Rear Drive JAGUAR XFR 2010 1.G Repair Manual

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 2010, Model line: XFR, Model: JAGUAR XFR 2010 1.GPages: 3039, PDF Size: 58.49 MB

Page 664 of 3039

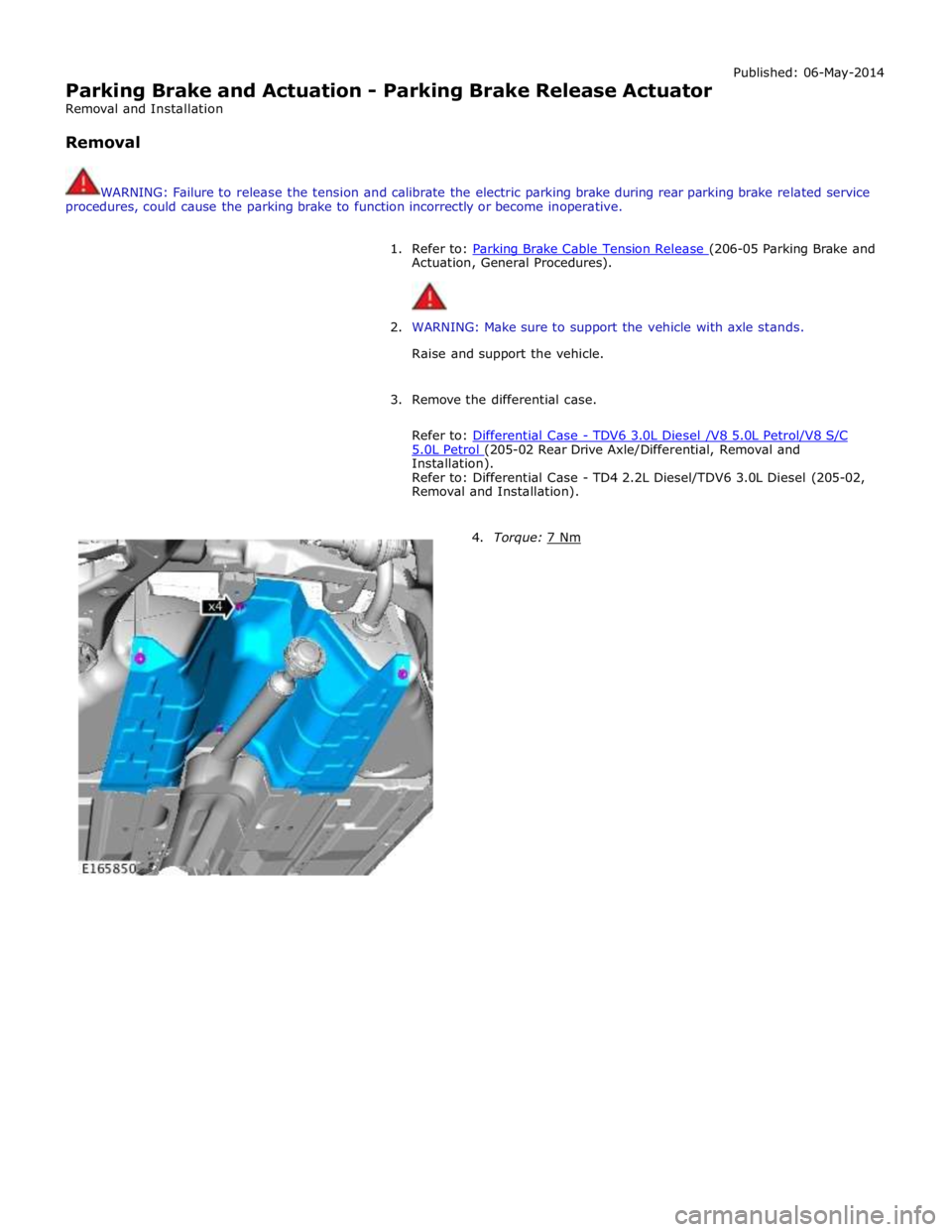

Parking Brake and Actuation - Parking Brake Release Actuator

Removal and Installation

Removal Published: 06-May-2014

WARNING: Failure to release the tension and calibrate the electric parking brake during rear parking brake related service

procedures, could cause the parking brake to function incorrectly or become inoperative.

1. Refer to: Parking Brake Cable Tension Release (206-05 Parking Brake and Actuation, General Procedures).

2. WARNING: Make sure to support the vehicle with axle stands.

Raise and support the vehicle.

3. Remove the differential case.

Refer to: Differential Case - TDV6 3.0L Diesel /V8 5.0L Petrol/V8 S/C 5.0L Petrol (205-02 Rear Drive Axle/Differential, Removal and Installation).

Refer to: Differential Case - TD4 2.2L Diesel/TDV6 3.0L Diesel (205-02,

Removal and Installation).

4. Torque: 7 Nm

Page 691 of 3039

Published: 02-Sep-2011

Anti-Lock Control - Stability Assist - Anti-Lock Control - Stability Assist - Component Location

Description and Operation

NOTE: RHD (right-hand drive) installation shown, LHD (left-hand drive) installation similar.

