battery JAGUAR XJ6 1994 2.G Electrical Diagnostic Manual

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 1994, Model line: XJ6, Model: JAGUAR XJ6 1994 2.GPages: 327, PDF Size: 13.73 MB

Page 109 of 327

Electrical rl

15.1.3 AIR BAG DISARMING/ ARMING PROCEDURE

warnings and cautions

WARNING: DISARM SRS BEFORE SERVICING ANY SRS OR STEERING COLUMN COMPONENT.

ALLOW A MINIMUM OF ONE MINUTE TIME DELAY FOR THE BACK

-UP POWER SUPPLY TO DISCHARGE,

AFTER THE BATTERY GROUND LEAD HAS BEEN DISCONNECTED.

THE SYSTEM COMPONENTS ARE NON

-SERVICEABLE, IF FAULTS ARE SUSPECTED, CHANGE COMPO- NENTS FOR NEW ITEMS ONLY.

NEVER PROBE THE CONNECTORS OF AN AIR BAG MODULE.

FAILURE TO OBSERVE THE ABOVE PROCEDURES MAY RESULT

IN ACCIDENTAL DEPLOYMENT OF AIR

BAG.

ALWAYS WEAR SAFETY GLASSES WHEN WORKING ON AIR BAG EQUIPPED VEHICLES.

PERSONNEL CARRYING AN AIR BAG MODULE MUST ENSURE THAT THE MODULE AND TRIM COVER

ARE POINTED AWAY FROM THE BODY. WHEN POSITIONED ON A BENCH

OR WORK SURFACE ENSURE

THAT THE AIR BAG MODULE AND TRIM COVER FACE UPWARDS, LIMITING MOTION ON ACCIDENTAL

DEPLOYMENT.

ALWAYS WEAR GLOVES WHEN HANDLING DEPLOYED AIR BAG MODULE, DEPOSITS OF SODIUM HY

- DROXIDE MAY BE PRESENT ON THE MODULE SURFACE. IF SODIUM HYDROXIDE CONTACTS ANY

AREA OF SKIN, WASH THE AFFECTED AREA IMMEDIATELY WITH MILD SOAP AND WATER. DISPOSE OF

THE DEPLOYED AIR BAG USING THE CORRECT PROCEDURES, REFER TO SECTION

15 OF THE VSM.

CAUTION:

When scrapping vehicles ensure air bags have been deployed.

If

a component has been renewed and the fault does not clear, refit original item and repeat diagnostic

procedure.

After servicing repeat diagnostic procedures to ensure correct system operation.

Renew air bag module if surrounding trim panels are damaged.

Do not attempt to repaint trim covers as paint may damage cover material.

Disarming

. Allow a minimum 1 minute time delay before attempting to diagnose or renew any component in the SRS system.

Remove driver-side air bag module and connect air bag simulator to cable reel cassette multi-plug.

. Remove passenger-side air bag module and connect air bag simulator to harness.

. Re-connect battery ground lead.

Disconnect

the battery ground lead.

This delay allows the DM back

-up power supply to discharge, preventing accidental firing of the air bag.

0

Arming

Disconnect the battery ground lead.

. Remove air bag simulators and install driver and passenger-side air bag modules. Ensure fasteners are tightened

. Re-connect battery ground lead.

Switch ignition 'on' and ensure air bag MIL Lamp extinguishes.

to specified torque.

