Module JAGUAR XFR 2010 1.G Workshop Manual

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 2010, Model line: XFR, Model: JAGUAR XFR 2010 1.GPages: 3039, PDF Size: 58.49 MB

Page 2653 of 3039

Supplemental Restraint System - Passenger Air Bag Module

Removal and Installation Published: 11-May-2011

Removal

NOTE: Removal steps in this procedure may contain installation details.

1. Refer to: Battery Disconnect and Connect (414-01 Battery, Mounting and Cables, General Procedures).

2. Refer to: Steering Wheel (211-04 Steering Column, Removal and Installation).

3. Refer to: Driver Side Register (412-01 Climate Control, Removal and Installation).

4. Refer to: Information and Entertainment Display (415-01A Information and Entertainment System, Removal and Installation).

5. Refer to: Instrument Panel Speaker (415-01A Information and Entertainment System, Removal and Installation).

6. Refer to: A-Pillar Trim Panel (501-05 Interior Trim and Ornamentation, Removal and Installation).

7. Refer to: Audio and Climate Control Assembly (415-01A Information and Entertainment System, Removal and Installation). 211-326

Locking Tool, Clockspring Special Tool(s)

Page 2665 of 3039

Published: 11-May-2011

Supplemental Restraint System - Restraints Control Module (RCM)

Removal and Installation

Removal

NOTE: Removal steps in this procedure may contain installation details.

1. Make the air bag supplemental restraint system (SRS) safe.

Refer to: Standard Workshop Practices (100-00 General Information, Description and Operation).

2. WARNING: To avoid accidental deployment and possible personal injury,

the backup power supply must be depleted before repairing or replacing

any air bag supplementary restraints system (SRS) components. To

deplete the backup power supply energy, disconnect the battery ground

cable and wait for one minute. Failure to follow this instruction may

result in personal injury.

Refer to: Battery Disconnect and Connect (414-01 Battery, Mounting and Cables, General Procedures).

3.

4.

