ABS JAGUAR XJ6 1994 2.G Electrical Diagnostic Manual

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 1994, Model line: XJ6, Model: JAGUAR XJ6 1994 2.GPages: 327, PDF Size: 13.73 MB

Page 163 of 327

rl E I ect r ica I

15.2.8 INSTRUMENT PACK PIN-POINT TESTS

15.2.8.1 Oil Pressure, Battery Condition, Coolant Temperature and Fuel Gauges

Gauge reads zero, full scale, too high or low

1.

2.

3. Oil

pressure and coolant gauges only; check relevant fluid level is within limits, top up if required and re-check

indication. If fluid levels are within limits on checking proceed to step 2.

Check connections to sensor are correct and secure. For battery gauge only check battery voltage is present at the

battery terminal posts.

Check resistance of sensor (if applicable) to ground, correct readings are as detailed in the following table:

Sensor title Resistance value

Oil pressure 3108 - 3308

Temperature

Fuel level 3461

(warm engine)

- 2418 (cold engine)

8061 (full tank) - 9008 (empty tank)

If resistance is out of range renew sensor.

If sensor resistance is proved correct, check the harness wiring continuity between the sensor and instrument pack

pin as detailed in the table below:

4.

I Sensor title I Instrument pack pin !

I Oil pressure I 21 (24-way connector) I Temperature I 19 (24-way connector) I

Fuel level 120 (24-way connector)

For battery condition gauge, checkvoltage between instrument pack 24

-way connector pins 2 and 4 is 13 f 2.5V. Refer to Section 15.5 for battery diagnostics.

If all previous checks prove correct remove and open the instrument pack. Examine flexi-circuit connections to

relevant gauge, ensuring correct and secure fitment.

Check continuity of flexi

-circuit tracks to gauge connections.

Check continuity of gauge driver windings by disconnecting gauge from flexi

-circuit and testing between the

upper central connection pin and each of the other two pins. If open circuit is recorded renew gauge.

5.

6.

7.

Gauge fluctuates

or gives erratic readings

1. Carry out steps 1 -4 above.

2.

Fit new sensor (where applicable) and re-check gauge.

3. Carry out steps 5

- 7 above

15.2.8.2 Speedometer

Gauge reads zero, full scale, too high or low

1.

2.

3.

4.

5. Refer

to Section 12,

ABS / Traction Control for fault diagnosis of wheel speed sensor.

Check harness wirin and connection from Instrument pack pin 15 (24

-way connector) and ABS /Traction Control

Control Module (AB!! /TC CM).

If all previous checks prove correct remove and open the instrument pack. Examine flexi

-circuit connections to

speedometer, ensuring correct and secure fitment.

Check continuity of flexi

-circuit tracks to speedometer connections.

Check continuity of speedometer driver windings by disconnecting from flexi

-circuit and testing between the

upper central connection pin and each of the other two pins. If open circuit is recorded renew speedometer.

Page 164 of 327

6 15.2.8.3 Tachometer

Gauge reads zero, full scale, too high or low

1.

2.

3.

4.

5. Refer

to Section 5, Engine Management for fault diagnosis of tachometer signal.

Check harness wiring and connection from Instrument pack pin

24 (24-way connector) and Engine Management

Control Module (ECM).

If all previous checks prove correct remove and open the instrument pack. Examine flexi-circuit connections to

tachometer, ensuring correct and secure fitment.

Check continuity of flexi

-circuit tracks to tachometer connections.

Check continuity of speedometer driver windings by disconnecting from flexi

-circuit and testing between the

upper central connection pin and each of the other two pins, If open circuit is recorded renew tachometer.

15.2.8.4 Liquid Crystal Display

No (or patchy) illumination

1.

2. If no illumination check rear of instrument pack for attachment of 'PECUS' label. If label is not present then pack

will not have been programmed.

Check bulbs in rear of LCD module, renew as necessary.

Missing or Corrupt Segments

1. Switch ignition off, leave off for a minimum of 5 minutes, switch on and re-check panel display.

2. If display is still faulty remove instrument pack from vehicle and checkconnections between flexi-circuit and LCD

module.

15.2.8.5 Trip Computer

Inaccuracy

1. Check fuel sender, ABS /TC CM and ECM signals to instrument pack.

Issue 1 August 1994 X300 EDM 15.2 - 11

Page 178 of 327

E I ect r ical IT

SPEED CONTROL

System Description

0 15.3 15.3.1

The speed control system provides an automatic cruise facility, allowing a constant speed to be maintained without

accelerator pedal operation. The system comprises the following components:

0 Electronic control unit

0 Vacuum dump valve

0 Control valve

0 Vacuum pump

0 Mechanical throttle linkage and bellows

0 Selection switch

0 Brake and clutch pedal switches

On selection of speed control, via the switches mounted on the driver's side fascia, the vacuum dump valve, pump and

control valve will energize, creating

a partial vacuum in the bellows assembly. The bellows assembly acts upon the

throttle linkage to adjust throttle position, maintaining vehicle speed at the value when control is selected.