X300 EDM 15.1 -3 Issue 1 August 1994

Page 111 of 327

Electrical IT

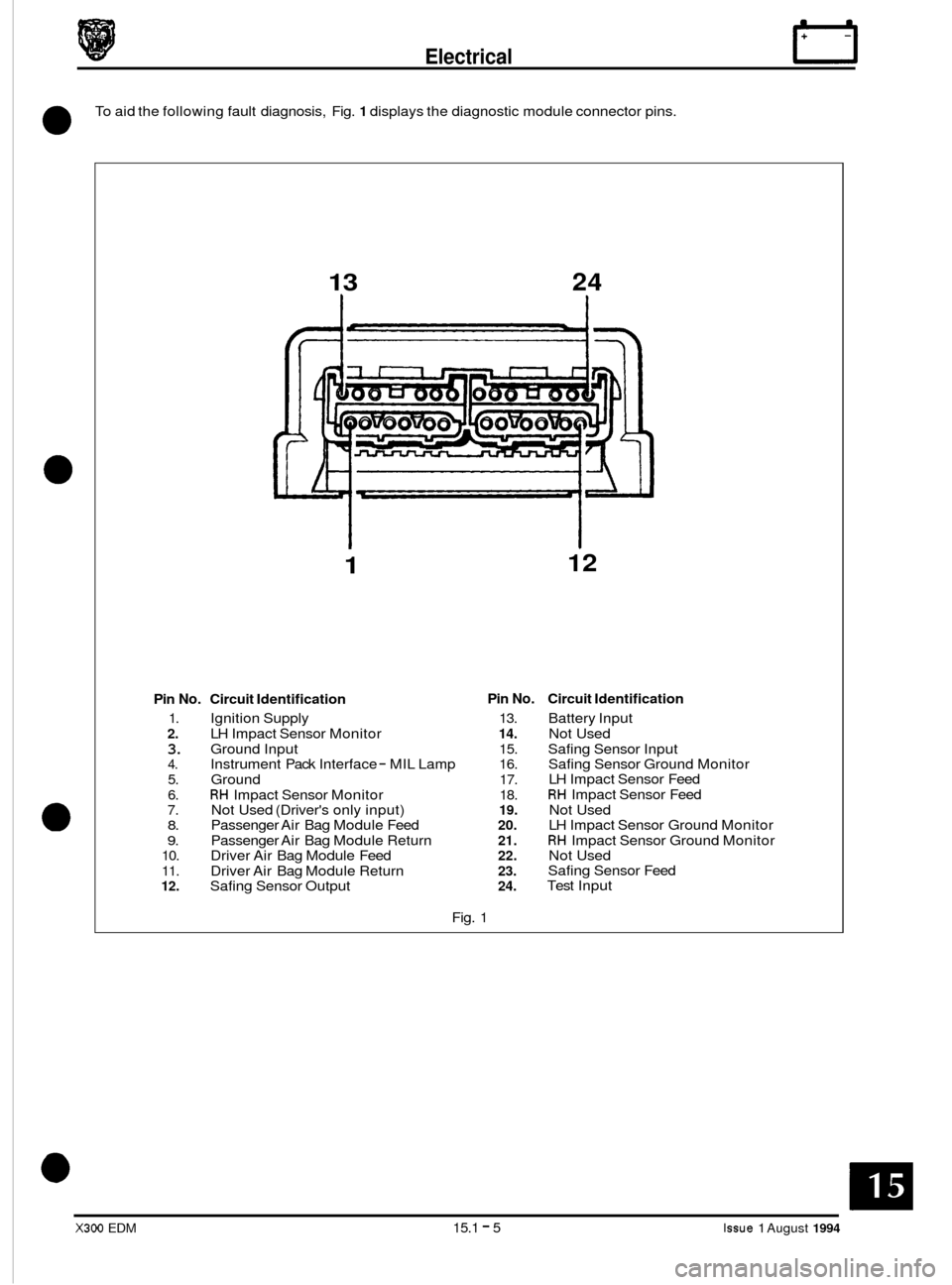

To aid the following fault diagnosis, Fig. 1 displays the diagnostic module connector pins.

0

13 24

1

Pin No. Circuit Identification

1. Ignition Supply

2. LH Impact Sensor Monitor

3. Ground Input 4.

5. Ground

6. RH Impact Sensor Monitor 7. 8.

9. 10.

11.

12. Safing Sensor Output

Instrument

Pack Interface

- MIL Lamp

Not Used (Driver's only input)

Passenger Air Bag Module Feed

Passenger Air Bag Module Return

Driver Air Bag Module Feed

Driver Air Bag Module Return

Fig.