Page 2666 of 3039

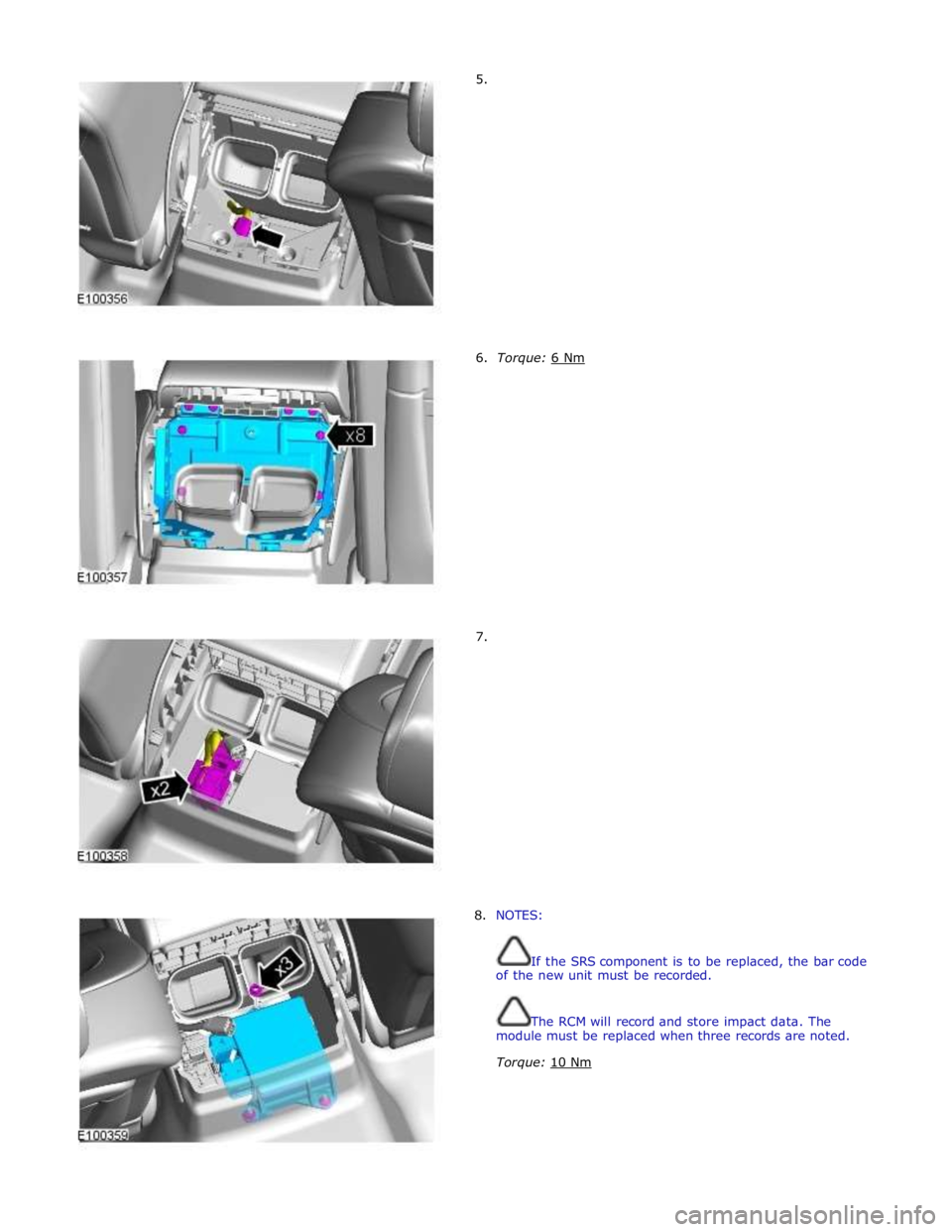

5.

