Transmission fluid JAGUAR XJ6 1994 2.G User Guide

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 1994, Model line: XJ6, Model: JAGUAR XJ6 1994 2.GPages: 521, PDF Size: 17.35 MB

Page 135 of 521

Manual Transmission & Clutch (AJ16)

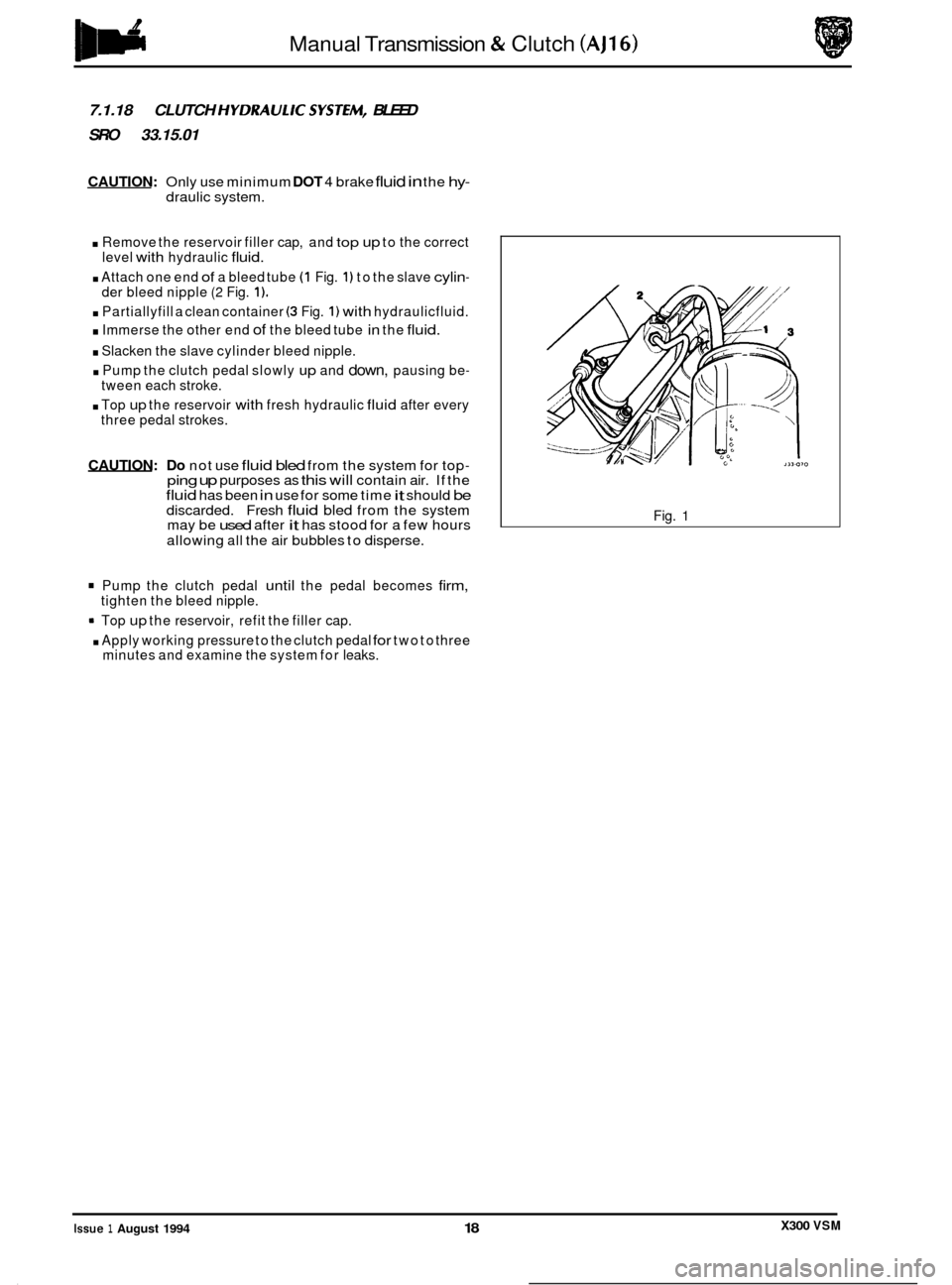

7.1.18 CLUTCH HYDRAULICSYSTEM, BLEED

SRO 33.15.01

CAUTION: Only use minimum DOT 4 brake fluid in the hy- draulic system.

. Remove the reservoir filler cap, and top up to the correct

level with hydraulic fluid.

. Attach one end of a bleed tube (1 Fig. 1) to the slave cylin- der bleed nipple (2 Fig. 1).

. Partiallyfill a clean container (3 Fig. 1) with hydraulicfluid.

. Immerse the other end of the bleed tube in the fluid.

. Slacken the slave cylinder bleed nipple.

. Pump the clutch pedal slowly up and down, pausing be-

. Top up the reservoir with fresh hydraulic fluid after every

tween

each stroke.

three pedal strokes.

CAUTION: Do not use fluid bled from the system for top- ping up purposes as this will contain air. If the fluid has been in use for some time it should be discarded. Fresh fluid bled from the system

may be used after it has stood for a few hours

allowing

all the air bubbles to disperse.

