ECO mode JAGUAR XJ6 1994 2.G User Guide

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 1994, Model line: XJ6, Model: JAGUAR XJ6 1994 2.GPages: 521, PDF Size: 17.35 MB

Page 330 of 521

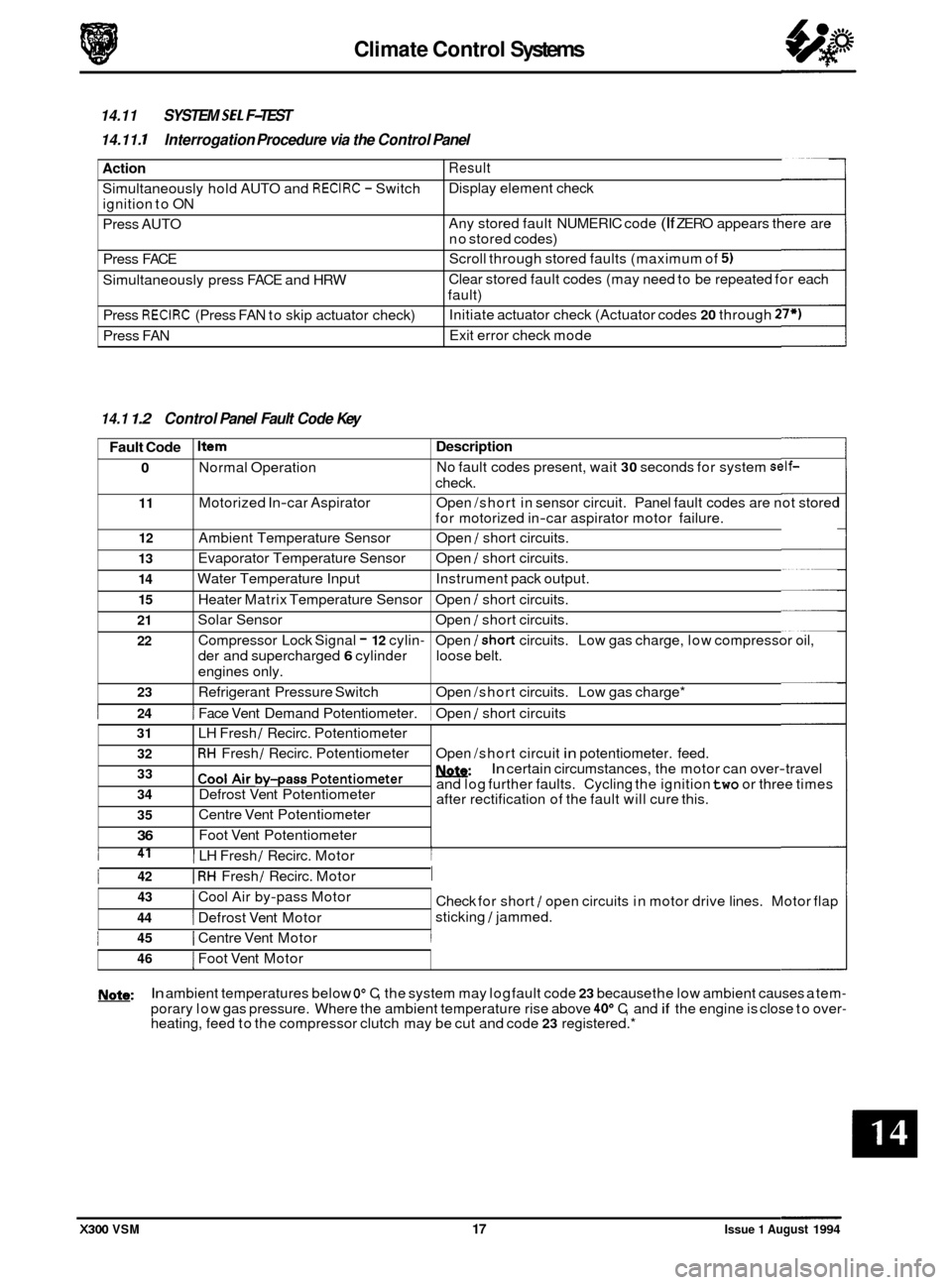

Climate Control Systems

Action

Simultaneously hold AUTO and RECIRC - Switch

ignition to ON

Press AUTO

Press FACE

Simultaneously press FACE and HRW

Press

RECIRC (Press FAN to skip actuator check)