Speed control is determined by the Speed Control Control Module

(SC CM) which monitors a speed signal delivered

from the instrument pack (initially from the ABS rear LH wheel speed sensor) to determine vehicle speed.

Speedcontrol isdisabled, returning control tothedriver,

byoperationofthevacuumdumpvalve,ifanyofthefollowing situations occur: 0

0 Braking

0 Clutch operation (3.2 / 4.0 litre manual transmission vehicles only)

o Drive de-select ie P, N or R (automatic transmissions only, both electronic and hydraulic)

0 Traction control system (where fitted) in operation

0 Rapid speed reduction without braking input, ie double brake switch failure

0 Actual speed drop to 3/4 of cruise setting (eg when towing excessive loads under adverse conditions)

0 Vehicle speeds below w 25 mph

0 Ignition OFF

0 De-selection at switch controls

15.3.2 COMPONENT DESCRlPTlO NS

15.3.2.1 Electronic Control Module

The Speed Control Control Module (SC CM), located behind the fascia, adjacent to the steering column, provides sys- tem control and an interface to external input signals from the instrument pack, gear selector module, traction control

system, control switches, and foot pedal switches. The set speed value is retained in SC CM memory and continuously

compared to actual vehicle speed. Adjustments are made, as necessary, to maintain set speed by control of the vac- uum pump and control valve. Connections to the SC CM are listed in the table on page 3.

X300 EDM 15.3 - 1 Issue 1 August 1994

Page 182 of 327

0 15.3.3 SYSTEM FLOW CHARTS

Systematic fault diagnosis of the speed control system cannot be accurately achieved by attempting to simulate actual

driving conditions. The system can only be reliably and safely tested using Jaguar Diagnostic Equipment.

15.3.4 DIAGNOSTIC SUB-ROUTINES

The following information details possible fault conditions, causes and remedies.

components are covered in Pin-point Tests. Detail test procedures

for

Fault: System inoperative

Possible causes:

1. Fuse FIO (LH 'A' post base fuse-box) blown.

2. Pneumatic circuit fault (ie vacuum leak)

3. Brake switch fault.

4. Clutch switch or link fault. Gear position input fault (automatic transmission only).

5. Harness wiring or connector faulty.

6. Set switch faulty.

7 Paddle switch faulty

8. Traction control input high.

9. Road speed input missing.

10 Dump valve failure.

11 Vacuum pump 1 control valve unit failure.

Remedy: 1. Examine fuse F10, if blown determine reason for failure and renew.

2. Examine all pipework, connections and components for damage or

disconnections, repair

or renew as necessary.

3. Check brake switch operation, renew if necessary.

4. Check clutch switch operation (manual transmission) or link connection I position input

(automatic transmission), renew if necessary.

5. Examine harness wiring. Examine connectors for corroded, damaged or distorted pins.

6. Check set switch operation and wiring, renew if necessary.

7. Check paddle switch operation and wiring, renew if necessary.

8. Examine harness wiring between SC CM and ABS / TC CM, check ABS /TC CM fault

diagnosis.

9. Examine harness wiring between SC CM and instrument pack, check pack fault diagnosis.

10 Renew faulty valve.

11 Renew faulty unit

0

Fault:

Cause:

1. Clutch pedal switch or harness failure.

Clutch pedal operation does not disable system

1. Remedy: Check switch operation and wiring connections. Repair or renew switch / wiring

as necessary.

Fault:

Cause:

1, Faulty signal from gear selection module.

Remedy: 1. Examine transmission fault diagnosis.

Neutral gear selection does not disable system (automatic transmissions only)

2.

2.

Harness wiring or connector fault

Examine harness between gear selection module and SC

CM pin 18.

X300 EDM 15.3 - 5 Issue 1 August 1994

Page 184 of 327

15.3.5 PIN-POINT TESTS

The following tests give detailed information on component fault diagnosis.

