JAGUAR XFR 2010 1.G Workshop Manual

XFR 2010 1.G

JAGUAR

JAGUAR

https://www.carmanualsonline.info/img/21/7642/w960_7642-0.png

JAGUAR XFR 2010 1.G Workshop Manual

Trending: navigation update, TPMS reset, C1A04, front brake pad, Dash, lug pattern, C1A04-78

Page 501 of 3039

Clunk

Clunk is a metallic noise heard when the automatic transmission is engaged in REVERSE or DRIVE. The noise may also occur

when the throttle is applied or released. Clunk is caused by transmission calibration, backlash in the driveline or loose

suspension components and is felt or heard in the vicinity of the rear drive axle.

Bearing Rumble

Bearing rumble sounds like marbles being tumbled. This condition is usually caused by a worn/damaged wheel bearing. The

lower pitch is because the wheel bearing turns at only about one-third of the driveshaft speed. Wheel bearing noise also may

be high-pitched, similar to gear noise, but will be evident in all four driving modes.

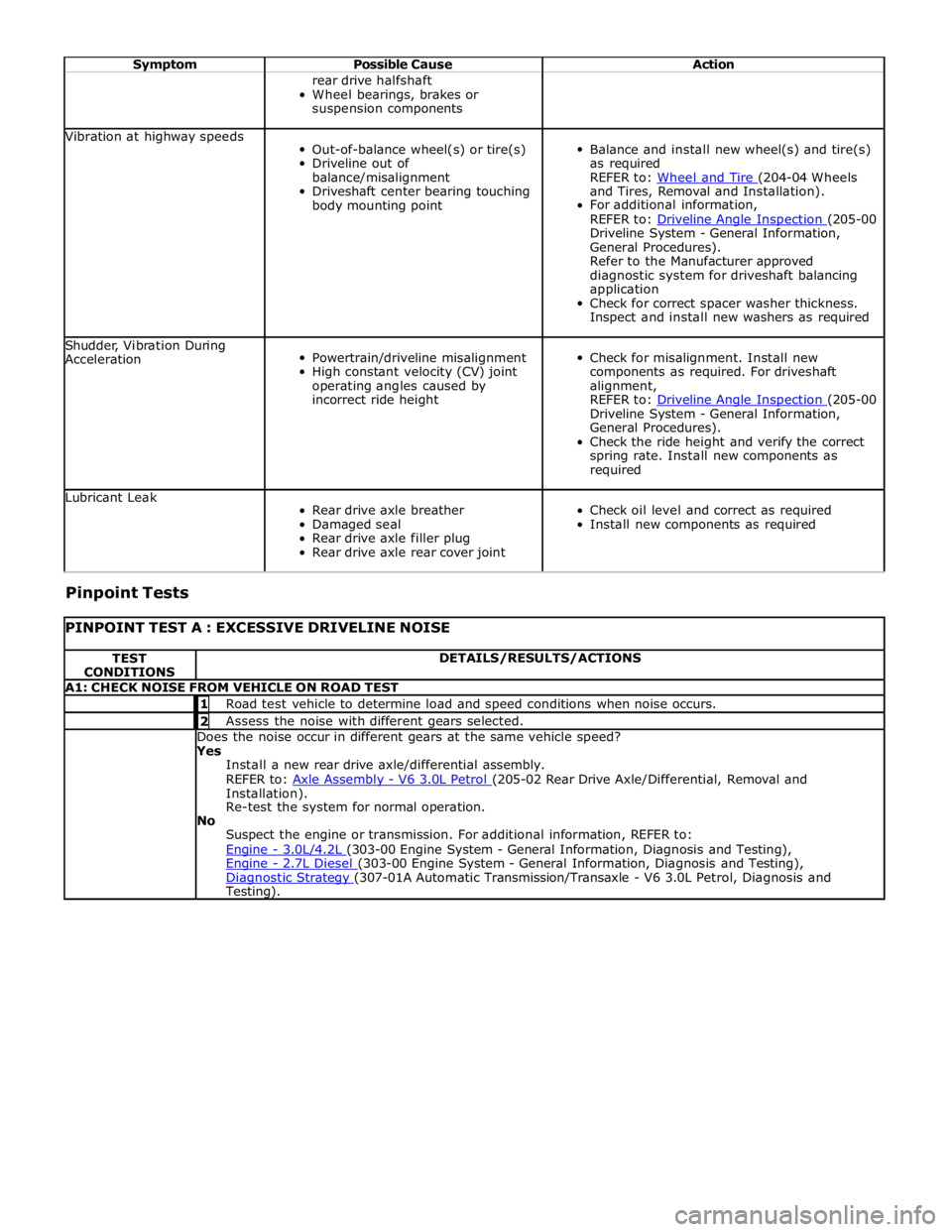

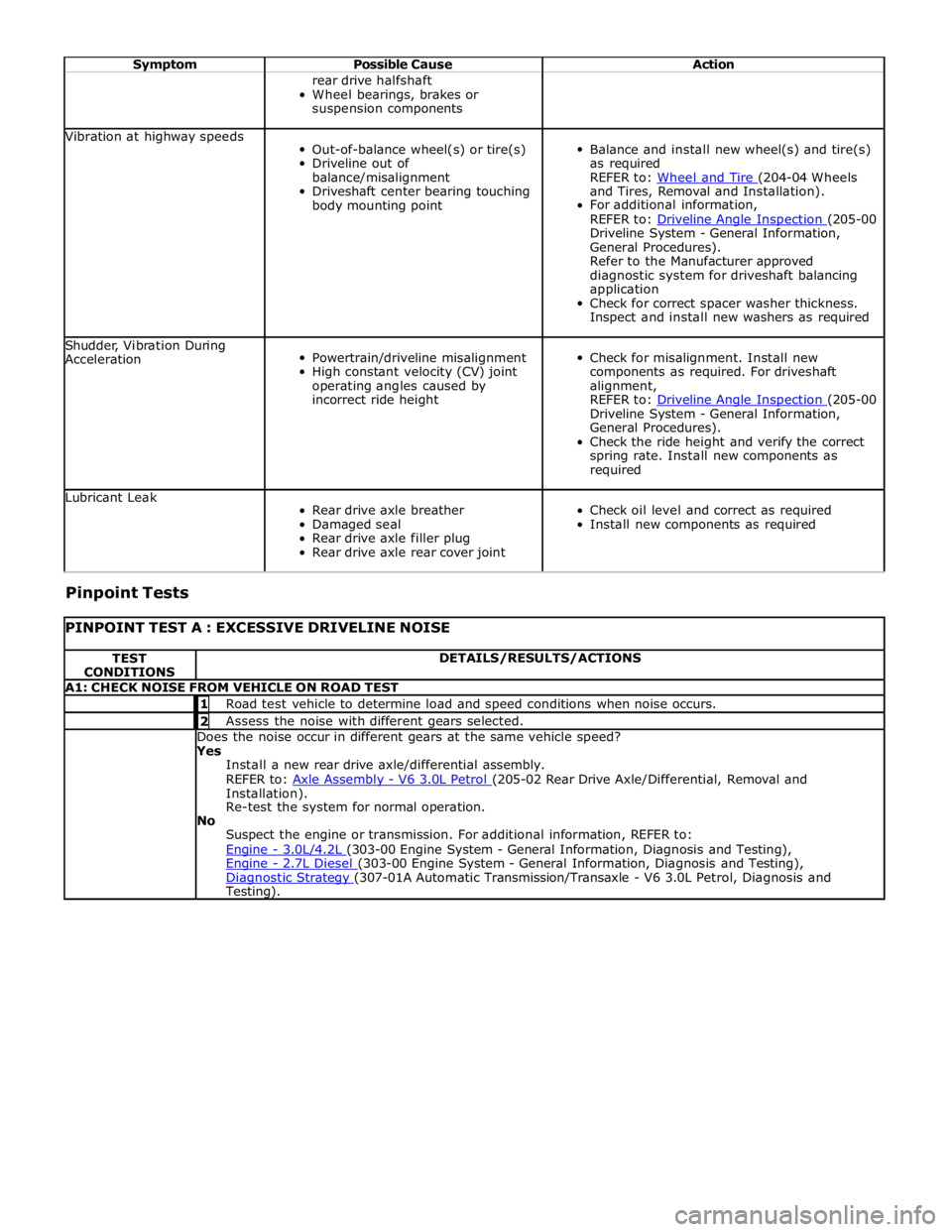

Symptom Chart

Symptom Possible Cause Action Noise is at constant tone over

a narrow vehicle speed range.

Usually heard on light drive

and coast conditions

Rear drive axle

For additional information, GO to Pinpoint

Test A. Noise is the same on drive or

coast

Road

Worn or damaged driveshaft joint

Driveshaft center bearing

Wheel bearing

No action required for road noise

Install new components as required Noise is produced with the

vehicle standing and driving

Engine

Transmission

For additional information, REFER to:

Engine - 3.0L/4.2L (303-00 Engine System - General Information, Diagnosis and Testing),

Engine - 2.7L Diesel (303-00 Engine System - General Information, Diagnosis and Testing),

Diagnostic Strategy (307-01A Automatic Transmission/Transaxle - V6 3.0L Petrol,

Diagnosis and Testing). Loud clunk in the driveline

when shifting from reverse to

forward

Transmission calibration

Transmission Mount

Transmission

Suspension components

Backlash in the driveline

Engine idle speed set too high

Engine mount

Using the Manufacturer approved diagnostic

system, re-configure the Transmission

Control Module (TCM) with the latest

available calibration

Inspect and install new transmission mounts

as required

For additional transmission information,

REFER to: Diagnostic Strategy (307-01A Automatic Transmission/Transaxle - V6 3.0L

Petrol, Diagnosis and Testing).

