clutch JAGUAR XJ 1994 2.G AJ16 Engine Manual

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 1994, Model line: XJ, Model: JAGUAR XJ 1994 2.GPages: 73, PDF Size: 2.06 MB

Page 8 of 73

AJ16 Engine Service Manual

Fixing

II.

Tightening Torque

(Nm)

TORQUE TlGH TENlNG SPECIFICATIONS

Air Cleaner

Air box bracket screw 8,5 - 11.5

9.5

- 12,5

9,5 - 12,5

6,3 - 8,7

8.5

- 11,5

7 -9

Air box to bracket

Air box to instrumount

Air cleaner bracket setscrew

Air cleaner support bracket

(4,O liter supercharged)

Air temperature sensor to air box

1 Hose clamp, air box to air meter ~

Hose

clamp, air box to body

1,2 - 1,6

1.2

- 1,6 , , lnstrumount bracket Taptite screw I 9,5 - 12,5

trumpet to body ~ 9,5 - 12,5

Compressor

to bracket

_________ Connecting rod bearing nut 52 - 55 (SPS System) _______ ~

Bypass

elbow to thermostat housing

Fan drive unit setscrew

Fan drive unit to pulley

Hose clamp, breather to thermostat

Hose clamp, breather to throttle body

Hose clamp, bypass hose

Hose clamp, water pump to pipe

Thermostat cover to housing

Thermostat housing to cylinder head

Water pipe bracket to intake manifold

Water pump assembly

Water pump to timing cover

Water pump to water

rail

Water rail to cylinder block

Water temperature sensor to thermostat housing

Water temperature transmitter to thermostat housing

9,5 - 12,5

12- 16

21,5 - 28,5

1,5-2,5

1,5 - 2,5

2,5

- 3.5

2,5

- 3,5

21,5 - 28,5

21,5 - 28,5

21.5- 28,5

21,5 - 28,5

21.5 - 28,5

2,5 - 3,5

21,5 - 28,5 1

14,5- 19,5

14,5- 19,5

1 Crankshaft

Clutch to flywheel (4,O liter)

Crankshaft bolt

Drive

-plate to crankshaft (3,2 liter) ~___~.~ Drive-plate to crankshaft (4,O liter supercharged automatic)

Flywheel to

crankshaft setscrew (4,O liter) _______

Timing ring to damper

22,5 - 27,5

183 - 223

88 - 108

123

- 149

123

- 149

15.5

- 20.5

-~

___________

vi i Issue 1 August 1994

Page 49 of 73

AJ16 Engine Service Manual

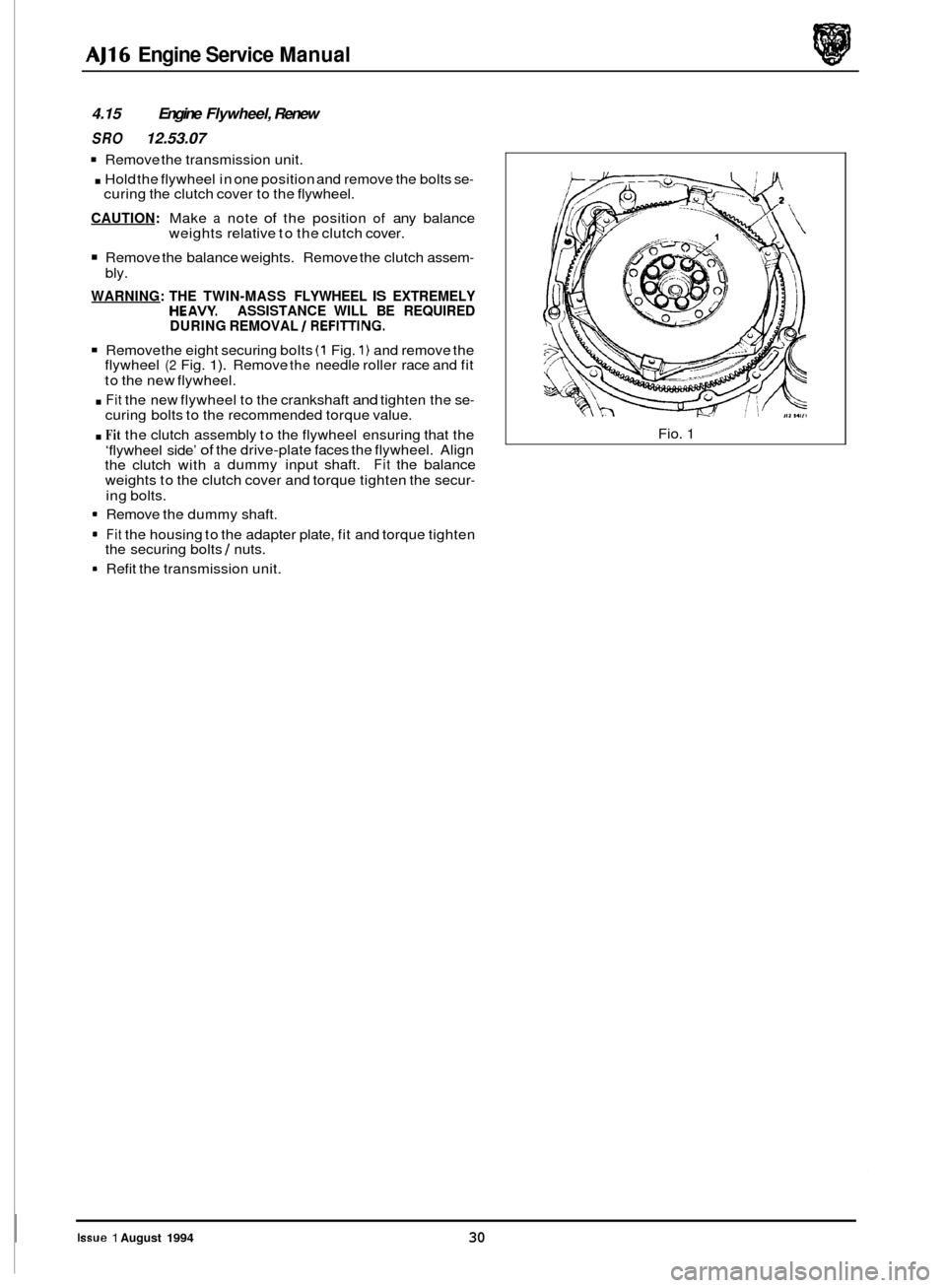

4.15 Engine Flywheel, Renew

SRO 12.53.07

1 Remove the transmission unit.

. Hold the flywheel in one position and remove the bolts se-

CAUTION: Make a note of the position of any balance

weights relative to the clutch cover.

Remove the balance weights. Remove the clutch assem-

curing the clutch cover to the flywheel.

bly.

WARNING: THE TWIN-MASS FLYWHEEL IS EXTREMELY HEAVY. ASSISTANCE WILL BE REQUIRED

DURING REMOVAL / REFIlTING.

Remove the eight securing bolts (1 Fig. 1) and remove the

flywheel (2 Fig. 1). Remove the needle roller race and fit

to the new flywheel.

. Fit the new flywheel to the crankshaft and tighten the se- curing bolts to the recommended torque value.

. Fit the clutch assembly to the flywheel ensuring that the

‘flywheel side’

of the drive-plate faces the flywheel. Align

the clutch with a dummy input shaft. Fit the balance

weights to the clutch cover and torque tighten the secur- ing bolts.

1 Remove the dummy shaft.

Fit the housing to the adapter plate, fit and torque tighten

the securing bolts I nuts.

1 Refit the transmission unit. Fio.

1

Issue 1 August 1994 30