Wiring JAGUAR XFR 2010 1.G Repair Manual

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 2010, Model line: XFR, Model: JAGUAR XFR 2010 1.GPages: 3039, PDF Size: 58.49 MB

Page 463 of 3039

No

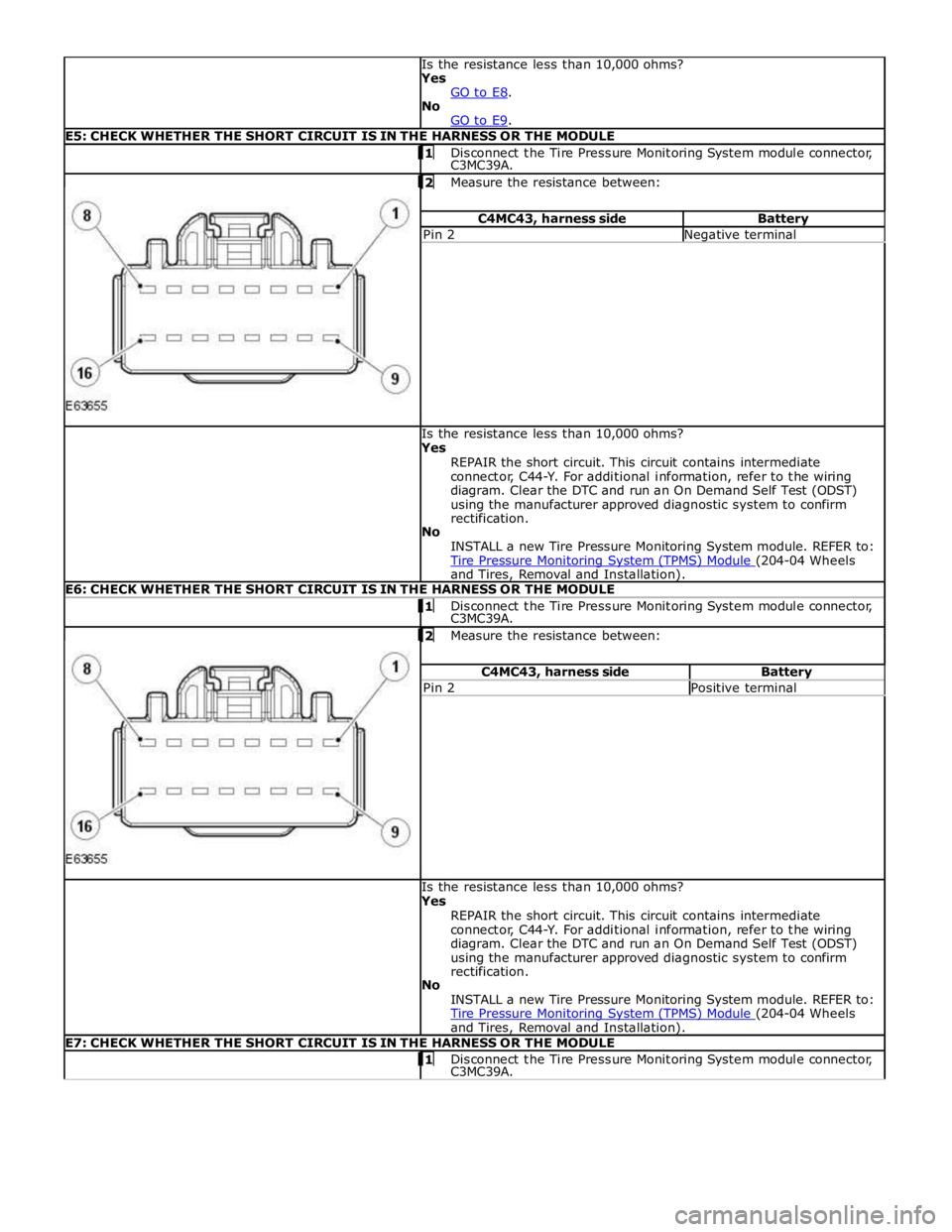

GO to E9. E5: CHECK WHETHER THE SHORT CIRCUIT IS IN THE HARNESS OR THE MODULE 1 Disconnect the Tire Pressure Monitoring System module connector, C3MC39A.

2 Measure the resistance between: C4MC43, harness side Battery Pin 2 Negative terminal Is the resistance less than 10,000 ohms?

