JAGUAR XJ 1994 2.G AJ16 Engine Manual

Manufacturer: JAGUAR, Model Year: 1994, Model line: XJ, Model: JAGUAR XJ 1994 2.GPages: 73, PDF Size: 2.06 MB

Page 11 of 73

AJ16 Engine Service Manual

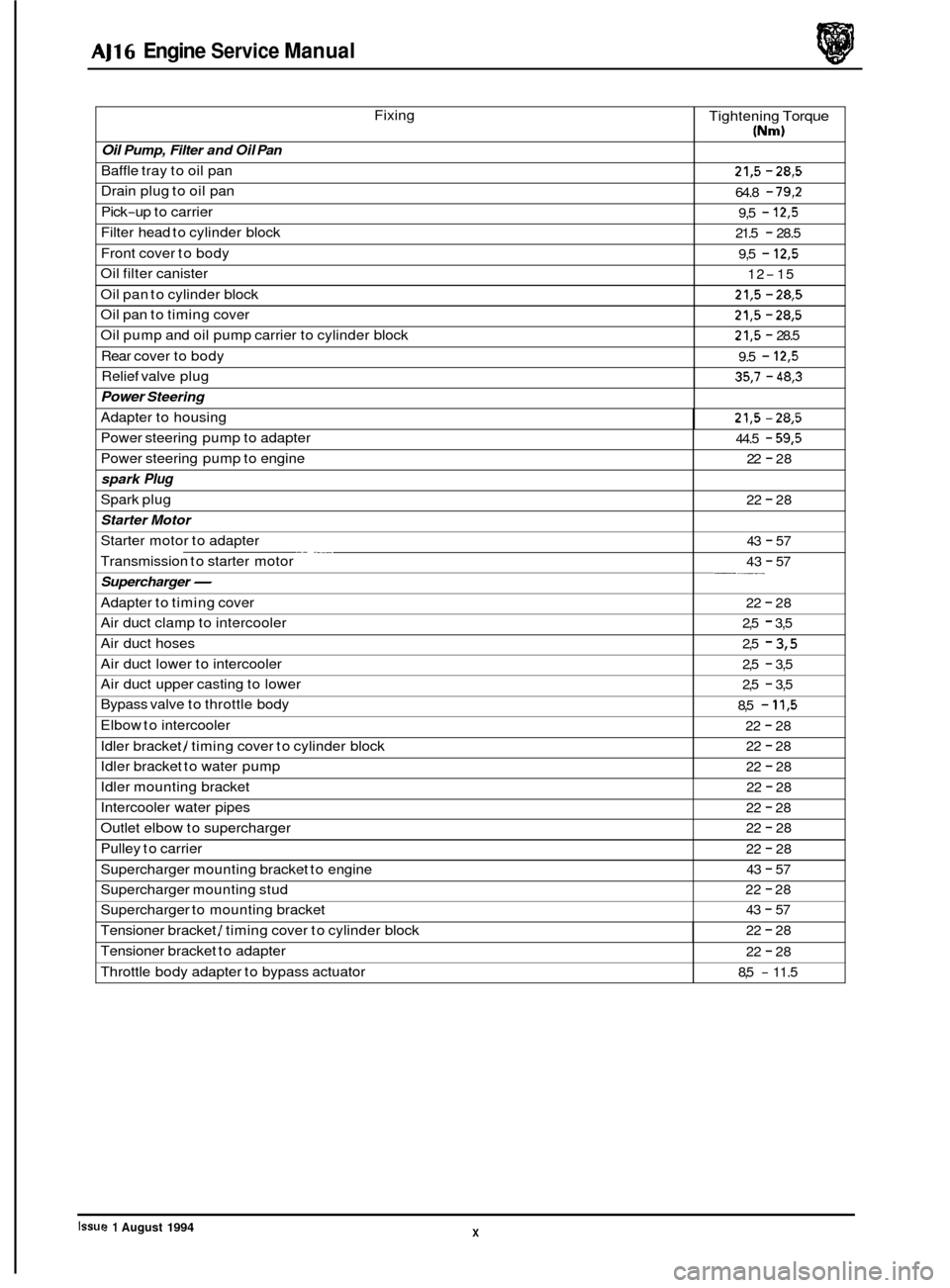

0 Fixing

Oil Pump, Filter and Oil Pan

Baffle tray to oil pan

Drain plug to oil pan

Pick

-up to carrier

Filter head to cylinder block

Front cover to body

Oil filter canister

Oil pan to cylinder block

Oil pan to timing cover

Oil pump and oil pump carrier to cylinder block

Rear cover to body

Relief valve plug Tightening

Torque

(Nm)