Pump the clutch pedal until the pedal becomes firm,

a Top up the reservoir, refit the filler cap.

tighten

the bleed nipple.

. Apply working pressure to the clutch pedal for two to three

minutes and examine the system for leaks.

X300 VSM Issue 1 August 1994 18

Fig. 1

Page 136 of 521

Automatic Transmission (AJ16)

SECTION CONTENTS

Subsection Title SRO Page

I to IV ............ Preliminary Pages .................................................................... i

8.1.1 ............. General Description .................................................................. 1

8.1.2 ............. Transmission Fluid. Renew (3. 2L and 4. OL) ......................... 44.24.02 ............. 6

8.1.3 ............. Transmission Control Module. Renew (4. OL) ........................ 44.15.32 ............. 7

8.1.4 ............. Transmission Rotary Switch. Adjust (4. OL) .......................... 44.15.37 ............. 8

8.1.5

............. Transmission Rotary Switch. Renew (4.0L) .......................... 44.15.36 ............. 9

8.1.6 ............. Transmission Fluid Filter, Renew (3. 2L and 4. OL)

8.1.7 ............. Fluid Pan. Renew (4. OL) ......................................... 44.24.04 ............

8.1.8 ............. Fluid Pan. Renew (3. 2L) ......................................... 44.24.04 ............ 12

8.1.9

............. Fluid Pan Gasket. Renew (3. 2L) .................................. 44.24.05 ............ 12

8.1.10.

........... Transmission Speed Sensor, Renew (4. OL) .......................... 44.15.34 ............ 13

8.1.1 1 ............ Transmission Internal Harness Multi-pin Socket '0' ring. Renew (4. OL) . 4424.20 ............ 14

Valve Body Assembly, Renew (4. OL) ............................... 44.40.01 ............ 15

.................... 44.24.07 ............ 11

11

8.1.12 ............

8.1.13 ............ Valve Body Assembly, Renew (3.2L) ............................... 44.40.01 ............ 16