Yes

REPAIR the short circuit. This circuit contains intermediate

connector, C44-Y. For additional information, refer to the wiring

diagram. Clear the DTC and run an On Demand Self Test (ODST)

using the manufacturer approved diagnostic system to confirm

rectification.

No

INSTALL a new Tire Pressure Monitoring System module. REFER to:

Tire Pressure Monitoring System (TPMS) Module (204-04 Wheels and Tires, Removal and Installation). E6: CHECK WHETHER THE SHORT CIRCUIT IS IN THE HARNESS OR THE MODULE 1 Disconnect the Tire Pressure Monitoring System module connector, C3MC39A.

2 Measure the resistance between: C4MC43, harness side Battery Pin 2 Positive terminal Is the resistance less than 10,000 ohms?

Yes

REPAIR the short circuit. This circuit contains intermediate

connector, C44-Y. For additional information, refer to the wiring

diagram. Clear the DTC and run an On Demand Self Test (ODST)

using the manufacturer approved diagnostic system to confirm

rectification.

No

INSTALL a new Tire Pressure Monitoring System module. REFER to:

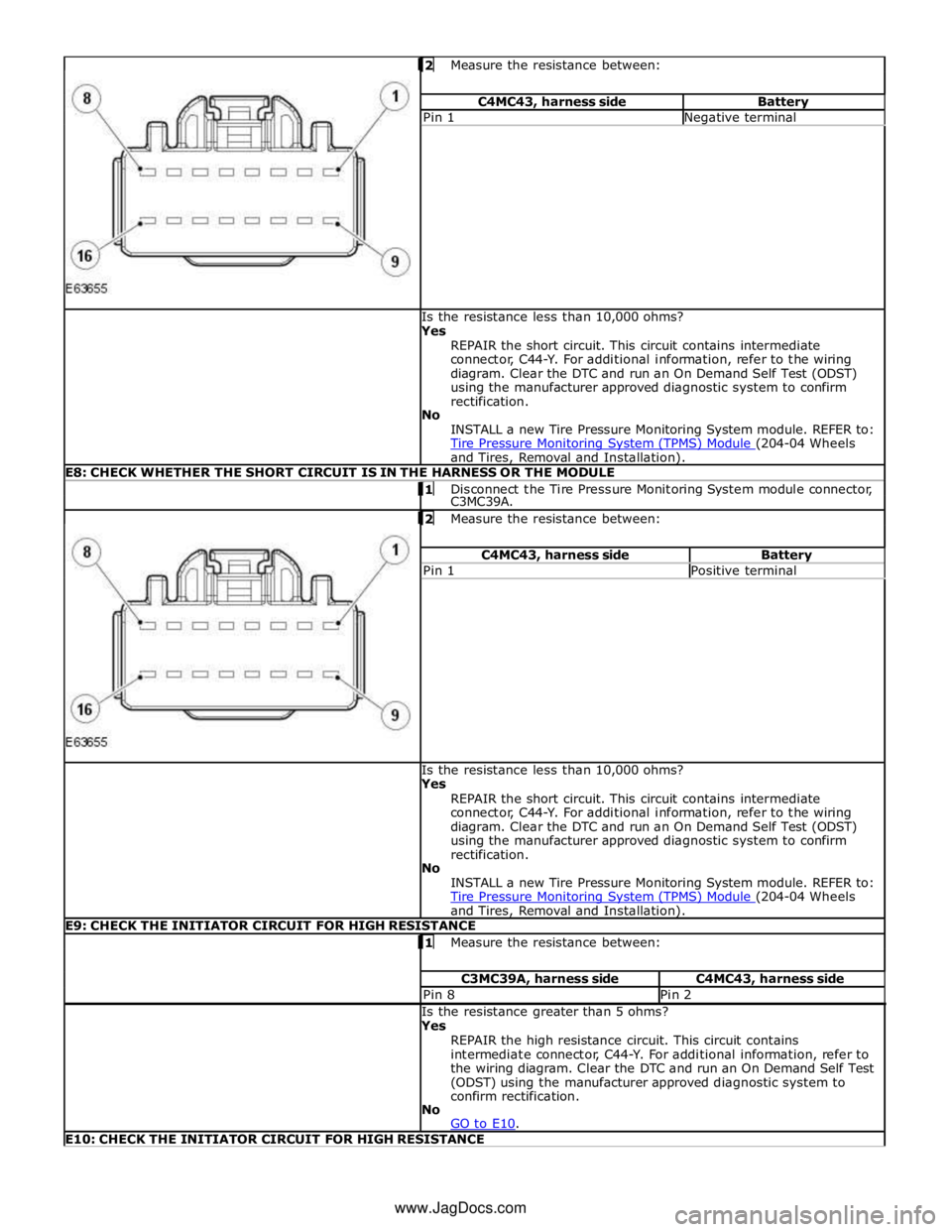

Tire Pressure Monitoring System (TPMS) Module (204-04 Wheels and Tires, Removal and Installation). E7: CHECK WHETHER THE SHORT CIRCUIT IS IN THE HARNESS OR THE MODULE 1 Disconnect the Tire Pressure Monitoring System module connector, C3MC39A.

Page 464 of 3039

Measure the resistance between: C4MC43, harness side Battery Pin 1 Negative terminal Is the resistance less than 10,000 ohms?

Yes

REPAIR the short circuit. This circuit contains intermediate

connector, C44-Y. For additional information, refer to the wiring

diagram. Clear the DTC and run an On Demand Self Test (ODST)

using the manufacturer approved diagnostic system to confirm

rectification.

No

INSTALL a new Tire Pressure Monitoring System module. REFER to:

Tire Pressure Monitoring System (TPMS) Module (204-04 Wheels and Tires, Removal and Installation). E8: CHECK WHETHER THE SHORT CIRCUIT IS IN THE HARNESS OR THE MODULE 1 Disconnect the Tire Pressure Monitoring System module connector, C3MC39A.

2 Measure the resistance between: C4MC43, harness side Battery Pin 1 Positive terminal Is the resistance less than 10,000 ohms?

Yes

REPAIR the short circuit. This circuit contains intermediate

connector, C44-Y. For additional information, refer to the wiring

diagram. Clear the DTC and run an On Demand Self Test (ODST)

using the manufacturer approved diagnostic system to confirm