21,5 - 28,5

64.8 - 79,2

9,5 - 12,5

21.5 - 28.5

9,5

- 12,5

12-15

21,5 - 28,5

21,5 - 28,5

21,5 - 28.5

9.5

- 12,5

35,7 - 48,3

Power Steering

Adapter to housing 21,5 - 28,5

Power steering pump to adapter

Power steering pump to engine

spark Plug

Starter Motor

Starter motor to adapter

Transmission to starter motor

Supercharger-

Spark plug

--

44.5 - 59,5

22 - 28

22

- 28

43

- 57

43

- 57 -___

Adapter to timing cover

Air duct clamp to intercooler

Air duct hoses

Air duct lower to intercooler 22 - 28

2,5

- 3,5

2,5

- 3,5

2,5 - 3,5

Air duct upper casting to lower

Bypass valve to throttle body

Elbow to intercooler

Idler bracket

/ timing cover to cylinder block

Idler bracket to water pump

X Issue 1 August 1994

2,5 - 3,5

8,5

- 11,5

22 - 28

22

- 28

22

- 28

Idler mounting bracket

Intercooler water pipes

Outlet elbow to supercharger

Pulley to carrier

Supercharger mounting bracket to engine

Supercharger mounting stud 22 - 28

22

- 28

22

- 28

22

- 28

43

- 57

22

- 28

Supercharger to mounting bracket 43 - 57

Tensioner bracket / timing cover to cylinder block 22 - 28

Tensioner bracket to adapter

Throttle body adapter to bypass actuator 22 - 28

8,5

- 11.5

Page 12 of 73

AJ16 Engine Service Manual

~- Fixing Tightening

Torque

r- (Nm)

____ liming Cover L 1 Auxiliary shaft blanking plate to timing cover 9,5 - 12,5

Generator adjuster to timing cover 8,5 - 11,5 ~ __ ____ ~ t Intermediate shaft blanking