Inspect and install new suspension

components as required

Inspect and install new driveline components

as required

Check and adjust the idle speed as required

Inspect and install new engine mounts as

required Clicking, popping, or grinding

noises

Inadequate or contaminated

lubrication in the rear drive

halfshaft constant velocity (CV)

joint

Another component contacting the

Inspect, clean and lubricate with new grease

as required

Inspect and repair as required

Inspect and install new components as

required

Page 502 of 3039

Symptom Possible Cause Action rear drive halfshaft

Wheel bearings, brakes or

suspension components Vibration at highway speeds

Out-of-balance wheel(s) or tire(s)

Driveline out of

balance/misalignment

Driveshaft center bearing touching

body mounting point

Balance and install new wheel(s) and tire(s)

as required

REFER to: Wheel and Tire (204-04 Wheels and Tires, Removal and Installation).

For additional information,

REFER to: Driveline Angle Inspection (205-00 Driveline System - General Information,

General Procedures).

Refer to the Manufacturer approved

diagnostic system for driveshaft balancing

application

Check for correct spacer washer thickness.

Inspect and install new washers as required Shudder, Vibration During

Acceleration

Powertrain/driveline misalignment

High constant velocity (CV) joint

operating angles caused by

incorrect ride height

Check for misalignment. Install new

components as required. For driveshaft

alignment,

REFER to: Driveline Angle Inspection (205-00 Driveline System - General Information,

General Procedures).

Check the ride height and verify the correct

spring rate. Install new components as

required Lubricant Leak

Rear drive axle breather

Damaged seal

Rear drive axle filler plug

Rear drive axle rear cover joint

Check oil level and correct as required

Install new components as required Pinpoint Tests

PINPOINT TEST A : EXCESSIVE DRIVELINE NOISE TEST

CONDITIONS DETAILS/RESULTS/ACTIONS A1: CHECK NOISE FROM VEHICLE ON ROAD TEST 1 Road test vehicle to determine load and speed conditions when noise occurs. 2 Assess the noise with different gears selected. Does the noise occur in different gears at the same vehicle speed? Yes

Install a new rear drive axle/differential assembly.

REFER to: Axle Assembly - V6 3.0L Petrol (205-02 Rear Drive Axle/Differential, Removal and Installation).

Re-test the system for normal operation.

No

Suspect the engine or transmission. For additional information, REFER to:

Engine - 3.0L/4.2L (303-00 Engine System - General Information, Diagnosis and Testing), Engine - 2.7L Diesel (303-00 Engine System - General Information, Diagnosis and Testing), Diagnostic Strategy (307-01A Automatic Transmission/Transaxle - V6 3.0L Petrol, Diagnosis and Testing).