Component Location

Item Description 1 ABS (anti-lock brake system) module 2 RH (right-hand) front wheel speed sensor 3 Instrument cluster 4 Steering angle sensor 5 Yaw rate and lateral acceleration sensor 6 RH rear wheel speed sensor 7 LH (left-hand) rear wheel speed sensor 8 LH front wheel speed sensor

Page 692 of 3039

Published: 11-May-2011

Anti-Lock Control - Stability Assist - Anti-Lock Control - Stability Assist - Overview

Description and Operation

Overview

The ABS (anti-lock brake system) and DSC (dynamic stability control) system features a Bosch modulator, which is an

integrated four-channel HCU (hydraulic control unit) and ABS module. The unit is located in the rear of the engine compartment on the passenger side, and is installed in the brake hydraulic circuit between the brake master cylinder and the four brake

calipers.

The ABS module is connected to the high speed CAN (controller area network) bus, and actively interacts with other vehicle system control modules and associated sensors to receive and transmit current vehicle operating information.

When required, the ABS module will actively intervene and operate the HCU during braking or vehicle maneuvers to correct the vehicle attitude, stability, traction or speed. During incidents of vehicle correction, the ABS module may also request the ECM (engine control module) to control engine power in order to further stabilize and correct the vehicle.

To provide full system functionality, the ABS and DSC system comprise the following components: DSC switch.

Four wheel speed sensors.

Steering angle sensor.

Yaw rate and lateral acceleration sensor.

Stoplamp switch.

Instrument cluster indicator lamps.

Integrated ABS module and HCU. Brake booster vacuum sensor (3.0L vehicles only).

Two variants of ABS module are available, Bosch ESP®8.1 and Bosch ESP®plus8.1. The Bosch ESP®plus8.1 system is fitted to vehicles with ACC (adaptive cruise control) and incorporates a new feature to Jaguar known as 'electronic brake prefill'.

Electronic brake prefill, senses any rapid throttle lift off, activating a small brake hydraulic pressure build-up of approximately 3

to 5 bar (43.5 to 72.5 lbf/in²) in anticipation of the brakes being applied. This application produces a quicker brake pedal

response and consequently slightly shorter stopping distances. When the ECM detects rapid throttle lift off it signals the ABS module which controls the HCU to apply a low brake pressure to assist in a quicker brake application.

NOTE: All vehicles with ACC are supported by the Bosch ESP®plus8.1 system.

The ABS provides the following brake functions that are designed to assist the vehicle or aid the driver: ABS. DSC, including Trac DSC.

CBC (corner brake control).

EBD (electronic brake force distribution).

ETC (electronic traction control).

EBA (emergency brake assist).

EDC (engine drag-torque control).

Understeer control.

Electronic brake prefill (vehicles with ACC only).

Brake vacuum assist (3.0L vehicles only).

All the brake functions listed are automatically active when the ignition is in power mode and the engine is running. The DSC

system can be selected to off using the DSC switch.

WARNING: Although the vehicle is fitted with DSC, it remains the drivers responsibility to drive safely according to the

prevailing conditions.

Page 694 of 3039

7 Brake fluid level switch 8 LH rear wheel speed sensor 9 RH rear wheel speed sensor 10 RJB (rear junction box) 11 High mounted stop lamp 12 LH stop lamp 13 RH stop lamp 14 Diagnostic socket 15 TCM (transmission control module) 16 Electronic parking brake module 17 ECM (engine control module) 18 Instrument cluster 19 ABS (anti-lock brake system) module 20 JaguarDrive selector module 21 Adaptive damping control module 22 Adaptive speed control module 23 Yaw rate and lateral acceleration sensor 24 Roof opening panel motor/module 25 Brake booster vacuum sensor (3.0L vehicles only) 26 Steering angle sensor

Anti-Lock Brake System System Operation

ABS controls the speed of all road wheels to ensure optimum wheel slip when braking at the adhesion limit. The wheels are prevented from locking to retain effective steering control of the vehicle.

The brake pressures are modulated separately for each wheel. Rear brake pressures are controlled to maintain rear stability on

split friction surfaces.

Dynamic Stability Control

DSC (dynamic stability control) uses brakes and powertrain torque control to assist in maintaining the yaw stability of the

vehicle. While the ignition is energized the DSC function is permanently enabled, unless selected off using the DSC switch.

DSC enhances driving safety in abrupt maneuvers and in under-steer or over-steer situations that may occur in a bend. The

ABS module monitors the yaw rate and lateral acceleration of the vehicle, steering input and individual wheel speeds, then selectively applies individual brakes and signals for powertrain torque adjustments to reduce under-steer or over-steer

conditions.

In general:

In an under-steer situation the inner wheels are braked to counteract the yaw movement towards the outer edge of the

bend.

In an over-steer situation the outer wheels are braked to prevent the rear end of the vehicle from pushing towards the

outer edge of the bend.