X300 VSM i Issue 1 August 1994

Page 137 of 521

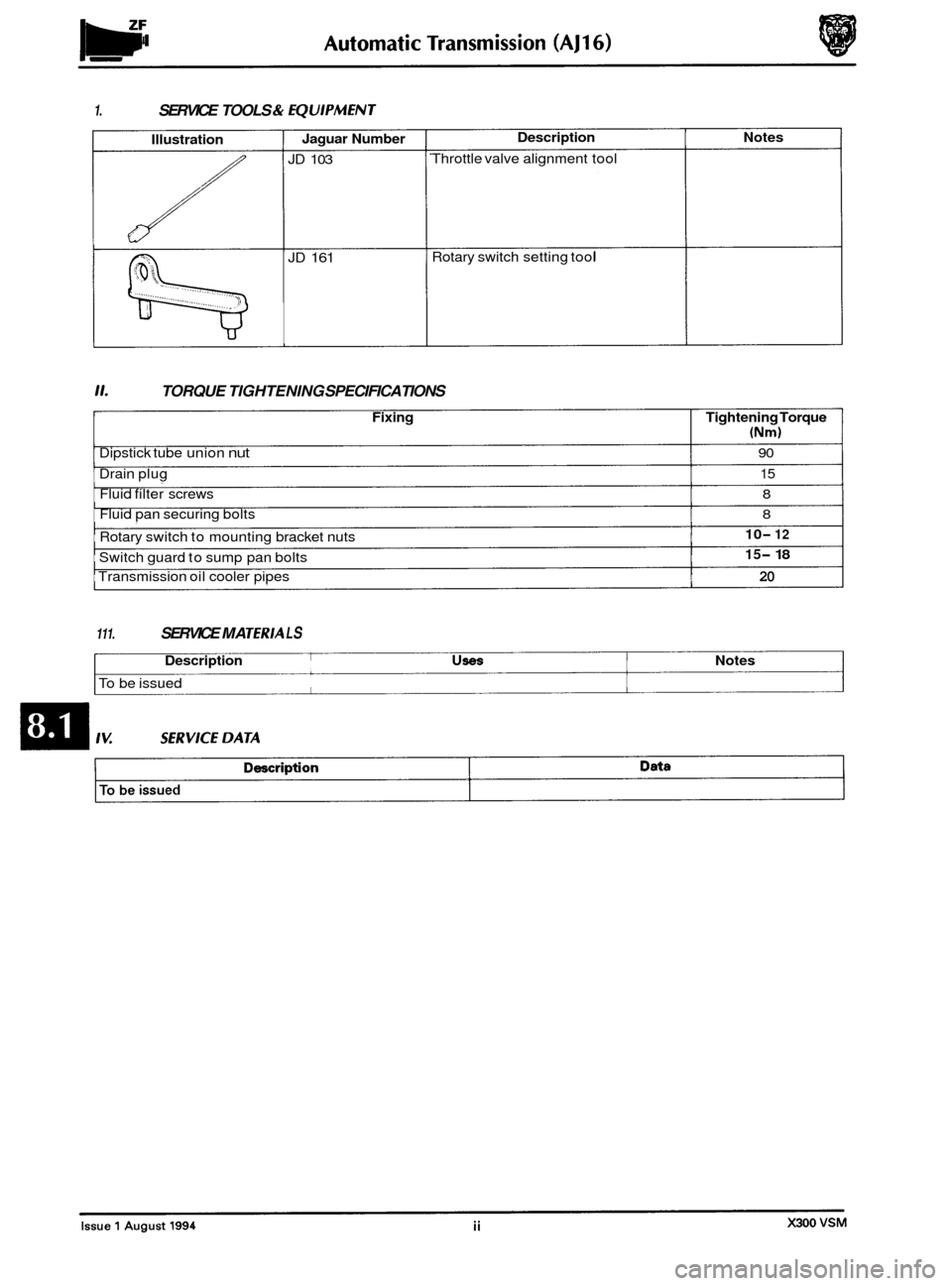

1. SERVICE TOOLS & fQUlPMENT

Illustration

::(())(((((

Jaguar Number

JD 103

JD 161

Description Notes

Throttle valve alignment tool

Rotary switch setting tool

11. TORQUE TIGHTENING SPECIFICATIONS

Fixing Tightening Torque

(Nm)

Dipstick tube union nut 90

Drain plug 15

Fluid filter screws 8

Fluid pan securing bolts 8

Rotary switch to mounting bracket nuts

Transmission oil cooler pipes

20

10- 12

15- 18 Switch guard to sump pan bolts

111. SERVICE MA TERlA L S

Description USeS Notes

To be issued

Page 143 of 521

bZF Automatic Transmission (AJ16) -

0

8.1.2 TRANSMISSION FLUID, RENEW

SRO 44.24.02

= Raise the hood and fit a fender cover.

. Raise the vehicle on a ramp.

. Place a drain tin in position beneath the transmission drain

Release and remove the transmission drain plug; allow

. Fit the drain plug with a new washer and torque tighten.

Reposition the drain tin beneath the dipstick tube union.

Remove the screw securing the dipstick tube bracket.

. Release the dipstick tube union nut and disconnect the

tube from the fluid pan.

. Drain the transmission fluid.

Clean the tube unions, reconnect the dipstick tube to the

. Lower the vehicle on the ramp.

. Remove the transmission dipstick.

. Renew the transmission fluid filter, see Subsection 8.1.6.

Fill the transmission with the correct fluid, see the ZF Auto-

Note: It will not be possible to get all the initial fill quantity

of fluid into the transmission.

. Refit the dipstick.

. Startthe engine, apply all brakes and run the transmission

With the engine still running, remove the dipstick.

Clean the dipstick and refit.

Remove the dipstick and check the transmission fluid

. Add fluid until the correct level is achieved.

. Stop the engine and refit the dipstick.

. Checkfluidleveltothe'HOT'marksaftera20mileroad run

(3,2L AND 4,OL)

Plug.

the fluid to drain.

fluid pan and torque tighten the union nut.

0

matic Transmissions Service Manual, General Data.

through

all gear positions and select 'Park'.

level. Remove the fender cover and lower the hood.

to ensure accurate results.

m

e

0

X300 VSM Issue 1 August 1994 6

Page 145 of 521

Automatic Transmission (AJ16)