Page 503 of 3039

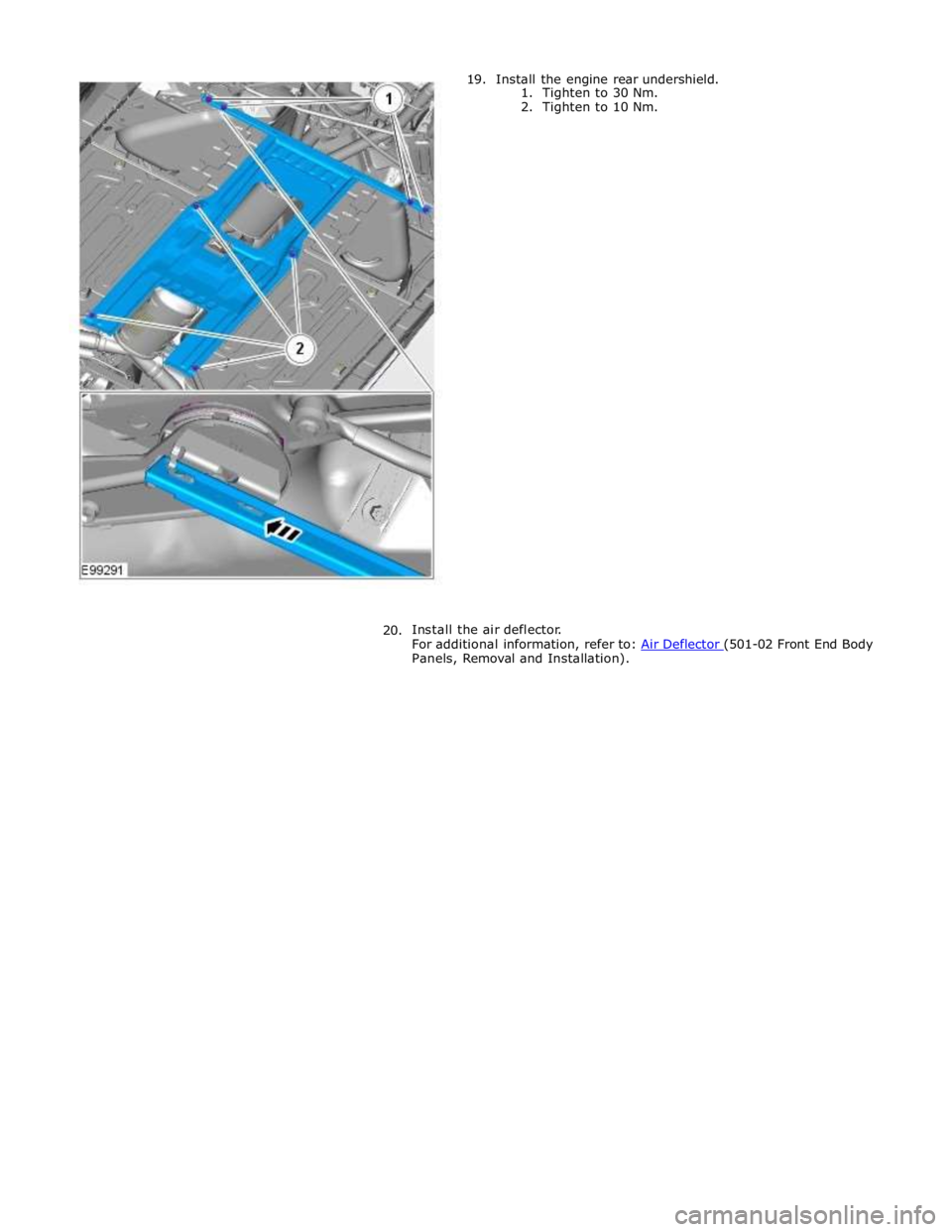

Panels, Removal and Installation).

3. Remove the engine rear undershield. Alignment Tool

205-535 Special Tool(s)