The ABS module monitors the tracking stability of the vehicle using inputs from the wheel speed sensors, the steering angle sensor, and the yaw rate and lateral acceleration sensor. The tracking stability is compared with stored target data. Whenever

the tracking stability deviates from the target data, the ABS module intervenes by applying the appropriate control strategy. The following interactions occur in an intervention situation:

High speed CAN signal to the ECM, to reduce engine torque. Application of braking to the appropriate corner of the vehicle.

Trac DSC

TracDSC is an alternative setting of DSC with reduced system interventions. With TracDSC engaged, traction may be somewhat

increased, although stability may be reduced compared to normal DSC. TracDSC is intended for use only on dry tarmac, by

suitably experienced drivers and should not be selected for other surfaces or by drivers with insufficient skill and training to

operate the vehicle safely with the TracDSC function engaged.

The less restrictive TracDSC setting may be preferred, for example, by expert drivers engaged in high performance driving on

dry Tarmac surfaces such as tracks and circuits.

Switching between DSC and Trac DSC:

Page 695 of 3039

Press and hold the DSC switch for less than 10 seconds.

The message center will temporarily display either Trac DSC or DSC ON.

The warning indicator in the instrument panel will illuminate while Trac DSC is selected.

The warning indicator will flash when DSC or Trac DSC is active.

NOTE: If cruise control is engaged, it will automatically disengage if DSC activates.

Refer to: Speed Control (310-03 Speed Control - 2.7L V6 - TdV6, Description and Operation).

Corner Brake Control

CBC (corner brake control) influences the brake pressures, below and within DSC and ABS thresholds, to counteract the yawing moment produced when braking in a corner. CBC produces a correction torque by limiting the brake pressure on one side of the

vehicle.

Electronic Brake Force Distribution

EBD (electronic brake force distribution) limits the brake pressure applied to the rear wheels. When the brakes are applied, the

weight of the vehicle transfers forwards, reducing the ability of the rear wheels to transfer braking effort to the road surface.

This may cause the rear wheels to slip and make the vehicle unstable.

EBD uses the ABS braking hardware to automatically optimize the pressure to the rear brakes, below the point where ABS is normally invoked.

NOTE: Only the rear brakes are controlled by the EBD function.

Electronic Traction Control

ETC (electronic traction control) attempts to optimize forward traction by reducing engine torque, or by applying the brake of a

spinning wheel until traction is regained.

ETC is activated if an individual wheel speed is above that of the vehicle reference speed (positive slip) and the brake pedal is

not pressed. The brake is applied to the spinning wheel, allowing the excess torque to be transmitted to the non-spinning

wheel through the drive line. If necessary, the ABS module also sends a high speed CAN bus message to the ECM to request a reduction in engine torque.

When the DSC function is selected off using the DSC switch, the braking and engine torque reduction features are both

disabled, except when the JaguarDrive control is in winter mode. When the JaguarDrive control is in winter mode, selecting the

DSC function off retains the braking and engine torque reduction features, but reduces intervention levels compared to DSC

and Trac DSC modes.

Emergency Brake Assist

EBA (emergency brake assist) assists the driver in emergency braking situations by automatically increasing the applied

braking effort. The ABS module invokes EBA when: The brake pedal is rapidly pressed.

The brake pedal is pressed hard enough to bring the front brakes into ABS operation.

When the brake pedal is rapidly pressed, the ABS module increases the hydraulic pressure to all of the brakes until the threshold for ABS operation is reached. This action applies the maximum braking effort for the available traction. The ABS module monitors for the sudden application of the brakes, using inputs from the brake pedal switch and from the pressure

sensor within the HCU (hydraulic control unit). With the brake pedal pressed, if the rate of increase of hydraulic pressure

exceeds the predetermined limit, the ABS module invokes emergency braking.

When the brake pedal is pressed hard enough to bring the front brakes into ABS operation, the ABS module increases the hydraulic pressure to the rear brakes up to the ABS threshold.

EBA operation continues until the driver releases the brake pedal, sufficiently for the hydraulic pressure in the HCU to drop below a threshold value stored in the ABS module.

Engine Drag-Torque Control

EDC (engine drag-torque control) prevents wheel slip caused by any of the following: A

sudden decrease in engine torque when the accelerator is suddenly released.

A downshift using the Jaguar sequential shift function on automatic transmission vehicles.

When the ABS module detects the onset of wheel slip without the brakes being applied, the ABS module signals the ECM via the high speed CAN bus to request a momentary increase in engine torque.

Understeer Control

Understeer Logic Control is a proactive system which monitors the vehicle for understeer by comparing signals from the yaw

rate and lateral acceleration sensor with signals from the steering angle sensor and wheel speed sensors. www.JagDocs.com

Page 697 of 3039

DSC becomes active whenever the engine is running. A momentary press of the switch allows the driver to toggle between the

standard DSC settings and the optimized 'Trac DSC' settings. The message 'Trac DSC' or 'DSC on' will temporarily be displayed

in the instrument cluster message center. The amber DSC warning indicator in the instrument cluster remains illuminated while

'Trac DSC' is selected.

The DSC can be switched off by pressing and holding the switch for more than 10 seconds.