1

Pin No.

13.

14.

15.

16. 17.

18.

19.

20.

21.

22.

23.

24.

12

Circuit Identification

Battery Input

Not Used

Safing Sensor Input

Safing Sensor Ground Monitor

LH Impact Sensor Feed

RH Impact Sensor Feed

Not Used

LH Impact Sensor Ground Monitor

RH Impact Sensor Ground Monitor

Not Used

Safing Sensor Feed

Test Input

X300 EDM 15.1 - 5 Issue 1 August 1994

Page 112 of 327

Electrical

0

NO AIR BAG MIl LAMP

Inoperative lamp Circuit or No Ignition to the Diagnostic Module

Normal Operation

The air bag MIL Lamp is designed to illuminate for approximately six seconds when the ignition is switched ‘on’; this

time has been allocated to prove the MIL Lamp operation.

The DM requires an ignition supply to Pin

1, to energize the air bag MIL Lamp circuit. If the MIL Lamp is open circuit

or the DM does not receive ignition voltage at Pin 1, the MII Lamp will not illuminate.

Open circuit in the

MII Lamp supply will cause the DM to emit five tones, or ‘beeps’ every 30 minutes while ignition

is on. Repair faulty circuitry before further diagnostics.

Possible Causes

0 Bulb blown or faulty wiring in the air bag MIL Lamp circuit.

0 Loss of ignition voltage at DM pin 1.

Fault Diagnosis

1. Ignition voltage -check

8 Disarm the SRS system.

8 Switch on the ignition.

8 Measure the voltage between pin 1 (+vel and pin 3 (-vel of the connector.

8 Battery voltage present, proceed with step 2.

8 Battery voltage not present; open circuit on R / W wire from RH fuse-box or faulty ground at pin 3.

8 Check fuse 17, RH fuse-box.

8 Check the fuse connectors and wiring.

8 Check the ground at pin 3 of the DM connector.

8 Arm and verify the SRS system.

2. MIL Lamp open circuit

8 Renew the DM.

8 Arm and verify the SRS system.

If the MIL Lamp is not illuminated, check the bulb, instrument pack and associated wiring.

Issue 1 August 1994 15.1 - 6 X300 EDM

Page 116 of 327

n E I ectr ica I

FAULT CODE 12

Low Battery Voltage

Normal Operation

The DM monitors voltage at pin 13 which should be equal to battery voltage. If a voltage lower than 9V is detected at pin 13 the MIL Lamp will illuminate and fault code 12 will be present.

Possible Causes

Drop in battery voltage to DM pin 13 caused by:

0 Open circuit to pin 13 from battery.

0 Short circuit to ground on battery feed circuit.

0 Safing sensor feed shorted to ground.

0 Safing sensor internal short to ground.

0 Faulty charging system draining battery voltage.

Fault Oiagnosis

1. Battery voltage test

Disarm the SRS system.

8 Disconnect the DM.

8 Switch on the ignition.

Measure the voltage between DM connector pin 13 (+ve) and pin 3(-ve).

If battery voltage is present at pin 13, renew the DM.

8 Arm and verify the SRS system.

8 If battery voltage is not present, go to step 2.

2.

Fusecheck

8 Check fuse 17 in the RH fuse-box.

If the fuse has blown, check for short circuit to ground between fuse and pin 13 DM connector.

8 Renew the fuse, go to step 3.

8 If the fuse has not blown, check for open circuit between battery positive terminal and pin 13 DM connector.

3. Short circuit check

* Switch off the ignition.

8 Connect the DM.

8 Has the fuse blown 1

Yes -

= Short circuit to ground from pin 15 DM (R/ W) to pin 3 safing sensor, or from pin 23 DM (Y / P) to pin 6 safing sensor.

8 Intermittent short circuit to ground; check wire (R / W) from pin 15 DM to pin 3 safing sensor, and, wire (Y/ P) from

NO -

pin 23 DM to pin 6 safing sensor.