Page 504 of 3039

Page 505 of 3039

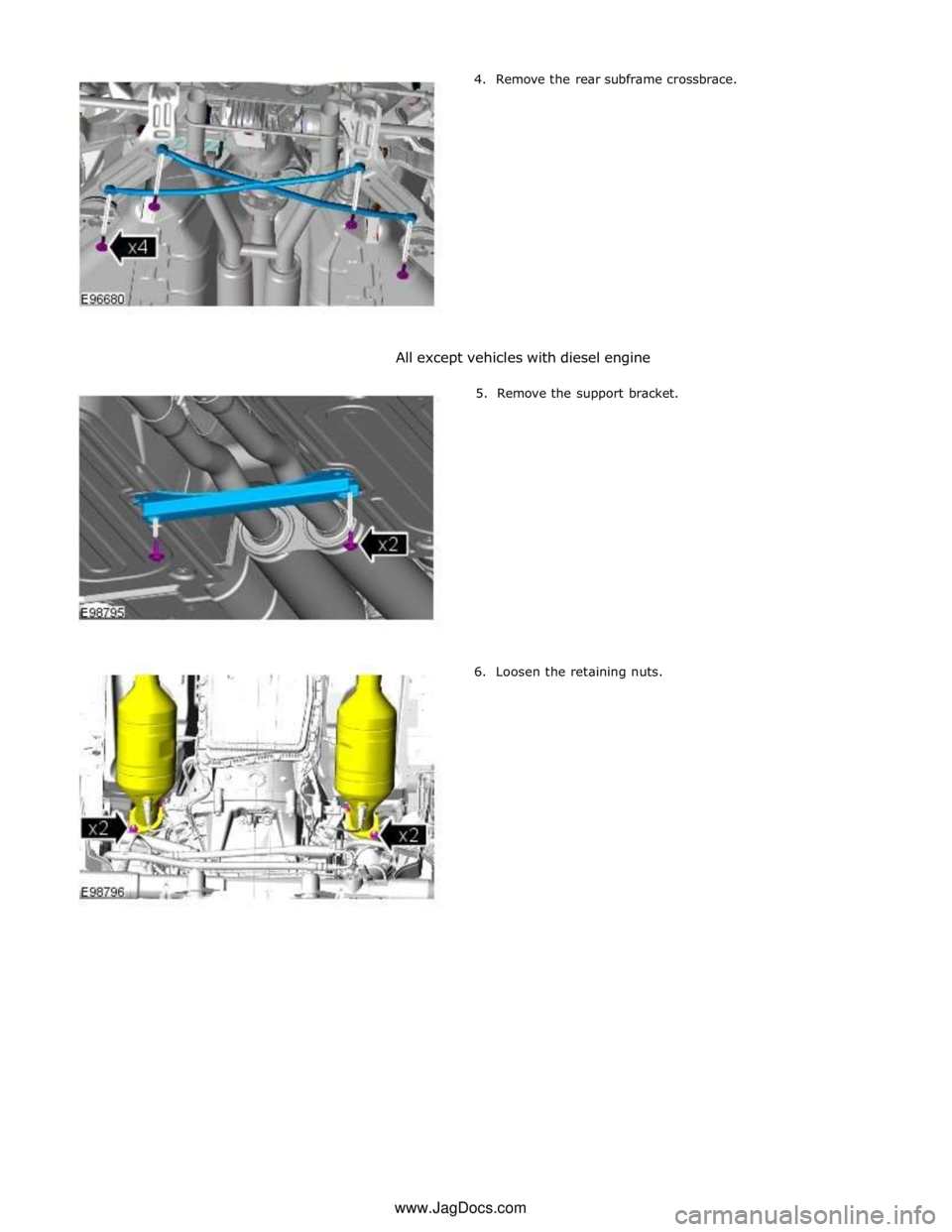

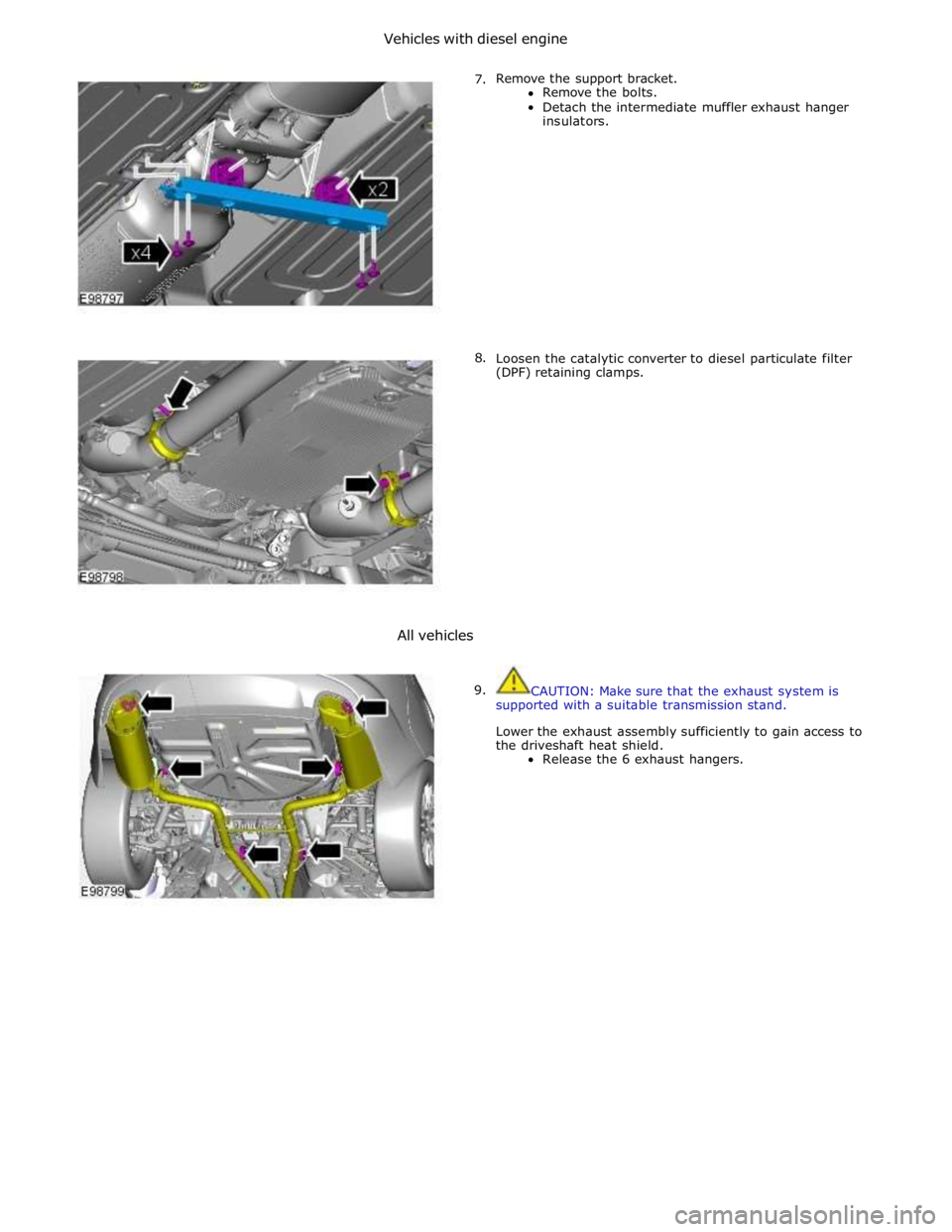

Vehicles with diesel engine

7.

8.

All vehicles

9.

Remove the support bracket.

Remove the bolts.

Detach the intermediate muffler exhaust hanger

insulators.

Loosen the catalytic converter to diesel particulate filter

(DPF) retaining clamps.

CAUTION: Make sure that the exhaust system is

supported with a suitable transmission stand.

Lower the exhaust assembly sufficiently to gain access to

the driveshaft heat shield.

Release the 6 exhaust hangers.

