Replace Battery JAGUAR XFR 2010 1.G Workshop Manual

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 2010, Model line: XFR, Model: JAGUAR XFR 2010 1.GPages: 3039, PDF Size: 58.49 MB

Page 49 of 3039

General Information - General Service Information

Description and Operation

Repairs and Replacements Published: 28-Dec-2012

When service parts are required, it is essential that only genuine Jaguar/Daimler replacements are used.

Attention is drawn to the following points concerning repairs and the installation of replacement parts and accessories:

Safety features embodied in the vehicle may be impaired if other than genuine parts are installed. In certain territories,

legislation prohibits the installation of parts which are not produced to the vehicle manufacturer's specification.

Torque wrench setting figures given in this manual must be strictly adhered to. Locking devices, where specified, must

be installed. If the efficiency of a locking device is impaired during removal it must be renewed.

Owners purchasing accessories while travelling abroad should make sure that the accessory and its installed location on

the vehicle conform to mandatory requirements existing in their country of origin.

The vehicle warranty may be invalidated by the installation of other than genuine Jaguar/Daimler parts. All

Jaguar/Daimler replacements have the full backing of the factory warranty.

Jaguar/Daimler dealers are obliged to supply only genuine service parts.

Vehicle Specifications

Purchasers are advised that the specification details set out in this manual apply to a range of vehicles and not to any specific

one. For the specification of a particular vehicle, purchasers should consult their dealer.

The Manufacturer reserves the right to vary the specifications, with or without notice, and at such times and in such manner as

the Manufacturer thinks fit. Major as well as minor changes may be involved, in accordance with the Manufacturer's policy of

continuous improvement.

Whilst every effort is made to make sure the accuracy of the particulars contained in this manual, neither the Manufacturer nor

the Dealer, by whom the manual is supplied, shall in any circumstances be held liable for any inaccuracy or the consequences

thereof.

Service Repair Operation Numbering

A master index of numbered operations has been compiled for universal application to all vehicles manufactured by Jaguar

Land Rover Limited.

Each operation is allocated a number from the master index and cross-refers with an identical number in the Repair Operation

Times schedule. The number consists of six digits arranged in three pairs.

Each maintenance procedure in this manual is described in the sequence necessary to complete the operation in the minimum

time, as specified in the Repair Operation Times schedule.

References to Bank-1 and Bank-2

References to Bank-1 and Bank-2 are made with regard to the engine. When viewed from the flywheel the right-hand bank will

be Bank-1 and the left-hand bank will be Bank-2.

Special Tools

Any special tools and equipment required to perform a maintenance procedure, are shown at the beginning of each procedure.

When possible, illustrations are given to assist in identifying the tool needed.

Disconnecting/Connecting the Battery

Always stop the engine before disconnecting the battery negative lead and make sure the battery positive lead is isolated i.e.

wrapped in a suitable cloth.

WARNING: Radio code saving devices must not be used when conducting work on Air Bag or Fuel systems. It must be

noted that, when using these devices, the vehicle electrical system is still live albeit with a reduced current flow.

NOTE: Before disconnecting the battery make sure that the radio receiver/cassette player/mini disc player and compact

disc player keycodes are known and, that no data is required from the Engine Control Module (ECM) as battery disconnection

will erase any fault codes and idle/drive values held in the Keep Alive Memory (KAM).

Always disconnect the battery before commencing repair operations which require:

The vehicle to be jacked up

Work on the engine

Work underneath the vehicle

Arc welding

Alternatively a Radio Code Saver may be used, when not working on the Air Bag or Fuel systems. With the battery

Page 51 of 3039

Always reduce the engine speed to idle before disconnecting the jump leads.

Before removing the jump leads, switch on the heater blower (high) or the heated rear screen, to reduce the voltage peak

when the leads are removed.

Always disconnect the jump leads in the reverse order to the connecting sequence and take great care not to short the ends of

the leads.

Do not rely on the generator to restore a discharged battery. For a generator to recharge a battery, it would take in excess of 8

hours continuous driving with no additional loads placed on the battery.

Component Cleaning

To prevent ingress of dirt, accumulations of loose dirt and greasy deposits should be removed before disconnecting or

dismantling components or assemblies.

Components should be thoroughly cleaned before inspection prior to reassembly.

Cleaning Methods:

Dry Cleaning

Removal of loose dirt with soft or wire brushes

Scraping dirt off with a piece of metal or wood

Wiping off with a rag

CAUTION: Compressed air is sometimes wet so use with caution, especially on hydraulic systems.

Blowing dirt off with compressed air (Eye protection should be worn when using this method)

Removal of dry dust using vacuum equipment. This method should always be used to remove friction lining material

dust (asbestos particles)

Steam Cleaning

Calibration of Essential Measuring Equipment

WARNING: Failure to comply may result in personal injury or damage to components.

It is of fundamental importance that certain essential equipment e.g. torque wrenches, multimeters, exhaust gas analysers,

rolling roads etc., are regularly calibrated in accordance with the manufacturers instructions.

Use of Control Modules

Control modules may only be used on the vehicle to which they were originally installed. Do not attempt to use or test a

control module on any other vehicle.

Functional Test

On completion of a maintenance procedure, a thorough test should be carried out, to ensure the relevant vehicle systems are

working correctly.

Preparation

Before disassembly, clean the surrounding area as thoroughly as possible. When components have been removed, blank off

any exposed openings using grease-proof paper and masking tape. Immediately seal fuel, oil and hydraulic lines when

separated, using plastic caps or plugs, to prevent loss of fluid and the entry of dirt. Close the open ends of oil ways, exposed

by component removal, with tapered hardwood plugs or readily visible plastic plugs. Immediately a component is removed,

place it in a suitable container; use a separate container for each component and its associated parts. Before dismantling a

component, clean it thoroughly with a recommended cleaning agent; check that the agent will not damage any of the materials

within the component. Clean the bench and obtain marking materials, labels, containers and locking wire before dismantling a

component.

Dismantling

Observe scrupulous cleanliness when dismantling components, particularly when parts of the brake, fuel or hydraulic systems

are being worked on. A particle of dirt or a fragment of cloth could cause a dangerous malfunction if trapped in these systems.

Clean all tapped holes, crevices, oil ways and fluid passages with compressed air.

WARNING: Do not permit compressed air to enter an open wound. Always use eye protection when using compressed air.

Make sure that any O-rings used for sealing are correctly reinstalled or renewed if disturbed. Mark mating parts to make sure

that they are replaced as dismantled. Whenever possible use marking materials which avoid the possibilities of causing

distortion or the initiation of cracks, which could occur if a center punch or scriber were used. Wire together mating parts where

necessary to prevent accidental interchange (e.g roller bearing components). Tie labels on to all parts to be renewed and to

parts requiring further inspection before being passed for reassembly. Place labelled parts and other parts for rebuild in

separate containers. Do not discard a part which is due for renewal until it has been compared with the new part, to make sure

Page 56 of 3039

General Information - Health and Safety Precautions

Description and Operation Published: 11-May-2011

The Health and Safety Precautions subsection refers to some commonly used chemicals and materials, hazards associated with

their use, and safety measures to be taken. Some of these chemicals may be included in the following list either in their own

right or as an ingredient in a sealer or adhesive.