plate to timing cover 1 21,5-28,5

I Sensor to timing cover

l Timing cover to cylinder block b+-- 21,5 - 28,5

21,5 - 28,5 _. ______

xi Issue 1 August 1994

Page 13 of 73

AJ16 Engine Service Manual

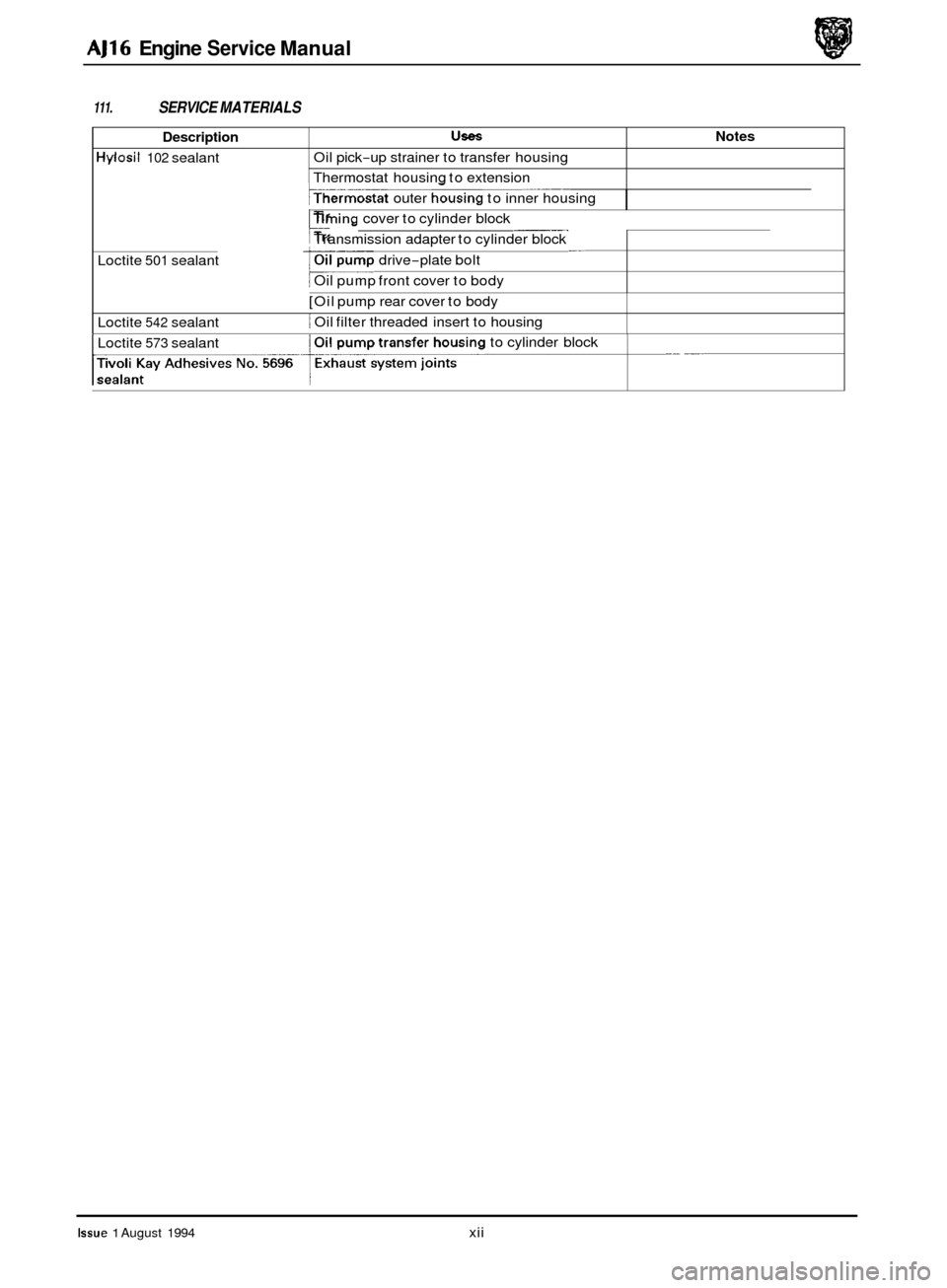

Description

Hylosil 102 sealant

111. SERVICE MATERIALS

UseS Notes

Oil pick-up strainer to transfer housing

Thermostat housing to extension

I jThermostat outer housing to inner housing

Loctite

501 sealant

~. Xming cover to cylinder block

t Transmission adapter to cylinder block

drive

-plate bolt

Oil pump front cover to body

[Oil pump rear cover to body

1 Oil filter threaded insert to housing

Loctite 542 sealant

__ __ Loctite 573 sealant to

cylinder block

Issue 1 August 1994 xii

Page 14 of 73

AJ16 Engine Service Manual

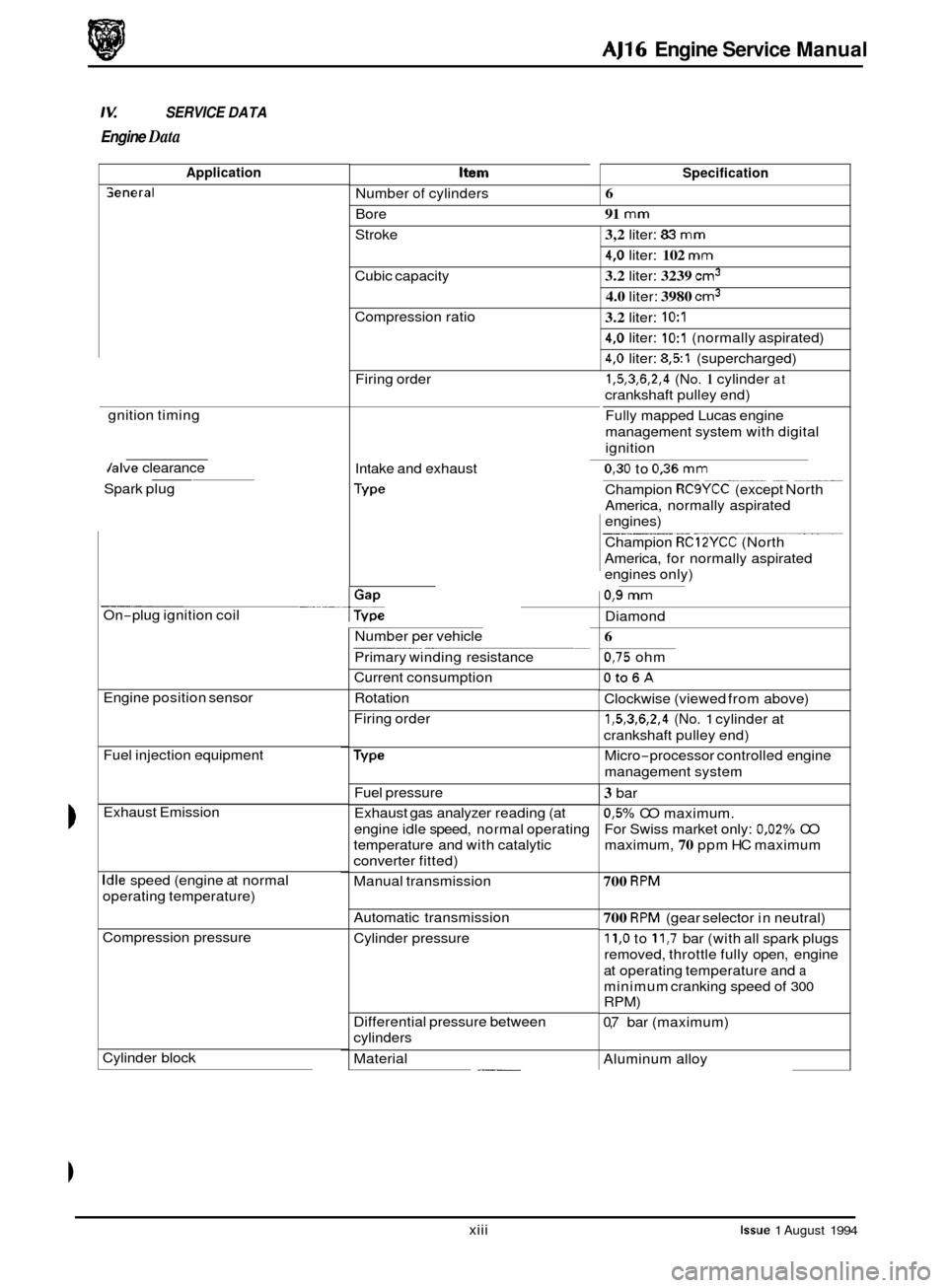

SERVICE DATA

Engine Data

Application Item

Number of cylinders

Bore

Specification

Seneral 6

91

mm

Stroke 3,2 liter: 83 mm

4,O liter: 102 mm

3.2 liter: 3239 cm3

4.0 liter: 3980 cm3

Cubic capacity

Compression ratio

3.2 liter: 1O:l

4,O liter: 1O:l (normally aspirated)

4,O liter: 8,51 (supercharged)

1,5,3,6,2,4 (No. 1 cylinder at

crankshaft pulley end)

Fully mapped Lucas engine

management system with digital

ignition

Firing

order

gnition timing

0

0

0

Jalve clearance

Intake and exhaust 0,30 to 0,36 mm

Champion RCSYCC (except North

America, normally aspirated

engines)

Champion

RC12YCC (North

America, for normally aspirated

engines only)

__ ~ ~

--__ ~~

Spark

plug

0,9 mm

On-plug ignition coil

Diamond

Number per vehicle

Primary winding resistance

Current consumption ~ ~~

6

0,75 ohm