4. On completion

8 Renew the fuse as necessary.

8 Arm and verify the SRS system.

Issue 1 August 1994 15.1 - 10 X300 EDM

Page 122 of 327

FAULTCODE 21

Safing impact Sensor Incorrectly Mounted to Vehicle

Normal Operation

The DM monitors the resistance value between pins 16 and 3. If a resistance value of greater than 2.051 is detected the

MIL Lamp will illuminate and fault code 21 will be present, indicating incorrect mounting of the safing impact sensor.

Secure connections to ground at both the sensor case and the vehicle are necessary to avoid this fault.

Possible Causes

0 Poor or dirty connection between safing sensor case and vehicle ground.

0 Poor or dirty termination at safing sensor internal ground.

0 Open circuit on wiring between DM pin 16 and safing sensor ground terminal.

Fault Diagnosis

1. Resistance - check

Disarm SRS system.

Disconnect battery ground lead.

Measure resistance between pin 3 (ground) and pin 16 (ground - safing sensor).

Is resistance value greater than 251 ?

No - Proceed to step 2

Yes

- Renew DM

2. Sensor ground

-check

Disconnect safing sensor from harness.

Measure resistance between sensor pin 5 and sensor mounting (chassis ground).

Is resistance value greater than 251 ?

Yes - Proceed to step 3

No - Examine wiring between internal sensor ground and harness connection 10. Rectify faults as necessary.

3. Sensor mounting -check

Remove safing sensor from mounting.

* Clean all mounting surfaces thoroughly and refit sensor.

Re-test resistance between harness connection 10 and sensor internal ground.

* Is resistance value greater than 251 ?

Yes - Renew sensor

No - Refit sensor and connect harness and battery ground lead.

4. On completion

Arm and verify the SRS system.