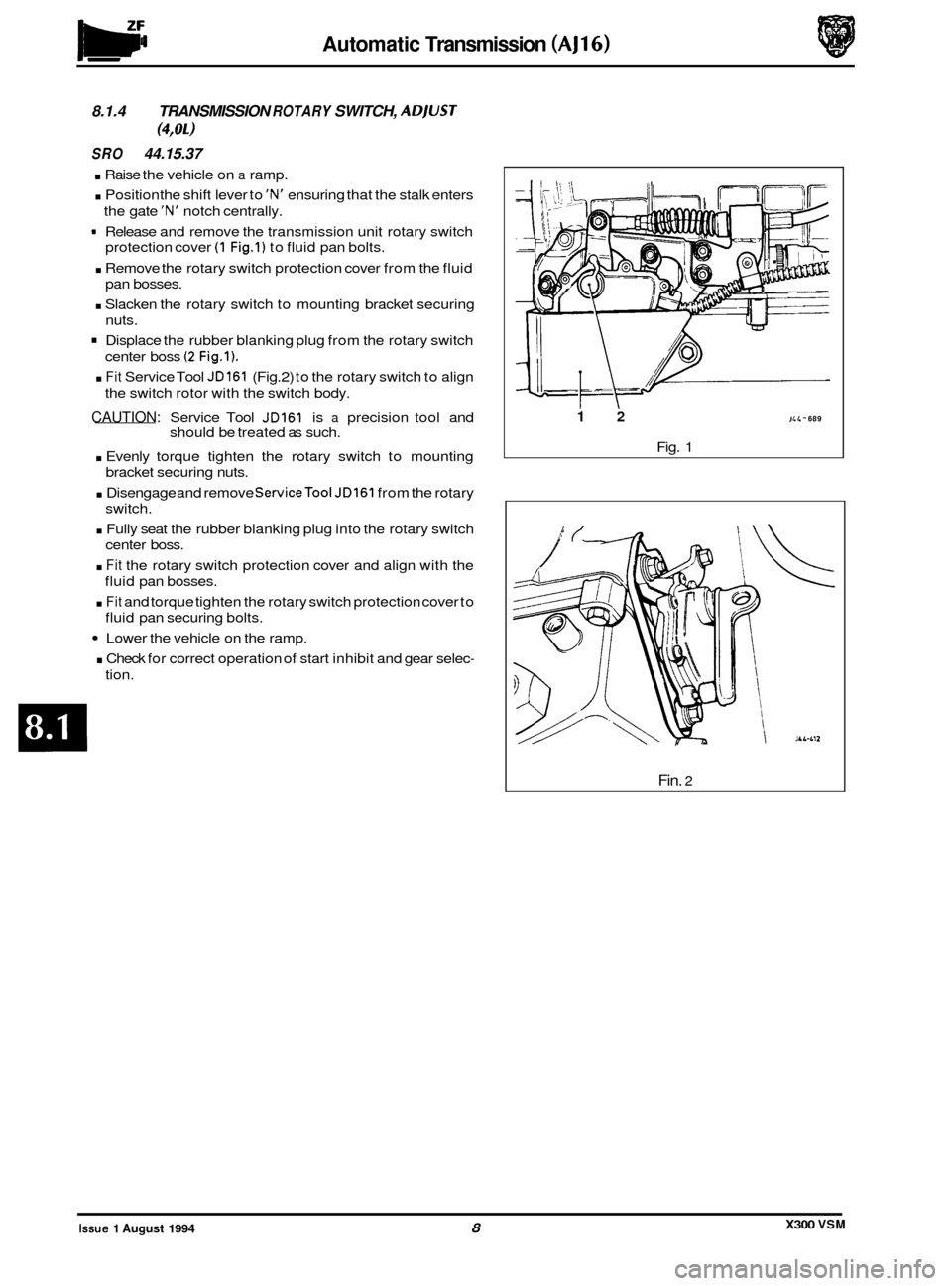

8.1.4 TRANSMISSION ROTARY SWITCH, ADjUST

SRO 44.15.37

. Raise the vehicle on a ramp.

. Position the shift lever to 'N' ensuring that the stalk enters

the gate

'N' notch centrally.

9 Release and remove the transmission unit rotary switch

protection cover

(1 Fig.1) to fluid pan bolts.

. Remove the rotary switch protection cover from the fluid

pan bosses.

. Slacken the rotary switch to mounting bracket securing

nuts.

Displace the rubber blanking plug from the rotary switch

center boss

(2 Fig.1).

. Fit Service Tool JD161 (Fig.2) to the rotary switch to align

the switch rotor with the switch body.

CAUTION: Service Tool JD161 is a precision tool and

. Evenly torque tighten the rotary switch to mounting

. Disengage and remove ServiceTool JD161 from the rotary

. Fully seat the rubber blanking plug into the rotary switch

. Fit the rotary switch protection cover and align with the

. Fit and torque tighten the rotary switch protection cover to

Lower the vehicle on the ramp.

. Check for correct operation of start inhibit and gear selec-

(4,011

should be treated as such.

bracket securing nuts.

switch.

center boss.

fluid pan bosses.

fluid pan securing bolts.

tion.

12 JL 4 - 689

Fig. 1

Fin. 2

X300 VSM Issue 1 August 1994 8

Page 148 of 521

Automatic Transmission (AJl6)

8.1.6 TRANSMISSION FLUID FILTER, RENEW

SRO 44.24.07

9 Raise the hood and fit a fender cover.

. Raise the vehicle on a ramp.

. Drain the transmission lubrication system, see Sub-sec-

. Removethefluid pan,seeSub-section8.1.7 (4,OL)orSub-

. Release and remove the fluid filter securing screws; dis-

. Remove and discard the filter '0' ring.

. Clean the new filter and mating faces.

. Fit the '0' ring to the new filter; fit and seat the filter assem-

. Fit and torque tighten the filter securing screws.

. Refitthefluidpan,seeSub-section8.1.7 (4,OL)orSub-sec-

. Lower the vehicle on the ramp.

. Refill the transmission unit with fluid, see Subsection

8.1.2.

Remove the fender cover and lower the hood.

(3,2L AND 4,011

tion 8.1.2.

section

8.1.8 (3,2L).

place and remove the fluid filter.

bly to the valve body.

tion 8.1.8

(3,2L).

8.1.7 FLUID PAN, RENEW (4,OL)

SRO 44.24.04

. Raise the hood and fit a fender cover.

. Raise the vehicle on a ramp.

. Drain the transmission lubrication system, see Sub-sec-

tion 8.1.2.