Page 506 of 3039

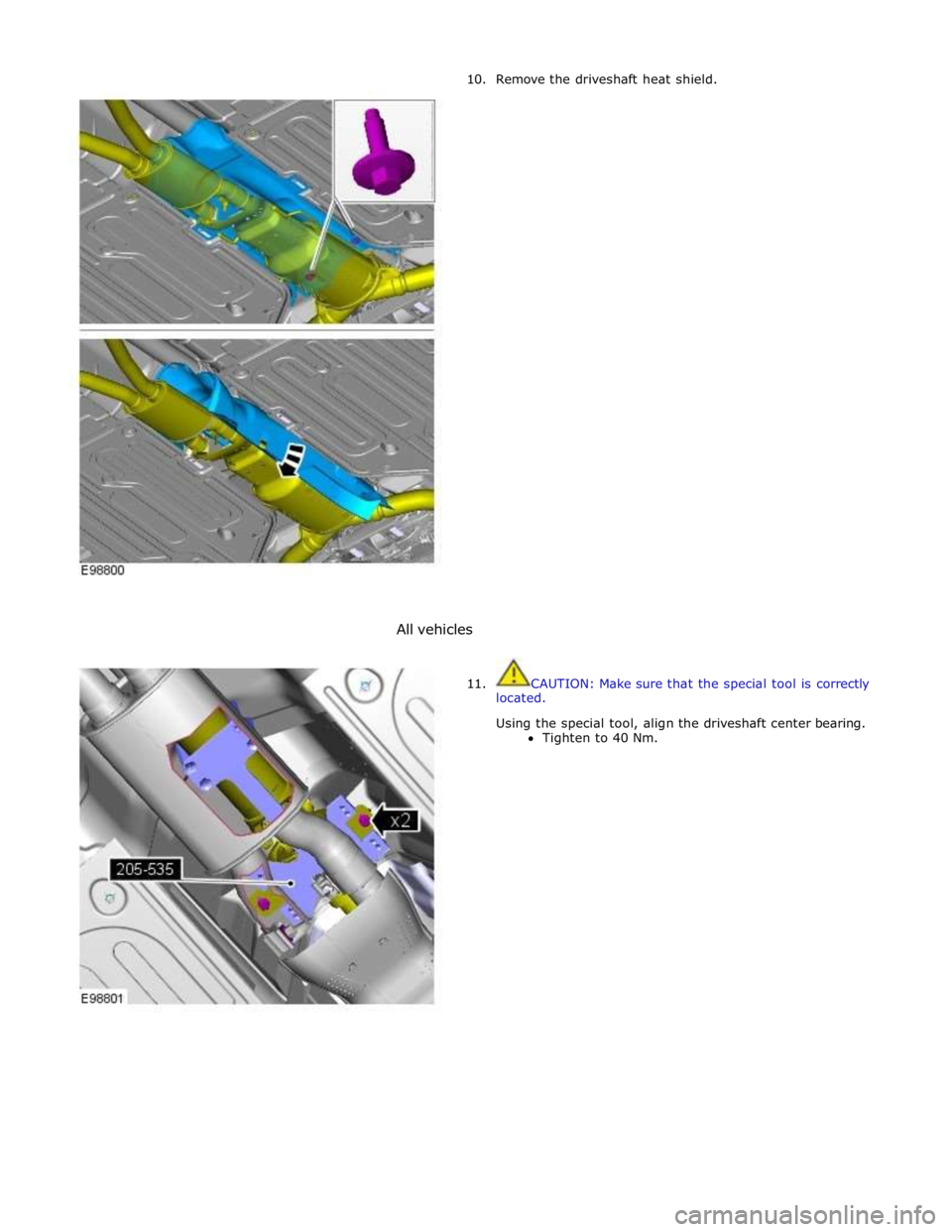

10. Remove the driveshaft heat shield.

All vehicles

11.

CAUTION: Make sure that the special tool is correctly

located.

Using the special tool, align the driveshaft center bearing.

Tighten to 40 Nm.