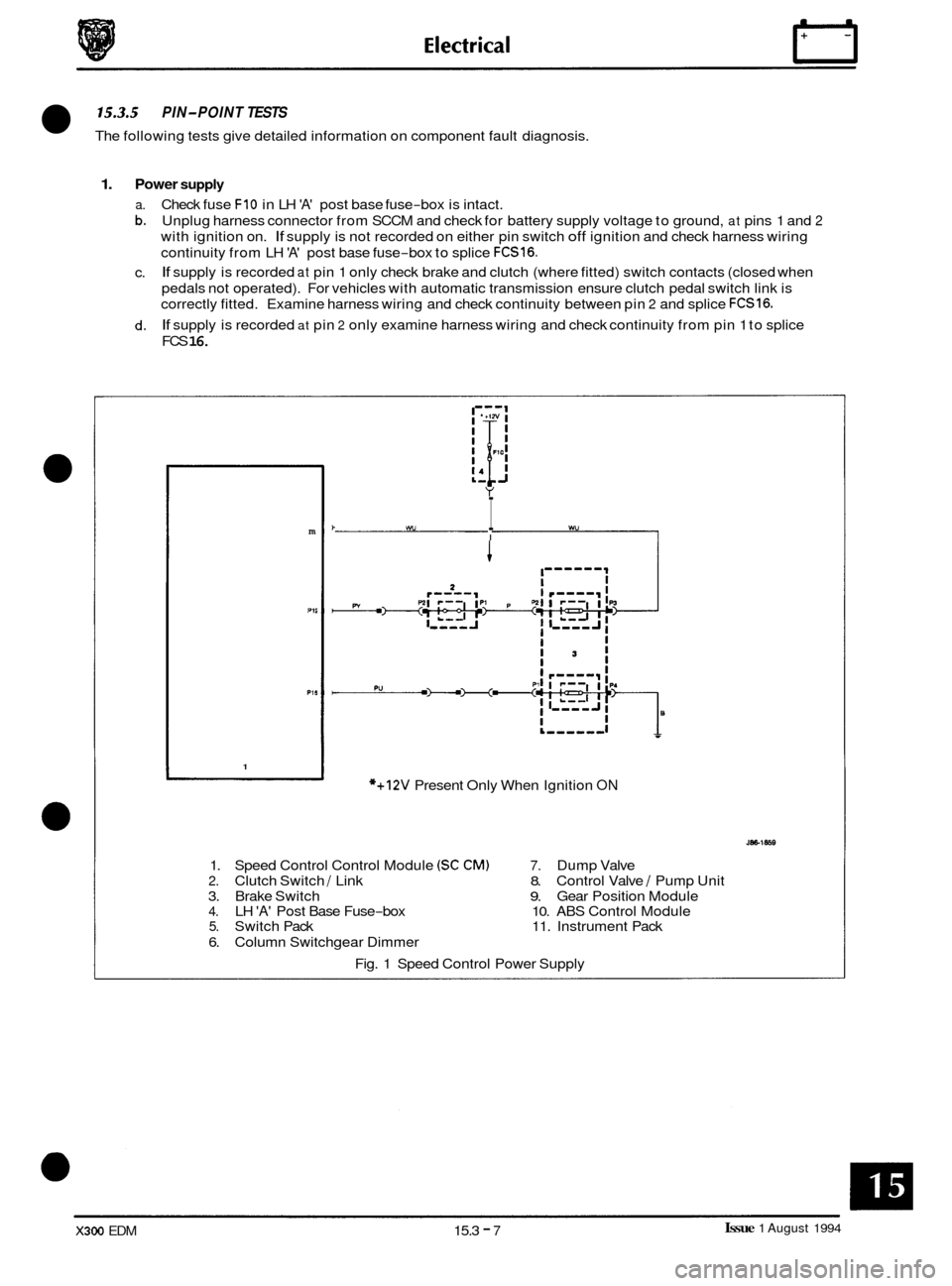

1. Power supply

a. Check fuse FIO in LH 'A' post base fuse-box is intact.

b. Unplug harness connector from SCCM and check for battery supply voltage to ground, at pins 1 and 2

with ignition on. If supply is not recorded on either pin switch off ignition and check harness wiring

continuity from LH

'A' post base fuse-box to splice FCS16.

If supply is recorded at pin 1 only check brake and clutch (where fitted) switch contacts (closed when

pedals not operated). For vehicles with automatic transmission ensure clutch pedal switch link is

correctly fitted. Examine harness wiring and check continuity between pin

2 and splice FCS16.