Press FAN

14.11 SYSTEM SE1 F-TEST

14.11. I Interrogation Procedure via the Control Panel

Result

Display element check

Any stored fault NUMERIC code

(If ZERO appears there are

no stored codes)

Scroll through stored faults (maximum of

5)

Clear stored fault codes (may need to be repeated for each

fault)

Initiate actuator check (Actuator codes

20 through 27*)

Exit error check mode

Fault Code

0

11

12

13

14

15

21

22

0

23

14.1 1.2 Control Panel Fault Code Key

Item Description

Normal Operation No

fault codes present, wait 30 seconds for system self-

check.

Motorized In

-car Aspirator Open /short in sensor circuit. Panel fault codes are not stored

for motorized in

-car aspirator motor failure.

Ambient Temperature Sensor Open

/ short circuits.

Evaporator Temperature Sensor Open

/ short circuits.

Water Temperature Input Instrument pack output.

Heater Matrix Temperature Sensor Open

/ short circuits.

Solar Sensor Open

/ short circuits.

Compressor Lock Signal

- 12 cylin- Open /short circuits. Low gas charge, low compressor oil,

der and supercharged

6 cylinder loose belt.

engines only.

Refrigerant Pressure Switch Open /short circuits. Low gas charge*

31

32

33

34

35

36 0

I 24 1 Face Vent Demand Potentiometer. 1 Open / short circuits

LH Fresh

/ Recirc. Potentiometer

RH Fresh / Recirc. Potentiometer

cool ~i~ by-pass potentiometer

Defrost Vent Potentiometer

Centre Vent Potentiometer

Foot Vent Potentiometer Open

/short circuit

in potentiometer. feed.

w: and log further faults. Cycling the ignition two or three times

after rectification of the fault will cure this.

In certain circumstances, the motor can over-travel

43

44

I Defrost Vent Motor

I Cool Air by-pass Motor

I 41 I LH Fresh / Recirc. Motor I

Check for short / open circuits in motor drive lines. Motor flap

sticking

/ jammed.

1 42 I RH Fresh / Recirc. Motor I

1 45 I Centre Vent Motor I

46 I Foot Vent Motor

w: In ambient temperatures below Oo C, the system may log fault code 23 because the low ambient causes a tem-

porary low gas pressure. Where the ambient temperature rise above 40" C, and if the engine is close to over- heating, feed to the compressor clutch may be cut and code 23 registered.*

X300 VSM 17 Issue 1 August 1994

Page 345 of 521

rl Electrical

15.1.6 Fire Hazard Infonnath

Thermal decomposition or combustion may produce dense smoke and other dangerous fumes which in fire situations

form

a highly toxic explosive.

In the event of fire the surrounding area must be evacuated and

all personnel kept well upwind of the area.

Full fire fighting protective gear and

a self contained breathing apparatus operating in the positive pressure mode must

be worn for combating fire. Material near fires must be cooled with water spray to prevent ignition.

Fires should be allowed to burn themselves

out if not threatening to life or property. If fire is threatening to life or prop- erty use copious quantities of water to extinguish.

15.1.7 Ventilath

Local exhaust ventilation designed by a professional engineer should be provided if vapours, fumes, or dusts are gen- erated whilst working with airbag module.

The latest issue of the manual for recommended practices on 'Industrial Ventilation' is available from the

ACGIH Com- mittee on Industrial Ventilation, PO Box 16153, Lansing, MI 48910, USA.

The need for local exhaust ventilation should be evaluated by a professional industrial hygienist.

15.1.8 Respiratory Precauth

To prevent the inhalation of dangerous fumes and dusts, an approved mask should be worn.

15.1.9 Eye Protection

Chemical protective goggles are recommended where there is a possibility of eye contact with the propellant.

Safety glasses with side shields are recommended for

all other operations.

15.1. I0 Protective Clothing

Approved protective gloves, overalls and shoes / boots should be worn.

