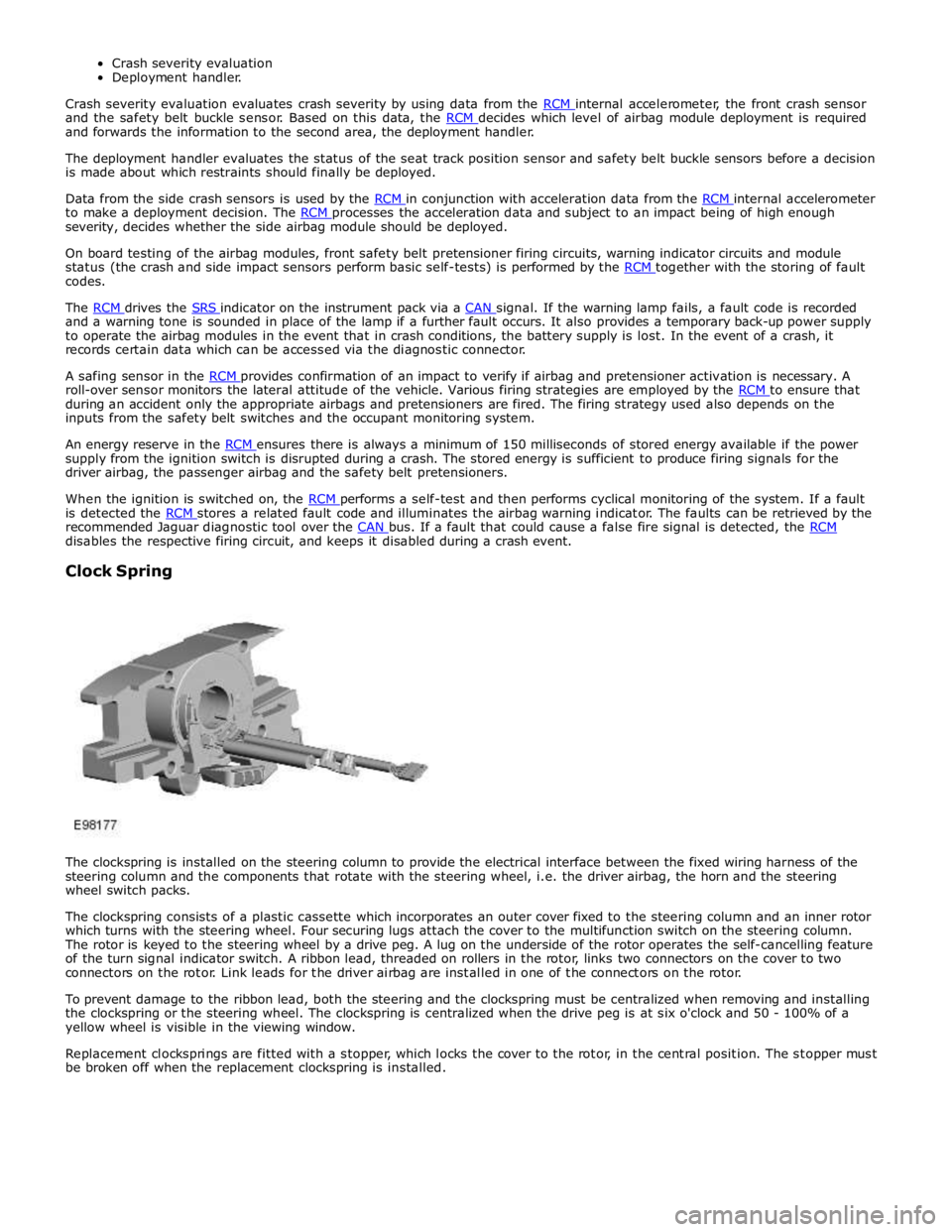

Clock Spring

The clockspring is installed on the steering column to provide the electrical interface between the fixed wiring harness of the

steering column and the components that rotate with the steering wheel, i.e. the driver airbag, the horn and the steering

wheel switch packs.