If supply is recorded at pin 2 only examine harness wiring and check continuity from pin 1 to splice

FCS

16.

c.

d.

m

P1I

1

k wv I wu I

I-------

*+12V Present Only When Ignition ON

1. Speed Control Control Module (SC CM) 7. Dump Valve

2. Clutch Switch / Link 8. Control Valve / Pump Unit

3. Brake Switch

9. Gear Position Module 4. LH 'A' Post Base Fuse-box 10. ABS Control Module 5. Switch Pack 11. Instrument Pack

6. Column Switchgear Dimmer

Fig. 1 Speed Control Power Supply

Issue 1 August 1994 X300 EDM 15.3 - 7

Page 185 of 327

n Electrical

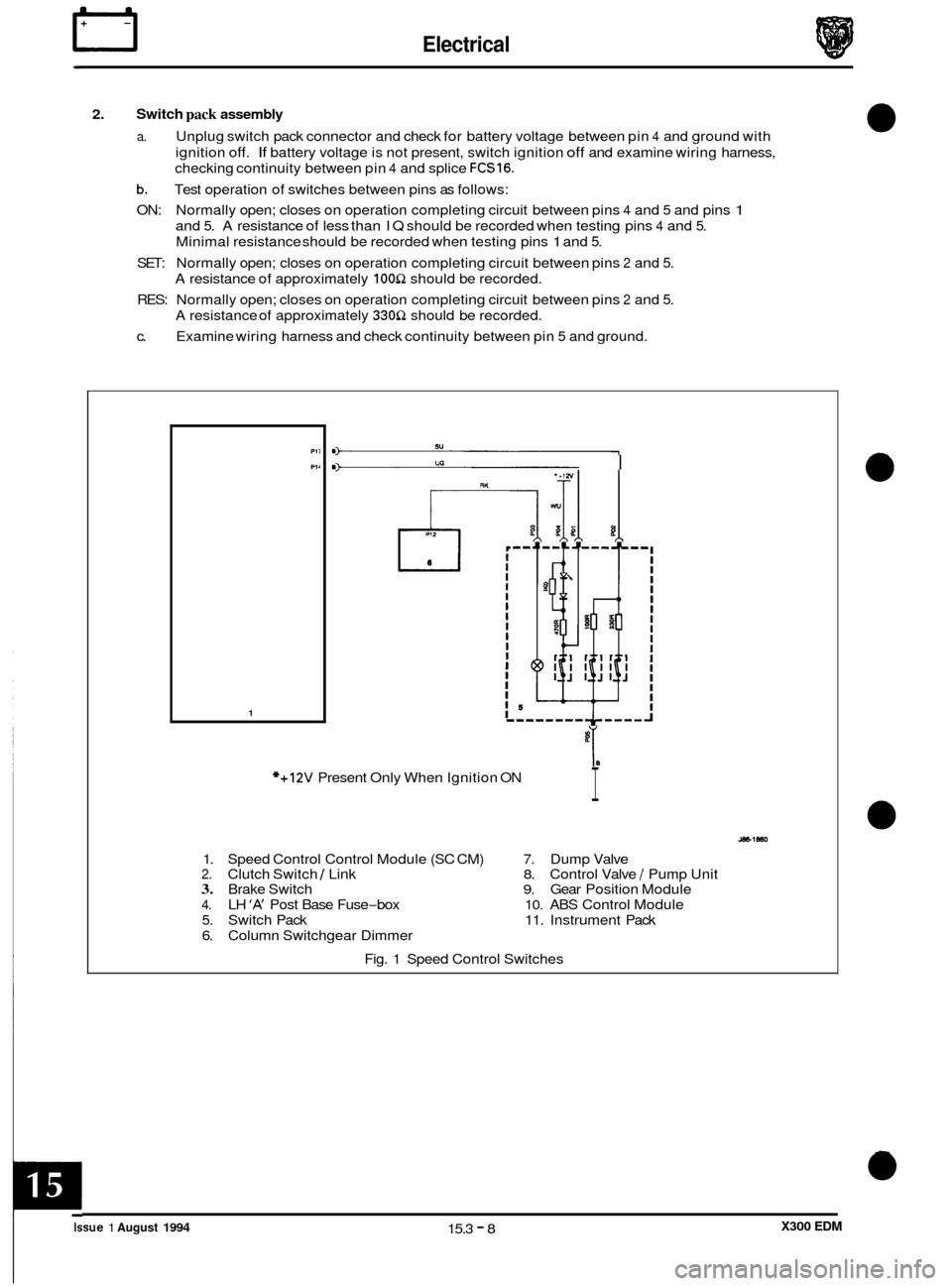

2. Switch pack assembly

a. Unplug switch pack connector and check for battery voltage between pin 4 and ground with

ignition

off. If battery voltage is not present, switch ignition off and examine wiring harness,

checking continuity between pin

4 and splice FCS16.

b. Test operation of switches between pins as follows:

ON: Normally open; closes on operation completing circuit between pins

4 and 5 and pins 1

and 5. A resistance of less than IQ should be recorded when testing pins 4 and 5.

Minimal resistance should be recorded when testing pins 1 and 5.

SET: Normally open; closes on operation completing circuit between pins 2 and 5.

A resistance of approximately 100Q should be recorded.

RES: Normally open; closes on operation completing circuit between pins

2 and 5.

A resistance of approximately 330Q should be recorded.

c. Examine wiring harness and check continuity between pin

5 and ground.

