Coolant JAGUAR XFR 2010 1.G Repair Manual

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 2010, Model line: XFR, Model: JAGUAR XFR 2010 1.GPages: 3039, PDF Size: 58.49 MB

Page 1169 of 3039

Published: 11-May-2011

Supercharger Cooling - V8 S/C 5.0L Petrol - Supercharger Cooling - System

Operation and Component Description

Description and Operation

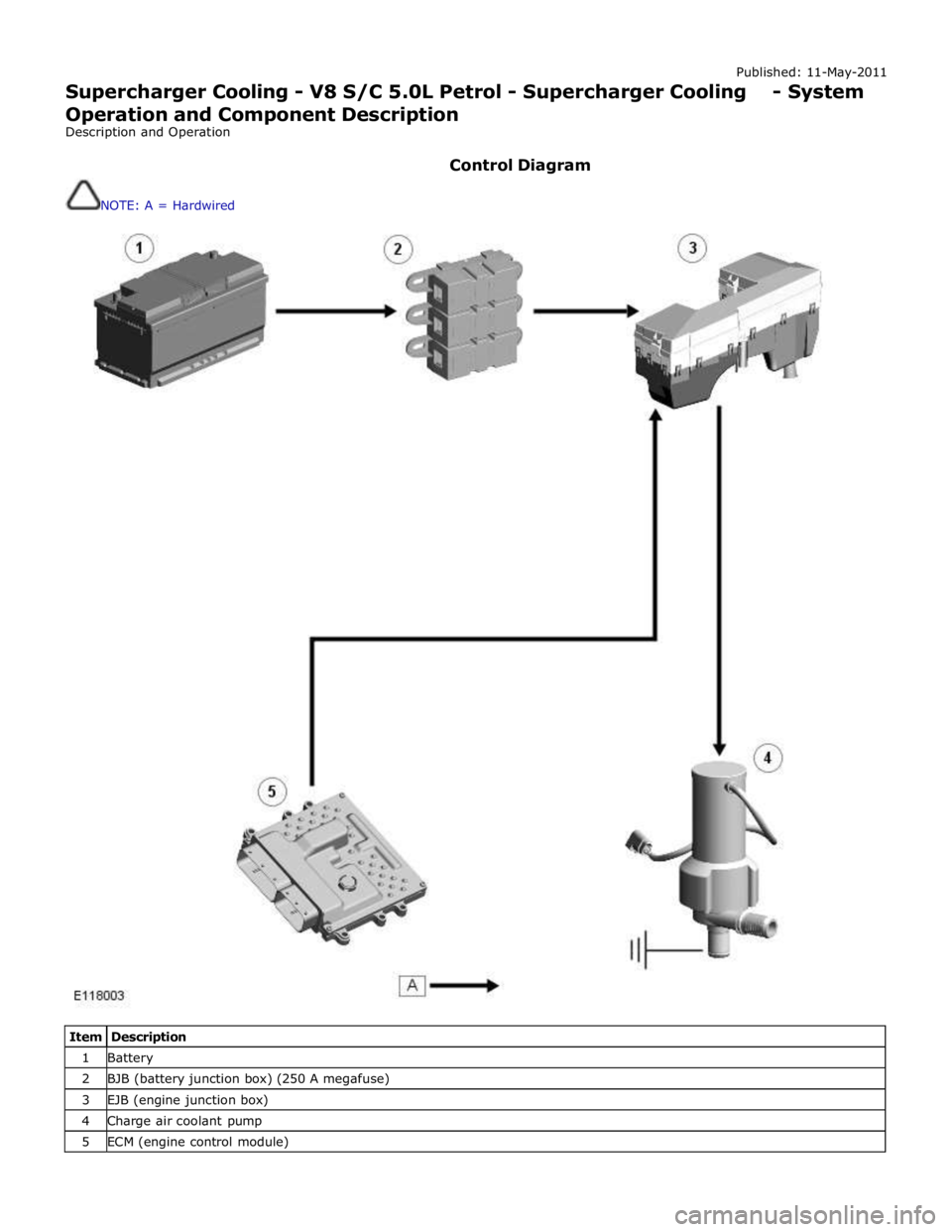

Control Diagram

NOTE: A = Hardwired

Item Description 1 Battery 2 BJB (battery junction box) (250 A megafuse) 3 EJB (engine junction box) 4 Charge air coolant pump 5 ECM (engine control module)