0

0

0

Issue 1 August 1994 15.1 - 16 X300 EDM

Page 124 of 327

rl E I ect r ica I

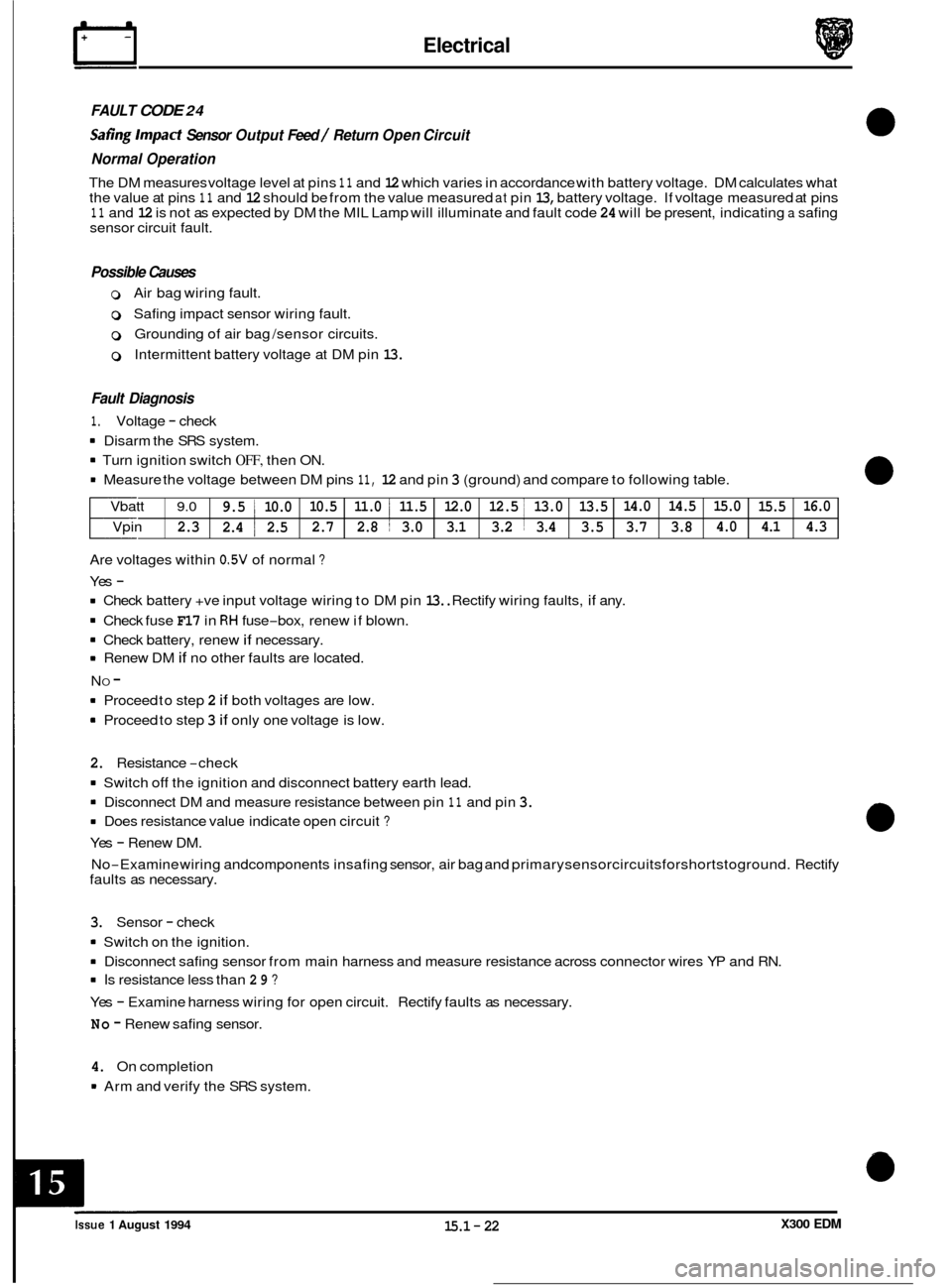

Vbatt 1 9.0 9.5

10.0 10.5

11.0 11.5 12.0 12.5 ~ 13.0

13.5

Vpin

I 2.3 2.4 2.5 2.7 2.8 3.0 3.1

3.2 1 3.4 3.5

FAULT CODE 22

Safing Impact Sensor

Output Circuit Shorted to Battery Voltage

Normal Operation

The DM measures voltage level at pins 11 and 12 which varies in accordance with charging voltage. If voltage

measured at these two pins exceeds

5V the MIL Lamp will illuminate and fault code 22 will be present, indicating a short

to battery voltage.

14.0 14.5 15.0 15.5 16.0

3.7 3.8 4.0

4.1 4.3

Possible Causes

0 Air bag supply

wiring faulty.

0 Safing impact sensor supply wiring faulty.

0 Safing impact sensor internal contacts short circuit.

0 Cable reel cassette faulty

0 Charging system voltage too high (above 17V).

2. Resistance - check

. Measure resistance across safing sensor contacts.

. Does resistance value indicate open circuit.

Yes

-Examine harness wiring for short circuits. Rectify faults as necessary.

No - Renew safing sensor.

3. On completion

Arm and verify the SRS system.