Oto6A

Clockwise

(viewed from above)

1,5,3,6,2,4 (No. 1 cylinder at

crankshaft pulley end)

-

Engine position sensor

Fuel injection equipment

Exhaust Emission Rotation

Firing order

Micro

-processor controlled engine

management system

Fuel pressure

Exhaust gas analyzer reading (at

engine idle speed, normal operating

temperature and with catalytic

converter fitted)

3 bar

0,5% CO maximum.

For Swiss market only:

0,02% CO

maximum,

70 ppm HC maximum

Idle speed (engine at normal

operating temperature) Manual transmission 700 RPM

Automatic

transmission 700 RPM (gear selector in neutral)

11,O to 11,7 bar (with all spark plugs

removed, throttle fully open, engine

at operating temperature and

a

minimum cranking speed of 300

RPM)

0,7 bar (maximum)

Compression pressure

Cylinder pressure

Differential pressure between

cylinders

Aluminum alloy

Cylinder block

. ___ Material

xiii

Issue 1 August 1994

Page 15 of 73

AJ16 Engine Service Manual

kern

For piston grade F

Application

alinder block bore diameter after

boning

Specification

90,990 to 90,998

mm

zylinder head For

piston grade

G

For piston grade H

t0.020 in.

:rankshaft

90,999 to 91,007 mm

91,008 to 91,016 mm

91,513 to 91,526 mm

:onnecting rod To

within 15

gm cm (imbalance to

be corrected by drilling up to four

holes in each balance weight

9,5

mm diameter x 29 mm deep

' maximum)

'iston

'iston diameter Length

between centers

Bore for connecting rod bearing

Connecting rod bearing diametrical

clearance

Connecting rod bearing side

clearance

Bore for small end bushing

Type

Skirt clearance

Grade

F

Grade G

Grade

H

+0.020 in.