Page 1170 of 3039

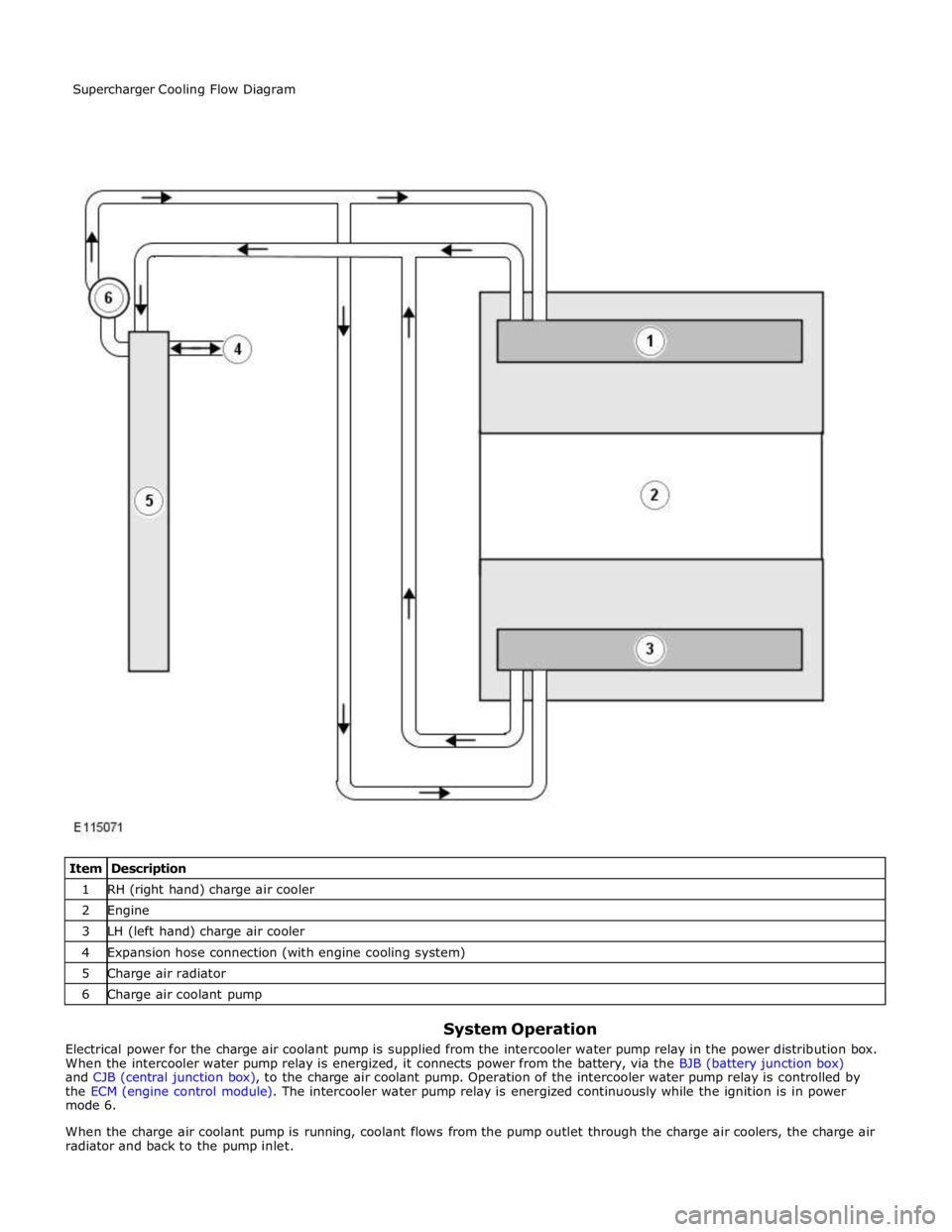

1 RH (right hand) charge air cooler 2 Engine 3 LH (left hand) charge air cooler 4 Expansion hose connection (with engine cooling system) 5 Charge air radiator 6 Charge air coolant pump

System Operation

Electrical power for the charge air coolant pump is supplied from the intercooler water pump relay in the power distribution box.

When the intercooler water pump relay is energized, it connects power from the battery, via the BJB (battery junction box)

and CJB (central junction box), to the charge air coolant pump. Operation of the intercooler water pump relay is controlled by

the ECM (engine control module). The intercooler water pump relay is energized continuously while the ignition is in power

mode 6.

When the charge air coolant pump is running, coolant flows from the pump outlet through the charge air coolers, the charge air