Acids and Alkalis

See also Battery Acids.

e.g. caustic soda, sulphuric acid.

Used in batteries and cleaning materials.

Irritant and corrosive to the skin, eyes, nose and throat. Cause burns. Can destroy ordinary protective clothing.

Avoid splashes to the skin, eyes and clothing. Wear suitable protective impervious apron, gloves and goggles. Do not breath

mists.

Ensure access to eye wash bottles, shower and soap are readily available for splashing accidents.

Display Eye Hazard sign.

Air Bags

See also Fire, Chemical Materials - General

Highly flammable, explosive – observe No Smoking policy.

Used as a part of the Supplemental Restraint System (SRS), mounted in various positions around the vehicle.

The inflator contains a high-energetic propellant which, when ignited, produces a VERY HOT GAS (2500° C).

The gas generant used in air bags is Sodium Azide. This material is hermetically sealed in the module and is completely

consumed during deployment. No attempt should be made to open an air bag inflator as this will lead to the risk of exposure

to Sodium Azide. If a gas generator is ruptured, full protective clothing should be worn when dealing with the spillage.

After normal deployment, gloves and safety goggles should be worn during the handling process.

Deployed air bags should be disposed of in a plastic bag in accordance with local regulations at an approved chemical waste

site.

Following any direct contact with gas generant.

Wash affected areas thoroughly with water

Seek medical assistance if necessary

WARNING: To avoid accidental deployment and possible personal injury, the backup power supply must be depleted

before repairing or replacing any SRS components. To deplete the backup power supply energy, disconnect the battery negative

cable and wait for one minute. Failure to follow this instruction may result in personal injury.

NOTE: The storage, transportation, disposal and/or recycling of air bag modules must be carried out in accordance with all

applicable federal, state and local regulations including, but not limited to, those governing building and fire codes,

environmental protection, occupational health and safety and transportation.

Air Bags - Do's

Do store in an air bag safe when not installed to the vehicle.

Do store modules in an upright position

Do keep modules dry

Do carry modules with the cover side pointing away from the body

Do place modules with their cover side upwards

Do carefully inspect modules for damage

Do stand to one side when connecting modules

Do make sure all test equipment is properly calibrated and maintained

Do wash you hands after handling deployed air bags

Do wear safety glasses when carrying out repairs to the SRS or when handling an air bag module

Only carry out a system test with the air bag modules fully installed

Do inspect the condition of the impact sensor mounting bracket and sensor flylead if the vehicle has been involved in

an impact. Replace if damaged, even if there has been no deployment.

Air Bags - Do Nots

Do not store highly flammable material together with modules or gas generators

Do not store gas generators at temperatures exceeding 80° C

Page 72 of 3039

General Information - Standard Workshop Practices

Description and Operation

Protecting the Vehicle Published: 04-Jul-2014

Always install covers to protect the fenders before commencing work in the engine compartment. Always install the interior

protection kit, wear clean overalls and wash hands or wear gloves before working inside the vehicle. Avoid spilling hydraulic

fluid, antifreeze or battery acid on the paintwork. In the event of spillage, wash off with water immediately. Use polythene

sheets in the luggage compartment to protect carpets. Always use the recommended service tool, or a satisfactory equivalent,

where specified. Protect temporarily exposed screw threads by replacing nuts or installing caps.

Vehicle in Workshop

When working on a vehicle in the workshop always make sure that:

The parking brake is applied or the wheels are securely chocked to prevent the vehicle moving forwards or backwards

If the engine is to be run, there is adequate ventilation, or an extraction hose to remove exhaust fumes is installed

There is adequate room to jack up the vehicle and remove the wheels, if necessary

Fender covers are always installed if any work is to be carried out in the engine compartment

The battery is disconnected if working on the engine, underneath the vehicle, or if the vehicle is jacked up

CAUTION: When electric arc welding on a vehicle, always disconnect the generator wiring to prevent the possibility of a

surge of current causing damage to the internal components of the generator.

If using welding equipment on the vehicle, ensure a suitable fire extinguisher is readily available.

Screw Threads

Damaged nuts, bolts and screws must always be discarded. Attempting to recut or repair damaged threads with a tap

or die impairs the strength and fit of the threads and is not recommended.

NOTES:

During certain repair operations, it may be necessary to remove traces of thread locking agents using a tap. Where this

is necessary, the instruction to do so will appear in the relevant operation and it is essential that a tap of the correct size and

thread is used.

New Taptite bolts when used cut their own threads on the first application.

Some bolts are coated with a thread locking agent and unless stated otherwise, they must not be reused. New bolts

having the same part number as the original must always be installed. When nuts or bolts are to be discarded, the

repair operation and relevant torque chart will include an instruction to that effect. Do not use proprietary thread

locking agents as they may not meet the specification required. See also Encapsulated ('Patched') Bolts and Screws.

Always make sure that replacement nuts and bolts are at least equal in strength to those that they are replacing.

Castellated nuts must not be loosened to accept a split pin except in recommended cases when this forms part of an

adjustment.

Do not allow oil or grease to enter blind holes, the hydraulic action resulting from tightening the bolt or stud can split

the housing and also give a false torque reading.

Always tighten a nut, bolt or screw to the specified torque figure, damaged or corroded threads can give a false torque

reading.

Nut and bolt loosening and tightening sequences, where given, must ALWAYS be followed. Distortion of components or

faulty sealing of joints will result if the sequences are not followed. Where an instruction is given to tighten in stages,

these stages must be adhered to; do not attempt to combine stages particularly where certain stages involve

tightening by degrees.

To check or re-tighten a fixing to a specified torque, first loosen a quarter of a turn, then retighten to the specified

torque figure.

Unless instructed otherwise, do not lubricate bolt or nut threads prior to installing.

Where it is stated that bolts and screws may be reused, the following procedures must be carried out:

Check that threads are undamaged.

Remove all traces of locking agent from the threads.

CAUTION: DO NOT use a wire brush; take care that threads are not damaged.

Make sure that threads are clean and free from oil or grease.

Apply the specified locking agent to the bolt threads.