15.1.1 1 Handling and Storage Precautions

Do not store airbag module near live electrical equipment or circuitry. Store in a dry environment at ambient tempera-

tures.

Good housekeeping and engineering practices should be employed to prevent the generation and accumulation of

dusts. Store in compliance with

all local state and federal regulations.

15.1.12 Driver And Passenger Airbag Modules Assembly / Removal / Service Instructions

Before starting work, ensure ignition switch is in 'IocK position, key is removed and negative terminal cable

is disconnected from the battery.

As the airbag is equipped with a back up power source and due to the risk of airbag being inadvertently

deployed, wait one minute or longer before starting work.

0 Disconnecting the battery cancels the memory for clock, radio, seats, mirrors, steering column and any other

components using battery power. Reset memory after work is completed.

0 Never use airbags from other vehicles, always use new parts.

0 After work is completed, reconnect battery and perform warning light check see diagnostic manual.

0 Never use electrical probes to check voltage or electrical resistance.

0 Disconnect the airbag before carrying out any work on, or in the vicinity of module, or when using electric weld- ing equipment.

0 Always ensure that battery negative has been disconnected for one minute or longer before commencing any

removal procedure.

EB

Issue 1 August 1994 4 X300 VSM

Page 384 of 521

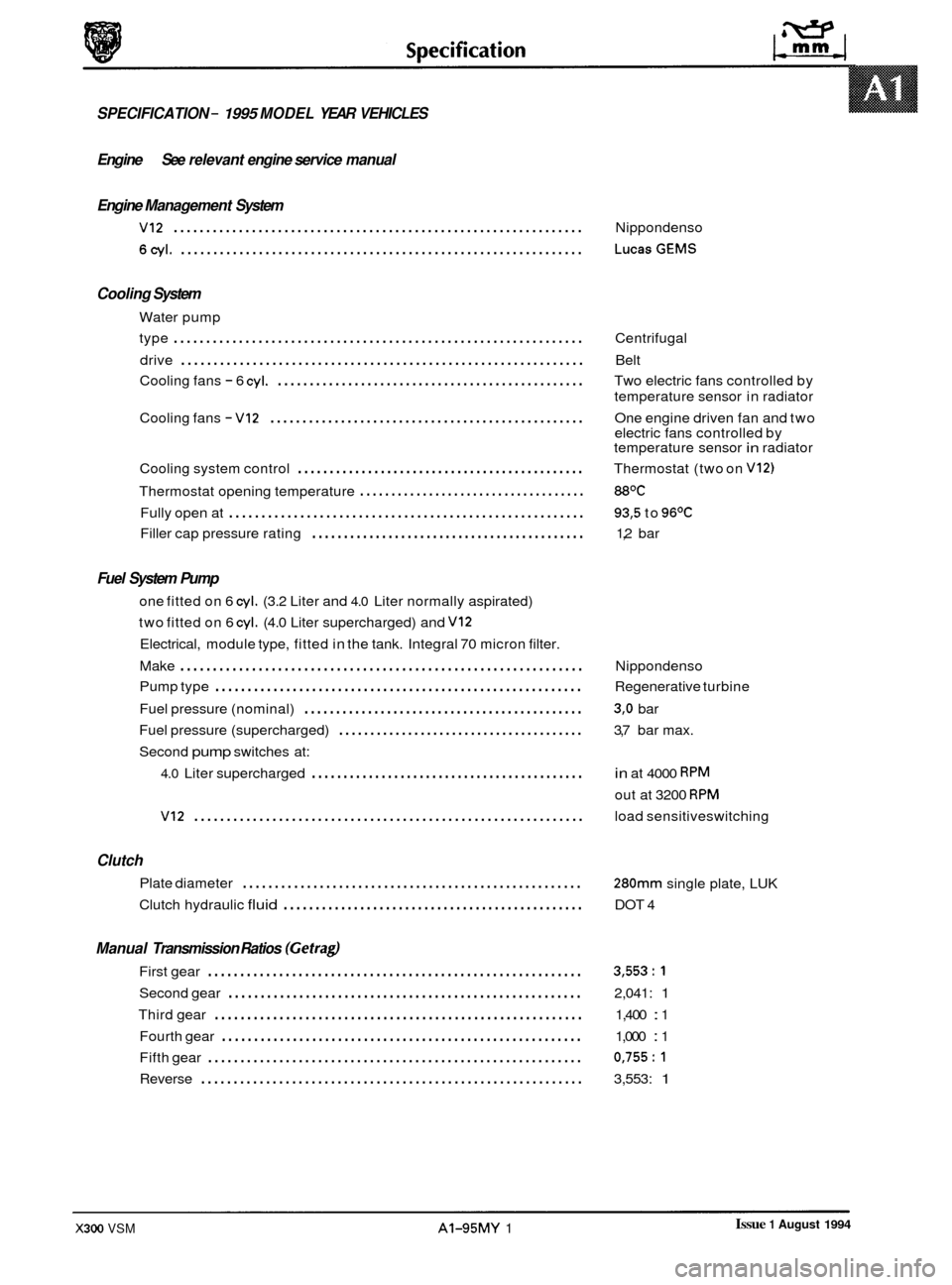

SPECIFICATION - 1995 MODEL YEAR VEHICLES

Engine See relevant engine service manual

Engine Management System

VI2 ............................................................... Nippondenso

6cyl. .............................................................. LucasGEMS

Cooling System

Water pump

type

............................................................... Centrifugal

Cooling fans

- 6 cyl. ................................................ Two electric fans controlled by

Cooling fans

- VI2 ................................................. One engine driven fan and two

Cooling system control

............................................. Thermostat (two on V12)

Thermostat opening temperature .................................... 88OC

Fully open at ....................................................... 93,5 to 96OC

Filler cap pressure rating ........................................... 1,2 bar

drive

.............................................................. Belt

temperature sensor in radiator