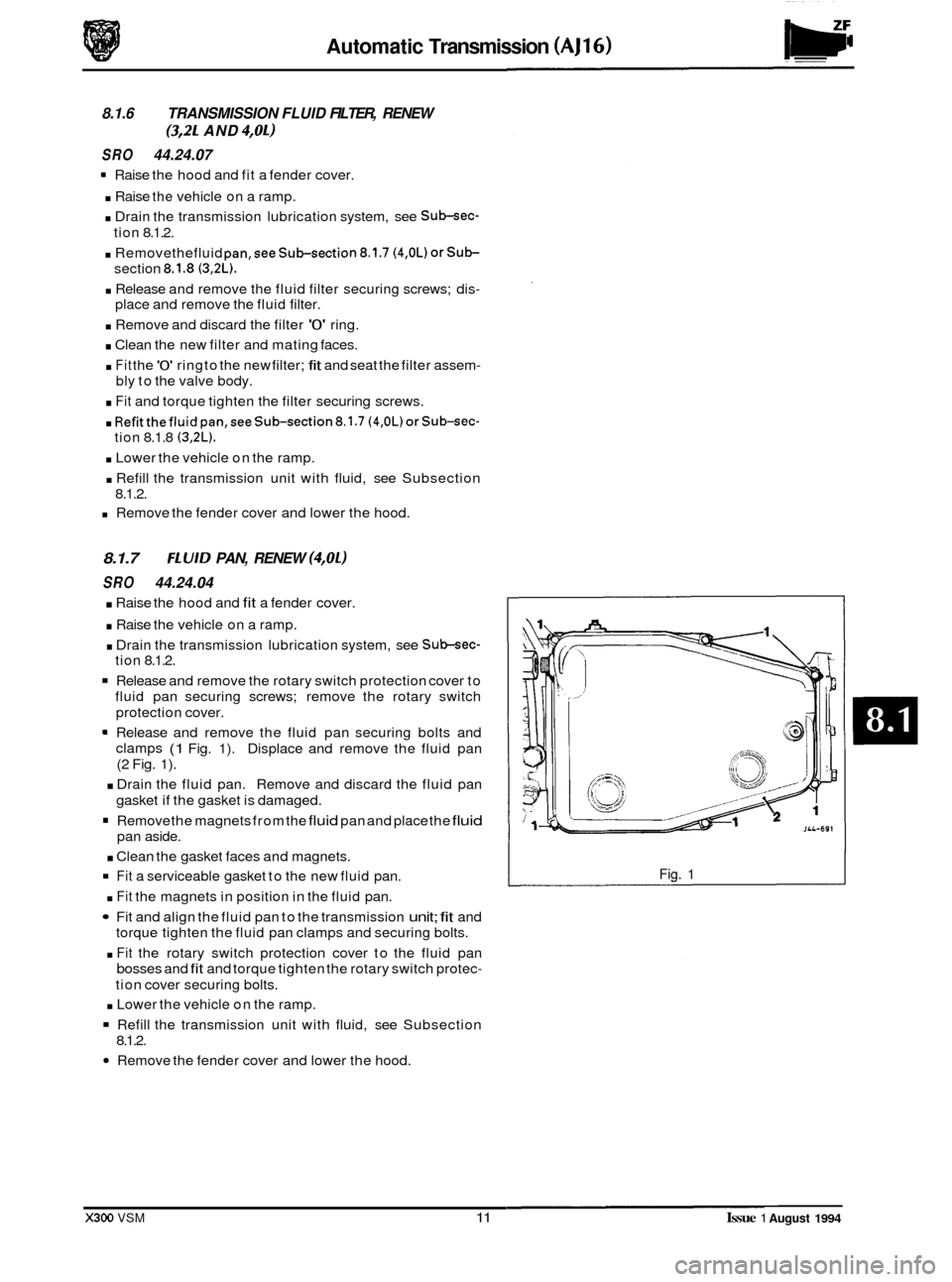

Release and remove the rotary switch protection cover to

fluid pan securing screws; remove the rotary switch

protect ion cover.

Release and remove the fluid pan securing bolts and

clamps

(1 Fig. 1). Displace and remove the fluid pan

(2 Fig. 1).

. Drain the fluid pan. Remove and discard the fluid pan

gasket if the gasket is damaged.

Remove the magnets from the fluid pan and place the fluid

pan aside.

. Clean the gasket faces and magnets.

Fit a serviceable gasket to the new fluid pan.

. Fit the magnets in position in the fluid pan.

Fit and align the fluid pan to the transmission unit; fit and

torque tighten the fluid pan clamps and securing bolts.

. Fit the rotary switch protection cover to the fluid pan

bosses and fit and torque tighten the rotary switch protec-

tion cover securing bolts.

. Lower the vehicle on the ramp.

Refill the transmission unit with fluid, see Subsection

Remove the fender cover and lower the hood.

8.1.2.

Fig. 1

X300 VSM 11 Issue 1 August 1994

Page 149 of 521

Automatic Transmission (AJ16)

8.1.8 FLUID PAN, RENEW (3,2L)

SRO 44.24.04

. Raise the vehicle on a ramp.

. Drain the transmission lubrication system, see Sub-sec-

tion 8.1.2.