0

0

0

0 ~

issue 1 August 1994 15.1 - 18 X300 EDM

Page 128 of 327

Electrical

0

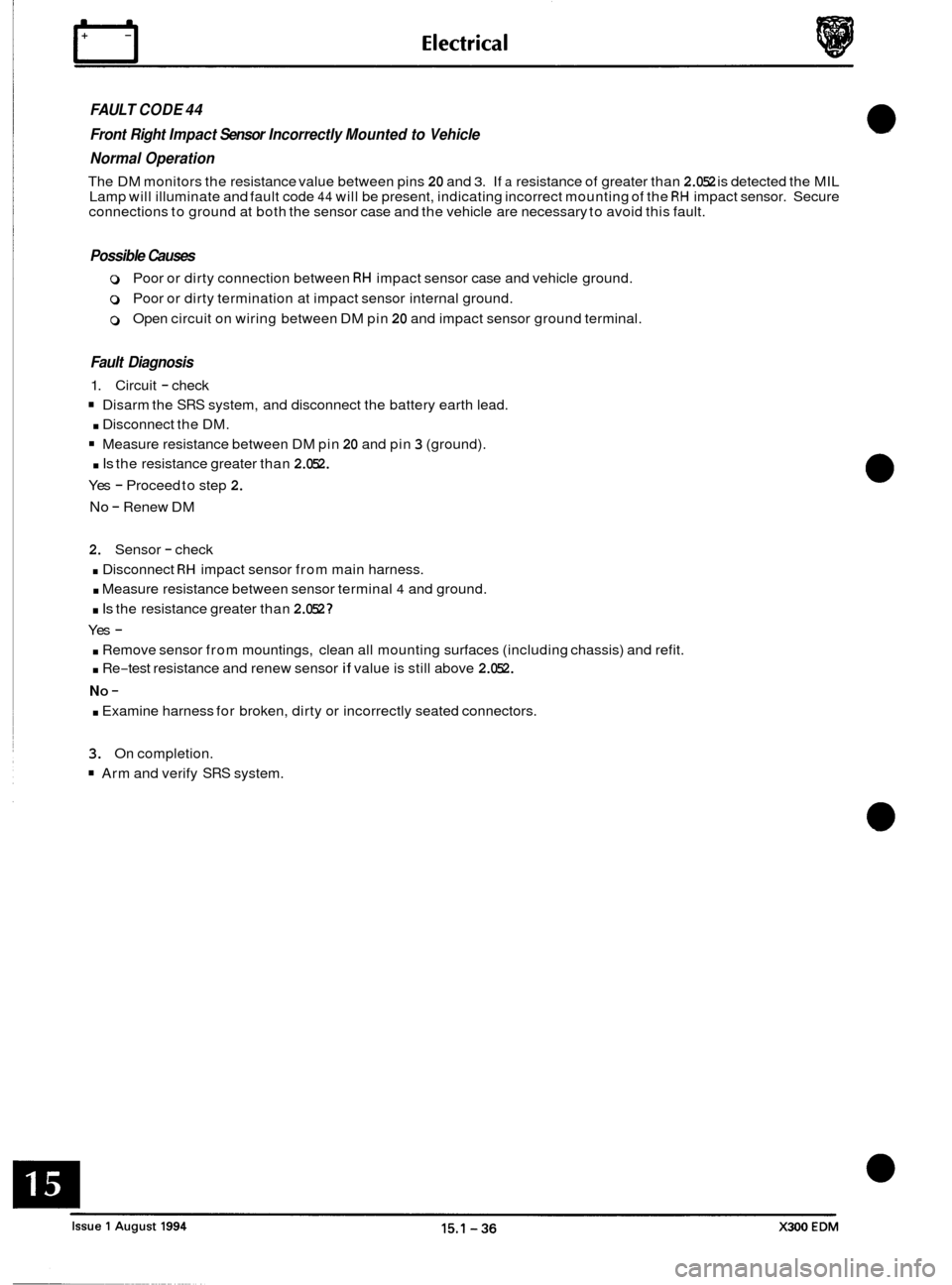

FAULT CODE 24

Safing Impact Sensor Output Feed / Return Open Circuit

Normal Operation

The DM measures voltage level at pins 11 and 12 which varies in accordance with battery voltage. DM calculates what

the value at pins 11 and 12 should be from the value measured at pin 13, battery voltage. If voltage measured at pins 11 and 12 is not as expected by DM the MIL Lamp will illuminate and fault code 24 will be present, indicating a safing

sensor circuit fault.