electric fans controlled by

temperature sensor

in radiator

Fuel System Pump

one fitted on 6 cyl. (3.2 Liter and 4.0 Liter normally aspirated)

two fitted on 6

cyl. (4.0 Liter supercharged) and VI2

Electrical, module type, fitted in the tank. Integral 70 micron filter.

Make

.............................................................. Nippondenso

Fuel pressure (nominal)

............................................ 3,O bar

Second

pump switches at:

Pump

type

......................................................... Regenerative turbine

Fuel pressure (supercharged)

....................................... 3,7 bar max.

4.0 Liter supercharged ........................................... in at 4000 RPM

out at 3200 RPM

VI2 ............................................................ load sensitiveswitching

Clutch

Plate diameter .....................................................

Clutch hydraulic fluid ............................................... DOT 4

280mm single plate, LUK

Manual Transmission Ratios (Gefragl

First gear .......................................................... 3,553:l

Second gear ....................................................... 2,041: 1

Third gear ......................................................... 1,400 : 1

Fourth gear

........................................................ 1,000 : 1

Fifth gear

.......................................................... 0,755:l

Reverse ........................................................... 3,553: 1

Issue 1 August 1994 X300 VSM AI-95MY 1

Page 452 of 521

A4.4.1 PAINT SYSTEMS - APPROVED

0 The manufacturer's paint systems listed below are currently approved for refinishing Jaguar vehicles.

I Manufacturer

Akzo Sikkens

1

Glasurit

0

1R-M

Bare metal etch primer Primer surfacer Base color coat

Washprimer Autocryll Autonova Autobase

, Centari 600*

System 56 (micatallic)

System 59 & 69 (pearl)

Wash

Etch+ System 54

(solidlmetallic)

Metal pre-treatment & Standox Basislak

rust remover 301.2595

I I

Galvaprep D840 Wash primer D831 Deltron HS 2

Eurof

il I

Hi-build primer

D855

Epoxy surfacer

DP40

Deltron

I non Iso-

cyanate Primer

D828

R-M Prof I Maxfill Diamont Basecoat

Clear lacquer

Autoclear 1000 - 3000

Automat

Centari

WO*

Clear lacquer 923-85

Standox Clearlak

Autocolor

Deltron Concept 2001

HS clear D880

Diamont Clearcoat

&&: * Not available North America

In markets which do not support any of the nominated systems, alternatives may

be used, provided that they comply

with the following company standards.