radiator and back to the pump inlet. Supercharger Cooling Flow Diagram

Page 1171 of 3039

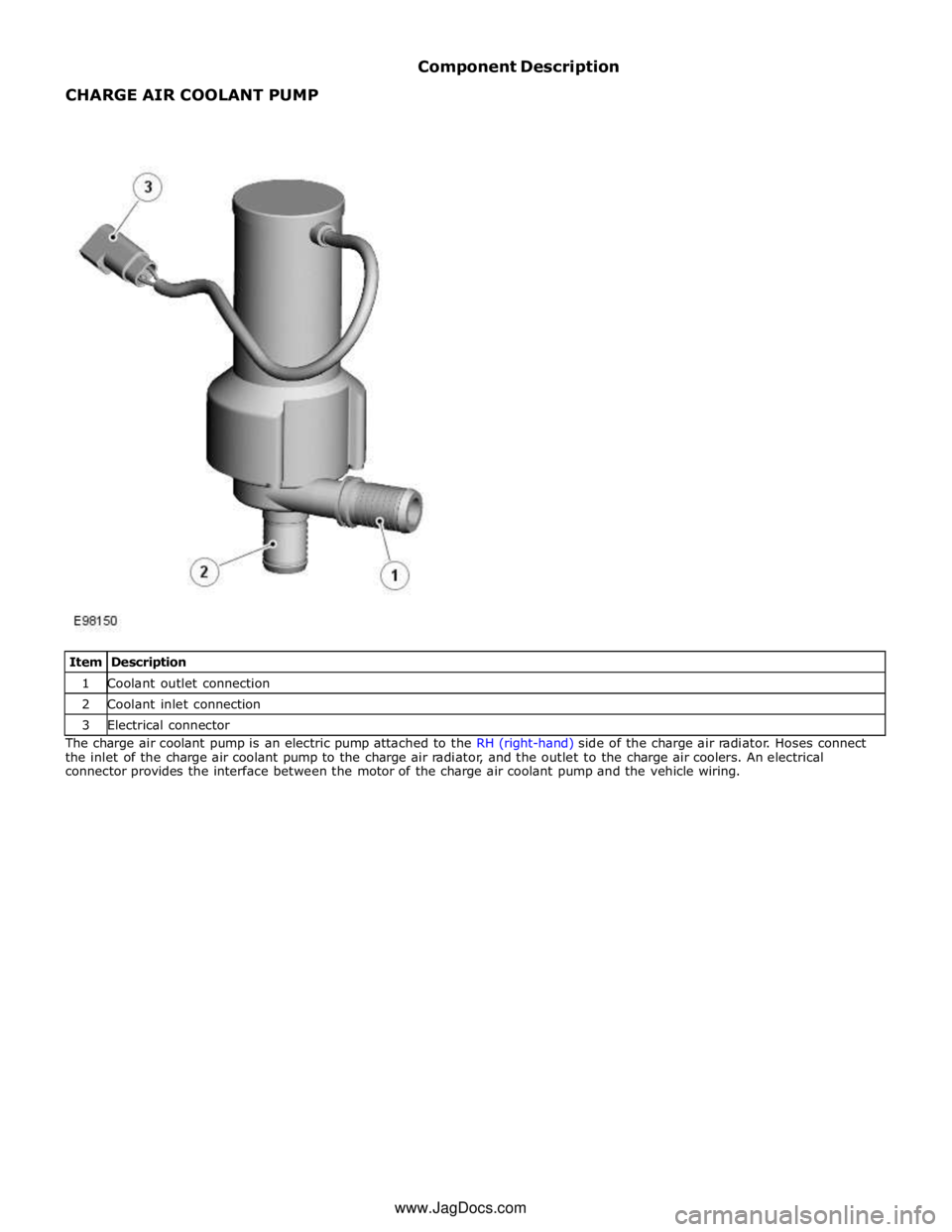

1 Coolant outlet connection 2 Coolant inlet connection 3 Electrical connector The charge air coolant pump is an electric pump attached to the RH (right-hand) side of the charge air radiator. Hoses connect

the inlet of the charge air coolant pump to the charge air radiator, and the outlet to the charge air coolers. An electrical

connector provides the interface between the motor of the charge air coolant pump and the vehicle wiring. www.JagDocs.com