Ptl

PI1

1

m) su

I U0

I

*+12V Present Only When Ignition ON

1. Speed Control Control Module (SC CM)

7. Dump Valve 2. Clutch Switch I Link 8. Control Valve / Pump Unit 3. Brake Switch 9. Gear Position Module

4. LH ‘A’ Post Base Fuse-box 10. ABS Control Module

5. Switch Pack 11. Instrument Pack

6. Column Switchgear Dimmer

Fig. 1 Speed Control Switches

0

0

0

0

Issue 1 August 1994 15.3 - 8 X300 EDM

Page 186 of 327

E I ect r ica I n

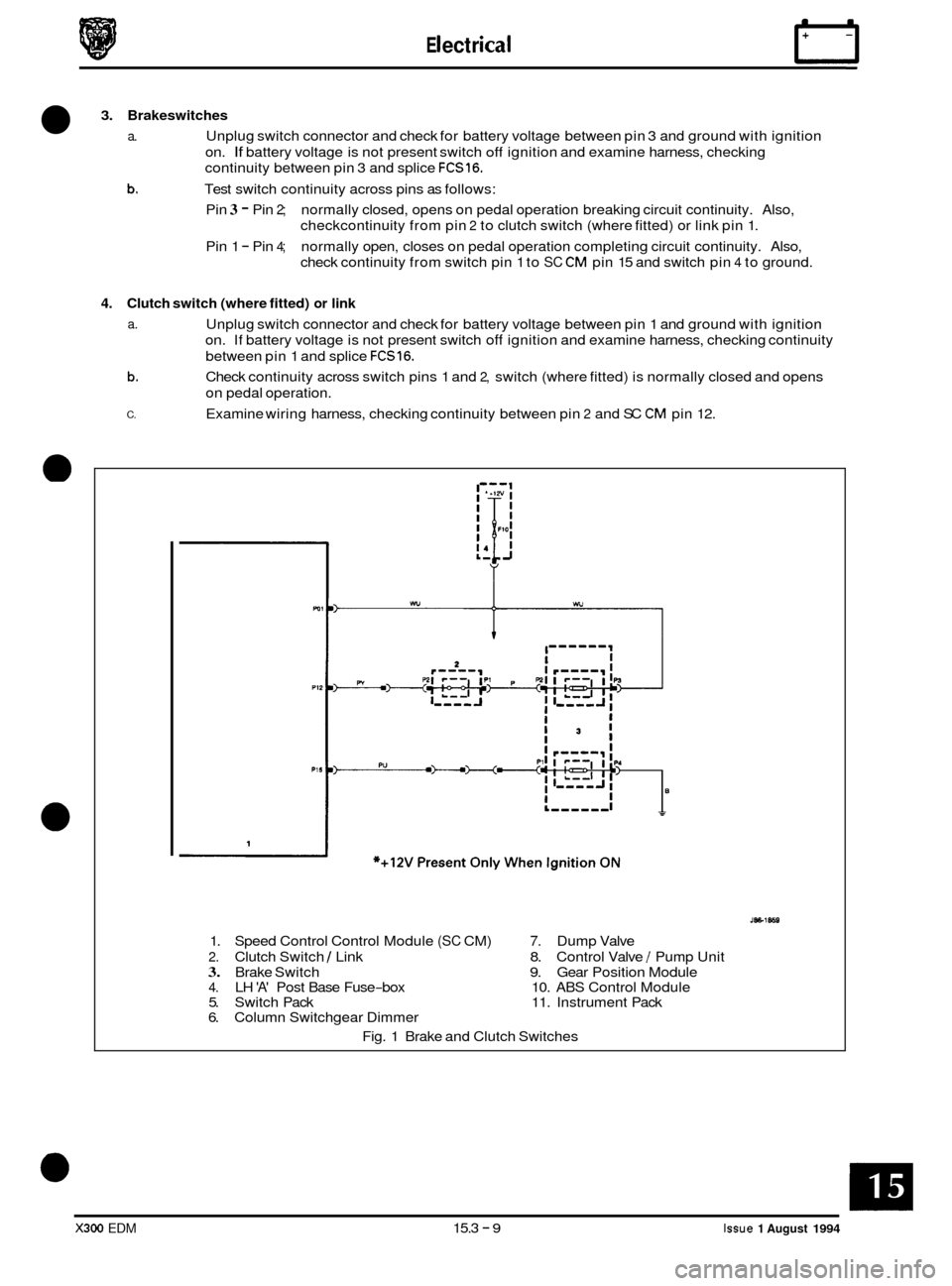

3. Brakeswitches

a. Unplug switch connector and check for battery voltage between pin 3 and ground with ignition

b.

on. If battery voltage is not present switch off ignition and examine harness, checking

continuity between pin 3 and splice

FCS16.