In each case the message 'DSC OFF' will be displayed in the instrument cluster message center to confirm DSC has been

switched off. The amber DSC warning indicator in the instrument cluster will remain illuminated. The system can be switched

back on again by simply pressing and releasing the switch. The message 'DSC ON' will then temporarily appear in the

instrument cluster message center to confirm the system is on.

NOTE: Switch requests may be delayed if the switch is pressed while a DSC operation is taking place. The switch request

will be displayed in the instrument cluster but the ABS module will not initiate any stability changes until it is safe to do so.

If a fault is detected with the DSC switch, the ABS module defaults to the 'DSC ON' setting and any switch requests are ignored.

WARNING: It is recommended that when using snow chains, Trac DSC is switched off and JaguarDrive control winter mode

is selected.

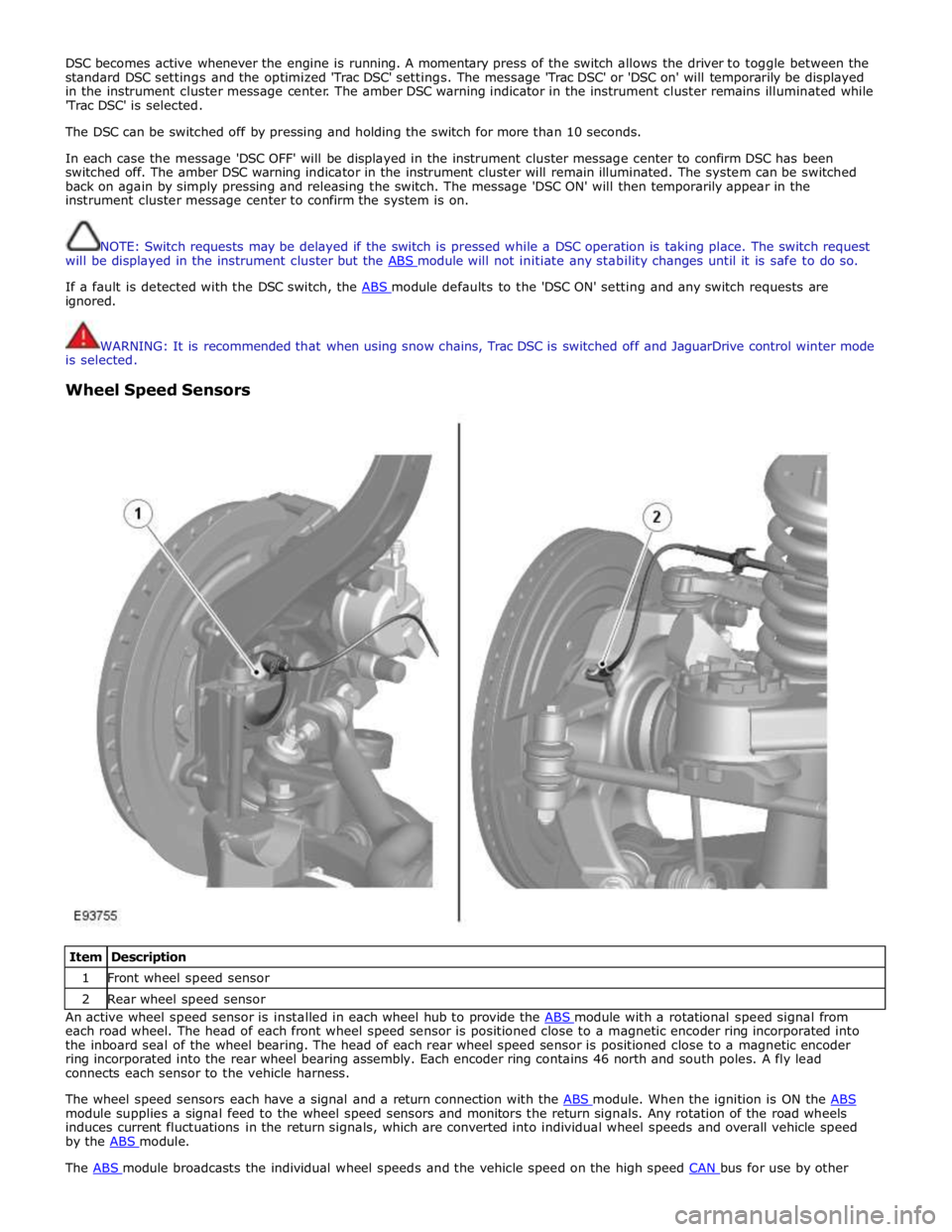

Wheel Speed Sensors

Item Description 1 Front wheel speed sensor 2 Rear wheel speed sensor An active wheel speed sensor is installed in each wheel hub to provide the ABS module with a rotational speed signal from each road wheel. The head of each front wheel speed sensor is positioned close to a magnetic encoder ring incorporated into

the inboard seal of the wheel bearing. The head of each rear wheel speed sensor is positioned close to a magnetic encoder

ring incorporated into the rear wheel bearing assembly. Each encoder ring contains 46 north and south poles. A fly lead

connects each sensor to the vehicle harness.