Page 1172 of 3039

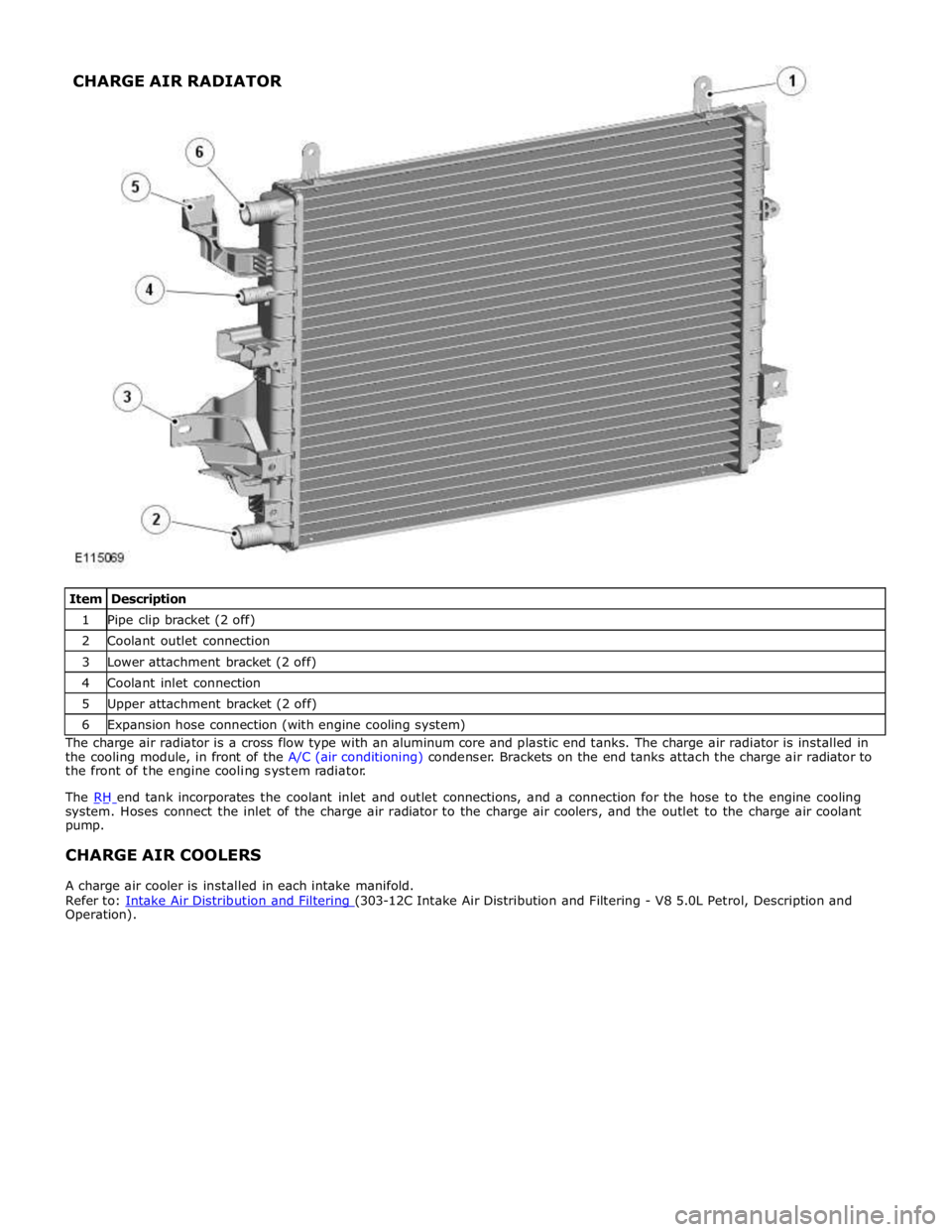

1 Pipe clip bracket (2 off) 2 Coolant outlet connection 3 Lower attachment bracket (2 off) 4 Coolant inlet connection 5 Upper attachment bracket (2 off) 6 Expansion hose connection (with engine cooling system) The charge air radiator is a cross flow type with an aluminum core and plastic end tanks. The charge air radiator is installed in

the cooling module, in front of the A/C (air conditioning) condenser. Brackets on the end tanks attach the charge air radiator to

the front of the engine cooling system radiator.

The RH end tank incorporates the coolant inlet and outlet connections, and a connection for the hose to the engine cooling system. Hoses connect the inlet of the charge air radiator to the charge air coolers, and the outlet to the charge air coolant

pump.

CHARGE AIR COOLERS