The clockspring consists of a plastic cassette which incorporates an outer cover fixed to the steering column and an inner rotor

which turns with the steering wheel. Four securing lugs attach the cover to the multifunction switch on the steering column.

The rotor is keyed to the steering wheel by a drive peg. A lug on the underside of the rotor operates the self-cancelling feature

of the turn signal indicator switch. A ribbon lead, threaded on rollers in the rotor, links two connectors on the cover to two

connectors on the rotor. Link leads for the driver airbag are installed in one of the connectors on the rotor.

To prevent damage to the ribbon lead, both the steering and the clockspring must be centralized when removing and installing

the clockspring or the steering wheel. The clockspring is centralized when the drive peg is at six o'clock and 50 - 100% of a

yellow wheel is visible in the viewing window.

Replacement clocksprings are fitted with a stopper, which locks the cover to the rotor, in the central position. The stopper must

be broken off when the replacement clockspring is installed.

Page 2629 of 3039

Supplemental Restraint System - Clockspring

Removal and Installation Published: 11-May-2011

Removal

WARNINGS:

Always wear safety glasses when repairing an air bag supplemental restraint system (SRS) vehicle and when handling an

air bag module.

Carry a live air bag module with the air bag and trim cover pointed away from your body. This will reduce the risk of injury

in the event of an accidental deployment. Failure to follow this instruction may result in personal injury.

Do not set a live air bag module down with the trim cover face down. Failure to follow this instruction may result in

personal injury.

After deployment, the air bag surface can contain deposits of sodium hydroxide, a product of the gas generant

combustion that is irritating to the skin. Wash your hands with soap and water afterwards. Failure to follow this instruction

may result in personal injury.

Never probe the connectors on the air bag module. Doing so may result in air bag deployment, which may result in

personal injury. Failure to follow this instruction may result in personal injury.

Air bag modules with discolored or damaged trim covers must be replaced, not repainted.

Vehicle sensor orientation is critical for correct system operation. If a vehicle equipped with an air bag supplemental

restraint system (SRS) is involved in a collision, inspect the sensor mounting bracket and wiring pigtail for deformation. If

damaged, replace the sensor whether or not the air bag is deployed.

To avoid accidental deployment and possible personal injury, the backup power supply must be depleted before repairing

or replacing any air bag supplemental restraint system (SRS) components. To deplete the backup power supply energy,

disconnect the battery ground cable and wait one minute. Failure to follow this instruction may result in personal injury.

CAUTION: Make sure the wheels are in the straight-ahead position. Failure to follow this instruction may result in

damage to the component.

NOTE: Removal steps in this procedure may contain installation details.

1. Make the SRS system safe.

Refer to: Standard Workshop Practices (100-00 General Information, Description and Operation).

2. CAUTIONS:

Make sure that special tool 211-326 is installed to the clockspring. 211-326

Locking Tool, Clockspring Special Tool(s)