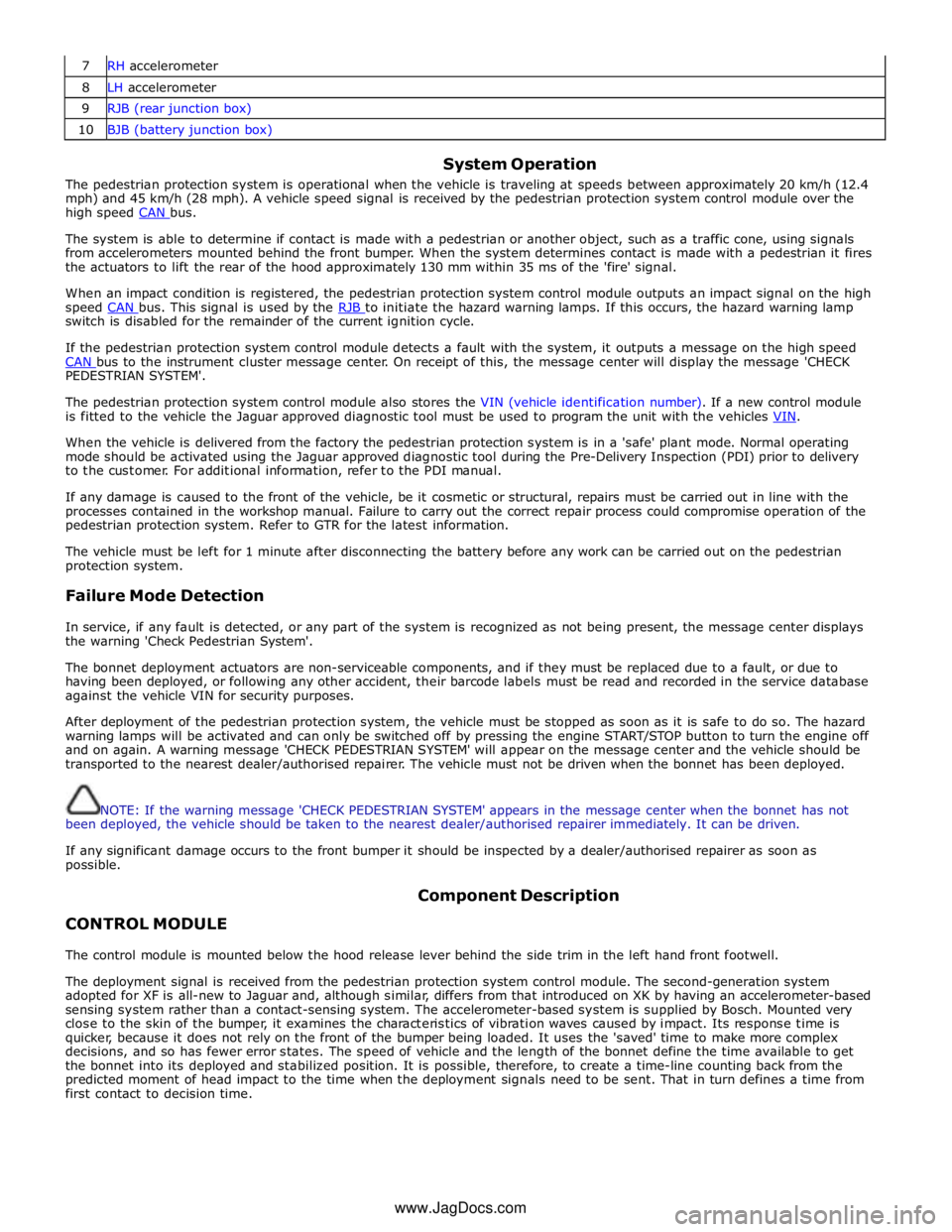

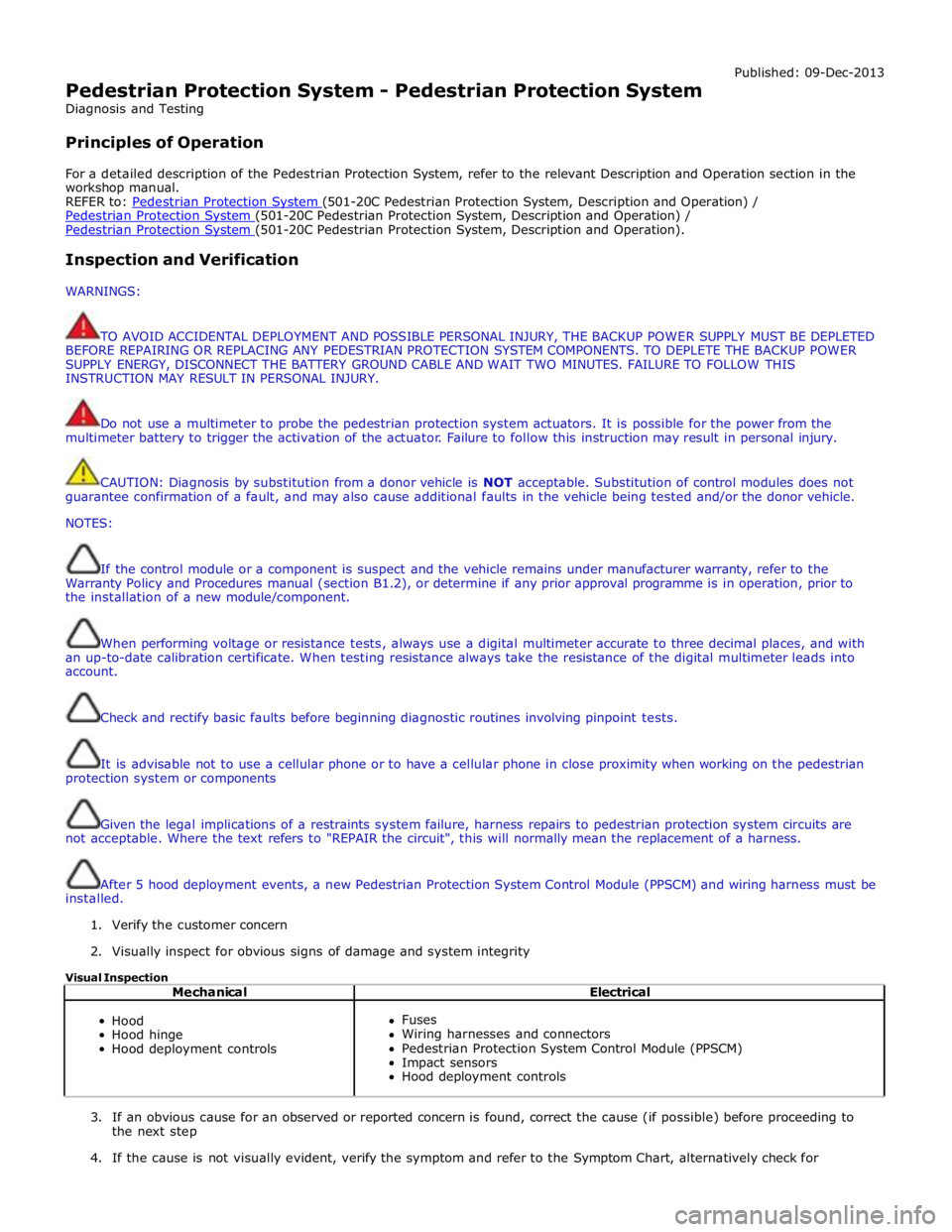

6. Torque: 6 Nm 7.

8. NOTES:

If the SRS component is to be replaced, the bar code

of the new unit must be recorded.

The RCM will record and store impact data. The

module must be replaced when three records are noted.

Torque: 10 Nm

Page 2668 of 3039

Supplemental Restraint System - Side Air Bag Module

Removal and Installation

Removal

NOTE: Removal steps in this procedure may contain installation details. Published: 07-Sep-2011

1. Make the air bag supplemental restraint system (SRS) safe.

For additional information, refer to: Standard Workshop Practices (100-00 General Information, Description and Operation).

2. Disconnect the battery ground cable.

For additional information, refer to: Battery Disconnect and Connect (414-01 Battery, Mounting and Cables, General Procedures).

3. Remove the front seat.

For additional information, refer to: Front Seat (501-10 Seating, Removal and Installation).

4. Remove the front seat backrest lower rear cover.

Page 2673 of 3039

Supplemental Restraint System - Side Air Curtain Module

Removal and Installation

Removal

NOTE: Removal steps in this procedure may contain installation details.

All vehicles Published: 19-May-2011

1. Make the air bag supplemental restraint system (SRS) safe.

Refer to: Standard Workshop Practices (100-00 General Information, Description and Operation).

2. Refer to: Battery Disconnect and Connect (414-01 Battery, Mounting and Cables, General Procedures).

3. Refer to: Interior Rear View Mirror (501-09 Rear View Mirrors, Removal and Installation).