Page 73 of 3039

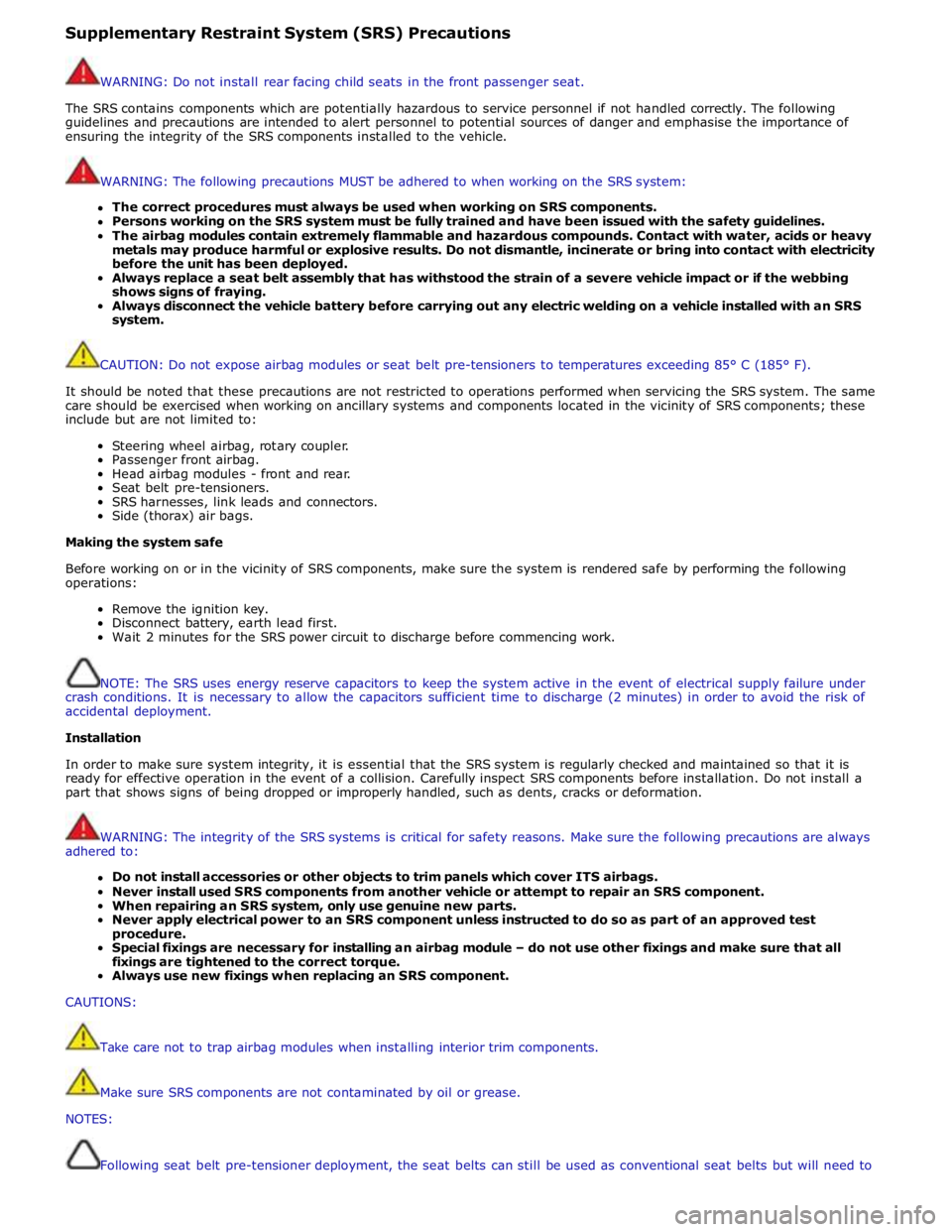

Supplementary Restraint System (SRS) Precautions

WARNING: Do not install rear facing child seats in the front passenger seat.

The SRS contains components which are potentially hazardous to service personnel if not handled correctly. The following

guidelines and precautions are intended to alert personnel to potential sources of danger and emphasise the importance of

ensuring the integrity of the SRS components installed to the vehicle.

WARNING: The following precautions MUST be adhered to when working on the SRS system:

The correct procedures must always be used when working on SRS components.

Persons working on the SRS system must be fully trained and have been issued with the safety guidelines.

The airbag modules contain extremely flammable and hazardous compounds. Contact with water, acids or heavy

metals may produce harmful or explosive results. Do not dismantle, incinerate or bring into contact with electricity

before the unit has been deployed.

Always replace a seat belt assembly that has withstood the strain of a severe vehicle impact or if the webbing

shows signs of fraying.

Always disconnect the vehicle battery before carrying out any electric welding on a vehicle installed with an SRS

system.

CAUTION: Do not expose airbag modules or seat belt pre-tensioners to temperatures exceeding 85° C (185° F).

It should be noted that these precautions are not restricted to operations performed when servicing the SRS system. The same

care should be exercised when working on ancillary systems and components located in the vicinity of SRS components; these

include but are not limited to:

Steering wheel airbag, rotary coupler.

Passenger front airbag.

Head airbag modules - front and rear.

Seat belt pre-tensioners.

SRS harnesses, link leads and connectors.

Side (thorax) air bags.

Making the system safe

Before working on or in the vicinity of SRS components, make sure the system is rendered safe by performing the following

operations:

Remove the ignition key.

Disconnect battery, earth lead first.

Wait 2 minutes for the SRS power circuit to discharge before commencing work.

NOTE: The SRS uses energy reserve capacitors to keep the system active in the event of electrical supply failure under

crash conditions. It is necessary to allow the capacitors sufficient time to discharge (2 minutes) in order to avoid the risk of

accidental deployment.

Installation

In order to make sure system integrity, it is essential that the SRS system is regularly checked and maintained so that it is

ready for effective operation in the event of a collision. Carefully inspect SRS components before installation. Do not install a

part that shows signs of being dropped or improperly handled, such as dents, cracks or deformation.

WARNING: The integrity of the SRS systems is critical for safety reasons. Make sure the following precautions are always

adhered to:

Do not install accessories or other objects to trim panels which cover ITS airbags.

Never install used SRS components from another vehicle or attempt to repair an SRS component.

When repairing an SRS system, only use genuine new parts.

Never apply electrical power to an SRS component unless instructed to do so as part of an approved test

procedure.

Special fixings are necessary for installing an airbag module – do not use other fixings and make sure that all

fixings are tightened to the correct torque.

Always use new fixings when replacing an SRS component.

CAUTIONS:

Take care not to trap airbag modules when installing interior trim components.

Make sure SRS components are not contaminated by oil or grease.