www.JagDocs.com

Page 2630 of 3039

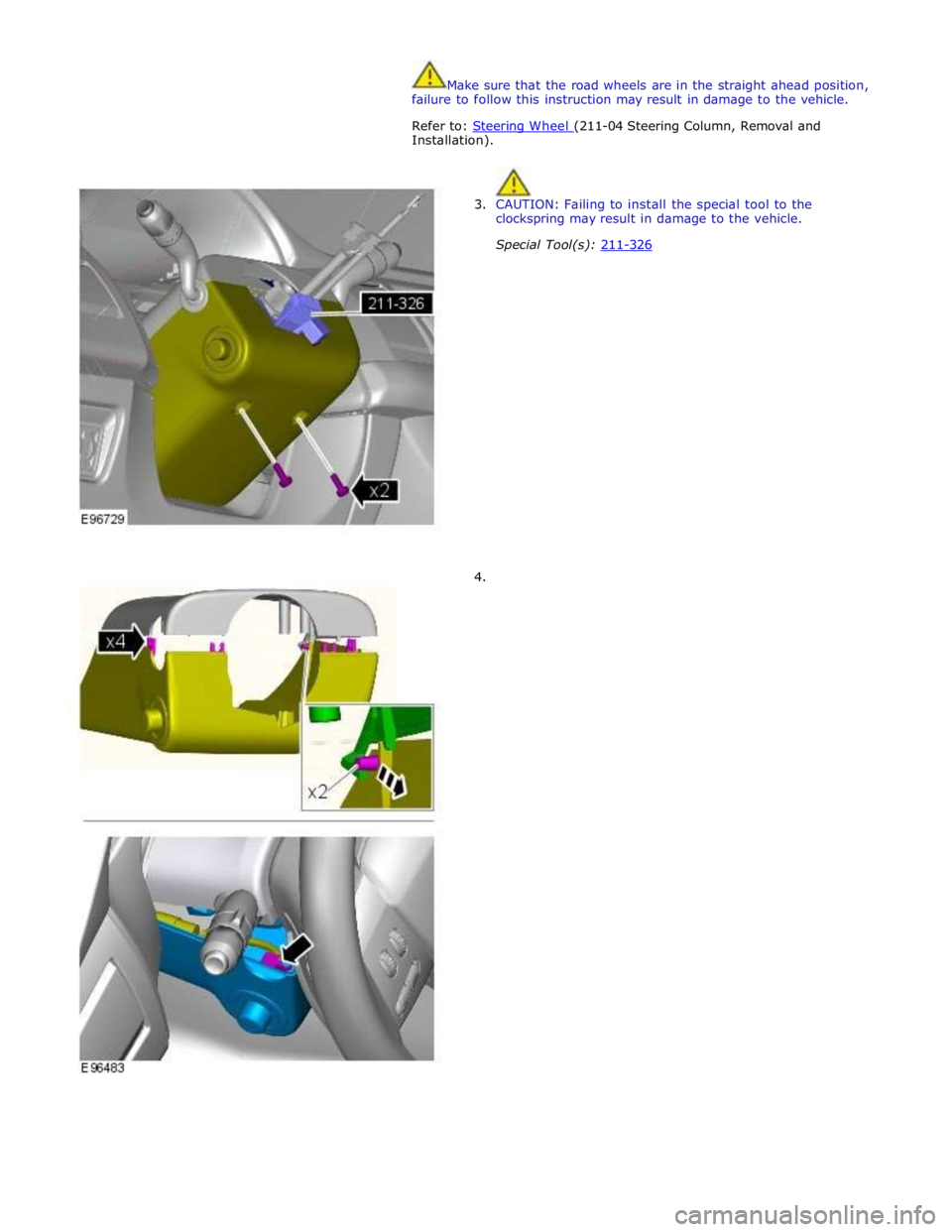

Make sure that the road wheels are in the straight ahead position,

failure to follow this instruction may result in damage to the vehicle.

Refer to: Steering Wheel (211-04 Steering Column, Removal and Installation).

3. CAUTION: Failing to install the special tool to the

clockspring may result in damage to the vehicle.

Special Tool(s): 211-326

4.