Test switch continuity across pins as follows:

Pin

3 - Pin 2; normally closed, opens on pedal operation breaking circuit continuity. Also,

checkcontinuity from pin

2 to clutch switch (where fitted) or link pin 1.

Pin 1

- Pin 4; normally open, closes on pedal operation completing circuit continuity. Also,

check continuity from switch pin 1 to

SC CM pin 15 and switch pin 4 to ground.

4. Clutch switch (where fitted) or link

a. Unplug switch connector and check for battery voltage between pin 1 and ground with ignition

on. If battery voltage is not present switch

off ignition and examine harness, checking continuity

between pin 1 and splice

FCS16.

Check continuity across switch pins 1 and 2, switch (where fitted) is normally closed and opens

on pedal operation.

Examine wiring harness, checking continuity between pin

2 and SC CM pin 12.

b.

C.

1

.---I

1. Speed Control Control Module (SC CM) 7. Dump Valve

2. Clutch Switch 1 Link 8. Control Valve / Pump Unit

3. Brake Switch 9. Gear Position Module 4. LH 'A' Post Base Fuse-box 10. ABS Control Module

5. Switch Pack 11. Instrument Pack

6. Column Switchgear Dimmer

Fig. 1 Brake and Clutch Switches

X300 EDM 15.3 - 9 Issue 1 August 1994

Page 187 of 327

rl E I ect r ica I

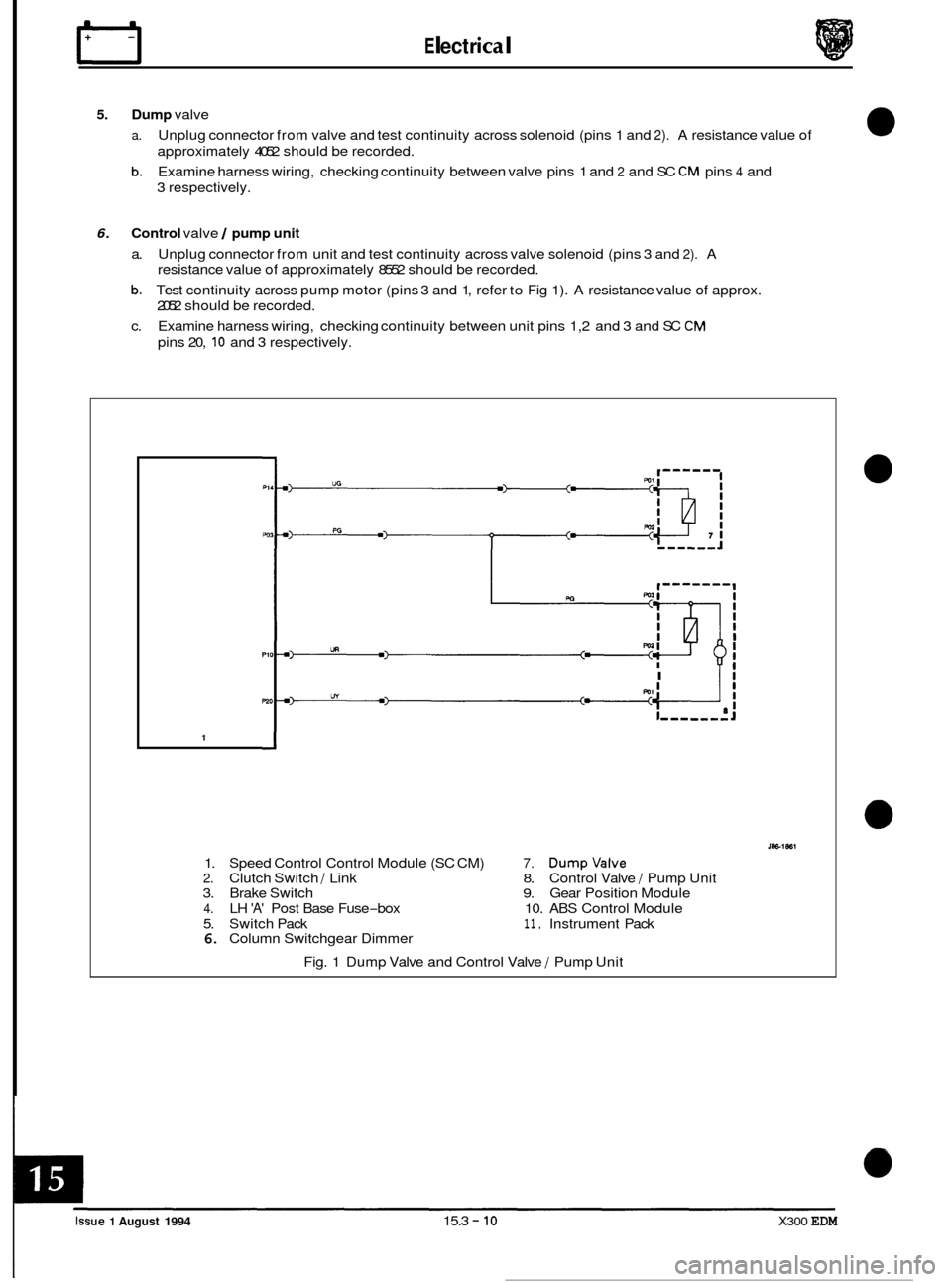

5. Dump valve

a.

b.

Unplug connector from valve and test continuity across solenoid (pins 1 and 2). A resistance value of

approximately 4052 should be recorded.

Examine harness wiring, checking continuity between valve pins 1 and

2 and SC CM pins 4 and

3 respectively.

6. Control valve / pump unit

a. Unplug connector from unit and test continuity across valve solenoid (pins 3 and 2). A

resistance value of approximately 8552 should be recorded.

b. Test continuity across pump motor (pins 3 and 1, refer to Fig 1). A resistance value of approx.

2052 should be recorded.

c. Examine harness wiring, checking continuity between unit pins 1,2 and 3 and SC

CM

pins 20, 10 and 3 respectively.