NOTES:

Following seat belt pre-tensioner deployment, the seat belts can still be used as conventional seat belts but will need to

Page 77 of 3039

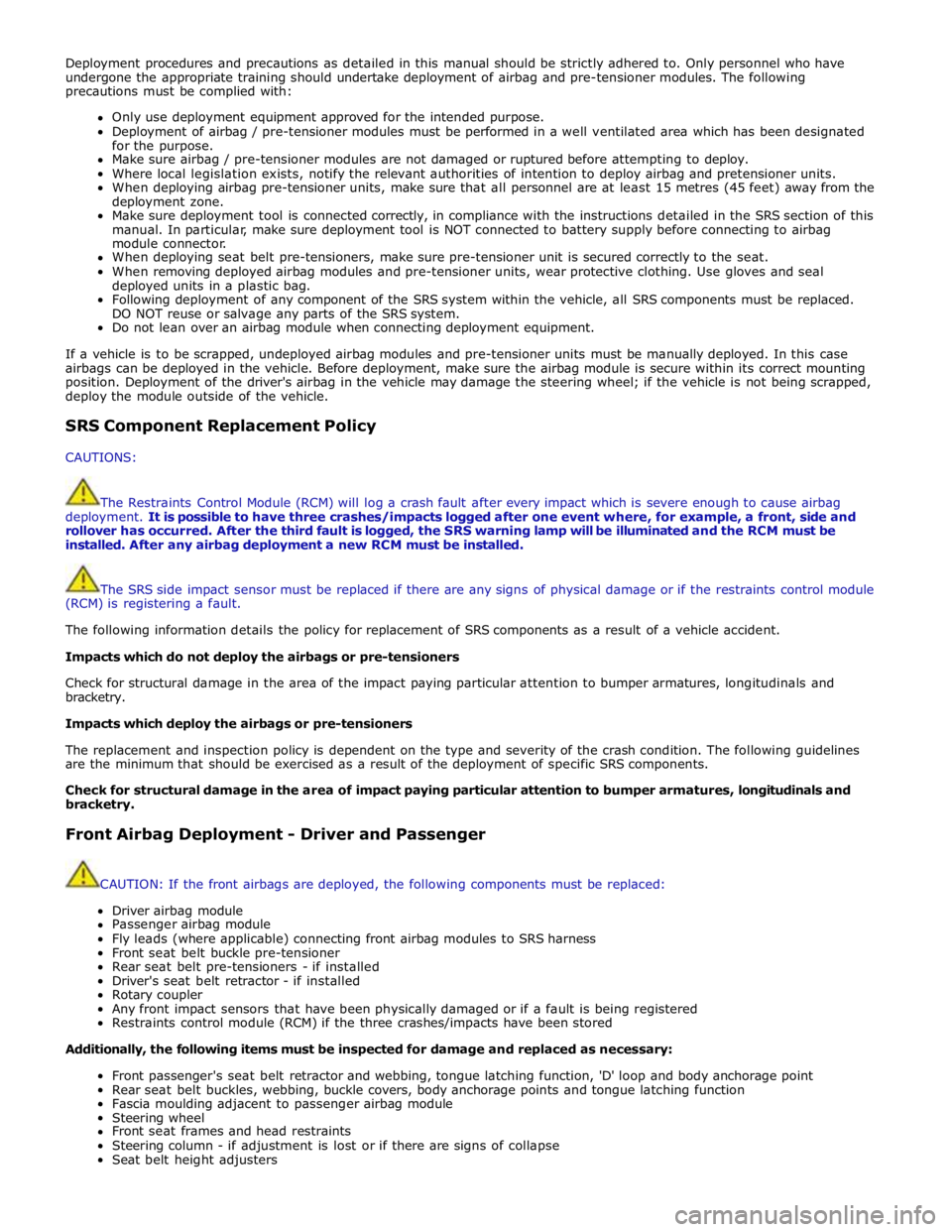

Deployment procedures and precautions as detailed in this manual should be strictly adhered to. Only personnel who have

undergone the appropriate training should undertake deployment of airbag and pre-tensioner modules. The following

precautions must be complied with:

Only use deployment equipment approved for the intended purpose.

Deployment of airbag / pre-tensioner modules must be performed in a well ventilated area which has been designated

for the purpose.

Make sure airbag / pre-tensioner modules are not damaged or ruptured before attempting to deploy.

Where local legislation exists, notify the relevant authorities of intention to deploy airbag and pretensioner units.

When deploying airbag pre-tensioner units, make sure that all personnel are at least 15 metres (45 feet) away from the

deployment zone.

Make sure deployment tool is connected correctly, in compliance with the instructions detailed in the SRS section of this

manual. In particular, make sure deployment tool is NOT connected to battery supply before connecting to airbag

module connector.

When deploying seat belt pre-tensioners, make sure pre-tensioner unit is secured correctly to the seat.

When removing deployed airbag modules and pre-tensioner units, wear protective clothing. Use gloves and seal

deployed units in a plastic bag.

Following deployment of any component of the SRS system within the vehicle, all SRS components must be replaced.

DO NOT reuse or salvage any parts of the SRS system.

Do not lean over an airbag module when connecting deployment equipment.

If a vehicle is to be scrapped, undeployed airbag modules and pre-tensioner units must be manually deployed. In this case

airbags can be deployed in the vehicle. Before deployment, make sure the airbag module is secure within its correct mounting

position. Deployment of the driver's airbag in the vehicle may damage the steering wheel; if the vehicle is not being scrapped,

deploy the module outside of the vehicle.

SRS Component Replacement Policy

CAUTIONS:

The Restraints Control Module (RCM) will log a crash fault after every impact which is severe enough to cause airbag

deployment. It is possible to have three crashes/impacts logged after one event where, for example, a front, side and

rollover has occurred. After the third fault is logged, the SRS warning lamp will be illuminated and the RCM must be

installed. After any airbag deployment a new RCM must be installed.

The SRS side impact sensor must be replaced if there are any signs of physical damage or if the restraints control module

(RCM) is registering a fault.

The following information details the policy for replacement of SRS components as a result of a vehicle accident.

Impacts which do not deploy the airbags or pre-tensioners

Check for structural damage in the area of the impact paying particular attention to bumper armatures, longitudinals and

bracketry.

Impacts which deploy the airbags or pre-tensioners

The replacement and inspection policy is dependent on the type and severity of the crash condition. The following guidelines

are the minimum that should be exercised as a result of the deployment of specific SRS components.

Check for structural damage in the area of impact paying particular attention to bumper armatures, longitudinals and

bracketry.

Front Airbag Deployment - Driver and Passenger

CAUTION: If the front airbags are deployed, the following components must be replaced:

Driver airbag module

Passenger airbag module

Fly leads (where applicable) connecting front airbag modules to SRS harness

Front seat belt buckle pre-tensioner

Rear seat belt pre-tensioners - if installed

Driver's seat belt retractor - if installed

Rotary coupler

Any front impact sensors that have been physically damaged or if a fault is being registered

Restraints control module (RCM) if the three crashes/impacts have been stored

Additionally, the following items must be inspected for damage and replaced as necessary:

Front passenger's seat belt retractor and webbing, tongue latching function, 'D' loop and body anchorage point

Rear seat belt buckles, webbing, buckle covers, body anchorage points and tongue latching function