rectification.

No

INSTALL a new Tire Pressure Monitoring System module. REFER to:

Tire Pressure Monitoring System (TPMS) Module (204-04 Wheels and Tires, Removal and Installation). E9: CHECK THE INITIATOR CIRCUIT FOR HIGH RESISTANCE 1 Measure the resistance between: C3MC39A, harness side C4MC43, harness side Pin 8 Pin 2 Is the resistance greater than 5 ohms?

Yes

REPAIR the high resistance circuit. This circuit contains

intermediate connector, C44-Y. For additional information, refer to

the wiring diagram. Clear the DTC and run an On Demand Self Test

(ODST) using the manufacturer approved diagnostic system to

confirm rectification.

No

GO to E10. E10: CHECK THE INITIATOR CIRCUIT FOR HIGH RESISTANCE www.JagDocs.com

Page 465 of 3039

Measure the resistance between: C3MC39A, harness side C4MC43, harness side Pin 7 Pin 1 Is the resistance greater than 5 ohms?

Yes

REPAIR the high resistance circuit. This circuit contains

intermediate connector, C44-Y. For additional information, refer to

the wiring diagram. Clear the DTC and run an On Demand Self Test

(ODST) using the manufacturer approved diagnostic system to

confirm rectification.

No

INSTALL a new rear right hand low-frequency initiator. REFER to:

Tire Pressure Monitoring System (TPMS) Rear Antenna (204-04 Wheels and Tires, Removal and Installation).

PINPOINT TEST F : MISSING, INCOMPATIBLE OR DEFECTIVE RUNNING TIRE LOW PRESSURE SENSOR

OR RECEIVER TEST

CONDITIONS DETAILS/RESULTS/ACTIONS F1: CHECK FOR CORRECT WHEEL AND TIRE ASSEMBLY AND TIRE LOW PRESSURE SENSOR 1 Establish that a full size running wheel and tire assembly has a tire low pressure sensor installed. As a visual confirmation, a tire low pressure sensor has a metal valve stem rather than a rubber one and

cannot be installed to a mini/space saver spare wheel. Is a full size wheel and tire assembly with tire low pressure sensor installed?

Yes

GO to F2. No

Install the correct wheel and tire assembly or tire low pressure sensor, of correct frequency, in accordance

with that defined in the manufacturer approved diagnostic system new tire low pressure sensor

application. F2: CHECK FOR ADDITIONAL DTCS 1 Remove the Tire Pressure Monitoring System power supply fuse and re-install it. Clear DTCs and leave the vehicle stationary for 15 minutes, then drive it at a speed greater than 15.5 mph (25 kph)

continuously for at least 10 minutes.