A charge air cooler is installed in each intake manifold.

Refer to: Intake Air Distribution and Filtering (303-12C Intake Air Distribution and Filtering - V8 5.0L Petrol, Description and Operation). CHARGE AIR RADIATOR

Page 1173 of 3039

Supercharger Cooling - V8 S/C 5.0L Petrol - Radiator

Removal and Installation

Removal

NOTE: Removal steps in this procedure may contain installation details. Published: 19-Nov-2013

1. Refer to: Battery Disconnect and Connect (414-01 Battery, Mounting and Cables, General Procedures).

2. Refer to: Air Cleaner LH (303-12C Intake Air Distribution and Filtering - V8 5.0L Petrol, Removal and Installation).

3. Refer to: Air Cleaner RH (303-12C Intake Air Distribution and Filtering - V8 5.0L Petrol, Removal and Installation).

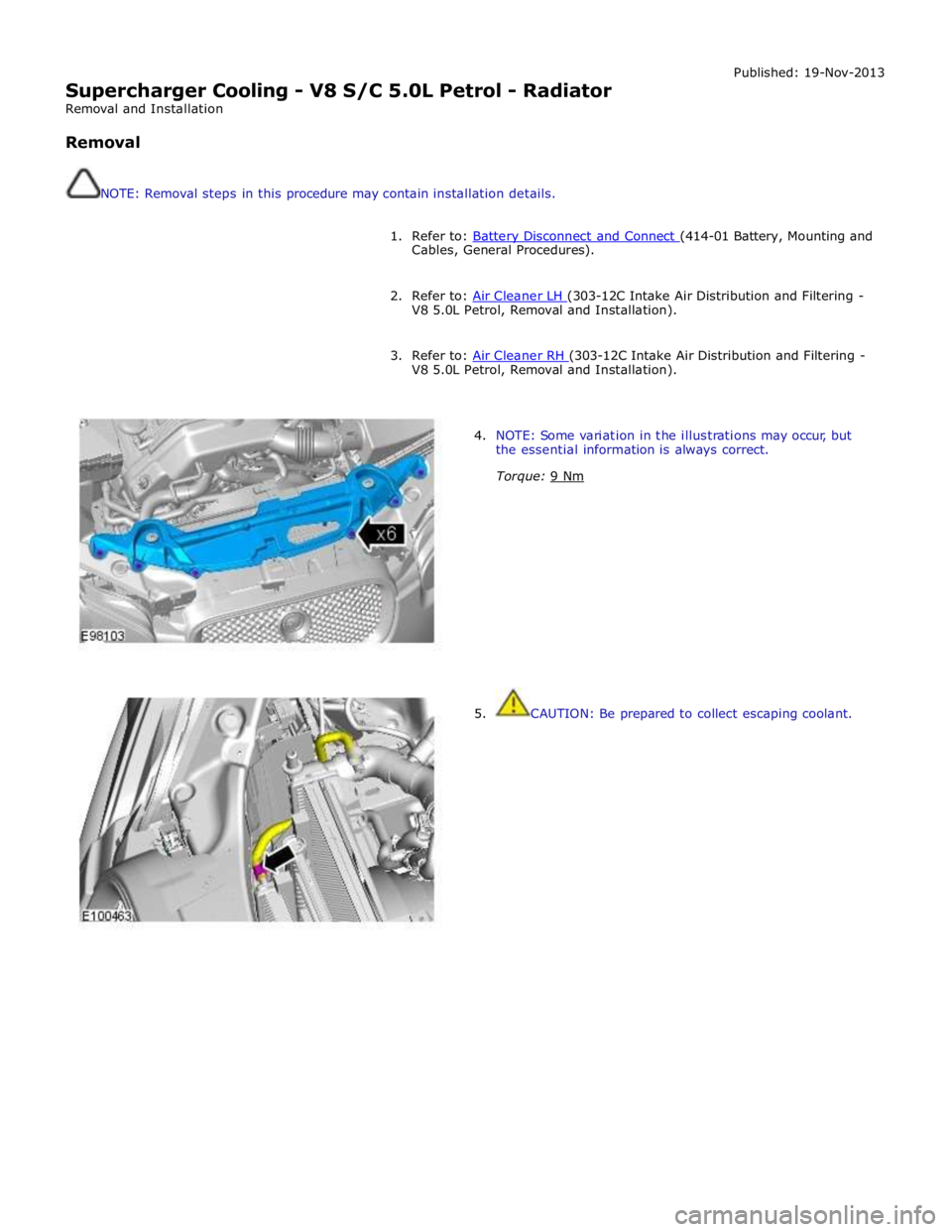

4. NOTE: Some variation in the illustrations may occur, but

the essential information is always correct.