Fascia moulding adjacent to passenger airbag module

Steering wheel

Front seat frames and head restraints

Steering column - if adjustment is lost or if there are signs of collapse

Seat belt height adjusters

Page 119 of 3039

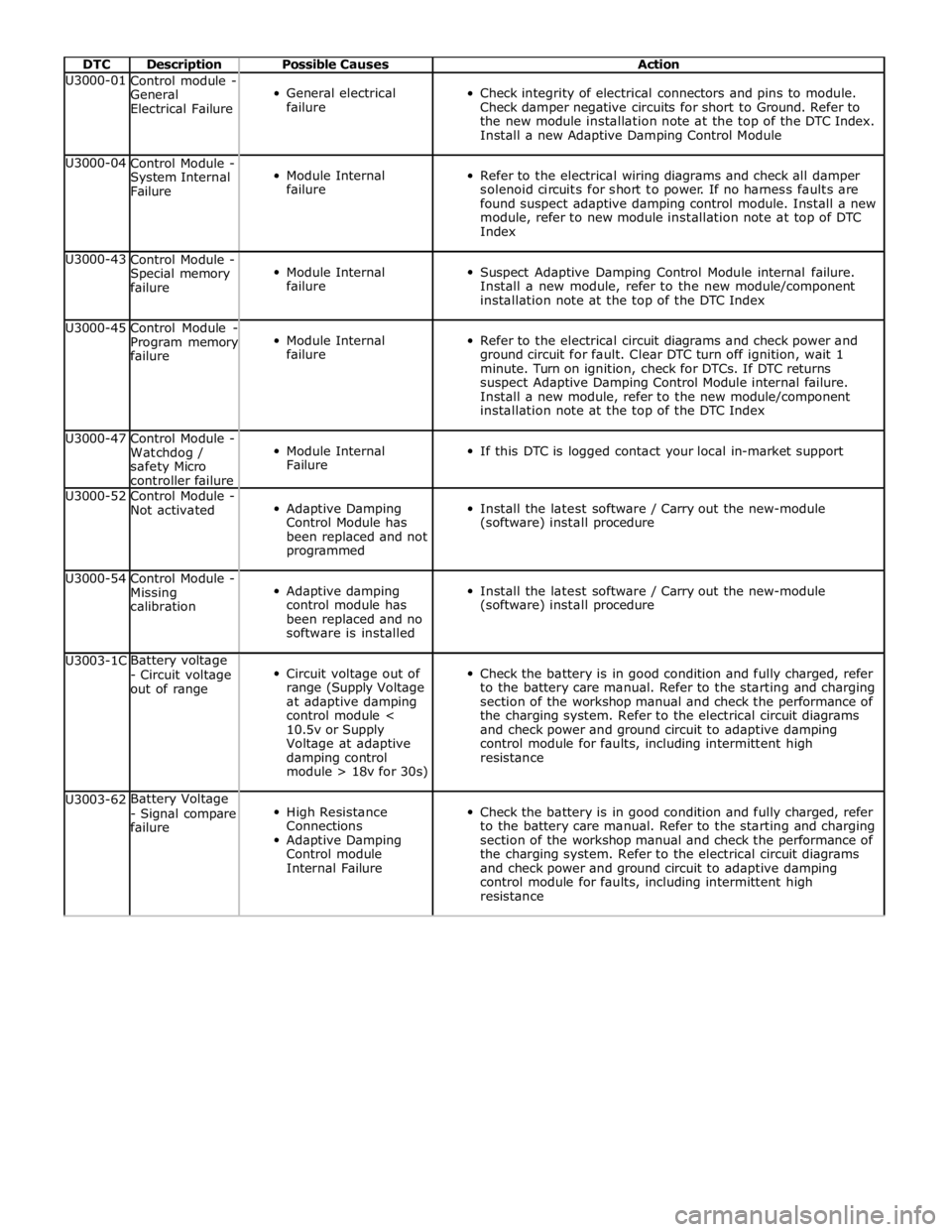

DTC Description Possible Causes Action U3000-01

Control module -

General

Electrical Failure

General electrical

failure

Check integrity of electrical connectors and pins to module.

Check damper negative circuits for short to Ground. Refer to

the new module installation note at the top of the DTC Index.

Install a new Adaptive Damping Control Module U3000-04

Control Module -

System Internal

Failure

Module Internal

failure

Refer to the electrical wiring diagrams and check all damper

solenoid circuits for short to power. If no harness faults are

found suspect adaptive damping control module. Install a new

module, refer to new module installation note at top of DTC

Index U3000-43

Control Module -

Special memory

failure

Module Internal

failure

Suspect Adaptive Damping Control Module internal failure.

Install a new module, refer to the new module/component

installation note at the top of the DTC Index U3000-45

Control Module -

Program memory

failure

Module Internal

failure

Refer to the electrical circuit diagrams and check power and

ground circuit for fault. Clear DTC turn off ignition, wait 1

minute. Turn on ignition, check for DTCs. If DTC returns

suspect Adaptive Damping Control Module internal failure.

Install a new module, refer to the new module/component

installation note at the top of the DTC Index U3000-47

Control Module -

Watchdog /

safety Micro

controller failure

Module Internal

Failure

If this DTC is logged contact your local in-market support U3000-52

Control Module -

Not activated

Adaptive Damping

Control Module has

been replaced and not

programmed

Install the latest software / Carry out the new-module

(software) install procedure U3000-54

Control Module -

Missing

calibration

Adaptive damping

control module has

been replaced and no

software is installed

Install the latest software / Carry out the new-module

(software) install procedure U3003-1C Battery voltage

- Circuit voltage

out of range

Circuit voltage out of

range (Supply Voltage

at adaptive damping

control module <

10.5v or Supply

Voltage at adaptive

damping control

module > 18v for 30s)