(Note: If the vehicle speed drops below this value, the drive time to complete the test will need to be increased.)

The use of the manufacturer approved diagnostic system, and the datalogger signal ’Tire pressure

monitor system status – learn mode status’ will verify the completion of the test when the value returns

to ‘Inactive’. 2 Check for additional DTCs C1A5631, C1A5831, C1A6031, C1A6231, with identical time stamps. Have all four DTCs logged with identical time stamps in the tire pressure monitoring system module?

Yes

Replace the tire pressure monitoring system radio frequency receiver.

REFER to: Tire Pressure Monitoring System (TPMS) Receiver (204-04 Wheels and Tires, Removal and Installation).

No

GO to F3. F3: VERIFY THE POSITION OF THE DEFECTIVE TIRE LOW PRESSURE SENSOR 1 Check tire pressure monitoring system DTCs. Are any C1AXX31 DTCs logged?

Yes

Install the correct tire low pressure sensor, of correct frequency, in accordance with that defined in the

manufacturer approved diagnostic system new tire low pressure sensor application, to the position

identified by the logged DTC.

REFER to: Tire Low Pressure Sensor (204-04 Wheels and Tires, Removal and Installation). No

No further action is required.

(Note: The use of the manufacturer approved diagnostic system, and the datalogger signal ’Tire pressure monitor system status – learn completed successfully’ will verify the successful completion of the test.)

PINPOINT TEST G : LOCALIZATION FAILURE TEST

CONDITIONS DETAILS/RESULTS/ACTIONS G1: CHECK FOR ADDITIONAL DTCS 1 Check for additional DTCs: C1A5711, C1A5712, C1A5713. C1A5911, C1A5912, C1A5913, C1A6111, C1A6112, C1A6113, C1A6311, C1A6312, C1A6313. Are any of the DTCs listed above also logged?

Yes

Refer to the DTC Index and remedial actions.

No

GO to G2. G2: CHECK FOR ADDITIONAL DTCS

Page 467 of 3039

TEST CONDITIONS DETAILS/RESULTS/ACTIONS I1: C1D1912 VERIFY EXTERNAL RECEIVER DATA LINE CIRCUIT SHORT TO POWER 1 Ignition off. 2 Disconnect the Tire Pressure Monitoring System Receiver electrical connector, C3MC45. 3 Measure the resistance between C3MC45, harness side Battery Pin 1 Positive terminal Is the resistance less than 5 Ohms?

Yes

GO to I2. No

GO to I3. I2: C1D1912 CHECK THE EXTERNAL RECEIVER DATA LINE CIRCUIT FOR SHORT CIRCUIT TO POWER 1 Disconnect the Tire Pressure Monitoring System Control Module electrical connector, C3MC39B. 2 Measure the resistance between C3MC45, harness side Battery Pin 1 Positive terminal Is the resistance less than 5 Ohms?

Yes

REPAIR the short circuit in wiring harness.

No

GO to I4. I3: C1D1912 CHECK THE TIRE PRESSURE MONITORING SYSTEM EXTERNAL RECEIVER FOR SHORT CIRCUIT TO

POWER 1 Reconnect the Tire Pressure Monitoring System Receiver electrical connector, C3MC45. 2 Using manufacturer approved diagnostic system run On Demand Self Test (0x0202). Is the DTC C1D1912 set?

Yes

Replace Tire Pressure Monitoring Receiver.

No

Investigate possible cause of intermittent failure. I4: C1D1912 CHECK THE TIRE PRESSURE MONITORING SYSTEM CONTROL MODULE FOR SHORT CIRCUIT TO POWER 1 Reconnect the Tire Pressure Monitoring System Control Module electrical connector, C3MC39B. 2 Reconnect the Tire Pressure Monitoring System Receiver electrical connector, C3MC45. 3 Using manufacturer approved diagnostic system run On Demand Self Test (0x0202). Is the DTC C1D1912 set?

Yes

Replace Tire Pressure Monitoring System Control Module.

No

Investigate possible cause of intermittent failure.