Product type Applicable standard

Bare metal etch primer

Base color and clear lacquer JMS

20.29.06

Primer surfacer JMS 20.29.11

JMS 20.29.09

CAUTION: To avoid damage to the vehicle interior, trim and plastic items, effective panel temperature must not ex- ceed 9S°C during paint cure process.

A4.4.1.1 General Recommendations

Recommendations and advice covering all aspects of refinishing may be found in the 'Paint Refinishing Manual'which

is available in the following languages:

Language Reference

Dutch AKM 9187

English AKM 9182

Italian AKM 9185

French AKM

9183

German AKM 9184

Spanish AKM 9186

0

A4.4.1.2 Manual Section Relevance

Section Relevance

Defect diagnosis Applicable

Refinish processes

Refinishing system

Color technique Applicable

Facilities and equipment Applicable

Safety Applicable

less 'De

-waxing' process

Applicable less model references (see table above)

Legislation applicable

U.K. only; general precautions and advice applicable to all

X300 VSM Issue 1 August 1994 25

Page 485 of 521

Security System - RESTRICTED ISSUE 8-8

-

A5.3.2 Security system

Base system

Provides standard vehicle arming, ie door ajar, actuator lockstatus, trunk lid or hood ajar and passenger door unlock- ing, does not include inclination or

Intrusion sensing

Detection of intrusion into the passenger compartment by removal or breakage of any glazed area, entry via any pro- tected enclosure and unauthorized door opening detection.

Inclination (tilt) sensing

Detection of unauthorized jacking /towing.

Passive arming

Arming of the security system, excluding intrusion sensors, without audible confirmation.

Audible tones

Audible indication of driver error when attempting to arm the system, or on initiation of deadlocking.

Engine immobilization

Automatic immobilization of the engine crank facility whenever the ignition key is turned to position 0.

A5.3.3 Convenience

All close

Automatic closure of open windows and sliding roof by prolonged action of key, or remote fob transmitter after door

locking.

Headlamp convenience

Automatic illumination of headlamps for driver convenience on operation of key fob button after locking sequence

completed.

Remote trunk lid release

Automatic release of the trunk lid lock on operation of the smaller key fob button after door unlocking.

Trunk valet isolate

Independent locking of the trunk lid to eliminate unauthorized entry to the luggage compartment.

Driver seat memory select

Automatic recall of a memorized driving position on operation of the smaller key fob button.

Intrusion sensing override

Allows intrusion sensing to be disabled until the next disarm action.

A5.3.4 Alarms

There are eight possible alarm activation modes; driver's door, hood, ignition key in (ignition auxiliary position, ignition ON), inclination, inner door handle action (causing actuator status switches to operate), intrusion, passenger door and

trunk.

Any of the above conditions occurring after the vehicle is fully armed will cause full alarm state.

Any of the above conditions, except door opening, occurring

after the vehicle is fully armed and active disarming is

selected will cause full alarm state. Door opening after active disarming selection will give a 30 second audible tick

period before full alarm is entered.

Any of the above conditions occurring

after the vehicle has been passively armed will give a 30 second audible tick

period before full alarm is entered.

Activation of full alarm state causes sidelights, direction indicators, interior lights or headlamps to flash (dependant

upon market variations), the security sounder to operate and the vehicle horns to operate

(if programmed to do so).

An error tone is generated if active arming is selected with either hood or trunk open, or the transmitter is pressed with

ignition key in auxiliary position.

0

X300 VSM Issue 1 August 1994 8

Page 493 of 521

Security System - RESTRICTED ISSUE

A5.6 SYSTEM DIAGNOSTIC METHODS

The following information details diagnostic proceduresfor system fault identification using a Portable Diagnostic Unit

(PDU).

PDU is designed and supplied by Jaguar Cars Ltd. to interrogate the electroniccontrol circuitry of the various vehicle

systems, diagnose fault conditions and indicate to the operator recorded faults and possible remedies. On initiation

of diagnostic procedures PDU will display the model variant and control module type,

a list of enabled functions can

also be accessed. Ensure that this information is correct for the vehicle under test, ie that the correct module is fitted

and

all appropriate options are enabled.

Detailed information on testing using PDU is detailed in the support documentation supplied with the unit.

Issue 1 August 1994 16 X300 VSM