Check the battery is in good condition and fully charged, refer

to the battery care manual. Refer to the starting and charging

section of the workshop manual and check the performance of

the charging system. Refer to the electrical circuit diagrams

and check power and ground circuit to adaptive damping

control module for faults, including intermittent high

resistance U3003-62 Battery Voltage

- Signal compare

failure

High Resistance

Connections

Adaptive Damping

Control module

Internal Failure

Check the battery is in good condition and fully charged, refer

to the battery care manual. Refer to the starting and charging

section of the workshop manual and check the performance of

the charging system. Refer to the electrical circuit diagrams

and check power and ground circuit to adaptive damping

control module for faults, including intermittent high

resistance

Page 120 of 3039

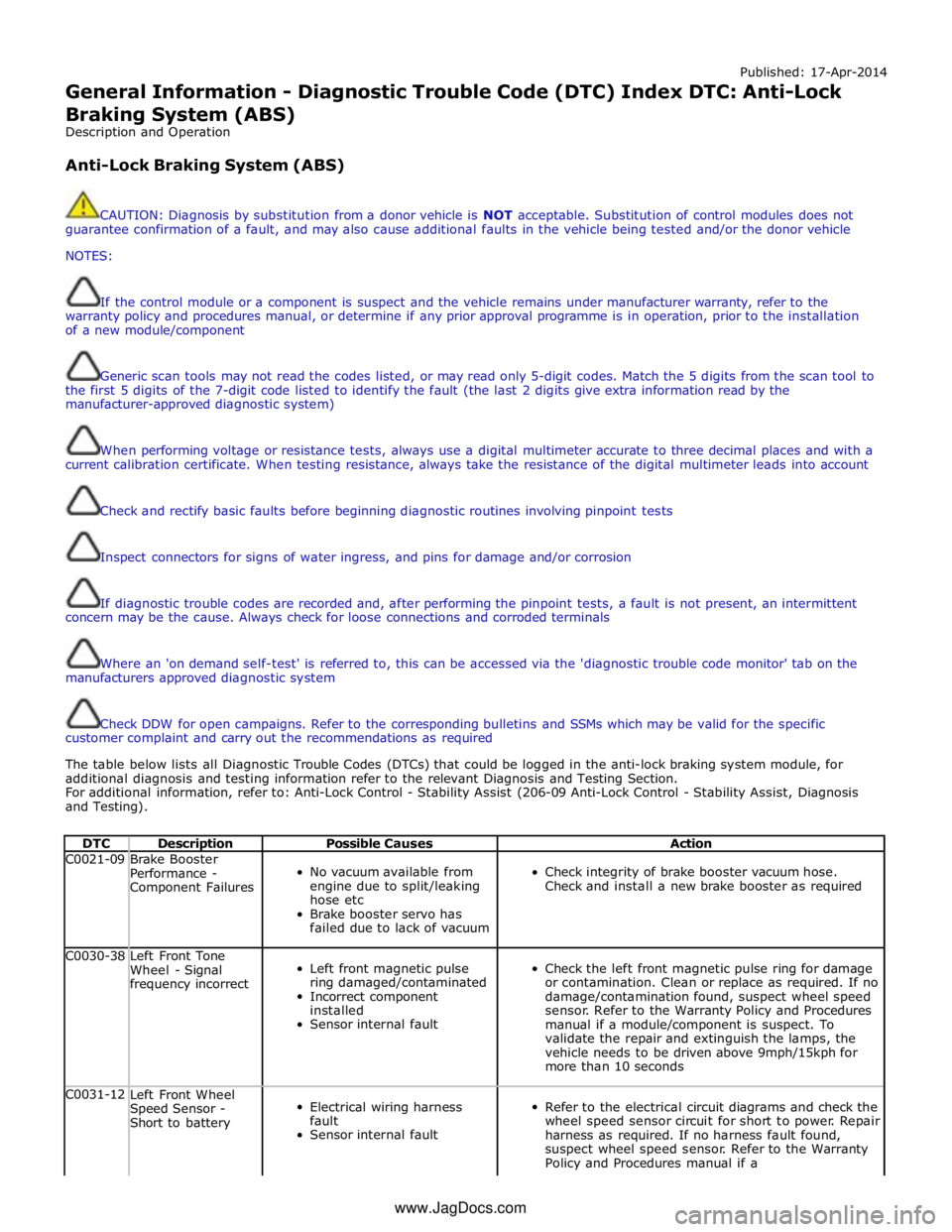

Published: 17-Apr-2014

General Information - Diagnostic Trouble Code (DTC) Index DTC: Anti-Lock Braking System (ABS)

Description and Operation

Anti-Lock Braking System (ABS)

CAUTION: Diagnosis by substitution from a donor vehicle is NOT acceptable. Substitution of control modules does not

guarantee confirmation of a fault, and may also cause additional faults in the vehicle being tested and/or the donor vehicle

NOTES:

If the control module or a component is suspect and the vehicle remains under manufacturer warranty, refer to the

warranty policy and procedures manual, or determine if any prior approval programme is in operation, prior to the installation

of a new module/component

Generic scan tools may not read the codes listed, or may read only 5-digit codes. Match the 5 digits from the scan tool to

the first 5 digits of the 7-digit code listed to identify the fault (the last 2 digits give extra information read by the

manufacturer-approved diagnostic system)

When performing voltage or resistance tests, always use a digital multimeter accurate to three decimal places and with a

current calibration certificate. When testing resistance, always take the resistance of the digital multimeter leads into account

Check and rectify basic faults before beginning diagnostic routines involving pinpoint tests

Inspect connectors for signs of water ingress, and pins for damage and/or corrosion

If diagnostic trouble codes are recorded and, after performing the pinpoint tests, a fault is not present, an intermittent

concern may be the cause. Always check for loose connections and corroded terminals

Where an 'on demand self-test' is referred to, this can be accessed via the 'diagnostic trouble code monitor' tab on the

manufacturers approved diagnostic system

Check DDW for open campaigns. Refer to the corresponding bulletins and SSMs which may be valid for the specific

customer complaint and carry out the recommendations as required

The table below lists all Diagnostic Trouble Codes (DTCs) that could be logged in the anti-lock braking system module, for

additional diagnosis and testing information refer to the relevant Diagnosis and Testing Section.

For additional information, refer to: Anti-Lock Control - Stability Assist (206-09 Anti-Lock Control - Stability Assist, Diagnosis

and Testing).

DTC Description Possible Causes Action C0021-09

Brake Booster

Performance -

Component Failures

No vacuum available from

engine due to split/leaking

hose etc

Brake booster servo has

failed due to lack of vacuum

Check integrity of brake booster vacuum hose.