Page 2632 of 3039

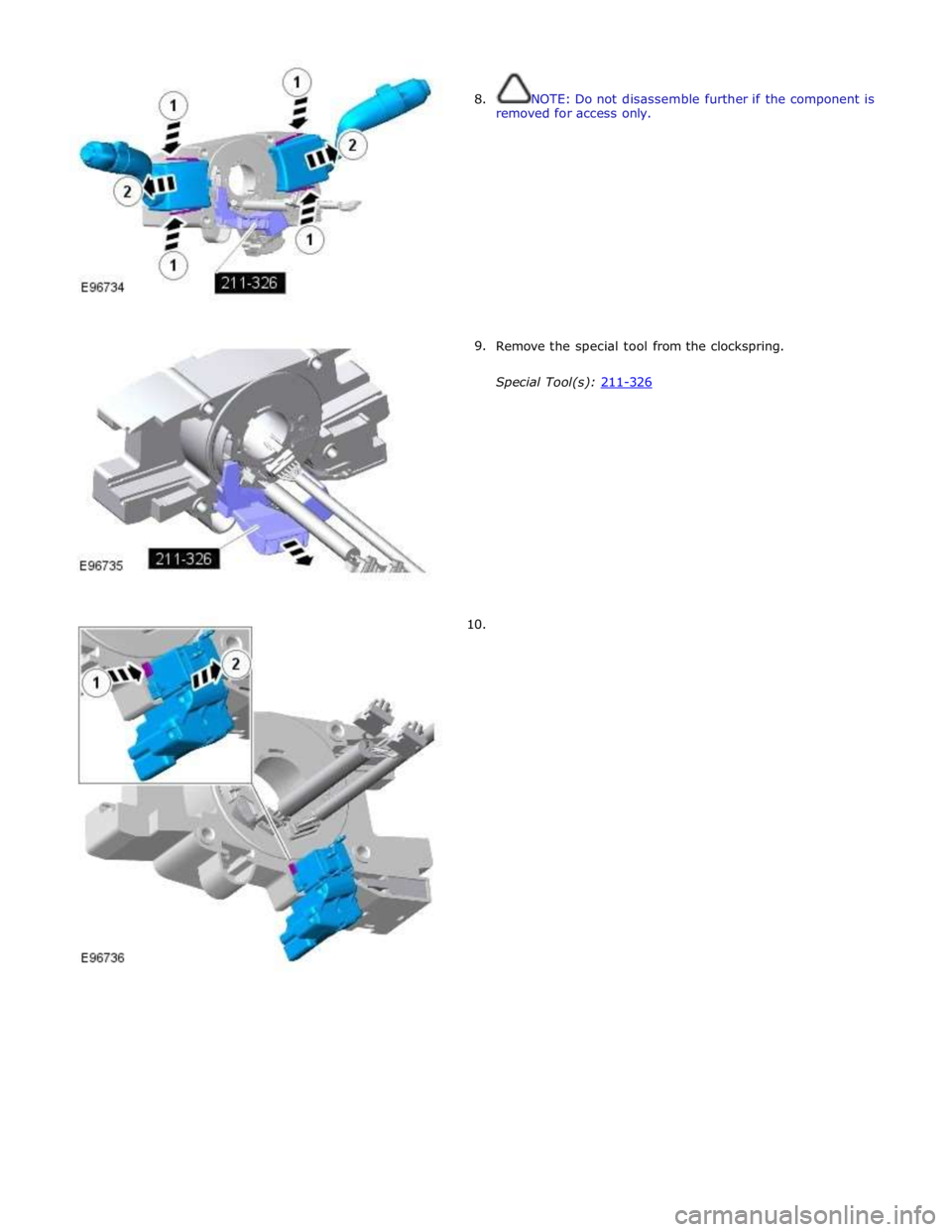

8.

9.

10.

NOTE: Do not disassemble further if the component is

removed for access only.

Remove the special tool from the clockspring.