Number

of compression rings

'iston ring

____ Blue: 52,990 to 53,000 mm

3,2 liter: 175785 to 175,285 mm

4,O liter: 166,320 to 166,420 mm

56,731 mm

0,023 to 0,059 mm

0,132 to 0,233 mm

26,975 to 27,000 mm

AE413P/PD (BS 1490-198SLM 13TF)

phosphorus treated

0,Ol to 0,026 mm

90,972 to 90,980 mm

90,980 to 90,989 mm

90,990 to 90,998 mm

91,480 to 91,506 mm

2

Material

I Aluminum

alloy

Material

I3,2 liter: cast iron

Number of main bearings

Main bearing type

Journal diameter

Thrust washer thickness

Permissible end float

Balancing

Diametrical clearance

Crankpin diameter

4,O liter: forged steel

7

Vandervell

VP2C

Pink 76,210 to 76,220 mm

White: 76.220 to 76,230 mm

Green: 76,230 to 76,240 mm

2.57 to 2,62 mm

0,lO to 0,28 mm

Number of oil control rings

Gap when fitted in bore 1

Top compression ring:

0,40 to 0,65

mm

Second compression ring: 0,40 to

0,65 mm

Oil control ring: 0.30 to 0,55 mm

Issue 1 August 1994 xiv

Page 16 of 73

AJ16 Engine Service Manual

Item

Type

Length

Outside diameter

Inside diameter

Material ~

Application

Specification

Chamfer locking

3,2

liter: 68,37 to 68,50 mm

4,O liter: 77,12 to 77,25 mm

23,807 to 23,812 mm

14,30 to 14.81 mm

Cast iron

'iston pin

2amshaft

dalve

Number of journals

Nominal

lift

Permissible end float

4djustment of valve clearance 7

9,95 mm

0.13 mm

rlalve Guide

Valve

stem diameter

Valve clearance

Jalve seat Intake

and exhaust: 6,947 to 6,960

mm

Intake and exhaust: 0,30 to 0,36 mm

Jalve seat insert outside diameter Outside

diameter

rappet

lalve spring Standard

- no

groove: 10,993 to

11,005 mm

1st oversize - 1 groove: 11,043 to

11,055

mm (production only)