Torque: 9 Nm

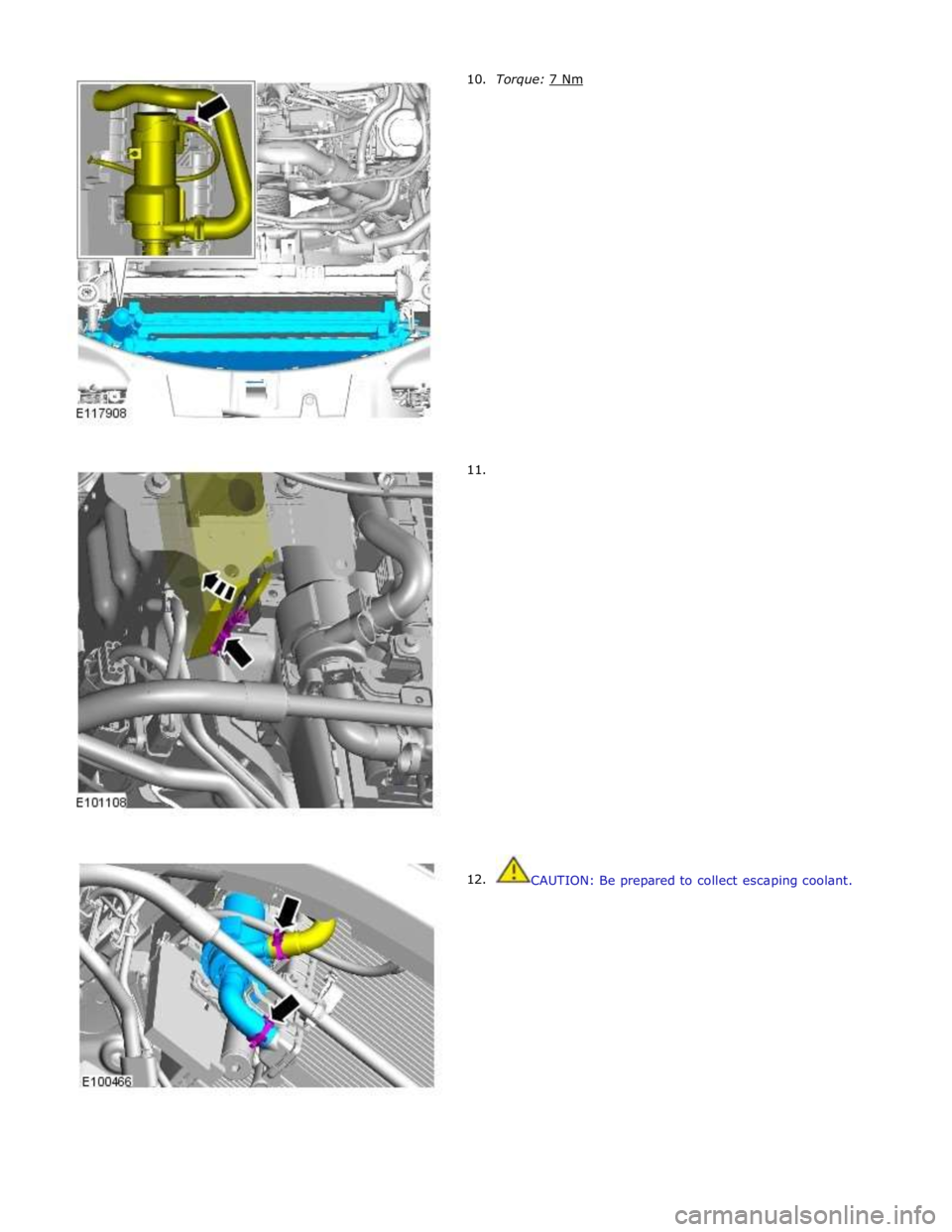

5. CAUTION: Be prepared to collect escaping coolant.

Page 1175 of 3039

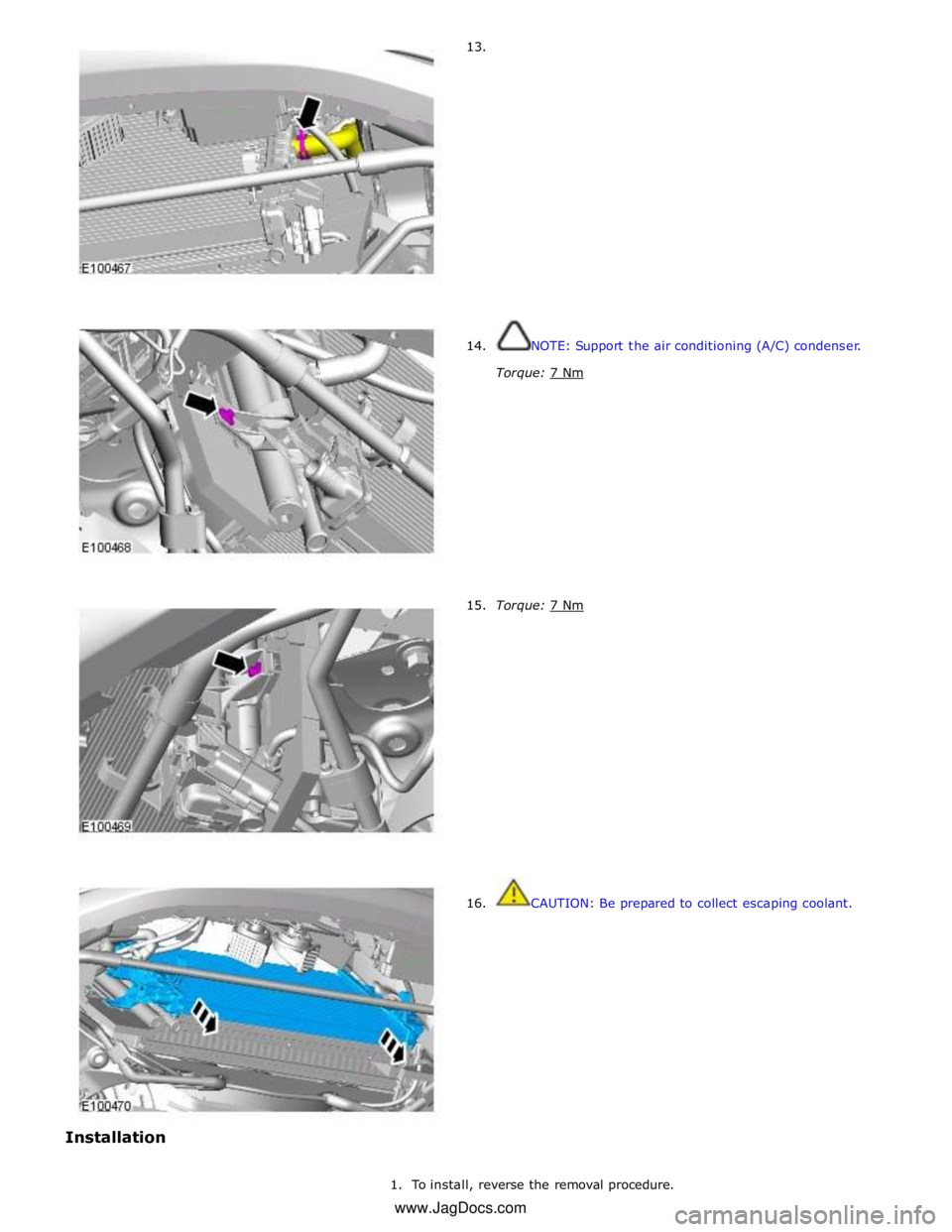

10.

11.

12. Torque: 7 Nm

CAUTION: Be prepared to collect escaping coolant.

Page 1176 of 3039

Installation 13.

14.

15.

16.

NOTE: Support the air conditioning (A/C) condenser.

Torque: 7 Nm

Torque: 7 Nm

CAUTION: Be prepared to collect escaping coolant.