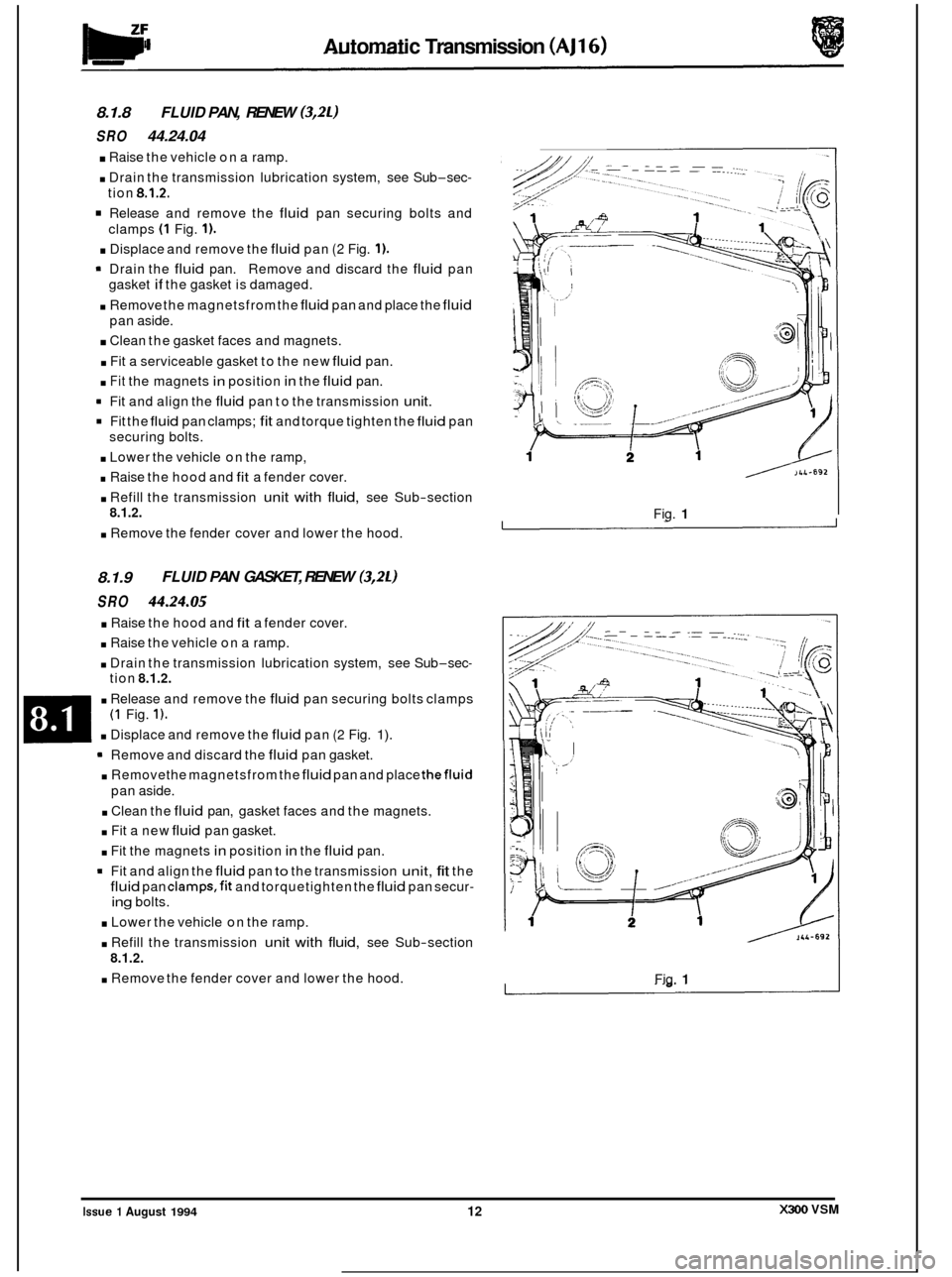

Release and remove the fluid pan securing bolts and

clamps

(1 Fig. 1).

. Displace and remove the fluid pan (2 Fig. 1).

= Drain the fluid pan. Remove and discard the fluid pan

. Remove the magnetsfrom the fluid pan and place the fluid

. Clean the gasket faces and magnets.

. Fit a serviceable gasket to the new fluid pan.

. Fit the magnets in position in the fluid pan.

9 Fit and align the fluid pan to the transmission unit.

Fit the fluid pan clamps; fit and torque tighten the fluid pan

. Lower the vehicle on the ramp,

. Raise the hood and fit a fender cover.

. Refill the transmission unit with fluid, see Sub-section

. Remove the fender cover and lower the hood.

gasket

if the

gasket is damaged.

pan aside.

securing bolts.

8.1.2.

8.1.9

SRO 44.24.05

. Raise the hood and fit a fender cover.

. Raise the vehicle on a ramp.

. Drain the transmission lubrication system, see Sub-sec-

FLUID PAN GASKET, RENEW (3,2L)

tion 8.1.2.

. Release and remove the fluid pan securing bolts clamps

. Displace and remove the fluid pan (2 Fig. 1).

(1 Fig. 1).

Remove and discard the fluid pan gasket.

pan aside.