4. Refer to: Overhead Console (501-12 Instrument Panel and Console, Removal and Installation).

5. Refer to: Sun Visor (501-05 Interior Trim and Ornamentation, Removal and Installation).

6. Refer to: A-Pillar Trim Panel (501-05 Interior Trim and Ornamentation, Removal and Installation).

7. Refer to: B-Pillar Upper Trim Panel (501-05 Interior Trim and Ornamentation, Removal and Installation).

8. Refer to: C-Pillar Lower Trim Panel (501-05 Interior Trim and Ornamentation, Removal and Installation).

9. Torque: 2 Nm

Page 2681 of 3039

1 RH (right-hand) hood actuator 2 Pedestrian protection system control module 3 LH (left-hand) hood actuator 4 LH accelerometer 5 RH accelerometer

Page 2683 of 3039

Published: 11-May-2011

Pedestrian Protection System - Pedestrian Protection System - System

Operation and Component Description

Description and Operation

Control Diagram

NOTE: A = Hardwired; D = High speed CAN (controller area network) bus; N = Medium speed CAN bus

Item Description 1 Battery 2 CJB (central junction box) 3 Instrument cluster 4 LH (left-hand) hood actuator 5 RH (right-hand) hood actuator 6 Pedestrian protection system control module

Page 2684 of 3039

7 RH accelerometer 8 LH accelerometer 9 RJB (rear junction box) 10 BJB (battery junction box)

System Operation

The pedestrian protection system is operational when the vehicle is traveling at speeds between approximately 20 km/h (12.4

mph) and 45 km/h (28 mph). A vehicle speed signal is received by the pedestrian protection system control module over the

high speed CAN bus.