The wheel speed sensors each have a signal and a return connection with the ABS module. When the ignition is ON the ABS module supplies a signal feed to the wheel speed sensors and monitors the return signals. Any rotation of the road wheels

induces current fluctuations in the return signals, which are converted into individual wheel speeds and overall vehicle speed

by the ABS module. The ABS module broadcasts the individual wheel speeds and the vehicle speed on the high speed CAN bus for use by other

Page 708 of 3039

Published: 11-May-2011

Anti-Lock Control - Stability Assist - Hydraulic Control Unit (HCU)

Removal and Installation

Removal

All vehicles

1. Disconnect the battery ground cable.

For additional information, refer to: Battery Disconnect and Connect (414-01 Battery, Mounting and Cables, General Procedures).

Left-hand drive vehicles

2. Remove the secondary bulkhead RH panel.

For additional information, refer to: Secondary Bulkhead Panel RH - 3.0L NA V6 - AJ27 (501-02 Front End Body Panels, Removal and Installation).

Right-hand drive vehicles

3. Remove the secondary bulkhead LH panel.

For additional information, refer to: Secondary Bulkhead Panel LH - 3.0L NA V6 - AJ27 (501-02 Front End Body Panels, Removal and Installation).

All vehicles

4. WARNING: Do not work on or under a vehicle supported only by a

jack. Always support the vehicle on safety stands.

Raise and support the vehicle.

5. Connect brake bleed pipes and bottles to the left-hand front and the

left-hand rear brake caliper bleed nipples and loosen the brake caliper

bleed nipples.

6. NOTE: To prevent the loss of brake fluid, using the special tool

apply the brake pedal and set to 40mm ( 1.6 in ) below the rest

position.

Using the special tool, press and hold the brake pedal.

7. Remove the bleed pipes and bottles.

Tighten the left-hand front brake caliper bleed nipple. 1. For vehicles with supercharger: Tighten to 14Nm.

2. For vehicles without supercharger: Tighten to 8 Nm.

Tighten the left-hand rear brake caliper bleed nipple.

1. All vehicles: Tighten to 14 Nm.

Disconnect and remove the brake bleed pipes and bottles.

Install the bleed nipple dust caps. Brake pedal hold down tool

JDS9013 Special Tool(s)