. Removethe magnetsfrom the fluid pan and place thefluid

. Clean the fluid pan, gasket faces and the magnets.

. Fit a new fluid pan gasket.

. Fit the magnets in position in the fluid pan.

9 Fit and align the fluid pan to the transmission unit, fit the

fluid pan clamps,fit and torquetighten the fluid pan secur-

ing bolts.

. Lower the vehicle on the ramp.

. Refill the transmission unit with fluid, see Sub-section

. Remove the fender cover and lower the hood.

8.1.2.

/>U492

Fig. 1

Fig. 1

j

X300 VSM Issue 1 August 1994 12

Page 150 of 521

Automatic Transmission (AJ16)

8.1.10 TRANSMISSION SPEED SENSOR, RENEW (4,OL)

SRO 44.15.34

9 Raise the hood and fit a fender cover.

. Raise the vehicle on a ramp.

. Drain the transmission lubrication system, see Sub-sec-

Remove the fluid pan, see Sub-section 8.1.7.

. Displace the transmission speed sensor harness from the

valve body rear securing clip.

Release and remove the speed sensor and connector re-

taining clip from the valve body.

. Displace the speed sensor and connector from the trans-

mission main casing.

9 Disconnect and remove the speed sensor from the har-

ness connector.

. Clean the speed sensor, retaining clip and mating surface.

Connect the new speed sensor to the harness connector.

Fully seat the speed sensor into the transmission unit

tion

8.1.2.

main

casing.

. Fit the speed sensor and connector retaining clip to the

valve body, engaging the tangs onto the connector.

clip securing screws.

the valve body rear; secure the clip.

. Fit and tighten the speed sensor and connector retaining

. Reposition and fully seat the speed sensor harness into

. Refit the fluid pan, see Sub-section 8.1.7.

. Lower the vehicle on the ramp.

. Refill the transmission unit with fluid, see Sub-section

8.1.2.

Remove the fender cover and lower the hood.

X300 VSM 13 Issue 1 August 1994

Page 151 of 521

Automatic Transmission (AJ16)

8.1.11 TRANSMISSION INTERNAL HARNESSMULTI-

PIN SOCKET '0' RING, RENEW (4,OL)

SRO 44.24.20

. Disconnect the battery.

. Raise the vehicle on a ramp.

. Drain the transmission lubrication system, see Sub-sec-

. Remove the fluid pan, see Sub-section 8.1.7.

. Remove the fluid filter, see Sub-section 8.1.6.

. Remove the transmission speed sensor, see Sub-section

8.1.10.