Vbatt

9.0 9.5 1 10.0 10.5

11.0 i 11.5 12.0 12.5 I 13.0 13.5 14.0

14.5 15.0

15.5

Vpin 2.3 2.4 ~ 2.5

2.7

2.8 ~ 3.0

3.1 3.2 1 3.4 3.5 3.7 3.8 4.0

4.1

Possible Causes

0 Air bag wiring fault.

0 Safing impact sensor wiring fault.

0 Grounding of air bag /sensor circuits.

0 Intermittent battery voltage at DM pin 13.

16.0 4.3

Fault Diagnosis

1. Voltage - check

8 Disarm the SRS system.

8 Turn ignition switch OFF, then ON.

8 Measure the voltage between DM pins 11, 12 and pin 3 (ground) and compare to following table.

Are voltages within

0.5V of normal ?

Yes -

8 Check battery +ve input voltage wiring to DM pin 13.. Rectify wiring faults, if any.

8 Check fuse F17 in RH fuse-box, renew if blown.

8 Check battery, renew if necessary.

8 Renew DM if no other faults are located.

8 Proceed to step 2 if both voltages are low.

8 Proceed to step 3 if only one voltage is low.

N

O -

2. Resistance -check

8 Switch off the ignition

and disconnect battery earth lead.

8 Disconnect DM and measure resistance between pin 11 and pin 3.

8 Does resistance value indicate open circuit ?

Yes - Renew DM.

No

-Examine wiring andcomponents insafing sensor, air bag and primarysensorcircuitsforshortstoground. Rectify

faults as necessary.

3. Sensor - check

8 Switch on the ignition.

8 Disconnect safing sensor from main harness and measure resistance across connector wires YP and RN.

8 Is resistance less than 29 ?

Yes - Examine harness wiring for open circuit. Rectify faults as necessary.

No - Renew safing sensor.

4. On completion

8 Arm and verify the SRS system.

X300 EDM Issue 1 August 1994 15.1 - 22

Page 142 of 327

FAULT CODE 44

Front Right Impact Sensor Incorrectly Mounted to Vehicle

Normal Operation

The DM monitors the resistance value between pins 20 and 3. If a resistance of greater than 2.052 is detected the MIL

Lamp will illuminate and fault code 44 will be present, indicating incorrect mounting of the RH impact sensor. Secure

connections to ground at both the sensor case and the vehicle are necessary to avoid this fault.

Possible Causes

0 Poor or dirty connection between RH impact sensor case and vehicle ground.

0 Poor or dirty termination at impact sensor internal ground.

0 Open circuit on wiring between DM pin 20 and impact sensor ground terminal.

Fault Diagnosis

1. Circuit - check

Disarm the SRS system, and disconnect the battery earth lead.

. Disconnect the DM.

Measure resistance between DM pin 20 and pin 3 (ground).

. Is the resistance greater than 2.052.

Yes - Proceed to step 2.

No - Renew DM

2. Sensor - check

. Disconnect RH impact sensor from main harness.

. Measure resistance between sensor terminal 4 and ground.

. Is the resistance greater than 2.052 7

Yes -

. Remove sensor from mountings, clean all mounting surfaces (including chassis) and refit.

. Re-test resistance and renew sensor if value is still above 2.052.

NO -

. Examine harness for broken, dirty or incorrectly seated connectors.

3. On completion.

Arm and verify SRS system.

e

0

Page 144 of 327

Electrical

FAULT CODE 45

Front Left Impact Sensor Incorrectly Mounted to Vehicle

Normal Operation

The DM monitors the resistance value between pins 21 and 3. If a resistance of greater than 2 Lamp will illuminate and fault code 45 will be present, indicating incorrect mounting of the LH

connections to ground at both the sensor case and the vehicle are necessaw to avoid this fa!

Possible Causes

0 Poor or dirty connection between LH impact sensor case and vehicle ground.

0 Poor or dirty termination at impact sensor internal ground.

0 Open circuit on wiring between DM pin 21 and impact sensor ground terminal.

Fault Diagnosis

1. Circuit -check

. Disarm the SRS system, and disconnect the battery earth lead.