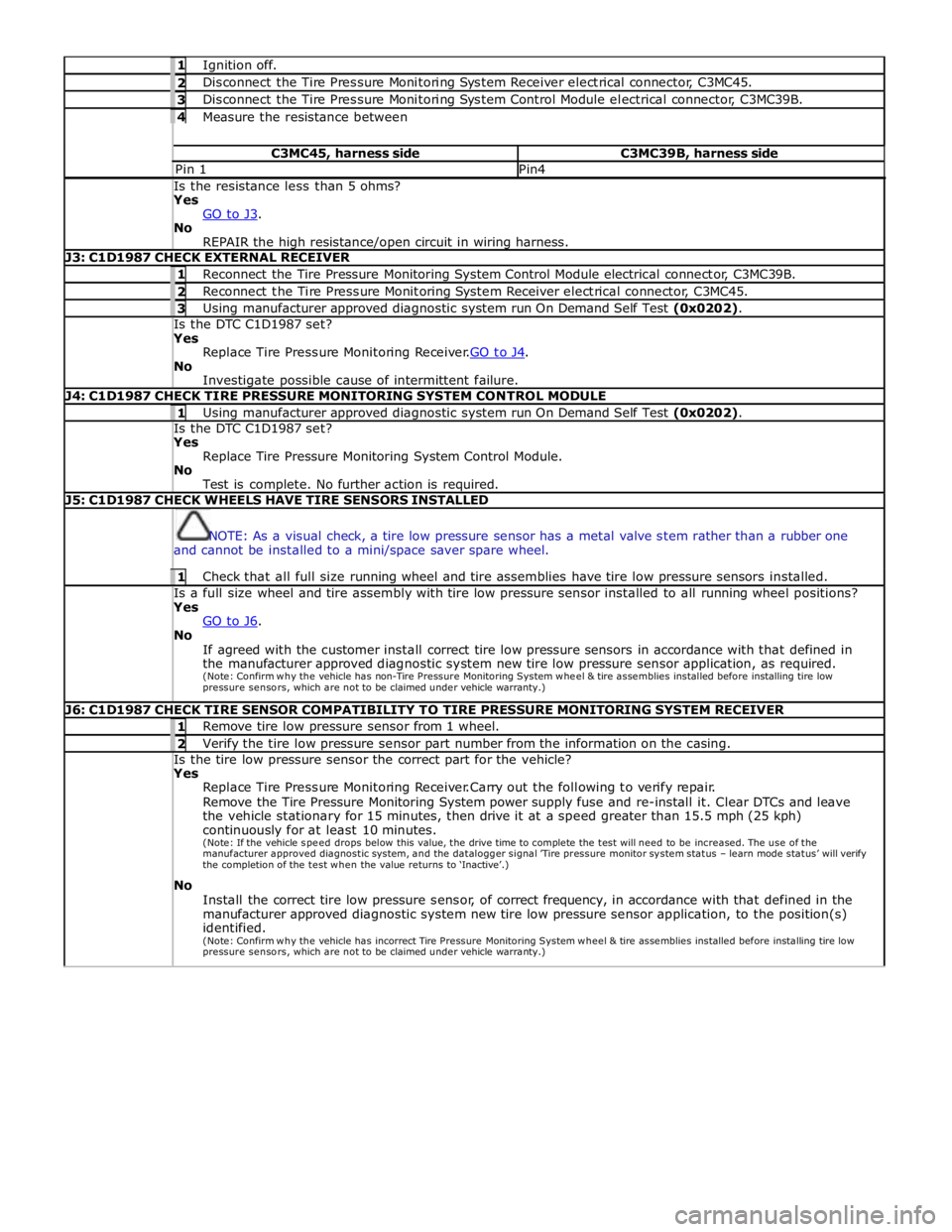

PINPOINT TEST J : C1D1987 TIRE PRESSURE MONITORING SYSTEM EXTERNAL RECEIVER DATA LINE

MISSING MESSAGE TEST

CONDITIONS DETAILS/RESULTS/ACTIONS J1: C1D1987 VERIFY EXTERNAL RECEIVER DATA LINE MISSING MESSAGE 1 Using manufacturer approved diagnostic system run On Demand Self Test (0x0202). Is the DTC C1D1987 set? Yes

GO to J2. No

GO to J5. J2: C1D1987 CHECK EXTERNAL RECEIVER DATA LINE CIRCUIT Do the IDs match?

Yes

Replace the spare tire low pressure sensor. Refer to the relevant installation section in the workshop

manual.

The identification for the sensor must be programmed into the tire pressure monitoring system module

using the manufacturer approved diagnostic system. The identification code is provided on a label with

the complete assembly and is also printed on the casing of each sensor.

No

Program the spare tire sensor ID, recorded in step 1, to the module using the approved diagnostic

system. The identification code is provided on a label with the complete assembly and is also printed on

the casing of each sensor.