2nd oversize

- 2 grooves: 1 1,143 to

11,155 mm

:amshaft sprocket

:rankshaft sprocket Diametrical

clearance

Free length

Number

of teeth

ntermediate sprocket

0,02 to 0,05 mm

43,5 mm

30

xv Issue 1 August 1994

Page 17 of 73

AJ16 Engine Service Manual

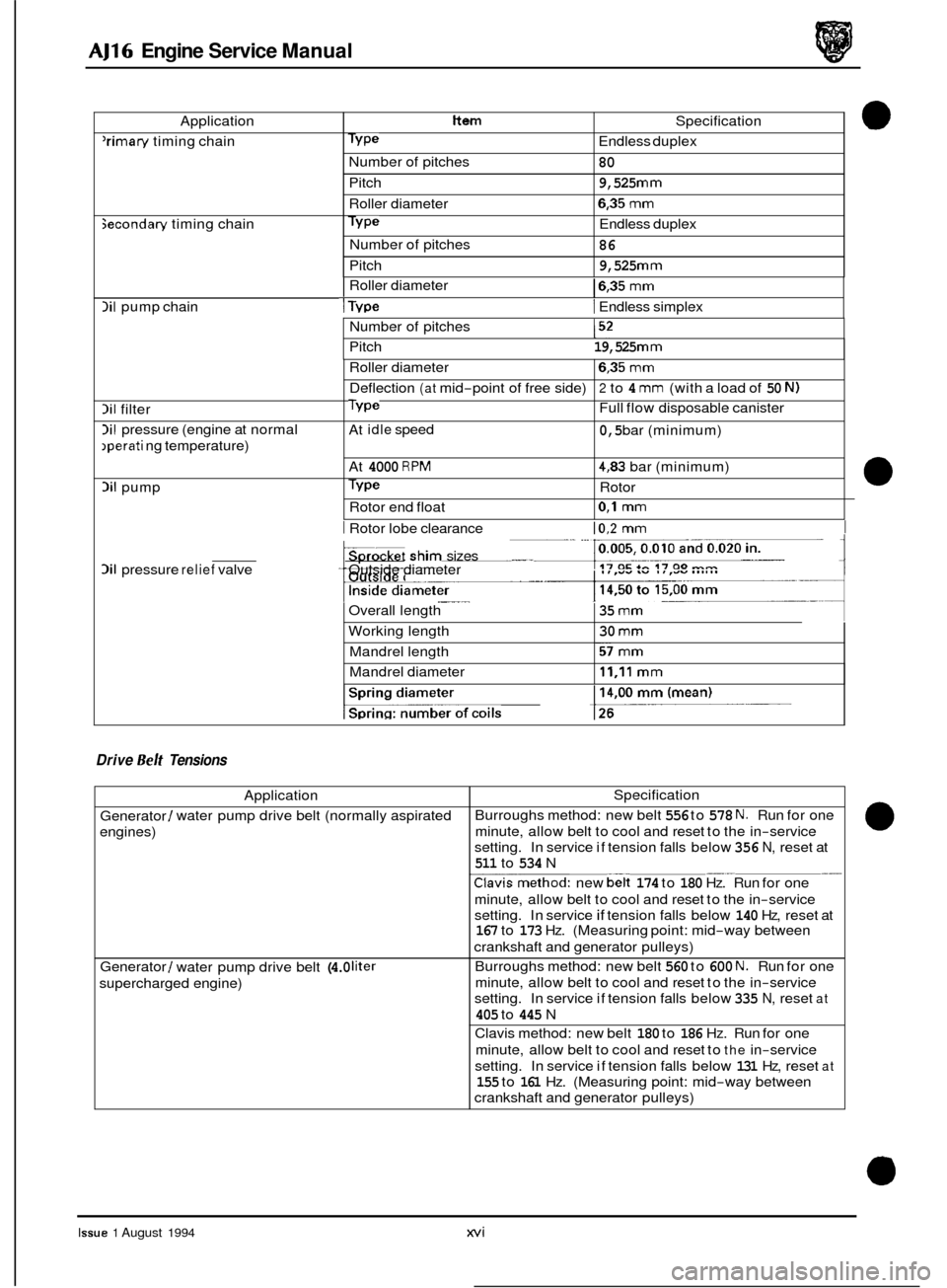

0 Application Item

'rimary timing chain Type

Pitch

Roller diameter

secondan/ timing chain Type

Number of pitches

Pitch

Number of

pitches Specification

Endless duplex

80

9,525

mm

6,35 mm

Endless duplex

86

9,525

mm

lil pump chain

lil filter

lil pressure (engine at normal

,perati ng temperature)

Si1 pump

I Roller diameter 16,35 mm

I Type I Endless simplex

Roller diameter

6,35 mm

Deflection (at mid-point of free side) 2 to 4 mm (with a load of 50 N)

Type Full flow disposable canister

At

idle speed 0,5 bar (minimum)

At

4000 RPM 4,83 bar (minimum)

Type Rotor

Rotor end float

0,l mm

Number of pitches I52

Pitch 19,525 mm

___ Overall length

Working length Mandrel length

Mandrel diameter 35 mm

30 mm

57 mm

11,ll mm

Si1 pressure relief valve

Application

Generator

/ water pump drive belt (normally aspirated

engines)

Generator

/ water pump drive belt (4.0 liter

supercharged engine)

I Rotor lobe clearance 10,2 mm I

Specification

Burroughs method: new belt

556 to 578 N. Run for one

minute, allow belt to cool and reset to the in

-service

setting. In service if tension falls below

356 N, reset at

511 to 534 N

.Clavismethod: new belt 174 to 180 Hz. Run for one

minute, allow belt to cool and reset to the in

-service

setting. In service

if tension falls below 140 Hz, reset at 167 to 173 Hz. (Measuring point: mid-way between

crankshaft and generator pulleys)

Burroughs method: new belt

560 to 600 N. Run for one

minute, allow belt to cool and reset to the in

-service

setting. In service if tension falls below

335 N, reset at

405 to 445 N

Clavis method: new belt

180 to 186 Hz. Run for one

minute, allow belt to cool and reset to

the in-service

setting. In service if tension falls below

131 Hz, reset at

155 to 161 Hz. (Measuring point: mid-way between

crankshaft and generator pulleys)

__ ___

.- ...