Page 507 of 3039

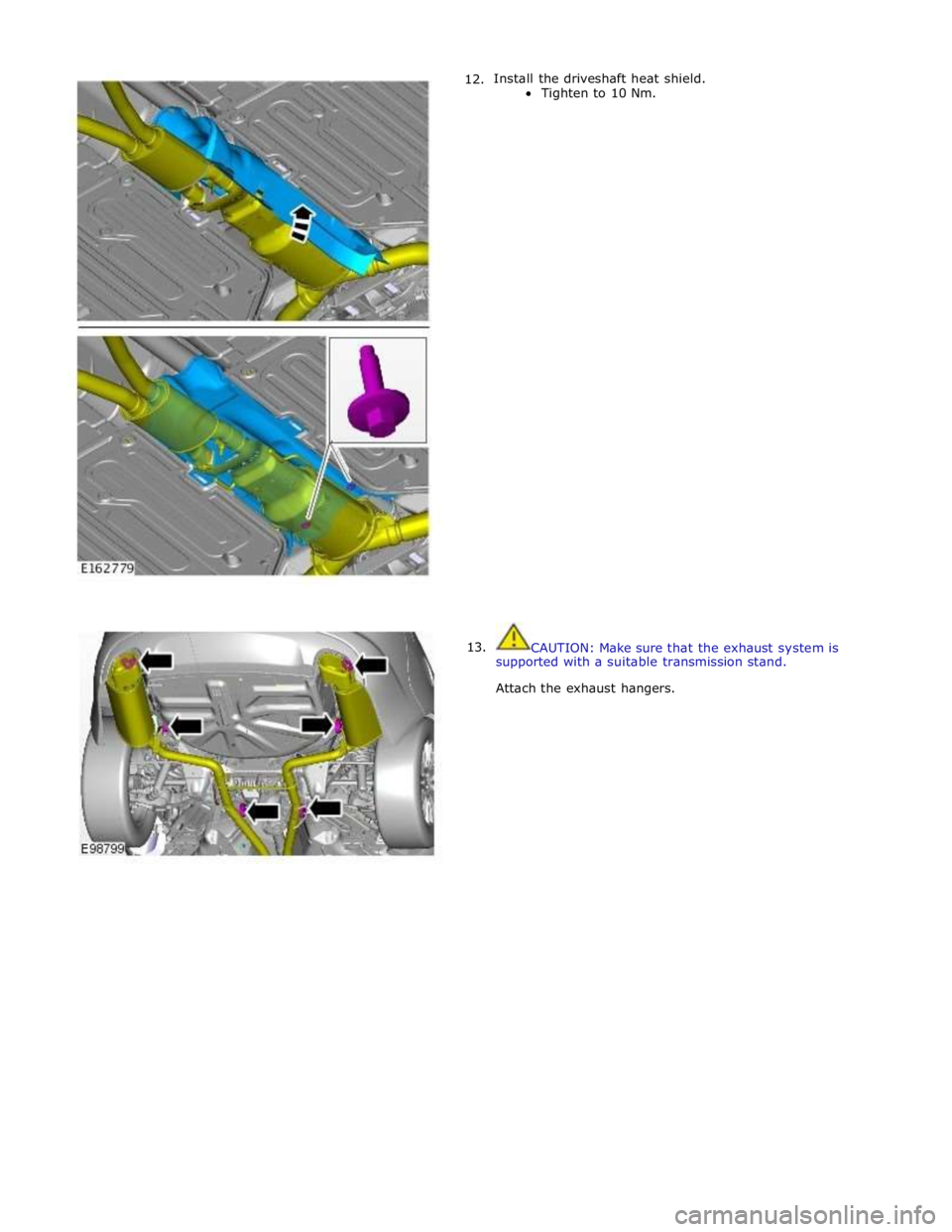

12.

13. Install the driveshaft heat shield.

Tighten to 10 Nm.

CAUTION: Make sure that the exhaust system is

supported with a suitable transmission stand.

Attach the exhaust hangers.

Page 508 of 3039

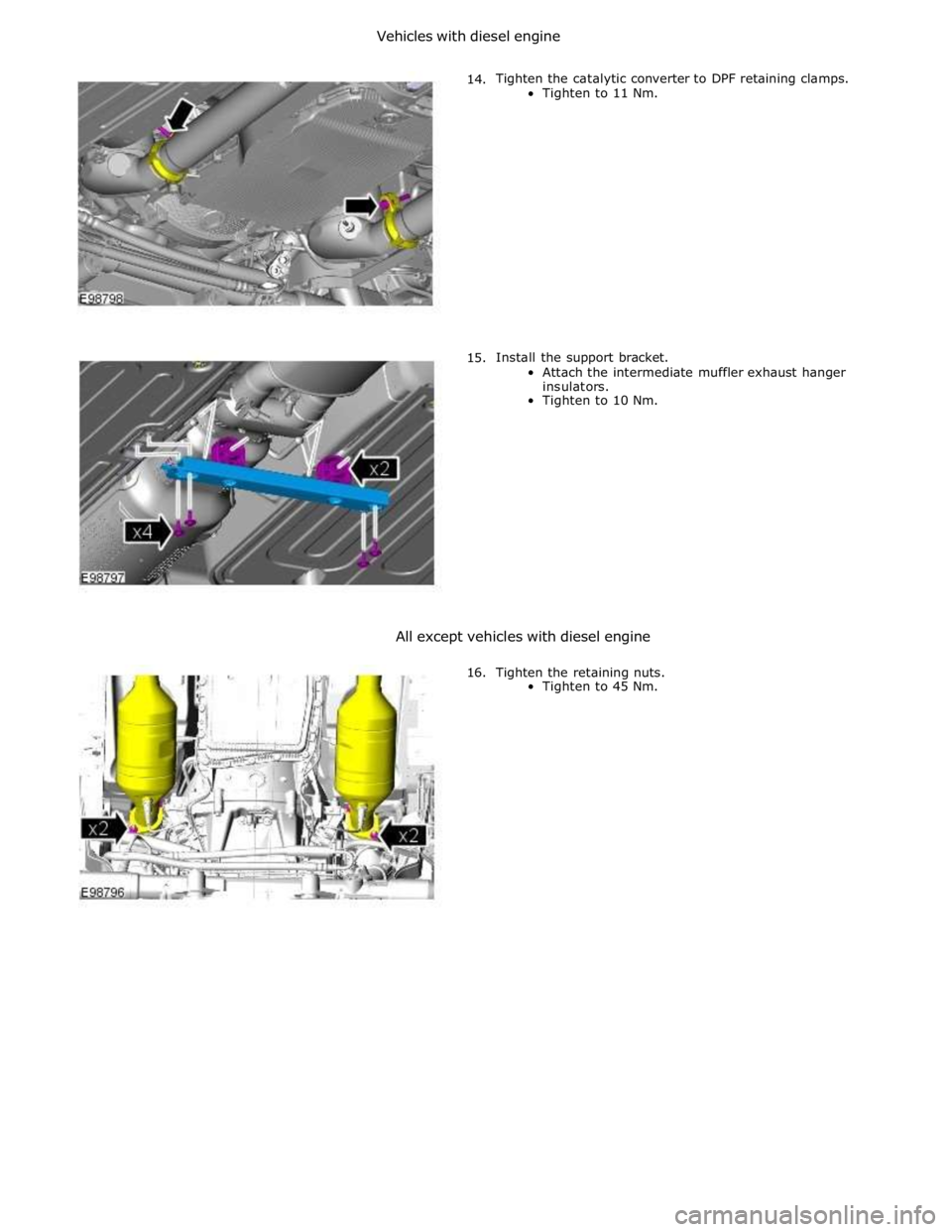

Vehicles with diesel engine

14.