Repeat test to ensure correct operation.GO to H3.

Page 468 of 3039

1 Ignition off. 2 Disconnect the Tire Pressure Monitoring System Receiver electrical connector, C3MC45. 3 Disconnect the Tire Pressure Monitoring System Control Module electrical connector, C3MC39B. 4 Measure the resistance between C3MC45, harness side C3MC39B, harness side Pin 1 Pin4 Is the resistance less than 5 ohms? Yes

GO to J3. No

REPAIR the high resistance/open circuit in wiring harness. J3: C1D1987 CHECK EXTERNAL RECEIVER 1 Reconnect the Tire Pressure Monitoring System Control Module electrical connector, C3MC39B. 2 Reconnect the Tire Pressure Monitoring System Receiver electrical connector, C3MC45. 3 Using manufacturer approved diagnostic system run On Demand Self Test (0x0202). Is the DTC C1D1987 set? Yes

Replace Tire Pressure Monitoring Receiver.GO to J4. No

Investigate possible cause of intermittent failure. J4: C1D1987 CHECK TIRE PRESSURE MONITORING SYSTEM CONTROL MODULE 1 Using manufacturer approved diagnostic system run On Demand Self Test (0x0202). Is the DTC C1D1987 set? Yes

Replace Tire Pressure Monitoring System Control Module.

No

Test is complete. No further action is required. J5: C1D1987 CHECK WHEELS HAVE TIRE SENSORS INSTALLED

NOTE: As a visual check, a tire low pressure sensor has a metal valve stem rather than a rubber one

and cannot be installed to a mini/space saver spare wheel. 1 Check that all full size running wheel and tire assemblies have tire low pressure sensors installed. Is a full size wheel and tire assembly with tire low pressure sensor installed to all running wheel positions? Yes

GO to J6. No

If agreed with the customer install correct tire low pressure sensors in accordance with that defined in

the manufacturer approved diagnostic system new tire low pressure sensor application, as required.

(Note: Confirm why the vehicle has non-Tire Pressure Monitoring System w he e l & tire assemblies installed before installing tire low

pressure sensors, which are not to be claimed under vehicle warranty.) J6: C1D1987 CHECK TIRE SENSOR COMPATIBILITY TO TIRE PRESSURE MONITORING SYSTEM RECEIVER 1 Remove tire low pressure sensor from 1 wheel. 2 Verify the tire low pressure sensor part number from the information on the casing. Is the tire low pressure sensor the correct part for the vehicle? Yes

Replace Tire Pressure Monitoring Receiver.Carry out the following to verify repair.

Remove the Tire Pressure Monitoring System power supply fuse and re-install it. Clear DTCs and leave

the vehicle stationary for 15 minutes, then drive it at a speed greater than 15.5 mph (25 kph)

continuously for at least 10 minutes.

(Note: If the vehicle spe e d drops below this value, the drive time to complete the test will need to be increased. The use of the manufacturer approved diagnostic system, and the datalogger signal ’Tire pressure monitor system status – learn mode status’ will verify the completion of the test w he n the value returns to ‘Inactive’.)

No

Install the correct tire low pressure sensor, of correct frequency, in accordance with that defined in the

manufacturer approved diagnostic system new tire low pressure sensor application, to the position(s)

identified.

(Note: Confirm why the vehicle has incorrect Tire Pressure Monitoring System w he e l & tire assemblies installed before installing tire low

pressure sensors, which are not to be claimed under vehicle warranty.)

Page 488 of 3039

Vehicle Dynamic Suspension - Vehicle Dynamic Suspension

Diagnosis and Testing

Principle of Operation Published: 09-Jul-2014

For a detailed description of the adaptive damping system operation, refer to the relevant Description and Operation section of

the workshop manual. REFER to: (204-05 Vehicle Dynamic Suspension)

Vehicle Dynamic Suspension - V8 5.0L Petrol/V8 S/C 5.0L Petrol (Description and Operation),

Inspection and Verification

1. Verify the customer concern.

2. Visually inspect for obvious signs of damage and system integrity.

Visual Inspection

Mechanical Electrical

Coil spring(s)

Shock absorber(s)

Accelerometer(s) installation

Height sensor(s) installation

Fuse(s)

Wiring harness/electrical connectors

Accelerometer(s)

Adaptive Damping Control Module

Height sensor(s)

3. If an obvious cause for an observed or reported concern is found, correct the cause (if possible) before proceeding to

the next step.