pket she sizes ___ Outside diameter

1

1

Drive Belt Tensions

0

Issue 1 August 1994 xvi

Page 18 of 73

AJ16 Engine Service Manual

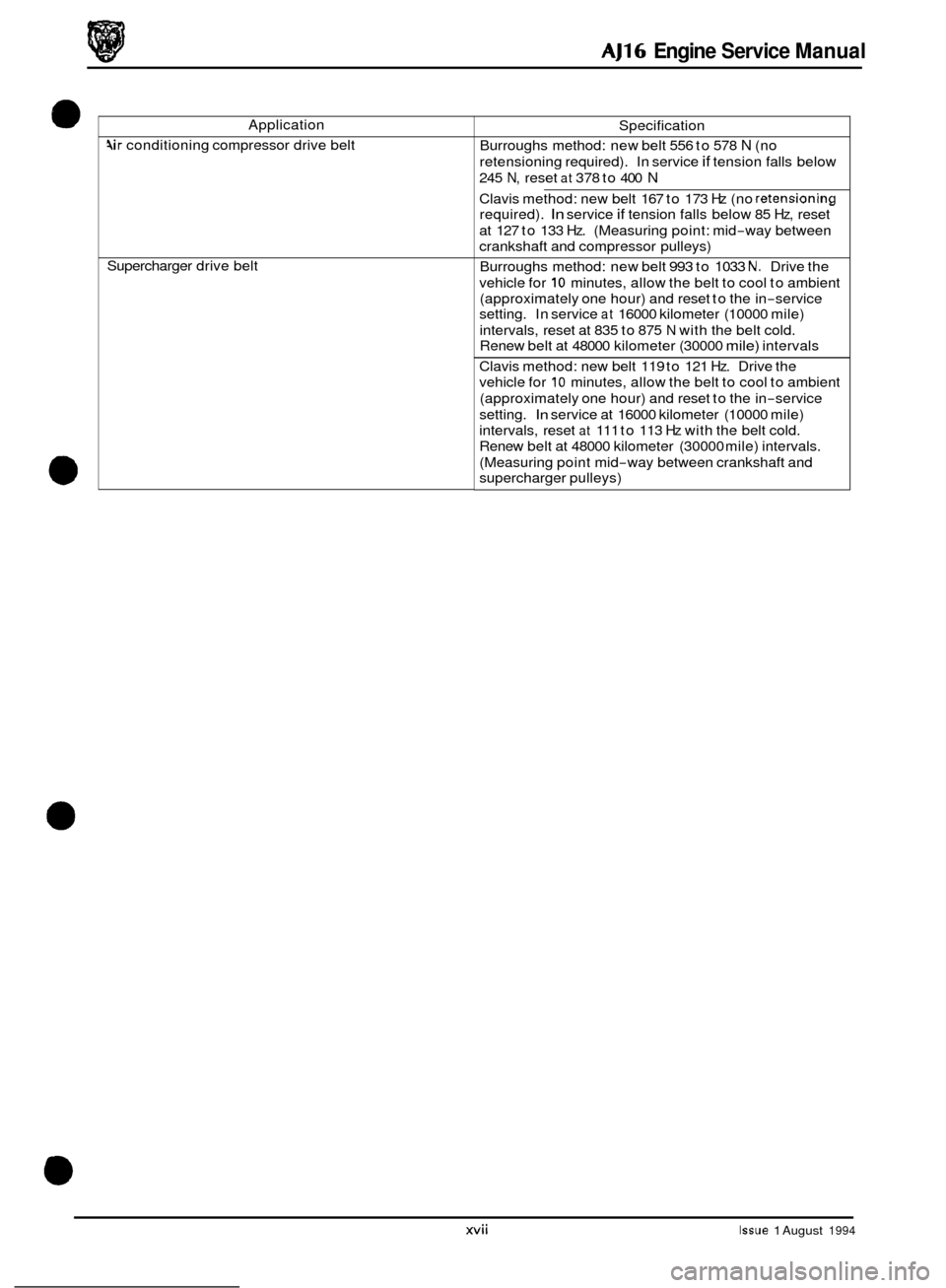

Application

4ir conditioning compressor drive belt

Supercharger drive belt Specification

Burroughs method: new belt 556 to 578 N (no

retensioning required). In service

if tension falls below

245

N, reset at 378 to 400 N

Clavis method: new belt 167 to 173 Hz (no retensioning

required). In service if tension falls below 85 Hz, reset

at 127 to 133

Hz. (Measuring point: mid-way between

crankshaft and compressor pulleys)

Burroughs method: new belt

993 to 1033 N. Drive the

vehicle for

10 minutes, allow the belt to cool to ambient

(approximately one hour) and reset to the in

-service

setting. In service

at 16000 kilometer (10000 mile)

intervals, reset at 835 to 875

N with the belt cold.

Renew belt at 48000 kilometer (30000

mile) intervals

Clavis method: new belt 119 to 121

Hz. Drive the

vehicle for

10 minutes, allow the belt to cool to ambient

(approximately one hour) and reset to the in

-service

setting.

In service at 16000 kilometer (10000 mile)

intervals, reset

at 11 1 to 113 Hz with the belt cold.

Renew belt at 48000 kilometer (30000 mile) intervals.

(Measuring point mid

-way between crankshaft and

supercharger pulleys)

xvii Issue 1 August 1994

Page 19 of 73

xviii

Page 20 of 73

AJ16 Engine Service Manual

0 GENERAL DESCRIPTION - The engine is available as a 3,2 and 4,O liter unit. A 4,O liter supercharged version is also available. Fuel is supplied

to each cylinder via an injector fed from a regulated fuel rail. To comply with statutory regulations in some countries

and to reduce emissions during the warm

-up period, secondary air is delivered to the exhaust manifold by an electri- cally operated air injection pump. This improves oxidation until the catalytic converters are fully effective. All engine

functions are controlled by an integrated engine management system, which incorporates the on-board diagnostic

system (OBDII).