1. To install, reverse the removal procedure. www.JagDocs.com

Page 1177 of 3039

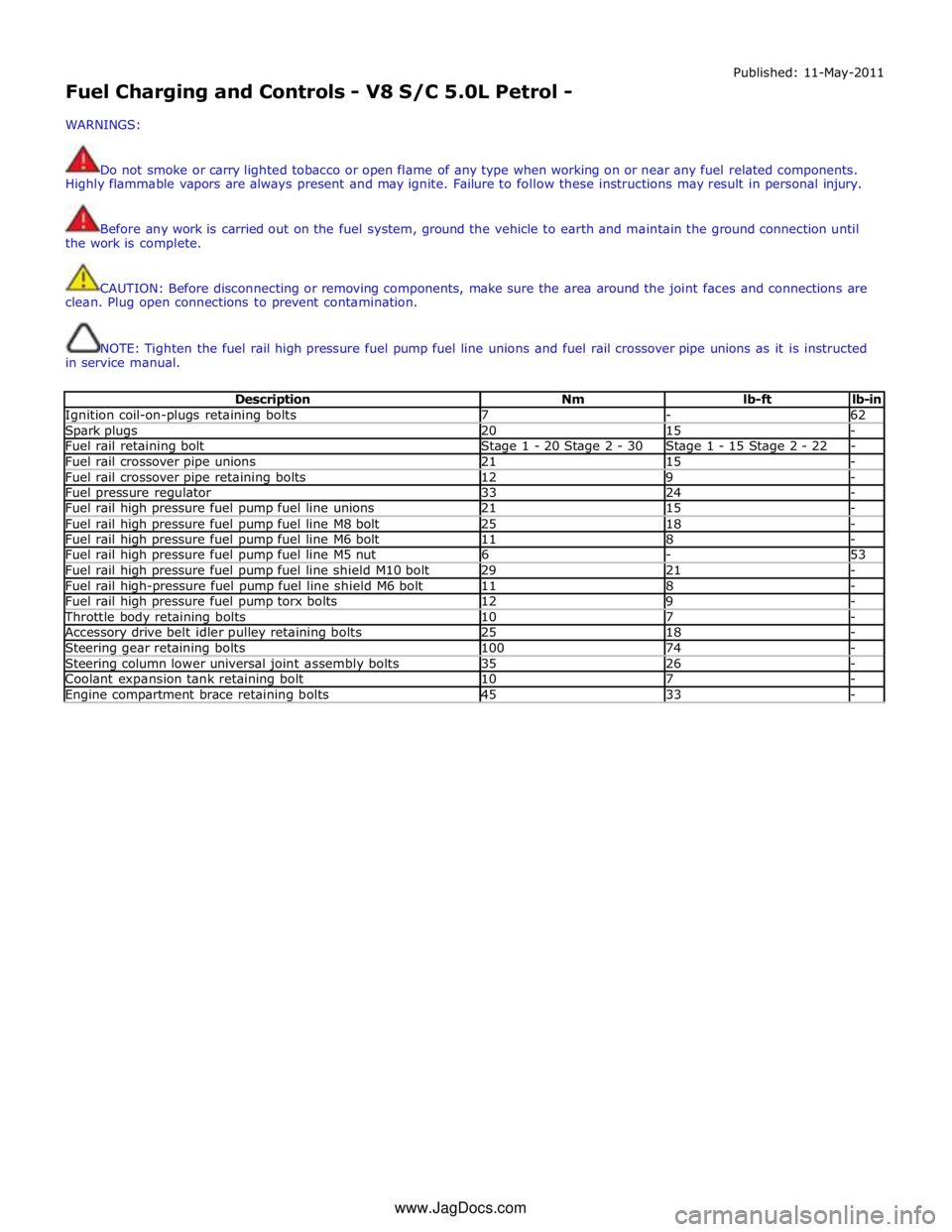

Fuel Charging and Controls - V8 S/C 5.0L Petrol -

WARNINGS: Published: 11-May-2011

Do not smoke or carry lighted tobacco or open flame of any type when working on or near any fuel related components.

Highly flammable vapors are always present and may ignite. Failure to follow these instructions may result in personal injury.

Before any work is carried out on the fuel system, ground the vehicle to earth and maintain the ground connection until

the work is complete.

CAUTION: Before disconnecting or removing components, make sure the area around the joint faces and connections are

clean. Plug open connections to prevent contamination.

NOTE: Tighten the fuel rail high pressure fuel pump fuel line unions and fuel rail crossover pipe unions as it is instructed

in service manual.

Description Nm lb-ft lb-in Ignition coil-on-plugs retaining bolts 7 - 62 Spark plugs 20 15 - Fuel rail retaining bolt Stage 1 - 20 Stage 2 - 30 Stage 1 - 15 Stage 2 - 22 - Fuel rail crossover pipe unions 21 15 - Fuel rail crossover pipe retaining bolts 12 9 - Fuel pressure regulator 33 24 - Fuel rail high pressure fuel pump fuel line unions 21 15 - Fuel rail high pressure fuel pump fuel line M8 bolt 25 18 - Fuel rail high pressure fuel pump fuel line M6 bolt 11 8 - Fuel rail high pressure fuel pump fuel line M5 nut 6 - 53 Fuel rail high pressure fuel pump fuel line shield M10 bolt 29 21 - Fuel rail high-pressure fuel pump fuel line shield M6 bolt 11 8 - Fuel rail high pressure fuel pump torx bolts 12 9 - Throttle body retaining bolts 10 7 - Accessory drive belt idler pulley retaining bolts 25 18 - Steering gear retaining bolts 100 74 - Steering column lower universal joint assembly bolts 35 26 - Coolant expansion tank retaining bolt 10 7 - Engine compartment brace retaining bolts 45 33 - www.JagDocs.com

Page 1187 of 3039

Published: 11-May-2011

Fuel Charging and Controls - V8 S/C 5.0L Petrol - Fuel Charging and Controls

Diagnosis and Testing

Principles of Operation

For a detailed description of the fuel charging and controls system and operation, refer to the relevant Description and

Operation section of the workshop manual. REFER to:

Fuel Charging and Controls (303-04D Fuel Charging and Controls - V8 5.0L Petrol, Description and Operation), Fuel Charging and Controls (303-04D Fuel Charging and Controls - V8 5.0L Petrol, Description and Operation), Fuel Charging and Controls (303-04D Fuel Charging and Controls - V8 5.0L Petrol, Description and Operation), Fuel Charging and Controls (303-04E Fuel Charging and Controls - V8 S/C 5.0L Petrol, Description and Operation), Fuel Charging and Controls (303-04E Fuel Charging and Controls - V8 S/C 5.0L Petrol, Description and Operation), Fuel Charging and Controls (303-04E Fuel Charging and Controls - V8 S/C 5.0L Petrol, Description and Operation).

Inspection and Verification

CAUTION: Diagnosis by substitution from a donor vehicle is NOT acceptable. Substitution of control modules does not

guarantee confirmation of a fault and may also cause additional faults in the vehicle being checked and/or the donor vehicle.

NOTE: Check and rectify basic faults before beginning diagnostic routines involving pinpoint tests.

1. Verify the customer concern.

2. Visually inspect for obvious signs of mechanical or electrical damage.

Visual Inspection

Mechanical Electrical

Fuel level

Fuel leaks

Damaged fuel lines

Damaged push connect fittings

Fuel contamination/grade/quality

Throttle body

Damaged fuel tank filler pipe cap

Damaged fuel tank filler pipe

Fuses

Loose or corroded electrical connectors

Harnesses

Sensor(s)

Engine Control Module (ECM)

3. If an obvious cause for an observed or reported concern is found, correct the cause (if possible) before proceeding to

the next step.