Page 721 of 3039

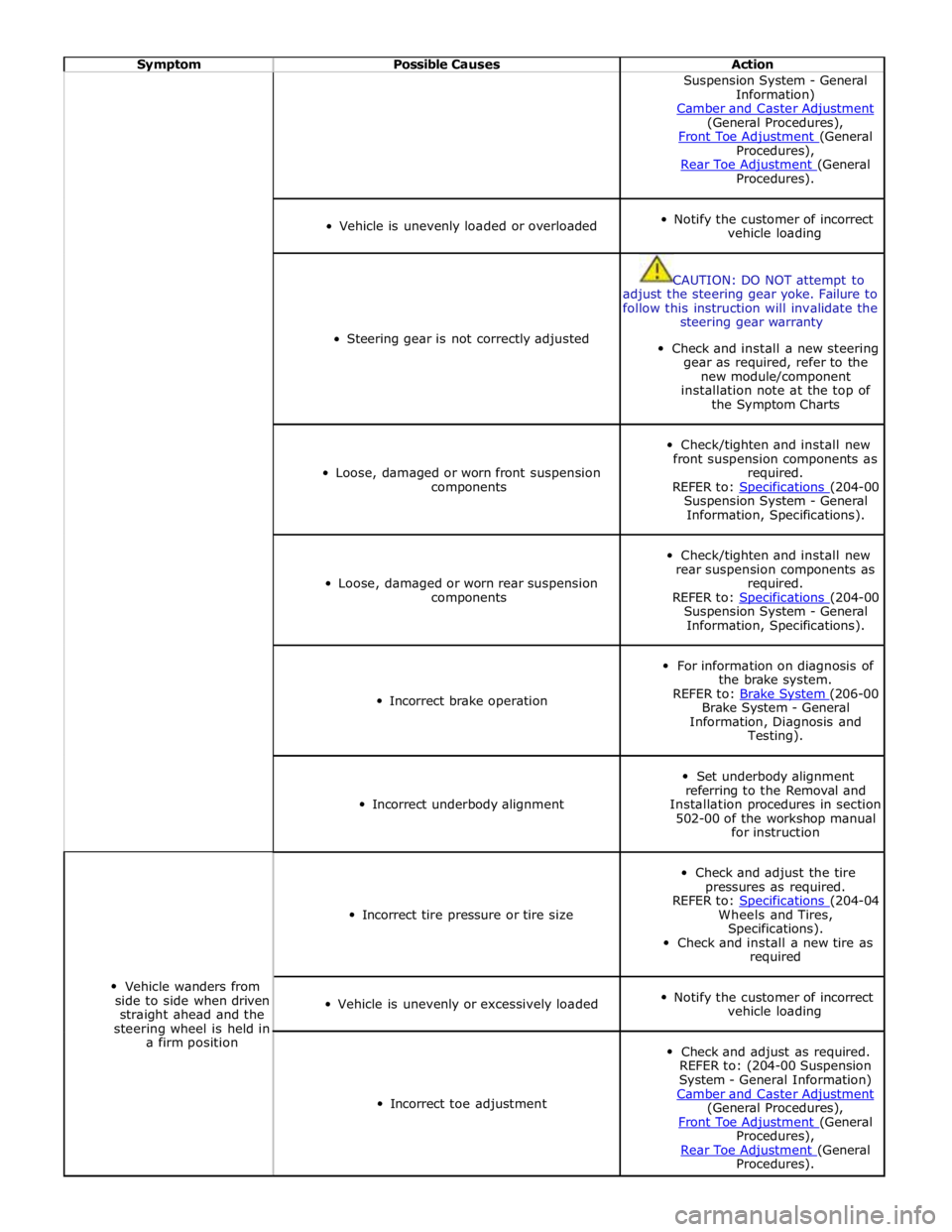

Symptom Possible Causes Action Suspension System - General

Information)

Camber and Caster Adjustment (General Procedures),

Front Toe Adjustment (General Procedures),

Rear Toe Adjustment (General Procedures).

Vehicle is unevenly loaded or overloaded

Notify the customer of incorrect

vehicle loading

Steering gear is not correctly adjusted

CAUTION: DO NOT attempt to

adjust the steering gear yoke. Failure to

follow this instruction will invalidate the

steering gear warranty

Check and install a new steering

gear as required, refer to the

new module/component

installation note at the top of

the Symptom Charts

Loose, damaged or worn front suspension

components

Check/tighten and install new

front suspension components as

required.

REFER to: Specifications (204-00 Suspension System - General

Information, Specifications).

Loose, damaged or worn rear suspension

components

Check/tighten and install new

rear suspension components as

required.

REFER to: Specifications (204-00 Suspension System - General

Information, Specifications).

Incorrect brake operation

For information on diagnosis of

the brake system.

REFER to: Brake System (206-00 Brake System - General

Information, Diagnosis and

Testing).

Incorrect underbody alignment

Set underbody alignment

referring to the Removal and

Installation procedures in section

502-00 of the workshop manual

for instruction

Vehicle wanders from

side to side when driven

straight ahead and the

steering wheel is held in

a firm position

Incorrect tire pressure or tire size

Check and adjust the tire

pressures as required.

REFER to: Specifications (204-04 Wheels and Tires,

Specifications).

Check and install a new tire as

required

Vehicle is unevenly or excessively loaded

Notify the customer of incorrect

vehicle loading

Incorrect toe adjustment

Check and adjust as required.

REFER to: (204-00 Suspension

System - General Information)

Camber and Caster Adjustment (General Procedures),

Front Toe Adjustment (General Procedures),

Rear Toe Adjustment (General Procedures).

Page 801 of 3039

battery power supply to be passed via the slip ring assembly in the steering wheel to the heated steering wheel control

module. The steering wheel module supplies power to the steering wheel heater element and also monitors the temperature

via a NTC (negative temperature coefficient) temperature sensor incorporated into the heater element. The control module

varies the power supply to the element to maintain the steering wheel rim at the optimum temperature.