I Ii

1

1. Speed Control Control Module (SC CM) 7. Dumpvalve

2. Clutch Switch / Link 8. Control Valve / Pump Unit

3. Brake Switch 9. Gear Position Module

4. LH 'A' Post Base Fuse-box 10. ABS Control Module

5. Switch Pack

11. Instrument Pack 6. Column Switchgear Dimmer

Fig. 1 Dump Valve and Control Valve

/ Pump Unit

0

0

0

0

Issue 1 August 1994 15.3 - 10 X300 EDM

Page 188 of 327

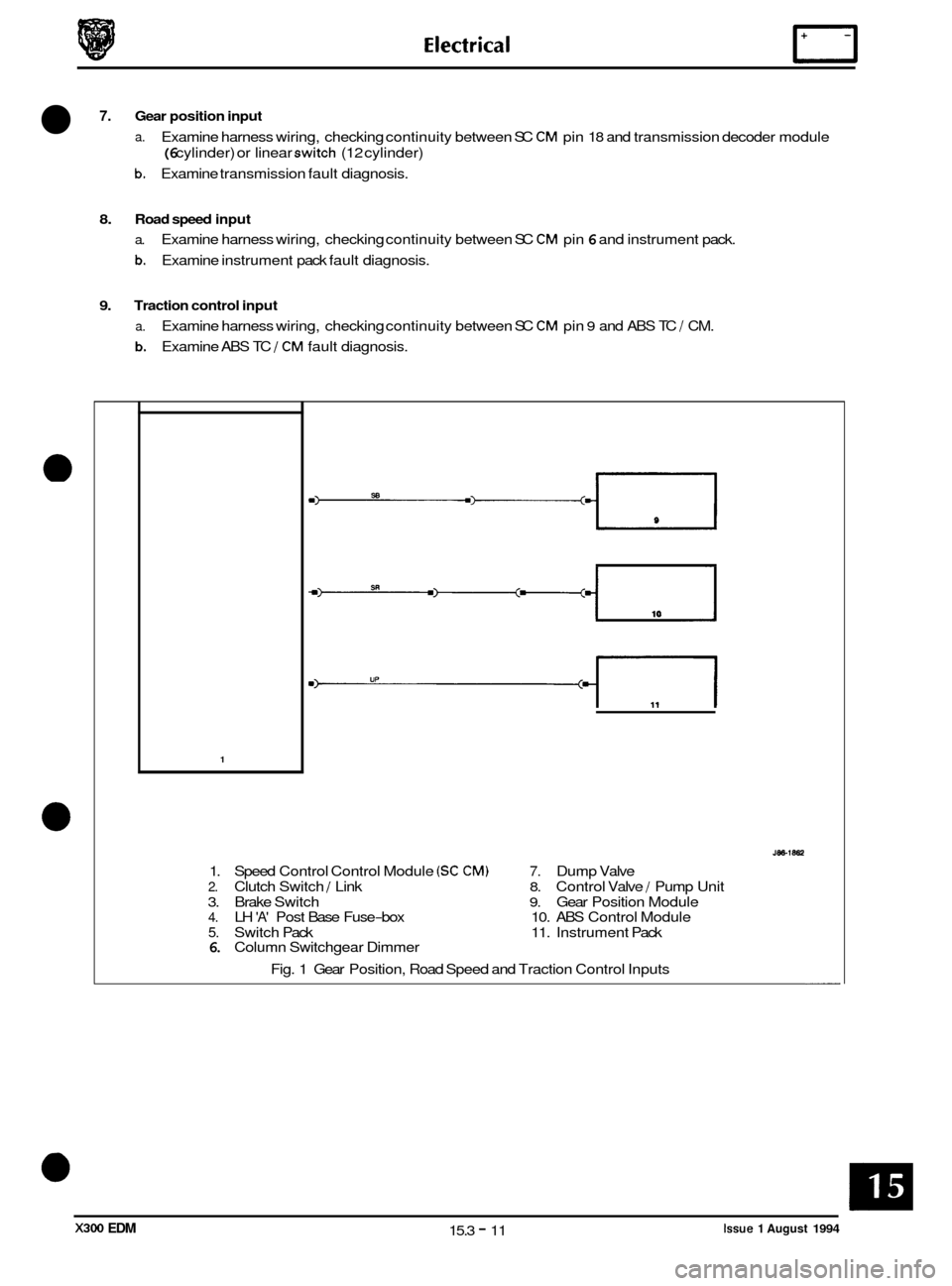

7. Gear position input

a. Examine harness wiring, checking continuity between SC CM pin 18 and transmission decoder module

(6 cylinder) or linear switch (12 cylinder)

b. Examine transmission fault diagnosis.

8. Road speed input

a. Examine harness wiring, checking continuity between SC CM pin 6 and instrument pack.