4. If the cause is not visually evident, verify the symptom and refer to the Symptom Chart, alternatively check for

Diagnostic Trouble Codes (DTCs) and refer to the DTC Index.

Symptom Chart

Symptom Possible Causes Action Engine cranks, but does not

fire

Engine breather system

disconnected/restricted

Ignition system

Fuel system

Electronic engine control Ensure the engine breather system is free from restriction

and is correctly installed. Check for ignition system, fuel

system and electronic engine control DTCs and refer to the

relevant DTC Index Engine cranks and fires, but

will not start

Evaporative emissions purge

valve

Fuel pump

Spark plugs

HT short to ground (tracking)

check rubber boots for

cracks/damage

Ignition system Check for evaporative emissions, fuel system and ignition

system related DTCs and refer to the relevant DTC Index Difficult cold start

Engine coolant level/anti-

freeze content

Battery

Electronic engine controls

Exhaust Gas Recirculation

(EGR) valve stuck open

Fuel pump Check the engine coolant level and condition. Ensure the

battery is in a fully charged and serviceable condition.

Check for electronic engine controls, engine emissions, fuel

system and evaporative emissions system related DTCs

and refer to the relevant DTC Index www.JagDocs.com

Page 1247 of 3039

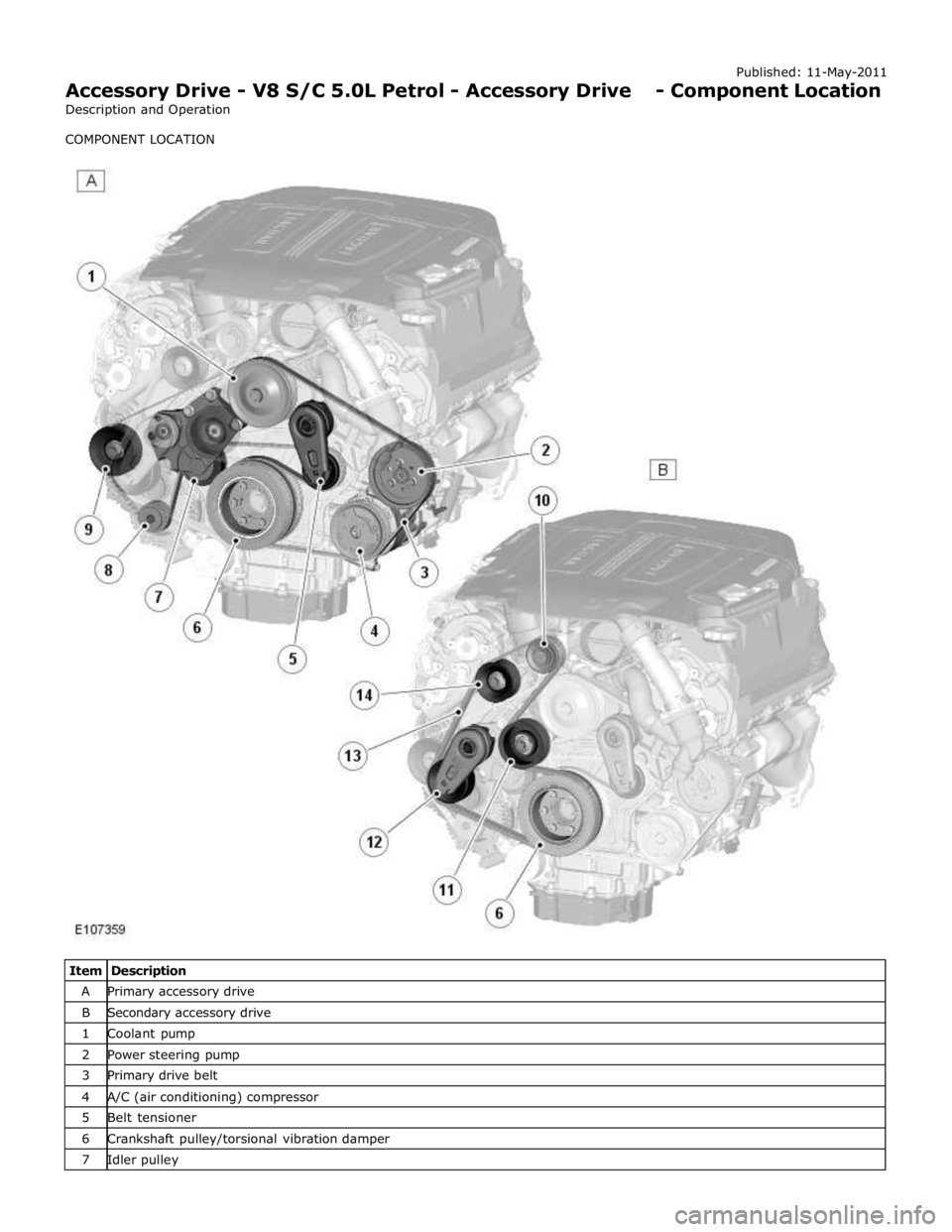

Published: 11-May-2011

Accessory Drive - V8 S/C 5.0L Petrol - Accessory Drive - Component Location

Description and Operation

COMPONENT LOCATION

Item Description A Primary accessory drive B Secondary accessory drive 1 Coolant pump 2 Power steering pump 3 Primary drive belt 4 A/C (air conditioning) compressor 5 Belt tensioner 6 Crankshaft pulley/torsional vibration damper 7 Idler pulley