4. If the cause is not visually evident, check the system for any logged Diagnostic Trouble Codes (DTCs) and refer to the

DTC index.

DTC Index

For a list of Diagnostic Trouble Codes (DTCs) that could be logged on this vehicle, please refer to Section 100-00.

REFER to: Diagnostic Trouble Code (DTC) Index - DTC: Adaptive Damping Module (SUMB) (100-00 General Information, Description and Operation).

Page 538 of 3039

Rear Drive Axle/Differential - Rear Drive Axle and Differential

Diagnosis and Testing

Principle of Operation Published: 12-May-2014

For a detailed description of the Rear Drive Axle and Differential, refer to the relevant Description and Operation section in the

workshop manual. REFER to: Rear Drive Axle and Differential (205-02 Rear Drive Axle/Differential, Description and Operation).

Inspection and Verification

CAUTION: Diagnosis by substitution from a donor vehicle is NOT acceptable. Substitution of control modules does not

guarantee confirmation of a fault, and may also cause additional faults in the vehicle being tested and/or the donor vehicle.

1. Verify the customer concern.

2. Visually inspect for obvious signs of damage and system integrity.

Mechanical Electrical

Fixings that secure Rear Differential Control Module (Heat path

for Module Heatsink)

Fuses/Relays

Damaged, Loose or Corroded Connector(s)

Damage to Wiring Loom/Incorrect Location,

Stretched or Taught

3. If an obvious cause for an observed or reported concern is found, correct the cause (if possible) before proceeding to

the next step.

4. If the cause is not visually evident, check the system for any logged Diagnostic Trouble Codes (DTCs) and refer to the

DTC index.

DTC Index

For a list of diagnostic trouble codes that could be logged on this vehicle, please refer to Section 100-00. REFER to: Diagnostic Trouble Code (DTC) Index - DTC: Rear Differential Control Module (RDCM) (100-00 General Information, Description and Operation).

Page 582 of 3039

Brake System - General Information - Brake System

Diagnosis and Testing

Principle of Operation Published: 11-May-2011

For a detailed description of the brake system, refer to the relevant Description and Operation sections in the workshop

manual. REFER to:

Front Disc Brake (206-03, Description and Operation),

Front Disc Brake (206-03, Description and Operation),

Front Disc Brake (206-03, Description and Operation),

Rear Disc Brake (206-04, Description and Operation),

Rear Disc Brake (206-04, Description and Operation),

Rear Disc Brake (206-04, Description and Operation),

Parking Brake (206-05 Parking Brake and Actuation, Description and Operation), Parking Brake (206-05 Parking Brake and Actuation, Description and Operation), Parking Brake (206-05 Parking Brake and Actuation, Description and Operation), Hydraulic Brake Actuation (206-06 Hydraulic Brake Actuation, Description and Operation), Hydraulic Brake Actuation (206-06 Hydraulic Brake Actuation, Description and Operation), Hydraulic Brake Actuation (206-06 Hydraulic Brake Actuation, Description and Operation), Brake Booster (206-07 Power Brake Actuation, Description and Operation), Brake Booster (206-07 Power Brake Actuation, Description and Operation), Brake Booster (206-07, Description and Operation).

Inspection and Verification

Visually examine the front and rear wheel and tire assemblies for damage such as uneven wear patterns, tread worn out or

sidewall damage. Verify the tires are the same size, type and, where possible, same manufacturer. Replace the damaged

wheel or excessively worn tire.

Wheels and tires must be cleared of any foreign matter and tire pressures adjusted to the correct specification.

If the tires exhibit uneven wear or feathering, the cause must be corrected. Check the steering and suspension components for

damage or wear and, if necessary, check and adjust front wheel alignment. REFER to: (204-00 Suspension System - General

Information)

Specifications (Specifications), Front Toe Adjustment (General Procedures).

Visual Inspection

Mechanical Electrical

Brake master cylinder

Brake caliper piston(s)

Brake discs

Wheel bearings

Brake pads

Power brake booster

Brake pedal linkage

Brake booster vacuum hose

Tires

Debris

Parking brake actuator

Parking brake module

Parking brake switch

Damaged or corroded wiring harness

Brake master cylinder fluid level switch Road Test

Carry out a road test to compare actual vehicle braking performance with the performance standards expected by the driver.

The ability of the test driver to make valid comparisons and detect performance deficiencies will depend on experience.