The system is able to determine if contact is made with a pedestrian or another object, such as a traffic cone, using signals

from accelerometers mounted behind the front bumper. When the system determines contact is made with a pedestrian it fires

the actuators to lift the rear of the hood approximately 130 mm within 35 ms of the 'fire' signal.

When an impact condition is registered, the pedestrian protection system control module outputs an impact signal on the high

speed CAN bus. This signal is used by the RJB to initiate the hazard warning lamps. If this occurs, the hazard warning lamp switch is disabled for the remainder of the current ignition cycle.

If the pedestrian protection system control module detects a fault with the system, it outputs a message on the high speed

CAN bus to the instrument cluster message center. On receipt of this, the message center will display the message 'CHECK PEDESTRIAN SYSTEM'.

The pedestrian protection system control module also stores the VIN (vehicle identification number). If a new control module

is fitted to the vehicle the Jaguar approved diagnostic tool must be used to program the unit with the vehicles VIN.

When the vehicle is delivered from the factory the pedestrian protection system is in a 'safe' plant mode. Normal operating

mode should be activated using the Jaguar approved diagnostic tool during the Pre-Delivery Inspection (PDI) prior to delivery

to the customer. For additional information, refer to the PDI manual.

If any damage is caused to the front of the vehicle, be it cosmetic or structural, repairs must be carried out in line with the

processes contained in the workshop manual. Failure to carry out the correct repair process could compromise operation of the

pedestrian protection system. Refer to GTR for the latest information.

The vehicle must be left for 1 minute after disconnecting the battery before any work can be carried out on the pedestrian

protection system.

Failure Mode Detection

In service, if any fault is detected, or any part of the system is recognized as not being present, the message center displays

the warning 'Check Pedestrian System'.

The bonnet deployment actuators are non-serviceable components, and if they must be replaced due to a fault, or due to

having been deployed, or following any other accident, their barcode labels must be read and recorded in the service database

against the vehicle VIN for security purposes.

After deployment of the pedestrian protection system, the vehicle must be stopped as soon as it is safe to do so. The hazard

warning lamps will be activated and can only be switched off by pressing the engine START/STOP button to turn the engine off

and on again. A warning message 'CHECK PEDESTRIAN SYSTEM' will appear on the message center and the vehicle should be

transported to the nearest dealer/authorised repairer. The vehicle must not be driven when the bonnet has been deployed.

NOTE: If the warning message 'CHECK PEDESTRIAN SYSTEM' appears in the message center when the bonnet has not

been deployed, the vehicle should be taken to the nearest dealer/authorised repairer immediately. It can be driven.

If any significant damage occurs to the front bumper it should be inspected by a dealer/authorised repairer as soon as

possible.

CONTROL MODULE Component Description

The control module is mounted below the hood release lever behind the side trim in the left hand front footwell.

The deployment signal is received from the pedestrian protection system control module. The second-generation system

adopted for XF is all-new to Jaguar and, although similar, differs from that introduced on XK by having an accelerometer-based

sensing system rather than a contact-sensing system. The accelerometer-based system is supplied by Bosch. Mounted very

close to the skin of the bumper, it examines the characteristics of vibration waves caused by impact. Its response time is

quicker, because it does not rely on the front of the bumper being loaded. It uses the 'saved' time to make more complex

decisions, and so has fewer error states. The speed of vehicle and the length of the bonnet define the time available to get

the bonnet into its deployed and stabilized position. It is possible, therefore, to create a time-line counting back from the

predicted moment of head impact to the time when the deployment signals need to be sent. That in turn defines a time from

first contact to decision time.

www.JagDocs.com

Page 2687 of 3039

Pedestrian Protection System - Pedestrian Protection System

Diagnosis and Testing

Principles of Operation Published: 09-Dec-2013

For a detailed description of the Pedestrian Protection System, refer to the relevant Description and Operation section in the

workshop manual.