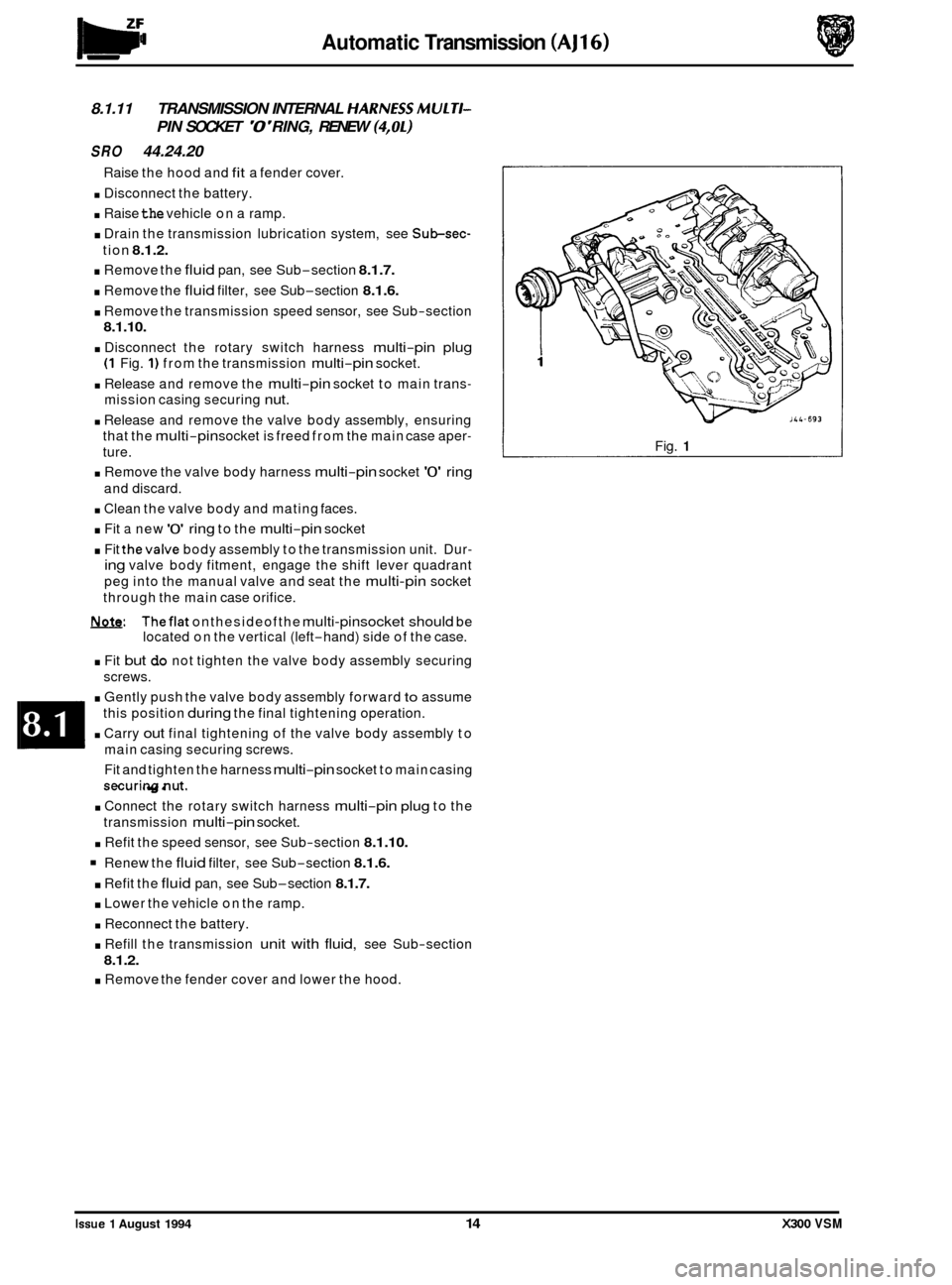

. Disconnect the rotary switch harness multi-pin plug

(1 Fig. 1) from the transmission multi-pin socket.

. Release and remove the multi-pin socket to main trans-

mission casing securing nut.

. Release and remove the valve body assembly, ensuring

that the

multi-pin socket is freed from the main case aper-

ture.

. Remove the valve body harness multi-pin socket '0' ring

and discard.

. Clean the valve body and mating faces.

. Fit a new '0' ring to the multi-pin socket

. Fit thevalve body assembly to the transmission unit. Dur-

ing valve body fitment, engage the shift lever quadrant

peg into the manual valve and seat the

multi-pin socket

through the main case orifice.

m. Theflat onthesideofthe multi-pinsocket should be

located on the vertical (left-hand) side of the case.

. Fit but do not tighten the valve body assembly securing

screws.

. Gently push the valve body assembly forward to assume

this position

during the final tightening operation.

. Carry out final tightening of the valve body assembly to

main casing securing screws.

Fit and tighten the harness

multi-pin socket to main casing

securingnut.

. Connect the rotary switch harness multi-pin plug to the

transmission

multi-pin socket.

. Refit the speed sensor, see Sub-section 8.1.10.

Renew the fluid filter, see Sub-section 8.1.6.

. Refit the fluid pan, see Sub-section 8.1.7.

. Lower the vehicle on the ramp.

. Reconnect the battery.

. Refill the transmission unit with fluid, see Sub-section

8.1.2.

. Remove the fender cover and lower the hood.

Raise

the hood and

fit a fender cover.

tion

8.1.2.

Fig. 1

Issue 1 August 1994 14 X300 VSM

Page 152 of 521

Automatic Transmission (AJ16)

8.1.12 VALVE BODY ASSEMBLY, RENEW (4,Ol)

SRO 44.40.01

Raise the hood and fit a fender cover.

. Disconnect the battery.

. Raise the vehicle on a ramp.

. Drain the transmission lubrication system, see Sub-sec-

. Remove the fluid pan, see Subsection 8.1.7.

. Remove the fluid filter, see Sub-section 8.1.6.

. Remove the transmission speed sensor, see Subsection

8.1.10.

. Disconnect the rotary switch harness multi-pin plug from

the transmission multi

-pin socket.

. Release and remove the multi-pin socket to main trans-

mission casing securing nut.

Release and remove the valve body assembly to main cas-

ing securing screws.

. DisDlace and remove the valve body assemblv, ensurina

tion

8.1.2.

that

the multi-pin socket is freed from the main case apery

ture. - . Remove the valve body harness multi-pin socket '0' ring

. Clean the valve body and main case mating faces. Check

. Fit a new '0' ring to the multi-pin socket.

. Fit the valve body assembly to the transmission unit. Dur-

ing valve body fitment, engage the shift lever quadrant

peg into the manual valve and seat the multi

-pin socket

through the main case orifice.

m: Theflat on the side of the multi-pin socket should be

located on the vertical (left-hand) side of the case.

. Fit but do not tighten the valve body assembly securing

screws.

Gently push the valve body assembly forward to assume

this position during the final tightening operation.

Carry out final tightening of the valve body assembly to

main casing securing screws.

. Fit and tighten the harness multi-pin socket to main casing

. Connect the rotary switch harness multi-pin plug to the

. Refit the speed sensor, see Subsection 8.1.10.

. Renew the fluid filter, see Subsection 8.1.6.

Refit the fluid pan, see Sub-section 8.1.7.

* Lower the vehicle on the ramp.

. Reconnect the battery.

. Refill the transmission unit with fluid, see Sub-section

8.1.2.

. Remove the fender cover and lower the hood.

and discard.

for any signs of damage.

securing nut.

transmission multi

-pin socket.

Issue 1 August 1994 X300 VSM 15