. Disconnect the DM.

. Measure resistance between DM pin 21 and pin 3 (ground).

. Is the resistance greater than 2.08.

Yes - Proceed to step 2.

No - Renew DM

2. Sensor - check

. Disconnect RH impact sensor from main harness.

Measure resistance between sensor terminal 4 and ground.

. Is the resistance greater than 2.051 7

Yes -

. Remove sensor from mountings, clean all mounting surfaces (including chassis) and refit.

Re-test resistance and renew sensor if value is still above 2.0Q.

NO -

. Examine harness for broken, dirty or incorrectly seated connectors.

3. On completion.

. Arm and verify SRS system.

Issue 1 August 1994 15.1 -38

!.On is detected the MIL

impact sensor. Secure

Jlt.

Electrical

FAULT CODE 45

Front Left Impact Sensor Incorrectly Mounted to Vehicle

Normal Operation

The DM monitors the resistance value between pins 21 and 3. If a resistance of greater than 2.08 is detected the MIL

Lamp will illuminate and fault code 45 will be present, indicating incorrect mounting of the LH impact sensor. Secure

connections to ground at both the sensor case and the vehicle are necessaw to avoid this fault.

Possible Causes

0 Poor or dirty connection between LH impact sensor case and vehicle ground.

0 Poor or dirty termination at impact sensor internal ground.

0 Open circuit on wiring between DM pin 21 and impact sensor ground terminal.

Fault Diagnosis

1. Circuit -check

. Disarm the SRS system, and disconnect the battery earth lead.

. Disconnect the DM.

. Measure resistance between DM pin 21 and pin 3 (ground).

. Is the resistance greater than 2.08.

Yes - Proceed to step 2.

No - Renew DM

2. Sensor - check

. Disconnect RH impact sensor from main harness.

Measure resistance between sensor terminal 4 and ground.

. Is the resistance greater than 2.051 7

Yes -

. Remove sensor from mountings, clean all mounting surfaces (including chassis) and refit.

Re-test resistance and renew sensor if value is still above 2.0Q.

NO -

. Examine harness for broken, dirty or incorrectly seated connectors.

3. On completion.

. Arm and verify SRS system.

Issue 1 August 1994 15.1 -38 X300 EDM - X300 EDM

e

0

0

0

Page 150 of 327

rl Electrical

FAULT CODE 53

Front Impact Sensor Circuits Resistance to Ground or Internal Diagnostic Monitor Failure

Normal Operation

The DM measures the voltage on pins 2,6,17 and 18. If there is any resistance to ground on any of these pins or across

the front impact sensors contacts, it will cause the diagnostic voltage on these pins to drop below normal levels. If the

DM measures voltage drop to between 5 and 10 volts, the DM senses an internal voltage regulation failure and code

53 will be present.

A direct short to ground in the front impact sensor circuits

will drop the voltage to less than 5 volts and code 14 will

be present.

!!IQ&: The DM also performs several system self-tests every ignition cycle. If any of these tests fail, fault code 53 will

be present.

Fault Diagnosis

1. System verification

. Disarm the SRS system.

. Disconnect the battery ground lead, allow one minute for DM back-up power to drain.

. Disconnect the DM.

Remove the plastic locking wedge from the grey harness multi-plug connector.

= Measure the resistance between pin 3 (ground) and the following circuits:

. Pin2(ON)

. Pin 6 (VU)

. Pin 17 (KU)

* Pin 18 (KG)

. Are all circuit readings infinite (open circuit) ?

Yes - Renew DM.

No

- Proceed to step 2.

2.

. Using schematic, identify suspect sensor and circuitry.

. Disconnect the suspect sensor.

9 Measure the resistance across the normally open contacts.

. Is the resistance reading infinite (open circuit) ?

Yes - Locate and rectify short to ground on low resistance circuit.

No - Renew front impact sensor.

Impact

sensor open circuit

- check

0

0

e

0

Issue 1 August 1994 15.1 - 44 X300 EDM