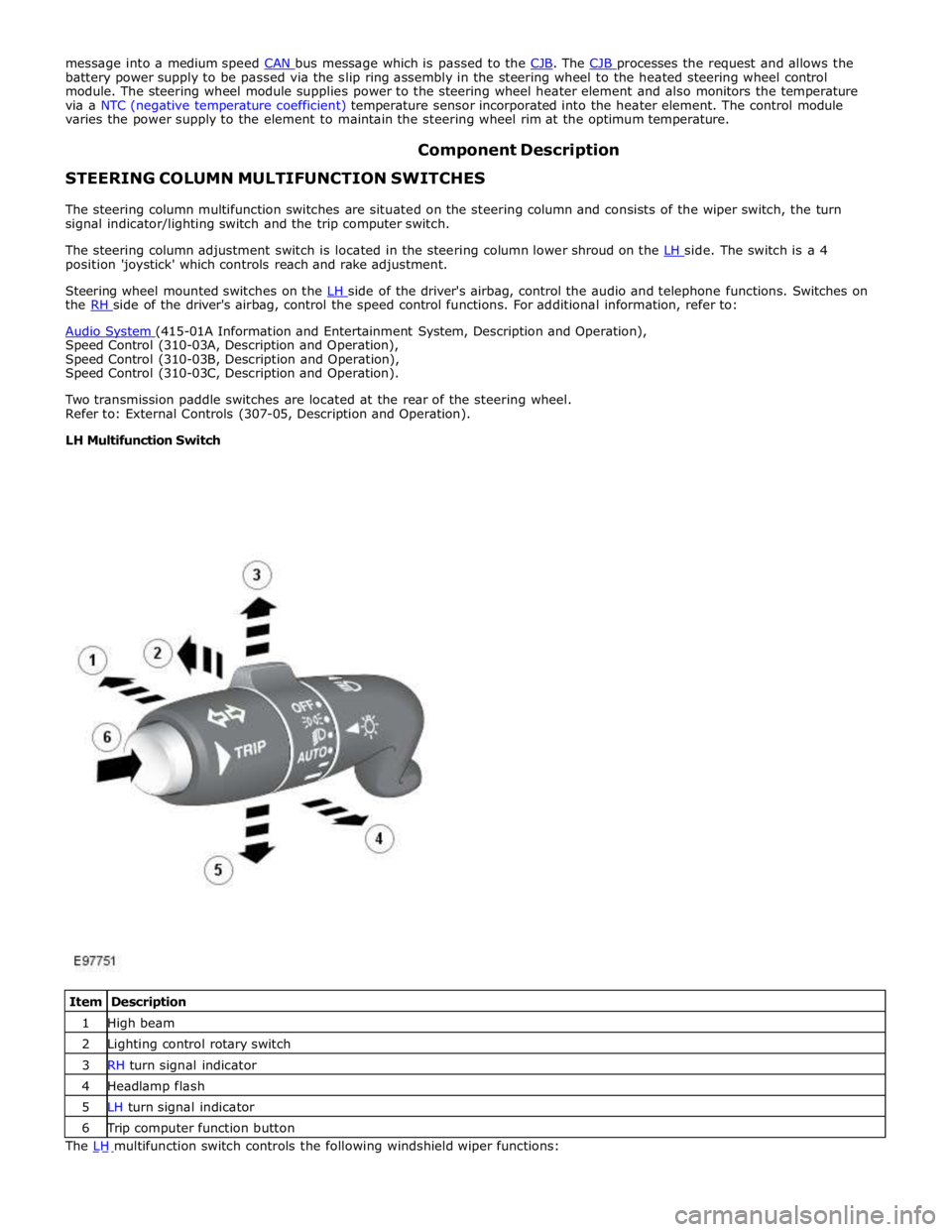

Component Description STEERING COLUMN MULTIFUNCTION SWITCHES

The steering column multifunction switches are situated on the steering column and consists of the wiper switch, the turn

signal indicator/lighting switch and the trip computer switch.

The steering column adjustment switch is located in the steering column lower shroud on the LH side. The switch is a 4 position 'joystick' which controls reach and rake adjustment.

Steering wheel mounted switches on the LH side of the driver's airbag, control the audio and telephone functions. Switches on the RH side of the driver's airbag, control the speed control functions. For additional information, refer to:

Audio System (415-01A Information and Entertainment System, Description and Operation), Speed Control (310-03A, Description and Operation),

Speed Control (310-03B, Description and Operation),

Speed Control (310-03C, Description and Operation).

Two transmission paddle switches are located at the rear of the steering wheel.

Refer to: External Controls (307-05, Description and Operation).

LH Multifunction Switch

Item Description 1 High beam 2 Lighting control rotary switch 3 RH turn signal indicator 4 Headlamp flash 5 LH turn signal indicator 6 Trip computer function button The LH multifunction switch controls the following windshield wiper functions:

Page 845 of 3039

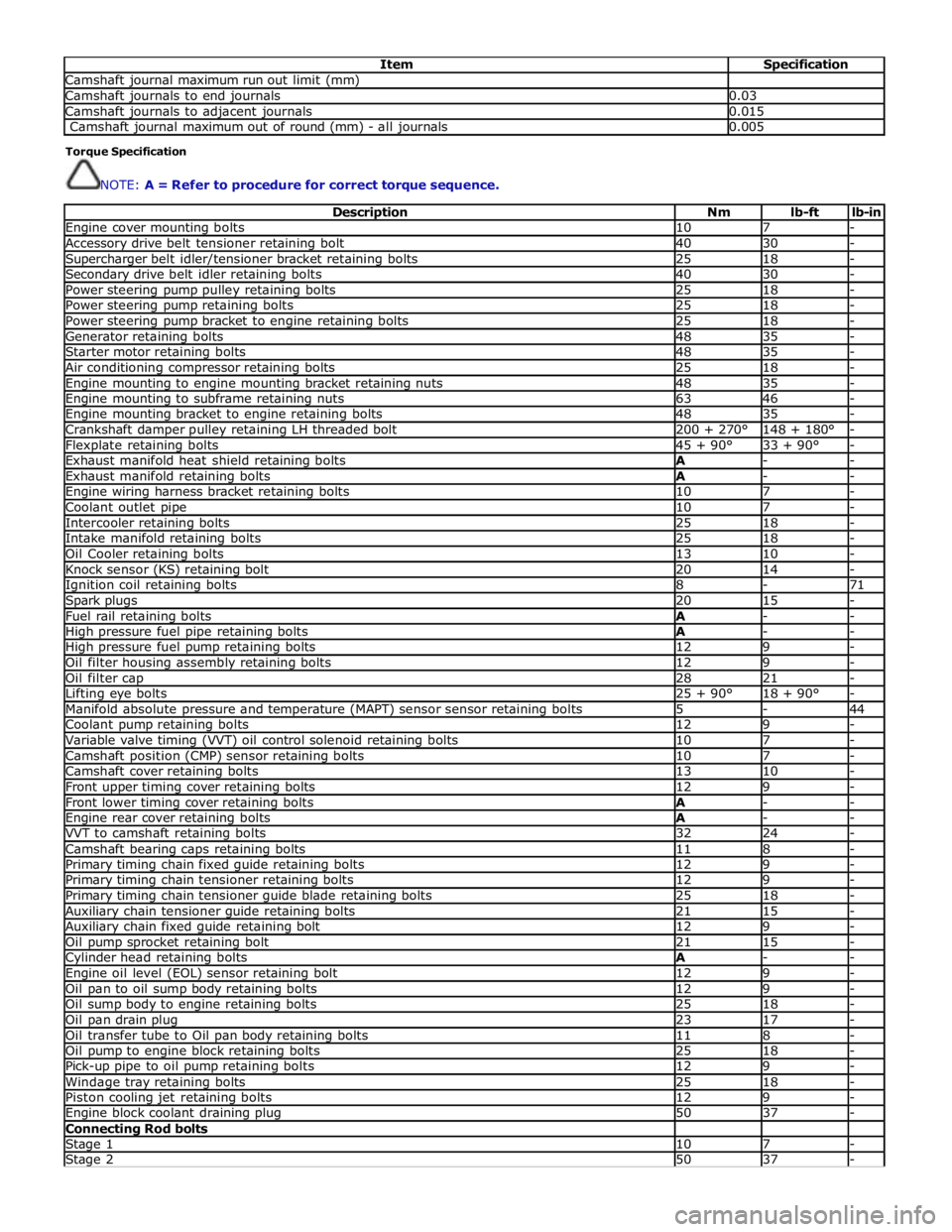

Item Specification Camshaft journal maximum run out limit (mm) Camshaft journals to end journals 0.03 Camshaft journals to adjacent journals 0.015 Camshaft journal maximum out of round (mm) - all journals 0.005 Torque Specification

NOTE: A = Refer to procedure for correct torque sequence.

Description Nm lb-ft lb-in Engine cover mounting bolts 10 7 - Accessory drive belt tensioner retaining bolt 40 30 - Supercharger belt idler/tensioner bracket retaining bolts 25 18 - Secondary drive belt idler retaining bolts 40 30 - Power steering pump pulley retaining bolts 25 18 - Power steering pump retaining bolts 25 18 - Power steering pump bracket to engine retaining bolts 25 18 - Generator retaining bolts 48 35 - Starter motor retaining bolts 48 35 - Air conditioning compressor retaining bolts 25 18 - Engine mounting to engine mounting bracket retaining nuts 48 35 - Engine mounting to subframe retaining nuts 63 46 - Engine mounting bracket to engine retaining bolts 48 35 - Crankshaft damper pulley retaining LH threaded bolt 200 + 270° 148 + 180° - Flexplate retaining bolts 45 + 90° 33 + 90° - Exhaust manifold heat shield retaining bolts A - - Exhaust manifold retaining bolts A - - Engine wiring harness bracket retaining bolts 10 7 - Coolant outlet pipe 10 7 - Intercooler retaining bolts 25 18 - Intake manifold retaining bolts 25 18 - Oil Cooler retaining bolts 13 10 - Knock sensor (KS) retaining bolt 20 14 - Ignition coil retaining bolts 8 - 71 Spark plugs 20 15 - Fuel rail retaining bolts A - - High pressure fuel pipe retaining bolts A - - High pressure fuel pump retaining bolts 12 9 - Oil filter housing assembly retaining bolts 12 9 - Oil filter cap 28 21 - Lifting eye bolts 25 + 90° 18 + 90° - Manifold absolute pressure and temperature (MAPT) sensor sensor retaining bolts 5 - 44 Coolant pump retaining bolts 12 9 - Variable valve timing (VVT) oil control solenoid retaining bolts 10 7 - Camshaft position (CMP) sensor retaining bolts 10 7 - Camshaft cover retaining bolts 13 10 - Front upper timing cover retaining bolts 12 9 - Front lower timing cover retaining bolts A - - Engine rear cover retaining bolts A - - VVT to camshaft retaining bolts 32 24 - Camshaft bearing caps retaining bolts 11 8 - Primary timing chain fixed guide retaining bolts 12 9 - Primary timing chain tensioner retaining bolts 12 9 - Primary timing chain tensioner guide blade retaining bolts 25 18 - Auxiliary chain tensioner guide retaining bolts 21 15 - Auxiliary chain fixed guide retaining bolt 12 9 - Oil pump sprocket retaining bolt 21 15 - Cylinder head retaining bolts A - - Engine oil level (EOL) sensor retaining bolt 12 9 - Oil pan to oil sump body retaining bolts 12 9 - Oil sump body to engine retaining bolts 25 18 - Oil pan drain plug 23 17 - Oil transfer tube to Oil pan body retaining bolts 11 8 - Oil pump to engine block retaining bolts 25 18 - Pick-up pipe to oil pump retaining bolts 12 9 - Windage tray retaining bolts 25 18 - Piston cooling jet retaining bolts 12 9 - Engine block coolant draining plug 50 37 - Connecting Rod bolts Stage 1 10 7 - Stage 2 50 37 -