15. Tighten the catalytic converter to DPF retaining clamps.

Tighten to 11 Nm.

Install the support bracket.

Attach the intermediate muffler exhaust hanger

insulators.

Tighten to 10 Nm.

All except vehicles with diesel engine

16. Tighten the retaining nuts.

Tighten to 45 Nm.

Page 509 of 3039

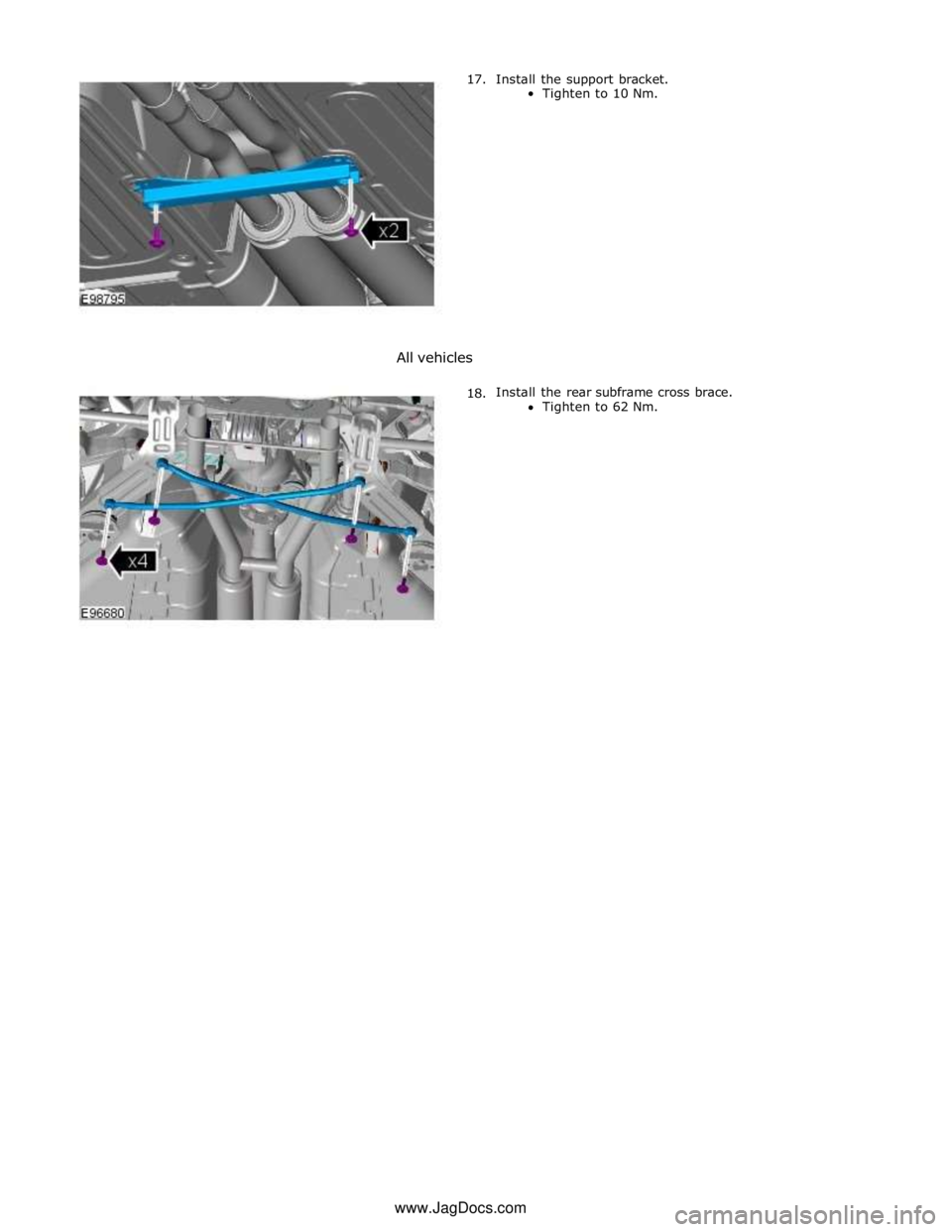

17. Install the support bracket.

Tighten to 10 Nm.

All vehicles

18. Install the rear subframe cross brace.

Tighten to 62 Nm. www.JagDocs.com

Page 510 of 3039

Panels, Removal and Installation).

Trending: fuse inspection, emergency towing, change language, Accessory Drive Belt Tensioner, octane, Map sensor, u1000