The driver should have a thorough knowledge of brake system operation and accepted general performance guidelines to make

good comparisons and detect performance concerns.

An experienced brake technician will always establish a route that will be used for all brake diagnosis road tests. The roads

selected will be reasonably smooth and level. Gravel or bumpy roads are not suitable because the surface does not allow the

tires to grip the road equally. Crowned roads should be avoided because of the large amount of weight shifted to the low set

of wheels on this type of road. Once the route is established and consistently used, the road surface variable can be

eliminated from the test results.

Before a road test, obtain a complete description of the customer concerns or suspected condition. From the description, the

technician's experience will allow the technician to match possible causes with symptoms. Certain components will be tagged

as possible suspects while others will be eliminated by the evidence. More importantly, the customer description can reveal

unsafe conditions which should be checked or corrected before the road test. The description will also help form the basic

approach to the road test by narrowing the concern to specific components, vehicle speed or conditions.

Begin the road test with a general brake performance check. Keeping the description of the concern in mind, test the brakes at

different vehicle speeds using both light and heavy pedal pressure. To determine if the concern is in the front or rear braking

system, use the brake pedal and then use the parking brake control. If the condition (pull, vibration, pulsation) occurs only

with the parking brake, the concern is in the rear brake system.

Page 653 of 3039

Parking Brake and Actuation - Parking Brake

Diagnosis and Testing

Principle of Operation Published: 12-May-2014

For a detailed description of the Parking Brake operation, refer to the relevant Description and Operation section of the

workshop manual. REFER to: (206-05 Parking Brake and Actuation)

Parking Brake (Description and Operation), Parking Brake (Description and Operation), Parking Brake (Description and Operation).

Parking Brake Calibration

The parking brake system must be calibrated whenever the battery has been disconnected or has been in a state of discharge,

or repairs have been carried out to the rear service or parking brake system.

NOTE: If new rear brake pads have been installed, pressure must be applied to the brake pedal a minimum of five times

prior to calibration of the parking brake system.

To calibrate the parking brake system:

1. Place gear selector lever in 'P' Park position.

2. Release parking brake cable tension to service position.

REFER to: Parking Brake Cable Tension Release (206-05 Parking Brake and Actuation, General Procedures).

3. Set the ignition status to 'ON'.

4. Apply and hold the footbrake then pull up the parking brake switch.

5. To release the parking brake, apply and hold the footbrake then release and press down the parking brake switch.

Inspection and Verification

CAUTION: Diagnosis by substitution from a donor vehicle is NOT acceptable. Substitution of control modules does not

guarantee confirmation of a fault, and may also cause additional faults in the vehicle being tested and/or the donor vehicle.

1. Verify the customer concern.

2. Visually inspect for obvious signs of damage and system integrity.

Visual Inspection

Mechanical Electrical

Parking brake cable

Parking brake actuator

Brake caliper

Brake pads

Stabilizer bar drop link caps

Fuse(s)

Wiring harness/electrical connectors

Check for bent/corroded pins

Parking brake switch

Parking brake module

3. If an obvious cause for an observed or reported concern is found, correct the cause (if possible) before proceeding to

the next step.

4. If the cause is not visually evident check the system for any logged Diagnostic Trouble Codes (DTCs) and proceed to

the DTC Index , alternatively, verify the customer concern and refer to the Symptom Chart.

Symptom Chart

Symptom Possible Cause Action The parking brake will not

engage or release (with no

parking brake warning

message)

Cables fouled, trapped or damaged

Cables incorrectly routed or installed

Rear lining wear

Service brake incorrectly adjusted following

lining change

Caliper malfunction

Check the rear and primary

cables for correct installation

and damage

Inspect the rear brake linings for

wear

Re-calibrate the parking brake,

refer to the calibration procedure

Check the rear service brake for

correct installation and operation

Page 666 of 3039

7.

Installation

1. To install, reverse the removal procedure.

2. CAUTION: Make sure the wiring harness is correctly routed

to avoid contact with the halfshaft. Failure to follow this

instruction may result in damage to the component.

3. CAUTION: Calibrate the electric park brake using Jaguar approved

diagnostic system. If the Jaguar approved diagnostic system is not

available disconnect the battery for approximately 30 seconds, the

vehicle will then prompt the driver to carry out the calibration procedure

as per the vehicle hand book on re-connection.

Calibrate the electric parking brake (EPB) using the diagnostic tool.