b. Examine instrument pack fault diagnosis.

9. Traction control input

a.

b.

Examine harness wiring, checking continuity between SC CM pin 9 and ABS TC J CM.

Examine ABS TC

J CM fault diagnosis.

1

1. Speed Control Control Module (SC CM) 7. Dump Valve

2. Clutch Switch J Link 8. Control Valve / Pump Unit

3. Brake Switch

9. Gear Position Module 4. LH 'A' Post Base Fuse-box 10. ABS Control Module

5. Switch Pack 11. Instrument Pack 6. Column Switchgear Dimmer

Fig. 1 Gear Position, Road Speed and Traction Control Inputs

Issue 1 August 1994 15.3 - 11 X300 EDM

Page 234 of 327

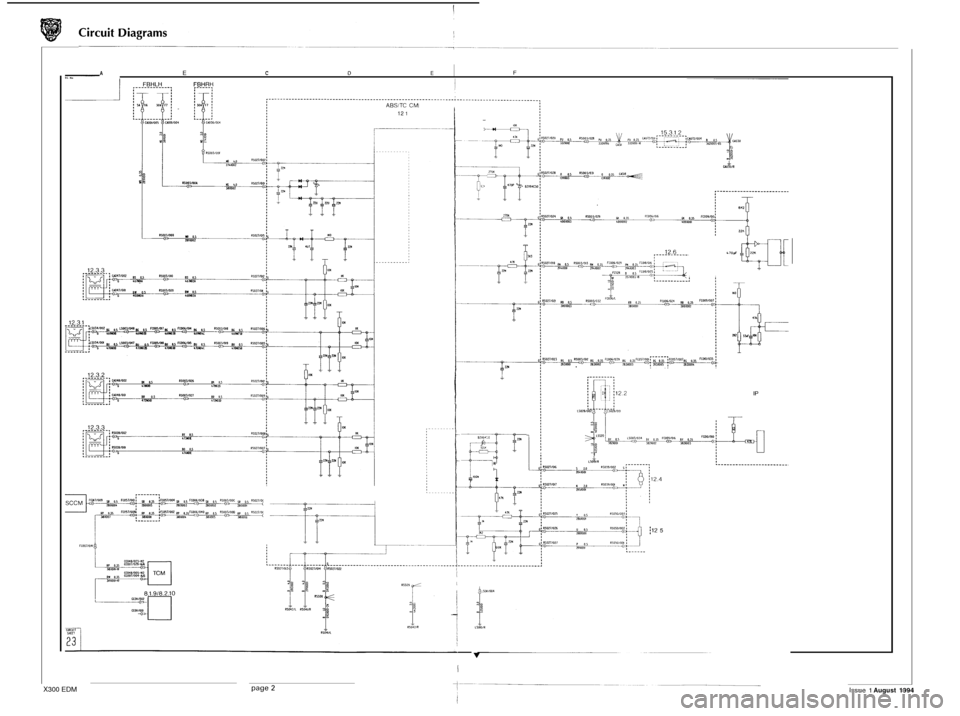

A E C D E F

ABSiTC CM 12 1

I UOJOIR

e

e

a

L70pF

IP

I

7

T

I

T[

j12 5

v

I

X300 EDM Issue 1 August 1994