REFER to: Pedestrian Protection System (501-20C Pedestrian Protection System, Description and Operation) / Pedestrian Protection System (501-20C Pedestrian Protection System, Description and Operation) / Pedestrian Protection System (501-20C Pedestrian Protection System, Description and Operation).

Inspection and Verification

WARNINGS:

TO AVOID ACCIDENTAL DEPLOYMENT AND POSSIBLE PERSONAL INJURY, THE BACKUP POWER SUPPLY MUST BE DEPLETED

BEFORE REPAIRING OR REPLACING ANY PEDESTRIAN PROTECTION SYSTEM COMPONENTS. TO DEPLETE THE BACKUP POWER

SUPPLY ENERGY, DISCONNECT THE BATTERY GROUND CABLE AND WAIT TWO MINUTES. FAILURE TO FOLLOW THIS

INSTRUCTION MAY RESULT IN PERSONAL INJURY.

Do not use a multimeter to probe the pedestrian protection system actuators. It is possible for the power from the

multimeter battery to trigger the activation of the actuator. Failure to follow this instruction may result in personal injury.

CAUTION: Diagnosis by substitution from a donor vehicle is NOT acceptable. Substitution of control modules does not

guarantee confirmation of a fault, and may also cause additional faults in the vehicle being tested and/or the donor vehicle.

NOTES:

If the control module or a component is suspect and the vehicle remains under manufacturer warranty, refer to the

Warranty Policy and Procedures manual (section B1.2), or determine if any prior approval programme is in operation, prior to

the installation of a new module/component.

When performing voltage or resistance tests, always use a digital multimeter accurate to three decimal places, and with

an up-to-date calibration certificate. When testing resistance always take the resistance of the digital multimeter leads into

account.

Check and rectify basic faults before beginning diagnostic routines involving pinpoint tests.

It is advisable not to use a cellular phone or to have a cellular phone in close proximity when working on the pedestrian

protection system or components

Given the legal implications of a restraints system failure, harness repairs to pedestrian protection system circuits are

not acceptable. Where the text refers to "REPAIR the circuit", this will normally mean the replacement of a harness.

After 5 hood deployment events, a new Pedestrian Protection System Control Module (PPSCM) and wiring harness must be

installed.

1. Verify the customer concern

2. Visually inspect for obvious signs of damage and system integrity

Visual Inspection

Mechanical Electrical

Hood

Hood hinge

Hood deployment controls

Fuses

Wiring harnesses and connectors

Pedestrian Protection System Control Module (PPSCM)

Impact sensors

Hood deployment controls

3. If an obvious cause for an observed or reported concern is found, correct the cause (if possible) before proceeding to

the next step

4. If the cause is not visually evident, verify the symptom and refer to the Symptom Chart, alternatively check for

Page 2688 of 3039

Diagnostic Trouble Codes (DTCs) and refer to the DTC Index

5. Check DDW for open campaigns. Refer to the corresponding bulletins and SSMs which may be valid for the specific

customer complaint and carry out the recommendations as required

Symptom Chart

Symptom Message Possible Causes Action Hood

deployed CHECK

PEDESTRIAN

SYSTEM

Low speed collision

with pedestrian or

other object

WARNING: The vehicle must not be driven if the hood has been

deployed.

NOTE: Repairs due to a collision are not warrantable.

Check the vehicle for collision damage. Repair as necessary Hood not

deployed CHECK

PEDESTRIAN

SYSTEM

Pedestrian

protection system

fault

NOTE: The vehicle may be driven if a pedestrian protection

system fault is present but the hood has not been deployed.

Check the vehicle for collision damage. Repair as necessary.

Using the manufacturer approved diagnostic system, check the

pedestrian protection system control module for related DTCs

and refer to the relevant DTC index

DTC Index

For a list of Diagnostic Trouble Codes (DTCs) that could be logged on this vehicle, please refer to Section 100-00.

REFER to: Diagnostic Trouble Code (DTC) Index - DTC: Pedestrian Protection System Control Module (PPSCM) (100-00 General Information, Description and Operation).