Special Tool(s): 211-326

Page 2633 of 3039

Installation

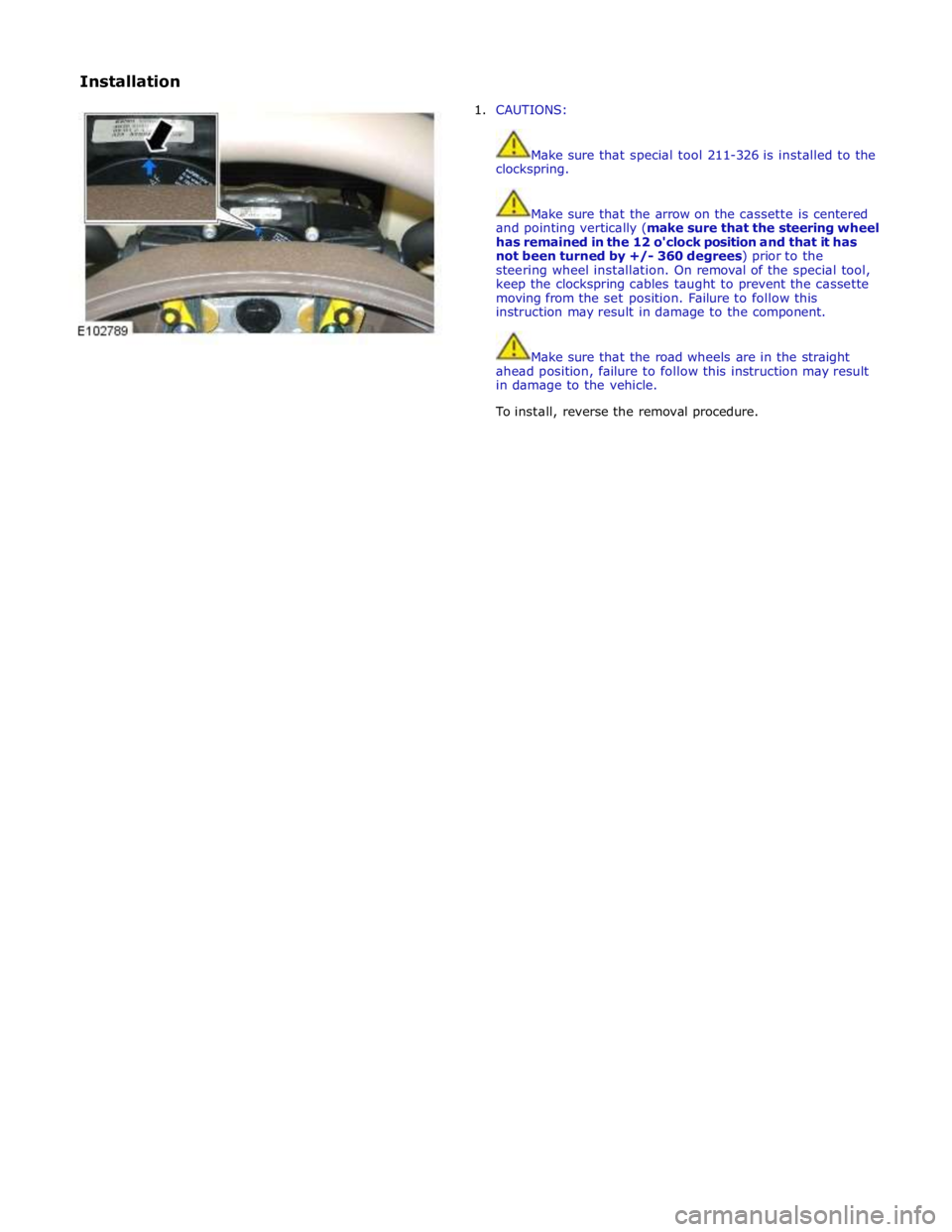

1. CAUTIONS:

Make sure that special tool 211-326 is installed to the

clockspring.

Make sure that the arrow on the cassette is centered

and pointing vertically (make sure that the steering wheel

has remained in the 12 o'clock position and that it has

not been turned by +/- 360 degrees) prior to the

steering wheel installation. On removal of the special tool,

keep the clockspring cables taught to prevent the cassette

moving from the set position. Failure to follow this

instruction may result in damage to the component.

Make sure that the road wheels are in the straight

ahead position, failure to follow this instruction may result

in damage to the vehicle.

To install, reverse the removal procedure.

Page 2653 of 3039

Supplemental Restraint System - Passenger Air Bag Module

Removal and Installation Published: 11-May-2011

Removal

NOTE: Removal steps in this procedure may contain installation details.

1. Refer to: Battery Disconnect and Connect (414-01 Battery, Mounting and Cables, General Procedures).

2. Refer to: Steering Wheel (211-04 Steering Column, Removal and Installation).

3. Refer to: Driver Side Register (412-01 Climate Control, Removal and Installation).

4. Refer to: Information and Entertainment Display (415-01A Information and Entertainment System, Removal and Installation).

5. Refer to: Instrument Panel Speaker (415-01A Information and Entertainment System, Removal and Installation).

6. Refer to: A-Pillar Trim Panel (501-05 Interior Trim and Ornamentation, Removal and Installation).

7. Refer to: Audio and Climate Control Assembly (415-01A Information and Entertainment System, Removal and Installation). 211-326

Locking Tool, Clockspring Special Tool(s)