1.1 Construction

The skirted design crankcase is manufactured in cast aluminum alloy with shrink fit dry cast iron cylinder sleeves.

Thecrankshaft ismanufactured from cast

ironforthe3,2 literengine,forged steel forthe 4,O liter engineand is nitro-car-

burize treated to give a very high quality finish on the bearing surfaces and increase the life of the journals.

The crankshaft is supported by seven iron bearing caps having bearings, which are lead bronze on split steel backed

shells with a lead indium overlay.

Crankshaft end

-float is controlled by half thrust washers fitted on each side of the center main bearing journal. The

connecting rods are manufactured from carbon manganese steel, forged in an 'H' section. The small end bushes are

lead bronze with steel backing, machined to size after being pressed into the connecting rods. The connecting rod bear- ings are of a lead bronze alloy on split steel backed shells and with lead indium overlay.

The pistons are of monometal construction (aluminum) and have a spring assisted micro

-land oil control ring situated

below a barrel-faced internally tapered chrome plated compression ring and an externally stepped taper-faced second-

ary ring.

The cylinder head is cast from aluminum alloy with pent

-roof shaped combustion chambers with cross-flow valve

porting. Running directly in the cylinder head are

twocast iron camshafts retained by machined aluminumcaps. Each

camshaft uses chilled cams to drive two valves per cylinder via chilled cast iron bucket tappets with shim adjustment.

Control of each of the four valves per cylinder is maintained by single valve springs.

The camshafts are operated by a two stage 'duplex' chain drive from the crankshaft. Each stage is controlled by a hy

- draulic tensioner operating through a pivoted rubber-faced curved tensioner blade. The first stage incorporates a three

point drive via the crankshaft, intermediate shaft and auxiliary shaft. The intermediate shaft is live and provides a 0.75 x crank speed drive through the timing cover. This drive access is blanked off. The 'live' auxiliary shaft is driven at

crankshaft speed and is situated on the right hand side of the engine (looking from rear). In addition to driving the

engine position sensor via a set of 2 : 1 reduction spiral gears, it provides an external drive for the power assisted steer- ing pump at the rear. The second stage is a three point drive via the intermediate shaft and two camshafts. The 2:l reduction ratio from crank speed is achieved by the combined ratio of the intermediate and camshaft sprockets sizes.

The oil pump is a rotor

-type mounted on the underside of the front of the crankcase and driven by a 'simplex' chain

from the crankshaft nose. The pump incorporates a built-in pressure relief valve. Below the line of the crankcase, but

abovetheoil pan

oillevel aretwowindagetrays; these prevent oil beingsucked upand thrown into thecrankcasethere- by alleviating windage and power losses through oil surge.

At the rear of the crankshaft is

a new design of lip-type PTFE oil seal which provides a high degree of oil retention. It also allows the use of higher engine speeds and easier serviceability.

1.2 Cylinder Head Design

The four valves per cylinder are smaller in diameter than on a conventional two valve per cylinder engine and have a greater combined effective area. They are also lighter and apply less stress to the operating gear. The design in- creases the power at high engine speeds and allows an efficient combustion of the fuel. It also allows the spark plug

to besituated in its ideal central position which creates efficient combustion and consequently enhancesfuel economy.

1.3 Crankcase Breather

Blow-by gases are recycled via the air intake system to maintain a crankcase depression and so prevent their escape

to the atmosphere. A baffled vent from the camshaft cover is used for both full and part load breathing. For full load

breathing,

a connection is made direct to the clean side ofthe air filter upstream ofthe throttle disc. Part load breathing is provided by a spur off the full load pipe to downstream ofthe throttle disc via the water heated restrictor. In this way,

a crankcase depression is maintained at all throttle settings.

1.4 Lubrication System

Oil is drawn from the oil pan via a gauze filter. Pressurized oil, having been regulated by a relief valve, is then fed via

internal galleries on the left hand side of the cylinder block. Pressurized and filtered oil is fed into the main oil gallery,

the seven main bearings are fed and thence via crankshaft drillings to the connecting rod bearings. The intermediate

shaft, auxiliary shaft and camshaft bearings are pressure lubricated by means of internal drillings directly fed from the

front of the main oil gallery. For some markets an oil cooler is fitted to vehicles with

4,O liter supercharged engines.

The pistons run on hardened steel piston pins offset from the center line of the piston towards the thrust face.

Issue 1 August 1994 1