Check and install a new brake booster as required C0030-38

Left Front Tone

Wheel - Signal

frequency incorrect

Left front magnetic pulse

ring damaged/contaminated

Incorrect component

installed

Sensor internal fault

Check the left front magnetic pulse ring for damage

or contamination. Clean or replace as required. If no

damage/contamination found, suspect wheel speed

sensor. Refer to the Warranty Policy and Procedures

manual if a module/component is suspect. To

validate the repair and extinguish the lamps, the

vehicle needs to be driven above 9mph/15kph for

more than 10 seconds C0031-12

Left Front Wheel

Speed Sensor -

Short to battery

Electrical wiring harness

fault

Sensor internal fault

Refer to the electrical circuit diagrams and check the

wheel speed sensor circuit for short to power. Repair

harness as required. If no harness fault found,

suspect wheel speed sensor. Refer to the Warranty

Policy and Procedures manual if a www.JagDocs.com

Page 122 of 3039

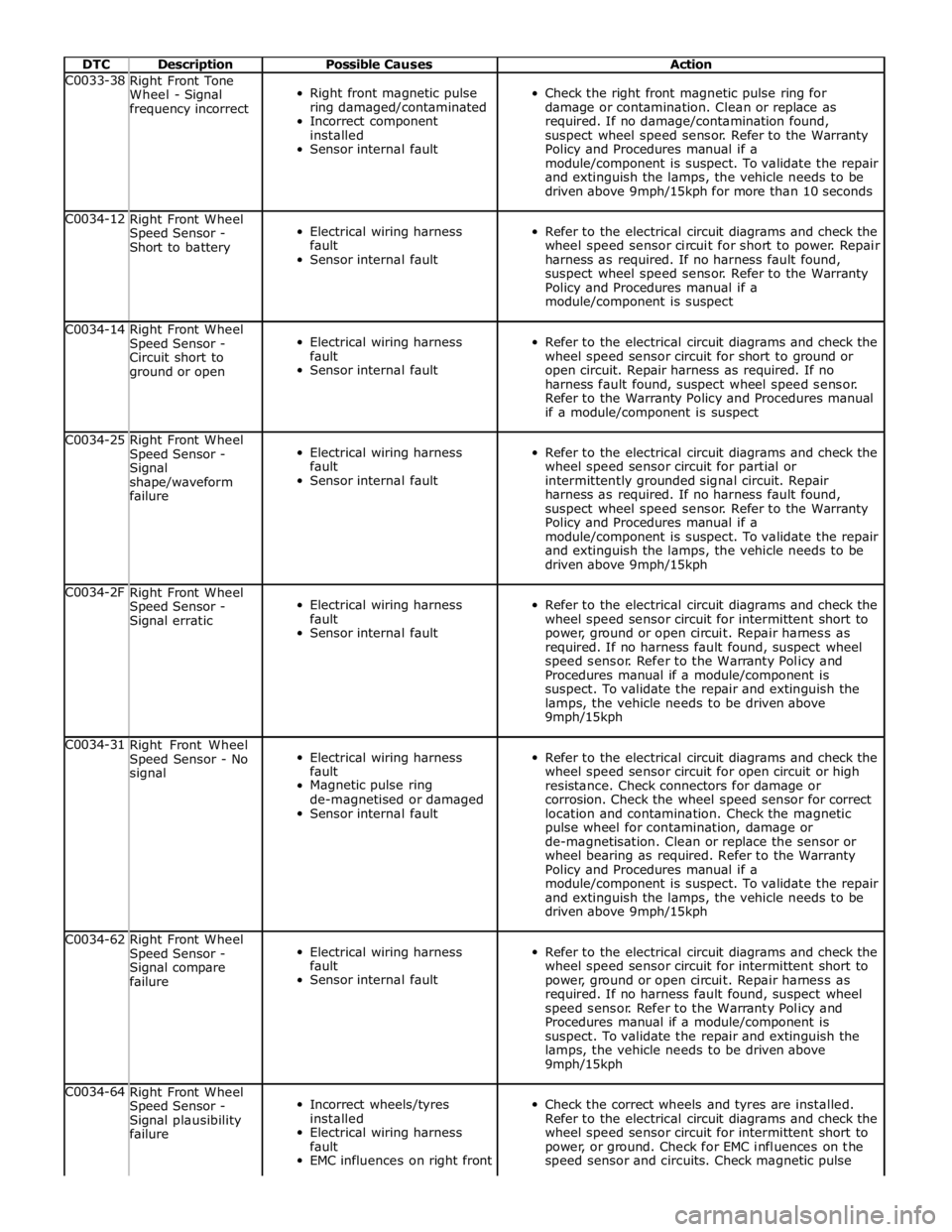

DTC Description Possible Causes Action C0033-38

Right Front Tone

Wheel - Signal

frequency incorrect

Right front magnetic pulse

ring damaged/contaminated

Incorrect component

installed

Sensor internal fault

Check the right front magnetic pulse ring for

damage or contamination. Clean or replace as

required. If no damage/contamination found,

suspect wheel speed sensor. Refer to the Warranty

Policy and Procedures manual if a

module/component is suspect. To validate the repair

and extinguish the lamps, the vehicle needs to be

driven above 9mph/15kph for more than 10 seconds C0034-12

Right Front Wheel

Speed Sensor -

Short to battery

Electrical wiring harness

fault

Sensor internal fault

Refer to the electrical circuit diagrams and check the

wheel speed sensor circuit for short to power. Repair

harness as required. If no harness fault found,

suspect wheel speed sensor. Refer to the Warranty

Policy and Procedures manual if a

module/component is suspect C0034-14

Right Front Wheel

Speed Sensor -

Circuit short to

ground or open

Electrical wiring harness

fault

Sensor internal fault

Refer to the electrical circuit diagrams and check the

wheel speed sensor circuit for short to ground or

open circuit. Repair harness as required. If no

harness fault found, suspect wheel speed sensor.

Refer to the Warranty Policy and Procedures manual

if a module/component is suspect C0034-25

Right Front Wheel

Speed Sensor -

Signal

shape/waveform

failure

Electrical wiring harness

fault

Sensor internal fault

Refer to the electrical circuit diagrams and check the

wheel speed sensor circuit for partial or

intermittently grounded signal circuit. Repair

harness as required. If no harness fault found,

suspect wheel speed sensor. Refer to the Warranty

Policy and Procedures manual if a

module/component is suspect. To validate the repair

and extinguish the lamps, the vehicle needs to be

driven above 9mph/15kph C0034-2F

Right Front Wheel

Speed Sensor -

Signal erratic

Electrical wiring harness

fault

Sensor internal fault

Refer to the electrical circuit diagrams and check the

wheel speed sensor circuit for intermittent short to

power, ground or open circuit. Repair harness as

required. If no harness fault found, suspect wheel

speed sensor. Refer to the Warranty Policy and

Procedures manual if a module/component is

suspect. To validate the repair and extinguish the

lamps, the vehicle needs to be driven above

9mph/15kph C0034-31

Right Front Wheel

Speed Sensor - No

signal

Electrical wiring harness

fault

Magnetic pulse ring

de-magnetised or damaged

Sensor internal fault

Refer to the electrical circuit diagrams and check the

wheel speed sensor circuit for open circuit or high

resistance. Check connectors for damage or

corrosion. Check the wheel speed sensor for correct

location and contamination. Check the magnetic

pulse wheel for contamination, damage or

de-magnetisation. Clean or replace the sensor or

wheel bearing as required. Refer to the Warranty

Policy and Procedures manual if a

module/component is suspect. To validate the repair

and extinguish the lamps, the vehicle needs to be

driven above 9mph/15kph C0034-62

Right Front Wheel

Speed Sensor -

Signal compare

failure

Electrical wiring harness

fault

Sensor internal fault

Refer to the electrical circuit diagrams and check the

wheel speed sensor circuit for intermittent short to

power, ground or open circuit. Repair harness as

required. If no harness fault found, suspect wheel

speed sensor. Refer to the Warranty Policy and

Procedures manual if a module/component is

suspect. To validate the repair and extinguish the

lamps, the vehicle needs to be driven above

9mph/15kph C0034-64

Right Front Wheel

Speed Sensor -

Signal plausibility

failure

Incorrect wheels/tyres

installed

Electrical wiring harness

fault

EMC influences on right front

Check the correct wheels and tyres are installed.

Refer to the electrical circuit diagrams and check the

wheel speed sensor circuit for intermittent short to

power, or ground. Check for EMC influences on the

speed sensor and circuits. Check magnetic pulse

Page 123 of 3039

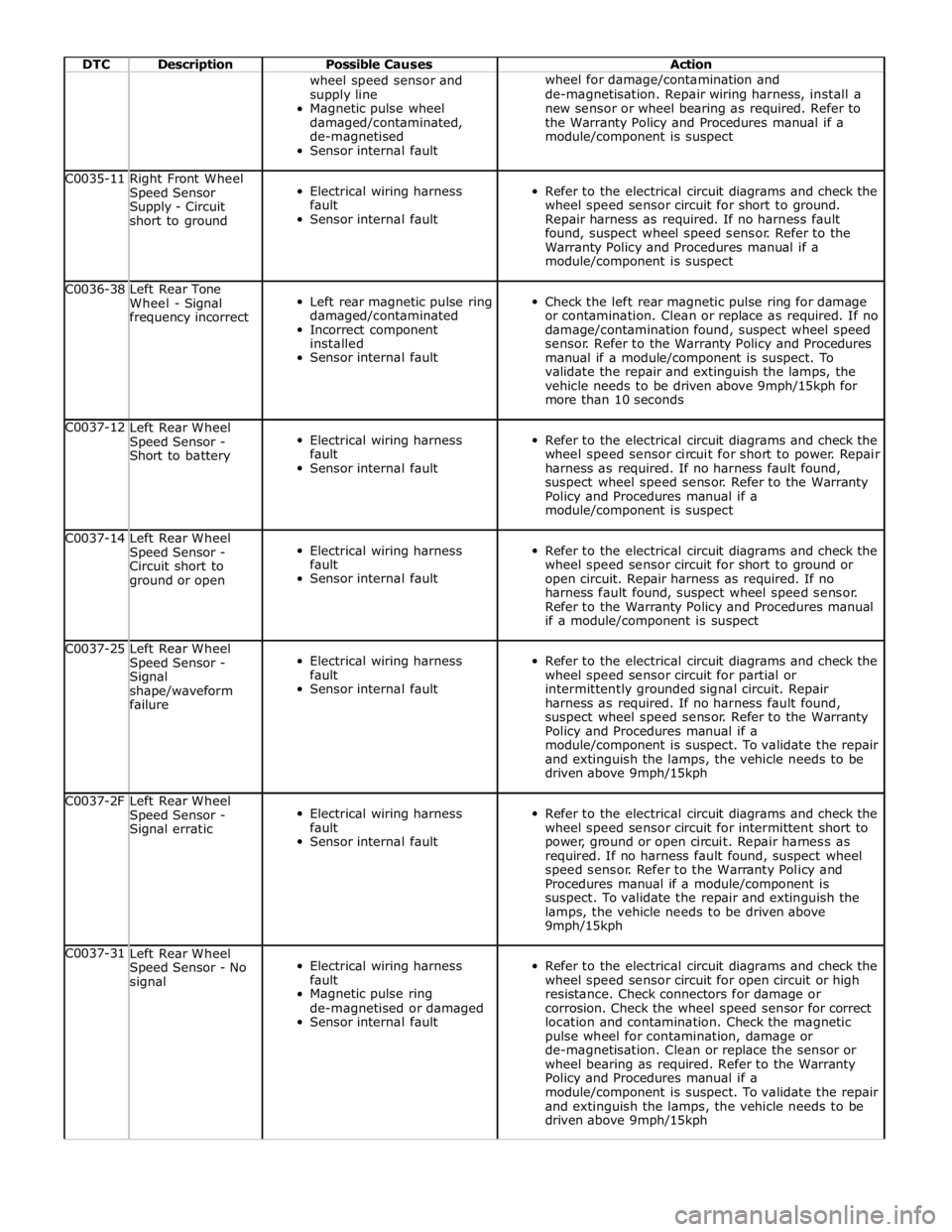

DTC Description Possible Causes Action wheel speed sensor and

supply line

Magnetic pulse wheel

damaged/contaminated,

de-magnetised

Sensor internal fault wheel for damage/contamination and

de-magnetisation. Repair wiring harness, install a

new sensor or wheel bearing as required. Refer to

the Warranty Policy and Procedures manual if a

module/component is suspect C0035-11

Right Front Wheel

Speed Sensor

Supply - Circuit

short to ground

Electrical wiring harness

fault

Sensor internal fault

Refer to the electrical circuit diagrams and check the

wheel speed sensor circuit for short to ground.

Repair harness as required. If no harness fault

found, suspect wheel speed sensor. Refer to the

Warranty Policy and Procedures manual if a

module/component is suspect C0036-38

Left Rear Tone

Wheel - Signal

frequency incorrect

Left rear magnetic pulse ring

damaged/contaminated

Incorrect component

installed

Sensor internal fault

Check the left rear magnetic pulse ring for damage

or contamination. Clean or replace as required. If no

damage/contamination found, suspect wheel speed

sensor. Refer to the Warranty Policy and Procedures

manual if a module/component is suspect. To

validate the repair and extinguish the lamps, the

vehicle needs to be driven above 9mph/15kph for

more than 10 seconds C0037-12

Left Rear Wheel

Speed Sensor -

Short to battery

Electrical wiring harness

fault

Sensor internal fault

Refer to the electrical circuit diagrams and check the

wheel speed sensor circuit for short to power. Repair

harness as required. If no harness fault found,

suspect wheel speed sensor. Refer to the Warranty

Policy and Procedures manual if a

module/component is suspect C0037-14

Left Rear Wheel

Speed Sensor -

Circuit short to

ground or open

Electrical wiring harness

fault

Sensor internal fault

Refer to the electrical circuit diagrams and check the

wheel speed sensor circuit for short to ground or

open circuit. Repair harness as required. If no

harness fault found, suspect wheel speed sensor.

Refer to the Warranty Policy and Procedures manual

if a module/component is suspect C0037-25

Left Rear Wheel

Speed Sensor -

Signal

shape/waveform

failure

Electrical wiring harness

fault

Sensor internal fault

Refer to the electrical circuit diagrams and check the

wheel speed sensor circuit for partial or

intermittently grounded signal circuit. Repair

harness as required. If no harness fault found,

suspect wheel speed sensor. Refer to the Warranty

Policy and Procedures manual if a

module/component is suspect. To validate the repair

and extinguish the lamps, the vehicle needs to be

driven above 9mph/15kph C0037-2F

Left Rear Wheel

Speed Sensor -

Signal erratic

Electrical wiring harness

fault

Sensor internal fault

Refer to the electrical circuit diagrams and check the

wheel speed sensor circuit for intermittent short to

power, ground or open circuit. Repair harness as

required. If no harness fault found, suspect wheel

speed sensor. Refer to the Warranty Policy and

Procedures manual if a module/component is

suspect. To validate the repair and extinguish the

lamps, the vehicle needs to be driven above

9mph/15kph C0037-31

Left Rear Wheel

Speed Sensor - No

signal

Electrical wiring harness

fault

Magnetic pulse ring

de-magnetised or damaged

Sensor internal fault

Refer to the electrical circuit diagrams and check the

wheel speed sensor circuit for open circuit or high

resistance. Check connectors for damage or

corrosion. Check the wheel speed sensor for correct

location and contamination. Check the magnetic

pulse wheel for contamination, damage or

de-magnetisation. Clean or replace the sensor or

wheel bearing as required. Refer to the Warranty

Policy and Procedures manual if a

module/component is suspect. To validate the repair

and extinguish the lamps, the vehicle needs to be

driven above 9mph/15kph